YAMAHA WR 250F 2017 Owners Manual

Manufacturer: YAMAHA, Model Year: 2017, Model line: WR 250F, Model: YAMAHA WR 250F 2017Pages: 432, PDF Size: 14.14 MB

Page 131 of 432

CHASSIS

3-31

EWA

WARNING

• Use only the designated brake fluid. Other

brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor

brake performance.

• Refill with the same type of brake fluid that

is already in the system. Mixing brake flu-

ids may result in a harmful chemical reac-

tion, leading to poor brake performance.

• When refilling, be careful that water does

not enter the brake fluid reservoir. Water

will significantly lower the boiling point of

the brake fluid and could cause vapor

lock.

ECA

NOTICE

Brake fluid may damage painted surfaces

and plastic parts. Therefore, always clean

up any spilt brake fluid immediately.

EAS2GBB110ADJUSTING THE DRIVE CHAIN SLACKECA

NOTICE

A drive chain that is too tight will overload

the engine and other vital parts, and one

that is too loose can skip and damage the

swingarm or cause an accident. Therefore,

keep the drive chain slack within the speci-

fied limits.

1. Use a suitable stand to raise the rear wheel

off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Shift the transmission into the neutral posi-

tion.

3. Pull the drive chain up above the drive chain

guide installation bolt with a force of about

50 N (5.0 kgf, 36 lbf).

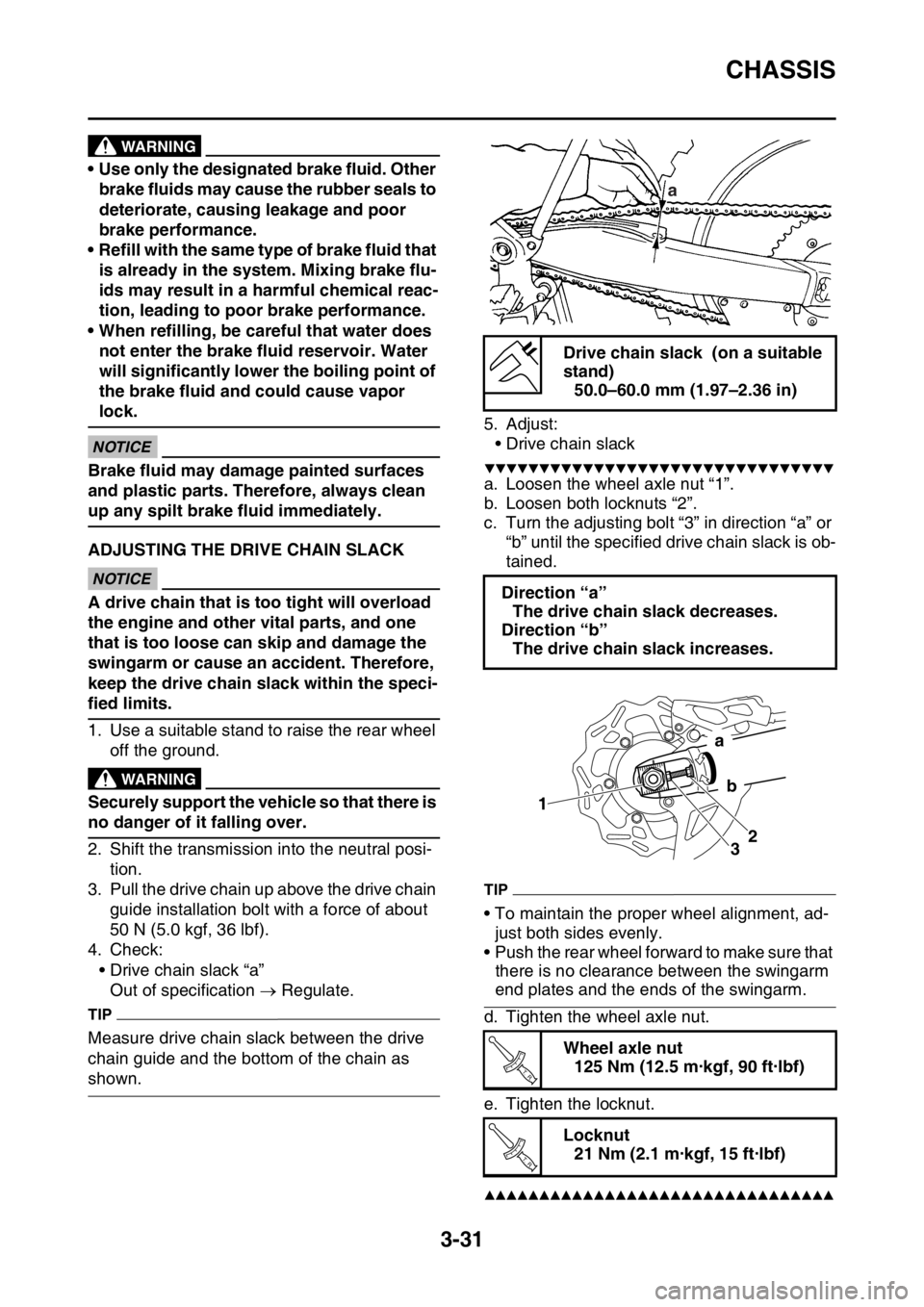

4. Check:

• Drive chain slack “a”

Out of specification Regulate.

TIP

Measure drive chain slack between the drive

chain guide and the bottom of the chain as

shown.5. Adjust:

• Drive chain slack

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the wheel axle nut “1”.

b. Loosen both locknuts “2”.

c. Turn the adjusting bolt “3” in direction “a” or

“b” until the specified drive chain slack is ob-

tained.

TIP

• To maintain the proper wheel alignment, ad-

just both sides evenly.

• Push the rear wheel forward to make sure that

there is no clearance between the swingarm

end plates and the ends of the swingarm.

d. Tighten the wheel axle nut.

e. Tighten the locknut.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Drive chain slack (on a suitable

stand)

50.0–60.0 mm (1.97–2.36 in)

Direction “a”

The drive chain slack decreases.

Direction “b”

The drive chain slack increases.

Wheel axle nut

125 Nm (12.5 m·kgf, 90 ft·lbf)

Locknut

21 Nm (2.1 m·kgf, 15 ft·lbf)

a

1

32

a

b

T R..

T R..

Page 132 of 432

CHASSIS

3-32

EAS2GBB111CHECKING THE FRONT FORK LEGS

1. Stand the vehicle upright on a level surface.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Check:

• Inner tube

Damage/scratches Replace.

• Front fork leg (s)

Oil leaks between inner tube and outer tube

Replace the oil seal.

3. Hold the vehicle upright and apply the front

brake.

4. Check:

• Front fork operation

Push down hard on the handlebar several

times and check if the front fork rebounds

smoothly.

Unsmooth operation Correct or replace.

Refer to “FRONT FORK” on page 5-40.

EAS2GBB112CHECKING THE FRONT FORK PROTEC-

TOR GUIDE

1. Check:

• Protector guide “1”

Out of specification Replace.

TIP

The protector guide reaches the limit of its use

when it is worn down to the same height “a” as

of the outer tube circumference.

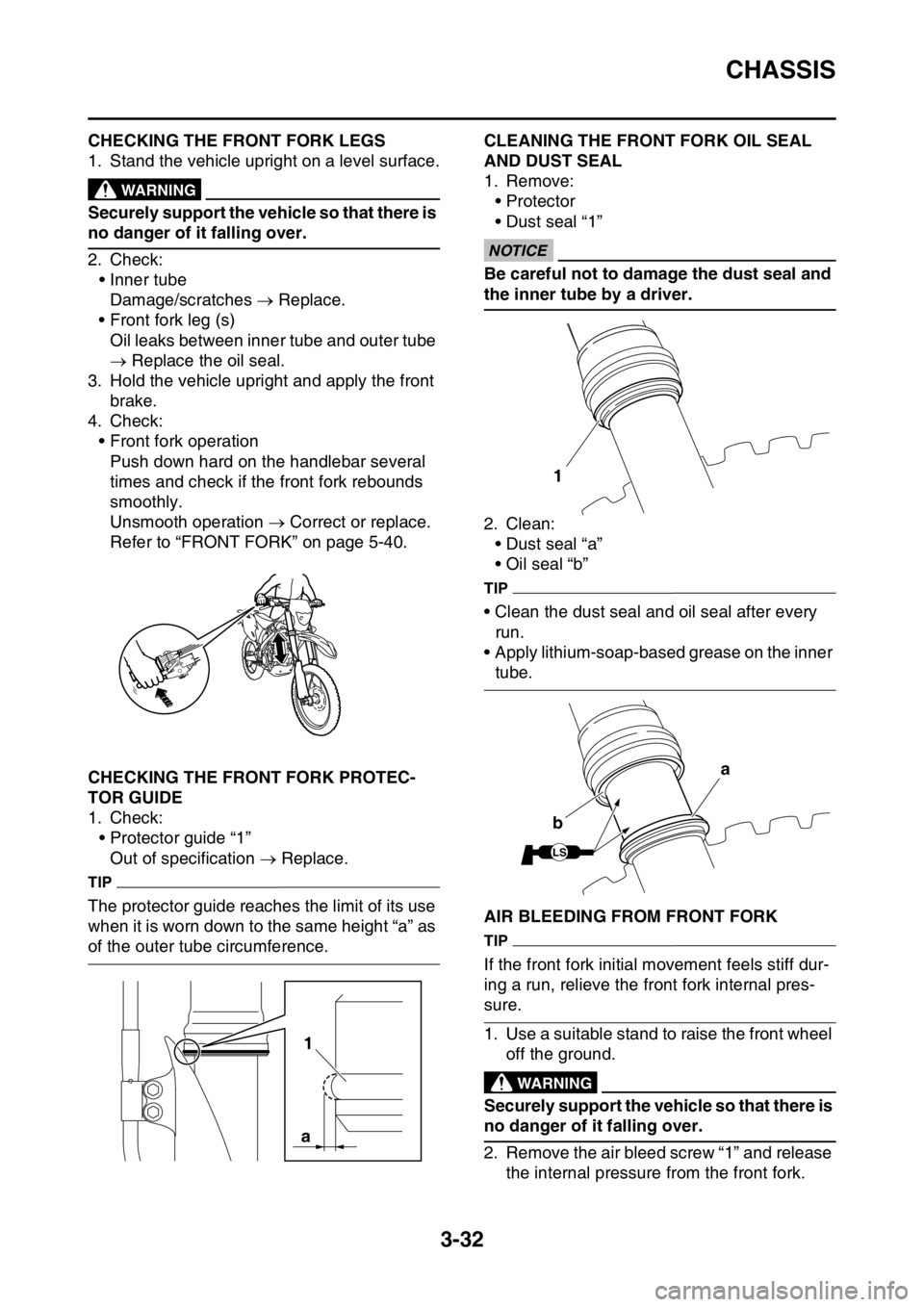

EAS2GBB113CLEANING THE FRONT FORK OIL SEAL

AND DUST SEAL

1. Remove:

•Protector

• Dust seal “1”

ECA

NOTICE

Be careful not to damage the dust seal and

the inner tube by a driver.

2. Clean:

• Dust seal “a”

• Oil seal “b”

TIP

• Clean the dust seal and oil seal after every

run.

• Apply lithium-soap-based grease on the inner

tube.

EAS2GBB114AIR BLEEDING FROM FRONT FORK

TIP

If the front fork initial movement feels stiff dur-

ing a run, relieve the front fork internal pres-

sure.

1. Use a suitable stand to raise the front wheel

off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Remove the air bleed screw “1” and release

the internal pressure from the front fork.

1

a

1

LS

a

b

Page 133 of 432

CHASSIS

3-33

3. Tighten:

• Air bleed screw

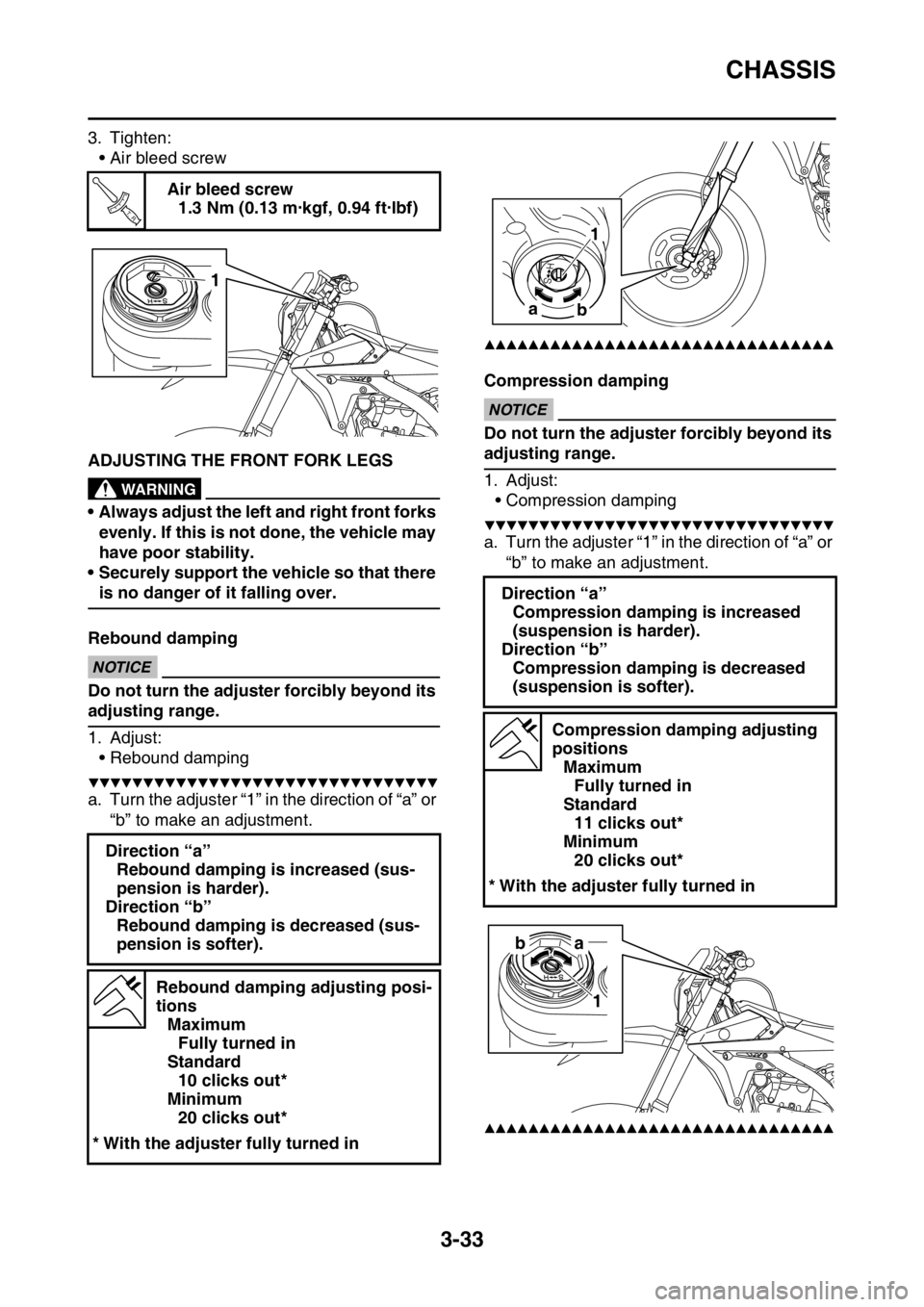

EAS2GBB115ADJUSTING THE FRONT FORK LEGSEWA

WARNING

• Always adjust the left and right front forks

evenly. If this is not done, the vehicle may

have poor stability.

• Securely support the vehicle so that there

is no danger of it falling over.

Rebound damping

ECA

NOTICE

Do not turn the adjuster forcibly beyond its

adjusting range.

1. Adjust:

• Rebound damping

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the adjuster “1” in the direction of “a” or

“b” to make an adjustment.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Compression dampingECA

NOTICE

Do not turn the adjuster forcibly beyond its

adjusting range.

1. Adjust:

• Compression damping

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the adjuster “1” in the direction of “a” or

“b” to make an adjustment.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Air bleed screw

1.3 Nm (0.13 m·kgf, 0.94 ft·lbf)

Direction “a”

Rebound damping is increased (sus-

pension is harder).

Direction “b”

Rebound damping is decreased (sus-

pension is softer).

Rebound damping adjusting posi-

tions

Maximum

Fully turned in

Standard

10 clicks out*

Minimum

20 clicks out*

* With the adjuster fully turned in

T R..

1

Direction “a”

Compression damping is increased

(suspension is harder).

Direction “b”

Compression damping is decreased

(suspension is softer).

Compression damping adjusting

positions

Maximum

Fully turned in

Standard

11 clicks out*

Minimum

20 clicks out*

* With the adjuster fully turned in

1

a

b

a b

1

Page 134 of 432

CHASSIS

3-34

EAS2GBB116CHECKING THE SWINGARM OPERATION

1. Check:

• Swingarm smooth action

• Swingarm free play

Refer to “SWINGARM” on page 5-65.

EAS2GBB117CHECKING THE REAR SUSPENSION

1. Stand the vehicle upright on a level surface.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Check:

• Rear shock absorber assembly

Gas leaks/oil leaks Replace the rear

shock absorber assembly.

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 5-58.

3. Check:

• Rear shock absorber assembly smooth ac-

tion

• Rear suspension link smooth action

Sit astride the seat and shake your body up

and down several times to check whether

the rear shock absorber assembly operates

smoothly.

Unsmooth operation Correct or replace.

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 5-58.

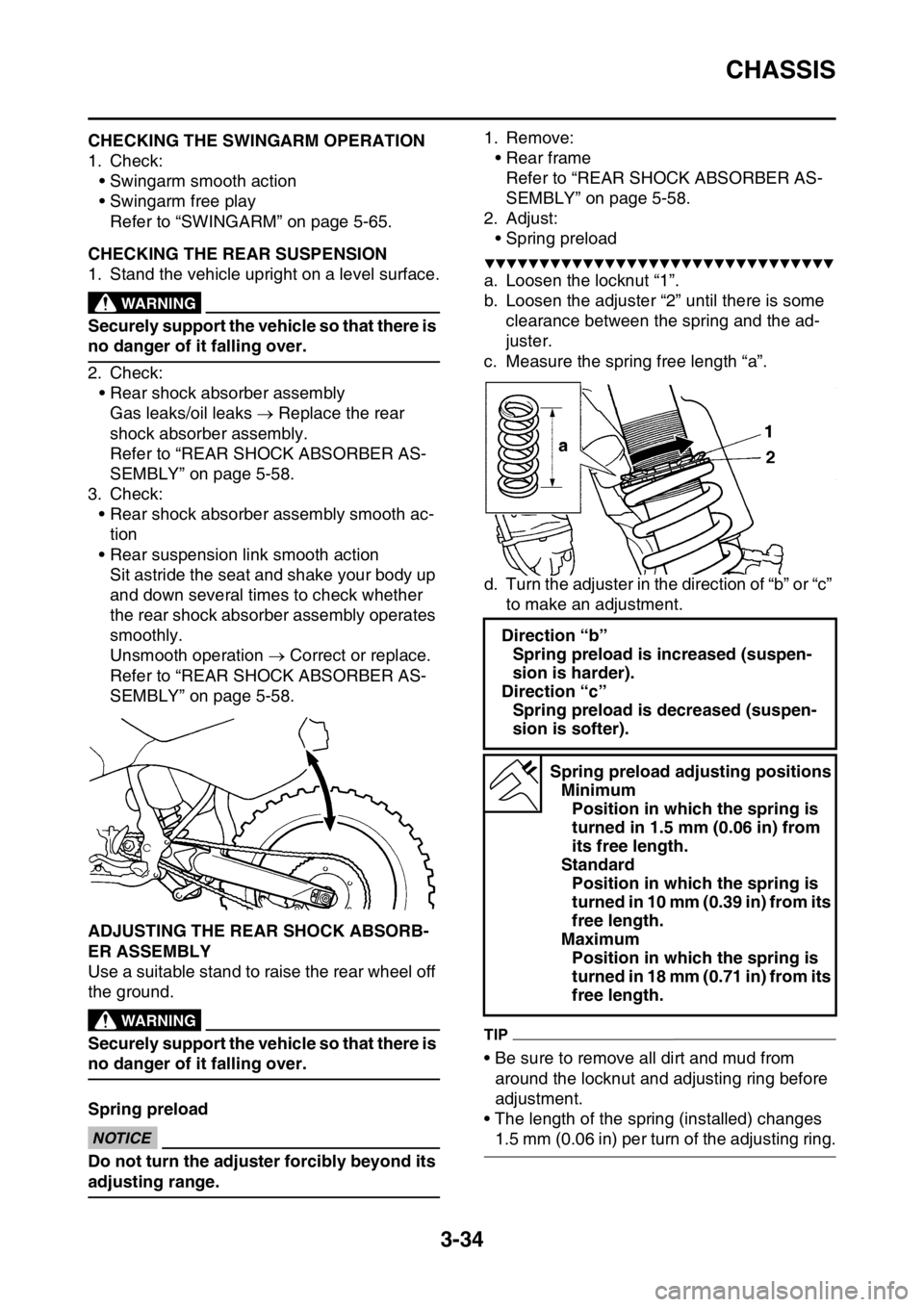

EAS2GBB118ADJUSTING THE REAR SHOCK ABSORB-

ER ASSEMBLY

Use a suitable stand to raise the rear wheel off

the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

Spring preload

ECA

NOTICE

Do not turn the adjuster forcibly beyond its

adjusting range.1. Remove:

• Rear frame

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 5-58.

2. Adjust:

• Spring preload

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

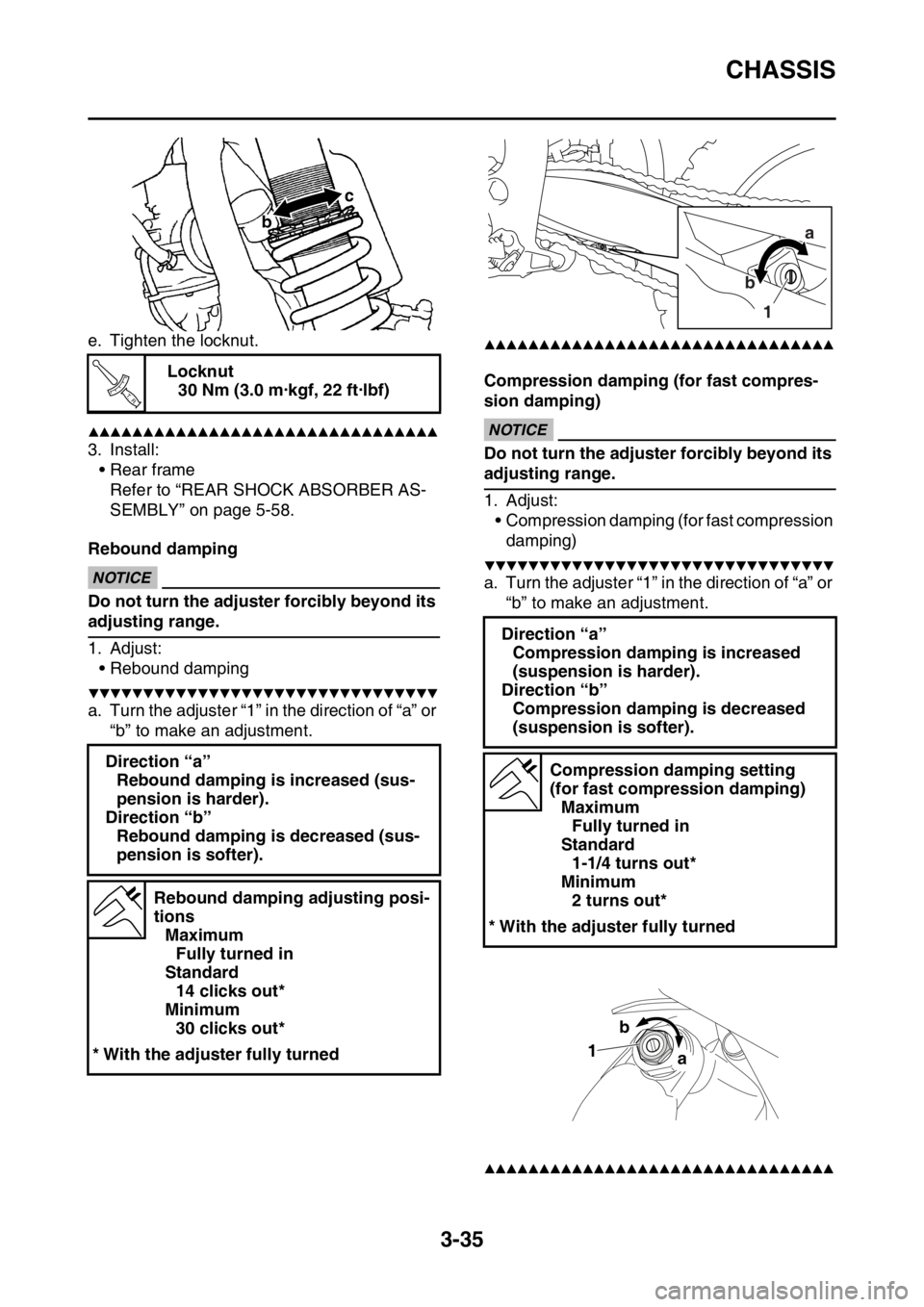

a. Loosen the locknut “1”.

b. Loosen the adjuster “2” until there is some

clearance between the spring and the ad-

juster.

c. Measure the spring free length “a”.

d. Turn the adjuster in the direction of “b” or “c”

to make an adjustment.

TIP

• Be sure to remove all dirt and mud from

around the locknut and adjusting ring before

adjustment.

• The length of the spring (installed) changes

1.5 mm (0.06 in) per turn of the adjusting ring.

Direction “b”

Spring preload is increased (suspen-

sion is harder).

Direction “c”

Spring preload is decreased (suspen-

sion is softer).

Spring preload adjusting positions

Minimum

Position in which the spring is

turned in 1.5 mm (0.06 in) from

its free length.

Standard

Position in which the spring is

turned in 10 mm (0.39 in) from its

free length.

Maximum

Position in which the spring is

turned in 18 mm (0.71 in) from its

free length.

Page 135 of 432

CHASSIS

3-35

e. Tighten the locknut.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Install:

• Rear frame

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 5-58.

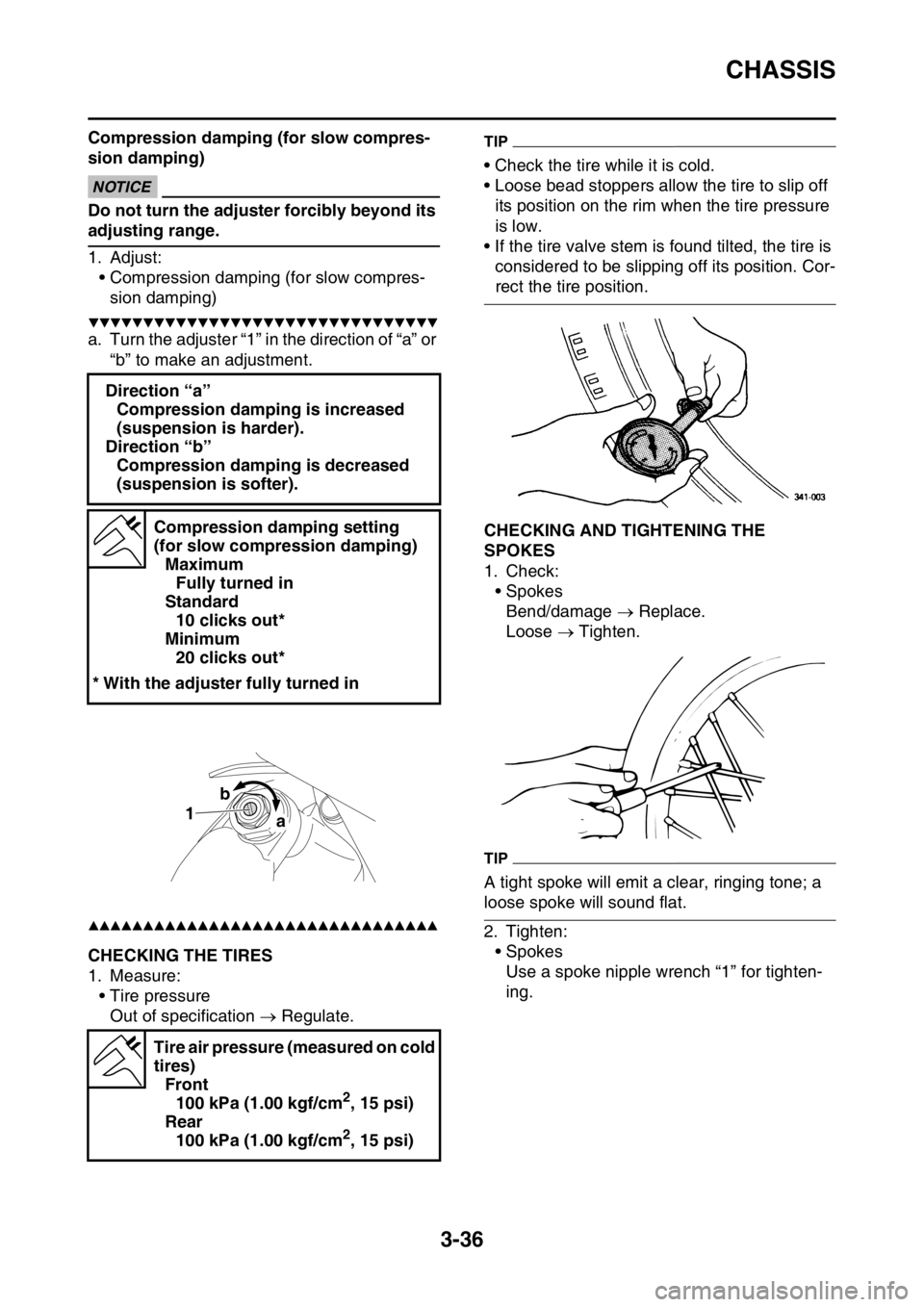

Rebound damping

ECA

NOTICE

Do not turn the adjuster forcibly beyond its

adjusting range.

1. Adjust:

• Rebound damping

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the adjuster “1” in the direction of “a” or

“b” to make an adjustment.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Compression damping (for fast compres-

sion damping)

ECA

NOTICE

Do not turn the adjuster forcibly beyond its

adjusting range.

1. Adjust:

• Compression damping (for fast compression

damping)

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the adjuster “1” in the direction of “a” or

“b” to make an adjustment.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Locknut

30 Nm (3.0 m·kgf, 22 ft·lbf)

Direction “a”

Rebound damping is increased (sus-

pension is harder).

Direction “b”

Rebound damping is decreased (sus-

pension is softer).

Rebound damping adjusting posi-

tions

Maximum

Fully turned in

Standard

14 clicks out*

Minimum

30 clicks out*

* With the adjuster fully turned

c

b

T R..

Direction “a”

Compression damping is increased

(suspension is harder).

Direction “b”

Compression damping is decreased

(suspension is softer).

Compression damping setting

(for fast compression damping)

Maximum

Fully turned in

Standard

1-1/4 turns out*

Minimum

2 turns out*

* With the adjuster fully turned

a

b

1

1

a b

Page 136 of 432

CHASSIS

3-36

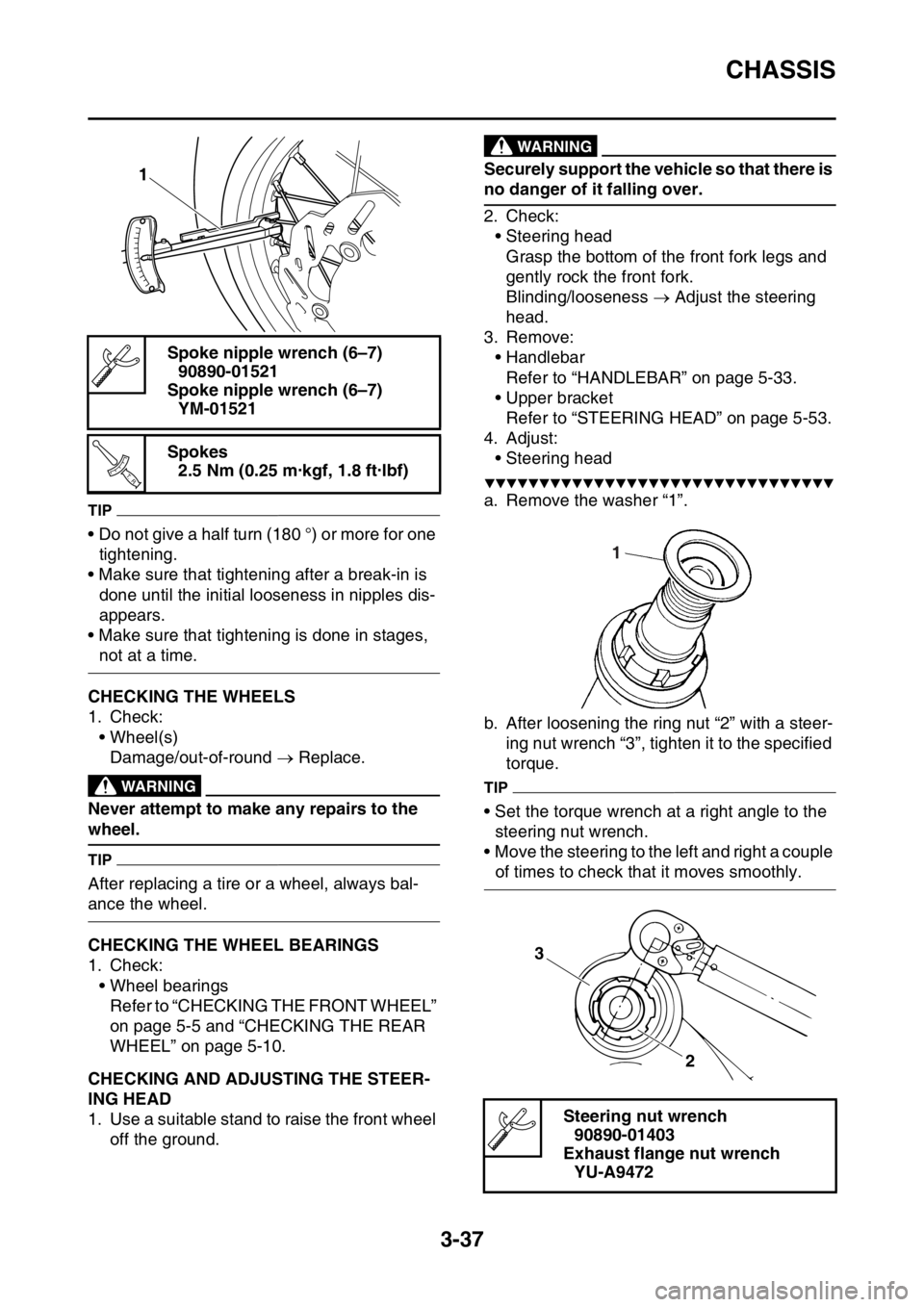

Compression damping (for slow compres-

sion damping)

ECA

NOTICE

Do not turn the adjuster forcibly beyond its

adjusting range.

1. Adjust:

• Compression damping (for slow compres-

sion damping)

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the adjuster “1” in the direction of “a” or

“b” to make an adjustment.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GBB119CHECKING THE TIRES

1. Measure:

• Tire pressure

Out of specification Regulate.

TIP

• Check the tire while it is cold.

• Loose bead stoppers allow the tire to slip off

its position on the rim when the tire pressure

is low.

• If the tire valve stem is found tilted, the tire is

considered to be slipping off its position. Cor-

rect the tire position.

EAS2GBB120CHECKING AND TIGHTENING THE

SPOKES

1. Check:

• Spokes

Bend/damage Replace.

Loose Tighten.

TIP

A tight spoke will emit a clear, ringing tone; a

loose spoke will sound flat.

2. Tighten:

• Spokes

Use a spoke nipple wrench “1” for tighten-

ing. Direction “a”

Compression damping is increased

(suspension is harder).

Direction “b”

Compression damping is decreased

(suspension is softer).

Compression damping setting

(for slow compression damping)

Maximum

Fully turned in

Standard

10 clicks out*

Minimum

20 clicks out*

* With the adjuster fully turned in

Tire air pressure (measured on cold

tires)

Front

100 kPa (1.00 kgf/cm

2, 15 psi)

Rear

100 kPa (1.00 kgf/cm

2, 15 psi)

1ba

Page 137 of 432

CHASSIS

3-37

TIP

• Do not give a half turn (180 °) or more for one

tightening.

• Make sure that tightening after a break-in is

done until the initial looseness in nipples dis-

appears.

• Make sure that tightening is done in stages,

not at a time.

EAS2GBB121CHECKING THE WHEELS

1. Check:

• Wheel(s)

Damage/out-of-round Replace.

EWA

WARNING

Never attempt to make any repairs to the

wheel.

TIP

After replacing a tire or a wheel, always bal-

ance the wheel.

EAS2GBB122CHECKING THE WHEEL BEARINGS

1. Check:

• Wheel bearings

Refer to “CHECKING THE FRONT WHEEL”

on page 5-5 and “CHECKING THE REAR

WHEEL” on page 5-10.

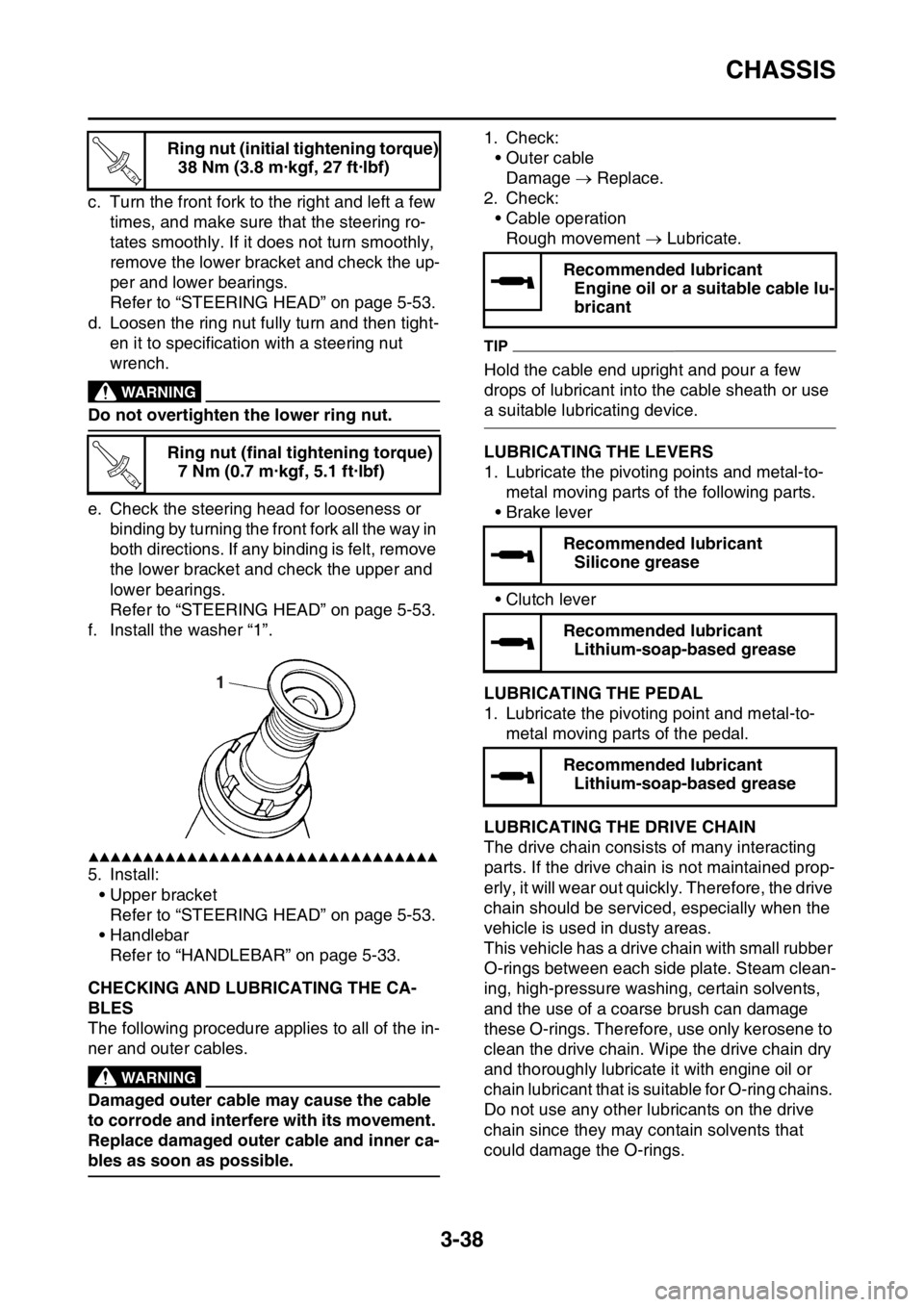

EAS2GBB123CHECKING AND ADJUSTING THE STEER-

ING HEAD

1. Use a suitable stand to raise the front wheel

off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Check:

• Steering head

Grasp the bottom of the front fork legs and

gently rock the front fork.

Blinding/looseness Adjust the steering

head.

3. Remove:

• Handlebar

Refer to “HANDLEBAR” on page 5-33.

• Upper bracket

Refer to “STEERING HEAD” on page 5-53.

4. Adjust:

• Steering head

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the washer “1”.

b. After loosening the ring nut “2” with a steer-

ing nut wrench “3”, tighten it to the specified

torque.

TIP

• Set the torque wrench at a right angle to the

steering nut wrench.

• Move the steering to the left and right a couple

of times to check that it moves smoothly. Spoke nipple wrench (6–7)

90890-01521

Spoke nipple wrench (6–7)

YM-01521

Spokes

2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

1

T R..

Steering nut wrench

90890-01403

Exhaust flange nut wrench

YU-A9472

1

3

2

Page 138 of 432

CHASSIS

3-38

c. Turn the front fork to the right and left a few

times, and make sure that the steering ro-

tates smoothly. If it does not turn smoothly,

remove the lower bracket and check the up-

per and lower bearings.

Refer to “STEERING HEAD” on page 5-53.

d. Loosen the ring nut fully turn and then tight-

en it to specification with a steering nut

wrench.

EWA

WARNING

Do not overtighten the lower ring nut.

e. Check the steering head for looseness or

binding by turning the front fork all the way in

both directions. If any binding is felt, remove

the lower bracket and check the upper and

lower bearings.

Refer to “STEERING HEAD” on page 5-53.

f. Install the washer “1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. Install:

• Upper bracket

Refer to “STEERING HEAD” on page 5-53.

• Handlebar

Refer to “HANDLEBAR” on page 5-33.

EAS2GBB124CHECKING AND LUBRICATING THE CA-

BLES

The following procedure applies to all of the in-

ner and outer cables.

EWA

WARNING

Damaged outer cable may cause the cable

to corrode and interfere with its movement.

Replace damaged outer cable and inner ca-

bles as soon as possible.1. Check:

• Outer cable

Damage Replace.

2. Check:

• Cable operation

Rough movement Lubricate.

TIP

Hold the cable end upright and pour a few

drops of lubricant into the cable sheath or use

a suitable lubricating device.

EAS2GBB125LUBRICATING THE LEVERS

1. Lubricate the pivoting points and metal-to-

metal moving parts of the following parts.

•Brake lever

• Clutch lever

EAS2GBB126LUBRICATING THE PEDAL

1. Lubricate the pivoting point and metal-to-

metal moving parts of the pedal.

EAS2GBB127LUBRICATING THE DRIVE CHAIN

The drive chain consists of many interacting

parts. If the drive chain is not maintained prop-

erly, it will wear out quickly. Therefore, the drive

chain should be serviced, especially when the

vehicle is used in dusty areas.

This vehicle has a drive chain with small rubber

O-rings between each side plate. Steam clean-

ing, high-pressure washing, certain solvents,

and the use of a coarse brush can damage

these O-rings. Therefore, use only kerosene to

clean the drive chain. Wipe the drive chain dry

and thoroughly lubricate it with engine oil or

chain lubricant that is suitable for O-ring chains.

Do not use any other lubricants on the drive

chain since they may contain solvents that

could damage the O-rings. Ring nut (initial tightening torque)

38 Nm (3.8 m·kgf, 27 ft·lbf)

Ring nut (final tightening torque)

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

T R..

T R..

1

Recommended lubricant

Engine oil or a suitable cable lu-

bricant

Recommended lubricant

Silicone grease

Recommended lubricant

Lithium-soap-based grease

Recommended lubricant

Lithium-soap-based grease

Page 139 of 432

CHASSIS

3-39

EAS2GBB128LUBRICATING THE SIDESTAND

Lubricate the pivoting point and metal-to-metal

moving parts of the sidestand.

EAS2GBB129CHECKING THE CHASSIS FASTENERS

Make sure that all nuts, bolts, and screws are

properly tightened.

Refer to “CHASSIS TIGHTENING TORQUES”

on page 2-16.Recommended lubricant

Chain lubricant suitable for O-

ring chains

Recommended lubricant

Lithium-soap-based grease

Page 140 of 432

ELECTRICAL SYSTEM

3-40

EAS2GBB130

ELECTRICAL SYSTEM

EAS2GBB131CHECKING THE SPARK PLUG

1. Remove:

• Seat

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 5-

1.

• Fuel tank “1”

Refer to “FUEL TANK” on page 8-1.

ECA

NOTICE

Do not use too much force to pull the hose.

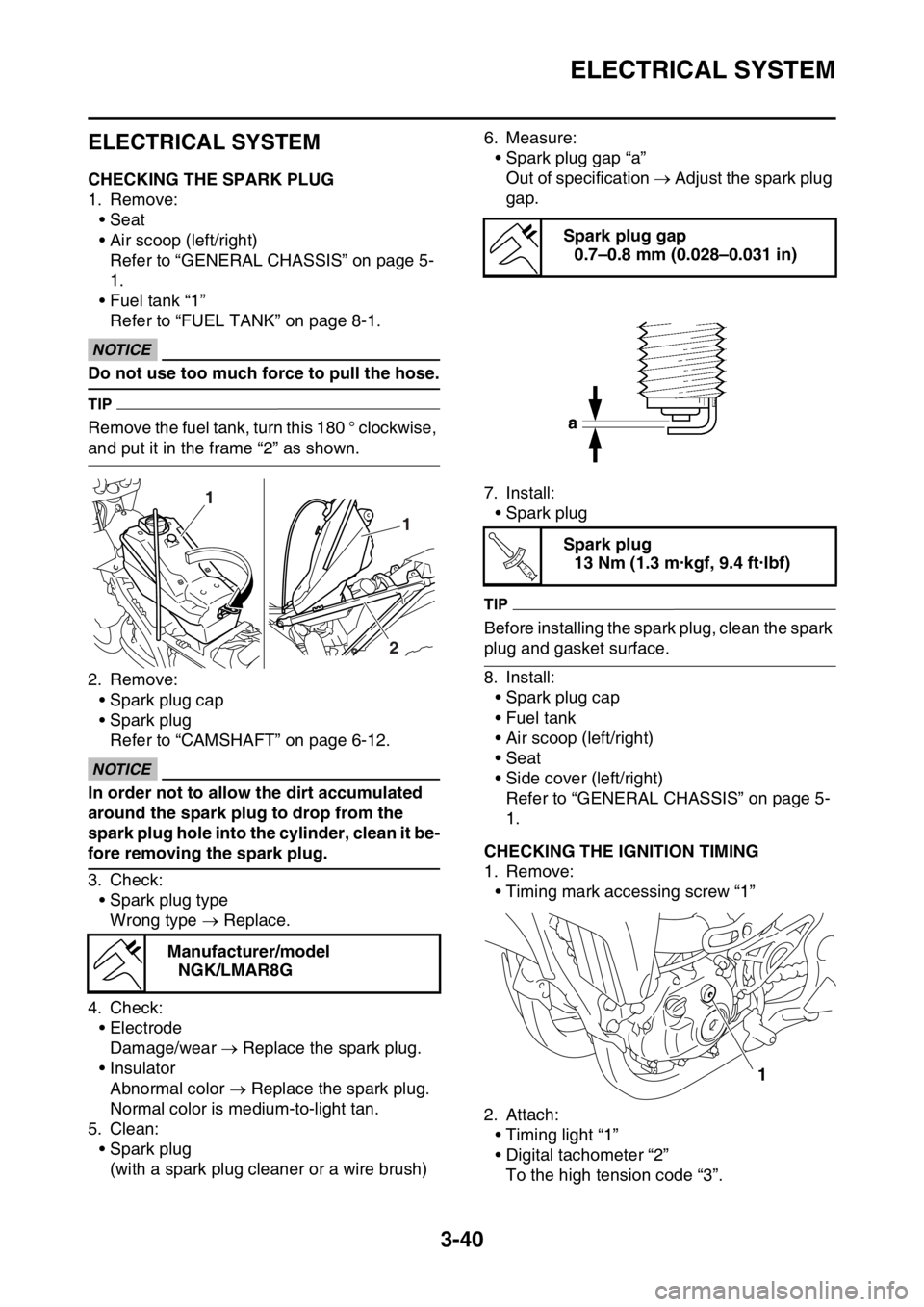

TIP

Remove the fuel tank, turn this 180 ° clockwise,

and put it in the frame “2” as shown.

2. Remove:

• Spark plug cap

• Spark plug

Refer to “CAMSHAFT” on page 6-12.

ECA

NOTICE

In order not to allow the dirt accumulated

around the spark plug to drop from the

spark plug hole into the cylinder, clean it be-

fore removing the spark plug.

3. Check:

• Spark plug type

Wrong type Replace.

4. Check:

• Electrode

Damage/wear Replace the spark plug.

• Insulator

Abnormal color Replace the spark plug.

Normal color is medium-to-light tan.

5. Clean:

• Spark plug

(with a spark plug cleaner or a wire brush)6. Measure:

• Spark plug gap “a”

Out of specification Adjust the spark plug

gap.

7. Install:

• Spark plug

TIP

Before installing the spark plug, clean the spark

plug and gasket surface.

8. Install:

• Spark plug cap

• Fuel tank

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 5-

1.

EAS2GBB132CHECKING THE IGNITION TIMING

1. Remove:

• Timing mark accessing screw “1”

2. Attach:

• Timing light “1”

• Digital tachometer “2”

To the high tension code “3”. Manufacturer/model

NGK/LMAR8G

1

1

2

Spark plug gap

0.7–0.8 mm (0.028–0.031 in)

Spark plug

13 Nm (1.3 m·kgf, 9.4 ft·lbf)

T R..

1