fork YAMAHA WR 450F 2006 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: WR 450F, Model: YAMAHA WR 450F 2006Pages: 786, PDF Size: 22.49 MB

Page 22 of 786

CHAPTER 4

ENGINE

SEAT, FUEL TANK

AND SIDE COVERS ..................................4-1

EXHAUST PIPE

AND SILENCER ........................................4-3

RADIATOR ................................................4-5

CARBURETOR ..........................................4-8

AIR INDUCTION SYSTEM ......................4-21

CAMSHAFTS ...........................................4-23

CYLINDER HEAD ....................................4-32

VALVES AND VALVE SPRINGS ............4-36

CYLINDER AND PISTON ........................4-45

CLUTCH ...................................................4-51

OIL FILTER, WATER PUMP

AND CRANKCASE COVER (RIGHT) .....4-58

BALANCER .............................................4-65

OIL PUMP ................................................4-68

KICK AXLE AND SHIFT SHAFT .............4-72

AC MAGNETO

AND STARTER CLUTCH ........................4-79

ENGINE REMOVAL .................................4-86

CRANKCASE AND CRANKSHAFT ........4-92

TRANSMISSION, SHIFT CAM

AND SHIFT FORK .................................4-101

CHAPTER 5

CHASSIS

FRONT WHEEL AND REAR WHEEL .......5-1

FRONT BRAKE AND REAR BRAKE .....5-10

FRONT FORK ..........................................5-26

HANDLEBAR ...........................................5-39

STEERING ...............................................5-46

SWINGARM .............................................5-53

REAR SHOCK ABSORBER ....................5-61

Page 26 of 786

GEN

INFO

1 - 1

DESCRIPTION

EC100000

GENERAL INFORMATION

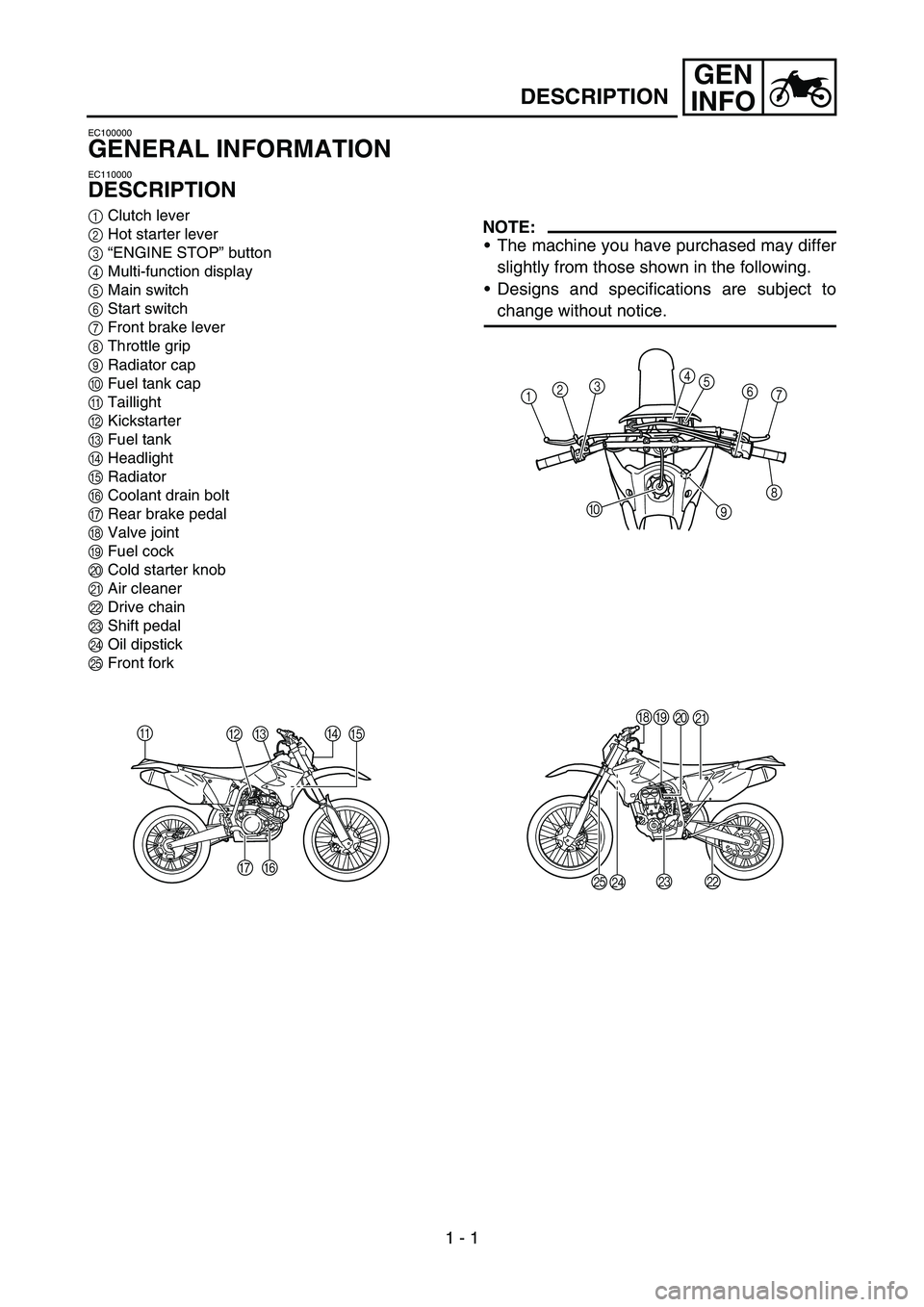

EC110000

DESCRIPTION

1Clutch lever

2Hot starter lever

3“ENGINE STOP” button

4Multi-function display

5Main switch

6Start switch

7Front brake lever

8Throttle grip

9Radiator cap

0Fuel tank cap

ATaillight

BKickstarter

CFuel tank

DHeadlight

ERadiator

FCoolant drain bolt

GRear brake pedal

HValve joint

IFuel cock

JCold starter knob

KAir cleaner

LDrive chain

MShift pedal

NOil dipstick

OFront forkNOTE:

The machine you have purchased may differ

slightly from those shown in the following.

Designs and specifications are subject to

change without notice.

A

BCD

E

F G

1234

5

6

7

8

9 0

HI

J

K

L M

N O

Page 39 of 786

GEN

INFO

1 - 8

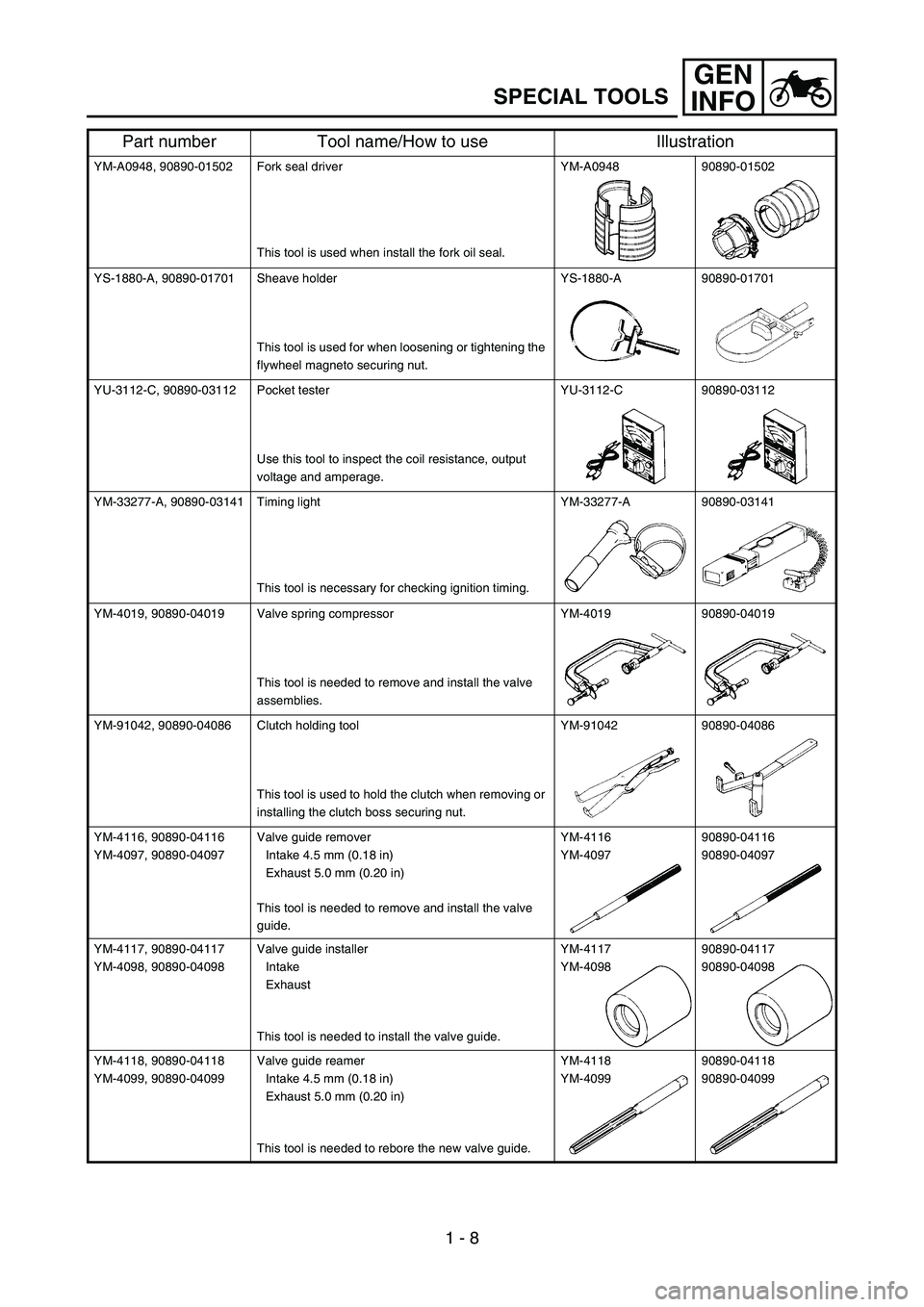

SPECIAL TOOLS

YM-A0948, 90890-01502 Fork seal driver

This tool is used when install the fork oil seal.YM-A0948 90890-01502

YS-1880-A, 90890-01701 Sheave holder

This tool is used for when loosening or tightening the

flywheel magneto securing nut.YS-1880-A 90890-01701

YU-3112-C, 90890-03112 Pocket tester

Use this tool to inspect the coil resistance, output

voltage and amperage.YU-3112-C 90890-03112

YM-33277-A, 90890-03141 Timing light

This tool is necessary for checking ignition timing.YM-33277-A 90890-03141

YM-4019, 90890-04019 Valve spring compressor

This tool is needed to remove and install the valve

assemblies.YM-4019 90890-04019

YM-91042, 90890-04086 Clutch holding tool

This tool is used to hold the clutch when removing or

installing the clutch boss securing nut.YM-91042 90890-04086

YM-4116, 90890-04116

YM-4097, 90890-04097Valve guide remover

Intake 4.5 mm (0.18 in)

Exhaust 5.0 mm (0.20 in)

This tool is needed to remove and install the valve

guide.YM-4116

YM-409790890-04116

90890-04097

YM-4117, 90890-04117

YM-4098, 90890-04098Valve guide installer

Intake

Exhaust

This tool is needed to install the valve guide.YM-4117

YM-409890890-04117

90890-04098

YM-4118, 90890-04118

YM-4099, 90890-04099Valve guide reamer

Intake 4.5 mm (0.18 in)

Exhaust 5.0 mm (0.20 in)

This tool is needed to rebore the new valve guide.YM-4118

YM-4099 90890-04118

90890-04099

Part number Tool name/How to use Illustration

Page 82 of 786

GEN

INFO

1 - 26

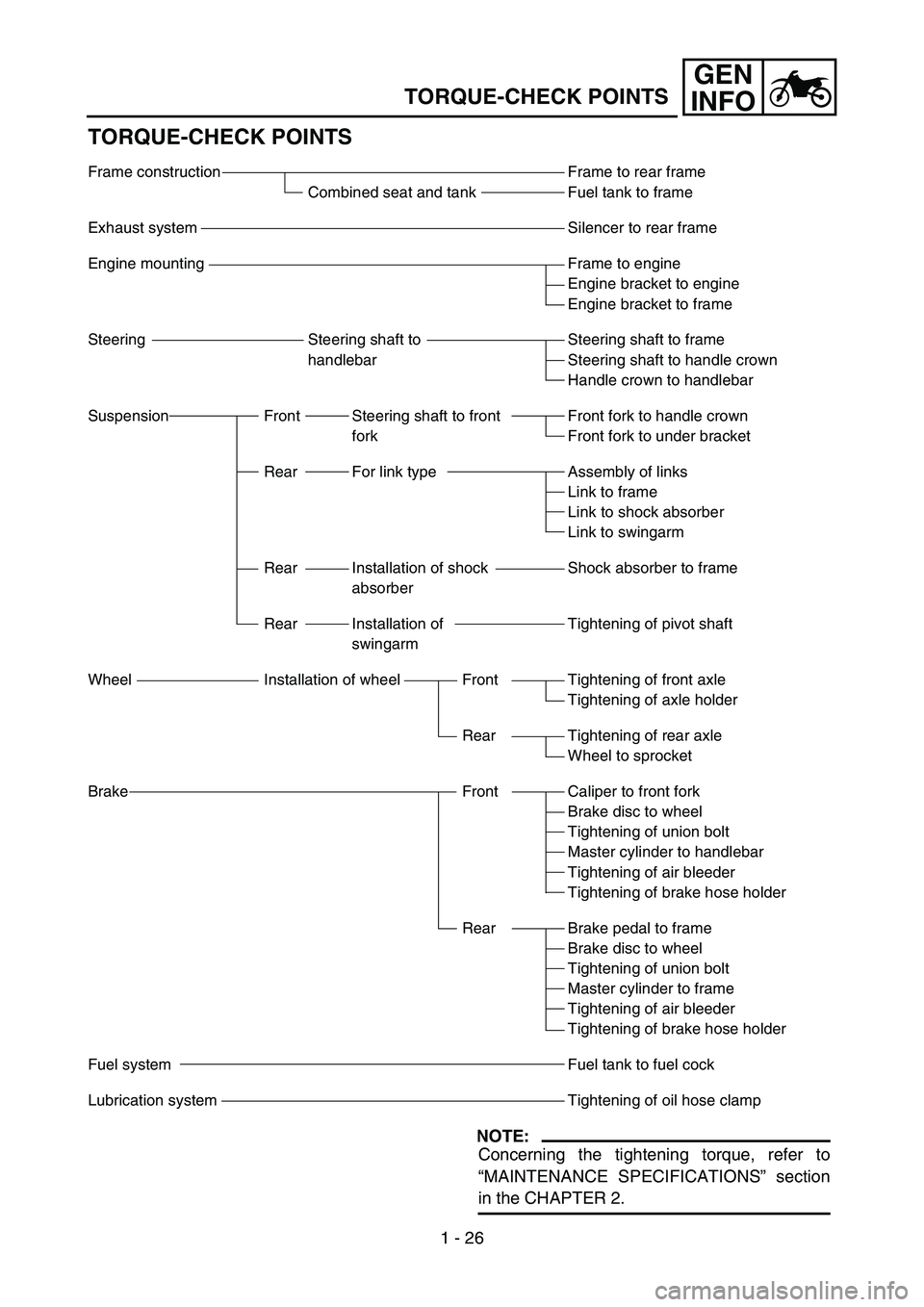

TORQUE-CHECK POINTS

TORQUE-CHECK POINTS

NOTE:

Concerning the tightening torque, refer to

“MAINTENANCE SPECIFICATIONS” section

in the CHAPTER 2.

Frame to rear frame

Fuel tank to frame

Silencer to rear frame

Frame to engine

Engine bracket to engine

Engine bracket to frame

Steering shaft to frame

Steering shaft to handle crown

Handle crown to handlebar

Front fork to handle crown

Front fork to under bracket

Assembly of links

Link to frame

Link to shock absorber

Link to swingarm

Shock absorber to frame

Tightening of pivot shaft

Tightening of front axle

Tightening of axle holder

Tightening of rear axle

Wheel to sprocket

Caliper to front fork

Brake disc to wheel

Tightening of union bolt

Master cylinder to handlebar

Tightening of air bleeder

Tightening of brake hose holder

Brake pedal to frame

Brake disc to wheel

Tightening of union bolt

Master cylinder to frame

Tightening of air bleeder

Tightening of brake hose holder

Fuel tank to fuel cock

Tightening of oil hose clamp Frame construction

Combined seat and tank

Exhaust system

Engine mounting

Steering Steering shaft to

handlebar

Suspension Front Steering shaft to front

fork

Rear For link type

Rear Installation of shock

absorber

Rear Installation of

swingarm

Wheel Installation of wheel Front

Rear

Brake Front

Rear

Fuel system

Lubrication system

Page 86 of 786

1 - 27

GEN

INFO

CLEANING AND STORAGE

EC1B0000

CLEANING AND STORAGE

EC1B1000

CLEANING

Frequent cleaning of your machine will

enhance its appearance, maintain good overall

performance, and extend the life of many com-

ponents.

1. Before washing the machine, block off the

end of the exhaust pipe to prevent water

from entering. A plastic bag secured with a

rubber band may be used for this purpose.

2. If the engine is excessively greasy, apply

some degreaser to it with a paint brush. Do

not apply degreaser to the chain, sprock-

ets, or wheel axles.

3. Rinse the dirt and degreaser off with a gar-

den hose; use only enough pressure to do

the job.

CAUTION:

Excessive hose pressure may cause water

seepage and contamination of wheel bear-

ings, front forks, brakes and transmission

seals. Many expensive repair bills have

resulted from improper high pressure

detergent applications such as those avail-

able in coin-operated car washers.

4. After the majority of the dirt has been

hosed off, wash all surfaces with warm

water and a mild detergent. Use an old

toothbrush to clean hard-to-reach places.

5. Rinse the machine off immediately with

clean water, and dry all surfaces with a soft

towel or cloth.

6. Immediately after washing, remove excess

water from the chain with a paper towel

and lubricate the chain to prevent rust.

7. Clean the seat with a vinyl upholstery

cleaner to keep the cover pliable and

glossy.

Page 92 of 786

SPEC

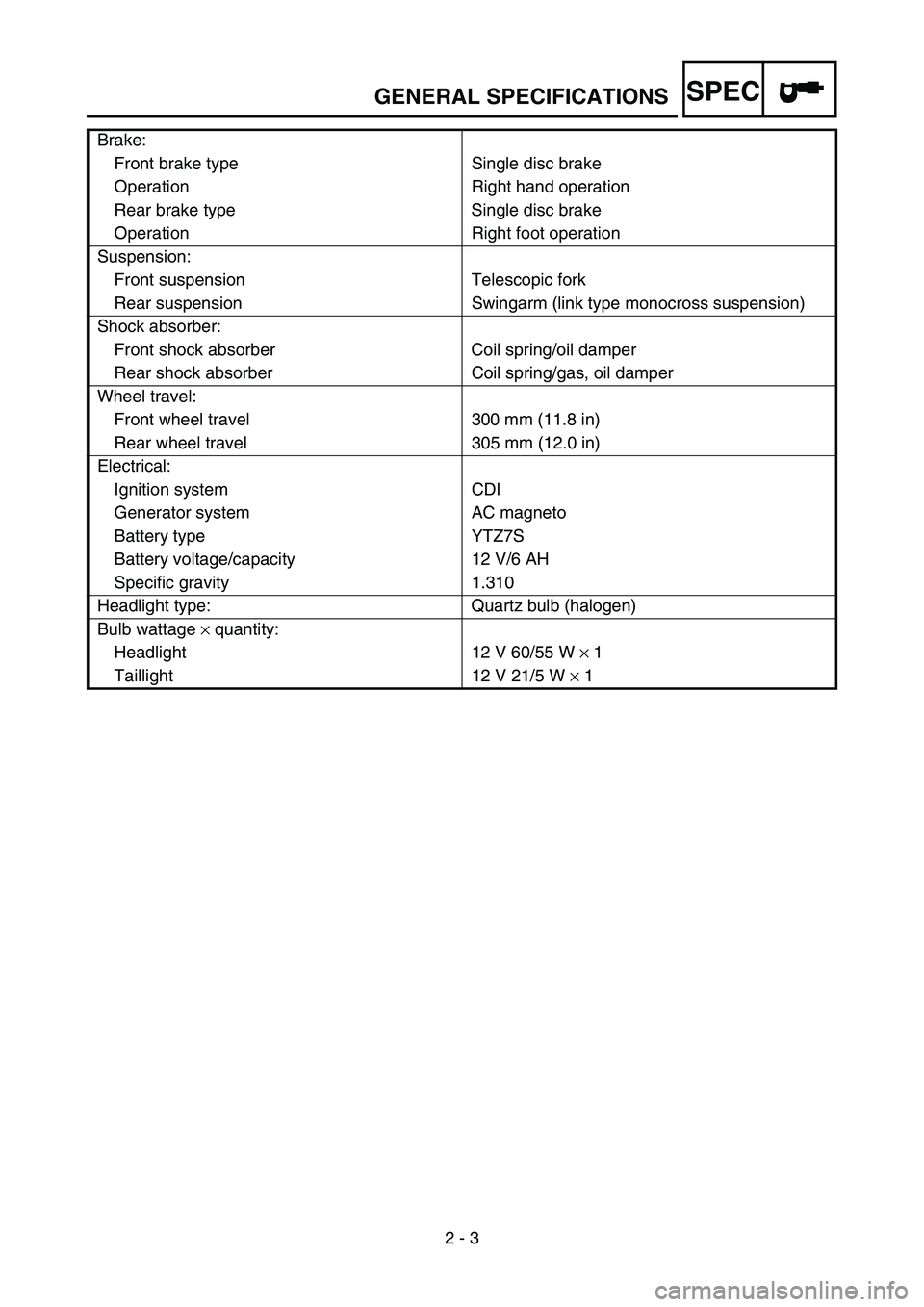

2 - 3 Brake:

Front brake type Single disc brake

Operation Right hand operation

Rear brake type Single disc brake

Operation Right foot operation

Suspension:

Front suspension Telescopic fork

Rear suspension Swingarm (link type monocross suspension)

Shock absorber:

Front shock absorber Coil spring/oil damper

Rear shock absorber Coil spring/gas, oil damper

Wheel travel:

Front wheel travel 300 mm (11.8 in)

Rear wheel travel 305 mm (12.0 in)

Electrical:

Ignition system CDI

Generator system AC magneto

Battery type YTZ7S

Battery voltage/capacity 12 V/6 AH

Specific gravity 1.310

Headlight type: Quartz bulb (halogen)

Bulb wattage × quantity:

Headlight 12 V 60/55 W × 1

Taillight 12 V 21/5 W × 1

GENERAL SPECIFICATIONS

Page 102 of 786

SPEC

2 - 13

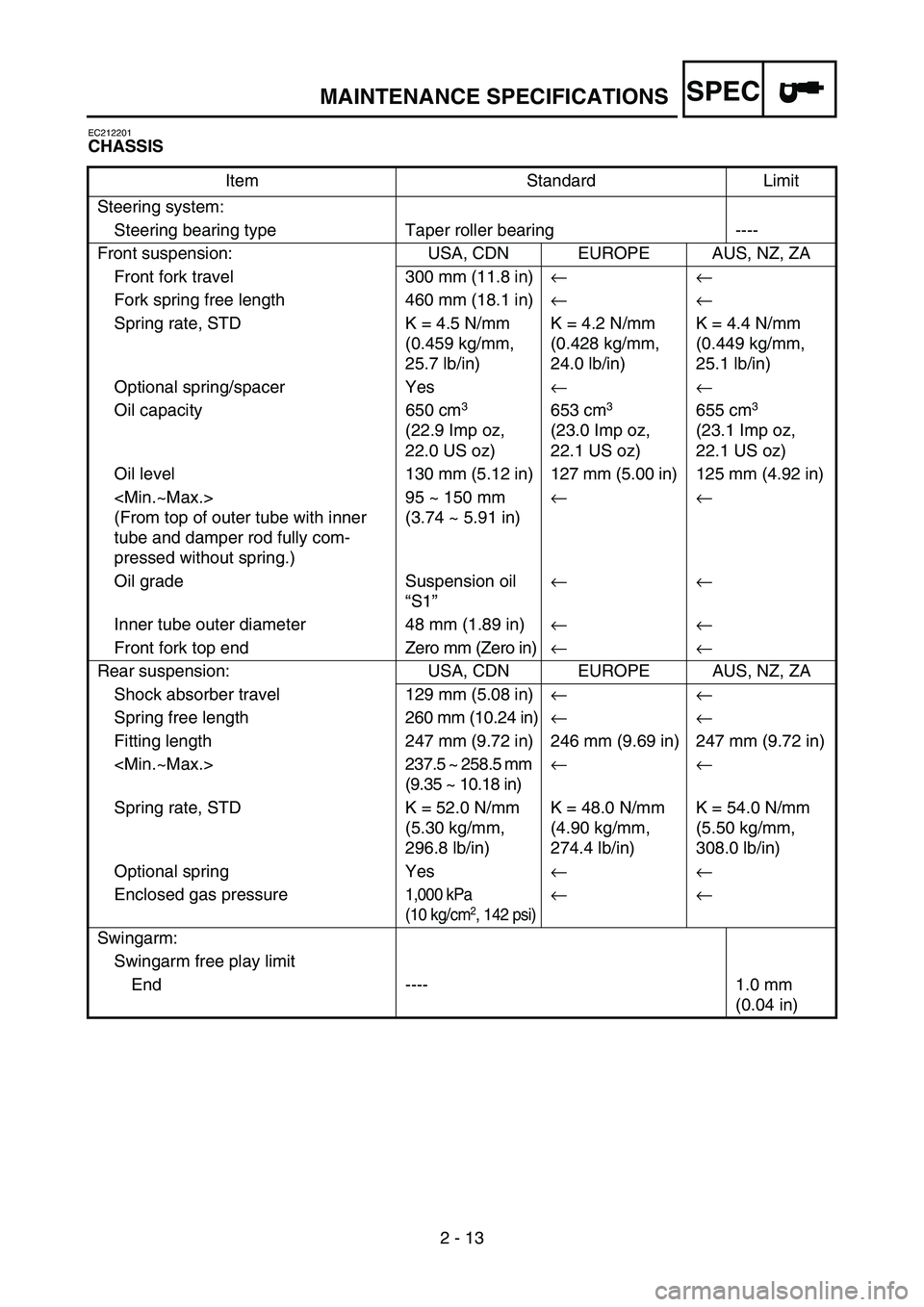

EC212201

CHASSIS

Item Standard Limit

Steering system:

Steering bearing type Taper roller bearing ----

Front suspension: USA, CDN EUROPE AUS, NZ, ZA

Front fork travel 300 mm (11.8 in)← ←

Fork spring free length 460 mm (18.1 in)← ←

Spring rate, STD K = 4.5 N/mm

(0.459 kg/mm,

25.7 lb/in)K = 4.2 N/mm

(0.428 kg/mm,

24.0 lb/in)K = 4.4 N/mm

(0.449 kg/mm,

25.1 lb/in)

Optional spring/spacer Yes← ←

Oil capacity 650 cm

3

(22.9 Imp oz,

22.0 US oz) 653 cm3

(23.0 Imp oz,

22.1 US oz) 655 cm3

(23.1 Imp oz,

22.1 US oz)

Oil level 130 mm (5.12 in) 127 mm (5.00 in) 125 mm (4.92 in)

(From top of outer tube with inner

tube and damper rod fully com-

pressed without spring.)95 ~ 150 mm

(3.74 ~ 5.91 in)← ←

Oil grade Suspension oil

“S1”← ←

Inner tube outer diameter 48 mm (1.89 in)← ←

Front fork top end Zero mm (Zero in)← ←

Rear suspension: USA, CDN EUROPE AUS, NZ, ZA

Shock absorber travel 129 mm (5.08 in)← ←

Spring free length260 mm (10.24 in)← ←

Fitting length 247 mm (9.72 in) 246 mm (9.69 in) 247 mm (9.72 in)

(9.35 ~ 10.18 in)← ←

Spring rate, STD K = 52.0 N/mm

(5.30 kg/mm,

296.8 lb/in)K = 48.0 N/mm

(4.90 kg/mm,

274.4 lb/in)K = 54.0 N/mm

(5.50 kg/mm,

308.0 lb/in)

Optional spring Yes← ←

Enclosed gas pressure

1,000 kPa

(10 kg/cm2, 142 psi)

← ←

Swingarm:

Swingarm free play limit

End ---- 1.0 mm

(0.04 in)

MAINTENANCE SPECIFICATIONS

Page 104 of 786

SPEC

2 - 15

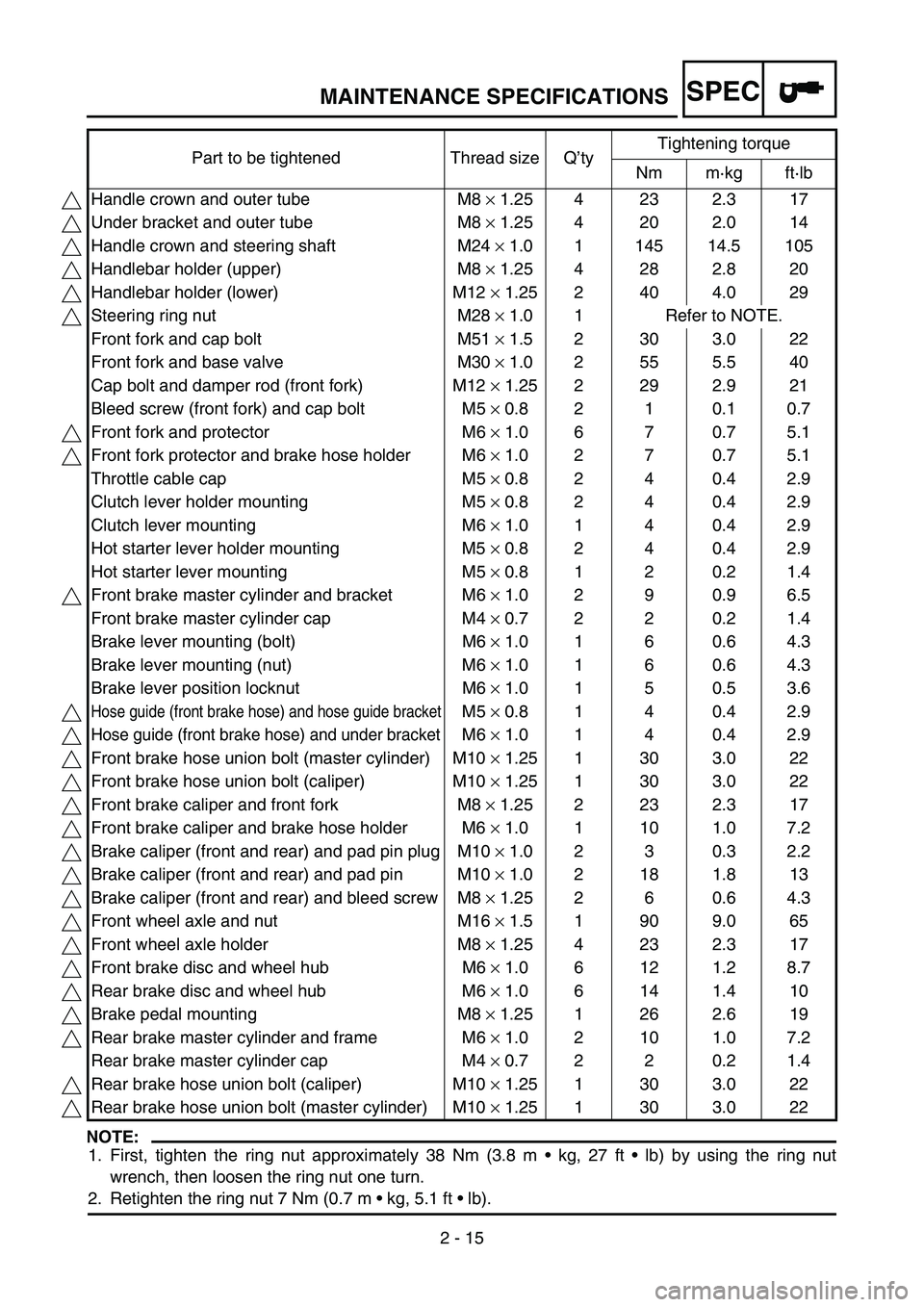

NOTE:

1. First, tighten the ring nut approximately 38 Nm (3.8 m kg, 27 ft lb) by using the ring nut

wrench, then loosen the ring nut one turn.

2. Retighten the ring nut 7 Nm (0.7 m kg, 5.1 ft lb). Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Handle crown and outer tube M8 × 1.25 4 23 2.3 17

Under bracket and outer tube M8 × 1.25 4 20 2.0 14

Handle crown and steering shaft M24 × 1.0 1 145 14.5 105

Handlebar holder (upper) M8 × 1.25 4 28 2.8 20

Handlebar holder (lower) M12 × 1.25 2 40 4.0 29

Steering ring nut M28 × 1.0 1 Refer to NOTE.

Front fork and cap bolt M51 × 1.5 2 30 3.0 22

Front fork and base valve M30 × 1.0 2 55 5.5 40

Cap bolt and damper rod (front fork) M12 × 1.25 2 29 2.9 21

Bleed screw (front fork) and cap bolt M5 × 0.8 2 1 0.1 0.7

Front fork and protector M6 × 1.0 6 7 0.7 5.1

Front fork protector and brake hose holder M6 × 1.0 2 7 0.7 5.1

Throttle cable cap M5 × 0.8 2 4 0.4 2.9

Clutch lever holder mounting M5 × 0.8 2 4 0.4 2.9

Clutch lever mounting M6 × 1.0 1 4 0.4 2.9

Hot starter lever holder mounting M5 × 0.8 2 4 0.4 2.9

Hot starter lever mounting M5 × 0.8 1 2 0.2 1.4

Front brake master cylinder and bracket M6 × 1.0 2 9 0.9 6.5

Front brake master cylinder cap M4 × 0.7 2 2 0.2 1.4

Brake lever mounting (bolt) M6 × 1.0 1 6 0.6 4.3

Brake lever mounting (nut) M6 × 1.0 1 6 0.6 4.3

Brake lever position locknut M6 × 1.0 1 5 0.5 3.6

Hose guide (front brake hose) and hose guide bracketM5 × 0.8 1 4 0.4 2.9

Hose guide (front brake hose) and under bracketM6 × 1.0 1 4 0.4 2.9

Front brake hose union bolt (master cylinder) M10 × 1.25 1 30 3.0 22

Front brake hose union bolt (caliper) M10 × 1.25 1 30 3.0 22

Front brake caliper and front fork M8 × 1.25 2 23 2.3 17

Front brake caliper and brake hose holder M6 × 1.0 1 10 1.0 7.2

Brake caliper (front and rear) and pad pin plug M10 × 1.0 2 3 0.3 2.2

Brake caliper (front and rear) and pad pin M10 × 1.0 2 18 1.8 13

Brake caliper (front and rear) and bleed screw M8 × 1.25 2 6 0.6 4.3

Front wheel axle and nut M16 × 1.5 1 90 9.0 65

Front wheel axle holder M8 × 1.25 4 23 2.3 17

Front brake disc and wheel hub M6 × 1.0 6 12 1.2 8.7

Rear brake disc and wheel hub M6 × 1.0 6 14 1.4 10

Brake pedal mounting M8 × 1.25 1 26 2.6 19

Rear brake master cylinder and frame M6 × 1.0 2 10 1.0 7.2

Rear brake master cylinder cap M4 × 0.7 2 2 0.2 1.4

Rear brake hose union bolt (caliper) M10 × 1.25 1 30 3.0 22

Rear brake hose union bolt (master cylinder) M10 × 1.25 1 30 3.0 22

MAINTENANCE SPECIFICATIONS

Page 186 of 786

2 - 29

SPECCABLE ROUTING DIAGRAM

ÒPass the speed sensor lead

through the guide on the out-

side of the front fork.

ÓPass the start switch lead and

multi-function display lead (on

the wire harness side) above

the multi-function display lead

(on the side of the multi-func-

tion display lead) and speed

sensor lead, and then to the

right of the chassis.

4

5

Î

Ê Ó

A

B

F-FE-E

C

D

A

D

7

7

Ò ËA

12

È32

É

6

Ê

6

8

Ì0

9

ËÑ C

BÏ

2

Ð 8

8

1Í

4

5

4

5B2

C

DC BB A

F F

EE

EE

Ë

2

Page 188 of 786

3 - 1

INSP

ADJ

MAINTENANCE INTERVALS

EC300000

REGULAR INSPECTION AND ADJUSTMENTS

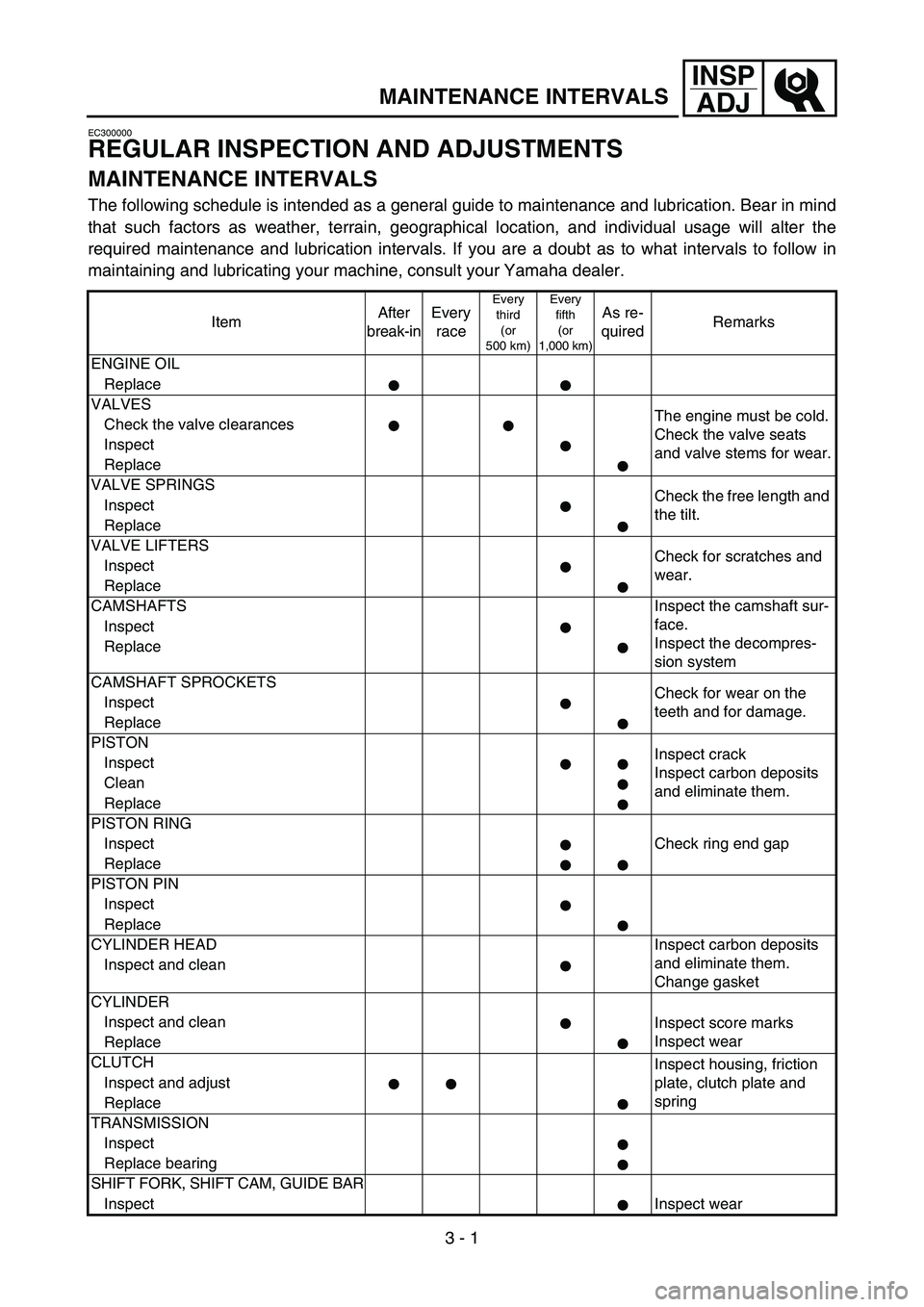

MAINTENANCE INTERVALS

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind

that such factors as weather, terrain, geographical location, and individual usage will alter the

required maintenance and lubrication intervals. If you are a doubt as to what intervals to follow in

maintaining and lubricating your machine, consult your Yamaha dealer.

ItemAfter

break-inEvery

race

Every

third

(or

500 km)Every

fifth

(or

1,000 km)As re-

quiredRemarks

ENGINE OIL

Replace

VALVES

The engine must be cold.

Check the valve seats

and valve stems for wear. Check the valve clearances

Inspect

Replace

VALVE SPRINGS

Check the free length and

the tilt. Inspect

Replace

VALVE LIFTERS

Check for scratches and

wear. Inspect

Replace

CAMSHAFTS Inspect the camshaft sur-

face.

Inspect the decompres-

sion system Inspect

Replace

CAMSHAFT SPROCKETS

Check for wear on the

teeth and for damage. Inspect

Replace

PISTON

Inspect crack

Inspect carbon deposits

and eliminate them. Inspect

Clean

Replace

PISTON RING

Check ring end gap Inspect

Replace

PISTON PIN

Inspect

Replace

CYLINDER HEAD Inspect carbon deposits

and eliminate them.

Change gasket Inspect and clean

CYLINDER

Inspect and clean

Inspect score marks

Inspect wear

Replace

CLUTCH

Inspect housing, friction

plate, clutch plate and

spring Inspect and adjust

Replace

TRANSMISSION

Inspect

Replace bearing

SHIFT FORK, SHIFT CAM, GUIDE BAR

InspectInspect wear