lock YAMAHA WR 250F 2015 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: WR 250F, Model: YAMAHA WR 250F 2015Pages: 430, PDF Size: 14.14 MB

Page 207 of 430

FRONT FORK

5-49

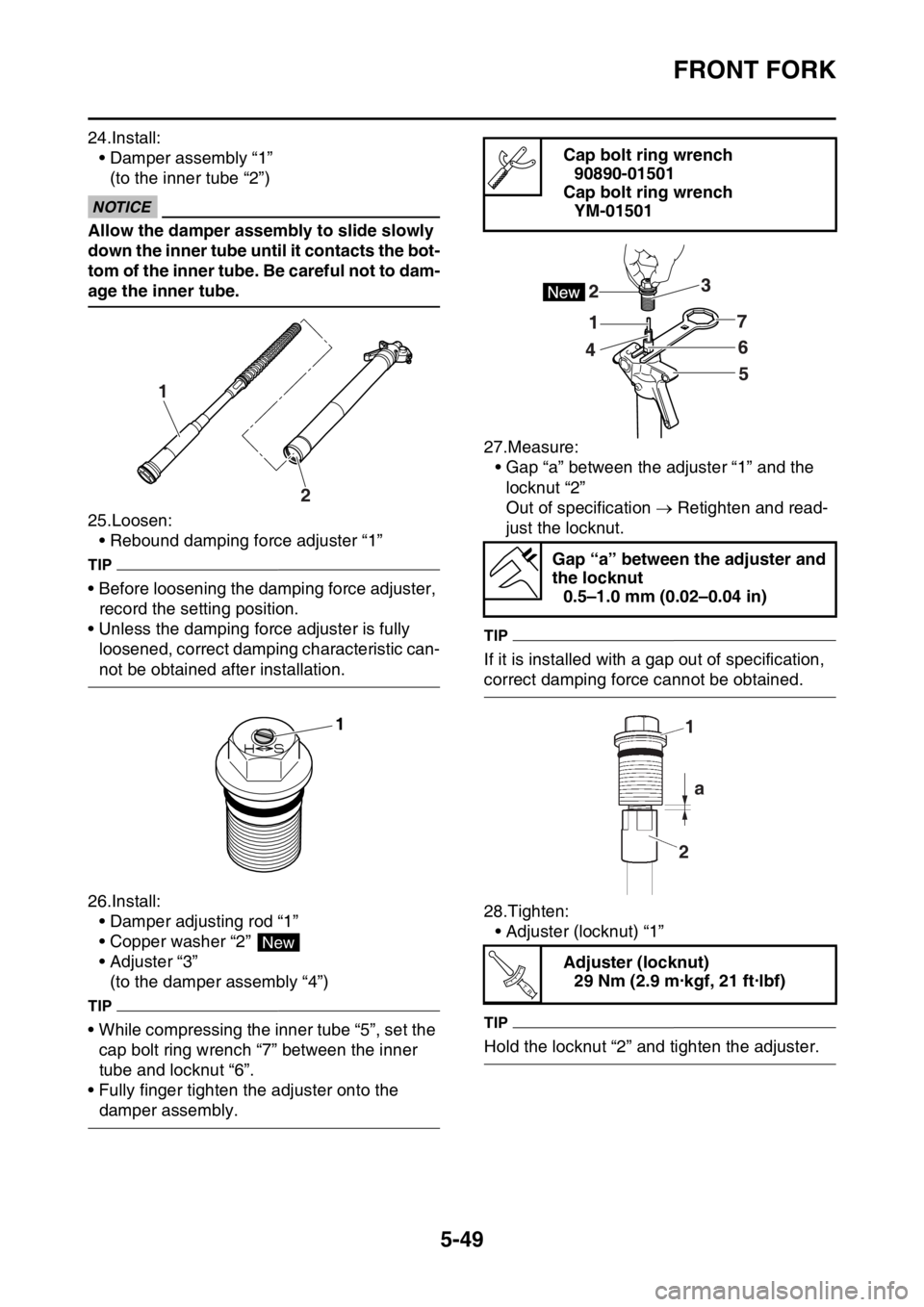

24.Install:

• Damper assembly “1”

(to the inner tube “2”)

ECA

NOTICE

Allow the damper assembly to slide slowly

down the inner tube until it contacts the bot-

tom of the inner tube. Be careful not to dam-

age the inner tube.

25.Loosen:

• Rebound damping force adjuster “1”

TIP

• Before loosening the damping force adjuster,

record the setting position.

• Unless the damping force adjuster is fully

loosened, correct damping characteristic can-

not be obtained after installation.

26.Install:

• Damper adjusting rod “1”

• Copper washer “2”

• Adjuster “3”

(to the damper assembly “4”)

TIP

• While compressing the inner tube “5”, set the

cap bolt ring wrench “7” between the inner

tube and locknut “6”.

• Fully finger tighten the adjuster onto the

damper assembly.27.Measure:

• Gap “a” between the adjuster “1” and the

locknut “2”

Out of specification Retighten and read-

just the locknut.

TIP

If it is installed with a gap out of specification,

correct damping force cannot be obtained.

28.Tighten:

• Adjuster (locknut) “1”

TIP

Hold the locknut “2” and tighten the adjuster.

1

2

1

New

Cap bolt ring wrench

90890-01501

Cap bolt ring wrench

YM-01501

Gap “a” between the adjuster and

the locknut

0.5–1.0 mm (0.02–0.04 in)

Adjuster (locknut)

29 Nm (2.9 m·kgf, 21 ft·lbf)

1

2a

T R..

Page 213 of 430

STEERING HEAD

5-55

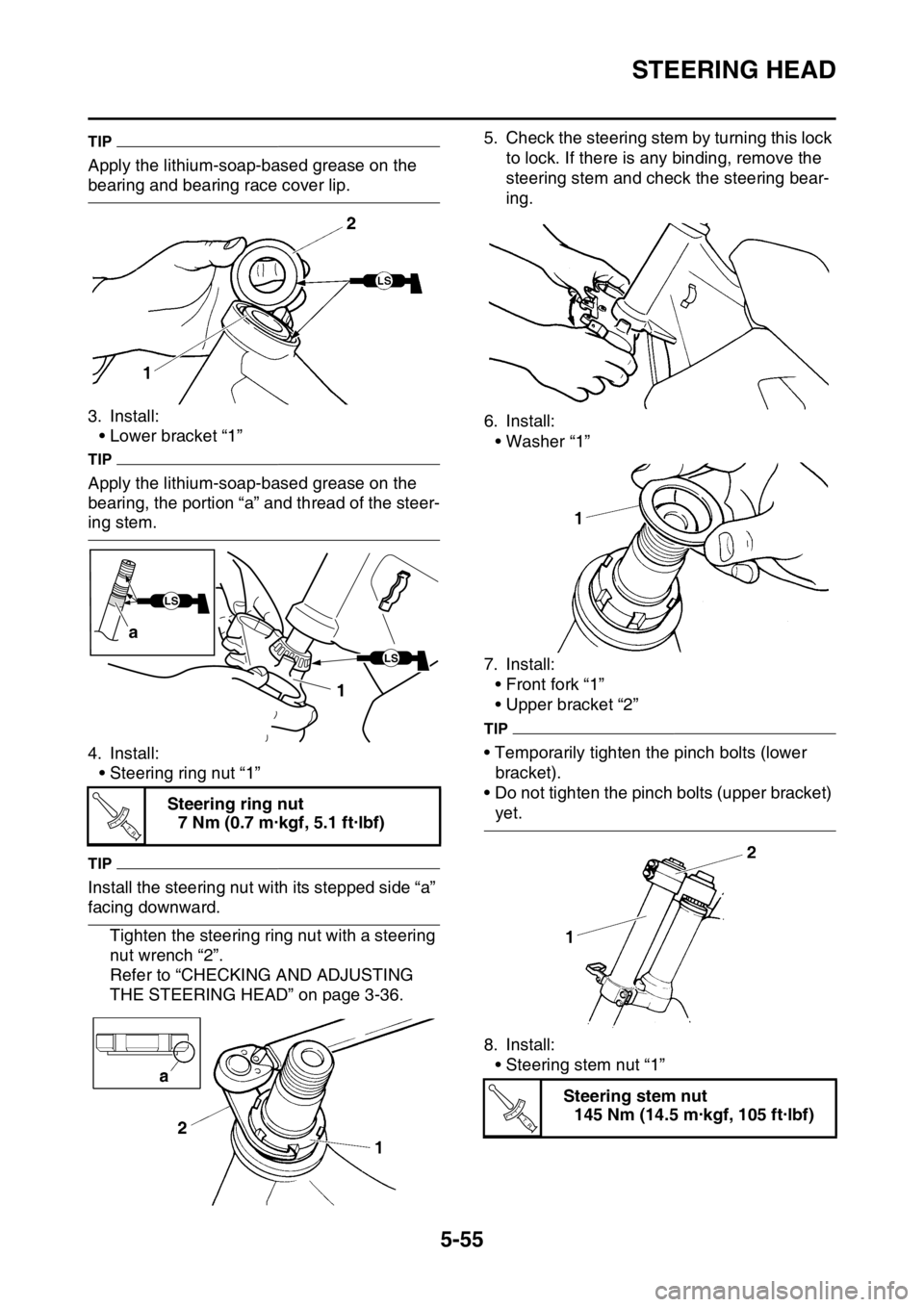

TIP

Apply the lithium-soap-based grease on the

bearing and bearing race cover lip.

3. Install:

• Lower bracket “1”

TIP

Apply the lithium-soap-based grease on the

bearing, the portion “a” and thread of the steer-

ing stem.

4. Install:

• Steering ring nut “1”

TIP

Install the steering nut with its stepped side “a”

facing downward.

Tighten the steering ring nut with a steering

nut wrench “2”.

Refer to “CHECKING AND ADJUSTING

THE STEERING HEAD” on page 3-36.5. Check the steering stem by turning this lock

to lock. If there is any binding, remove the

steering stem and check the steering bear-

ing.

6. Install:

• Washer “1”

7. Install:

• Front fork “1”

• Upper bracket “2”

TIP

• Temporarily tighten the pinch bolts (lower

bracket).

• Do not tighten the pinch bolts (upper bracket)

yet.

8. Install:

• Steering stem nut “1” Steering ring nut

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

LS

1 a

LSLS

T R..

Steering stem nut

145 Nm (14.5 m·kgf, 105 ft·lbf)

T R..

Page 215 of 430

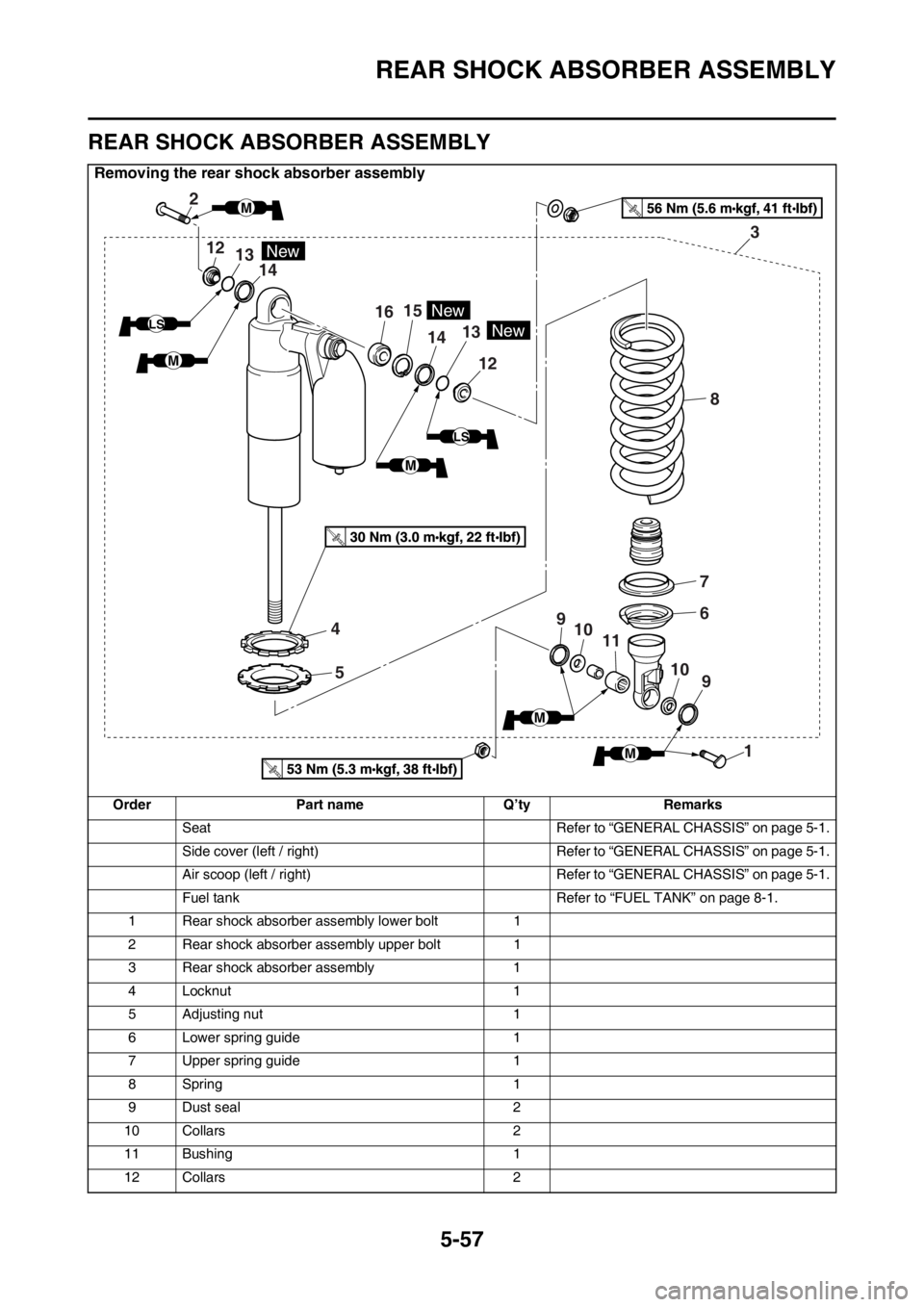

REAR SHOCK ABSORBER ASSEMBLY

5-57

EAS2GB2209

REAR SHOCK ABSORBER ASSEMBLY

Removing the rear shock absorber assembly

Order Part name Q’ty Remarks

Seat Refer to “GENERAL CHASSIS” on page 5-1.

Side cover (left / right) Refer to “GENERAL CHASSIS” on page 5-1.

Air scoop (left / right) Refer to “GENERAL CHASSIS” on page 5-1.

Fuel tank Refer to “FUEL TANK” on page 8-1.

1 Rear shock absorber assembly lower bolt 1

2 Rear shock absorber assembly upper bolt 1

3 Rear shock absorber assembly 1

4 Locknut 1

5 Adjusting nut 1

6 Lower spring guide 1

7 Upper spring guide 1

8Spring 1

9 Dust seal 2

10 Collars 2

11 Bushing 1

12 Collars 2

2

12

1615

1413

12

14

4

5

7

6

83

9

9 10

10 11

1

New

New

13New

LS

LS

M

M

M

M

M

Page 228 of 430

CHAIN DRIVE

5-70

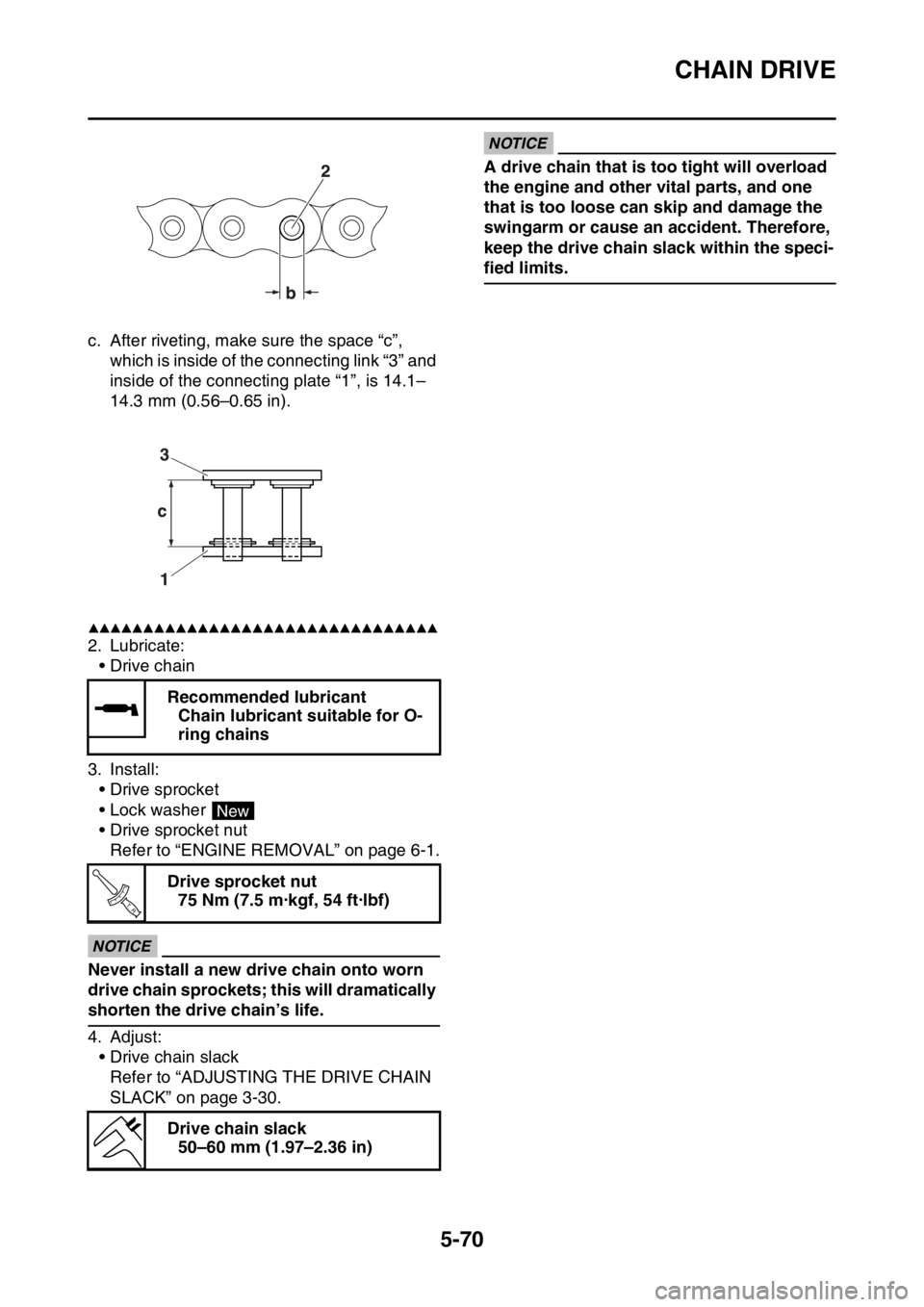

c. After riveting, make sure the space “c”,

which is inside of the connecting link “3” and

inside of the connecting plate “1”, is 14.1–

14.3 mm (0.56–0.65 in).

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

2. Lubricate:

•Drive chain

3. Install:

• Drive sprocket

• Lock washer

• Drive sprocket nut

Refer to “ENGINE REMOVAL” on page 6-1.

ECA

NOTICE

Never install a new drive chain onto worn

drive chain sprockets; this will dramatically

shorten the drive chain’s life.

4. Adjust:

• Drive chain slack

Refer to “ADJUSTING THE DRIVE CHAIN

SLACK” on page 3-30.

ECA

NOTICE

A drive chain that is too tight will overload

the engine and other vital parts, and one

that is too loose can skip and damage the

swingarm or cause an accident. Therefore,

keep the drive chain slack within the speci-

fied limits.

Recommended lubricant

Chain lubricant suitable for O-

ring chains

Drive sprocket nut

75 Nm (7.5 m·kgf, 54 ft·lbf)

Drive chain slack

50–60 mm (1.97–2.36 in)

New

T R..

Page 237 of 430

ENGINE REMOVAL

6-6

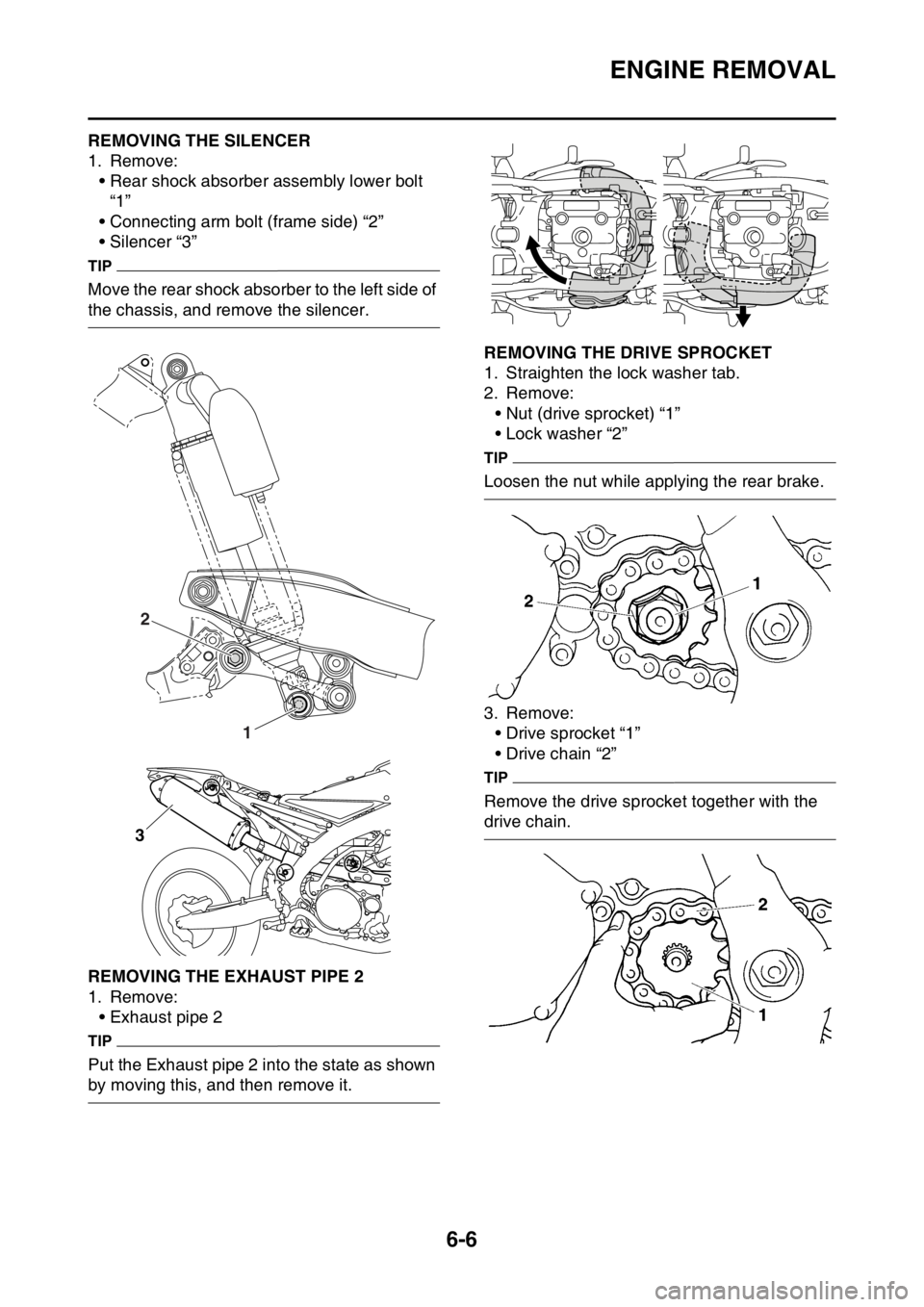

EAS2GB2229REMOVING THE SILENCER

1. Remove:

• Rear shock absorber assembly lower bolt

“1”

• Connecting arm bolt (frame side) “2”

• Silencer “3”

TIP

Move the rear shock absorber to the left side of

the chassis, and remove the silencer.

EAS2GB2230REMOVING THE EXHAUST PIPE 2

1. Remove:

• Exhaust pipe 2

TIP

Put the Exhaust pipe 2 into the state as shown

by moving this, and then remove it.

EAS2GB2231REMOVING THE DRIVE SPROCKET

1. Straighten the lock washer tab.

2. Remove:

• Nut (drive sprocket) “1”

• Lock washer “2”

TIP

Loosen the nut while applying the rear brake.

3. Remove:

• Drive sprocket “1”

• Drive chain “2”

TIP

Remove the drive sprocket together with the

drive chain.

1 2

3

Page 240 of 430

ENGINE REMOVAL

6-9

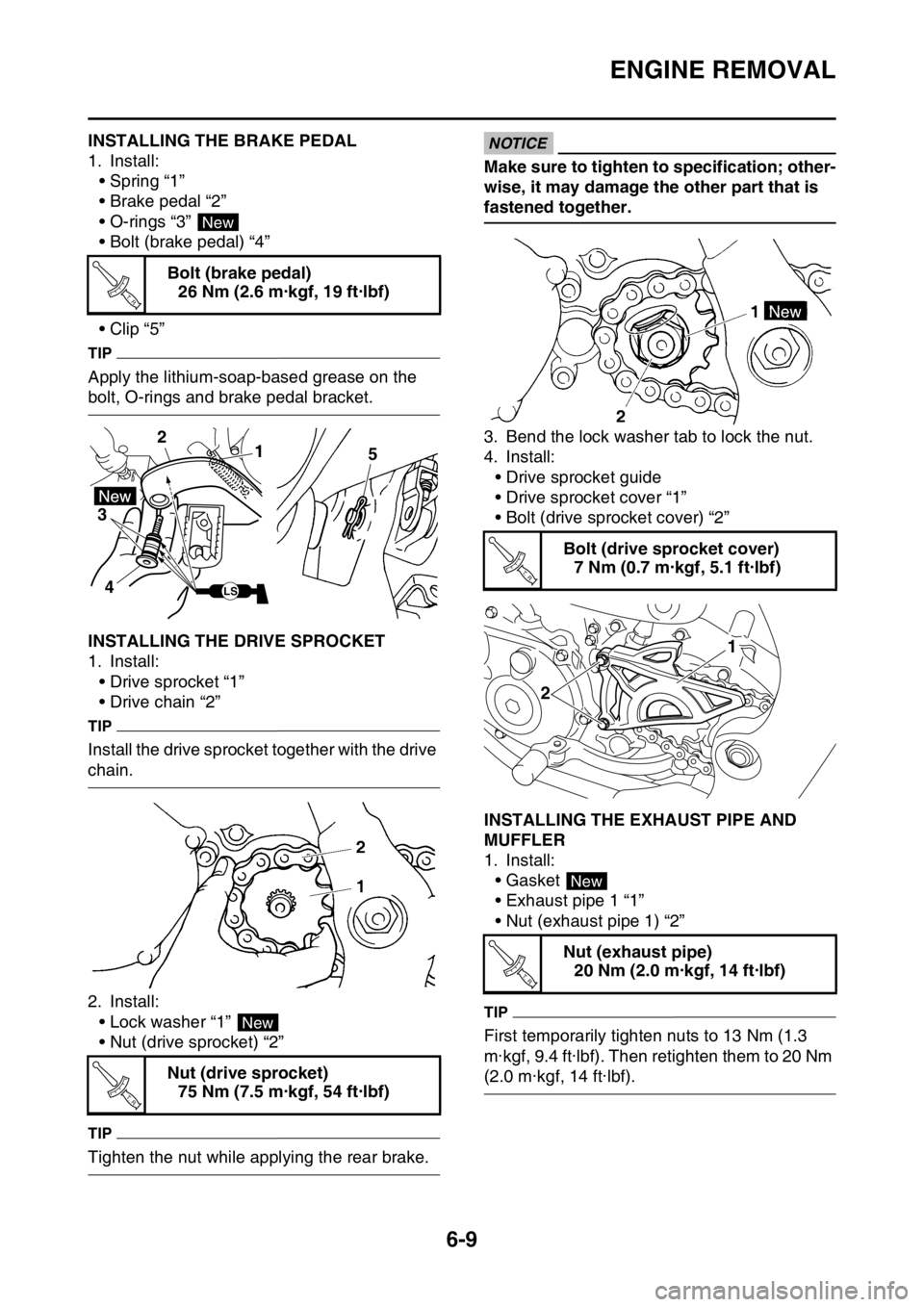

EAS2GB2236INSTALLING THE BRAKE PEDAL

1. Install:

• Spring “1”

• Brake pedal “2”

• O-rings “3”

• Bolt (brake pedal) “4”

•Clip “5”

TIP

Apply the lithium-soap-based grease on the

bolt, O-rings and brake pedal bracket.

EAS2GB2237INSTALLING THE DRIVE SPROCKET

1. Install:

• Drive sprocket “1”

• Drive chain “2”

TIP

Install the drive sprocket together with the drive

chain.

2. Install:

• Lock washer “1”

• Nut (drive sprocket) “2”

TIP

Tighten the nut while applying the rear brake.

ECA

NOTICE

Make sure to tighten to specification; other-

wise, it may damage the other part that is

fastened together.

3. Bend the lock washer tab to lock the nut.

4. Install:

• Drive sprocket guide

• Drive sprocket cover “1”

• Bolt (drive sprocket cover) “2”

EAS2GB2238INSTALLING THE EXHAUST PIPE AND

MUFFLER

1. Install:

•Gasket

• Exhaust pipe 1 “1”

• Nut (exhaust pipe 1) “2”

TIP

First temporarily tighten nuts to 13 Nm (1.3

m·kgf, 9.4 ft·lbf). Then retighten them to 20 Nm

(2.0 m·kgf, 14 ft·lbf). Bolt (brake pedal)

26 Nm (2.6 m·kgf, 19 ft·lbf)

Nut (drive sprocket)

75 Nm (7.5 m·kgf, 54 ft·lbf)

New

T R..

1 2

3

45

LS

New

T R..

Bolt (drive sprocket cover)

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Nut (exhaust pipe)

20 Nm (2.0 m·kgf, 14 ft·lbf)

T R..

21

New

T R..

Page 244 of 430

CAMSHAFT

6-13

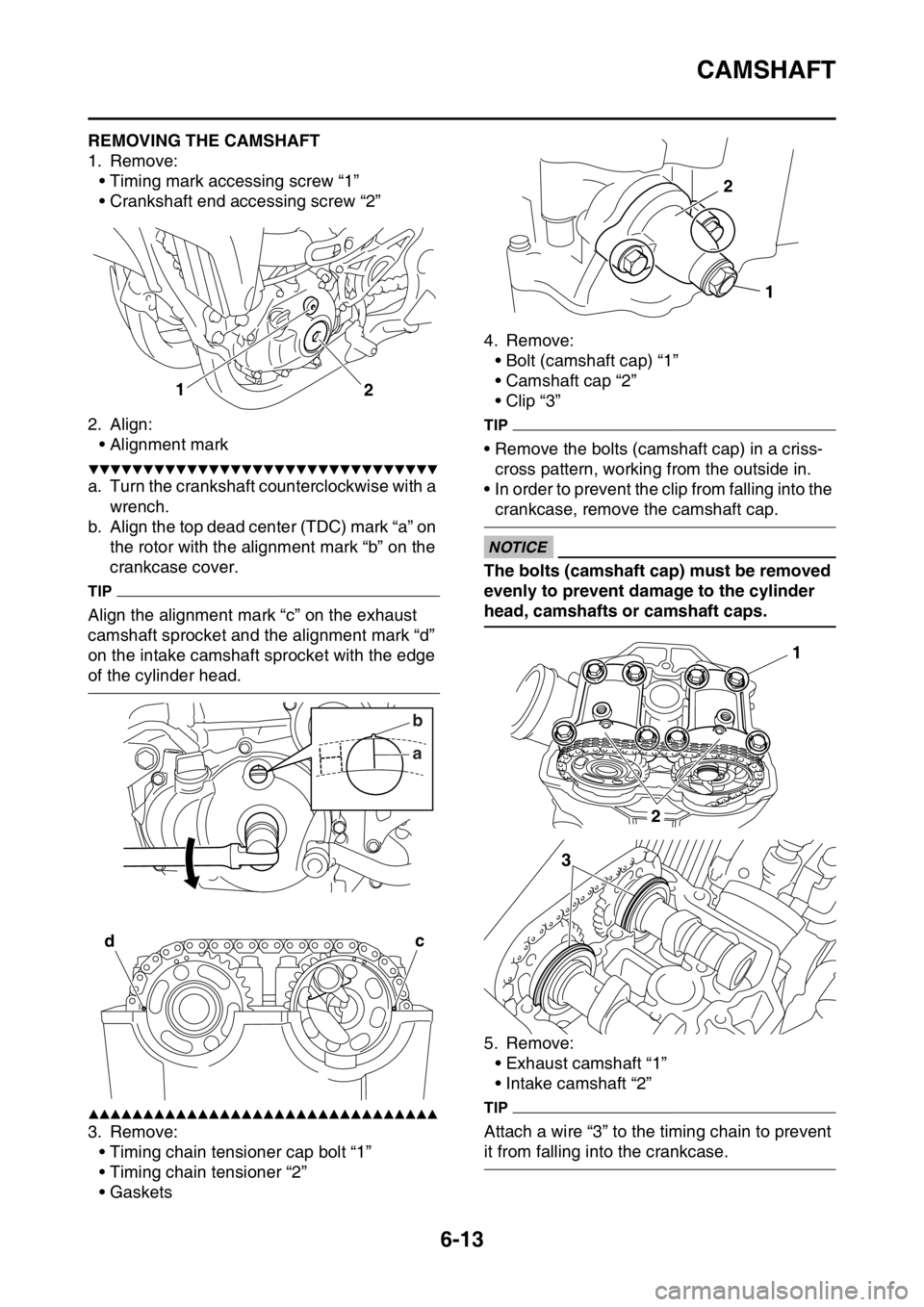

EAS2GB2240REMOVING THE CAMSHAFT

1. Remove:

• Timing mark accessing screw “1”

• Crankshaft end accessing screw “2”

2. Align:

• Alignment mark

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the crankshaft counterclockwise with a

wrench.

b. Align the top dead center (TDC) mark “a” on

the rotor with the alignment mark “b” on the

crankcase cover.

TIP

Align the alignment mark “c” on the exhaust

camshaft sprocket and the alignment mark “d”

on the intake camshaft sprocket with the edge

of the cylinder head.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Remove:

• Timing chain tensioner cap bolt “1”

• Timing chain tensioner “2”

•Gaskets4. Remove:

• Bolt (camshaft cap) “1”

• Camshaft cap “2”

• Clip “3”

TIP

• Remove the bolts (camshaft cap) in a criss-

cross pattern, working from the outside in.

• In order to prevent the clip from falling into the

crankcase, remove the camshaft cap.

ECA

NOTICE

The bolts (camshaft cap) must be removed

evenly to prevent damage to the cylinder

head, camshafts or camshaft caps.

5. Remove:

• Exhaust camshaft “1”

• Intake camshaft “2”

TIP

Attach a wire “3” to the timing chain to prevent

it from falling into the crankcase.

1

2

ab

dc

1 2

1

2

3

Page 246 of 430

CAMSHAFT

6-15

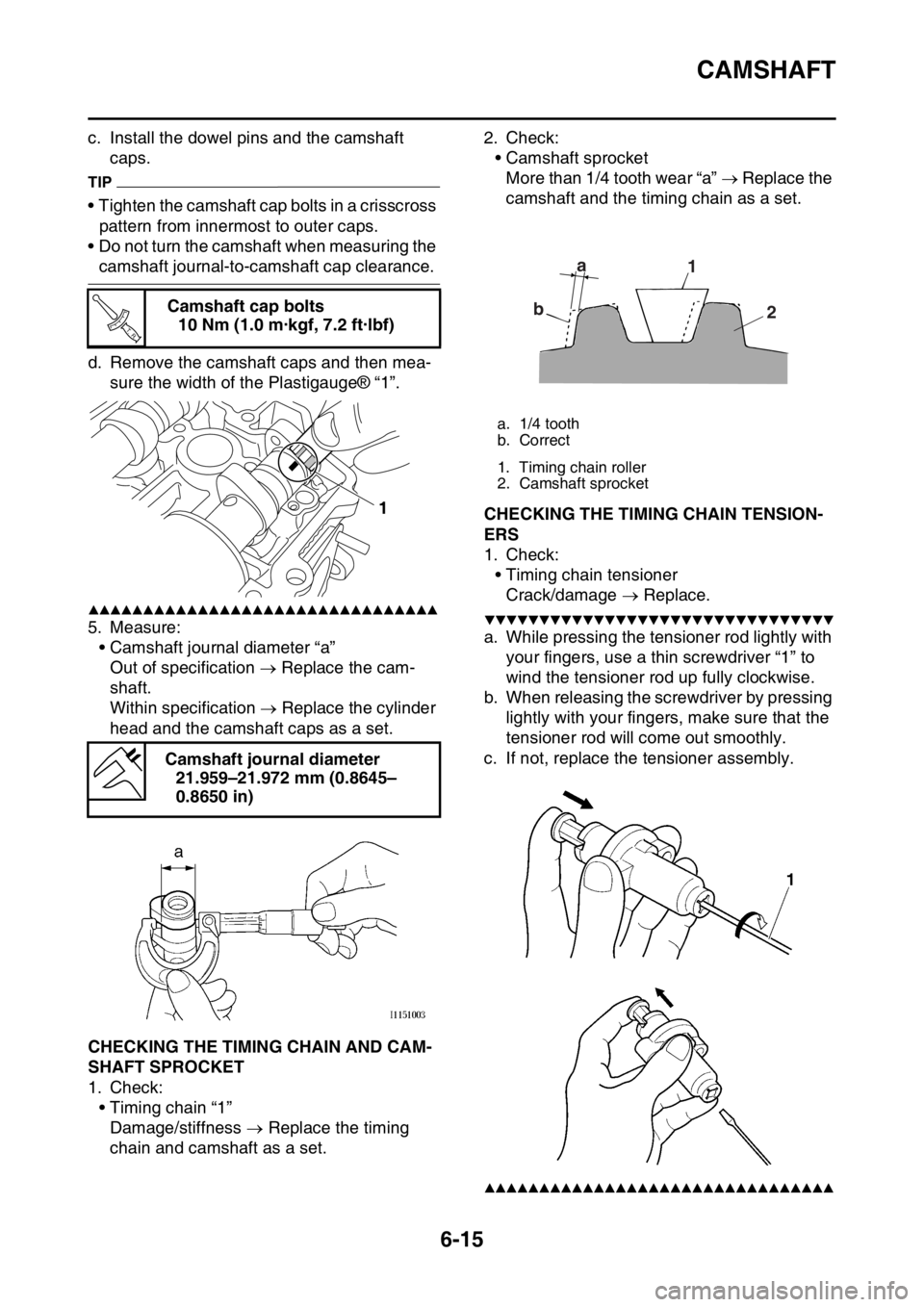

c. Install the dowel pins and the camshaft

caps.

TIP

• Tighten the camshaft cap bolts in a crisscross

pattern from innermost to outer caps.

• Do not turn the camshaft when measuring the

camshaft journal-to-camshaft cap clearance.

d. Remove the camshaft caps and then mea-

sure the width of the Plastigauge® “1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. Measure:

• Camshaft journal diameter “a”

Out of specification Replace the cam-

shaft.

Within specification Replace the cylinder

head and the camshaft caps as a set.

EAS2GB2242CHECKING THE TIMING CHAIN AND CAM-

SHAFT SPROCKET

1. Check:

• Timing chain “1”

Damage/stiffness Replace the timing

chain and camshaft as a set.2. Check:

• Camshaft sprocket

More than 1/4 tooth wear “a” Replace the

camshaft and the timing chain as a set.

EAS2GB2243CHECKING THE TIMING CHAIN TENSION-

ERS

1. Check:

• Timing chain tensioner

Crack/damage Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. While pressing the tensioner rod lightly with

your fingers, use a thin screwdriver “1” to

wind the tensioner rod up fully clockwise.

b. When releasing the screwdriver by pressing

lightly with your fingers, make sure that the

tensioner rod will come out smoothly.

c. If not, replace the tensioner assembly.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Camshaft cap bolts

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Camshaft journal diameter

21.959–21.972 mm (0.8645–

0.8650 in)

T R..

1

a. 1/4 tooth

b. Correct

1. Timing chain roller

2. Camshaft sprocket

a

b1

2

Page 247 of 430

CAMSHAFT

6-16

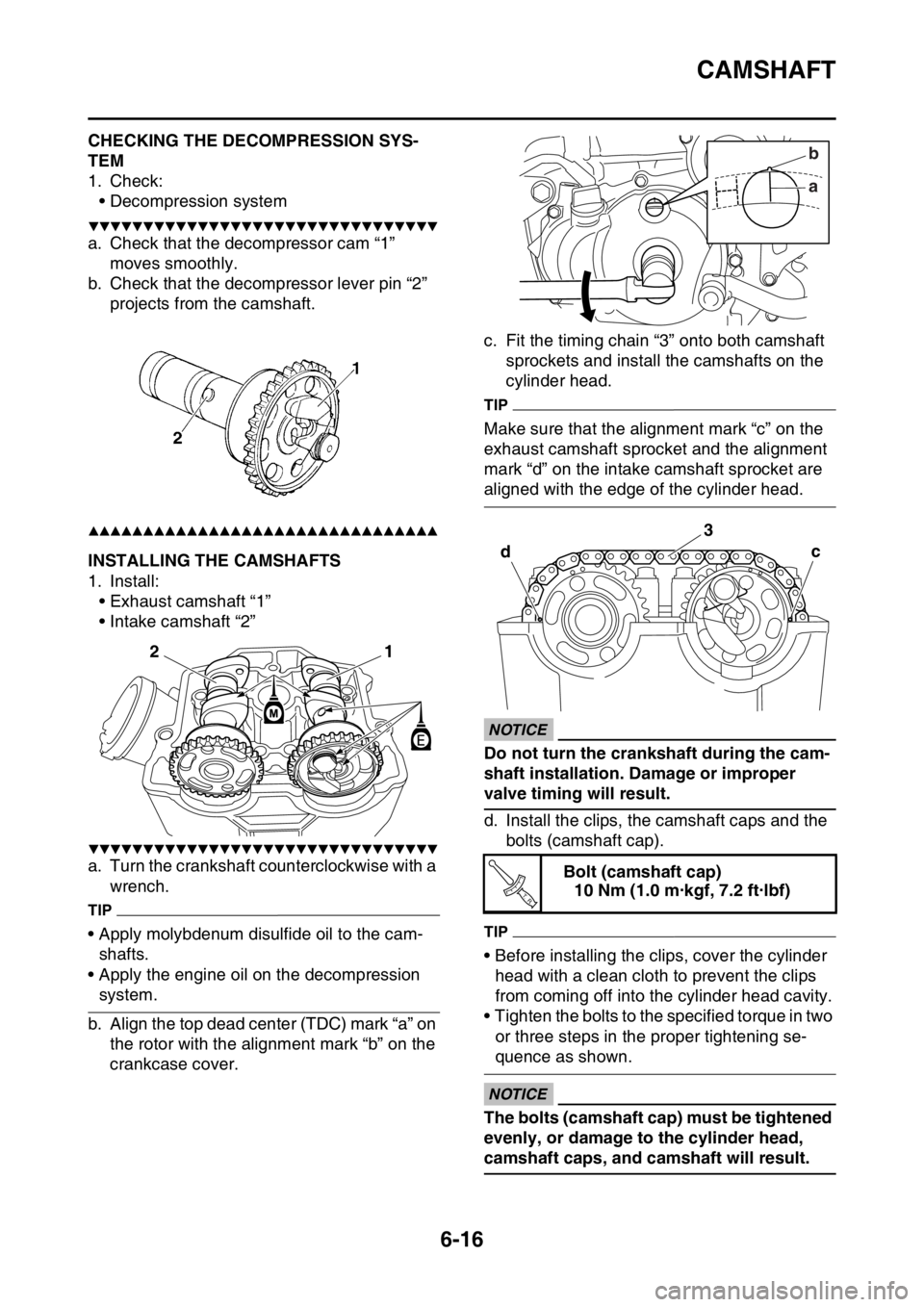

EAS2GB2244CHECKING THE DECOMPRESSION SYS-

TEM

1. Check:

• Decompression system

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Check that the decompressor cam “1”

moves smoothly.

b. Check that the decompressor lever pin “2”

projects from the camshaft.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GB2245INSTALLING THE CAMSHAFTS

1. Install:

• Exhaust camshaft “1”

• Intake camshaft “2”

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the crankshaft counterclockwise with a

wrench.

TIP

• Apply molybdenum disulfide oil to the cam-

shafts.

• Apply the engine oil on the decompression

system.

b. Align the top dead center (TDC) mark “a” on

the rotor with the alignment mark “b” on the

crankcase cover.c. Fit the timing chain “3” onto both camshaft

sprockets and install the camshafts on the

cylinder head.

TIP

Make sure that the alignment mark “c” on the

exhaust camshaft sprocket and the alignment

mark “d” on the intake camshaft sprocket are

aligned with the edge of the cylinder head.

ECA

NOTICE

Do not turn the crankshaft during the cam-

shaft installation. Damage or improper

valve timing will result.

d. Install the clips, the camshaft caps and the

bolts (camshaft cap).

TIP

• Before installing the clips, cover the cylinder

head with a clean cloth to prevent the clips

from coming off into the cylinder head cavity.

• Tighten the bolts to the specified torque in two

or three steps in the proper tightening se-

quence as shown.

ECA

NOTICE

The bolts (camshaft cap) must be tightened

evenly, or damage to the cylinder head,

camshaft caps, and camshaft will result.

1

2

Bolt (camshaft cap)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

ab

dc

3

T R..

Page 248 of 430

CAMSHAFT

6-17

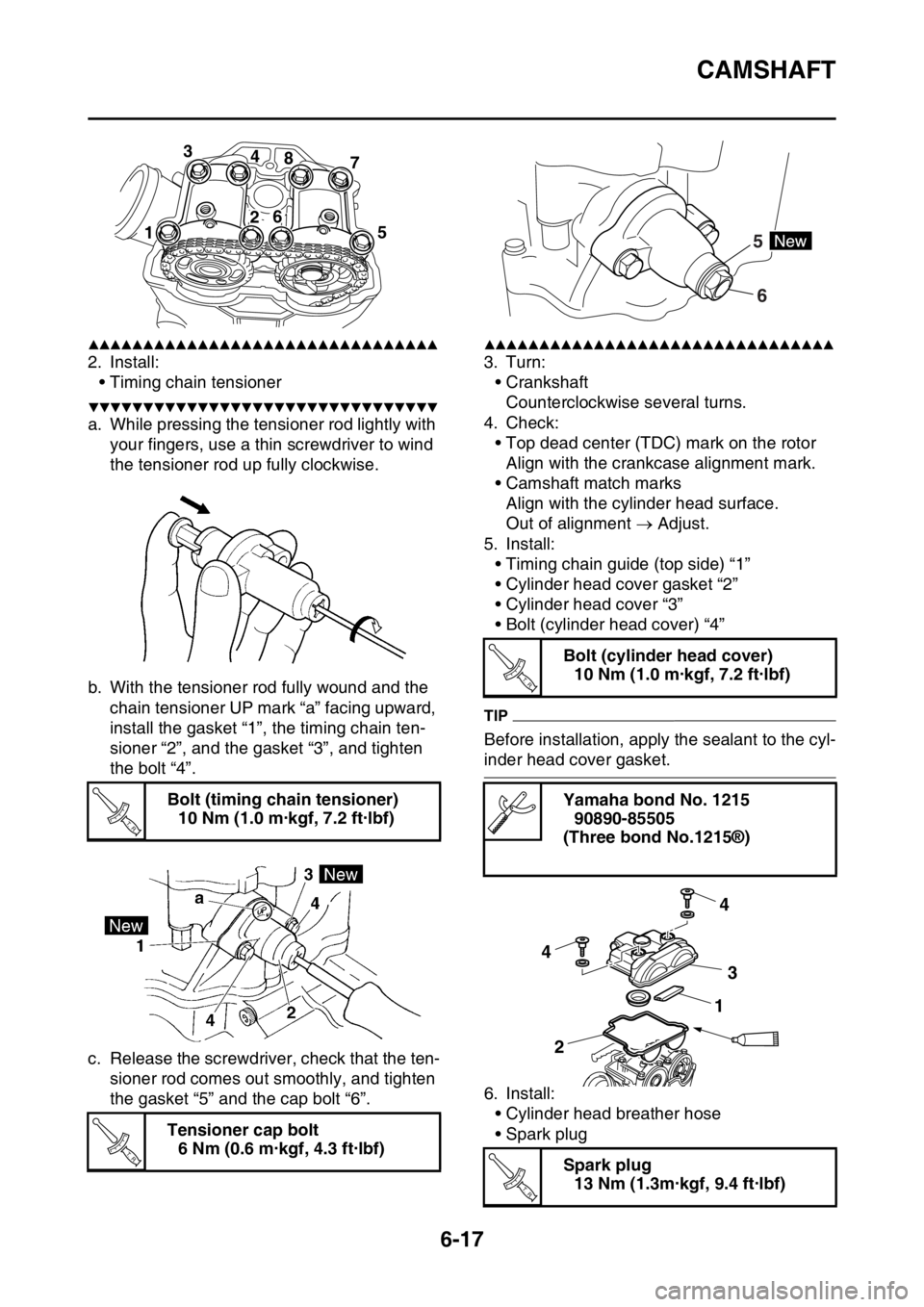

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

2. Install:

• Timing chain tensioner

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. While pressing the tensioner rod lightly with

your fingers, use a thin screwdriver to wind

the tensioner rod up fully clockwise.

b. With the tensioner rod fully wound and the

chain tensioner UP mark “a” facing upward,

install the gasket “1”, the timing chain ten-

sioner “2”, and the gasket “3”, and tighten

the bolt “4”.

c. Release the screwdriver, check that the ten-

sioner rod comes out smoothly, and tighten

the gasket “5” and the cap bolt “6”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Turn:

• Crankshaft

Counterclockwise several turns.

4. Check:

• Top dead center (TDC) mark on the rotor

Align with the crankcase alignment mark.

• Camshaft match marks

Align with the cylinder head surface.

Out of alignment Adjust.

5. Install:

• Timing chain guide (top side) “1”

• Cylinder head cover gasket “2”

• Cylinder head cover “3”

• Bolt (cylinder head cover) “4”

TIP

Before installation, apply the sealant to the cyl-

inder head cover gasket.

6. Install:

• Cylinder head breather hose

• Spark plug Bolt (timing chain tensioner)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Tensioner cap bolt

6 Nm (0.6 m·kgf, 4.3 ft·lbf)

3

4

8

7

15

26

T R..

T R..

Bolt (cylinder head cover)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Yamaha bond No. 1215

90890-85505

(Three bond No.1215®)

Spark plug

13 Nm (1.3m·kgf, 9.4 ft·lbf)

6 5

T R..

4

4

3

21

T R..