Carburetor YAMAHA WR 250F 2006 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: WR 250F, Model: YAMAHA WR 250F 2006Pages: 900, PDF Size: 23.77 MB

Page 196 of 900

SPEC

2 - 103

CABLE ROUTING DIAGRAM

1Hot starter cable

2Throttle cable (return)

3Throttle cable (pull)

4Cable guide

5Ignition coil

6Coolant reservoir breather hose

7Coolant reservoir hose

8Clamp

9CDI unit lead

0CDI unit

ACDI unit band

BCDI unit stayÈPass the throttle cables and hot starter cable through the cable

guides.

ÉPass the throttle cables and hot starter cable between the radi-

ator and frame, then under the radiator mounting boss.

ÊPass the throttle cables on the outside of the ignition coil.

ËPass the carburetor breather hose (of the throttle cable cover)

through the hose holder.

ÌFasten the coolant reservoir breather hose and carburetor

breather hoses together.

A B

0

A

0

891

32

4

É

Ê

5

67

Ë ÌÎ

ÍÈ

Page 209 of 900

3 - 2

INSP

ADJ

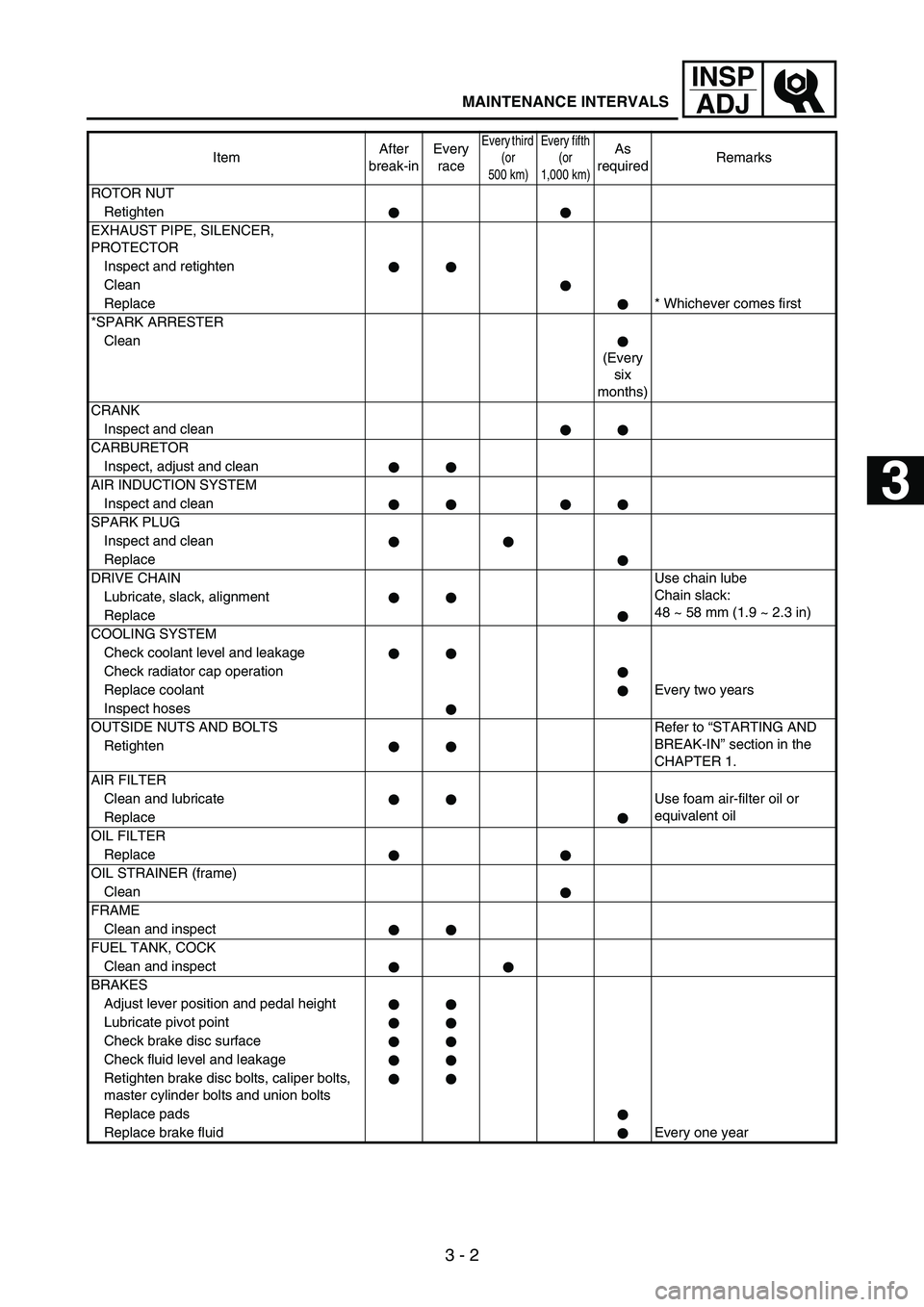

MAINTENANCE INTERVALS

ROTOR NUT

Retighten

EXHAUST PIPE, SILENCER,

PROTECTOR

Inspect and retighten

Clean

Replace* Whichever comes first

*SPARK ARRESTER

Clean

(Every

six

months)

CRANK

Inspect and clean

CARBURETOR

Inspect, adjust and clean

AIR INDUCTION SYSTEM

Inspect and clean

SPARK PLUG

Inspect and clean

Replace

DRIVE CHAINUse chain lube

Chain slack:

48 ~ 58 mm (1.9 ~ 2.3 in) Lubricate, slack, alignment

Replace

COOLING SYSTEM

Check coolant level and leakage

Check radiator cap operation

Replace coolantEvery two years

Inspect hoses

OUTSIDE NUTS AND BOLTS Refer to “STARTING AND

BREAK-IN” section in the

CHAPTER 1. Retighten

AIR FILTER

Clean and lubricate Use foam air-filter oil or

equivalent oil

Replace

OIL FILTER

Replace

OIL STRAINER (frame)

Clean

FRAME

Clean and inspect

FUEL TANK, COCK

Clean and inspect

BRAKES

Adjust lever position and pedal height

Lubricate pivot point

Check brake disc surface

Check fluid level and leakage

Retighten brake disc bolts, caliper bolts,

master cylinder bolts and union bolts

Replace pads

Replace brake fluid Every one yearItemAfter

break-inEvery

race

Every third

(or

500 km)Every fifth

(or

1,000 km)As

requiredRemarks

1

2

3

4

5

6

7

Page 210 of 900

3 - 3

INSP

ADJ

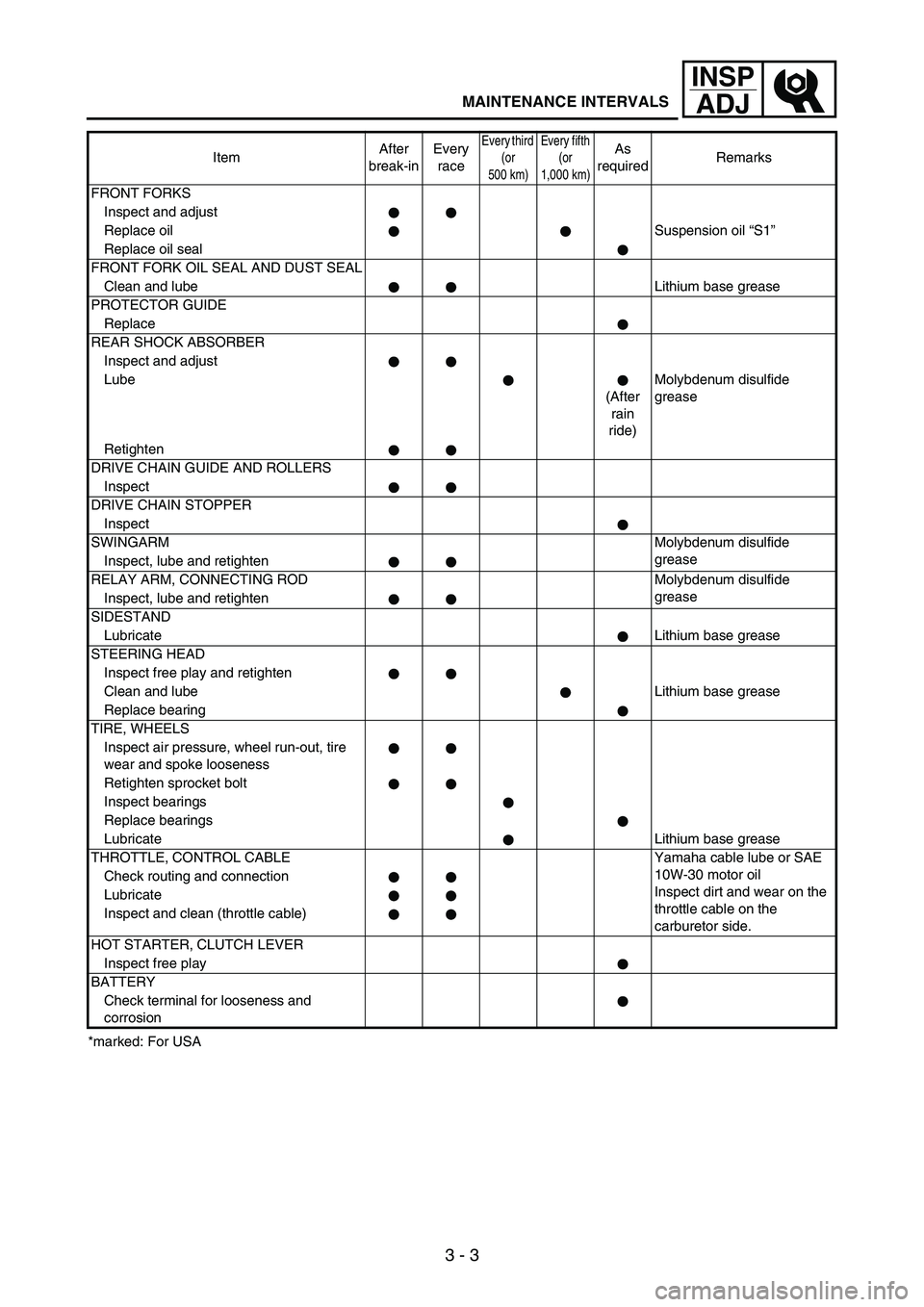

MAINTENANCE INTERVALS

*marked: For USAFRONT FORKS

Inspect and adjust

Replace oilSuspension oil “S1”

Replace oil seal

FRONT FORK OIL SEAL AND DUST SEAL

Clean and lubeLithium base grease

PROTECTOR GUIDE

Replace

REAR SHOCK ABSORBER

Inspect and adjust

Lube

(After

rain

ride)Molybdenum disulfide

grease

Retighten

DRIVE CHAIN GUIDE AND ROLLERS

Inspect

DRIVE CHAIN STOPPER

Inspect

SWINGARMMolybdenum disulfide

grease

Inspect, lube and retighten

RELAY ARM, CONNECTING ROD Molybdenum disulfide

grease

Inspect, lube and retighten

SIDESTAND

LubricateLithium base grease

STEERING HEAD

Inspect free play and retighten

Clean and lubeLithium base grease

Replace bearing

TIRE, WHEELS

Inspect air pressure, wheel run-out, tire

wear and spoke looseness

Retighten sprocket bolt

Inspect bearings

Replace bearings

LubricateLithium base grease

THROTTLE, CONTROL CABLE Yamaha cable lube or SAE

10W-30 motor oil

Inspect dirt and wear on the

throttle cable on the

carburetor side. Check routing and connection

Lubricate

Inspect and clean (throttle cable)

HOT STARTER, CLUTCH LEVER

Inspect free play

BATTERY

Check terminal for looseness and

corrosionItemAfter

break-inEvery

race

Every third

(or

500 km)Every fifth

(or

1,000 km)As

requiredRemarks

Page 256 of 900

3 - 49

INSP

ADJ

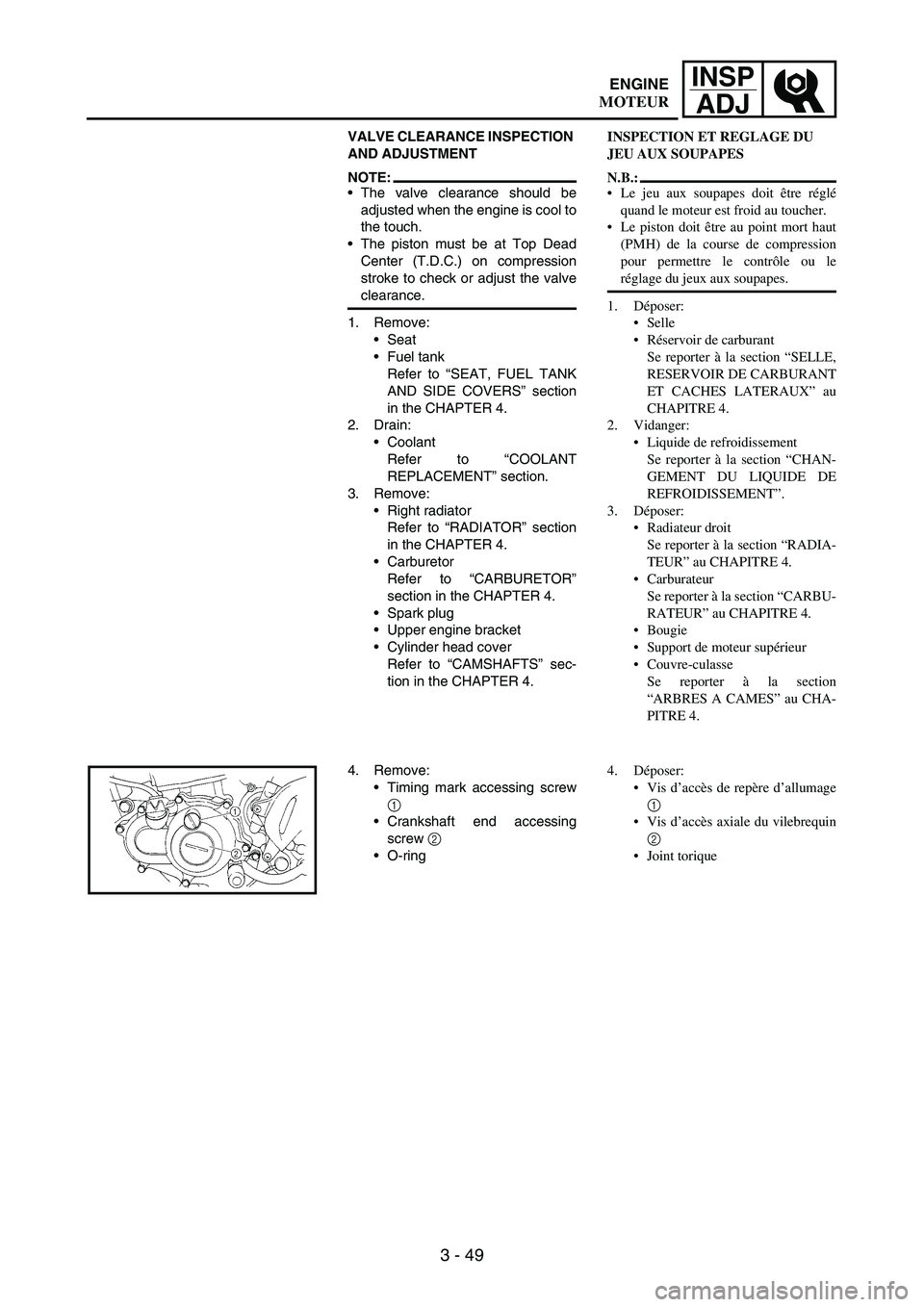

VALVE CLEARANCE INSPECTION

AND ADJUSTMENT

NOTE:The valve clearance should be

adjusted when the engine is cool to

the touch.

The piston must be at Top Dead

Center (T.D.C.) on compression

stroke to check or adjust the valve

clearance.

1. Remove:

Seat

Fuel tank

Refer to “SEAT, FUEL TANK

AND SIDE COVERS” section

in the CHAPTER 4.

2. Drain:

Coolant

Refer to “COOLANT

REPLACEMENT” section.

3. Remove:

Right radiator

Refer to “RADIATOR” section

in the CHAPTER 4.

Carburetor

Refer to “CARBURETOR”

section in the CHAPTER 4.

Spark plug

Upper engine bracket

Cylinder head cover

Refer to “CAMSHAFTS” sec-

tion in the CHAPTER 4.

4. Remove:

Timing mark accessing screw

1

Crankshaft end accessing

screw

2

O-ring

INSPECTION ET REGLAGE DU

JEU AUX SOUPAPES

N.B.:

Le jeu aux soupapes doit être réglé

quand le moteur est froid au toucher.

Le piston doit être au point mort haut

(PMH) de la course de compression

pour permettre le contrôle ou le

réglage du jeux aux soupapes.

1. Déposer:

Selle

Réservoir de carburant

Se reporter à la section “SELLE,

RESERVOIR DE CARBURANT

ET CACHES LATERAUX” au

CHAPITRE 4.

2. Vidanger:

Liquide de refroidissement

Se reporter à la section “CHAN-

GEMENT DU LIQUIDE DE

REFROIDISSEMENT”.

3. Déposer:

Radiateur droit

Se reporter à la section “RADIA-

TEUR” au CHAPITRE 4.

Carburateur

Se reporter à la section “CARBU-

RATEUR” au CHAPITRE 4.

Bougie

Support de moteur supérieur

Couvre-culasse

Se reporter à la section

“ARBRES A CAMES” au CHA-

PITRE 4.

4. Déposer:

Vis d’accès de repère d’allumage

1

Vis d’accès axiale du vilebrequin

2

Joint torique

ENGINE

MOTEUR

Page 314 of 900

3 - 107

INSP

ADJ

EC370000

ELECTRICAL

EC371001SPARK PLUG INSPECTION

1. Remove:

Spark plug

2. Inspect:

Electrode

1

Wear/damage

→ Replace.

Insulator color

2

Normal condition is a medium

to light tan color.

Distinctly different color

→

Check the engine condition.

NOTE:When the engine runs for many

hours at low speeds, the spark plug

insulator will become sooty, even if

the engine and carburetor are in

good operating condition.

3. Measure:

Plug gap

a

Use a wire gauge or thickness

gauge.

Out of specification

→ Regap.

4. Clean the plug with a spark plug

cleaner if necessary.

Spark plug gap:

0.7 ~ 0.8 mm

(0.028 ~ 0.031 in)

5. Tighten:

Spark plug

NOTE:Before installing a spark plug,

clean the gasket surface and plug

surface.

Finger-tighten

a the spark plug

before torquing to specification

b.

T R..13 Nm (1.3 m · kg, 9.4 ft · lb)

IGNITION TIMING CHECK

1. Remove:

Timing mark accessing screw

1

PARTIE ELECTRIQUE

CONTROLE DE LA BOUGIE

1. Déposer:

Bougie

2. Contrôler:

Electrode 1

Usure/endommagement → Rem-

placer.

Couleur de l’isolant 2

La couleur normale est une cou-

leur bronze clair ou légèrement

foncé.

Couleur franchement différente

→ Contrôler l’état du moteur.

N.B.:

Lorsque le moteur tourne pendant des

heures à bas régime, l’isolant de la bou-

gie s’encrasse, même si le moteur et le

carburateur sont en bon état de fonction-

nement.

3. Mesurer:

Ecartement a

Utiliser un calibre pour fils ou un

calibre d’épaisseur.

Hors spécifications → Régler.

4. Si nécessaire, nettoyer la bougie à

l’aide d’un nettoie-bougies.

Ecartement des électrodes:

0,7 à 0,8 mm

(0,028 à 0,031 in)

5. Serrer:

Bougie

N.B.:

Avant de monter une bougie, nettoyer

la surface du joint et la surface de la

bougie.

Serrer la bougie à la main a avant de

la serrer au couple correct b.

T R..13 Nm (1,3 m · kg, 9,4 ft · lb)

CONTROLE DE L’AVANCE A

L’ALLUMAGE

1. Déposer:

Vis d’accès de repère d’allumage

1

ELECTRICAL

PARTIE ELECTRIQUE

Page 362 of 900

4 - 21

ENGCARBURETOR

CARBURETOR

9

6

T R..4 Nm (0.4 m •

kg, 2.9 ft • Ib)

T R..2 Nm (0.2 m •

kg, 1.4 ft • Ib)

T R..11 Nm (1.1 m •

kg, 8.0 ft • Ib)

T R..4 Nm (0.4 m •

kg, 2.9 ft • Ib)

T R..3 Nm (0.3 m • kg, 2.2 ft • Ib)

T R..3 Nm (0.3 m • kg, 2.2 ft • Ib)

7

8

5 1

2

64

4

1

3

1

Extent of removal:

1 Carburetor removal

Extent of removal Order Part name Q’ty Remarks

CARBURETOR REMOVAL

Preparation for removal Seat and fuel tank Refer to “SEAT, FUEL TANK AND SIDE COVERS”

section.

1 Clamp 3

2 Throttle position sensor lead coupler 1

3 Throttle cable cover 1

4 Throttle cable 2

5 Clamp (air filter joint) 1 Loosen the screw (air filter joint).

6 Clamp (carburetor joint) 2 Loosen the screws (carburetor joint).

7 Hot starter plunger 1

8 Carburetor assembly 1

9 Carburetor joint 1

1

Page 366 of 900

4 - 25

ENGCARBURETOR

EC468000CARBURETOR DISASSEMBLY

Extent of removal:

1 Carburetor disassembly

Extent of removal Order Part name Q’ty Remarks

CARBURETOR DISASSEMBLY

1 Carburetor breather hose 4

2 Valve lever housing cover 1

3 Screw (throttle shaft) 1

4 Throttle valve 1

5 Needle holder 1

6 Jet needle 1

7 Accelerator pump cover 1

8 Spring 1

9 Diaphragm (accelerator pump) 1

0 Air cut valve cover 1

A Spring (air cut valve) 1

B Diaphragm (air cut valve) 1

C Float chamber 1

D Leak jet 1

1

Page 370 of 900

4 - 29

ENGCARBURETOR

Extent of removal Order Part name Q’ty Remarks

E Float pin 1

F Float 1

G Needle valve 1

H Main jet 1

I Needle jet 1

J Spacer 1

K Pilot jet 1

L Starter jet 1

M Push rod 1 Pull the push rod.

N Throttle shaft assembly 1

O Push rod link lever assembly 1

P Main air jet 1

Q Pilot air jet 1

R Cold starter plunger 1

1

Page 374 of 900

4 - 33

ENGCARBURETOR

HANDLING NOTE

CAUTION:

Do not loosen the screws (throttle

position sensor) 1

except when

changing the throttle position sen-

sor due to failure because it will

cause a drop in engine perfor-

mance.

1

INSPECTION

Carburetor

1. Inspect:

Carburetor body

Contamination

→ Clean.

NOTE:Use a petroleum based solvent for

cleaning. Blow out all passages

and jets with compressed air.

Never use a wire.

2. Inspect:

Main jet

1

Pilot jet

2

Needle jet 3

Starter jet 4

Pilot air jet 5

Leak jet 6

Main air jet 7

Damage → Replace.

Contamination → Clean.

NOTE:Use a petroleum based solvent for

cleaning. Blow out all passages

and jets with compressed air.

Never use a wire.

Needle valve

1. Inspect:

Needle valve 1

Valve seat 2

Grooved wear a → Replace.

Dust b → Clean.

Filter c

Clogged → Clean.

REMARQUES CONCERNANT LA

MANIPULATION

ATTENTION:

Ne pas desserrer les vis (capteur de

position de papillon des gaz) 1 sauf

en cas de remplacement du capteur de

position de papillon des gaz en raison

d’une panne, car cela provoquerait

une baisse des performances du

moteur.

CONTROLE

Carburateur

1. Contrôler:

Corps du carburateur

Encrassé → Nettoyer.

N.B.:

Nettoyer avec un solvant à base de

pétrole. Nettoyer tous les conduits et

gicleurs à l’air comprimé.

Ne jamais utiliser de fil métallique.

2. Contrôler:

Gicleur principal 1

Gicleur de ralenti 2

Gicleur d’aiguille 3

Gicleur de starter 4

Gicleur d’air de ralenti 5

Gicleur de fuite 6

Gicleur d’air principal 7

Endommagement → Remplacer.

Encrassé → Nettoyer.

N.B.:

Nettoyer avec un solvant à base de

pétrole. Nettoyer tous les conduits et

gicleurs à l’air comprimé.

Ne jamais utiliser de fil métallique.

Pointeau

1. Contrôler:

Pointeau 1

Siège de pointeau 2

Usure en creux a → Remplacer.

Poussière b → Nettoyer.

Filtre c

Bouché → Nettoyer.

CARBURATEUR

Page 376 of 900

4 - 35

ENGCARBURETOR

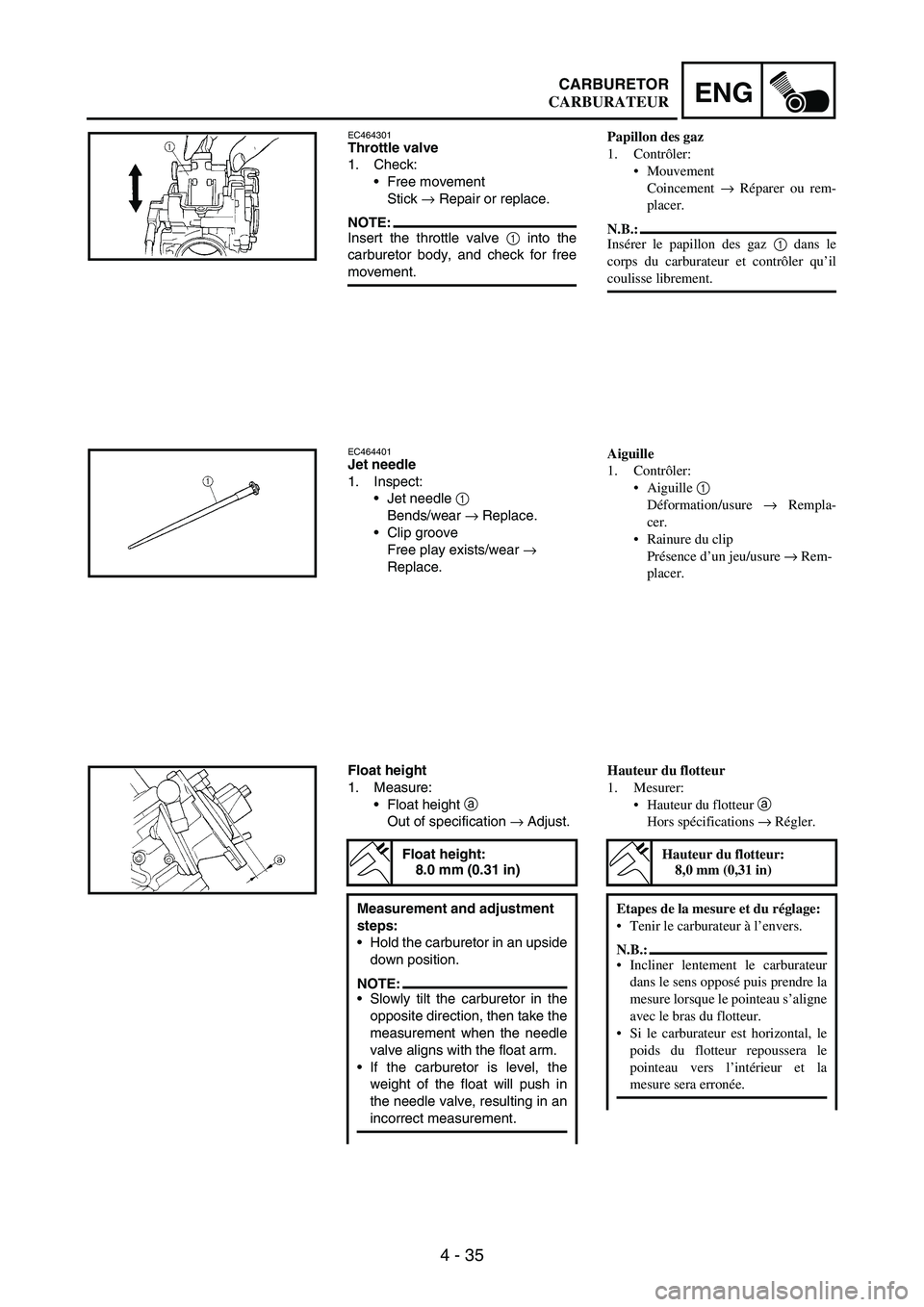

EC464301Throttle valve

1. Check:

Free movement

Stick

→ Repair or replace.

NOTE:Insert the throttle valve

1 into the

carburetor body, and check for free

movement.

EC464401Jet needle

1. Inspect:

Jet needle

1

Bends/wear

→ Replace.

Clip groove

Free play exists/wear

→

Replace.

Float height

1. Measure:

Float height

a

Out of specification

→ Adjust.

Float height:

8.0 mm (0.31 in)

Measurement and adjustment

steps:

Hold the carburetor in an upside

down position.

NOTE:Slowly tilt the carburetor in the

opposite direction, then take the

measurement when the needle

valve aligns with the float arm.

If the carburetor is level, the

weight of the float will push in

the needle valve, resulting in an

incorrect measurement.

Papillon des gaz

1. Contrôler:

Mouvement

Coincement → Réparer ou rem-

placer.

N.B.:

Insérer le papillon des gaz 1 dans le

corps du carburateur et contrôler qu’il

coulisse librement.

Aiguille

1. Contrôler:

Aiguille 1

Déformation/usure → Rempla-

cer.

Rainure du clip

Présence d’un jeu/usure → Rem-

placer.

Hauteur du flotteur

1. Mesurer:

Hauteur du flotteur a

Hors spécifications → Régler.

Hauteur du flotteur:

8,0 mm (0,31 in)

Etapes de la mesure et du réglage:

Tenir le carburateur à l’envers.

N.B.:

Incliner lentement le carburateur

dans le sens opposé puis prendre la

mesure lorsque le pointeau s’aligne

avec le bras du flotteur.

Si le carburateur est horizontal, le

poids du flotteur repoussera le

pointeau vers l’intérieur et la

mesure sera erronée.

CARBURATEUR