stop start YAMAHA WR 250F 2015 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: WR 250F, Model: YAMAHA WR 250F 2015Pages: 430, PDF Size: 14.14 MB

Page 71 of 430

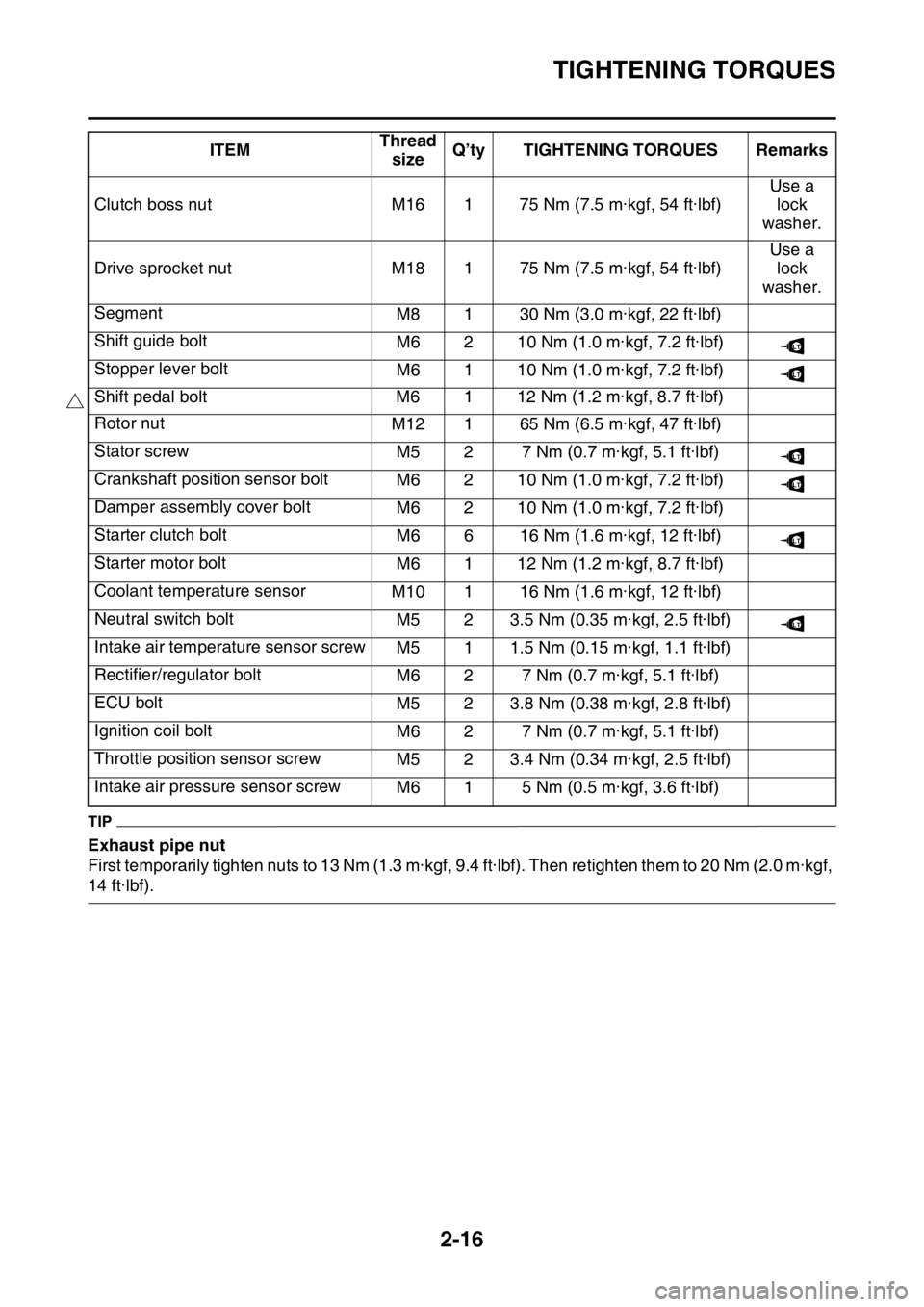

TIGHTENING TORQUES

2-16

TIP

Exhaust pipe nut

First temporarily tighten nuts to 13 Nm (1.3 m·kgf, 9.4 ft·lbf). Then retighten them to 20 Nm (2.0 m·kgf,

14 ft·lbf).Clutch boss nut M16 1 75 Nm (7.5 m·kgf, 54 ft·lbf)Use a

lock

washer.

Drive sprocket nut M18 1 75 Nm (7.5 m·kgf, 54 ft·lbf)Use a

lock

washer.

Segment

M8 1 30 Nm (3.0 m·kgf, 22 ft·lbf)

Shift guide bolt

M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Stopper lever bolt

M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Shift pedal bolt M6 1 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Rotor nut

M12 1 65 Nm (6.5 m·kgf, 47 ft·lbf)

Stator screw

M5 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Crankshaft position sensor bolt

M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Damper assembly cover bolt

M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Starter clutch bolt

M6 6 16 Nm (1.6 m·kgf, 12 ft·lbf)

Starter motor bolt

M6 1 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Coolant temperature sensor

M10 1 16 Nm (1.6 m·kgf, 12 ft·lbf)

Neutral switch bolt

M5 2 3.5 Nm (0.35 m·kgf, 2.5 ft·lbf)

Intake air temperature sensor screw

M5 1 1.5 Nm (0.15 m·kgf, 1.1 ft·lbf)

Rectifier/regulator bolt

M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

ECU bolt

M5 2 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

Ignition coil bolt

M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Throttle position sensor screw

M5 2 3.4 Nm (0.34 m·kgf, 2.5 ft·lbf)

Intake air pressure sensor screw

M6 1 5 Nm (0.5 m·kgf, 3.6 ft·lbf) ITEMThread

sizeQ’ty TIGHTENING TORQUES Remarks

LT

LT

LT

LT

LT

LT

Page 72 of 430

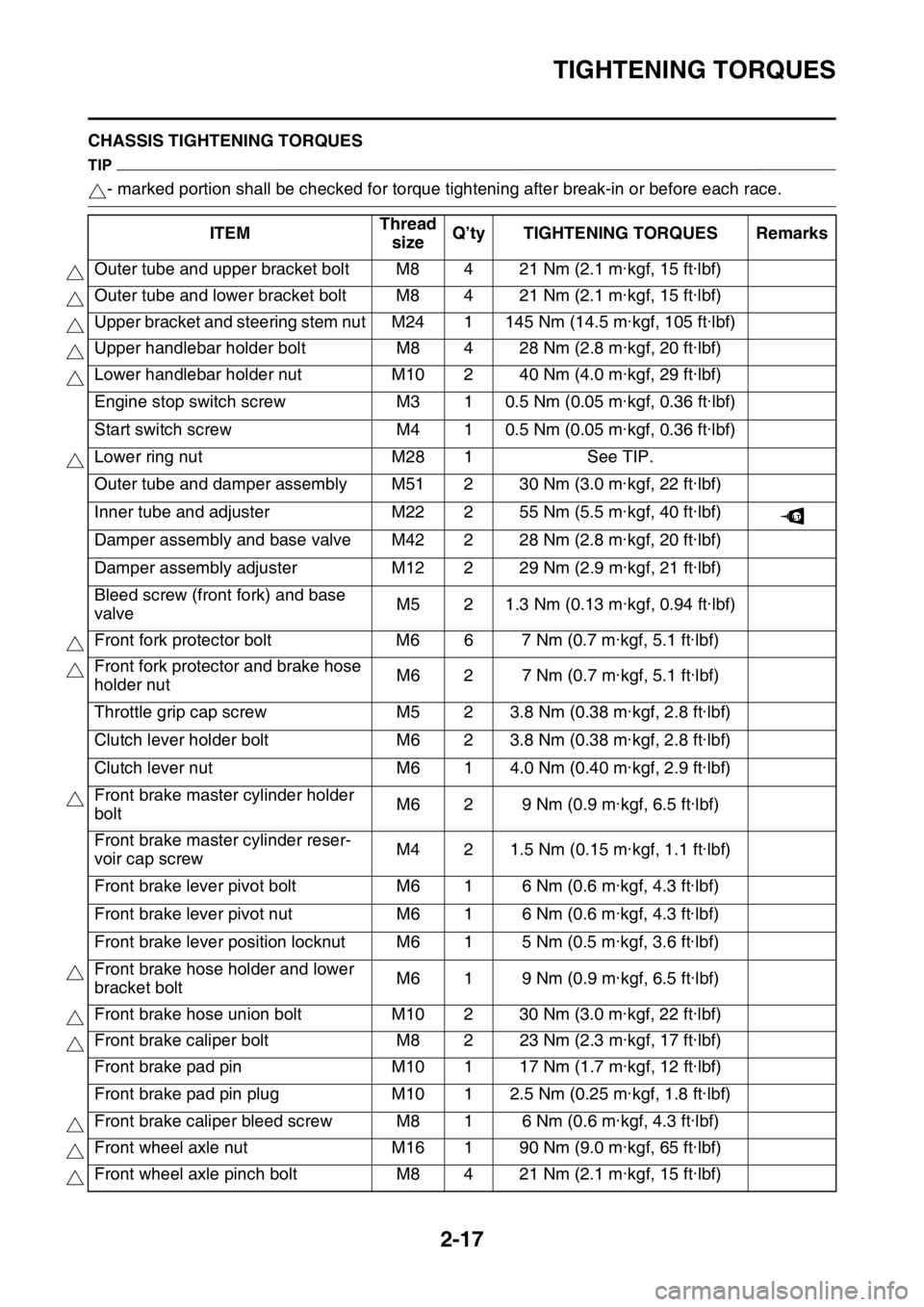

TIGHTENING TORQUES

2-17

EAS2GB2069CHASSIS TIGHTENING TORQUES

TIP

- marked portion shall be checked for torque tightening after break-in or before each race.

ITEMThread

sizeQ’ty TIGHTENING TORQUES Remarks

Outer tube and upper bracket bolt M8 4 21 Nm (2.1 m·kgf, 15 ft·lbf)

Outer tube and lower bracket bolt M8 4 21 Nm (2.1 m·kgf, 15 ft·lbf)

Upper bracket and steering stem nut M24 1 145 Nm (14.5 m·kgf, 105 ft·lbf)

Upper handlebar holder bolt M8 4 28 Nm (2.8 m·kgf, 20 ft·lbf)

Lower handlebar holder nut M10 2 40 Nm (4.0 m·kgf, 29 ft·lbf)

Engine stop switch screw M3 1 0.5 Nm (0.05 m·kgf, 0.36 ft·lbf)

Start switch screw M4 1 0.5 Nm (0.05 m·kgf, 0.36 ft·lbf)

Lower ring nut M28 1 See TIP.

Outer tube and damper assembly M51 2 30 Nm (3.0 m·kgf, 22 ft·lbf)

Inner tube and adjuster M22 2 55 Nm (5.5 m·kgf, 40 ft·lbf)

Damper assembly and base valve M42 2 28 Nm (2.8 m·kgf, 20 ft·lbf)

Damper assembly adjuster M12 2 29 Nm (2.9 m·kgf, 21 ft·lbf)

Bleed screw (front fork) and base

valveM5 2 1.3 Nm (0.13 m·kgf, 0.94 ft·lbf)

Front fork protector bolt M6 6 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Front fork protector and brake hose

holder nutM6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Throttle grip cap screw M5 2 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

Clutch lever holder bolt M6 2 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

Clutch lever nut M6 1 4.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

Front brake master cylinder holder

boltM6 2 9 Nm (0.9 m·kgf, 6.5 ft·lbf)

Front brake master cylinder reser-

voir cap screwM4 2 1.5 Nm (0.15 m·kgf, 1.1 ft·lbf)

Front brake lever pivot bolt M6 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Front brake lever pivot nut M6 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Front brake lever position locknut M6 1 5 Nm (0.5 m·kgf, 3.6 ft·lbf)

Front brake hose holder and lower

bracket boltM6 1 9 Nm (0.9 m·kgf, 6.5 ft·lbf)

Front brake hose union bolt M10 2 30 Nm (3.0 m·kgf, 22 ft·lbf)

Front brake caliper bolt M8 2 23 Nm (2.3 m·kgf, 17 ft·lbf)

Front brake pad pin M10 1 17 Nm (1.7 m·kgf, 12 ft·lbf)

Front brake pad pin plug M10 1 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Front brake caliper bleed screw M8 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Front wheel axle nut M16 1 90 Nm (9.0 m·kgf, 65 ft·lbf)

Front wheel axle pinch bolt M8 4 21 Nm (2.1 m·kgf, 15 ft·lbf)

LT

Page 89 of 430

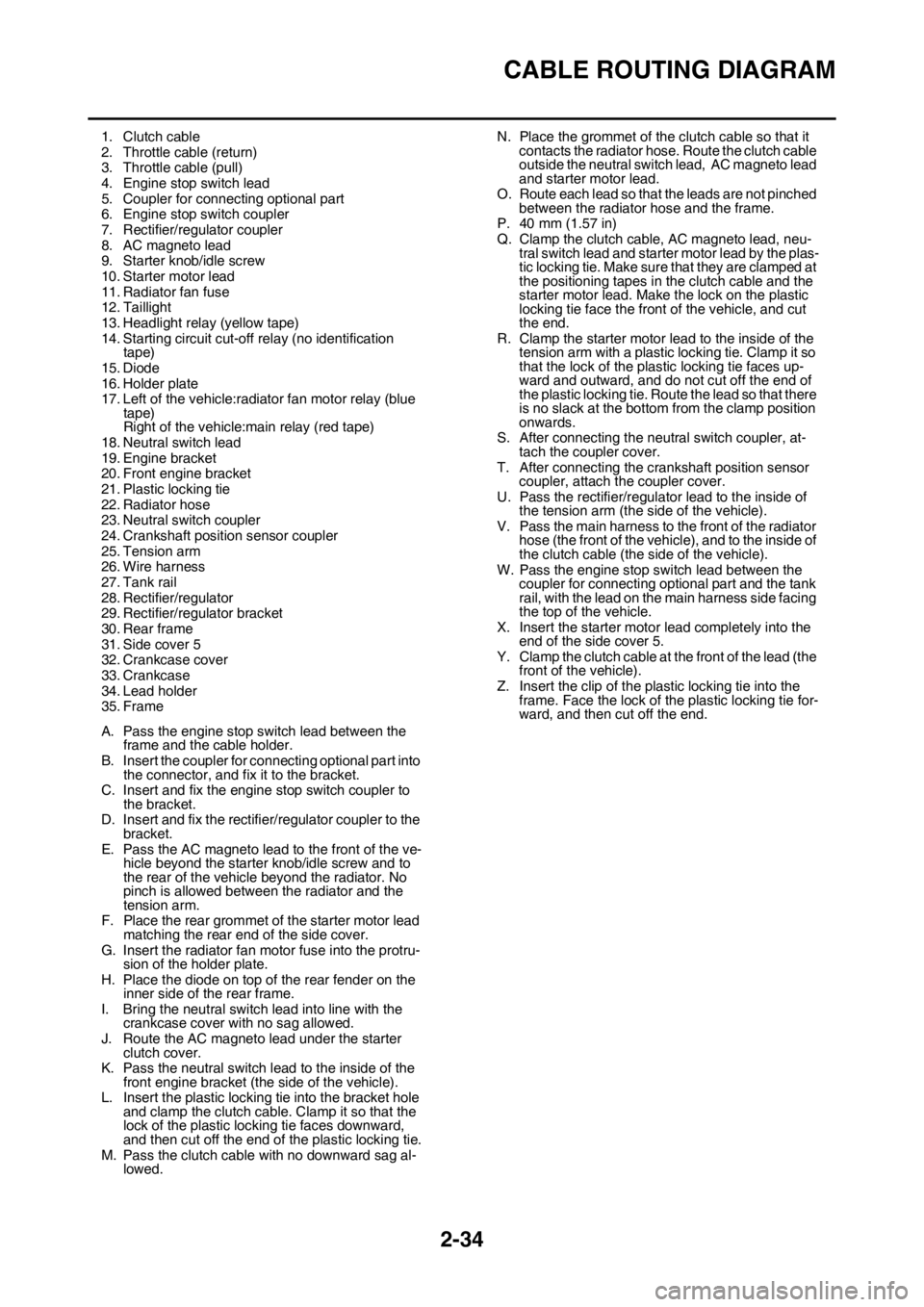

CABLE ROUTING DIAGRAM

2-34

1. Clutch cable

2. Throttle cable (return)

3. Throttle cable (pull)

4. Engine stop switch lead

5. Coupler for connecting optional part

6. Engine stop switch coupler

7. Rectifier/regulator coupler

8. AC magneto lead

9. Starter knob/idle screw

10. Starter motor lead

11. Radiator fan fuse

12. Taillight

13. Headlight relay (yellow tape)

14. Starting circuit cut-off relay (no identification

tape)

15. Diode

16. Holder plate

17. Left of the vehicle:radiator fan motor relay (blue

tape)

Right of the vehicle:main relay (red tape)

18. Neutral switch lead

19. Engine bracket

20. Front engine bracket

21. Plastic locking tie

22. Radiator hose

23. Neutral switch coupler

24. Crankshaft position sensor coupler

25. Tension arm

26. Wire harness

27. Tank rail

28. Rectifier/regulator

29. Rectifier/regulator bracket

30. Rear frame

31. Side cover 5

32. Crankcase cover

33. Crankcase

34. Lead holder

35. Frame

A. Pass the engine stop switch lead between the

frame and the cable holder.

B. Insert the coupler for connecting optional part into

the connector, and fix it to the bracket.

C. Insert and fix the engine stop switch coupler to

the bracket.

D. Insert and fix the rectifier/regulator coupler to the

bracket.

E. Pass the AC magneto lead to the front of the ve-

hicle beyond the starter knob/idle screw and to

the rear of the vehicle beyond the radiator. No

pinch is allowed between the radiator and the

tension arm.

F. Place the rear grommet of the starter motor lead

matching the rear end of the side cover.

G. Insert the radiator fan motor fuse into the protru-

sion of the holder plate.

H. Place the diode on top of the rear fender on the

inner side of the rear frame.

I. Bring the neutral switch lead into line with the

crankcase cover with no sag allowed.

J. Route the AC magneto lead under the starter

clutch cover.

K. Pass the neutral switch lead to the inside of the

front engine bracket (the side of the vehicle).

L. Insert the plastic locking tie into the bracket hole

and clamp the clutch cable. Clamp it so that the

lock of the plastic locking tie faces downward,

and then cut off the end of the plastic locking tie.

M. Pass the clutch cable with no downward sag al-

lowed.N. Place the grommet of the clutch cable so that it

contacts the radiator hose. Route the clutch cable

outside the neutral switch lead, AC magneto lead

and starter motor lead.

O. Route each lead so that the leads are not pinched

between the radiator hose and the frame.

P. 40 mm (1.57 in)

Q. Clamp the clutch cable, AC magneto lead, neu-

tral switch lead and starter motor lead by the plas-

tic locking tie. Make sure that they are clamped at

the positioning tapes in the clutch cable and the

starter motor lead. Make the lock on the plastic

locking tie face the front of the vehicle, and cut

the end.

R. Clamp the starter motor lead to the inside of the

tension arm with a plastic locking tie. Clamp it so

that the lock of the plastic locking tie faces up-

ward and outward, and do not cut off the end of

the plastic locking tie. Route the lead so that there

is no slack at the bottom from the clamp position

onwards.

S. After connecting the neutral switch coupler, at-

tach the coupler cover.

T. After connecting the crankshaft position sensor

coupler, attach the coupler cover.

U. Pass the rectifier/regulator lead to the inside of

the tension arm (the side of the vehicle).

V. Pass the main harness to the front of the radiator

hose (the front of the vehicle), and to the inside of

the clutch cable (the side of the vehicle).

W. Pass the engine stop switch lead between the

coupler for connecting optional part and the tank

rail, with the lead on the main harness side facing

the top of the vehicle.

X. Insert the starter motor lead completely into the

end of the side cover 5.

Y. Clamp the clutch cable at the front of the lead (the

front of the vehicle).

Z. Insert the clip of the plastic locking tie into the

frame. Face the lock of the plastic locking tie for-

ward, and then cut off the end.

Page 97 of 430

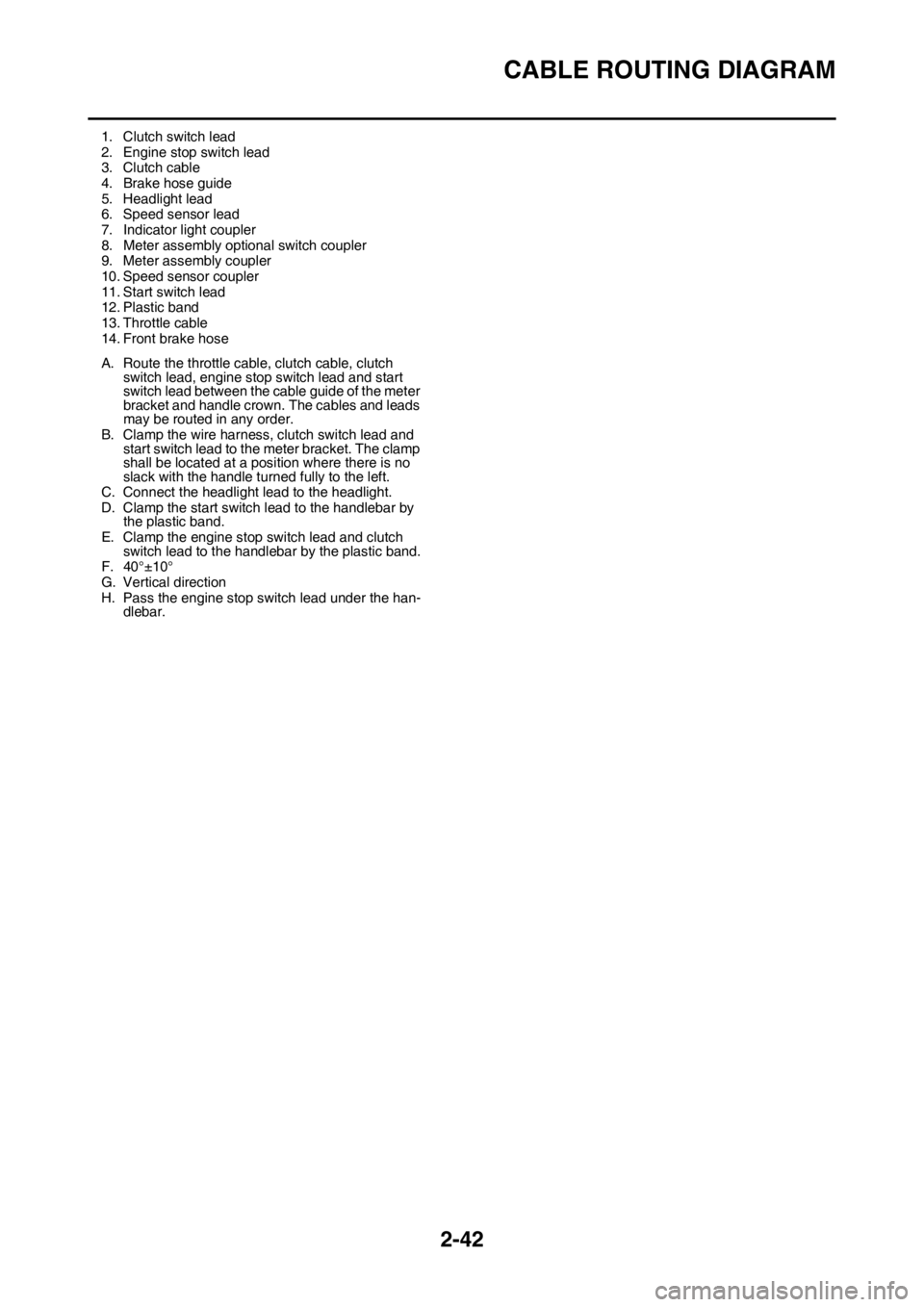

CABLE ROUTING DIAGRAM

2-42

1. Clutch switch lead

2. Engine stop switch lead

3. Clutch cable

4. Brake hose guide

5. Headlight lead

6. Speed sensor lead

7. Indicator light coupler

8. Meter assembly optional switch coupler

9. Meter assembly coupler

10. Speed sensor coupler

11. Start switch lead

12. Plastic band

13. Throttle cable

14. Front brake hose

A. Route the throttle cable, clutch cable, clutch

switch lead, engine stop switch lead and start

switch lead between the cable guide of the meter

bracket and handle crown. The cables and leads

may be routed in any order.

B. Clamp the wire harness, clutch switch lead and

start switch lead to the meter bracket. The clamp

shall be located at a position where there is no

slack with the handle turned fully to the left.

C. Connect the headlight lead to the headlight.

D. Clamp the start switch lead to the handlebar by

the plastic band.

E. Clamp the engine stop switch lead and clutch

switch lead to the handlebar by the plastic band.

F. 40°±10°

G. Vertical direction

H. Pass the engine stop switch lead under the han-

dlebar.

Page 114 of 430

ENGINE

3-10

EAS2GB2083

ENGINE

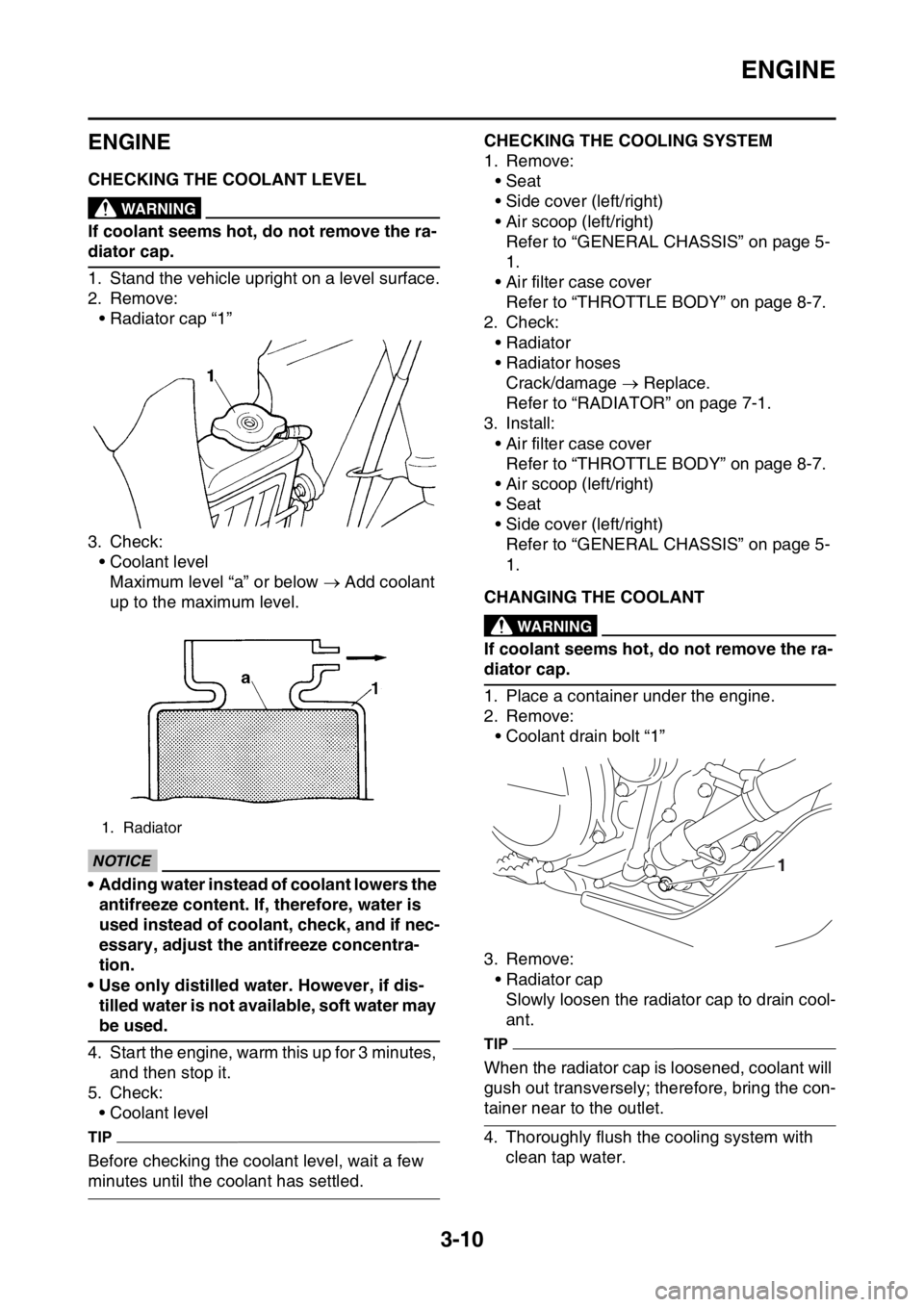

EAS2GB2084CHECKING THE COOLANT LEVELEWA

WARNING

If coolant seems hot, do not remove the ra-

diator cap.

1. Stand the vehicle upright on a level surface.

2. Remove:

• Radiator cap “1”

3. Check:

• Coolant level

Maximum level “a” or below Add coolant

up to the maximum level.

ECA

NOTICE

• Adding water instead of coolant lowers the

antifreeze content. If, therefore, water is

used instead of coolant, check, and if nec-

essary, adjust the antifreeze concentra-

tion.

• Use only distilled water. However, if dis-

tilled water is not available, soft water may

be used.

4. Start the engine, warm this up for 3 minutes,

and then stop it.

5. Check:

• Coolant level

TIP

Before checking the coolant level, wait a few

minutes until the coolant has settled.

EAS2GB2085CHECKING THE COOLING SYSTEM

1. Remove:

• Seat

• Side cover (left/right)

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 5-

1.

• Air filter case cover

Refer to “THROTTLE BODY” on page 8-7.

2. Check:

• Radiator

• Radiator hoses

Crack/damage Replace.

Refer to “RADIATOR” on page 7-1.

3. Install:

• Air filter case cover

Refer to “THROTTLE BODY” on page 8-7.

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 5-

1.

EAS2GB2086CHANGING THE COOLANTEWA

WARNING

If coolant seems hot, do not remove the ra-

diator cap.

1. Place a container under the engine.

2. Remove:

• Coolant drain bolt “1”

3. Remove:

• Radiator cap

Slowly loosen the radiator cap to drain cool-

ant.

TIP

When the radiator cap is loosened, coolant will

gush out transversely; therefore, bring the con-

tainer near to the outlet.

4. Thoroughly flush the cooling system with

clean tap water.

1. Radiator

1

Page 115 of 430

ENGINE

3-11

5. Install:

• Copper washer

• Coolant drain bolt

6. Pour coolant.

EWA

WARNING

• If coolant splashes in your eyes, thorough-

ly wash them with water and consult a

doctor.

• If coolant splashes on your clothes, quick-

ly wash it away with water and then with

soap and water.

• If coolant is swallowed, induce vomiting

and get immediate medical attention.

ECA

NOTICE

• Adding water instead of coolant lowers the

antifreeze content of the coolant. If water

is used instead of coolant check, and if

necessary, correct the antifreeze concen-

tration of the coolant.

• Use only distilled water. However, if dis-

tilled water is not available, soft water may

be used.

• If coolant comes into contact with painted

surfaces, immediately wash them with wa-

ter.

• Do not mix different types of antifreeze.

7. Install:

• Radiator cap

8. Start the engine, warm this up for 3 minutes,

stop it, and then wait for it to cool down.

9. Check:

• Coolant level

Refer to “CHECKING THE COOLANT LEV-

EL” on page 3-10.

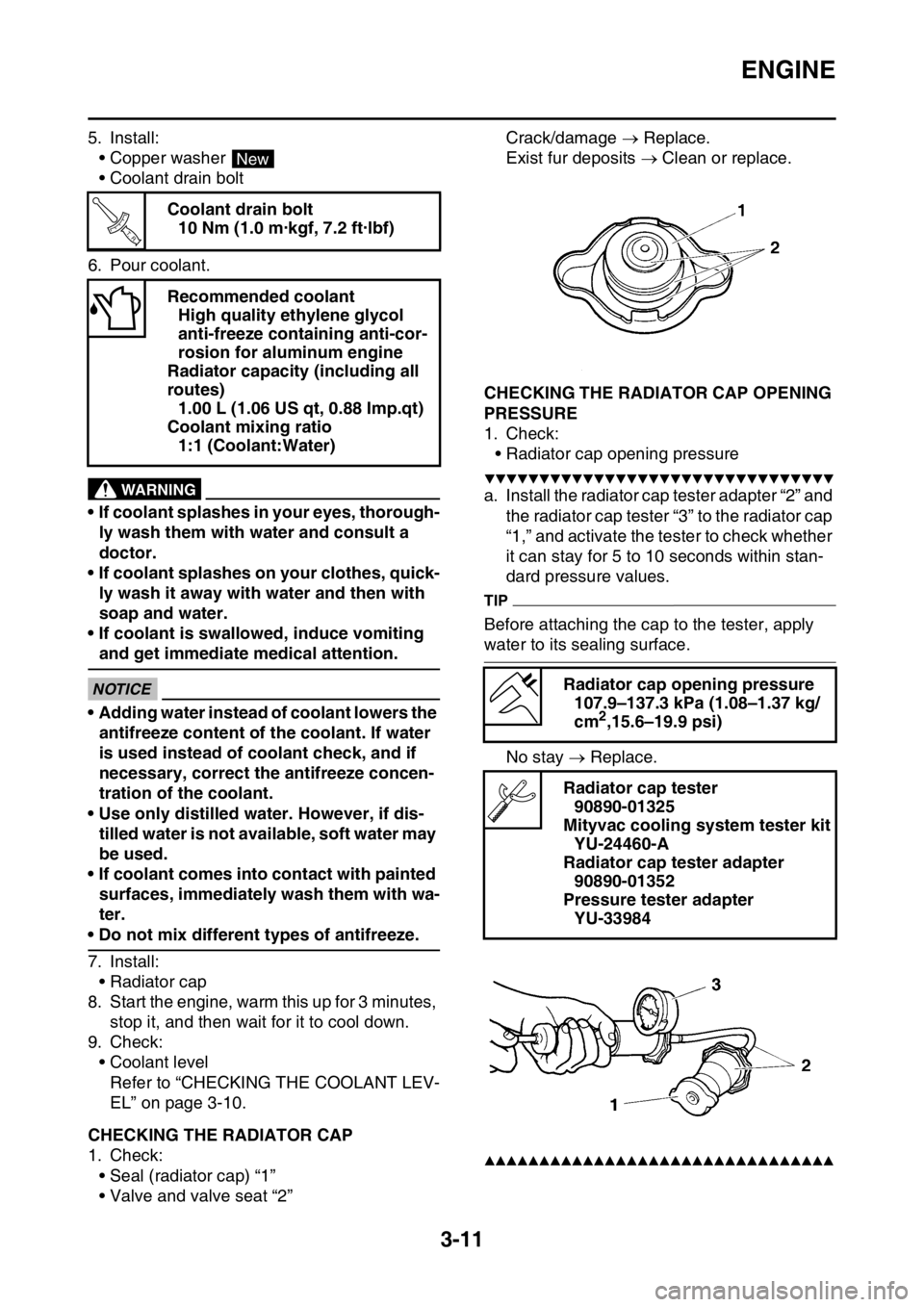

EAS2GB2087CHECKING THE RADIATOR CAP

1. Check:

• Seal (radiator cap) “1”

• Valve and valve seat “2”Crack/damage Replace.

Exist fur deposits Clean or replace.

EAS2GB2088CHECKING THE RADIATOR CAP OPENING

PRESSURE

1. Check:

• Radiator cap opening pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Install the radiator cap tester adapter “2” and

the radiator cap tester “3” to the radiator cap

“1,” and activate the tester to check whether

it can stay for 5 to 10 seconds within stan-

dard pressure values.

TIP

Before attaching the cap to the tester, apply

water to its sealing surface.

No stay Replace.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Coolant drain bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Recommended coolant

High quality ethylene glycol

anti-freeze containing anti-cor-

rosion for aluminum engine

Radiator capacity (including all

routes)

1.00 L (1.06 US qt, 0.88 Imp.qt)

Coolant mixing ratio

1:1 (Coolant:Water)

New

T R..

Radiator cap opening pressure

107.9–137.3 kPa (1.08–1.37 kg/

cm

2,15.6–19.9 psi)

Radiator cap tester

90890-01325

Mityvac cooling system tester kit

YU-24460-A

Radiator cap tester adapter

90890-01352

Pressure tester adapter

YU-33984

Page 120 of 430

ENGINE

3-16

4. Install:

• Exhaust pipe protector

EAS2GB2097CHECKING THE FUEL LINE

1. Remove:

• Seat

• Side cover (left/right)

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 5-

1.

• Fuel tank

Refer to “FUEL TANK” on page 8-1.

2. Check:

• Fuel hose “1”

Crack/damage Replace.

Loose connection Connect properly.

3. Install:

• Fuel tank

Refer to “FUEL TANK” on page 8-1.

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 5-

1.

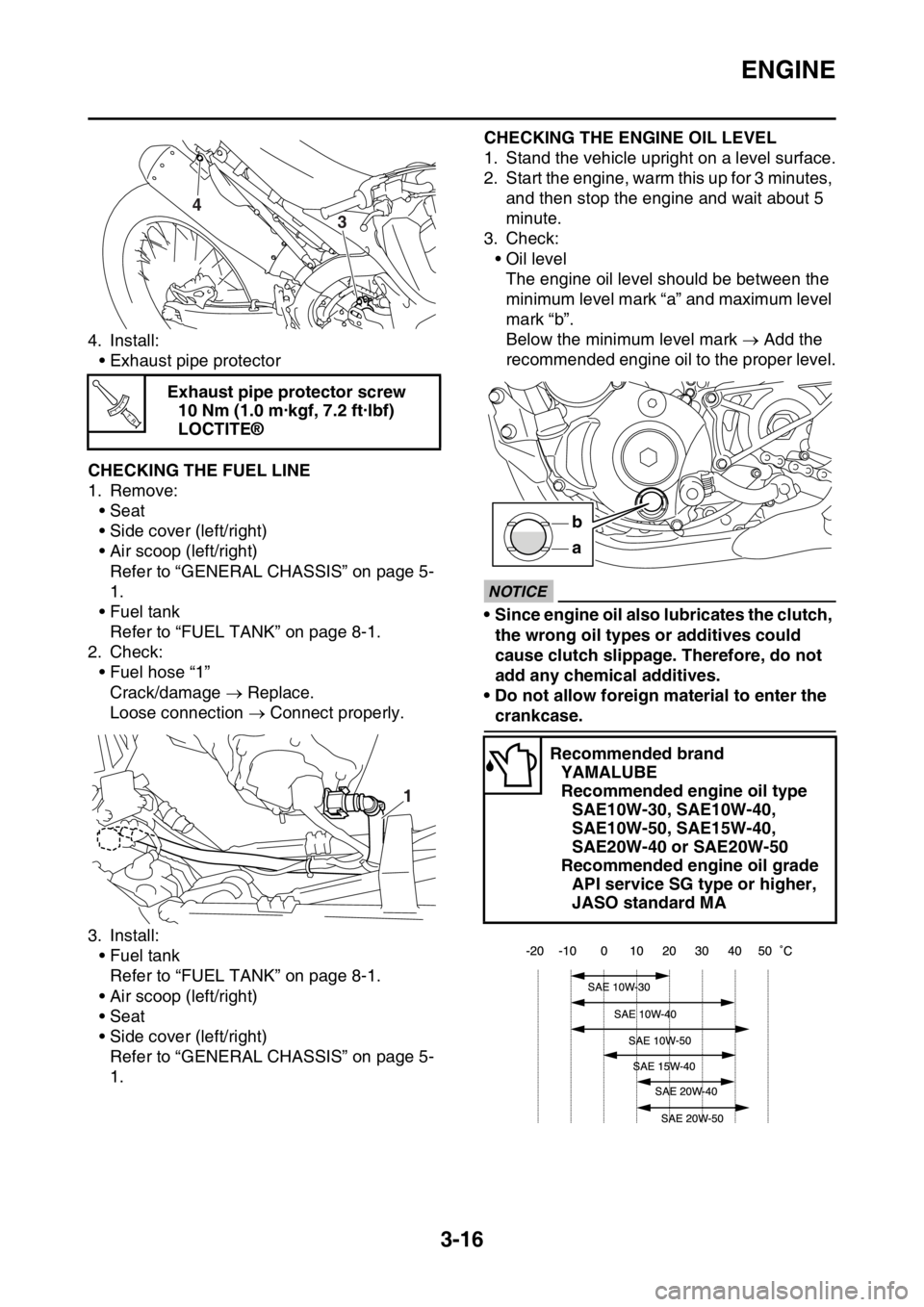

EAS2GB2098

CHECKING THE ENGINE OIL LEVEL

1. Stand the vehicle upright on a level surface.

2. Start the engine, warm this up for 3 minutes,

and then stop the engine and wait about 5

minute.

3. Check:

• Oil level

The engine oil level should be between the

minimum level mark “a” and maximum level

mark “b”.

Below the minimum level mark Add the

recommended engine oil to the proper level.

ECA

NOTICE

• Since engine oil also lubricates the clutch,

the wrong oil types or additives could

cause clutch slippage. Therefore, do not

add any chemical additives.

• Do not allow foreign material to enter the

crankcase. Exhaust pipe protector screw

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

LOCTITE®

4

3

T R..

1

Recommended brand

YAMALUBE

Recommended engine oil type

SAE10W-30, SAE10W-40,

SAE10W-50, SAE15W-40,

SAE20W-40 or SAE20W-50

Recommended engine oil grade

API service SG type or higher,

JASO standard MA

a b

Page 121 of 430

ENGINE

3-17

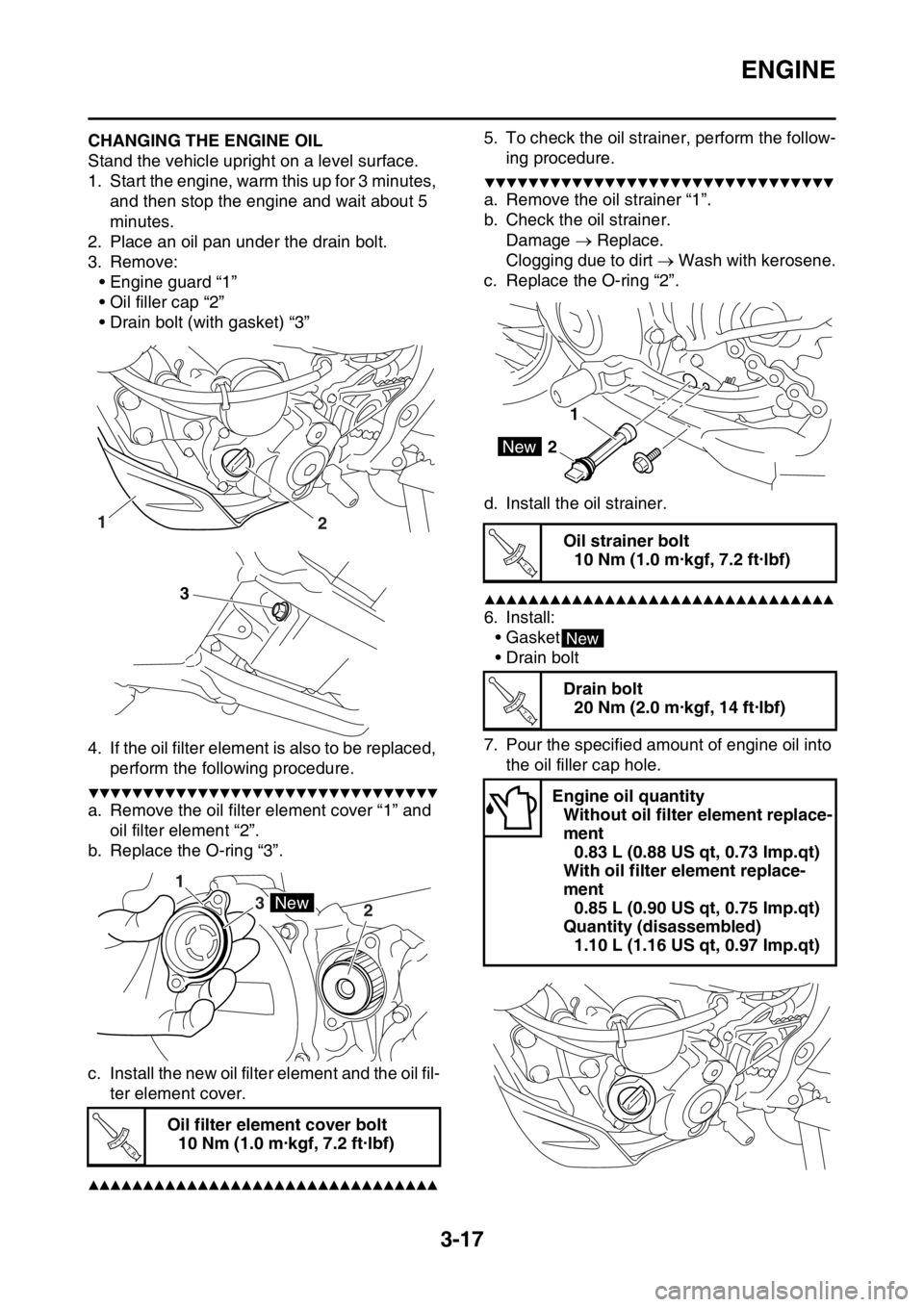

EAS2GB2099CHANGING THE ENGINE OIL

Stand the vehicle upright on a level surface.

1. Start the engine, warm this up for 3 minutes,

and then stop the engine and wait about 5

minutes.

2. Place an oil pan under the drain bolt.

3. Remove:

• Engine guard “1”

• Oil filler cap “2”

• Drain bolt (with gasket) “3”

4. If the oil filter element is also to be replaced,

perform the following procedure.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the oil filter element cover “1” and

oil filter element “2”.

b. Replace the O-ring “3”.

c. Install the new oil filter element and the oil fil-

ter element cover.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. To check the oil strainer, perform the follow-

ing procedure.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the oil strainer “1”.

b. Check the oil strainer.

Damage Replace.

Clogging due to dirt Wash with kerosene.

c. Replace the O-ring “2”.

d. Install the oil strainer.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

6. Install:

•Gasket

• Drain bolt

7. Pour the specified amount of engine oil into

the oil filler cap hole.

Oil filter element cover bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

12

3

1

3

2

New

T R..

Oil strainer bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Drain bolt

20 Nm (2.0 m·kgf, 14 ft·lbf)

Engine oil quantity

Without oil filter element replace-

ment

0.83 L (0.88 US qt, 0.73 Imp.qt)

With oil filter element replace-

ment

0.85 L (0.90 US qt, 0.75 Imp.qt)

Quantity (disassembled)

1.10 L (1.16 US qt, 0.97 Imp.qt)

1

2New

T R..

New

T R..

Page 191 of 430

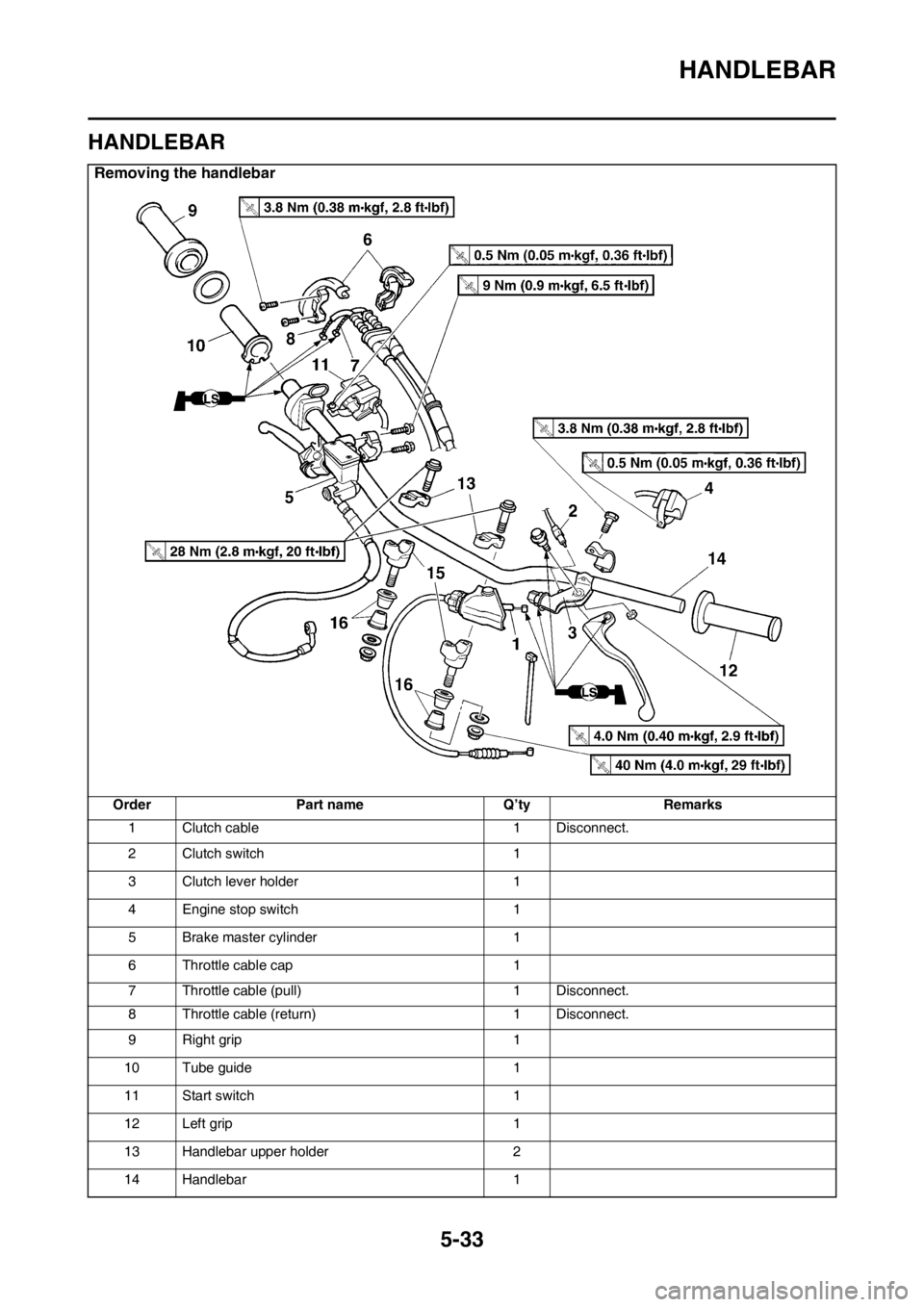

HANDLEBAR

5-33

EAS2GB2195

HANDLEBAR

Removing the handlebar

Order Part name Q’ty Remarks

1 Clutch cable 1 Disconnect.

2 Clutch switch 1

3 Clutch lever holder 1

4 Engine stop switch 1

5 Brake master cylinder 1

6 Throttle cable cap 1

7 Throttle cable (pull) 1 Disconnect.

8 Throttle cable (return) 1 Disconnect.

9 Right grip 1

10 Tube guide 1

11 Start switch 1

12 Left grip 1

13 Handlebar upper holder 2

14 Handlebar 1

Page 230 of 430

CLUTCH......................................................................................................... 6-40

REMOVING THE CLUTCH ...................................................................... 6-43

CHECKING THE FRICTION PLATES...................................................... 6-43

CHECKING THE CLUTCH PLATES ........................................................ 6-43

CHECKING THE CLUTCH SPRINGS...................................................... 6-43

CHECKING THE CLUTCH HOUSING ..................................................... 6-44

CHECKING THE CLUTCH BOSS ............................................................ 6-44

CHECKING THE PRESSURE PLATE ..................................................... 6-44

CHECKING THE PUSH LEVER SHAFT .................................................. 6-44

CHECKING THE CLUTCH PUSH RODS ................................................ 6-44

CHECKING THE PRIMARY DRIVE GEAR .............................................. 6-44

CHECKING THE PRIMARY DRIVEN GEAR ........................................... 6-45

INSTALLING THE OIL SEAL................................................................... 6-45

INSTALLING THE RIGHT CRANKCASE COVER ................................... 6-45

INSTALLING THE CLUTCH ..................................................................... 6-45

INSTALLING THE KICKSTARTER LEVER ............................................. 6-48

KICKSTATER................................................................................................. 6-49

REMOVING THE KICK SHAFT ASSEMBLY ........................................... 6-50

CHECKING THE KICK SHAFT AND RATCHET WHEEL ........................ 6-50

CHECKING THE KICK GEAR, KICK IDLE GEAR AND RATCHET

WHEEL .................................................................................................... 6-50

INSTALLING THE KICK SHAFT ASSEMBLY .......................................... 6-50

INSTALLING THE KICK IDLE GEAR ....................................................... 6-51

SHIFT SHAFT................................................................................................. 6-52

REMOVING THE SHIFT GUIDE AND SHIFT LEVER ASSEMBLY ......... 6-53

REMOVING THE SEGMENT ................................................................... 6-53

CHECKING THE SHIFT SHAFT .............................................................. 6-53

CHECKING THE SHIFT GUIDE AND SHIFT LEVER ASSEMBLY ......... 6-53

CHECKING THE STOPPER LEVER ....................................................... 6-53

INSTALLING THE STOPPER LEVER ..................................................... 6-54

INSTALLING THE SEGMENT.................................................................. 6-54

INSTALLING THE SHIFT GUIDE AND SHIFT LEVER ASSEMBLY ....... 6-54

INSTALLING THE SHIFT SHAFT ............................................................ 6-55

INSTALLING THE SHIFT PEDAL ............................................................ 6-55

OIL PUMP AND BALANCER GEAR............................................................. 6-56

REMOVING THE BALANCER ................................................................. 6-58

CHECKING THE PRIMARY DRIVE GEAR, BALANCER SHAFT DRIVE

GEAR, AND BALANCER WEIGHT GEAR .............................................. 6-58

CHECKING THE BALANCER .................................................................. 6-58

CHECKING THE OIL PUMP .................................................................... 6-58

ASSEMBLING THE OIL PUMP ................................................................ 6-59

INSTALLING THE OIL PUMP AND BALANCER GEAR .......................... 6-59