engine YAMAHA WR 450F 2008 Manual PDF

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: WR 450F, Model: YAMAHA WR 450F 2008Pages: 224, PDF Size: 13.7 MB

Page 152 of 224

5-56

ENGINE REMOVAL

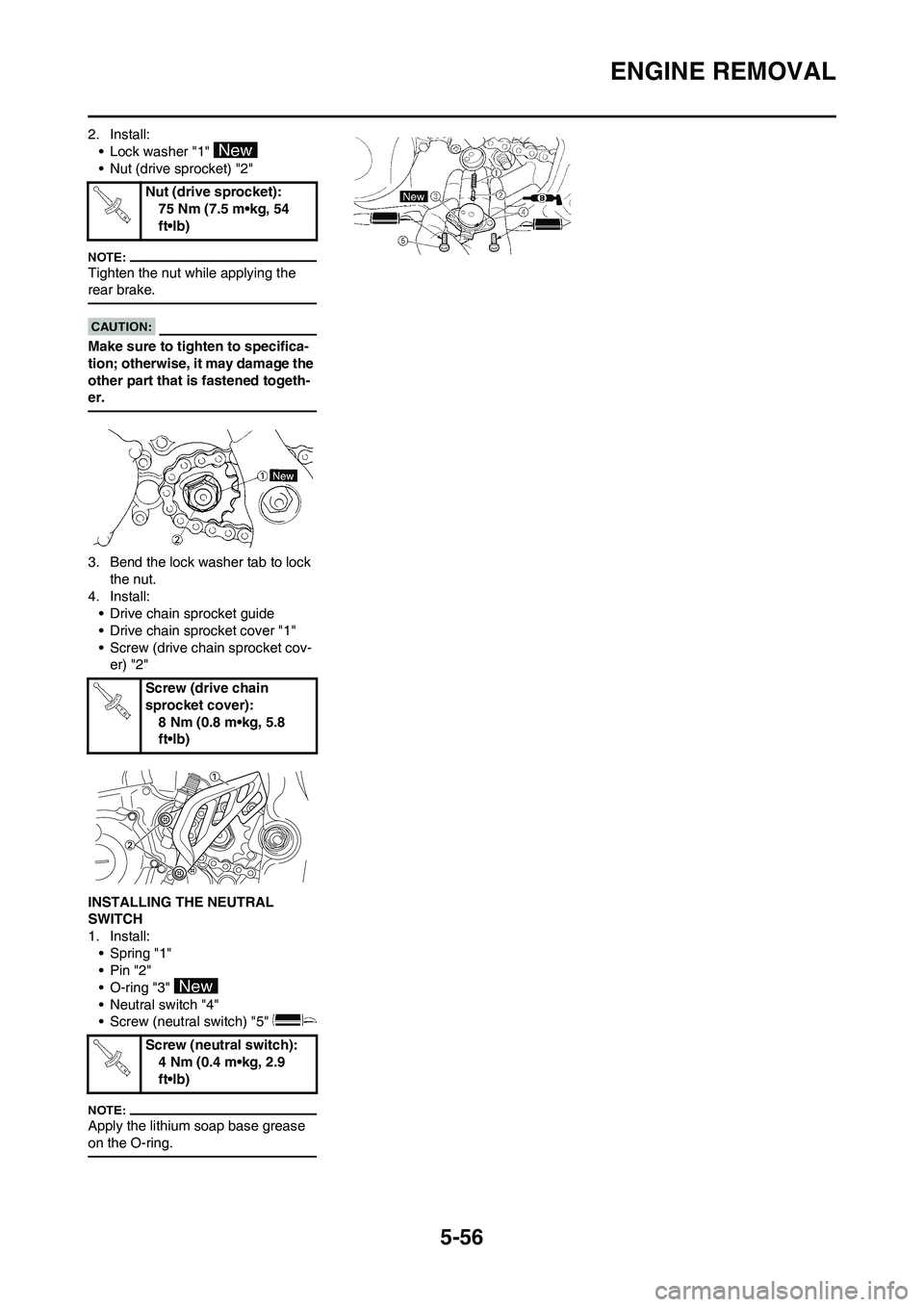

2. Install:

• Lock washer "1"

• Nut (drive sprocket) "2"

Tighten the nut while applying the

rear brake.

Make sure to tighten to specifica-

tion; otherwise, it may damage the

other part that is fastened togeth-

er.

3. Bend the lock washer tab to lock

the nut.

4. Install:

• Drive chain sprocket guide

• Drive chain sprocket cover "1"

• Screw (drive chain sprocket cov-

er) "2"

INSTALLING THE NEUTRAL

SWITCH

1. Install:

• Spring "1"

•Pin "2"

• O-ring "3"

• Neutral switch "4"

• Screw (neutral switch) "5"

Apply the lithium soap base grease

on the O-ring.

Nut (drive sprocket):

75 Nm (7.5 m•kg, 54

ft•lb)

Screw (drive chain

sprocket cover):

8 Nm (0.8 m•kg, 5.8

ft•lb)

Screw (neutral switch):

4 Nm (0.4 m•kg, 2.9

ft•lb)

Page 153 of 224

5-57

CRANKCASE AND CRANKSHAFT

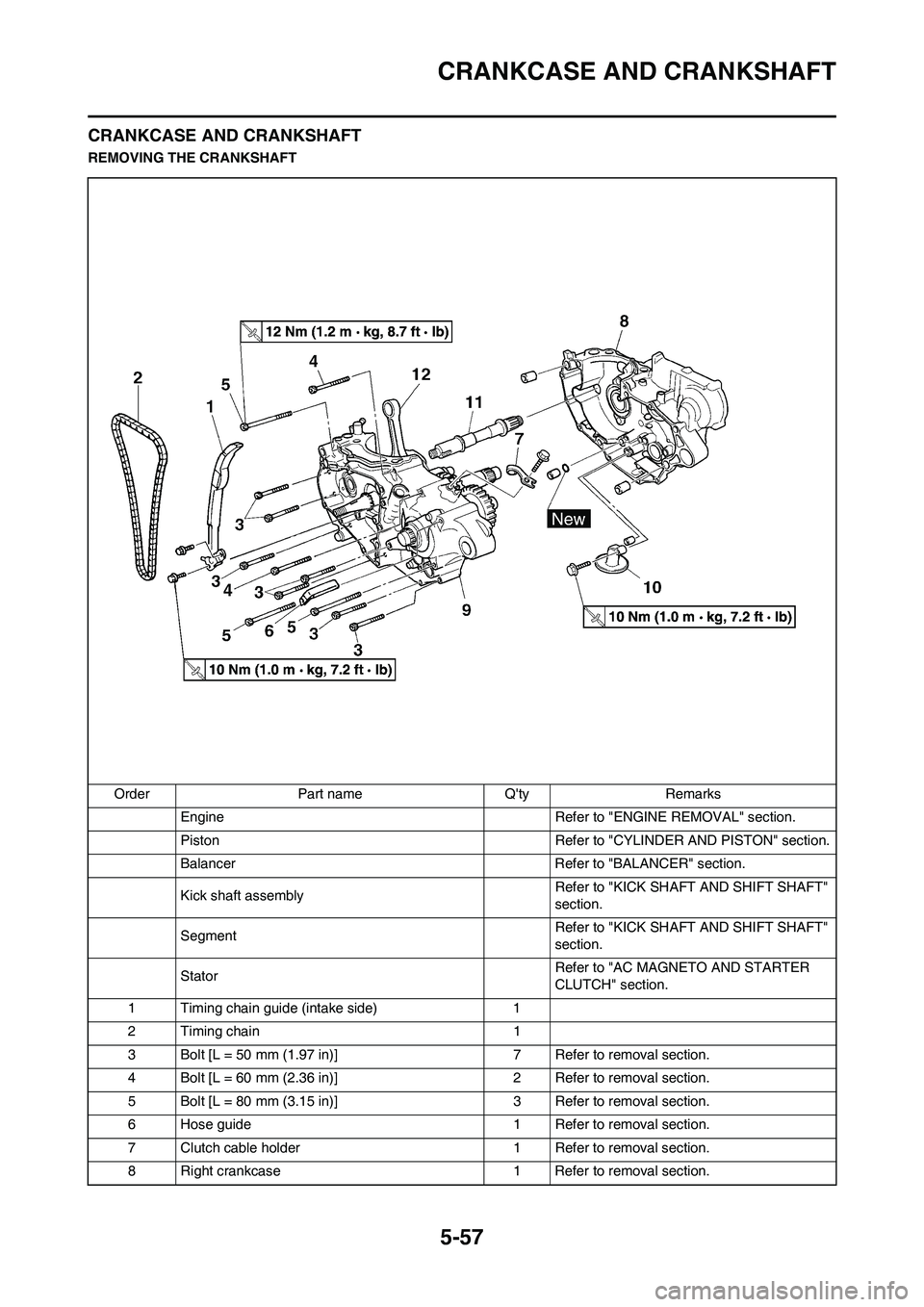

CRANKCASE AND CRANKSHAFT

REMOVING THE CRANKSHAFT

Order Part name Q'ty Remarks

Engine Refer to "ENGINE REMOVAL" section.

Piston Refer to "CYLINDER AND PISTON" section.

Balancer Refer to "BALANCER" section.

Kick shaft assemblyRefer to "KICK SHAFT AND SHIFT SHAFT"

section.

SegmentRefer to "KICK SHAFT AND SHIFT SHAFT"

section.

StatorRefer to "AC MAGNETO AND STARTER

CLUTCH" section.

1 Timing chain guide (intake side) 1

2 Timing chain 1

3 Bolt [L = 50 mm (1.97 in)] 7 Refer to removal section.

4 Bolt [L = 60 mm (2.36 in)] 2 Refer to removal section.

5 Bolt [L = 80 mm (3.15 in)] 3 Refer to removal section.

6 Hose guide 1 Refer to removal section.

7 Clutch cable holder 1 Refer to removal section.

8 Right crankcase 1 Refer to removal section.

Page 156 of 224

5-60

CRANKCASE AND CRANKSHAFT

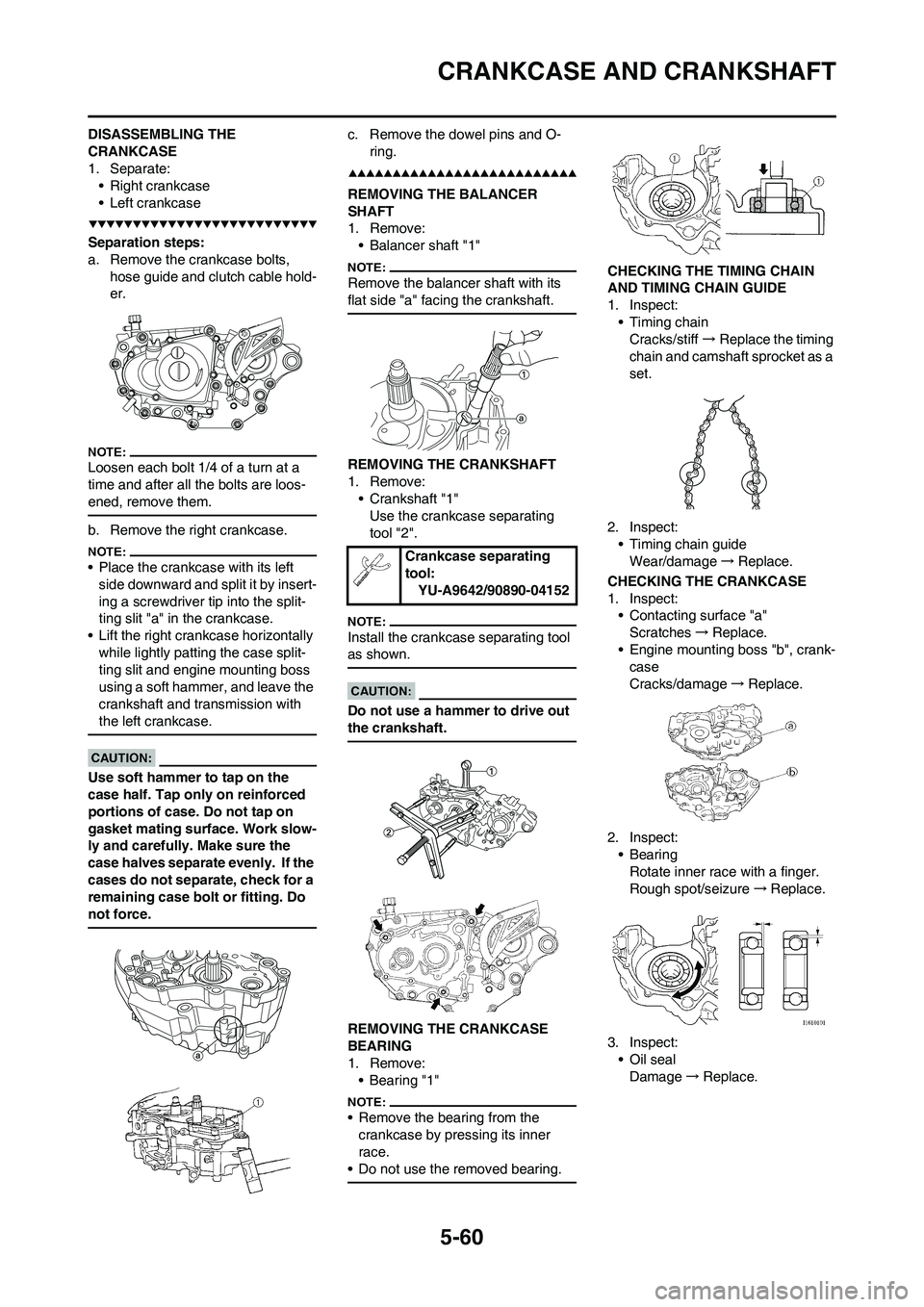

DISASSEMBLING THE

CRANKCASE

1. Separate:

• Right crankcase

• Left crankcase

Separation steps:

a. Remove the crankcase bolts,

hose guide and clutch cable hold-

er.

Loosen each bolt 1/4 of a turn at a

time and after all the bolts are loos-

ened, remove them.

b. Remove the right crankcase.

• Place the crankcase with its left

side downward and split it by insert-

ing a screwdriver tip into the split-

ting slit "a" in the crankcase.

• Lift the right crankcase horizontally

while lightly patting the case split-

ting slit and engine mounting boss

using a soft hammer, and leave the

crankshaft and transmission with

the left crankcase.

Use soft hammer to tap on the

case half. Tap only on reinforced

portions of case. Do not tap on

gasket mating surface. Work slow-

ly and carefully. Make sure the

case halves separate evenly. If the

cases do not separate, check for a

remaining case bolt or fitting. Do

not force.

c. Remove the dowel pins and O-

ring.

REMOVING THE BALANCER

SHAFT

1. Remove:

• Balancer shaft "1"

Remove the balancer shaft with its

flat side "a" facing the crankshaft.

REMOVING THE CRANKSHAFT

1. Remove:

• Crankshaft "1"

Use the crankcase separating

tool "2".

Install the crankcase separating tool

as shown.

Do not use a hammer to drive out

the crankshaft.

REMOVING THE CRANKCASE

BEARING

1. Remove:

•Bearing "1"

• Remove the bearing from the

crankcase by pressing its inner

race.

• Do not use the removed bearing.

CHECKING THE TIMING CHAIN

AND TIMING CHAIN GUIDE

1. Inspect:

• Timing chain

Cracks/stiff→Replace the timing

chain and camshaft sprocket as a

set.

2. Inspect:

• Timing chain guide

Wear/damage→Replace.

CHECKING THE CRANKCASE

1. Inspect:

• Contacting surface "a"

Scratches→Replace.

• Engine mounting boss "b", crank-

case

Cracks/damage→Replace.

2. Inspect:

• Bearing

Rotate inner race with a finger.

Rough spot/seizure→Replace.

3. Inspect:

• Oil seal

Damage→Replace.

Crankcase separating

tool:

YU-A9642/90890-04152

Page 158 of 224

5-62

CRANKCASE AND CRANKSHAFT

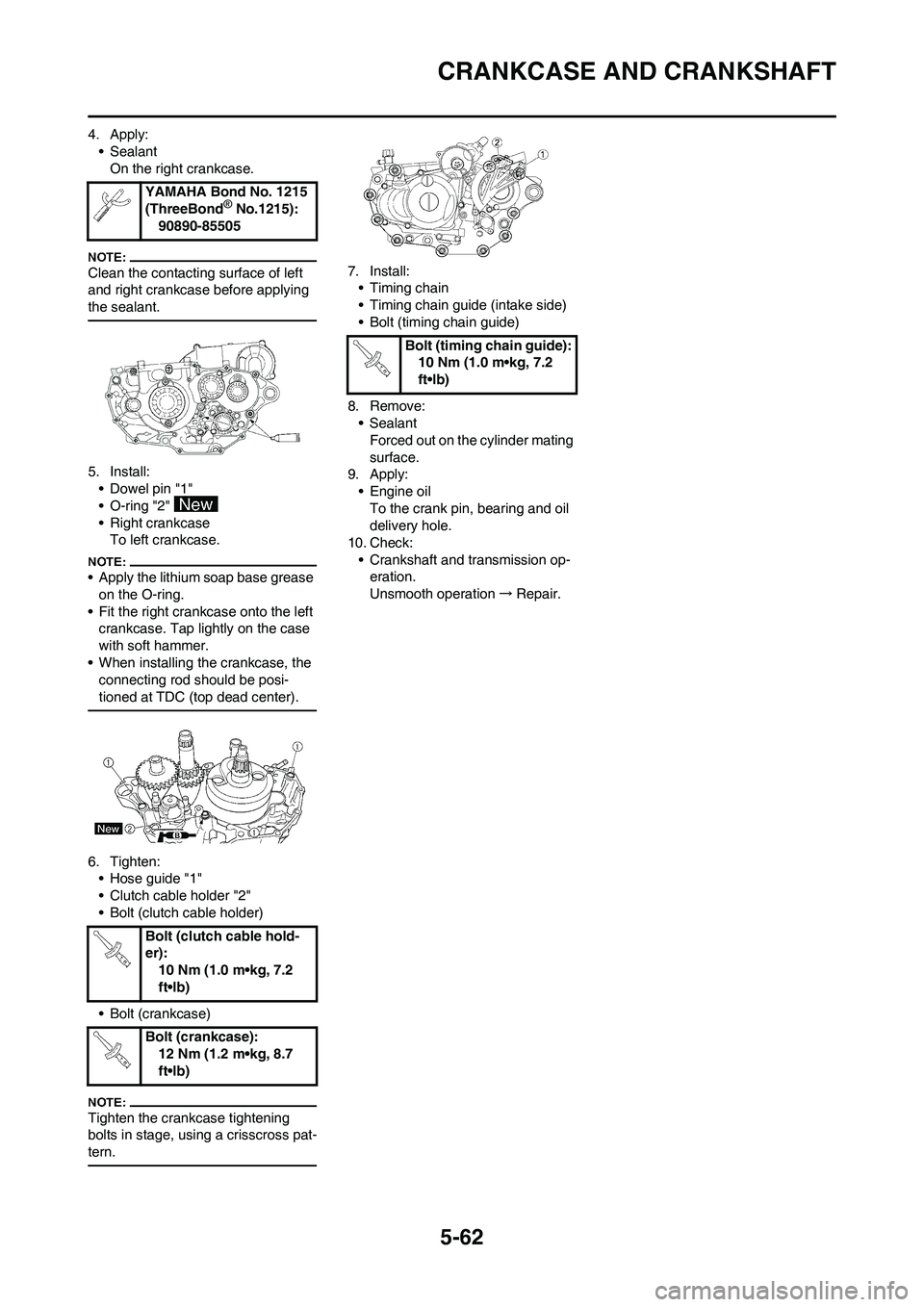

4. Apply:

• Sealant

On the right crankcase.

Clean the contacting surface of left

and right crankcase before applying

the sealant.

5. Install:

• Dowel pin "1"

• O-ring "2"

• Right crankcase

To left crankcase.

• Apply the lithium soap base grease

on the O-ring.

• Fit the right crankcase onto the left

crankcase. Tap lightly on the case

with soft hammer.

• When installing the crankcase, the

connecting rod should be posi-

tioned at TDC (top dead center).

6. Tighten:

• Hose guide "1"

• Clutch cable holder "2"

• Bolt (clutch cable holder)

• Bolt (crankcase)

Tighten the crankcase tightening

bolts in stage, using a crisscross pat-

tern.

7. Install:

• Timing chain

• Timing chain guide (intake side)

• Bolt (timing chain guide)

8. Remove:

• Sealant

Forced out on the cylinder mating

surface.

9. Apply:

• Engine oil

To the crank pin, bearing and oil

delivery hole.

10. Check:

• Crankshaft and transmission op-

eration.

Unsmooth operation→Repair. YAMAHA Bond No. 1215

(ThreeBond

® No.1215):

90890-85505

Bolt (clutch cable hold-

er):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (crankcase):

12 Nm (1.2 m•kg, 8.7

ft•lb)

Bolt (timing chain guide):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 159 of 224

5-63

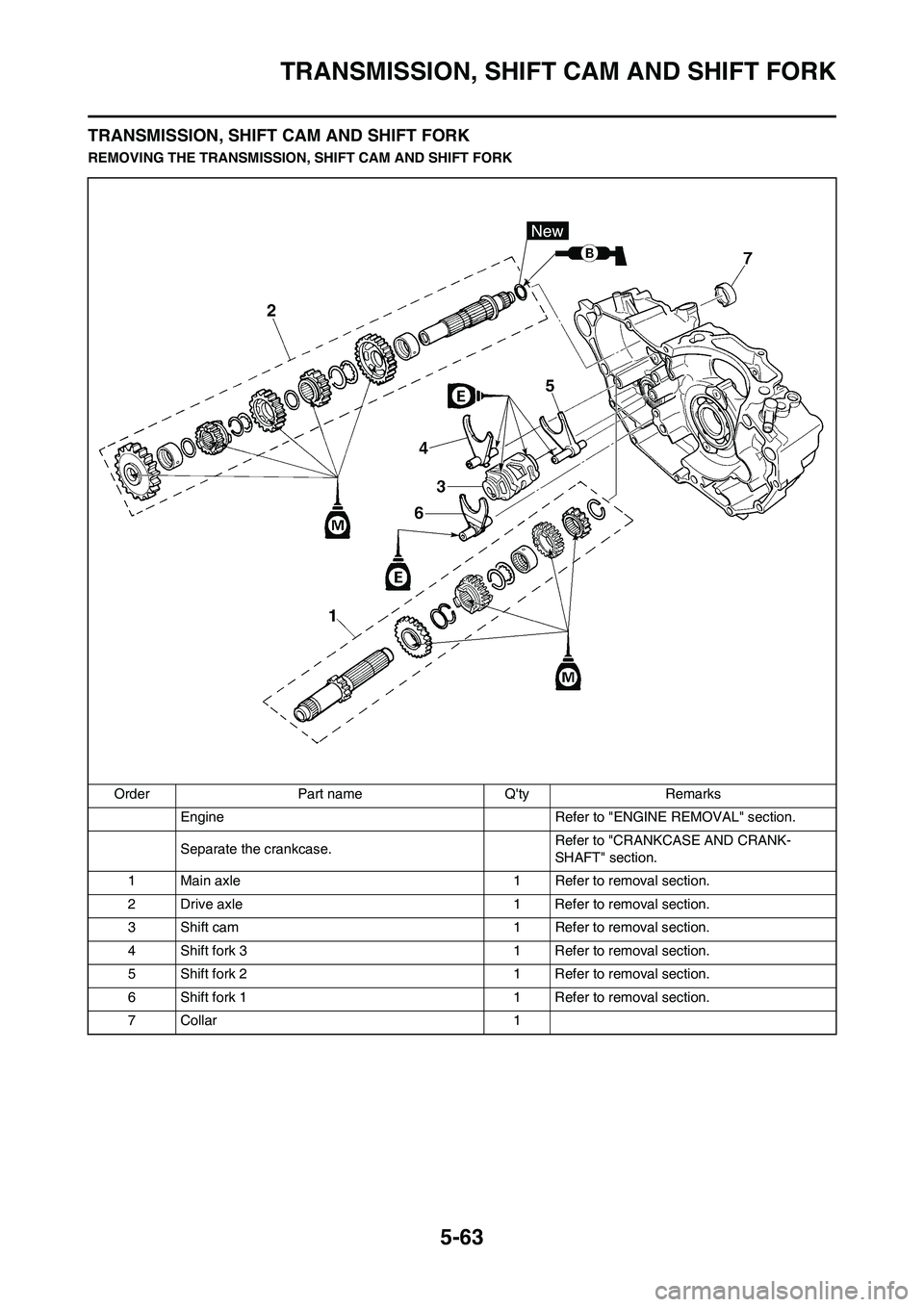

TRANSMISSION, SHIFT CAM AND SHIFT FORK

TRANSMISSION, SHIFT CAM AND SHIFT FORK

REMOVING THE TRANSMISSION, SHIFT CAM AND SHIFT FORK

Order Part name Q'ty Remarks

Engine Refer to "ENGINE REMOVAL" section.

Separate the crankcase.Refer to "CRANKCASE AND CRANK-

SHAFT" section.

1 Main axle 1 Refer to removal section.

2 Drive axle 1 Refer to removal section.

3 Shift cam 1 Refer to removal section.

4 Shift fork 3 1 Refer to removal section.

5 Shift fork 2 1 Refer to removal section.

6 Shift fork 1 1 Refer to removal section.

7 Collar 1

Page 161 of 224

5-65

TRANSMISSION, SHIFT CAM AND SHIFT FORK

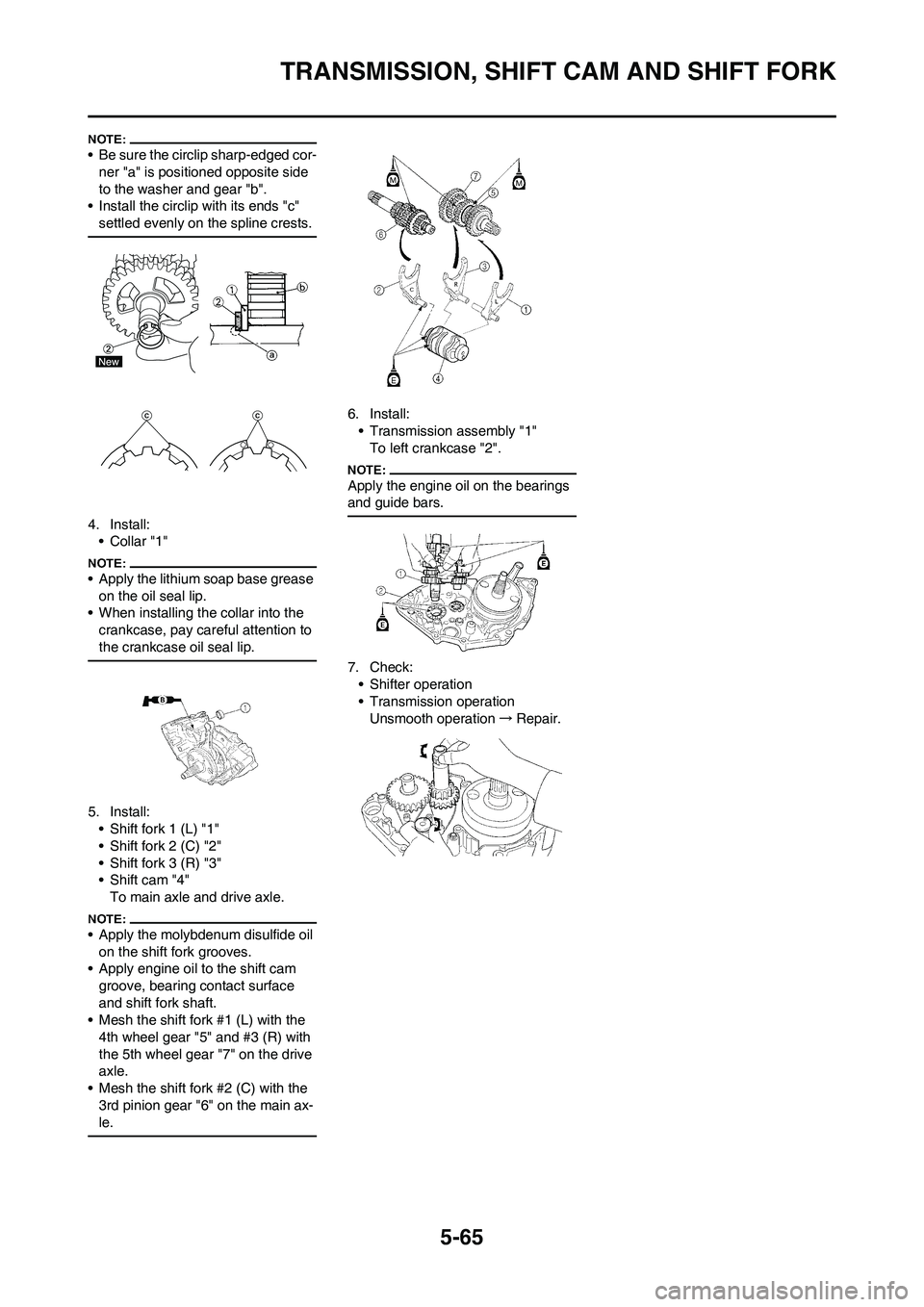

• Be sure the circlip sharp-edged cor-

ner "a" is positioned opposite side

to the washer and gear "b".

• Install the circlip with its ends "c"

settled evenly on the spline crests.

4. Install:

•Collar "1"

• Apply the lithium soap base grease

on the oil seal lip.

• When installing the collar into the

crankcase, pay careful attention to

the crankcase oil seal lip.

5. Install:

• Shift fork 1 (L) "1"

• Shift fork 2 (C) "2"

• Shift fork 3 (R) "3"

• Shift cam "4"

To main axle and drive axle.

• Apply the molybdenum disulfide oil

on the shift fork grooves.

• Apply engine oil to the shift cam

groove, bearing contact surface

and shift fork shaft.

• Mesh the shift fork #1 (L) with the

4th wheel gear "5" and #3 (R) with

the 5th wheel gear "7" on the drive

axle.

• Mesh the shift fork #2 (C) with the

3rd pinion gear "6" on the main ax-

le.

6. Install:

• Transmission assembly "1"

To left crankcase "2".

Apply the engine oil on the bearings

and guide bars.

7. Check:

• Shifter operation

• Transmission operation

Unsmooth operation→Repair.

Page 162 of 224

6-1

FRONT WHEEL AND REAR WHEEL

CHASSIS

FRONT WHEEL AND REAR WHEEL

REMOVING THE FRONT WHEEL

Order Part name Q'ty Remarks

Hold the machine by placing the suitable stand

under the engine.Refer to "HANDLING NOTE".

1 Bolt (axle holder) 4 Only loosening.

2 Nut (front wheel axle) 1

3 Front wheel axle 1

4 Front wheel 1

5 Speed sensor 1

6 Collar 1

7 Oil seal 1

8 Bearing 2 Refer to removal section.

9 Brake disc 1

21 Nm (2.1 m kg, 15 ft lb)

21 Nm (2.1 m kg, 15 ft lb)

12 Nm (1.2 m kg, 8.7 ft lb)

90 Nm (9.0 m kg, 65 ft lb)

Page 163 of 224

6-2

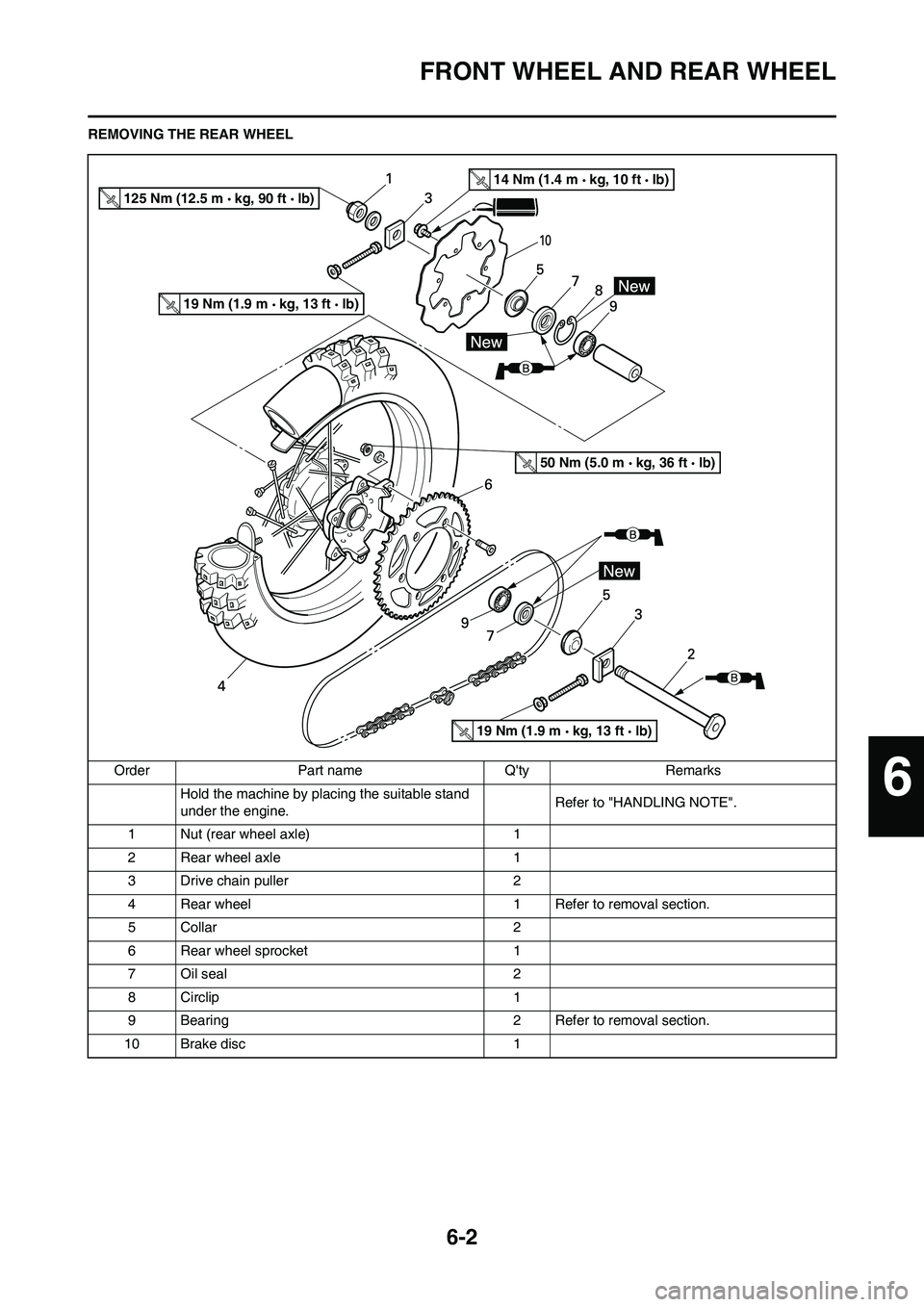

FRONT WHEEL AND REAR WHEEL

REMOVING THE REAR WHEEL

Order Part name Q'ty Remarks

Hold the machine by placing the suitable stand

under the engine.Refer to "HANDLING NOTE".

1 Nut (rear wheel axle) 1

2 Rear wheel axle 1

3 Drive chain puller 2

4 Rear wheel 1 Refer to removal section.

5 Collar 2

6 Rear wheel sprocket 1

7 Oil seal 2

8 Circlip 1

9 Bearing 2 Refer to removal section.

10 Brake disc 1

125 Nm (12.5 m kg, 90 ft lb)

14 Nm (1.4 m kg, 10 ft lb)

19 Nm (1.9 m kg, 13 ft lb)

19 Nm (1.9 m kg, 13 ft lb)

50 Nm (5.0 m kg, 36 ft lb)

6

Page 167 of 224

6-6

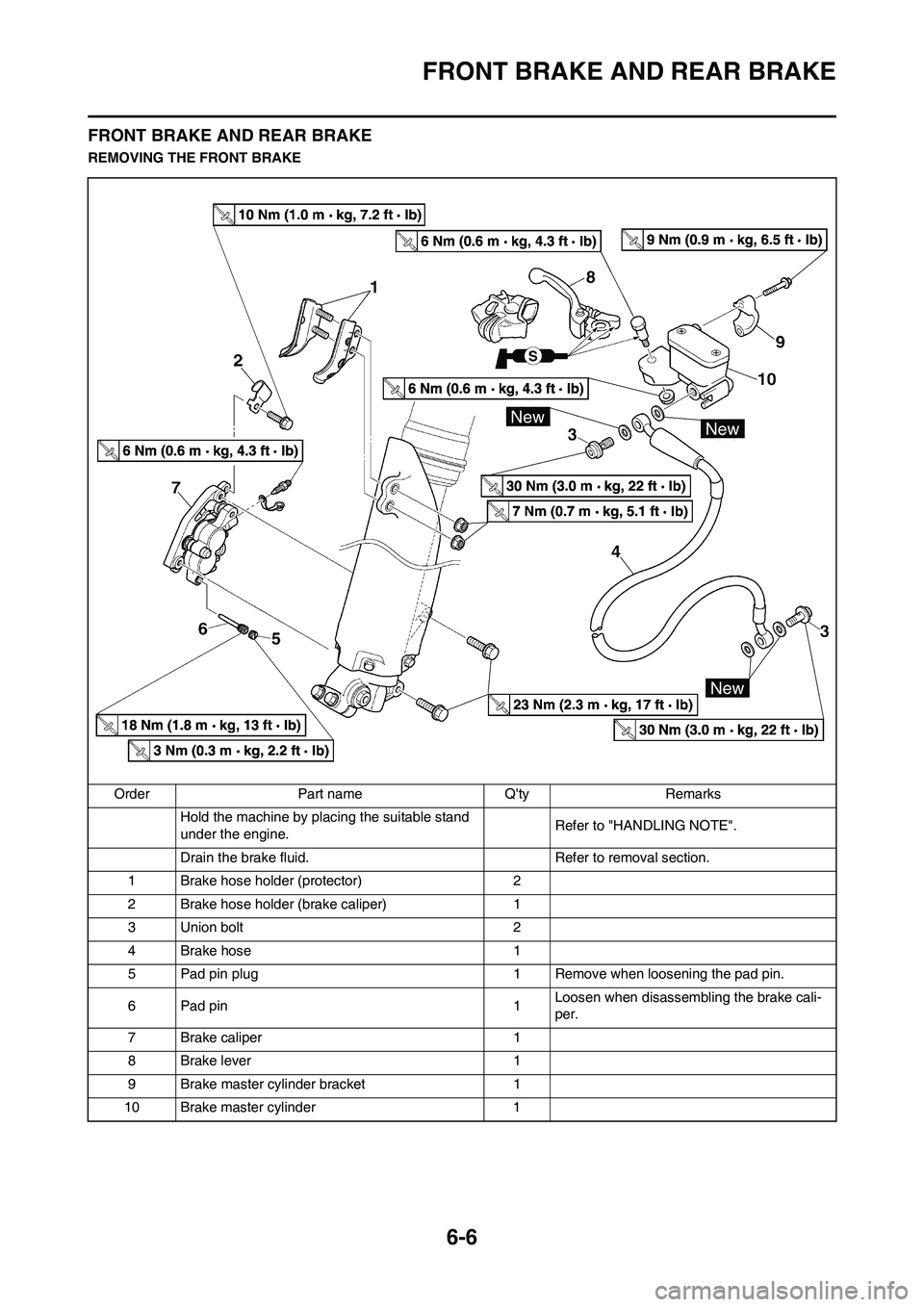

FRONT BRAKE AND REAR BRAKE

FRONT BRAKE AND REAR BRAKE

REMOVING THE FRONT BRAKE

Order Part name Q'ty Remarks

Hold the machine by placing the suitable stand

under the engine.Refer to "HANDLING NOTE".

Drain the brake fluid. Refer to removal section.

1 Brake hose holder (protector) 2

2 Brake hose holder (brake caliper) 1

3 Union bolt 2

4 Brake hose 1

5 Pad pin plug 1 Remove when loosening the pad pin.

6Pad pin 1Loosen when disassembling the brake cali-

per.

7 Brake caliper 1

8Brake lever 1

9 Brake master cylinder bracket 1

10 Brake master cylinder 1

Page 168 of 224

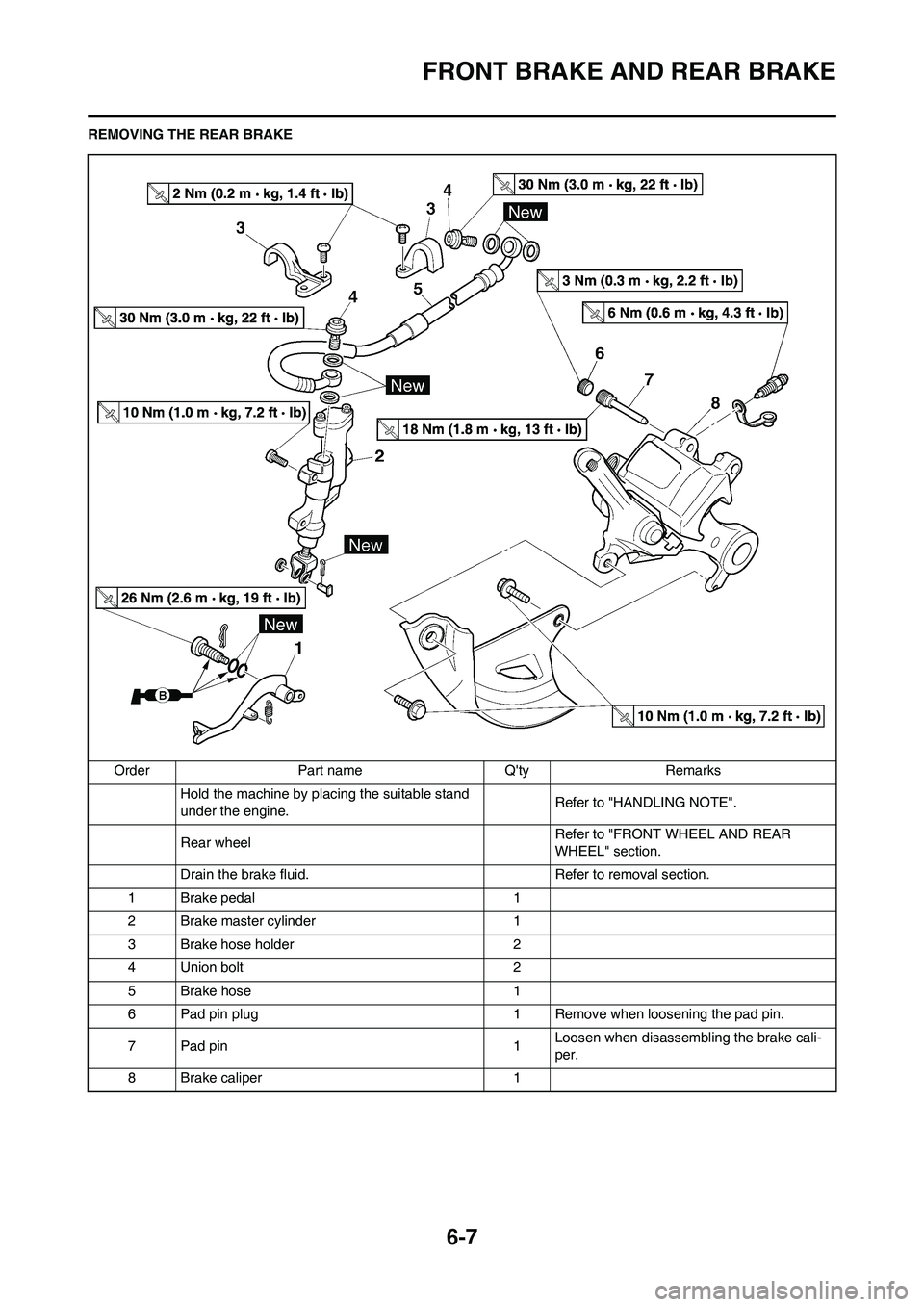

6-7

FRONT BRAKE AND REAR BRAKE

REMOVING THE REAR BRAKE

Order Part name Q'ty Remarks

Hold the machine by placing the suitable stand

under the engine.Refer to "HANDLING NOTE".

Rear wheel Refer to "FRONT WHEEL AND REAR

WHEEL" section.

Drain the brake fluid. Refer to removal section.

1 Brake pedal 1

2 Brake master cylinder 1

3 Brake hose holder 2

4 Union bolt 2

5 Brake hose 1

6 Pad pin plug 1 Remove when loosening the pad pin.

7Pad pin 1Loosen when disassembling the brake cali-

per.

8 Brake caliper 1