light YAMAHA VX110 2005 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 28 of 347

2-7

ESPECMAINTENANCE SPECIFICATIONS

ELECTRICAL

Item UnitModel

VX110 Sport VX110 Deluxe

Battery

Type Fluid

Capacity V/Ah 12/19

Specific gravity 1.28

ECM unit

(B/R – R/Y, B/W – R/Y,

B/Y – R/Y, B/G – R/Y)

Output peak voltage lower limit

@cranking (loaded) V 90

@2,000 r/min (loaded) V 130

@3,500 r/min (loaded) V 140

Stator

Pickup coil (W/B – B/O)

Output peak voltage

@cranking (unloaded) V 8.0

@cranking (loaded) V 6.9

@2,000 r/min (loaded) V 19.4

@3,500 r/min (loaded) V 25.1

Lighting coil (G – G)

Output peak voltage

@cranking (unloaded) V 7.8

@2,000 r/min (unloaded) V 24.5

@3,500 r/min (unloaded) V 41.6

Pickup coil resistance

(W/B – B/O)Ω

(color) 459–561

Lighting coil resistance (G – G)Ω

(color) 0.23–0.29

Minimum charging current A @ r/min 14 @ 6,000

Ignition coil

Primary coil resistance

@20 °C (68 °F)Ω

1.19–1.61

Secondary coil resistance

@20 °C (68 °F) kΩ

8.5–11.5

Rectifier/regulator (R – B)

Output peak voltage

@3,500 r/min (unloaded) V 13.0

ProCarManuals.com

Page 33 of 347

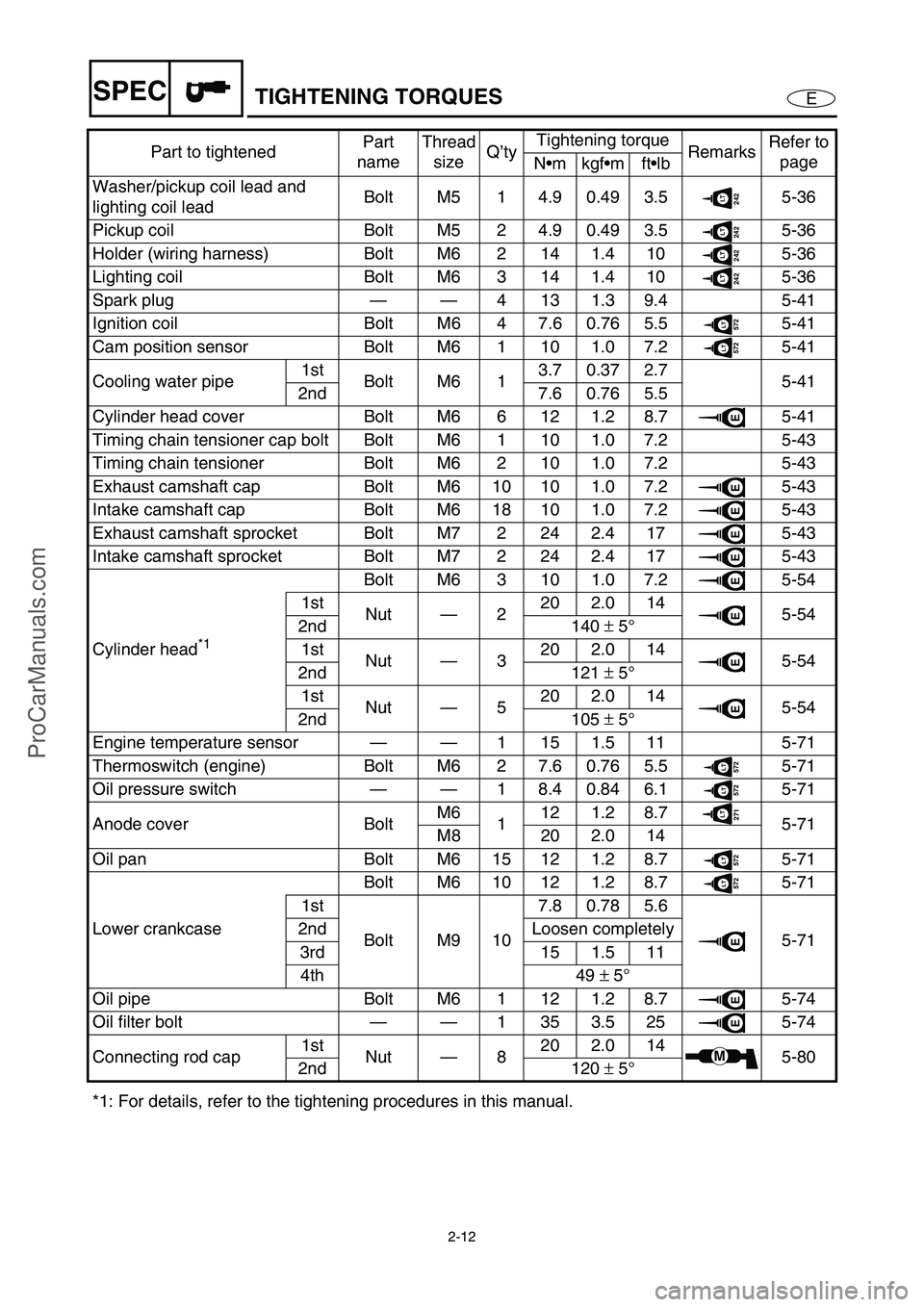

2-12

ESPECTIGHTENING TORQUES

Washer/pickup coil lead and

lighting coil leadBolt M5 1 4.9 0.49 3.5242LT5-36

Pickup coil Bolt M5 2 4.9 0.49 3.5

242LT5-36

Holder (wiring harness) Bolt M6 2 14 1.4 10

242LT5-36

Lighting coil Bolt M6 3 14 1.4 10

242LT5-36

Spark plug——4131.39.4 5-41

Ignition coil Bolt M6 4 7.6 0.76 5.5

572LT5-41

Cam position sensor Bolt M6 1 10 1.0 7.2

572LT5-41

Cooling water pipe1st

Bolt M6 13.70.372.7

5-41

2nd 7.6 0.76 5.5

Cylinder head cover Bolt M6 6 12 1.2 8.7

E5-41

Timing chain tensioner cap bolt Bolt M6 1 10 1.0 7.2 5-43

Timing chain tensioner Bolt M6 2 10 1.0 7.2 5-43

Exhaust camshaft cap Bolt M6 10 10 1.0 7.2

E5-43

Intake camshaft cap Bolt M6 18 10 1.0 7.2

E5-43

Exhaust camshaft sprocket Bolt M7 2 24 2.4 17

E5-43

Intake camshaft sprocket Bolt M7 2 24 2.4 17

E5-43

Cylinder head

*1 Bolt M6 3 10 1.0 7.2

E5-54

1st

Nut—220 2.0 14

E5-54

2nd 140 ±

5°

1st

Nut—320 2.0 14

E5-54

2nd 121 ±

5°

1st

Nut—520 2.0 14

E5-54

2nd 105 ±

5°

Engine temperature sensor——1 15 1.5 11 5-71

Thermoswitch (engine) Bolt M6 2 7.6 0.76 5.5

572LT5-71

Oil pressure switch——1 8.4 0.84 6.1

572LT5-71

Anode cover BoltM6

112 1.2 8.7

271LT5-71

M8 20 2.0 14

Oil pan Bolt M6 15 12 1.2 8.7

572LT5-71

Lower crankcaseBolt M6 10 12 1.2 8.7

572LT5-71

1st

Bolt M9 107.80.785.6

E5-71 2nd Loosen completely

3rd 15 1.5 11

4th 49 ±

5°

Oil pipe Bolt M6 1 12 1.2 8.7

E5-74

Oil filter bolt——1353.525

E5-74

Connecting rod cap1st

Nut—820 2.0 14

M5-80

2nd 120 ±

5°

*1: For details, refer to the tightening procedures in this manual.Part to tightenedPart

nameThread

sizeQ’tyTightening torque

RemarksRefer to

page

Nmkgfmftlb

ProCarManuals.com

Page 69 of 347

3-20

E

INSP

ADJ

POWER UNIT

Spark plug inspection

1. Remove:

Ignition coils

CAUTION:

Be careful not to get any foreign sub-

stances or water in spark plug hole.

2. Inspect:

Electrodes 1

Damage/wear →

Replace.

Insulator color 2

Distinctly different color →

Check the

engine condition.

Color guide:

Medium to light tan color:

Normal

Whitish color:

Lean fuel mixture

Air leak

Incorrect settings

Blackish color:

Overly rich mixture

Electrical malfunction

Defective spark plug

3. Clean:

Spark plug

(with a spark plug cleaner or wire brush)

4. Measure:

Spark plug gap a

Out of specification →

Regap.

Spark plug gap:

0.7–0.8 mm (0.028–0.031 in)

ProCarManuals.com

Page 132 of 347

5-33

EPOWRGENERATOR AND STARTER MOTOR

GENERATOR AND STARTER MOTOR

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

GENERATOR COVER AND

FLYWHEEL MAGNETO

REMOVALFollow the left “Step” for removal.

Engine unit Refer to “ENGINE UNIT”.

1 Nut/washer 1/1

2 Starter motor lead 1

3Bolt 2

4 Battery negative lead 1

5 Starter motor 1

6 Band 1

7 Lighting coil coupler 1

4 3

2 1

5

7

89

1113 12

18 16171920 21

15 14

AA

E

E

E

LT

572

LT

572

AA

AA

8 × 30 mm

18 N m (1.8 kgf

m, 13 ft

Ib)

4.9 N

m (0.49 kgf m, 3.5 ft Ib)

10 × 47 mm

75 N m (7.5 kgf

m, 54 ft

Ib) 8 × 20 mm

24 N m (2.4 kgf

m, 17 ft

Ib)

10 × 60 mm

2nd 50 N m (5.0 kgf

m, 36 ft

Ib) 1st 15 N m (1.5 kgf

m, 11 ft

Ib)

6

2nd 50 N m (5.0 kgf

m, 36 ft

Ib) 1st 15 N m (1.5 kgf m, 11 ft Ib)

10 × 135 mm

10

LT

572

LT

572

ProCarManuals.com

Page 136 of 347

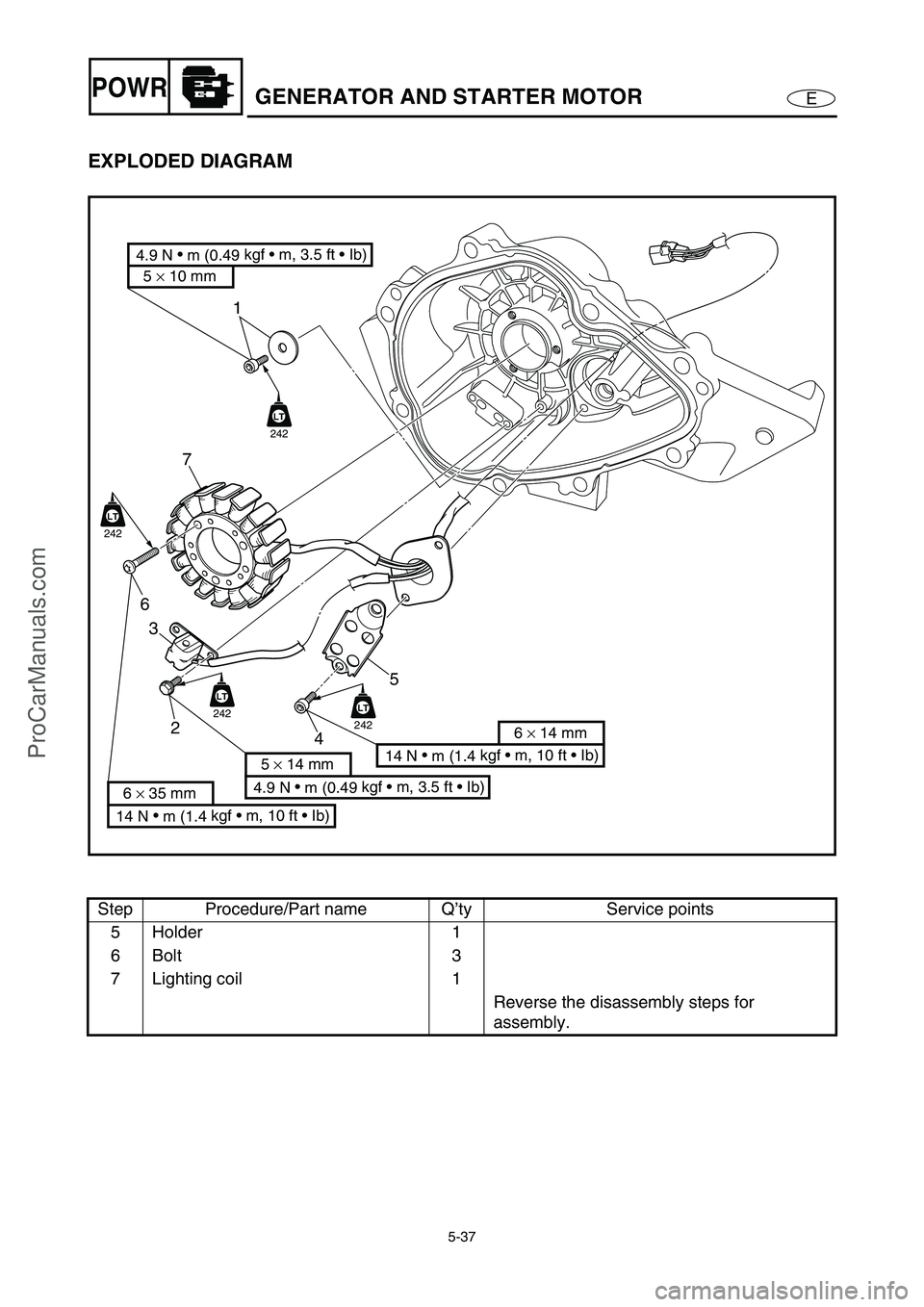

5-37

EPOWRGENERATOR AND STARTER MOTOR

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

5 Holder 1

6Bolt 3

7 Lighting coil 1

Reverse the disassembly steps for

assembly.

1

7

6

3

2

45

LT

242

LT

242

LT

242LT

242

14 N

m (1.4 kgf m, 10 ft Ib)

6 × 14 mm

4.9 N

m (0.49 kgf m, 3.5 ft Ib)

5 × 14 mm

14 N

m (1.4 kgf m, 10 ft Ib)

6 × 35 mm

4.9 N

m (0.49 kgf m, 3.5 ft Ib)

5 × 10 mm

ProCarManuals.com

Page 148 of 347

5-49

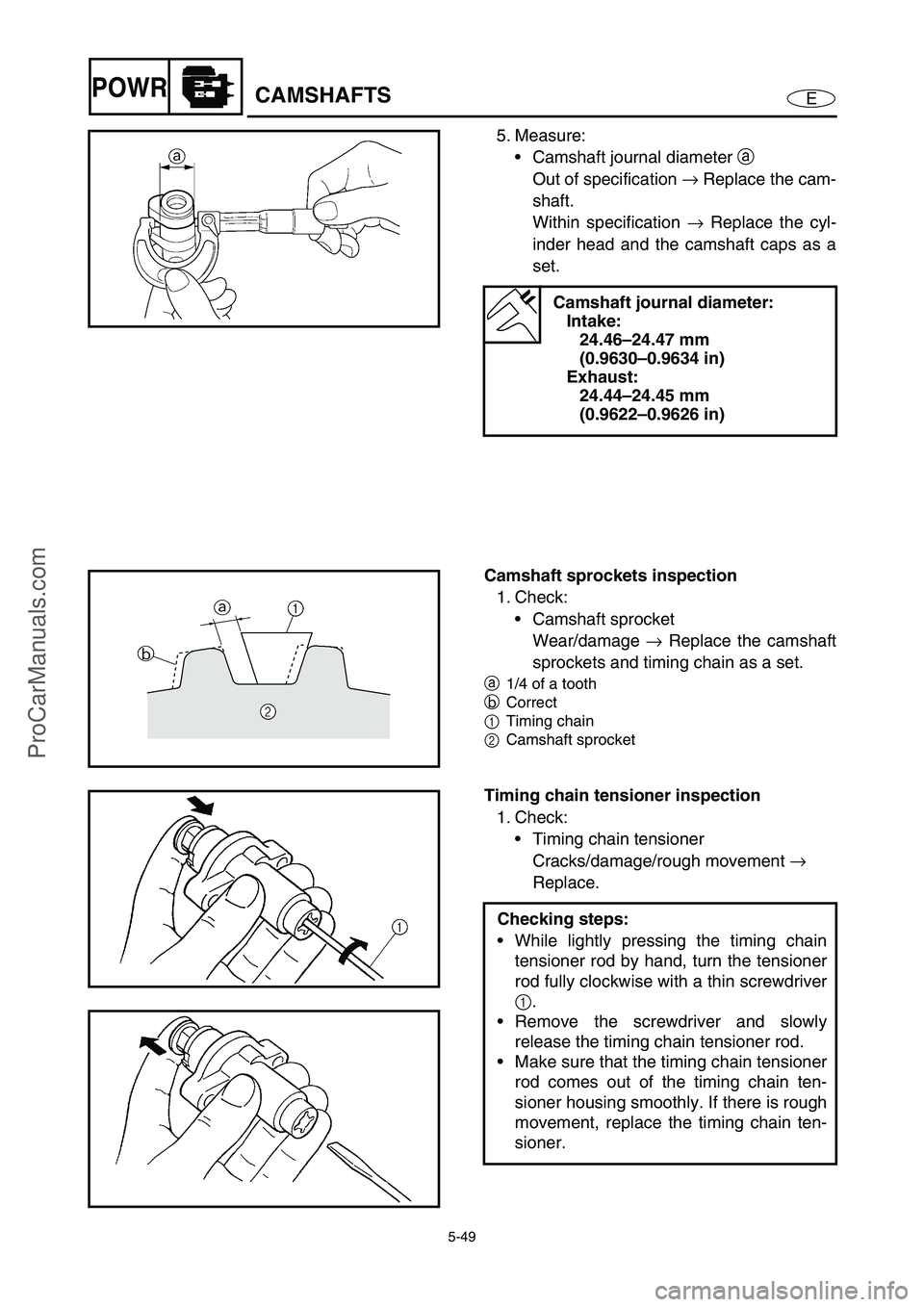

EPOWRCAMSHAFTS

5. Measure:

Camshaft journal diameter a

Out of specification →

Replace the cam-

shaft.

Within specification →

Replace the cyl-

inder head and the camshaft caps as a

set.

Camshaft journal diameter:

Intake:

24.46–24.47 mm

(0.9630–0.9634 in)

Exhaust:

24.44–24.45 mm

(0.9622–0.9626 in)

Camshaft sprockets inspection

1. Check:

Camshaft sprocket

Wear/damage →

Replace the camshaft

sprockets and timing chain as a set.

a

1/4 of a tooth

b

Correct

1Timing chain

2Camshaft sprocket

Timing chain tensioner inspection

1. Check:

Timing chain tensioner

Cracks/damage/rough movement →

Replace.

Checking steps:

While lightly pressing the timing chain

tensioner rod by hand, turn the tensioner

rod fully clockwise with a thin screwdriver

1

.

Remove the screwdriver and slowly

release the timing chain tensioner rod.

Make sure that the timing chain tensioner

rod comes out of the timing chain ten-

sioner housing smoothly. If there is rough

movement, replace the timing chain ten-

sioner.

ProCarManuals.com

Page 150 of 347

5-51

EPOWRCAMSHAFTS

Install the exhaust and intake camshaft

caps.

NOTE:

Gradually tighten the intake and exhaust

camshaft cap bolts in 2–3 steps in the

sequence shown.

T R..

Camshaft cap bolt:

10 N m (1.0 kgf m, 7.2 ft lb)

NOTE:

Make sure that the punch marks c

on the

camshafts are aligned with the arrow marks

d

on the camshaft caps.

Out of alignment →

Reinstall.

Remove the wire from the timing chain.

10 1 4 5 8

17 5 1 4 8 15 9 12 149 3 2

7 6

18 7 3 2 6

13 11 10 16

3. Install:

Timing chain tensioner

Installation steps:

While lightly pressing the timing chain

tensioner rod by hand, turn the tensioner

rod fully clockwise with a thin screwdriver

1

.

NOTE:

Make sure that the tensioner rod has been

fully set clockwise.

With the timing chain tensioner rod

turned all the way into the timing chain

tensioner housing (with the thin screw-

driver still installed), install the gasket and

the timing chain tensioner 2

onto the cyl-

inder block.

WARNING

Always use a new gasket.

Tighten the timing chain tensioner bolts

3

to the specified torque.

NOTE:

The “UP” mark on the timing chain ten-

sioner should face up.

33

2

ProCarManuals.com

Page 169 of 347

5-70

EPOWRVALVES AND VALVE SPRINGS

2. Compress the valve spring, and then

install the valve cotter 1

using a thin

screwdriver with a small amount of grease

applied to it.

Valve spring compressor:

YM-01253/90890-04019

Valve spring compressor

attachment:

(for the intake valve):

YM-04114/90890-04114

(for the exhaust valve):

YM-04108/90890-04108

3. Lightly tap the valve spring retainer with a

plastic hammer to set the valve cotter

securely.

NOTE:

Apply engine oil to the valve pads and valve

lifters before installation.

ProCarManuals.com

Page 226 of 347

E

–+ELEC

FUEL CONTROL SYSTEM ........................................................................... 7-31

WIRING DIAGRAM ................................................................................. 7-31

ELECTRIC FUEL PUMP ......................................................................... 7-33

FUEL SENDER ....................................................................................... 7-33

FUEL INJECTOR .................................................................................... 7-34

MAIN AND FUEL PUMP RELAY............................................................. 7-34

OIL PRESSURE SWITCH ....................................................................... 7-34

THERMOSWITCH (ENGINE).................................................................. 7-34

THERMOSWITCH (EXHAUST) .............................................................. 7-34

SLANT DETECTION SWITCH ................................................................ 7-34

REMOTE CONTROL UNIT (DELUXE MODEL ONLY) ........................... 7-34

THROTTLE POSITION SENSOR ........................................................... 7-34

ACCELERATOR POSITION SENSOR ................................................... 7-34

STARTING SYSTEM ..................................................................................... 7-35

WIRING DIAGRAM ................................................................................. 7-35

BATTERY ................................................................................................ 7-37

WIRING CONNECTIONS........................................................................ 7-37

FUSES..................................................................................................... 7-37

START SWITCH...................................................................................... 7-37

STARTER RELAY ................................................................................... 7-38

REMOTE CONTROL UNIT (DELUXE MODEL ONLY) ........................... 7-38

THROTTLE POSITION SENSOR ........................................................... 7-38

ACCELERATOR POSITION SENSOR ................................................... 7-38

STARTER MOTOR ........................................................................................ 7-39

EXPLODED DIAGRAM ........................................................................... 7-39

REMOVAL AND INSTALLATION CHART ............................................. 7-39

SERVICE POINTS .................................................................................. 7-41

Armature inspection .......................................................................... 7-41

Brush holder inspection..................................................................... 7-42

Starter motor front cover inspection .................................................. 7-42

CHARGING SYSTEM .................................................................................... 7-43

WIRING DIAGRAM ................................................................................. 7-43

FUSE ....................................................................................................... 7-44

BATTERY ................................................................................................ 7-44

LIGHTING COIL ...................................................................................... 7-44

RECTIFIER/REGULATOR ...................................................................... 7-44

OFF THROTTLE STEERING SYSTEM......................................................... 7-45

WIRING DIAGRAM ................................................................................. 7-45

STEERING SENSOR .............................................................................. 7-47

ECM......................................................................................................... 7-47

PICKUP COIL .......................................................................................... 7-47

THROTTLE POSITION SENSOR ........................................................... 7-47

ACCELERATOR POSITION SENSOR ................................................... 7-47

ProCarManuals.com

Page 228 of 347

7-1

E

–+ELECELECTRICAL COMPONENTS

ELECTRICAL COMPONENTS

O

N

M

L

K

J

I

H

G

F

E

D

C

B

A

0

91

2

3

4

5

6

7

8

1Thermoswitch (engine)

2Fuse box

3Slant detection switch

4Starter motor

5Engine temperature sensor

6Spark plugs and ignition coils

7Cam position sensor

8Battery

9Speed sensor

0Sensor assembly (intake air

pressure and intake air tem-

perature)AOil pressure switch

BFuel injectors

CThermoswitch (exhaust)

DRectifier/regulator

EECM

FThrottle body assembly

GLighting coil and pickup coil

HEngine stop switch, engine

shut-off switch, and start

switch

ISteering sensor

JBuzzerKAccelerator position sensor

LElectric fuel pump

MFuel sender

NMultifunction meter

ORemote control unit (Deluxe

model only)

ProCarManuals.com