lock YAMAHA WR 250F 2015 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: WR 250F, Model: YAMAHA WR 250F 2015Pages: 430, PDF Size: 14.14 MB

Page 130 of 430

CHASSIS

3-26

EAS2GB2107ADJUSTING THE REAR BRAKE

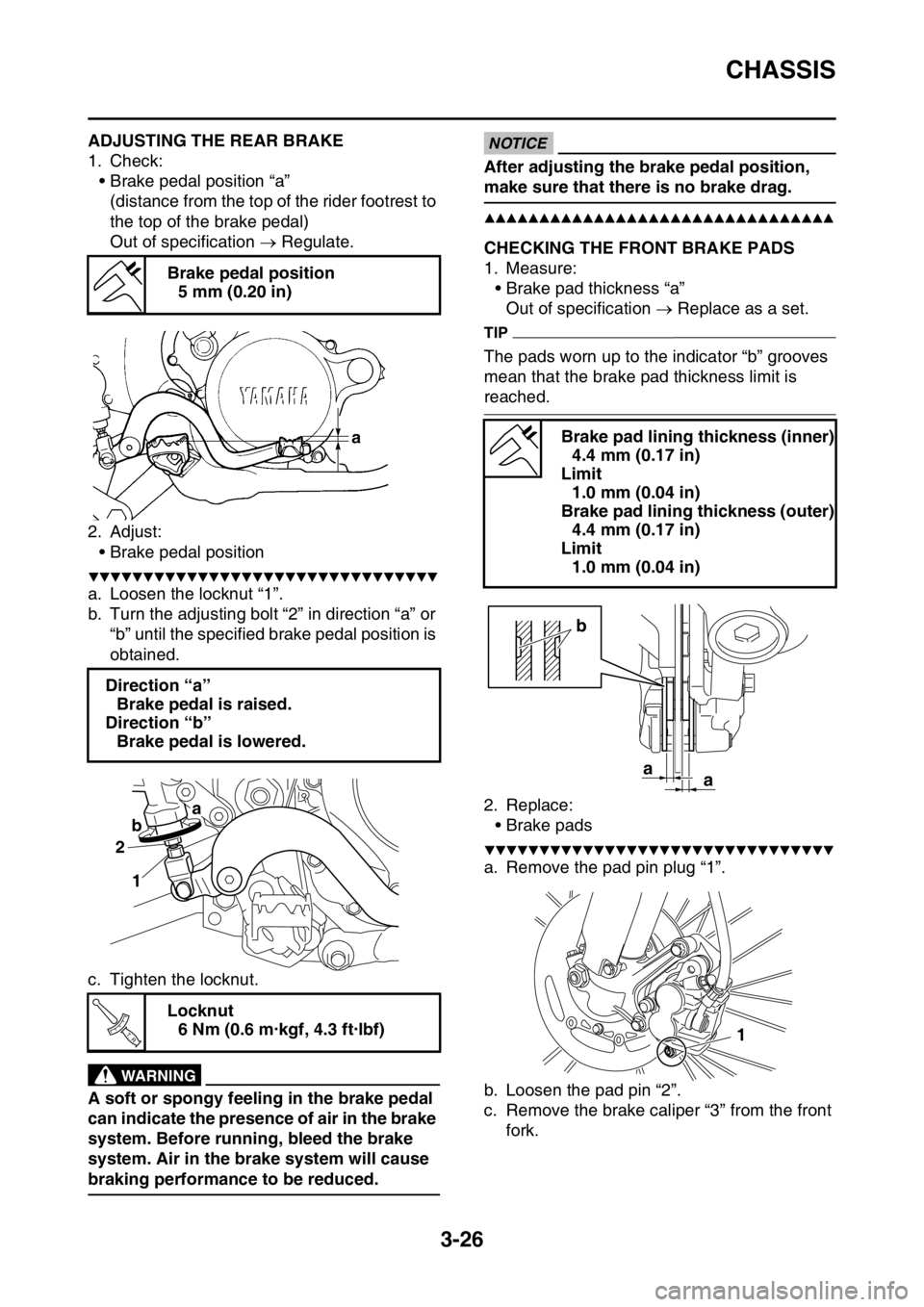

1. Check:

• Brake pedal position “a”

(distance from the top of the rider footrest to

the top of the brake pedal)

Out of specification Regulate.

2. Adjust:

• Brake pedal position

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the locknut “1”.

b. Turn the adjusting bolt “2” in direction “a” or

“b” until the specified brake pedal position is

obtained.

c. Tighten the locknut.

EWA

WARNING

A soft or spongy feeling in the brake pedal

can indicate the presence of air in the brake

system. Before running, bleed the brake

system. Air in the brake system will cause

braking performance to be reduced.

ECA

NOTICE

After adjusting the brake pedal position,

make sure that there is no brake drag.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2108CHECKING THE FRONT BRAKE PADS

1. Measure:

• Brake pad thickness “a”

Out of specification Replace as a set.

TIP

The pads worn up to the indicator “b” grooves

mean that the brake pad thickness limit is

reached.

2. Replace:

• Brake pads

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the pad pin plug “1”.

b. Loosen the pad pin “2”.

c. Remove the brake caliper “3” from the front

fork. Brake pedal position

5 mm (0.20 in)

Direction “a”

Brake pedal is raised.

Direction “b”

Brake pedal is lowered.

Locknut

6 Nm (0.6 m·kgf, 4.3 ft·lbf)1 2

a

b

T R..

Brake pad lining thickness (inner)

4.4 mm (0.17 in)

Limit

1.0 mm (0.04 in)

Brake pad lining thickness (outer)

4.4 mm (0.17 in)

Limit

1.0 mm (0.04 in)

a

b

a

1

Page 134 of 430

CHASSIS

3-30

EWA

WARNING

• Use only the designated brake fluid. Other

brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor

brake performance.

• Refill with the same type of brake fluid that

is already in the system. Mixing brake flu-

ids may result in a harmful chemical reac-

tion, leading to poor brake performance.

• When refilling, be careful that water does

not enter the brake fluid reservoir. Water

will significantly lower the boiling point of

the brake fluid and could cause vapor

lock.

ECA

NOTICE

Brake fluid may damage painted surfaces

and plastic parts. Therefore, always clean

up any spilt brake fluid immediately.

EAS2GB2112ADJUSTING THE DRIVE CHAIN SLACKECA

NOTICE

A drive chain that is too tight will overload

the engine and other vital parts, and one

that is too loose can skip and damage the

swingarm or cause an accident. Therefore,

keep the drive chain slack within the speci-

fied limits.

1. Use a suitable stand to raise the rear wheel

off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Shift the transmission into the neutral posi-

tion.

3. Pull the drive chain up above the drive chain

guide installation bolt with a force of about

50 N (5.0 kgf, 36 lbf).

4. Check:

• Drive chain slack “a”

Out of specification Regulate.

TIP

Measure drive chain slack between the drive

chain guide and the bottom of the chain as

shown.5. Adjust:

• Drive chain slack

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the wheel axle nut “1”.

b. Loosen both locknuts “2”.

c. Turn the adjusting bolt “3” in direction “a” or

“b” until the specified drive chain slack is ob-

tained.

TIP

• To maintain the proper wheel alignment, ad-

just both sides evenly.

• Push the rear wheel forward to make sure that

there is no clearance between the swingarm

end plates and the ends of the swingarm.

d. Tighten the locknut.

e. Tighten the wheel axle nut.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Drive chain slack

50–60 mm (1.97–2.36 in)

Direction “a”

The drive chain slack decreases.

Direction “b”

The drive chain slack increases.

Locknut

21 Nm (2.1 m·kgf, 15 ft·lbf)

Wheel axle nut

125 Nm (12.5 m·kgf, 90 ft·lbf)

a

1

32

a

b

T R..

T R..

Page 137 of 430

CHASSIS

3-33

EAS2GB2118CHECKING THE SWINGARM OPERATION

1. Check:

• Swingarm smooth action

• Swingarm free play

Refer to “SWINGARM” on page 5-64.

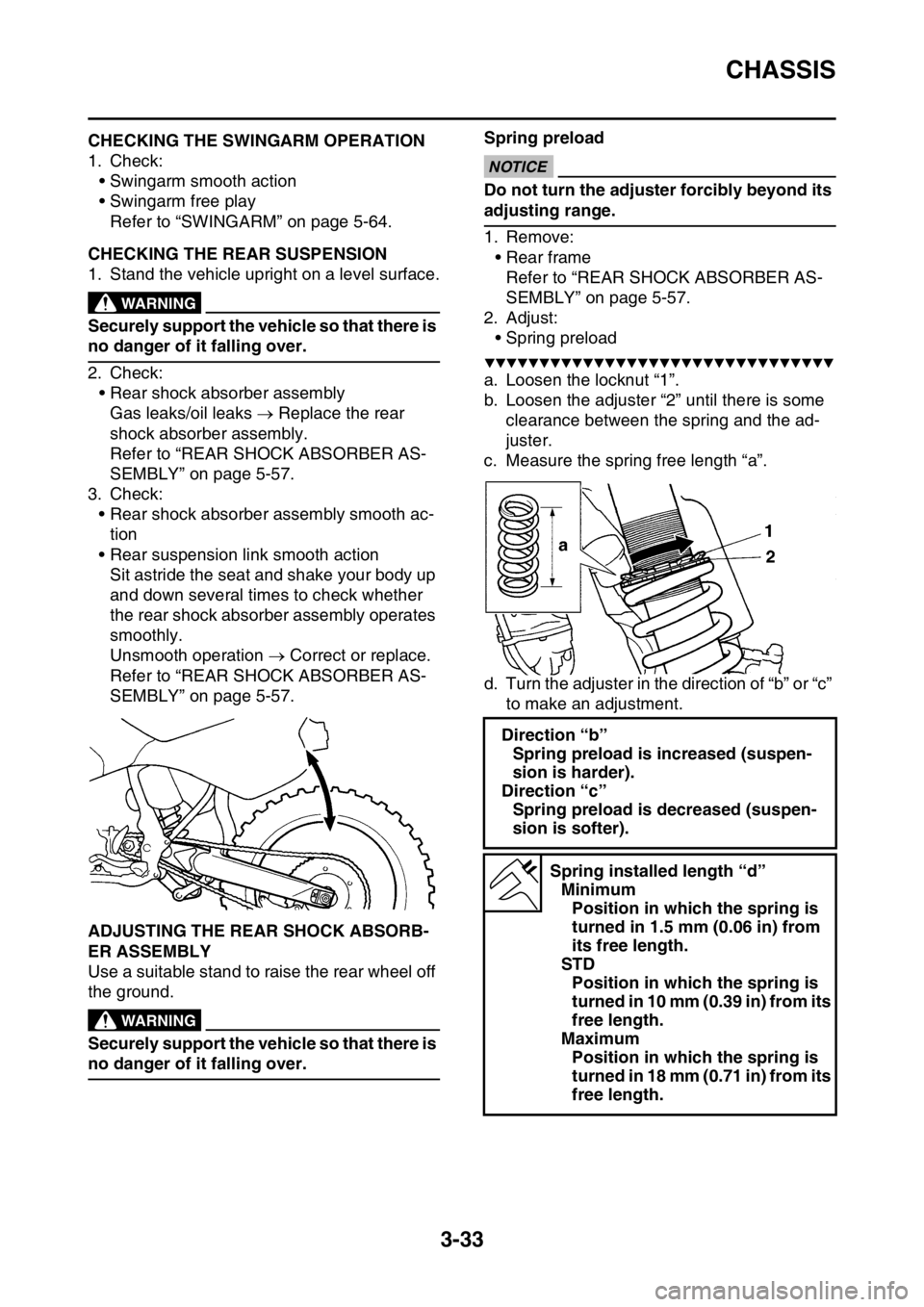

EAS2GB2119CHECKING THE REAR SUSPENSION

1. Stand the vehicle upright on a level surface.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Check:

• Rear shock absorber assembly

Gas leaks/oil leaks Replace the rear

shock absorber assembly.

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 5-57.

3. Check:

• Rear shock absorber assembly smooth ac-

tion

• Rear suspension link smooth action

Sit astride the seat and shake your body up

and down several times to check whether

the rear shock absorber assembly operates

smoothly.

Unsmooth operation Correct or replace.

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 5-57.

EAS2GB2120ADJUSTING THE REAR SHOCK ABSORB-

ER ASSEMBLY

Use a suitable stand to raise the rear wheel off

the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.Spring preload

ECA

NOTICE

Do not turn the adjuster forcibly beyond its

adjusting range.

1. Remove:

• Rear frame

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 5-57.

2. Adjust:

• Spring preload

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the locknut “1”.

b. Loosen the adjuster “2” until there is some

clearance between the spring and the ad-

juster.

c. Measure the spring free length “a”.

d. Turn the adjuster in the direction of “b” or “c”

to make an adjustment.

Direction “b”

Spring preload is increased (suspen-

sion is harder).

Direction “c”

Spring preload is decreased (suspen-

sion is softer).

Spring installed length “d”

Minimum

Position in which the spring is

turned in 1.5 mm (0.06 in) from

its free length.

STD

Position in which the spring is

turned in 10 mm (0.39 in) from its

free length.

Maximum

Position in which the spring is

turned in 18 mm (0.71 in) from its

free length.

Page 138 of 430

CHASSIS

3-34

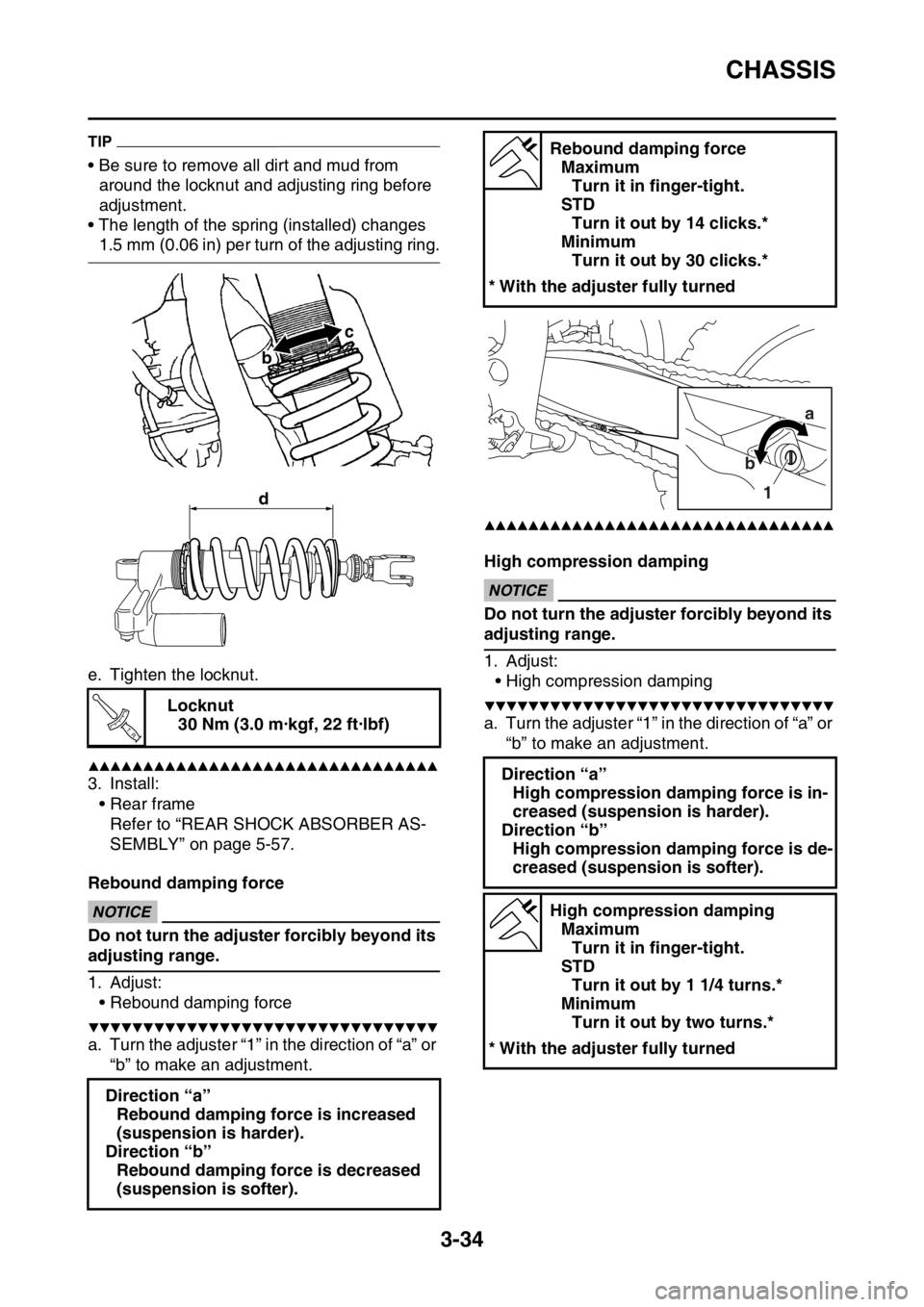

TIP

• Be sure to remove all dirt and mud from

around the locknut and adjusting ring before

adjustment.

• The length of the spring (installed) changes

1.5 mm (0.06 in) per turn of the adjusting ring.

e. Tighten the locknut.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Install:

• Rear frame

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 5-57.

Rebound damping force

ECA

NOTICE

Do not turn the adjuster forcibly beyond its

adjusting range.

1. Adjust:

• Rebound damping force

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the adjuster “1” in the direction of “a” or

“b” to make an adjustment.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

High compression dampingECA

NOTICE

Do not turn the adjuster forcibly beyond its

adjusting range.

1. Adjust:

• High compression damping

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the adjuster “1” in the direction of “a” or

“b” to make an adjustment. Locknut

30 Nm (3.0 m·kgf, 22 ft·lbf)

Direction “a”

Rebound damping force is increased

(suspension is harder).

Direction “b”

Rebound damping force is decreased

(suspension is softer).

c

b

d

T R..

Rebound damping force

Maximum

Turn it in finger-tight.

STD

Turn it out by 14 clicks.*

Minimum

Turn it out by 30 clicks.*

* With the adjuster fully turned

Direction “a”

High compression damping force is in-

creased (suspension is harder).

Direction “b”

High compression damping force is de-

creased (suspension is softer).

High compression damping

Maximum

Turn it in finger-tight.

STD

Turn it out by 1 1/4 turns.*

Minimum

Turn it out by two turns.*

* With the adjuster fully turned

a

b

1

Page 143 of 430

ELECTRICAL SYSTEM

3-39

EAS2GB2132

ELECTRICAL SYSTEM

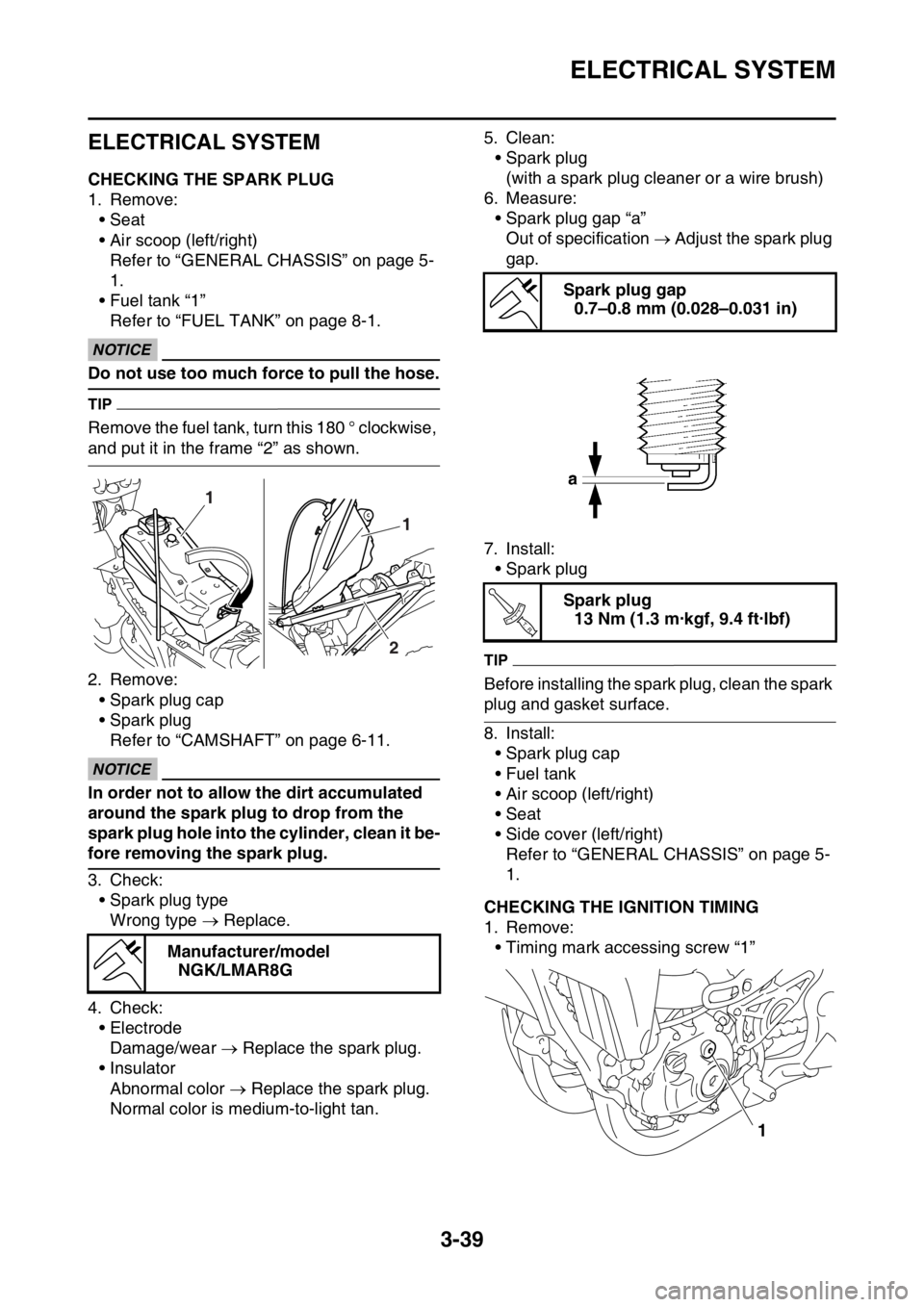

EAS2GB2133CHECKING THE SPARK PLUG

1. Remove:

• Seat

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 5-

1.

• Fuel tank “1”

Refer to “FUEL TANK” on page 8-1.

ECA

NOTICE

Do not use too much force to pull the hose.

TIP

Remove the fuel tank, turn this 180 ° clockwise,

and put it in the frame “2” as shown.

2. Remove:

• Spark plug cap

• Spark plug

Refer to “CAMSHAFT” on page 6-11.

ECA

NOTICE

In order not to allow the dirt accumulated

around the spark plug to drop from the

spark plug hole into the cylinder, clean it be-

fore removing the spark plug.

3. Check:

• Spark plug type

Wrong type Replace.

4. Check:

• Electrode

Damage/wear Replace the spark plug.

• Insulator

Abnormal color Replace the spark plug.

Normal color is medium-to-light tan.5. Clean:

• Spark plug

(with a spark plug cleaner or a wire brush)

6. Measure:

• Spark plug gap “a”

Out of specification Adjust the spark plug

gap.

7. Install:

• Spark plug

TIP

Before installing the spark plug, clean the spark

plug and gasket surface.

8. Install:

• Spark plug cap

• Fuel tank

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 5-

1.

EAS2GB2134CHECKING THE IGNITION TIMING

1. Remove:

• Timing mark accessing screw “1”

Manufacturer/model

NGK/LMAR8G

1

1

2

Spark plug gap

0.7–0.8 mm (0.028–0.031 in)

Spark plug

13 Nm (1.3 m·kgf, 9.4 ft·lbf)

T R..

1

Page 150 of 430

CHASSIS

4-3

TIP

Generally a stiff spring gives a stiff riding feel-

ing. Rebound damping tends to become weak-

er, resulting in lack of a sense of contact with

the road surface or in a vibrating handlebar.

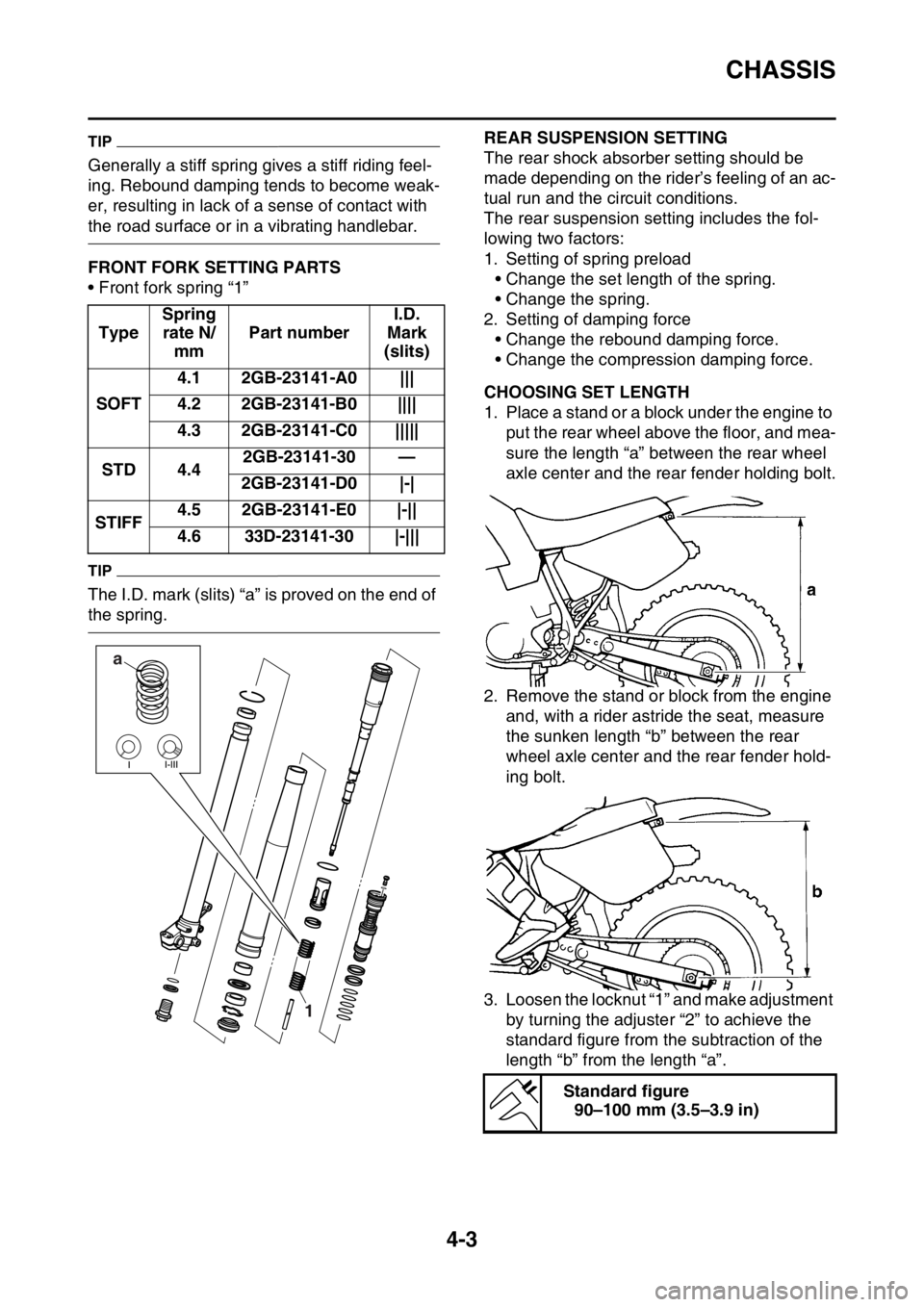

EAS2GB2145FRONT FORK SETTING PARTS

• Front fork spring “1”

TIP

The I.D. mark (slits) “a” is proved on the end of

the spring.

EAS2GB2146

REAR SUSPENSION SETTING

The rear shock absorber setting should be

made depending on the rider’s feeling of an ac-

tual run and the circuit conditions.

The rear suspension setting includes the fol-

lowing two factors:

1. Setting of spring preload

• Change the set length of the spring.

• Change the spring.

2. Setting of damping force

• Change the rebound damping force.

• Change the compression damping force.

EAS2GB2147CHOOSING SET LENGTH

1. Place a stand or a block under the engine to

put the rear wheel above the floor, and mea-

sure the length “a” between the rear wheel

axle center and the rear fender holding bolt.

2. Remove the stand or block from the engine

and, with a rider astride the seat, measure

the sunken length “b” between the rear

wheel axle center and the rear fender hold-

ing bolt.

3. Loosen the locknut “1” and make adjustment

by turning the adjuster “2” to achieve the

standard figure from the subtraction of the

length “b” from the length “a”. TypeSpring

rate N/

mmPart numberI.D.

Mark

(slits)

SOFT4.1 2GB-23141-A0 |||

4.2 2GB-23141-B0 ||||

4.3 2GB-23141-C0 |||||

STD 4.42GB-23141-30 —

2GB-23141-D0 |-|

STIFF4.5 2GB-23141-E0 |-||

4.6 33D-23141-30 |-|||

a

1

Standard figure

90–100 mm (3.5–3.9 in)

Page 153 of 430

CHASSIS

4-6

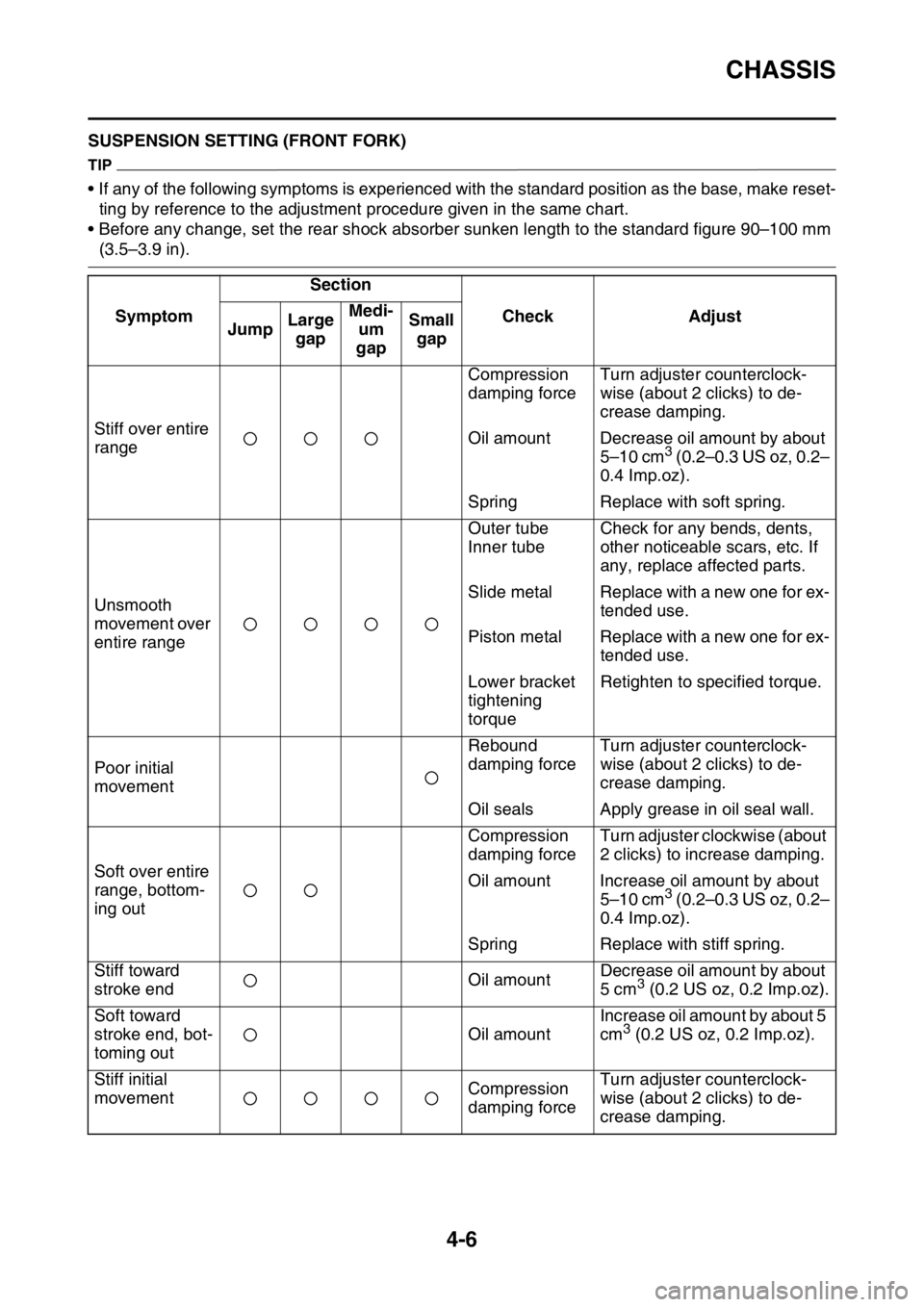

EAS2GB2150SUSPENSION SETTING (FRONT FORK)

TIP

• If any of the following symptoms is experienced with the standard position as the base, make reset-

ting by reference to the adjustment procedure given in the same chart.

• Before any change, set the rear shock absorber sunken length to the standard figure 90–100 mm

(3.5–3.9 in).

SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap

Stiff over entire

rangeCompression

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Oil amount Decrease oil amount by about

5–10 cm

3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

Spring Replace with soft spring.

Unsmooth

movement over

entire rangeOuter tube

Inner tubeCheck for any bends, dents,

other noticeable scars, etc. If

any, replace affected parts.

Slide metal Replace with a new one for ex-

tended use.

Piston metal Replace with a new one for ex-

tended use.

Lower bracket

tightening

torqueRetighten to specified torque.

Poor initial

movementRebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Oil seals Apply grease in oil seal wall.

Soft over entire

range, bottom-

ing outCompression

damping forceTurn adjuster clockwise (about

2 clicks) to increase damping.

Oil amount Increase oil amount by about

5–10 cm

3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

Spring Replace with stiff spring.

Stiff toward

stroke endOil amountDecrease oil amount by about

5 cm

3 (0.2 US oz, 0.2 Imp.oz).

Soft toward

stroke end, bot-

toming outOil amountIncrease oil amount by about 5

cm

3 (0.2 US oz, 0.2 Imp.oz).

Stiff initial

movementCompression

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Page 154 of 430

CHASSIS

4-7

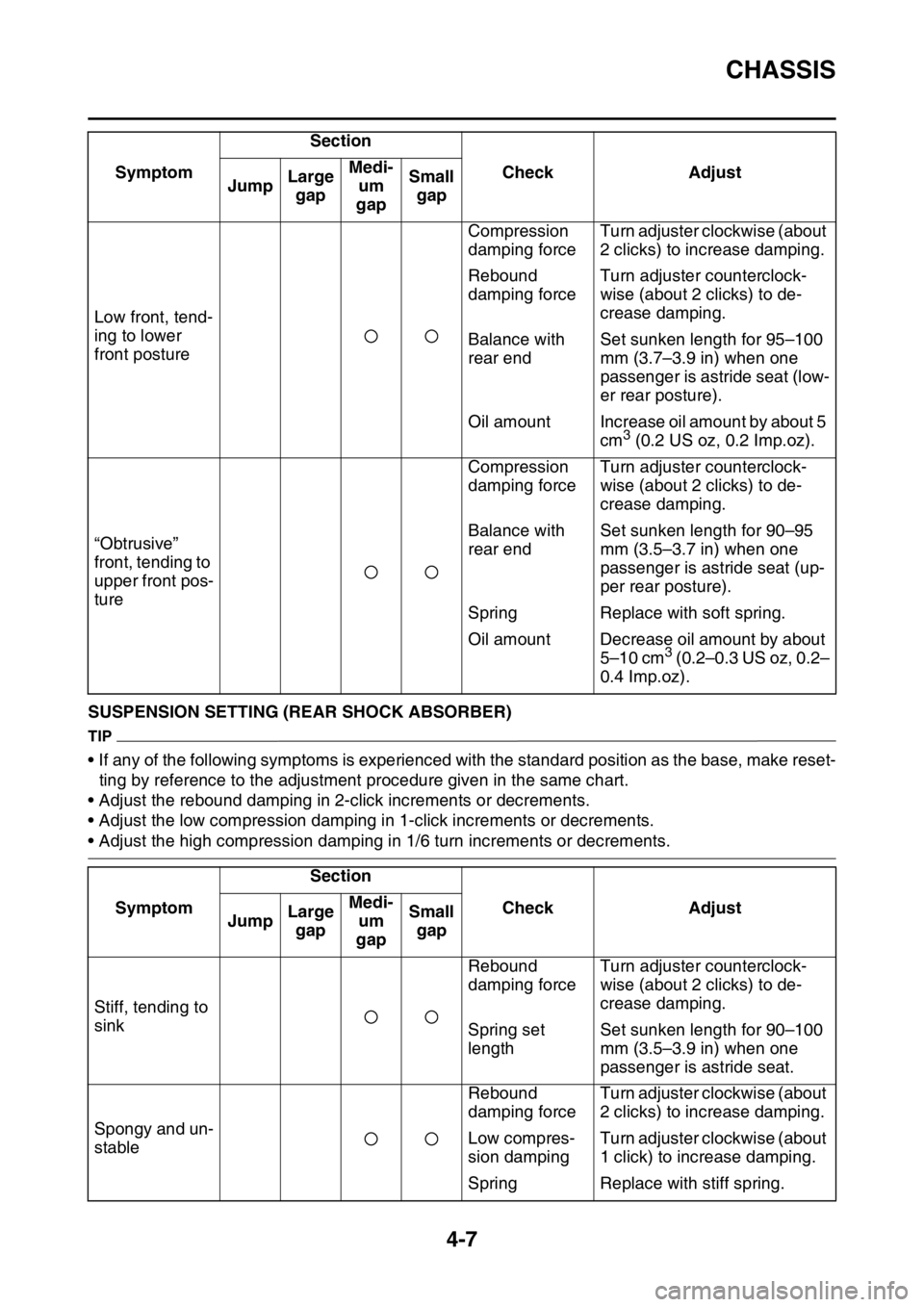

EAS2GB2151SUSPENSION SETTING (REAR SHOCK ABSORBER)

TIP

• If any of the following symptoms is experienced with the standard position as the base, make reset-

ting by reference to the adjustment procedure given in the same chart.

• Adjust the rebound damping in 2-click increments or decrements.

• Adjust the low compression damping in 1-click increments or decrements.

• Adjust the high compression damping in 1/6 turn increments or decrements. Low front, tend-

ing to lower

front postureCompression

damping forceTurn adjuster clockwise (about

2 clicks) to increase damping.

Rebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Balance with

rear endSet sunken length for 95–100

mm (3.7–3.9 in) when one

passenger is astride seat (low-

er rear posture).

Oil amount Increase oil amount by about 5

cm

3 (0.2 US oz, 0.2 Imp.oz).

“Obtrusive”

front, tending to

upper front pos-

tureCompression

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Balance with

rear endSet sunken length for 90–95

mm (3.5–3.7 in) when one

passenger is astride seat (up-

per rear posture).

Spring Replace with soft spring.

Oil amount Decrease oil amount by about

5–10 cm

3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap

Stiff, tending to

sinkRebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Spring set

lengthSet sunken length for 90–100

mm (3.5–3.9 in) when one

passenger is astride seat.

Spongy and un-

stableRebound

damping forceTurn adjuster clockwise (about

2 clicks) to increase damping.

Low compres-

sion dampingTurn adjuster clockwise (about

1 click) to increase damping.

Spring Replace with stiff spring. SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap

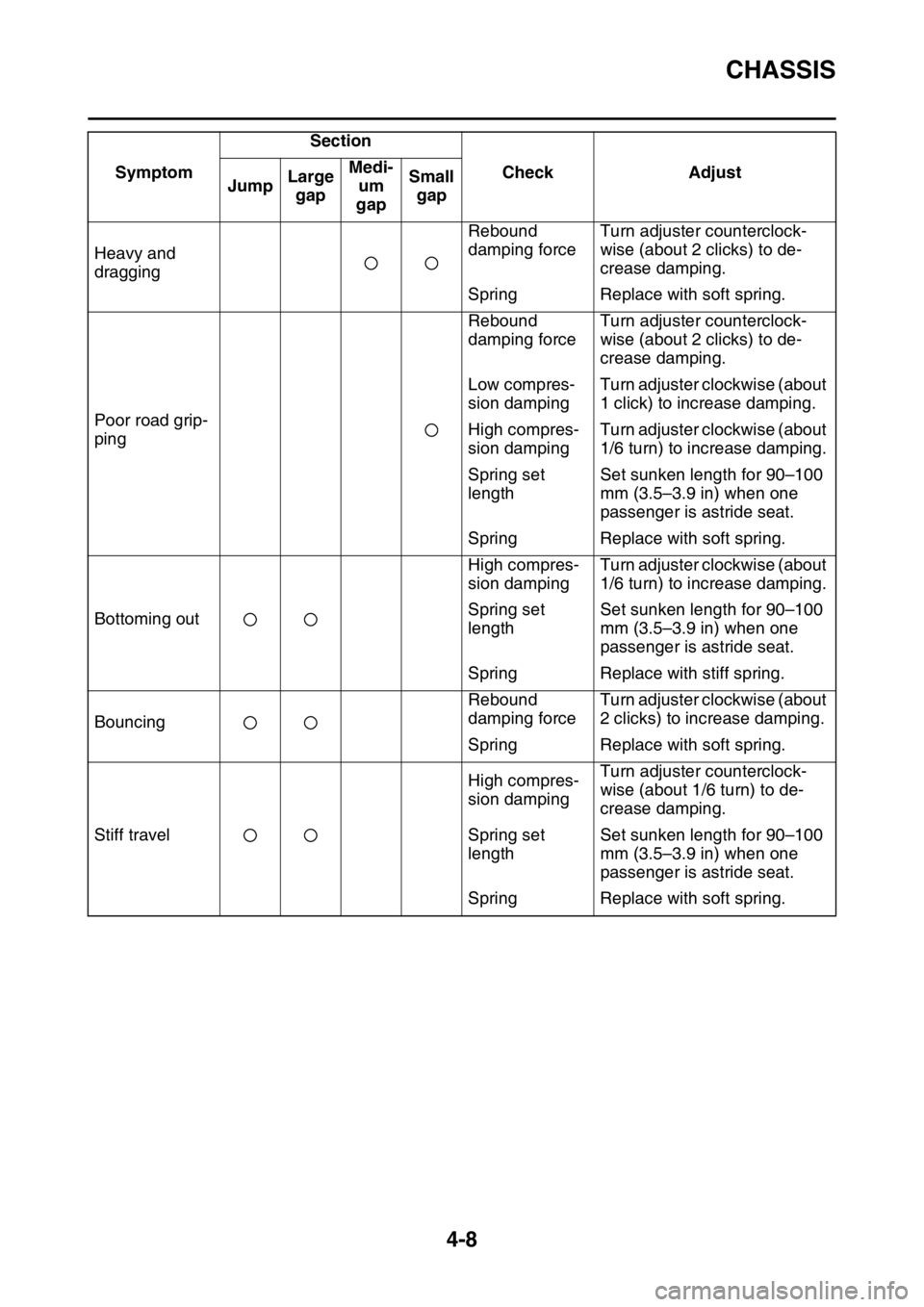

Page 155 of 430

CHASSIS

4-8

Heavy and

draggingRebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Spring Replace with soft spring.

Poor road grip-

pingRebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Low compres-

sion dampingTurn adjuster clockwise (about

1 click) to increase damping.

High compres-

sion dampingTurn adjuster clockwise (about

1/6 turn) to increase damping.

Spring set

lengthSet sunken length for 90–100

mm (3.5–3.9 in) when one

passenger is astride seat.

Spring Replace with soft spring.

Bottoming outHigh compres-

sion dampingTurn adjuster clockwise (about

1/6 turn) to increase damping.

Spring set

lengthSet sunken length for 90–100

mm (3.5–3.9 in) when one

passenger is astride seat.

Spring Replace with stiff spring.

BouncingRebound

damping forceTurn adjuster clockwise (about

2 clicks) to increase damping.

Spring Replace with soft spring.

Stiff travelHigh compres-

sion dampingTurn adjuster counterclock-

wise (about 1/6 turn) to de-

crease damping.

Spring set

lengthSet sunken length for 90–100

mm (3.5–3.9 in) when one

passenger is astride seat.

Spring Replace with soft spring. SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap

Page 168 of 430

REAR WHEEL

5-10

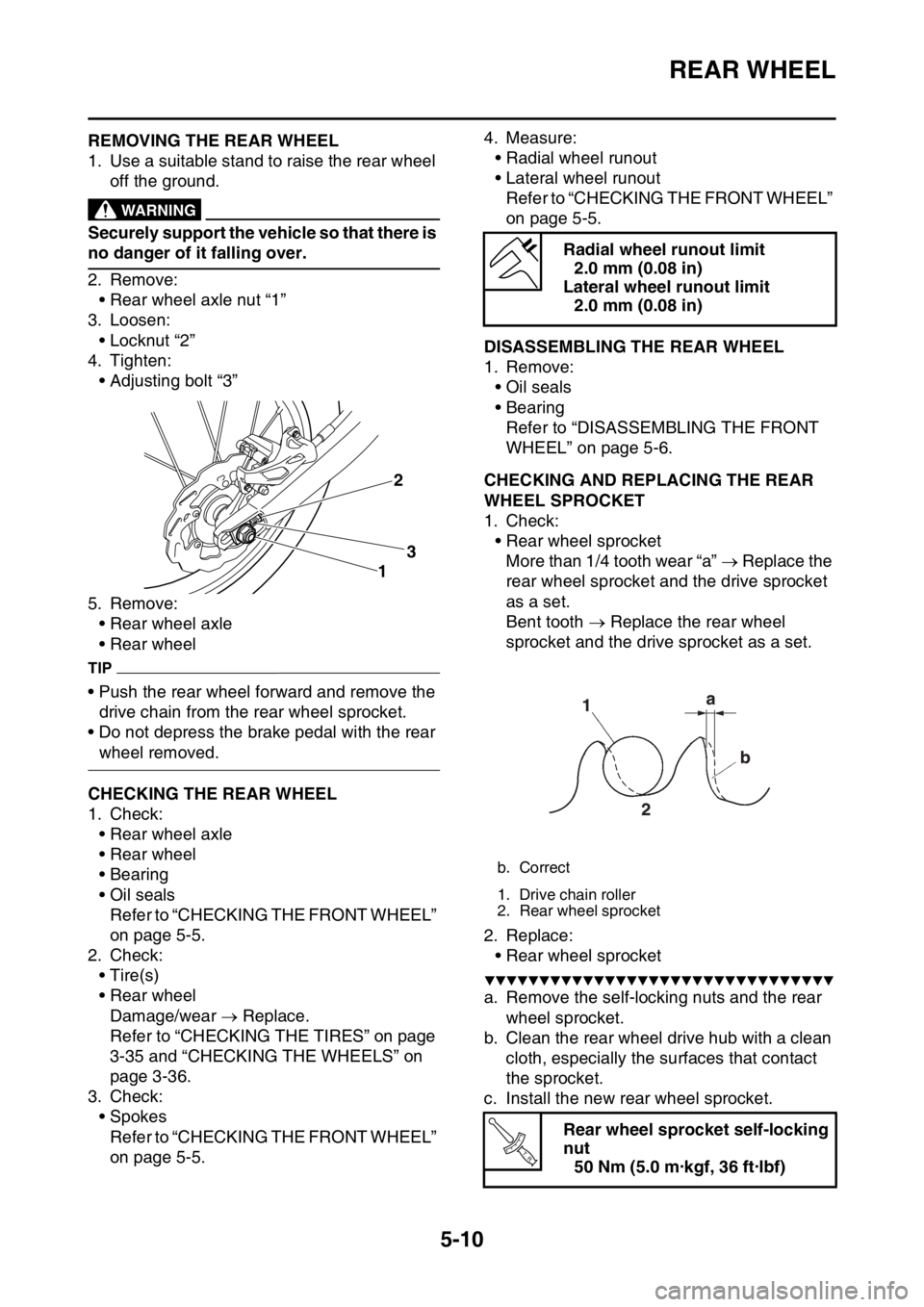

EAS2GB2163REMOVING THE REAR WHEEL

1. Use a suitable stand to raise the rear wheel

off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Remove:

• Rear wheel axle nut “1”

3. Loosen:

• Locknut “2”

4. Tighten:

• Adjusting bolt “3”

5. Remove:

• Rear wheel axle

• Rear wheel

TIP

• Push the rear wheel forward and remove the

drive chain from the rear wheel sprocket.

• Do not depress the brake pedal with the rear

wheel removed.

EAS2GB2164CHECKING THE REAR WHEEL

1. Check:

• Rear wheel axle

• Rear wheel

• Bearing

• Oil seals

Refer to “CHECKING THE FRONT WHEEL”

on page 5-5.

2. Check:

•Tire(s)

• Rear wheel

Damage/wear Replace.

Refer to “CHECKING THE TIRES” on page

3-35 and “CHECKING THE WHEELS” on

page 3-36.

3. Check:

• Spokes

Refer to “CHECKING THE FRONT WHEEL”

on page 5-5.4. Measure:

• Radial wheel runout

• Lateral wheel runout

Refer to “CHECKING THE FRONT WHEEL”

on page 5-5.

EAS2GB2165DISASSEMBLING THE REAR WHEEL

1. Remove:

• Oil seals

• Bearing

Refer to “DISASSEMBLING THE FRONT

WHEEL” on page 5-6.

EAS2GB2166CHECKING AND REPLACING THE REAR

WHEEL SPROCKET

1. Check:

• Rear wheel sprocket

More than 1/4 tooth wear “a” Replace the

rear wheel sprocket and the drive sprocket

as a set.

Bent tooth Replace the rear wheel

sprocket and the drive sprocket as a set.

2. Replace:

• Rear wheel sprocket

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the self-locking nuts and the rear

wheel sprocket.

b. Clean the rear wheel drive hub with a clean

cloth, especially the surfaces that contact

the sprocket.

c. Install the new rear wheel sprocket.

3

12

Radial wheel runout limit

2.0 mm (0.08 in)

Lateral wheel runout limit

2.0 mm (0.08 in)

b. Correct

1. Drive chain roller

2. Rear wheel sprocket

Rear wheel sprocket self-locking

nut

50 Nm (5.0 m·kgf, 36 ft·lbf)

T R..