YAMAHA WR 250F 2015 Owner's Guide

Manufacturer: YAMAHA, Model Year: 2015, Model line: WR 250F, Model: YAMAHA WR 250F 2015Pages: 430, PDF Size: 14.14 MB

Page 31 of 430

SPECIAL TOOLS

1-17

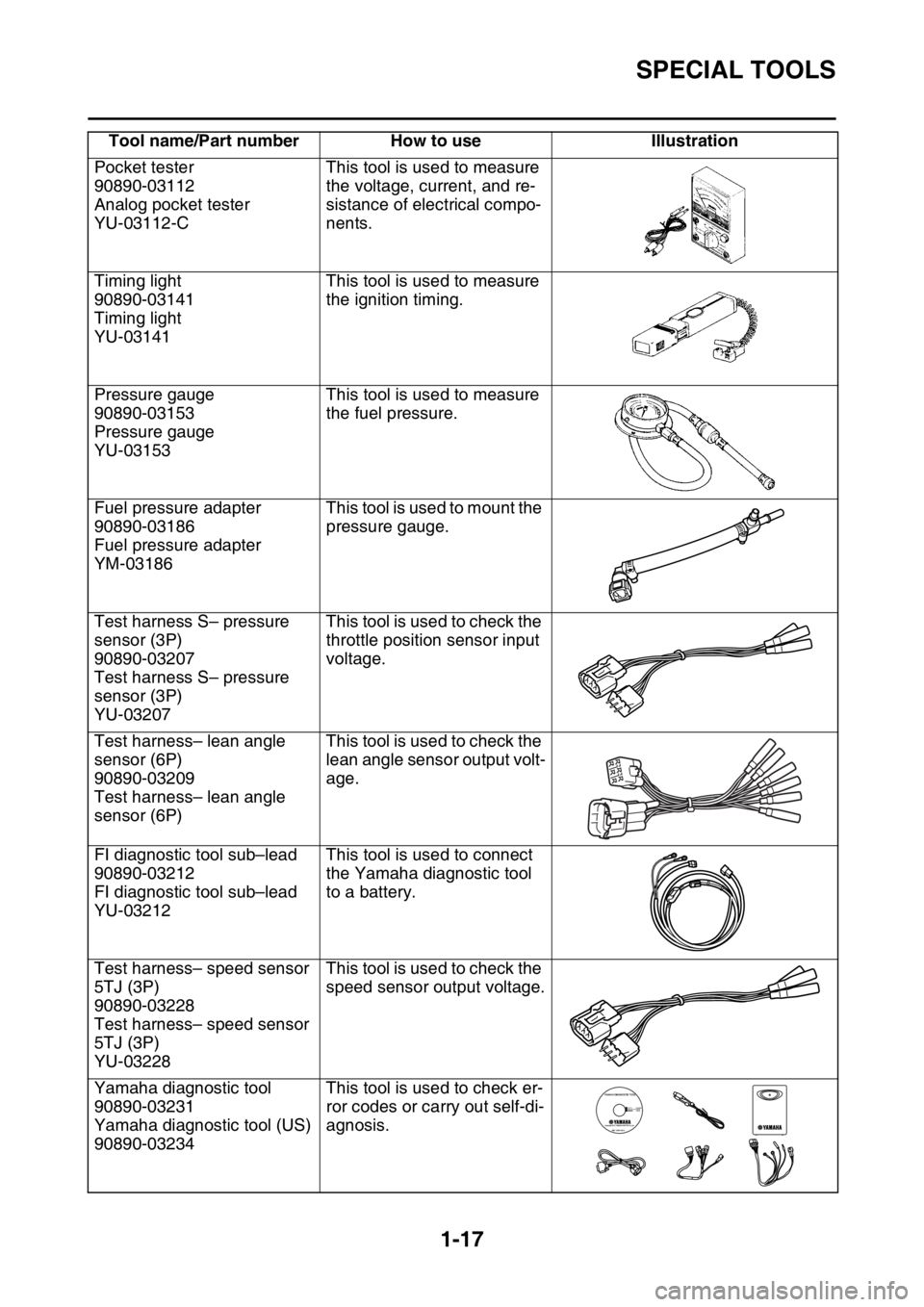

Pocket tester

90890-03112

Analog pocket tester

YU-03112-CThis tool is used to measure

the voltage, current, and re-

sistance of electrical compo-

nents.

Timing light

90890-03141

Timing light

YU-03141This tool is used to measure

the ignition timing.

Pressure gauge

90890-03153

Pressure gauge

YU-03153This tool is used to measure

the fuel pressure.

Fuel pressure adapter

90890-03186

Fuel pressure adapter

YM-03186This tool is used to mount the

pressure gauge.

Test harness S– pressure

sensor (3P)

90890-03207

Test harness S– pressure

sensor (3P)

YU-03207This tool is used to check the

throttle position sensor input

voltage.

Test harness– lean angle

sensor (6P)

90890-03209

Test harness– lean angle

sensor (6P)This tool is used to check the

lean angle sensor output volt-

age.

FI diagnostic tool sub–lead

90890-03212

FI diagnostic tool sub–lead

YU-03212This tool is used to connect

the Yamaha diagnostic tool

to a battery.

Test harness– speed sensor

5TJ (3P)

90890-03228

Test harness– speed sensor

5TJ (3P)

YU-03228This tool is used to check the

speed sensor output voltage.

Yamaha diagnostic tool

90890-03231

Yamaha diagnostic tool (US)

90890-03234This tool is used to check er-

ror codes or carry out self-di-

agnosis. Tool name/Part number How to use Illustration

Page 32 of 430

SPECIAL TOOLS

1-18

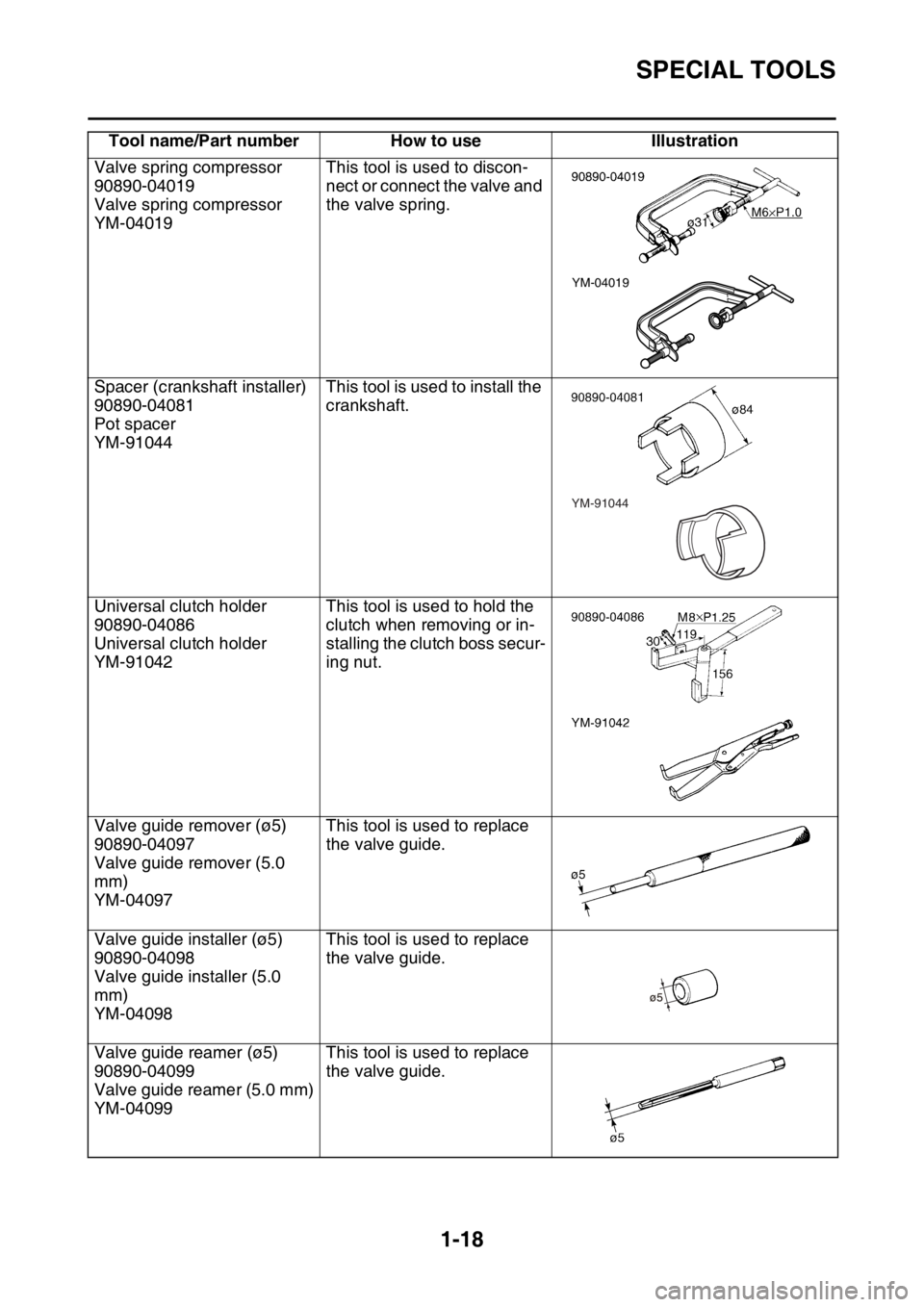

Valve spring compressor

90890-04019

Valve spring compressor

YM-04019This tool is used to discon-

nect or connect the valve and

the valve spring.

Spacer (crankshaft installer)

90890-04081

Pot spacer

YM-91044This tool is used to install the

crankshaft.

Universal clutch holder

90890-04086

Universal clutch holder

YM-91042This tool is used to hold the

clutch when removing or in-

stalling the clutch boss secur-

ing nut.

Valve guide remover (ø5)

90890-04097

Valve guide remover (5.0

mm)

YM-04097This tool is used to replace

the valve guide.

Valve guide installer (ø5)

90890-04098

Valve guide installer (5.0

mm)

YM-04098This tool is used to replace

the valve guide.

Valve guide reamer (ø5)

90890-04099

Valve guide reamer (5.0 mm)

YM-04099This tool is used to replace

the valve guide. Tool name/Part number How to use Illustration

YM-04019

YM-91044

Page 33 of 430

SPECIAL TOOLS

1-19

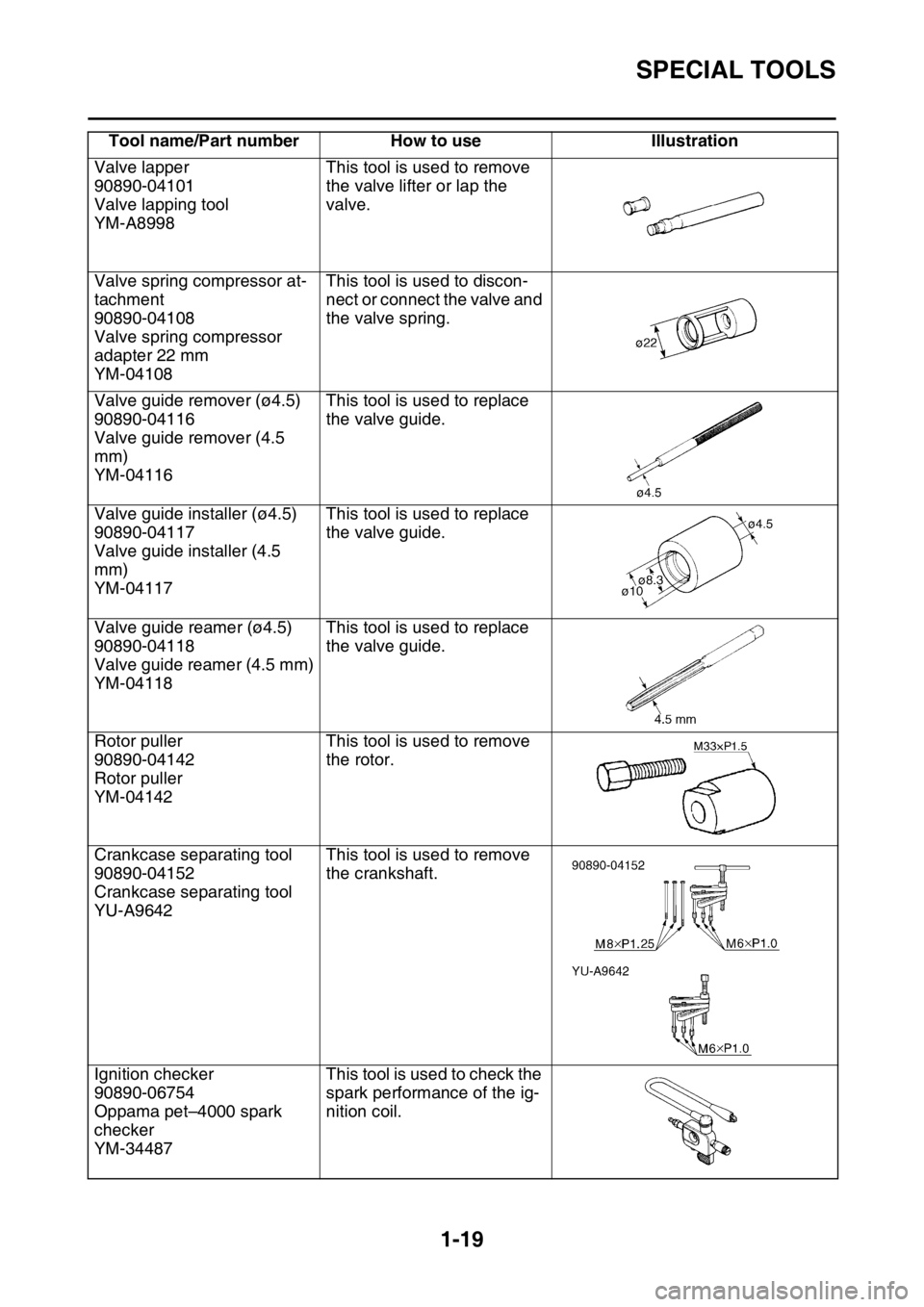

Valve lapper

90890-04101

Valve lapping tool

YM-A8998This tool is used to remove

the valve lifter or lap the

valve.

Valve spring compressor at-

tachment

90890-04108

Valve spring compressor

adapter 22 mm

YM-04108This tool is used to discon-

nect or connect the valve and

the valve spring.

Valve guide remover (ø4.5)

90890-04116

Valve guide remover (4.5

mm)

YM-04116This tool is used to replace

the valve guide.

Valve guide installer (ø4.5)

90890-04117

Valve guide installer (4.5

mm)

YM-04117This tool is used to replace

the valve guide.

Valve guide reamer (ø4.5)

90890-04118

Valve guide reamer (4.5 mm)

YM-04118This tool is used to replace

the valve guide.

Rotor puller

90890-04142

Rotor puller

YM-04142This tool is used to remove

the rotor.

Crankcase separating tool

90890-04152

Crankcase separating tool

YU-A9642This tool is used to remove

the crankshaft.

Ignition checker

90890-06754

Oppama pet–4000 spark

checker

YM-34487This tool is used to check the

spark performance of the ig-

nition coil. Tool name/Part number How to use Illustration

Page 34 of 430

SPECIAL TOOLS

1-20

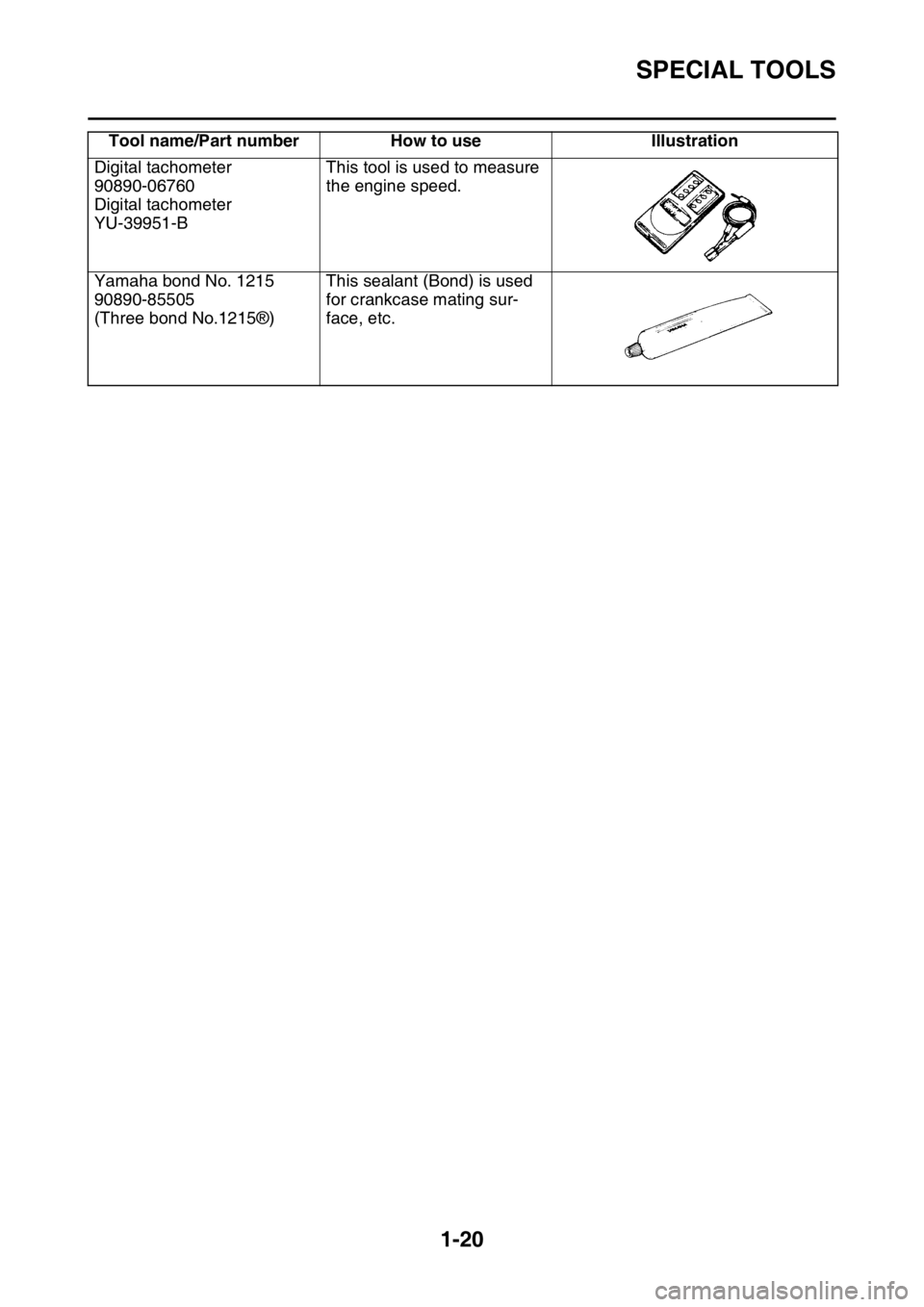

Digital tachometer

90890-06760

Digital tachometer

YU-39951-BThis tool is used to measure

the engine speed.

Yamaha bond No. 1215

90890-85505

(Three bond No.1215®)This sealant (Bond) is used

for crankcase mating sur-

face, etc. Tool name/Part number How to use Illustration

Page 35 of 430

CONTROL FUNCTIONS

1-21

EAS2GB2031

CONTROL FUNCTIONS

EAS2GB2032INDICATOR LIGHTS AND WARNING

LIGHTS

1. Engine trouble warning light “ ”

2. Fuel level warning light “ ”

Fuel level warning light “ ”

This warning light comes on when the fuel level

drops below approximately 1.6 L (0.42 US gal,

0.35 Imp.gal). When this occurs, refuel as soon

as possible.

The electrical circuit of the warning light can be

checked by pushing the start switch. The warn-

ing light should come on for a few seconds, and

then go off.

If the warning light does not come on initially

when the start switch is pushed, or if the warn-

ing light remains on, have a Yamaha dealer

check the electrical circuit.

Engine trouble warning light “ ”

This warning light comes on or flashes if a prob-

lem is detected in the electrical circuit monitor-

ing the engine. If this occurs, have a Yamaha

dealer check the vehicle.

The electrical circuit of the warning light can be

checked by pushing the start switch. The warn-

ing light should come on for a few seconds, and

then go off.

If the warning light does not come on initially

when the start switch is pushed, or if the warn-

ing light remains on, have a Yamaha dealer

check the electrical circuit.

EAS2GB2033ENGINE STOP SWITCH

The engine stop switch “1” is located on the left

handlebar. Continue pushing the engine stop

switch till the engine comes to a stop.

After the engine stops, the multi-function dis-

play will go off and the power supply to the ECU

(Electronic Control Unit) will be cut off if the en-

gine stop switch is pushed and held.

TIP

The multi-function display will go off after one

minute if the engine stop switch is not pushed.

EAS2GB2034START SWITCH

The start switch “1” is located on the right han-

dlebar. Push this switch to crank the engine

with the starter.

EAS2GB2035CLUTCH LEVER

The clutch lever “1” is located on the left han-

dlebar. The clutch lever disengages or engag-

es the clutch.

Pull the clutch lever toward the handlebar to

disengage the clutch, and release the lever to

engage the clutch.

12

Page 36 of 430

CONTROL FUNCTIONS

1-22

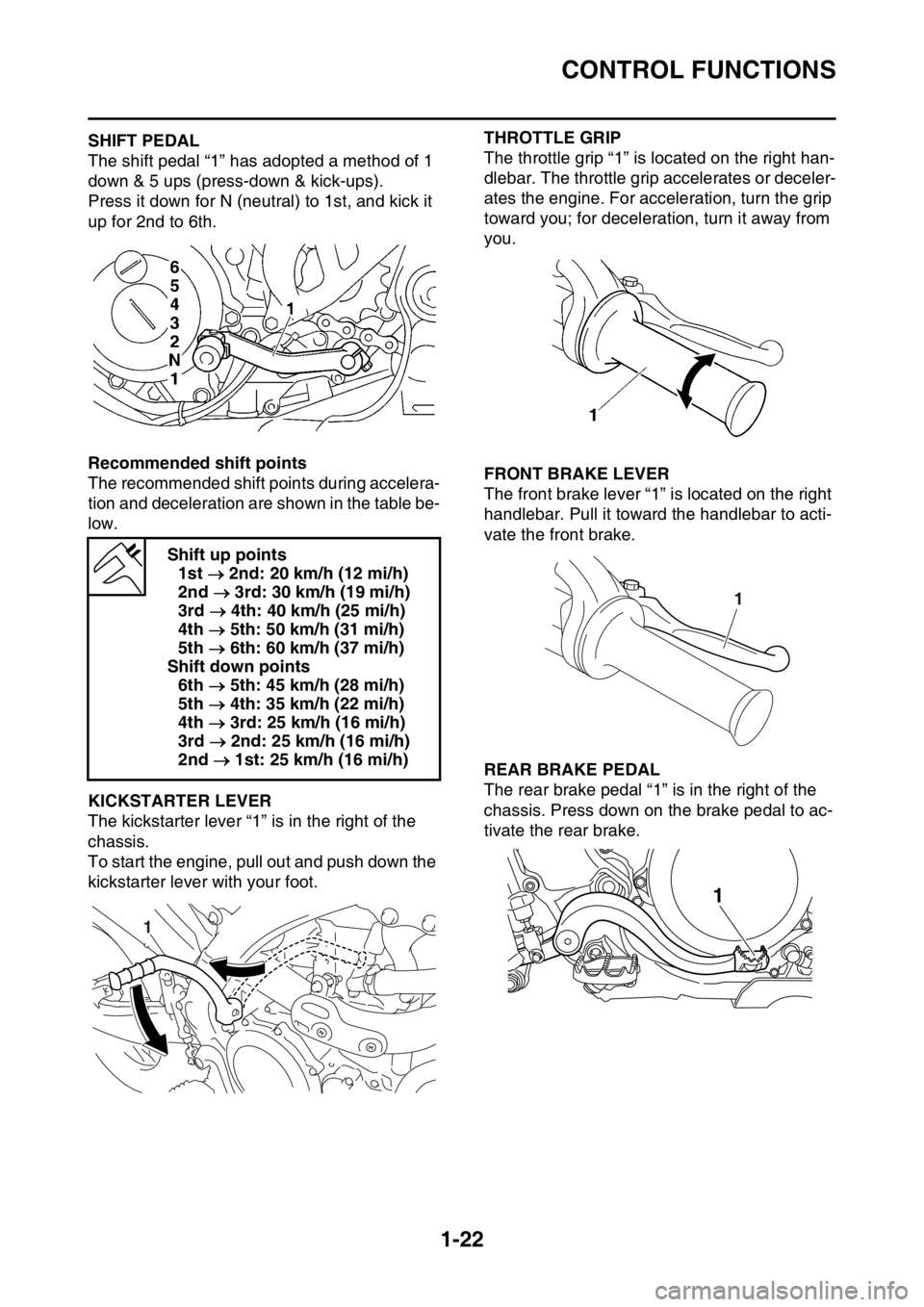

EAS2GB2036SHIFT PEDAL

The shift pedal “1” has adopted a method of 1

down & 5 ups (press-down & kick-ups).

Press it down for N (neutral) to 1st, and kick it

up for 2nd to 6th.

Recommended shift points

The recommended shift points during accelera-

tion and deceleration are shown in the table be-

low.

EAS2GB2037KICKSTARTER LEVER

The kickstarter lever “1” is in the right of the

chassis.

To start the engine, pull out and push down the

kickstarter lever with your foot.

EAS2GB2038

THROTTLE GRIP

The throttle grip “1” is located on the right han-

dlebar. The throttle grip accelerates or deceler-

ates the engine. For acceleration, turn the grip

toward you; for deceleration, turn it away from

you.

EAS2GB2039FRONT BRAKE LEVER

The front brake lever “1” is located on the right

handlebar. Pull it toward the handlebar to acti-

vate the front brake.

EAS2GB2040REAR BRAKE PEDAL

The rear brake pedal “1” is in the right of the

chassis. Press down on the brake pedal to ac-

tivate the rear brake. Shift up points

1st 2nd: 20 km/h (12 mi/h)

2nd 3rd: 30 km/h (19 mi/h)

3rd 4th: 40 km/h (25 mi/h)

4th 5th: 50 km/h (31 mi/h)

5th 6th: 60 km/h (37 mi/h)

Shift down points

6th 5th: 45 km/h (28 mi/h)

5th 4th: 35 km/h (22 mi/h)

4th 3rd: 25 km/h (16 mi/h)

3rd 2nd: 25 km/h (16 mi/h)

2nd 1st: 25 km/h (16 mi/h)

1

1

1

Page 37 of 430

CONTROL FUNCTIONS

1-23

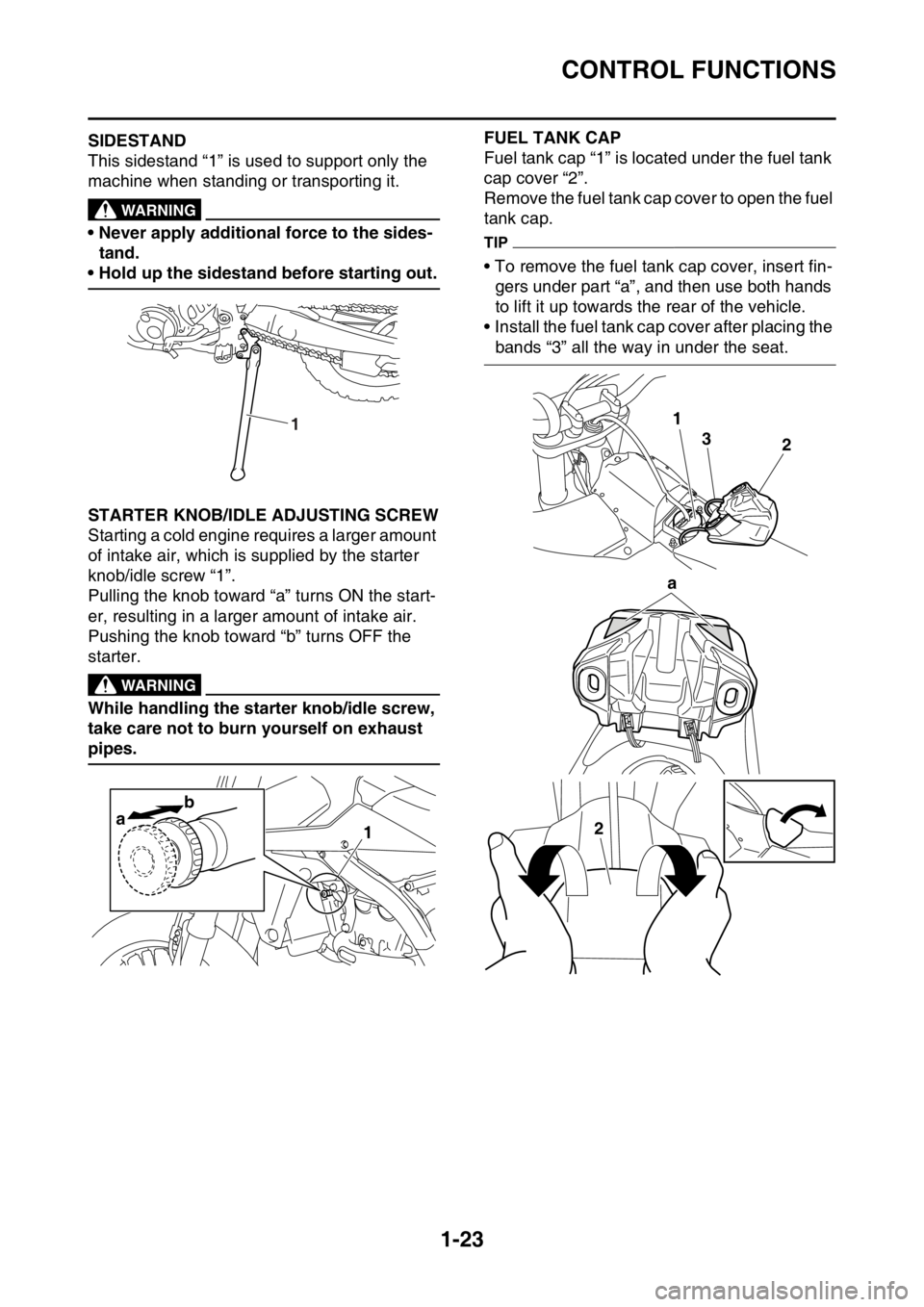

EAS2GB2041SIDESTAND

This sidestand “1” is used to support only the

machine when standing or transporting it.

EWA

WARNING

• Never apply additional force to the sides-

tand.

• Hold up the sidestand before starting out.

EAS2GB2042STARTER KNOB/IDLE ADJUSTING SCREW

Starting a cold engine requires a larger amount

of intake air, which is supplied by the starter

knob/idle screw “1”.

Pulling the knob toward “a” turns ON the start-

er, resulting in a larger amount of intake air.

Pushing the knob toward “b” turns OFF the

starter.

EWA

WARNING

While handling the starter knob/idle screw,

take care not to burn yourself on exhaust

pipes.

EAS2GB2043

FUEL TANK CAP

Fuel tank cap “1” is located under the fuel tank

cap cover “2”.

Remove the fuel tank cap cover to open the fuel

tank cap.

TIP

• To remove the fuel tank cap cover, insert fin-

gers under part “a”, and then use both hands

to lift it up towards the rear of the vehicle.

• Install the fuel tank cap cover after placing the

bands “3” all the way in under the seat.

1

ab1

1

23

a

2

Page 38 of 430

MULTI-FUNCTION DISPLAY

1-24

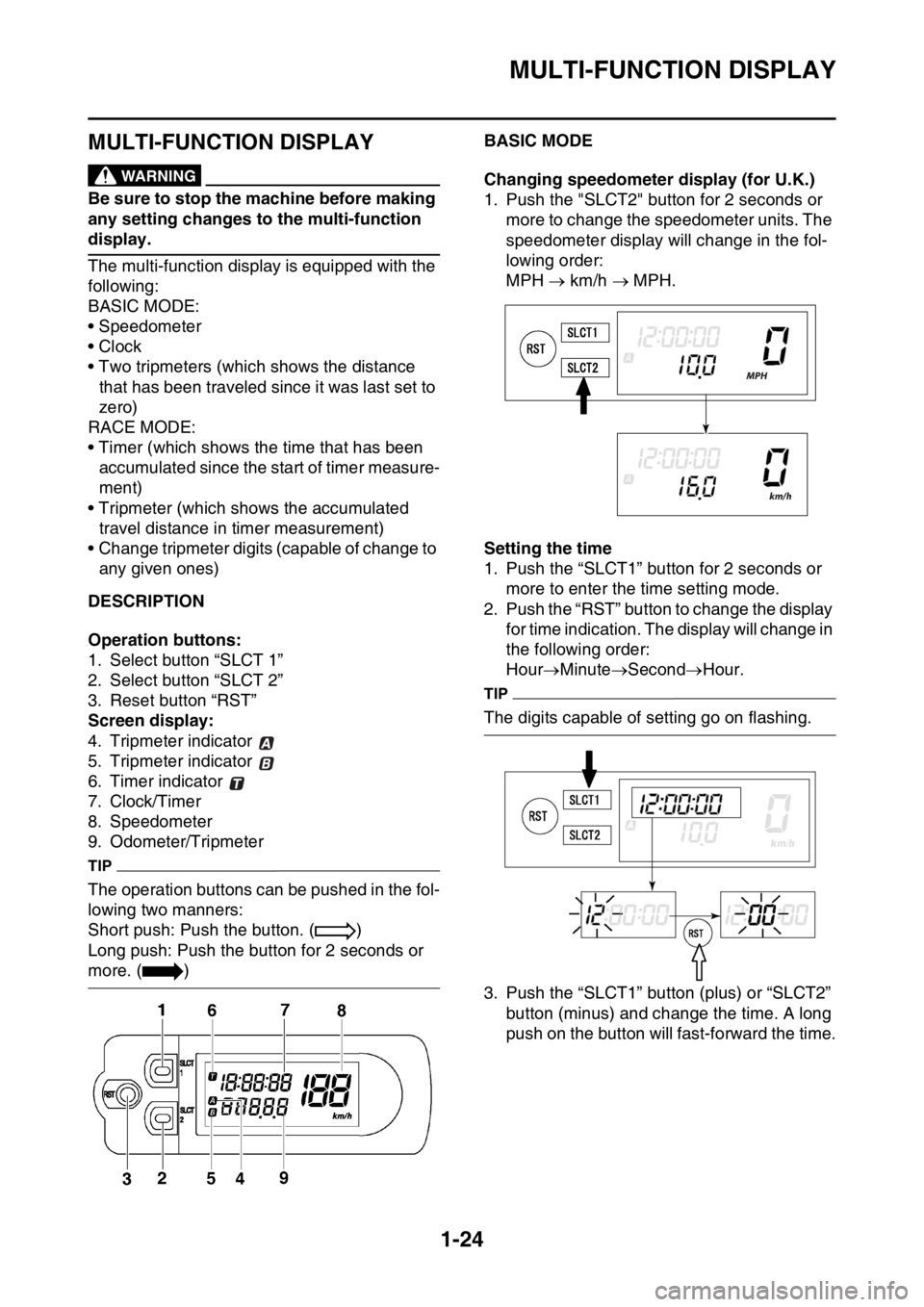

EAS2GB2044

MULTI-FUNCTION DISPLAYEWA

WARNING

Be sure to stop the machine before making

any setting changes to the multi-function

display.

The multi-function display is equipped with the

following:

BASIC MODE:

• Speedometer

•Clock

• Two tripmeters (which shows the distance

that has been traveled since it was last set to

zero)

RACE MODE:

• Timer (which shows the time that has been

accumulated since the start of timer measure-

ment)

• Tripmeter (which shows the accumulated

travel distance in timer measurement)

• Change tripmeter digits (capable of change to

any given ones)

EAS2GB2045DESCRIPTION

Operation buttons:

1. Select button “SLCT 1”

2. Select button “SLCT 2”

3. Reset button “RST”

Screen display:

4. Tripmeter indicator

5. Tripmeter indicator

6. Timer indicator

7. Clock/Timer

8. Speedometer

9. Odometer/Tripmeter

TIP

The operation buttons can be pushed in the fol-

lowing two manners:

Short push: Push the button. ( )

Long push: Push the button for 2 seconds or

more. ( )

EAS2GB2046BASIC MODE

Changing speedometer display (for U.K.)

1. Push the "SLCT2" button for 2 seconds or

more to change the speedometer units. The

speedometer display will change in the fol-

lowing order:

MPH km/h MPH.

Setting the time

1. Push the “SLCT1” button for 2 seconds or

more to enter the time setting mode.

2. Push the “RST” button to change the display

for time indication. The display will change in

the following order:

HourMinuteSecondHour.

TIP

The digits capable of setting go on flashing.

3. Push the “SLCT1” button (plus) or “SLCT2”

button (minus) and change the time. A long

push on the button will fast-forward the time.

Page 39 of 430

MULTI-FUNCTION DISPLAY

1-25

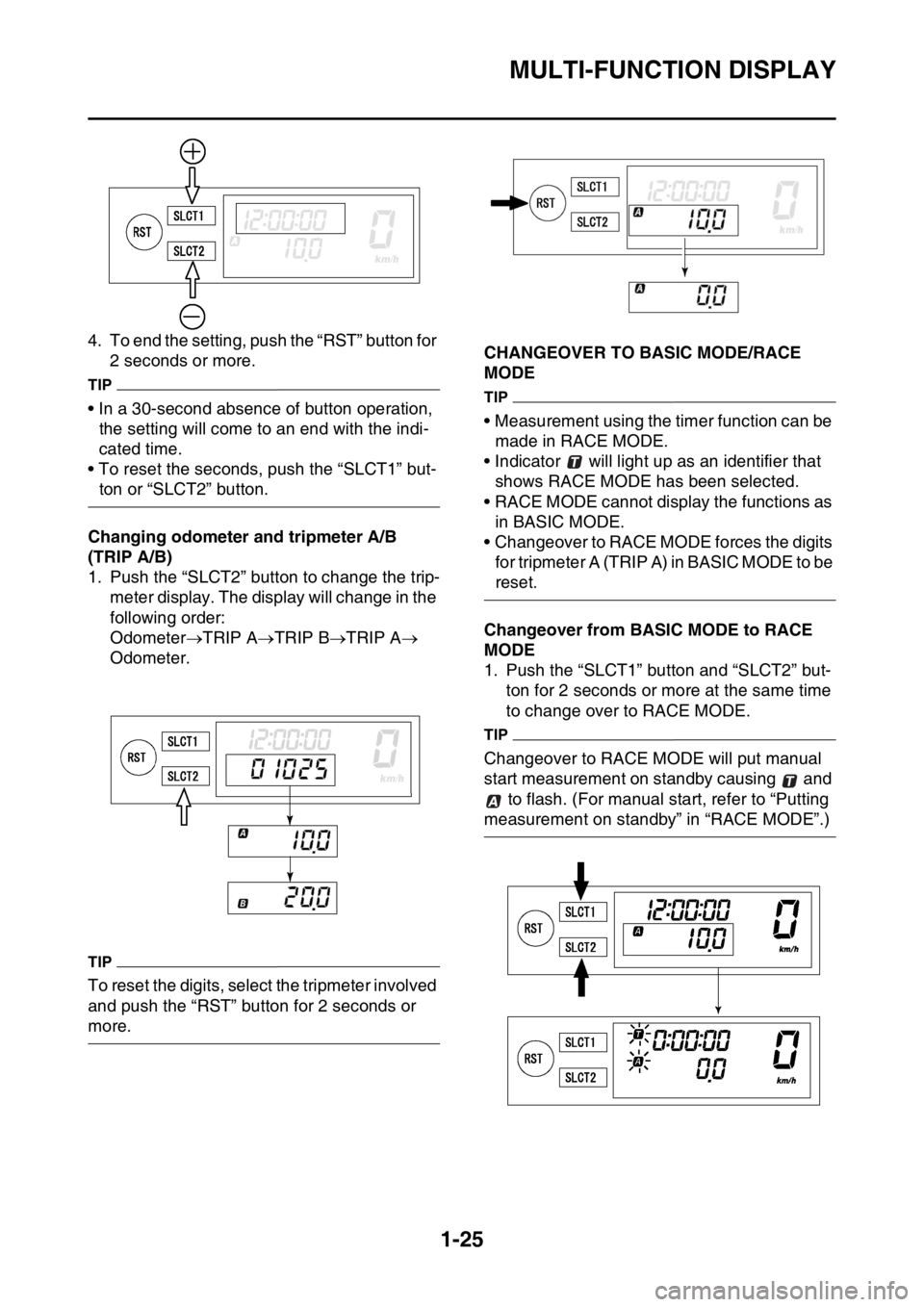

4. To end the setting, push the “RST” button for

2 seconds or more.

TIP

• In a 30-second absence of button operation,

the setting will come to an end with the indi-

cated time.

• To reset the seconds, push the “SLCT1” but-

ton or “SLCT2” button.

Changing odometer and tripmeter A/B

(TRIP A/B)

1. Push the “SLCT2” button to change the trip-

meter display. The display will change in the

following order:

OdometerTRIP ATRIP BTRIP A

Odometer.

TIP

To reset the digits, select the tripmeter involved

and push the “RST” button for 2 seconds or

more.

EAS2GB2047CHANGEOVER TO BASIC MODE/RACE

MODE

TIP

• Measurement using the timer function can be

made in RACE MODE.

• Indicator will light up as an identifier that

shows RACE MODE has been selected.

• RACE MODE cannot display the functions as

in BASIC MODE.

• Changeover to RACE MODE forces the digits

for tripmeter A (TRIP A) in BASIC MODE to be

reset.

Changeover from BASIC MODE to RACE

MODE

1. Push the “SLCT1” button and “SLCT2” but-

ton for 2 seconds or more at the same time

to change over to RACE MODE.

TIP

Changeover to RACE MODE will put manual

start measurement on standby causing and

to flash. (For manual start, refer to “Putting

measurement on standby” in “RACE MODE”.)

Page 40 of 430

MULTI-FUNCTION DISPLAY

1-26

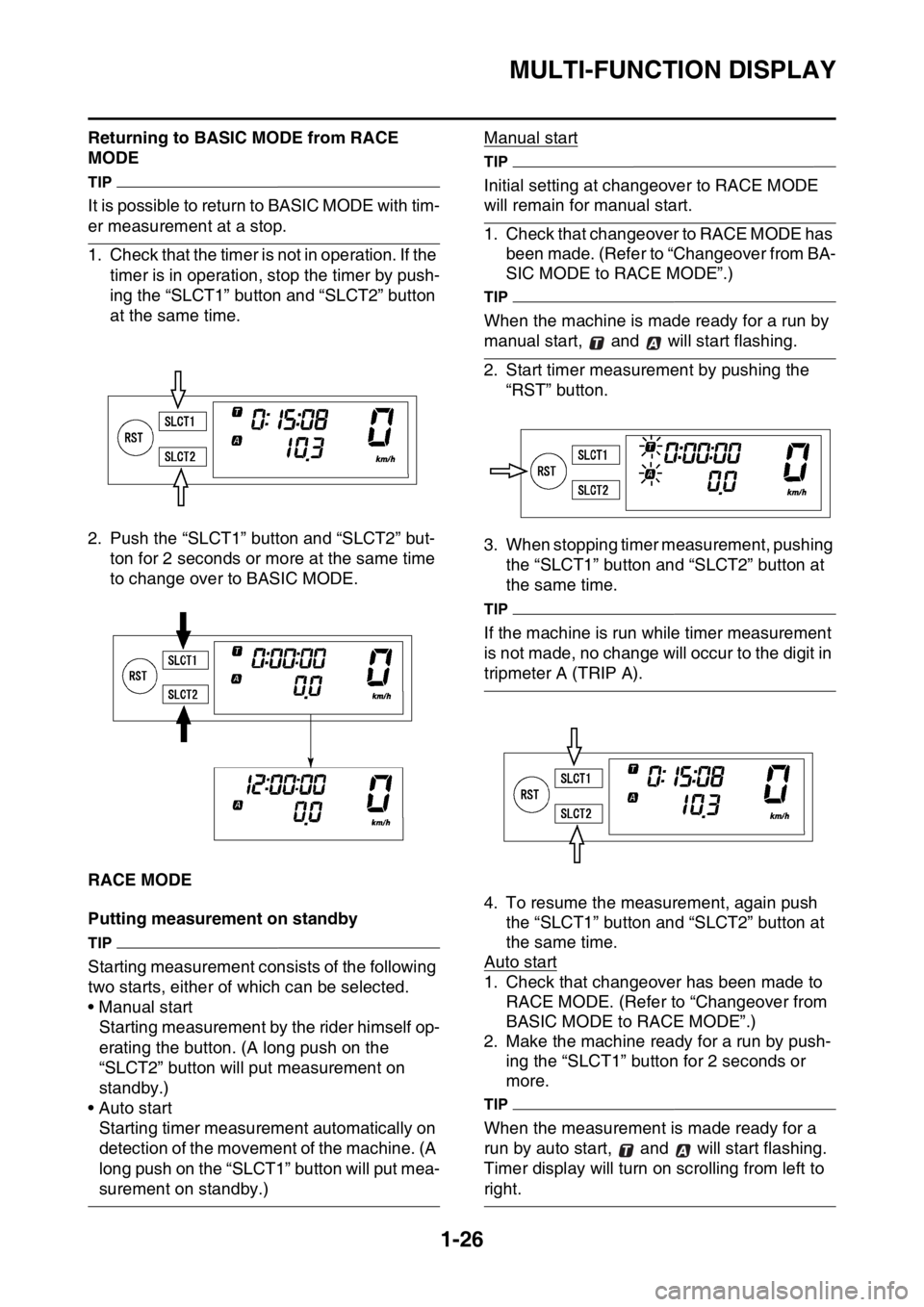

Returning to BASIC MODE from RACE

MODE

TIP

It is possible to return to BASIC MODE with tim-

er measurement at a stop.

1. Check that the timer is not in operation. If the

timer is in operation, stop the timer by push-

ing the “SLCT1” button and “SLCT2” button

at the same time.

2. Push the “SLCT1” button and “SLCT2” but-

ton for 2 seconds or more at the same time

to change over to BASIC MODE.

EAS2GB2048RACE MODE

Putting measurement on standby

TIP

Starting measurement consists of the following

two starts, either of which can be selected.

• Manual start

Starting measurement by the rider himself op-

erating the button. (A long push on the

“SLCT2” button will put measurement on

standby.)

• Auto start

Starting timer measurement automatically on

detection of the movement of the machine. (A

long push on the “SLCT1” button will put mea-

surement on standby.)Manual start

TIP

Initial setting at changeover to RACE MODE

will remain for manual start.

1. Check that changeover to RACE MODE has

been made. (Refer to “Changeover from BA-

SIC MODE to RACE MODE”.)

TIP

When the machine is made ready for a run by

manual start, and will start flashing.

2. Start timer measurement by pushing the

“RST” button.

3. When stopping timer measurement, pushing

the “SLCT1” button and “SLCT2” button at

the same time.

TIP

If the machine is run while timer measurement

is not made, no change will occur to the digit in

tripmeter A (TRIP A).

4. To resume the measurement, again push

the “SLCT1” button and “SLCT2” button at

the same time.

Auto start

1. Check that changeover has been made to

RACE MODE. (Refer to “Changeover from

BASIC MODE to RACE MODE”.)

2. Make the machine ready for a run by push-

ing the “SLCT1” button for 2 seconds or

more.

TIP

When the measurement is made ready for a

run by auto start, and will start flashing.

Timer display will turn on scrolling from left to

right.