set clock YAMAHA WR 250F 2015 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: WR 250F, Model: YAMAHA WR 250F 2015Pages: 430, PDF Size: 14.14 MB

Page 38 of 430

MULTI-FUNCTION DISPLAY

1-24

EAS2GB2044

MULTI-FUNCTION DISPLAYEWA

WARNING

Be sure to stop the machine before making

any setting changes to the multi-function

display.

The multi-function display is equipped with the

following:

BASIC MODE:

• Speedometer

•Clock

• Two tripmeters (which shows the distance

that has been traveled since it was last set to

zero)

RACE MODE:

• Timer (which shows the time that has been

accumulated since the start of timer measure-

ment)

• Tripmeter (which shows the accumulated

travel distance in timer measurement)

• Change tripmeter digits (capable of change to

any given ones)

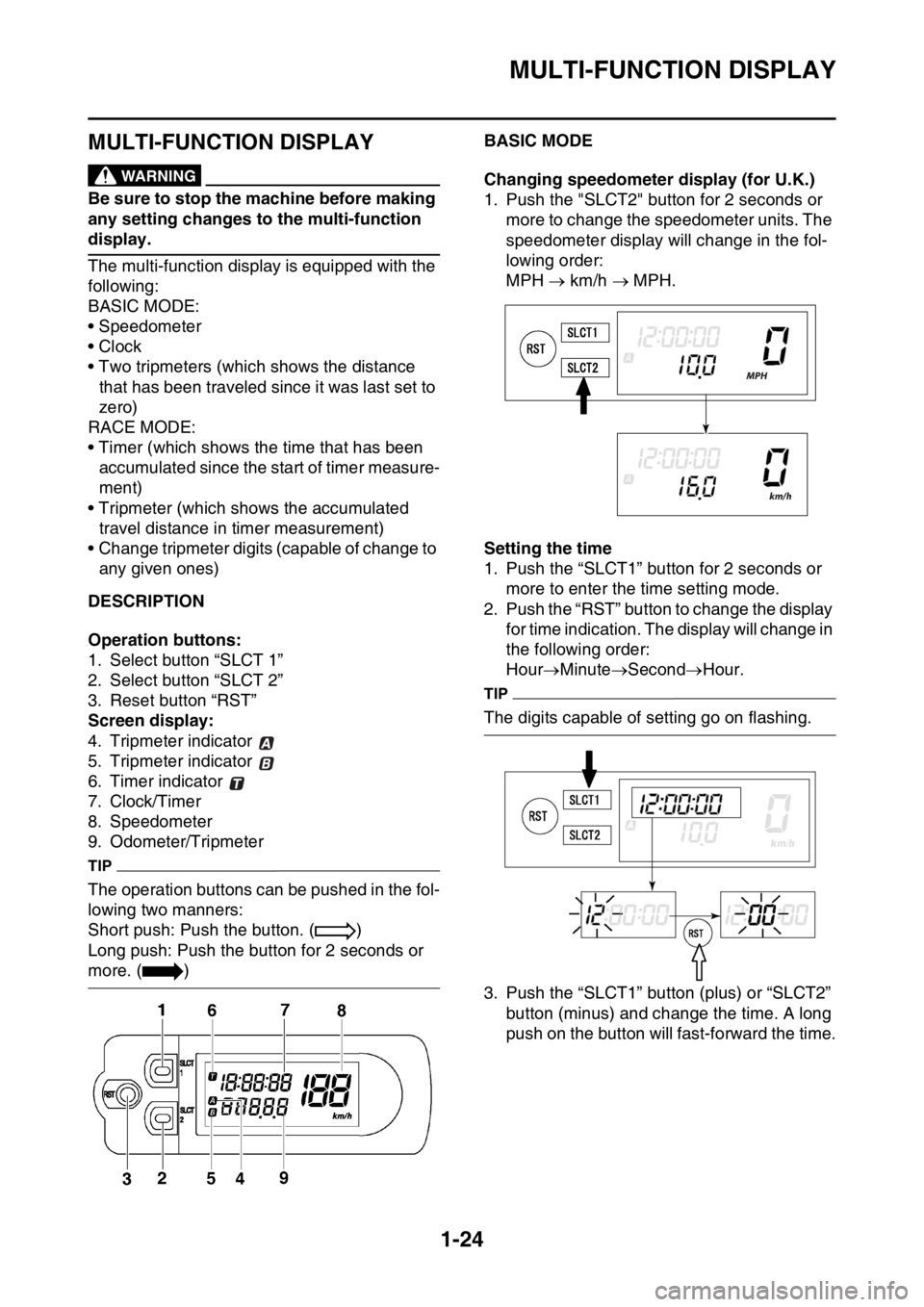

EAS2GB2045DESCRIPTION

Operation buttons:

1. Select button “SLCT 1”

2. Select button “SLCT 2”

3. Reset button “RST”

Screen display:

4. Tripmeter indicator

5. Tripmeter indicator

6. Timer indicator

7. Clock/Timer

8. Speedometer

9. Odometer/Tripmeter

TIP

The operation buttons can be pushed in the fol-

lowing two manners:

Short push: Push the button. ( )

Long push: Push the button for 2 seconds or

more. ( )

EAS2GB2046BASIC MODE

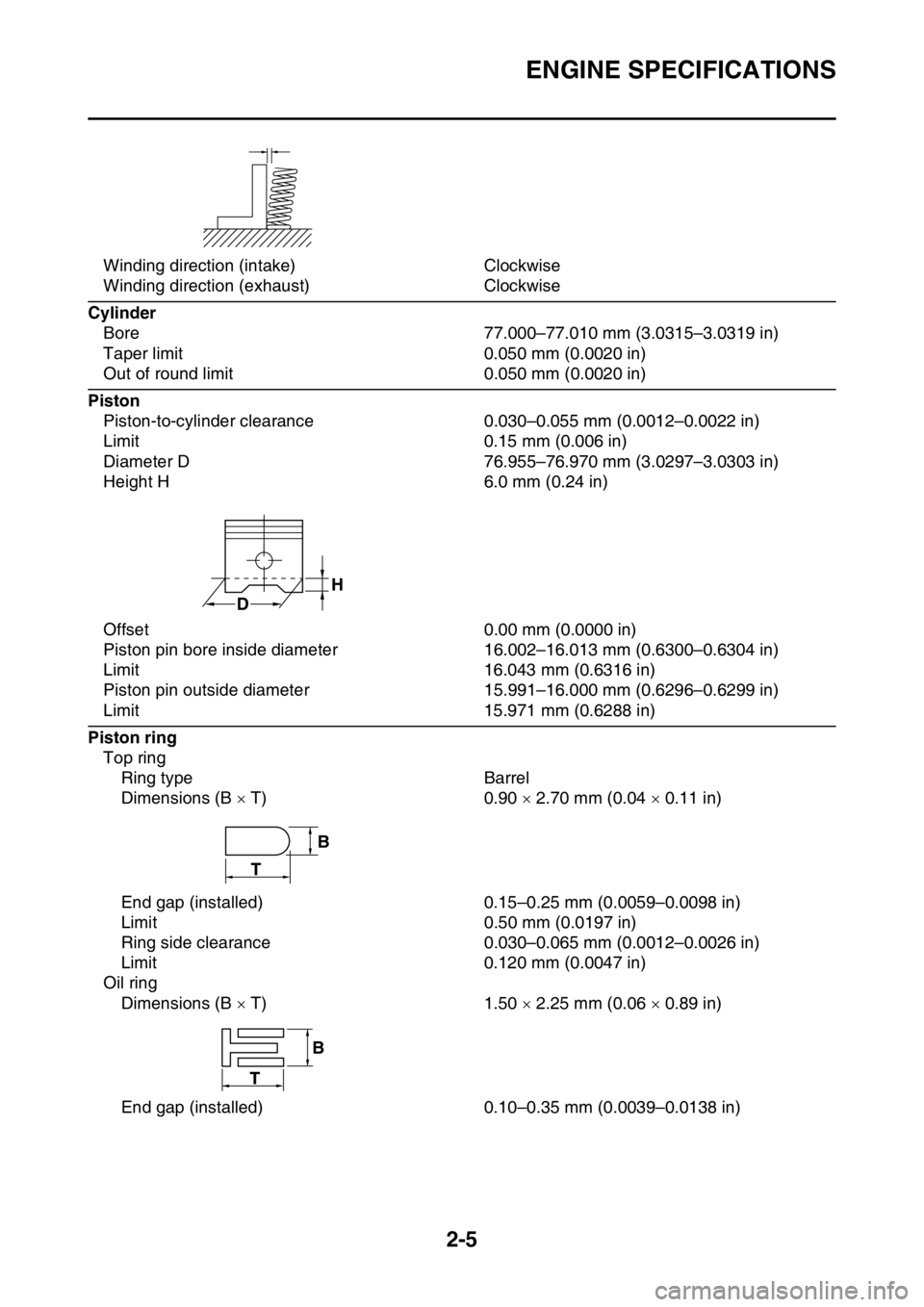

Changing speedometer display (for U.K.)

1. Push the "SLCT2" button for 2 seconds or

more to change the speedometer units. The

speedometer display will change in the fol-

lowing order:

MPH km/h MPH.

Setting the time

1. Push the “SLCT1” button for 2 seconds or

more to enter the time setting mode.

2. Push the “RST” button to change the display

for time indication. The display will change in

the following order:

HourMinuteSecondHour.

TIP

The digits capable of setting go on flashing.

3. Push the “SLCT1” button (plus) or “SLCT2”

button (minus) and change the time. A long

push on the button will fast-forward the time.

Page 44 of 430

MULTI-FUNCTION DISPLAY

1-30

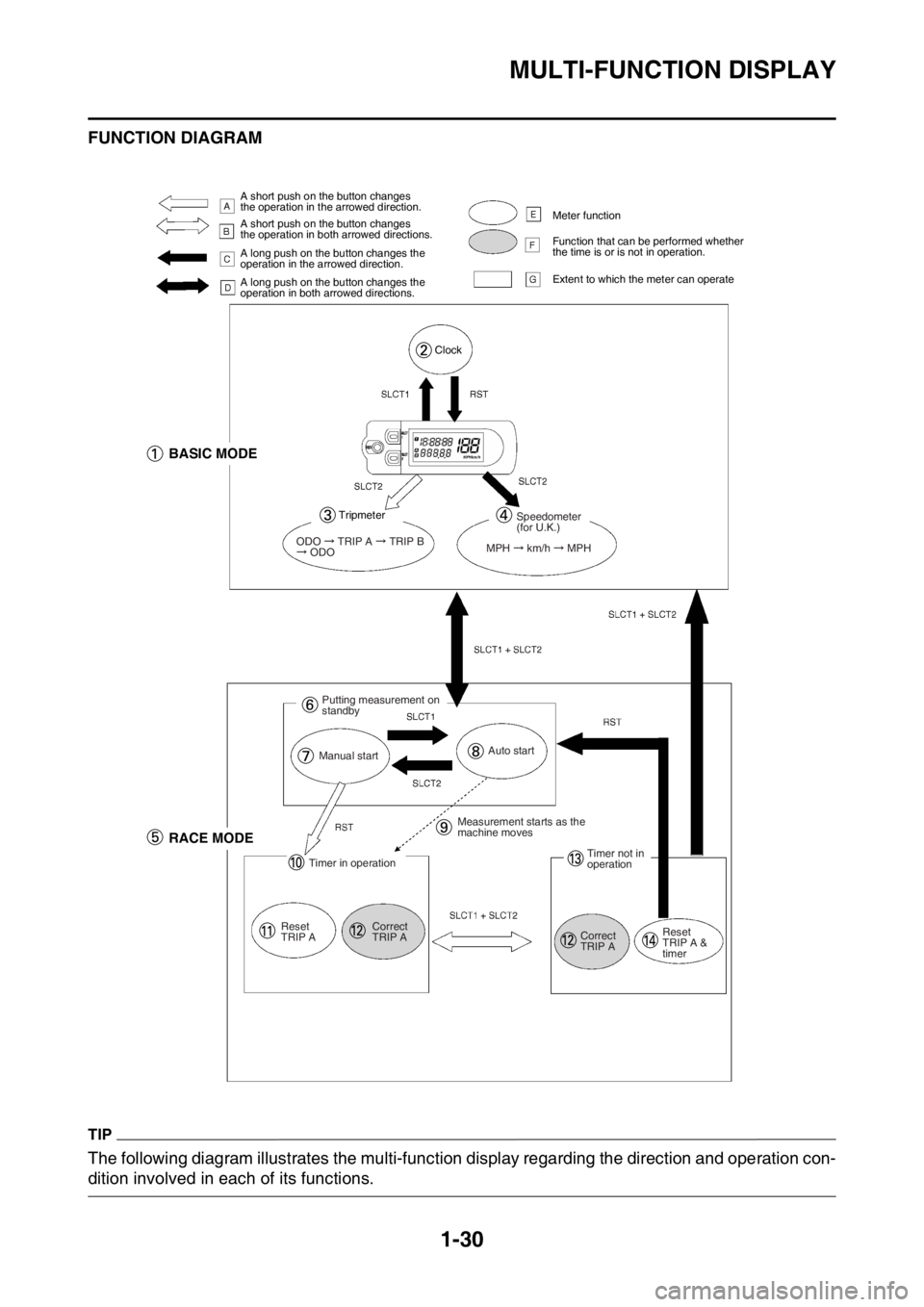

FUNCTION DIAGRAM

TIP

The following diagram illustrates the multi-function display regarding the direction and operation con-

dition involved in each of its functions.

A short push on the button changes

the operation in the arrowed direction.

A short push on the button changes

the operation in both arrowed directions.

A long push on the button changes the

operation in the arrowed direction.

A long push on the button changes the

operation in both arrowed directions.Meter function

Function that can be performed whether

the time is or is not in operation.

Extent to which the meter can operate

Clock

BASIC MODE

Tripmeter

ODO TRIP A TRIP B ODO

Speedometer

(for U.K.)

MPH

km/h MPH

Putting measurement on

standby

Manual startAuto start

RACE MODE

Timer in operation

Reset

TRIP ACorrect

TRIP AMeasurement starts as the

machine moves

Timer not in

operation

Correct

TRIP AReset

TRIP A &

timer

Page 45 of 430

MULTI-FUNCTION DISPLAY

1-31

A.A short push on the button changes the oper-

ation in the arrowed direction.

B.A short push on the button changes the oper-

ation in both arrowed directions.

C.A long push on the button changes the oper-

ation in the arrowed direction.

D.A long push on the button changes the oper-

ation in both arrowed directions.

E.Meter function

F.Function that can be performed whether the

time is or is not in operation.

G.Extent to which the meter can operate

1. BASIC MODE

2. Clock

3. Trip meter

4. Speedometer (for U.K.)

5. RACE MODE

6. Putting measurement on standby

7. Manual start

8. Auto start

9. Measurement starts as the machine moves

10.Timer in operation

11.Reset TRIP A

12.Correct TRIP A

13.Timer not in operation

14.Reset TRIP A and timer

Page 60 of 430

ENGINE SPECIFICATIONS

2-5

Winding direction (intake) Clockwise

Winding direction (exhaust) Clockwise

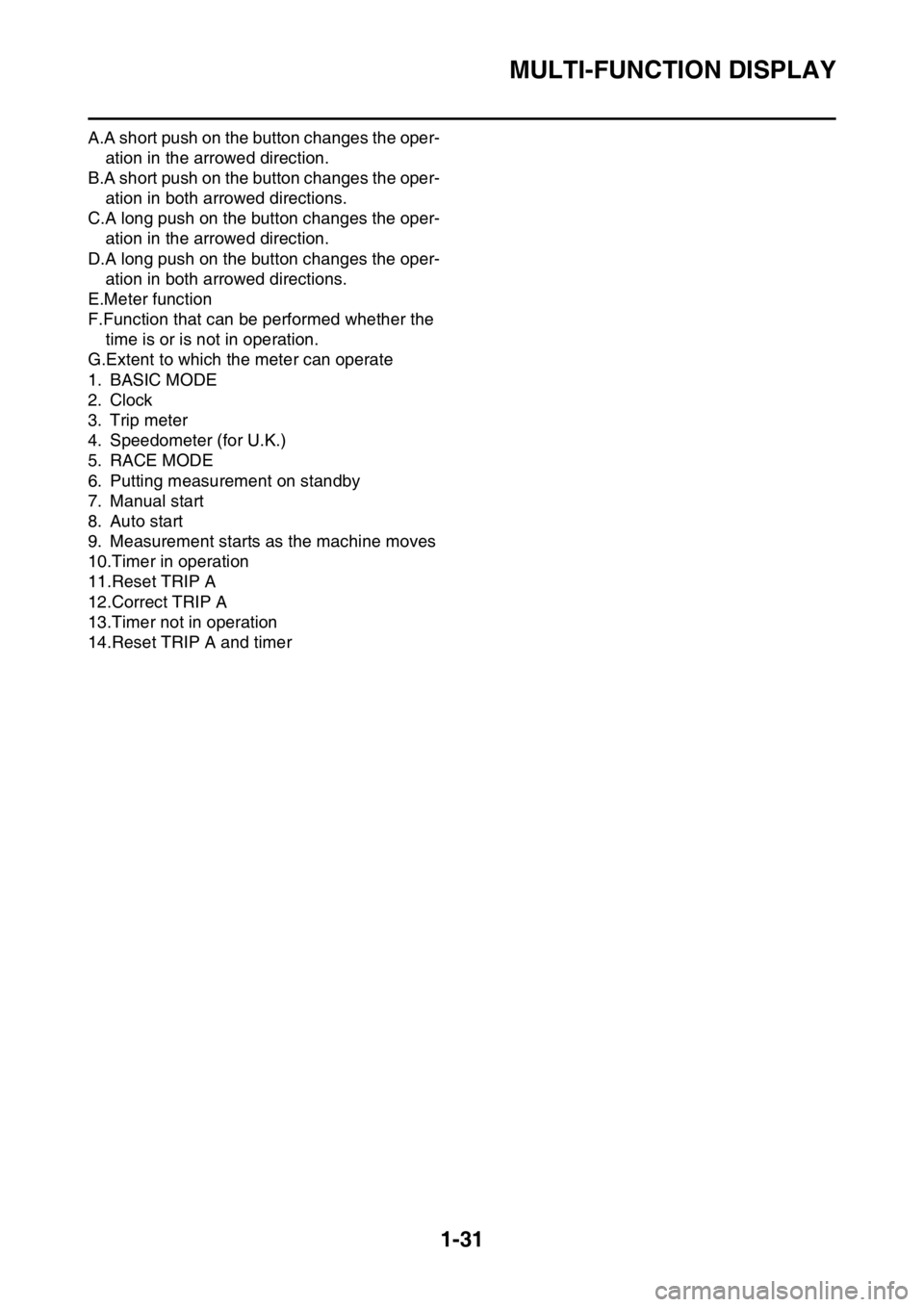

Cylinder

Bore 77.000–77.010 mm (3.0315–3.0319 in)

Taper limit 0.050 mm (0.0020 in)

Out of round limit 0.050 mm (0.0020 in)

Piston

Piston-to-cylinder clearance 0.030–0.055 mm (0.0012–0.0022 in)

Limit 0.15 mm (0.006 in)

Diameter D 76.955–76.970 mm (3.0297–3.0303 in)

Height H 6.0 mm (0.24 in)

Offset 0.00 mm (0.0000 in)

Piston pin bore inside diameter 16.002–16.013 mm (0.6300–0.6304 in)

Limit 16.043 mm (0.6316 in)

Piston pin outside diameter 15.991–16.000 mm (0.6296–0.6299 in)

Limit 15.971 mm (0.6288 in)

Piston ring

Top ring

Ring type Barrel

Dimensions (B T) 0.90 2.70 mm (0.04 0.11 in)

End gap (installed) 0.15–0.25 mm (0.0059–0.0098 in)

Limit 0.50 mm (0.0197 in)

Ring side clearance 0.030–0.065 mm (0.0012–0.0026 in)

Limit 0.120 mm (0.0047 in)

Oil ring

Dimensions (B T) 1.50 2.25 mm (0.06 0.89 in)

End gap (installed) 0.10–0.35 mm (0.0039–0.0138 in)

H

D

T

B

B

T

Page 153 of 430

CHASSIS

4-6

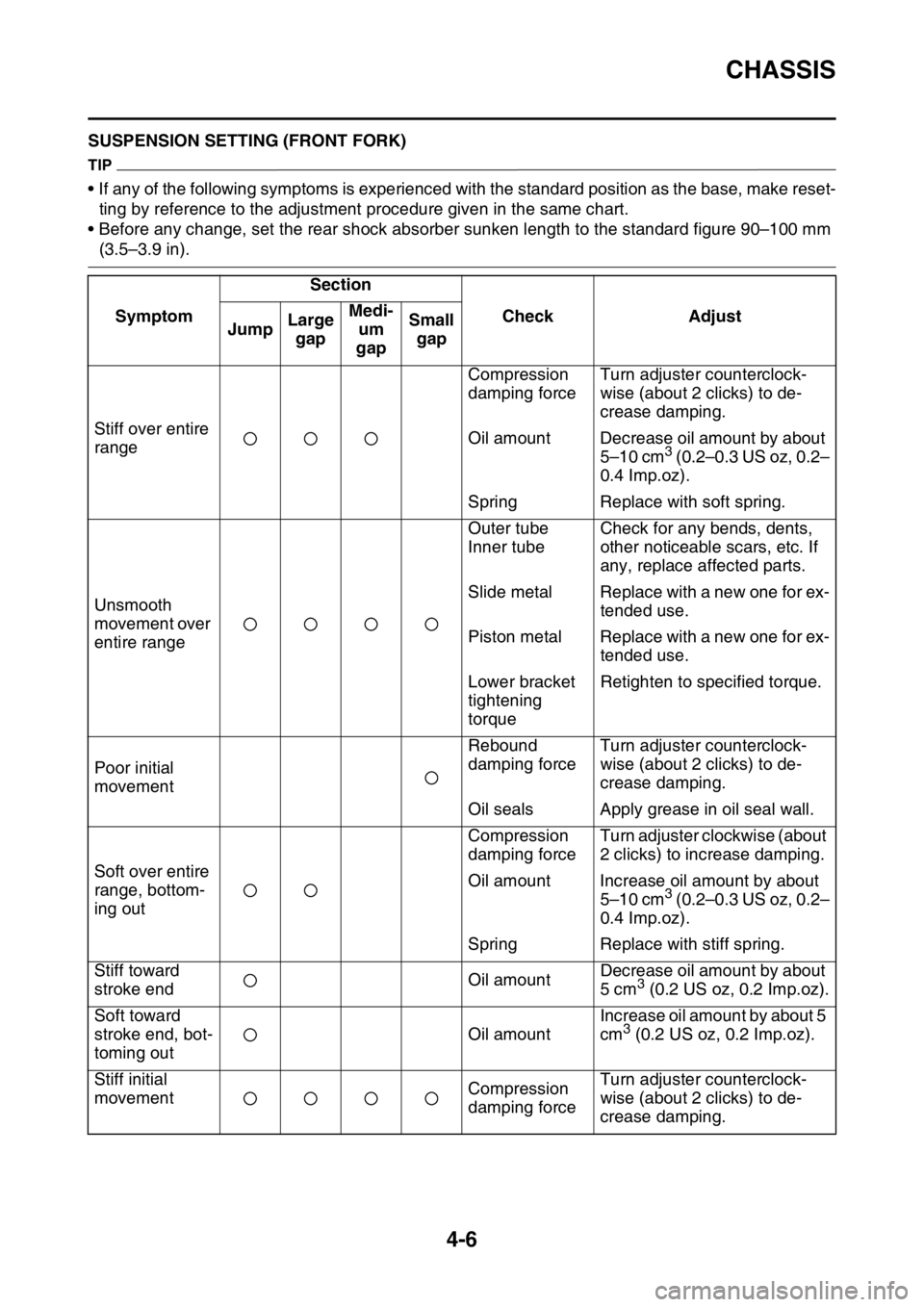

EAS2GB2150SUSPENSION SETTING (FRONT FORK)

TIP

• If any of the following symptoms is experienced with the standard position as the base, make reset-

ting by reference to the adjustment procedure given in the same chart.

• Before any change, set the rear shock absorber sunken length to the standard figure 90–100 mm

(3.5–3.9 in).

SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap

Stiff over entire

rangeCompression

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Oil amount Decrease oil amount by about

5–10 cm

3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

Spring Replace with soft spring.

Unsmooth

movement over

entire rangeOuter tube

Inner tubeCheck for any bends, dents,

other noticeable scars, etc. If

any, replace affected parts.

Slide metal Replace with a new one for ex-

tended use.

Piston metal Replace with a new one for ex-

tended use.

Lower bracket

tightening

torqueRetighten to specified torque.

Poor initial

movementRebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Oil seals Apply grease in oil seal wall.

Soft over entire

range, bottom-

ing outCompression

damping forceTurn adjuster clockwise (about

2 clicks) to increase damping.

Oil amount Increase oil amount by about

5–10 cm

3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

Spring Replace with stiff spring.

Stiff toward

stroke endOil amountDecrease oil amount by about

5 cm

3 (0.2 US oz, 0.2 Imp.oz).

Soft toward

stroke end, bot-

toming outOil amountIncrease oil amount by about 5

cm

3 (0.2 US oz, 0.2 Imp.oz).

Stiff initial

movementCompression

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Page 154 of 430

CHASSIS

4-7

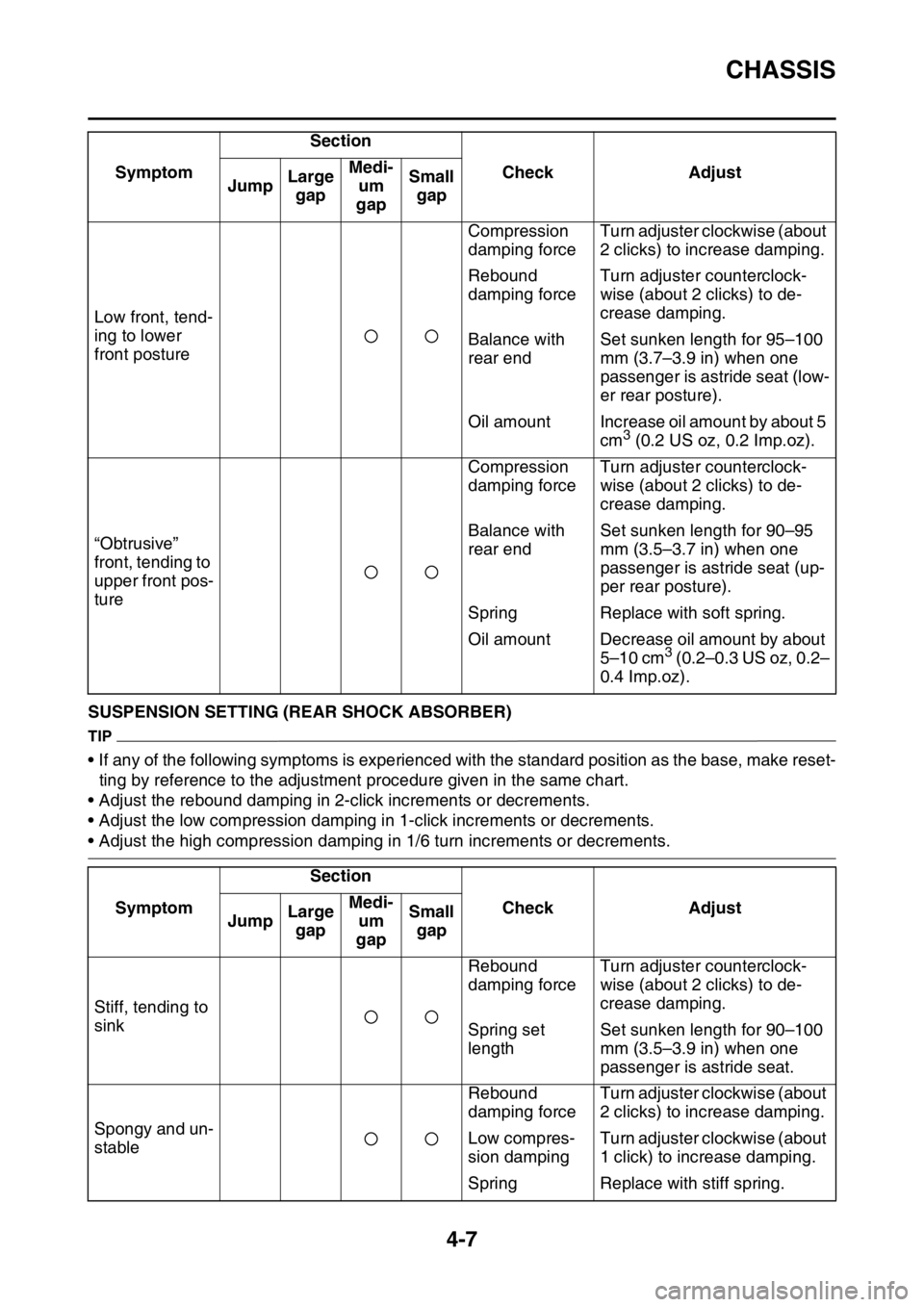

EAS2GB2151SUSPENSION SETTING (REAR SHOCK ABSORBER)

TIP

• If any of the following symptoms is experienced with the standard position as the base, make reset-

ting by reference to the adjustment procedure given in the same chart.

• Adjust the rebound damping in 2-click increments or decrements.

• Adjust the low compression damping in 1-click increments or decrements.

• Adjust the high compression damping in 1/6 turn increments or decrements. Low front, tend-

ing to lower

front postureCompression

damping forceTurn adjuster clockwise (about

2 clicks) to increase damping.

Rebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Balance with

rear endSet sunken length for 95–100

mm (3.7–3.9 in) when one

passenger is astride seat (low-

er rear posture).

Oil amount Increase oil amount by about 5

cm

3 (0.2 US oz, 0.2 Imp.oz).

“Obtrusive”

front, tending to

upper front pos-

tureCompression

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Balance with

rear endSet sunken length for 90–95

mm (3.5–3.7 in) when one

passenger is astride seat (up-

per rear posture).

Spring Replace with soft spring.

Oil amount Decrease oil amount by about

5–10 cm

3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap

Stiff, tending to

sinkRebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Spring set

lengthSet sunken length for 90–100

mm (3.5–3.9 in) when one

passenger is astride seat.

Spongy and un-

stableRebound

damping forceTurn adjuster clockwise (about

2 clicks) to increase damping.

Low compres-

sion dampingTurn adjuster clockwise (about

1 click) to increase damping.

Spring Replace with stiff spring. SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap

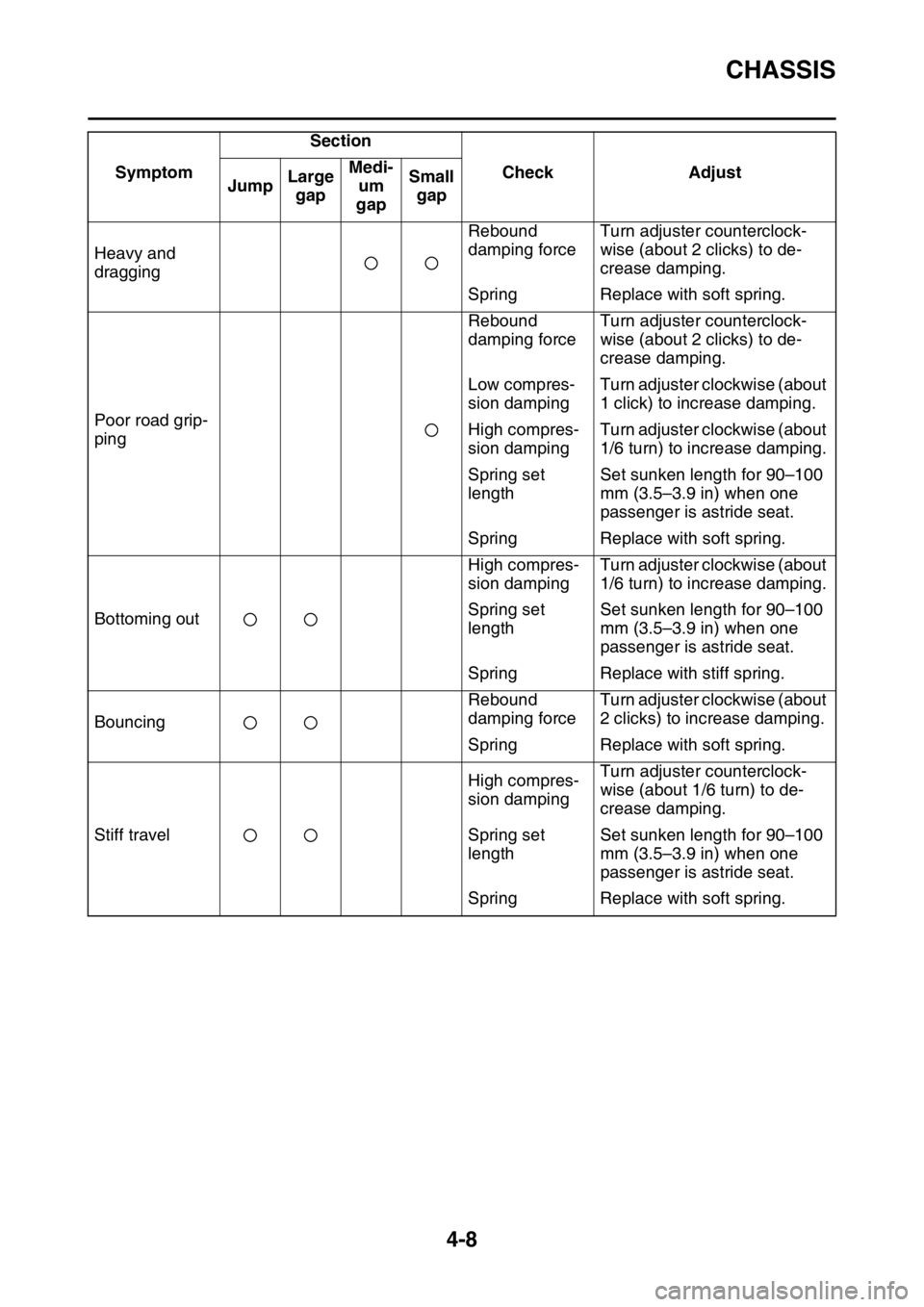

Page 155 of 430

CHASSIS

4-8

Heavy and

draggingRebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Spring Replace with soft spring.

Poor road grip-

pingRebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Low compres-

sion dampingTurn adjuster clockwise (about

1 click) to increase damping.

High compres-

sion dampingTurn adjuster clockwise (about

1/6 turn) to increase damping.

Spring set

lengthSet sunken length for 90–100

mm (3.5–3.9 in) when one

passenger is astride seat.

Spring Replace with soft spring.

Bottoming outHigh compres-

sion dampingTurn adjuster clockwise (about

1/6 turn) to increase damping.

Spring set

lengthSet sunken length for 90–100

mm (3.5–3.9 in) when one

passenger is astride seat.

Spring Replace with stiff spring.

BouncingRebound

damping forceTurn adjuster clockwise (about

2 clicks) to increase damping.

Spring Replace with soft spring.

Stiff travelHigh compres-

sion dampingTurn adjuster counterclock-

wise (about 1/6 turn) to de-

crease damping.

Spring set

lengthSet sunken length for 90–100

mm (3.5–3.9 in) when one

passenger is astride seat.

Spring Replace with soft spring. SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap

Page 246 of 430

CAMSHAFT

6-15

c. Install the dowel pins and the camshaft

caps.

TIP

• Tighten the camshaft cap bolts in a crisscross

pattern from innermost to outer caps.

• Do not turn the camshaft when measuring the

camshaft journal-to-camshaft cap clearance.

d. Remove the camshaft caps and then mea-

sure the width of the Plastigauge® “1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. Measure:

• Camshaft journal diameter “a”

Out of specification Replace the cam-

shaft.

Within specification Replace the cylinder

head and the camshaft caps as a set.

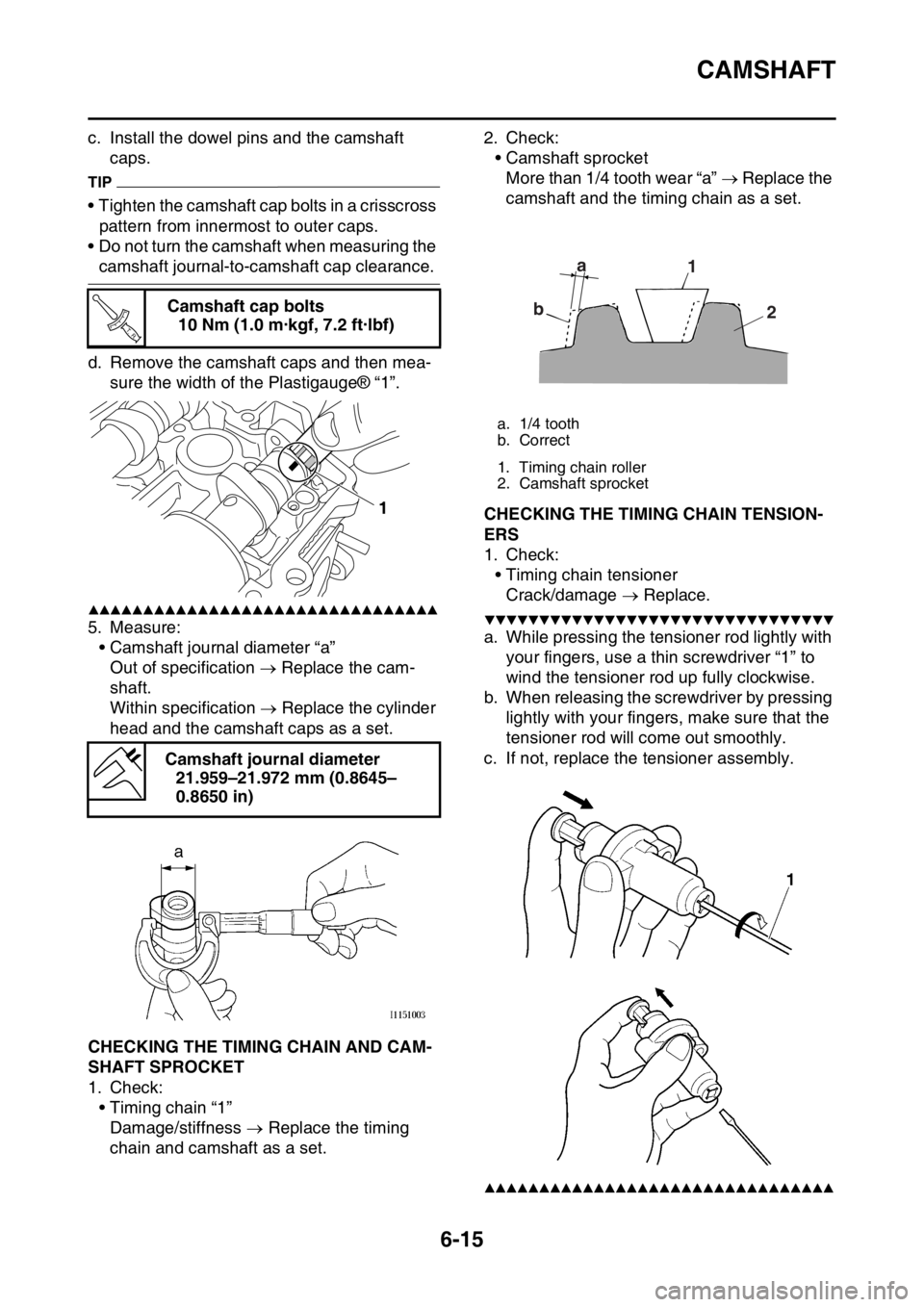

EAS2GB2242CHECKING THE TIMING CHAIN AND CAM-

SHAFT SPROCKET

1. Check:

• Timing chain “1”

Damage/stiffness Replace the timing

chain and camshaft as a set.2. Check:

• Camshaft sprocket

More than 1/4 tooth wear “a” Replace the

camshaft and the timing chain as a set.

EAS2GB2243CHECKING THE TIMING CHAIN TENSION-

ERS

1. Check:

• Timing chain tensioner

Crack/damage Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. While pressing the tensioner rod lightly with

your fingers, use a thin screwdriver “1” to

wind the tensioner rod up fully clockwise.

b. When releasing the screwdriver by pressing

lightly with your fingers, make sure that the

tensioner rod will come out smoothly.

c. If not, replace the tensioner assembly.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Camshaft cap bolts

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Camshaft journal diameter

21.959–21.972 mm (0.8645–

0.8650 in)

T R..

1

a. 1/4 tooth

b. Correct

1. Timing chain roller

2. Camshaft sprocket

a

b1

2

Page 401 of 430

ELECTRICAL COMPONENTS

9-67

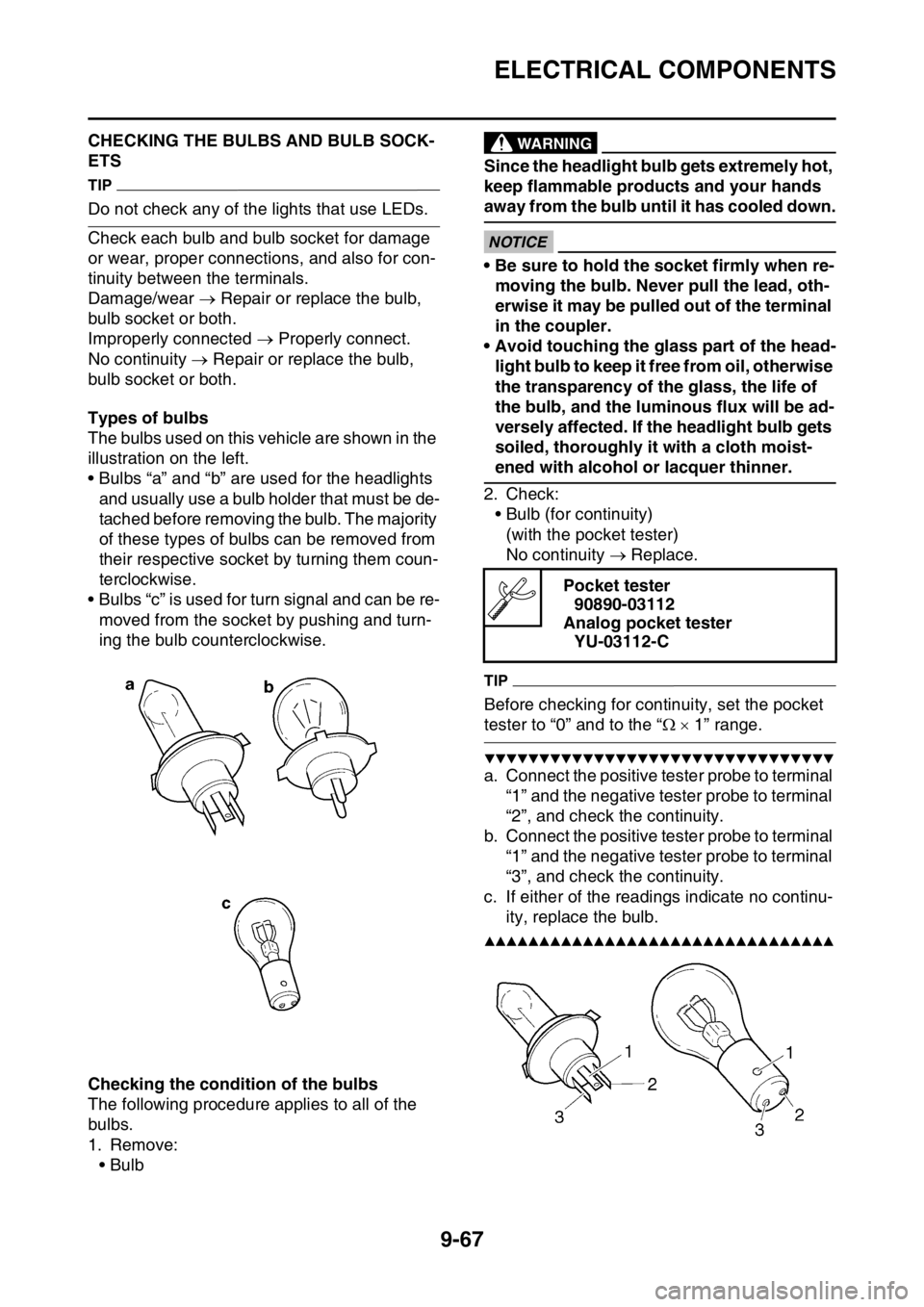

EAS27990CHECKING THE BULBS AND BULB SOCK-

ETS

TIP

Do not check any of the lights that use LEDs.

Check each bulb and bulb socket for damage

or wear, proper connections, and also for con-

tinuity between the terminals.

Damage/wear Repair or replace the bulb,

bulb socket or both.

Improperly connected Properly connect.

No continuity Repair or replace the bulb,

bulb socket or both.

Types of bulbs

The bulbs used on this vehicle are shown in the

illustration on the left.

• Bulbs “a” and “b” are used for the headlights

and usually use a bulb holder that must be de-

tached before removing the bulb. The majority

of these types of bulbs can be removed from

their respective socket by turning them coun-

terclockwise.

• Bulbs “c” is used for turn signal and can be re-

moved from the socket by pushing and turn-

ing the bulb counterclockwise.

Checking the condition of the bulbs

The following procedure applies to all of the

bulbs.

1. Remove:

•Bulb

EWA

WARNING

Since the headlight bulb gets extremely hot,

keep flammable products and your hands

away from the bulb until it has cooled down.

ECA

NOTICE

• Be sure to hold the socket firmly when re-

moving the bulb. Never pull the lead, oth-

erwise it may be pulled out of the terminal

in the coupler.

• Avoid touching the glass part of the head-

light bulb to keep it free from oil, otherwise

the transparency of the glass, the life of

the bulb, and the luminous flux will be ad-

versely affected. If the headlight bulb gets

soiled, thoroughly it with a cloth moist-

ened with alcohol or lacquer thinner.

2. Check:

• Bulb (for continuity)

(with the pocket tester)

No continuity Replace.

TIP

Before checking for continuity, set the pocket

tester to “0” and to the “ 1” range.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the positive tester probe to terminal

“1” and the negative tester probe to terminal

“2”, and check the continuity.

b. Connect the positive tester probe to terminal

“1” and the negative tester probe to terminal

“3”, and check the continuity.

c. If either of the readings indicate no continu-

ity, replace the bulb.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C