YAMAHA WR 450F 2016 Owners Manual

Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 121 of 426

ENGINE

3-23

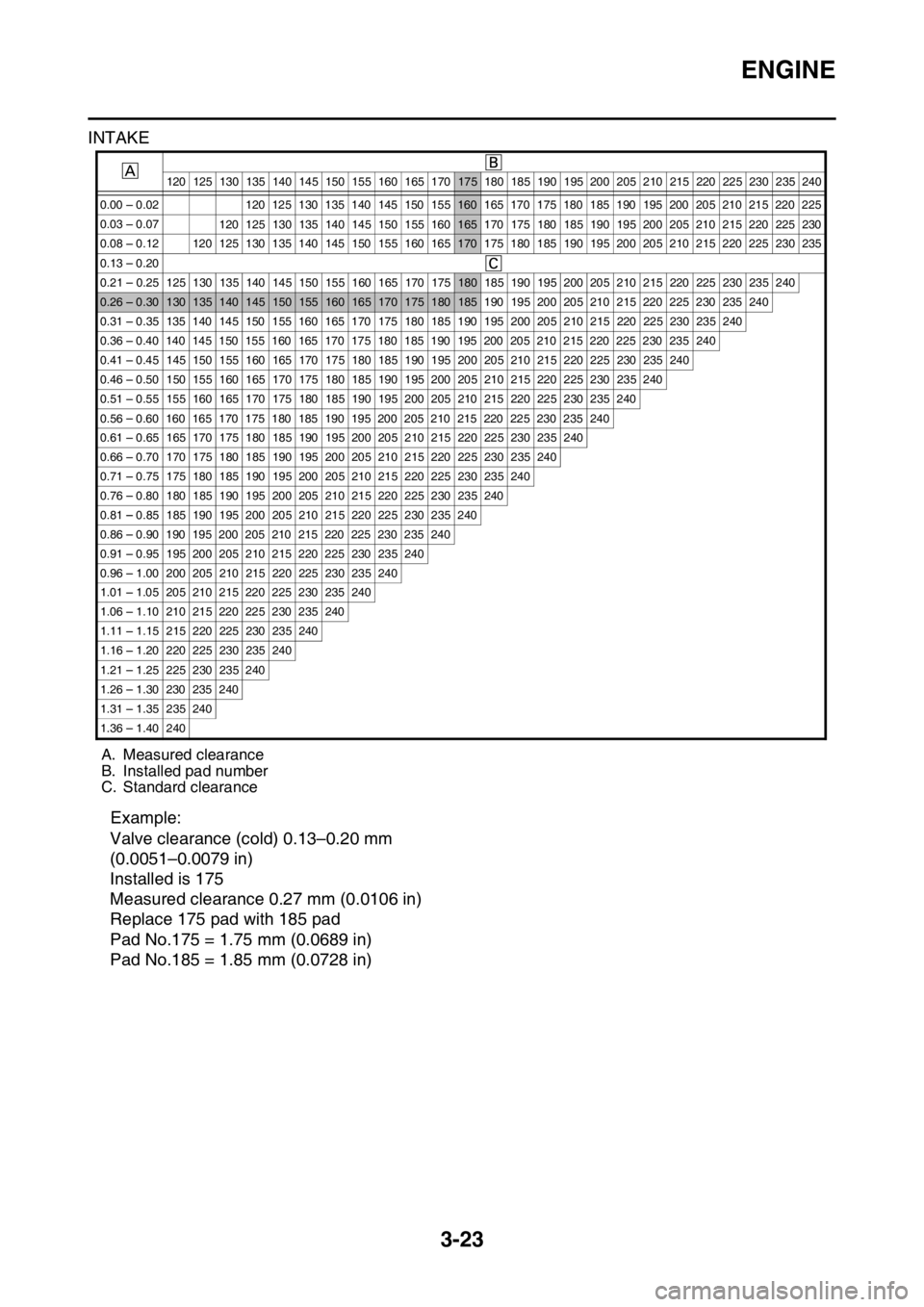

INTAKE

Example:

Valve clearance (cold) 0.13–0.20 mm

(0.0051–0.0079 in)

Installed is 175

Measured clearance 0.27 mm (0.0106 in)

Replace 175 pad with 185 pad

Pad No.175 = 1.75 mm (0.0689 in)

Pad No.185 = 1.85 mm (0.0728 in)

120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.03 0.07120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230

0.00 0.02

120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225

0.08 0.12 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235

0.13 0.20 0.21 0.25 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.26 0.30 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.31 0.35 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.36 0.40 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.41 0.45 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.46 0.50 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.51 0.55 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.56 0.60 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.61 0.65 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.66 0.70 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.71 0.75 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.76 0.80 180 185 190 195 200 205 210 215 220 225 230 235 240

0.81 0.85 185 190 195 200 205 210 215 220 225 230 235 240

0.86 0.90 190 195 200 205 210 215 220 225 230 235 240

0.91 0.95 195 200 205 210 215 220 225 230 235 240

0.96 1.00 200 205 210 215 220 225 230 235 240

1.01 1.05 205 210 215 220 225 230 235 240

1.06 1.10 210 215 220 225 230 235 240

1.11 1.15 215 220 225 230 235 240

1.16 1.20 220 225 230 235 240

1.21 1.25 225 230 235 240

1.26 1.30 230 235 240

1.31 1.35 235 240

1.36 1.40 240

A. Measured clearance

B. Installed pad number

C. Standard clearance

Page 122 of 426

ENGINE

3-24

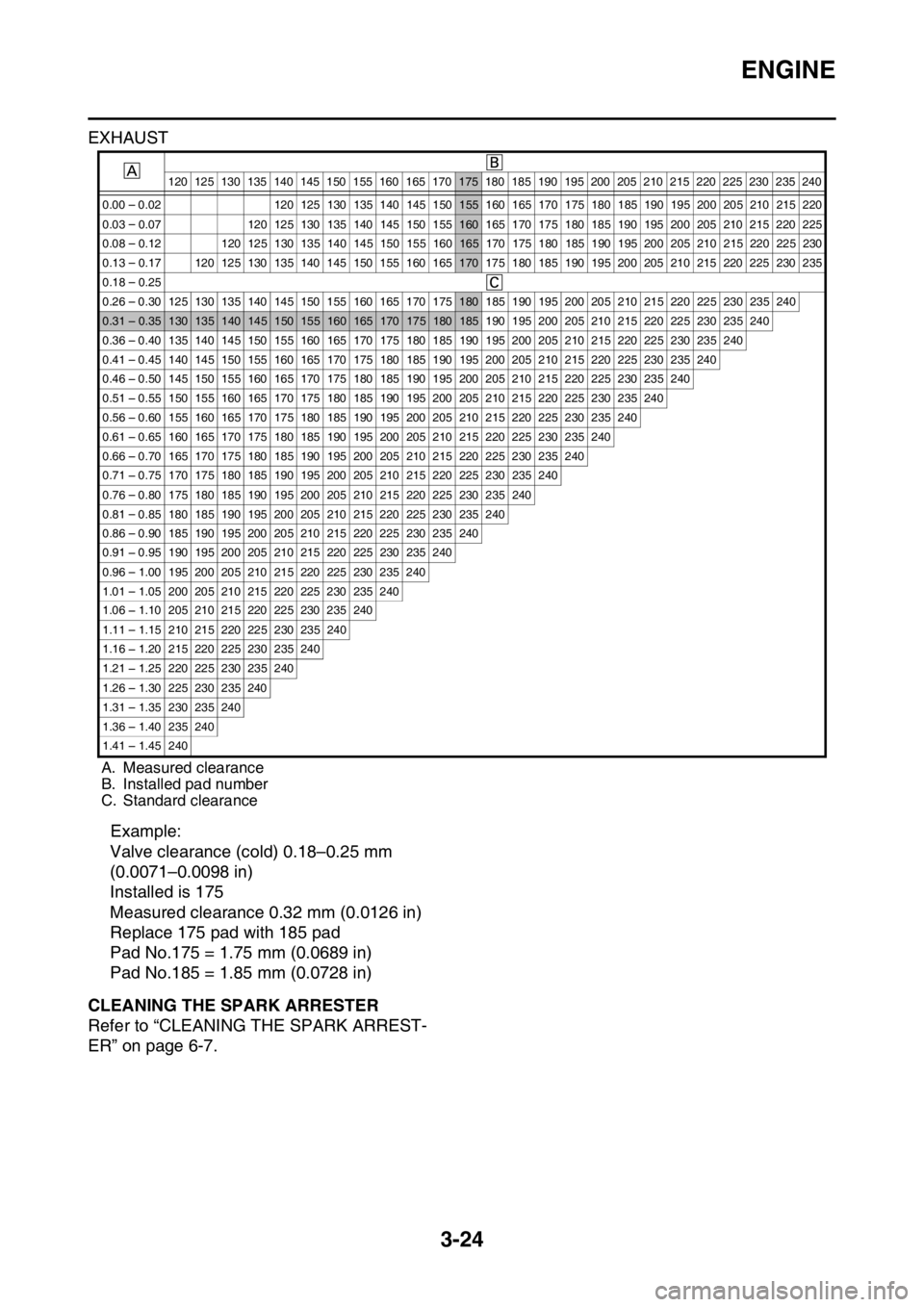

EXHAUST

Example:

Valve clearance (cold) 0.18–0.25 mm

(0.0071–0.0098 in)

Installed is 175

Measured clearance 0.32 mm (0.0126 in)

Replace 175 pad with 185 pad

Pad No.175 = 1.75 mm (0.0689 in)

Pad No.185 = 1.85 mm (0.0728 in)

EAS2GC1100CLEANING THE SPARK ARRESTER

Refer to “CLEANING THE SPARK ARREST-

ER” on page 6-7.

120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.00 0.02120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220

0.03 0.07 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225

0.08 0.12 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230

0.13 0.17 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235

0.18 0.25

0.26 0.30 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.31 0.35 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.36 0.40 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.41 0.45 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.46 0.50 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.51 0.55 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.56 0.60 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.61 0.65 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.66 0.70 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.71 0.75 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.76 0.80 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.81 0.85 180 185 190 195 200 205 210 215 220 225 230 235 240

0.86 0.90 185 190 195 200 205 210 215 220 225 230 235 240

0.91 0.95 190 195 200 205 210 215 220 225 230 235 240

0.96 1.00 195 200 205 210 215 220 225 230 235 240

1.01 1.05 200 205 210 215 220 225 230 235 240

1.06 1.10 205 210 215 220 225 230 235 240

1.11 1.15 210 215 220 225 230 235 240

1.16 1.20 215 220 225 230 235 240

1.21 1.25 220 225 230 235 240

1.26 1.30 225 230 235 240

1.31 1.35 230 235 240

1.36 1.40 235 240

1.41 1.45 240

A. Measured clearance

B. Installed pad number

C. Standard clearance

Page 123 of 426

CHASSIS

3-25

EAS2GC1101

CHASSIS

EAS2GC1102BLEEDING THE BRAKE SYSTEMEWA

WARNING

Bleed the brake system whenever:

• The system is disassembled.

• A brake hose is loosened, disconnected, or replaced.

• The brake fluid level is very low.

• Brake operation is faulty.

1. Remove: • Brake master cylinder cap

• Reservoir diaphragm

• Reservoir float (front brake)

• Protector (rear brake)

TIP

• Be careful not to spill any brake fluid or allow the reservoir to overflow.

• Make sure that there is enough brake fluid be-

fore applying the brake. Ignoring this precau-

tion could allow air to enter the brake system,

considerably lengthening the bleeding proce-

dure.

• If bleeding is difficult, it may be necessary to let the brake fluid settle for a few hours. Re-

peat the bleeding procedure when the tiny

bubbles in the hose have disappeared.

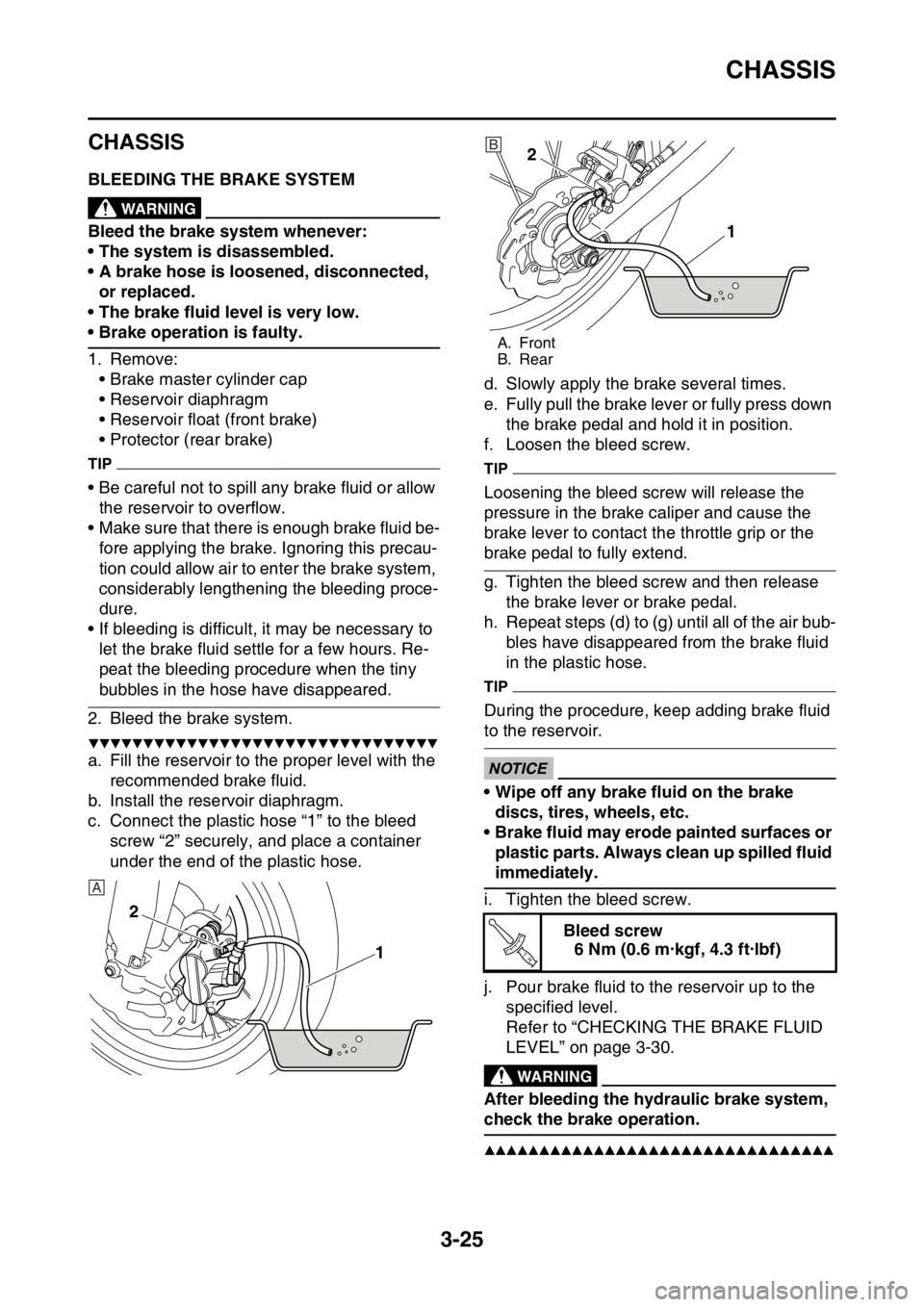

2. Bleed the brake system.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Fill the reservoir to the proper level with the recommended brake fluid.

b. Install the reservoir diaphragm.

c. Connect the plastic hose “1” to the bleed screw “2” securely, and place a container

under the end of the plastic hose. d. Slowly apply the brake several times.

e. Fully pull the brake lever or fully press down

the brake pedal and hold it in position.

f. Loosen the bleed screw.

TIP

Loosening the bleed screw will release the

pressure in the brake caliper and cause the

brake lever to contact the throttle grip or the

brake pedal to fully extend.

g. Tighten the bleed screw and then release the brake lever or brake pedal.

h. Repeat steps (d) to (g) until all of the air bub- bles have disappeared from the brake fluid

in the plastic hose.

TIP

During the procedure, keep adding brake fluid

to the reservoir.

ECA

NOTICE

• Wipe off any brake fluid on the brake discs, tires, wheels, etc.

• Brake fluid may erode painted surfaces or

plastic parts. Always clean up spilled fluid

immediately.

i. Tighten the bleed screw.

j. Pour brake fluid to the reservoir up to the specified level.

Refer to “CHECKING THE BRAKE FLUID

LEVEL” on page 3-30.

EWA

WARNING

After bleeding the hydraulic brake system,

check the brake operation.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

1

2

A

A. Front

B. Rear

Bleed screw

6 Nm (0.6 m·kgf, 4.3 ft·lbf)

2

1B

T R..

Page 124 of 426

CHASSIS

3-26

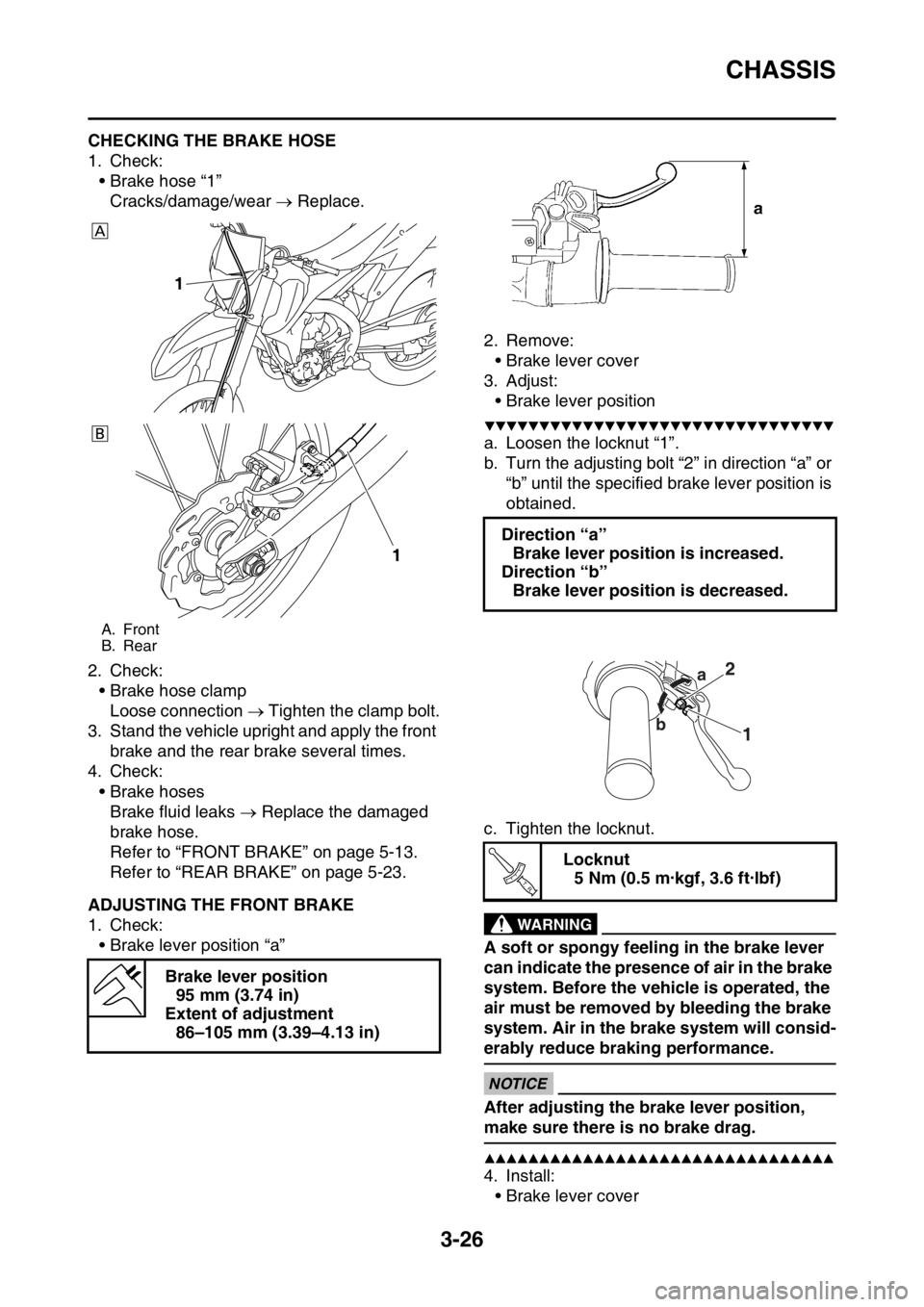

EAS2GC1103CHECKING THE BRAKE HOSE

1. Check:• Brake hose “1”Cracks/damage/wear Replace.

2. Check: • Brake hose clamp

Loose connection Tighten the clamp bolt.

3. Stand the vehicle upright and apply the front brake and the rear brake several times.

4. Check: • Brake hosesBrake fluid leaks Replace the damaged

brake hose.

Refer to “FRONT BRAKE” on page 5-13.

Refer to “REAR BRAKE” on page 5-23.

EAS2GC1104ADJUSTING THE FRONT BRAKE

1. Check: • Brake lever position “a” 2. Remove:

• Brake lever cover

3. Adjust: • Brake lever position

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the locknut “1”.

b. Turn the adjusting bolt “2” in direction “a” or “b” until the specified brake lever position is

obtained.

c. Tighten the locknut.

EWA13050

WARNING

A soft or spongy feeling in the brake lever

can indicate the presence of air in the brake

system. Before the vehicle is operated, the

air must be removed by bleeding the brake

system. Air in the brake system will consid-

erably reduce braking performance.

ECA13490

NOTICE

After adjusting the brake lever position,

make sure there is no brake drag.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

4. Install: • Brake lever cover

A. Front

B. Rear

Brake lever position95 mm (3.74 in)

Extent of adjustment 86–105 mm (3.39–4.13 in)

1

1

Direction “a”Brake lever position is increased.

Direction “b” Brake lever position is decreased.

Locknut5 Nm (0.5 m·kgf, 3.6 ft·lbf)

a

b

T R..

Page 125 of 426

CHASSIS

3-27

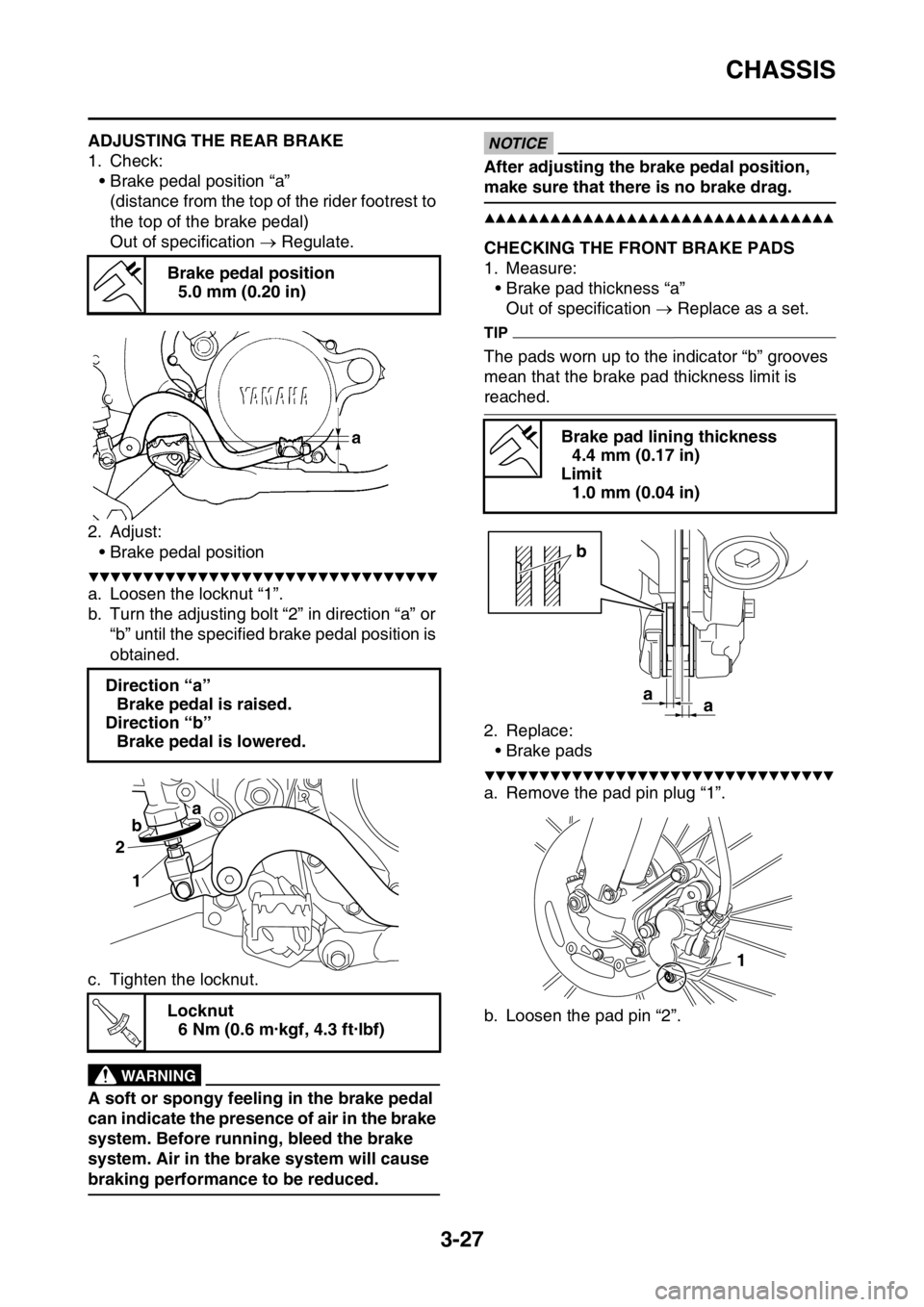

EAS2GC1105ADJUSTING THE REAR BRAKE

1. Check:• Brake pedal position “a”(distance from the top of the rider footrest to

the top of the brake pedal)

Out of specification Regulate.

2. Adjust: • Brake pedal position

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the locknut “1”.

b. Turn the adjusting bolt “2” in direction “a” or “b” until the specified brake pedal position is

obtained.

c. Tighten the locknut.

EWA

WARNING

A soft or spongy feeling in the brake pedal

can indicate the presence of air in the brake

system. Before running, bleed the brake

system. Air in the brake system will cause

braking performance to be reduced.

ECA

NOTICE

After adjusting the brake pedal position,

make sure that there is no brake drag.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GC1106CHECKING THE FRONT BRAKE PADS

1. Measure: • Brake pad thickness “a”Out of specification Replace as a set.

TIP

The pads worn up to the indicator “b” grooves

mean that the brake pad thickness limit is

reached.

2. Replace:

• Brake pads

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the pad pin plug “1”.

b. Loosen the pad pin “2”.

Brake pedal position

5.0 mm (0.20 in)

Direction “a” Brake pedal is raised.

Direction “b”

Brake pedal is lowered.

Locknut6 Nm (0.6 m·kgf, 4.3 ft·lbf)

1

2

a

b

T R..

Brake pad lining thickness

4.4 mm (0.17 in)

Limit 1.0 mm (0.04 in)

a

b

a

1

Page 126 of 426

CHASSIS

3-28

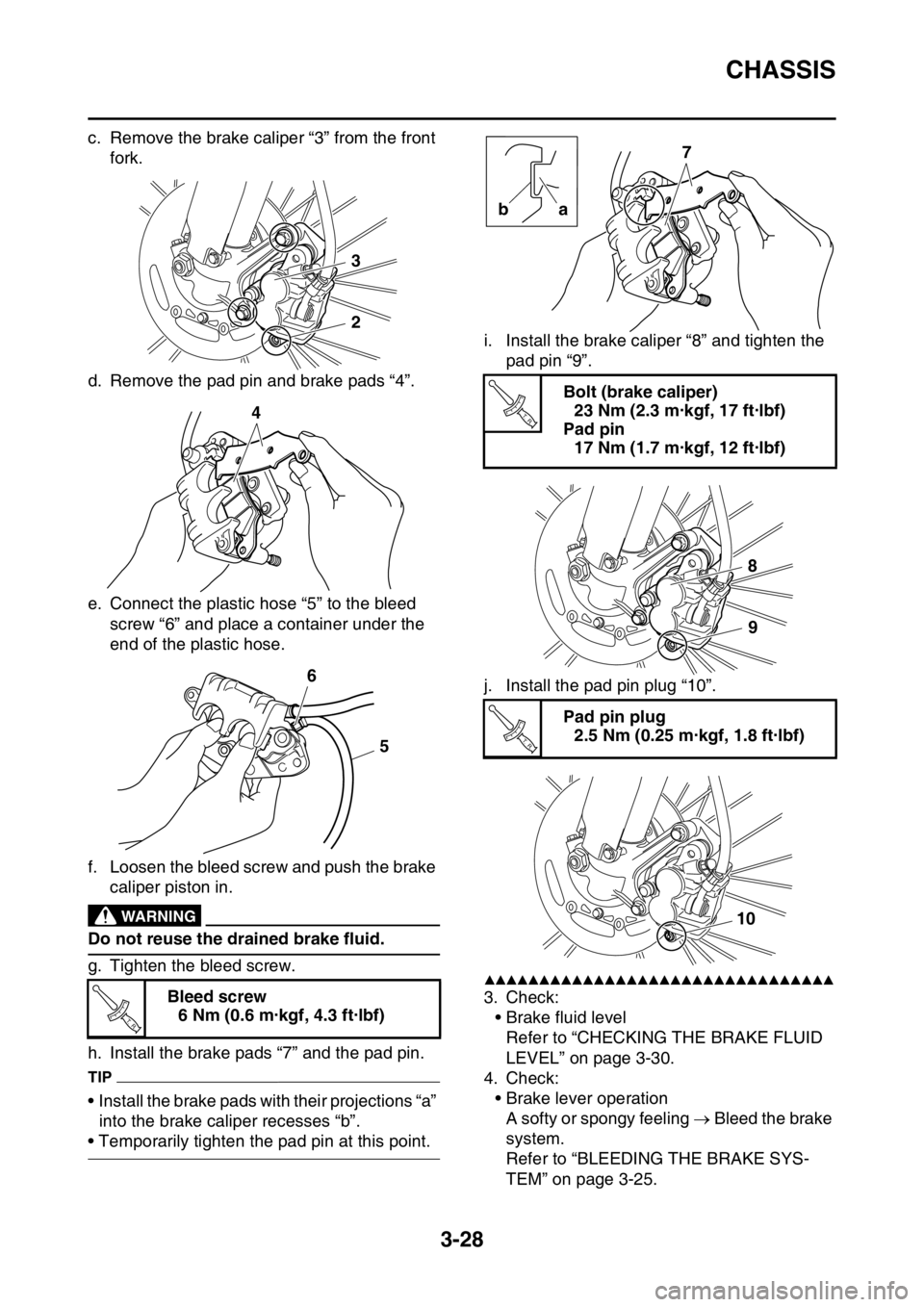

c. Remove the brake caliper “3” from the front fork.

d. Remove the pad pin and brake pads “4”.

e. Connect the plastic hose “5” to the bleed screw “6” and place a container under the

end of the plastic hose.

f. Loosen the bleed screw and push the brake caliper piston in.

EWA

WARNING

Do not reuse the drained brake fluid.

g. Tighten the bleed screw.

h. Install the brake pads “7” and the pad pin.

TIP

• Install the brake pads with their projections “a” into the brake caliper recesses “b”.

• Temporarily tighten the pad pin at this point. i. Install the brake caliper “8” and tighten the

pad pin “9”.

j. Install the pad pin plug “10”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Check: • Brake fluid levelRefer to “CHECKING THE BRAKE FLUID

LEVEL” on page 3-30.

4. Check: • Brake lever operation

A softy or spongy feeling Bleed the brake

system.

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-25.

Bleed screw

6 Nm (0.6 m·kgf, 4.3 ft·lbf)

3

2

4

6

5

T R..

Bolt (brake caliper)23 Nm (2.3 m·kgf, 17 ft·lbf)

Pad pin 17 Nm (1.7 m·kgf, 12 ft·lbf)

Pad pin plug 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

7

a

b

T R..

8

9

T R..

10

Page 127 of 426

CHASSIS

3-29

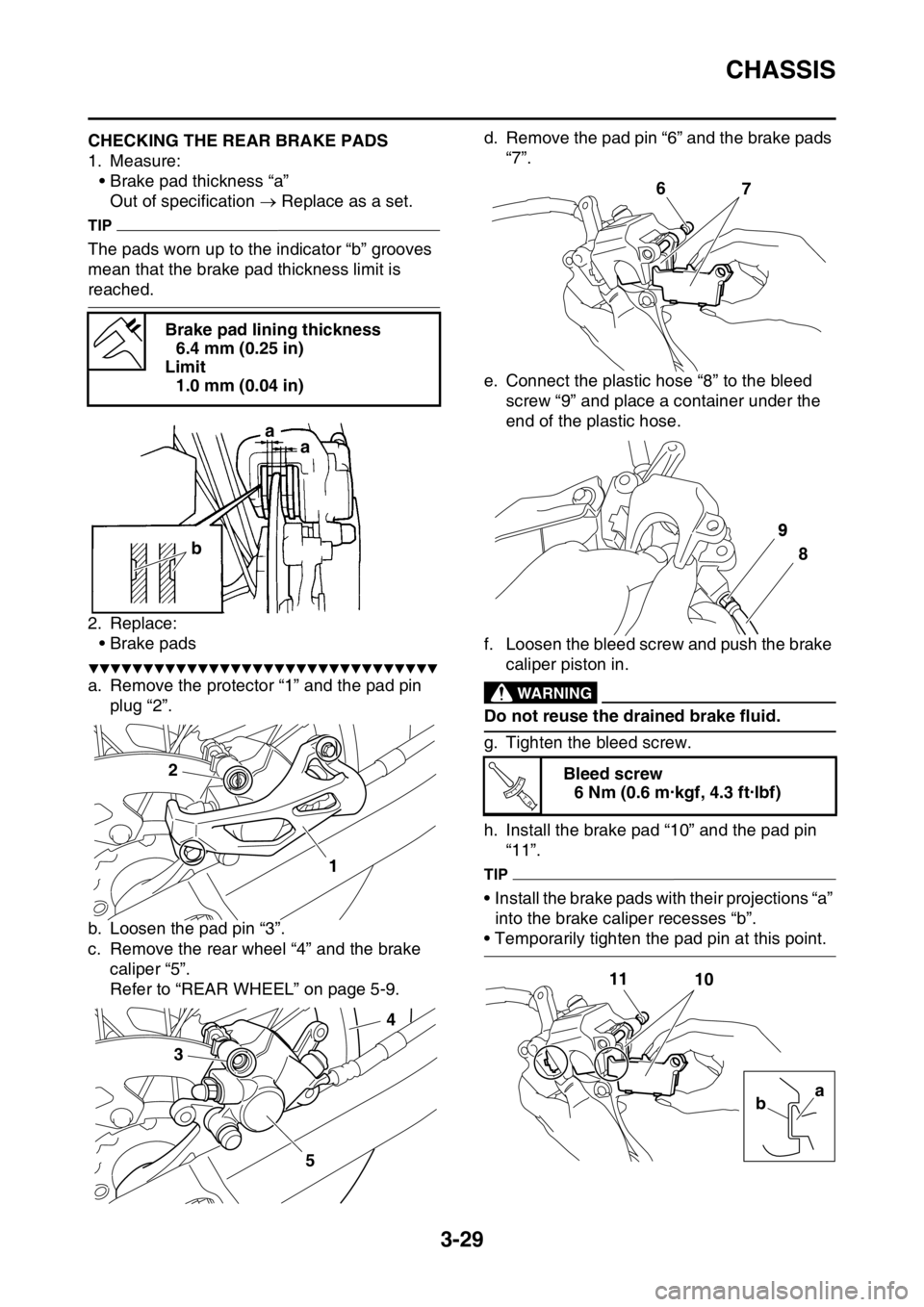

EAS2GC1107CHECKING THE REAR BRAKE PADS

1. Measure:• Brake pad thickness “a”Out of specification Replace as a set.

TIP

The pads worn up to the indicator “b” grooves

mean that the brake pad thickness limit is

reached.

2. Replace:

• Brake pads

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the protector “1” and the pad pin

plug “2”.

b. Loosen the pad pin “3”.

c. Remove the rear wheel “4” and the brake caliper “5”.

Refer to “REAR WHEEL” on page 5-9. d. Remove the pad pin “6” and the brake pads

“7”.

e. Connect the plastic hose “8” to the bleed screw “9” and place a container under the

end of the plastic hose.

f. Loosen the bleed screw and push the brake caliper piston in.EWA

WARNING

Do not reuse the drained brake fluid.

g. Tighten the bleed screw.

h. Install the brake pad “10” and the pad pin “11”.

TIP

• Install the brake pads with their projections “a” into the brake caliper recesses “b”.

• Temporarily tighten the pad pin at this point.

Brake pad lining thickness

6.4 mm (0.25 in)

Limit 1.0 mm (0.04 in)

b a

a

1

2

3

4

5

Bleed screw 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

7

6

9

8

T R..

10

11

a

b

Page 128 of 426

CHASSIS

3-30

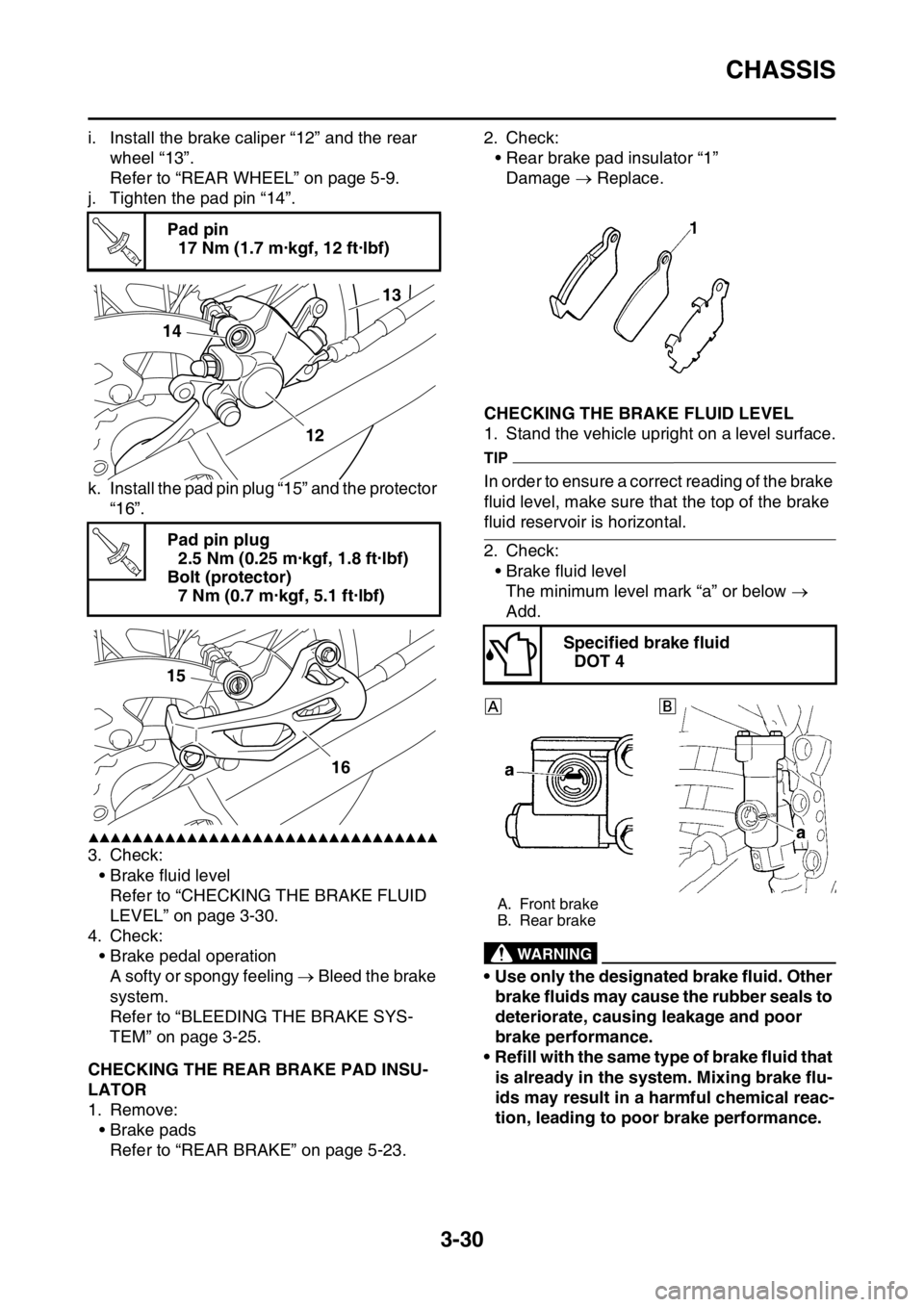

i. Install the brake caliper “12” and the rear wheel “13”.

Refer to “REAR WHEEL” on page 5-9.

j. Tighten the pad pin “14”.

k. Install the pad pin plug “15” and the protector “16”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Check:• Brake fluid levelRefer to “CHECKING THE BRAKE FLUID

LEVEL” on page 3-30.

4. Check: • Brake pedal operationA softy or spongy feeling Bleed the brake

system.

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-25.

EAS2GC1108CHECKING THE REAR BRAKE PAD INSU-

LATOR

1. Remove: • Brake padsRefer to “REAR BRAKE” on page 5-23. 2. Check:

• Rear brake pad insulator “1”Damage Replace.

EAS2GC1109CHECKING THE BRAKE FLUID LEVEL

1. Stand the vehicle upright on a level surface.

TIP

In order to ensure a correct reading of the brake

fluid level, make sure that the top of the brake

fluid reservoir is horizontal.

2. Check:

• Brake fluid levelThe minimum level mark “a” or below

Add.

EWA

WARNING

• Use only the designated brake fluid. Other brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor

brake performance.

• Refill with the same type of brake fluid that

is already in the system. Mixing brake flu-

ids may result in a harmful chemical reac-

tion, leading to poor brake performance.

Pad pin

17 Nm (1.7 m·kgf, 12 ft·lbf)

Pad pin plug 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Bolt (protector) 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

T R..

13

14

12

T R..

15 16

Specified brake fluidDOT 4

A. Front brake

B. Rear brake

Page 129 of 426

CHASSIS

3-31

• When refilling, be careful that water does not enter the brake fluid reservoir. Water

will significantly lower the boiling point of

the brake fluid and could cause vapor

lock.

ECA

NOTICE

Brake fluid may damage painted surfaces

and plastic parts. Therefore, always clean

up any spilt brake fluid immediately.

EAS2GC1110ADJUSTING THE DRIVE CHAIN SLACKECA

NOTICE

A drive chain that is too tight will overload

the engine and other vital parts, and one

that is too loose can skip and damage the

swingarm or cause an accident. Therefore,

keep the drive chain slack within the speci-

fied limits.

1. Use a suitable stand to raise the rear wheel off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Shift the transmission into the neutral posi-

tion.

3. Pull the drive chain up above the drive chain guide installation bolt with a force of about

50 N (5.0 kgf, 36 lbf).

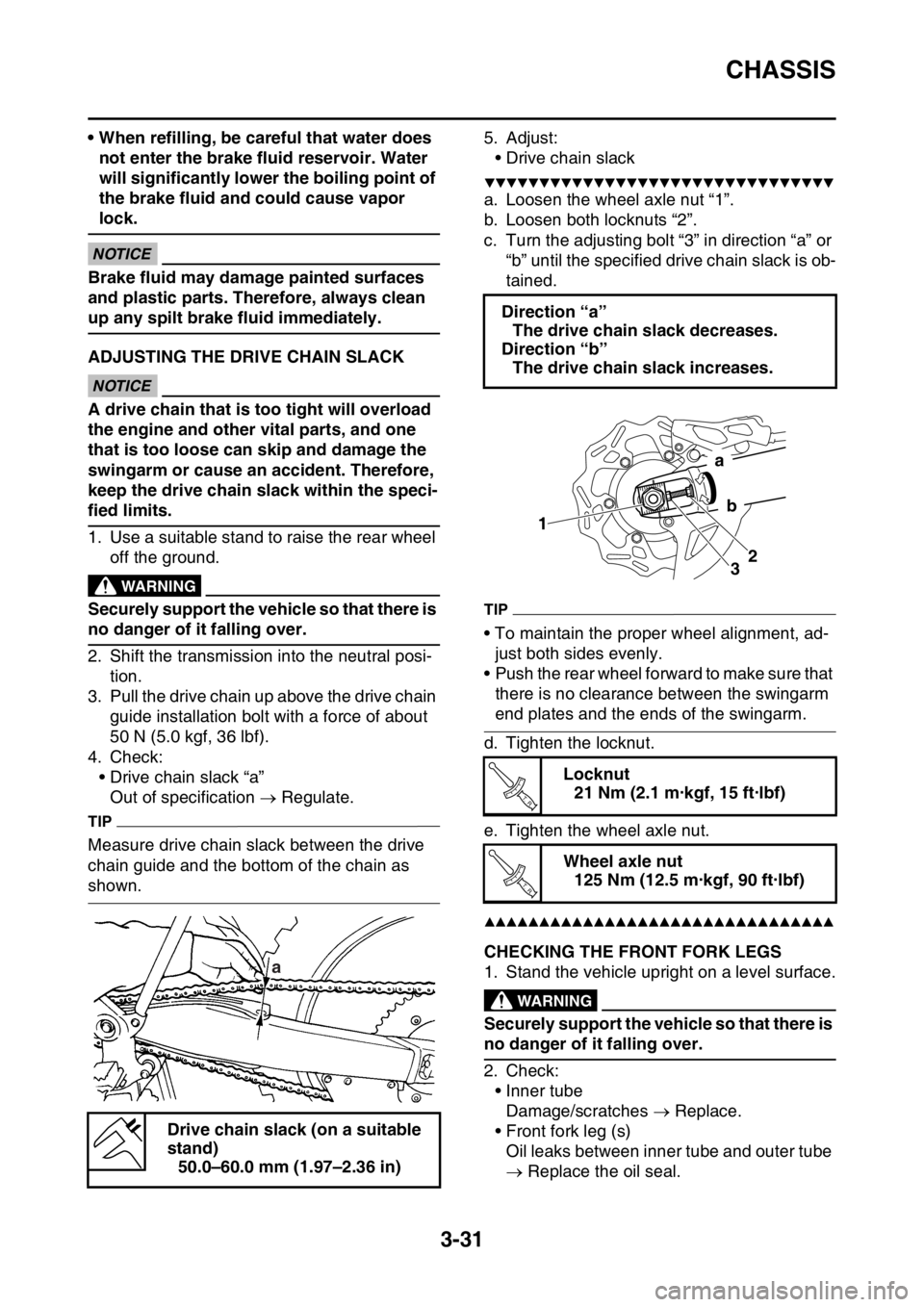

4. Check: • Drive chain slack “a”

Out of specification Regulate.

TIP

Measure drive chain slack between the drive

chain guide and the bottom of the chain as

shown. 5. Adjust:

• Drive chain slack

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the wheel axle nut “1”.

b. Loosen both locknuts “2”.

c. Turn the adjusting bolt “3” in direction “a” or “b” until the specified drive chain slack is ob-

tained.

TIP

• To maintain the proper wheel alignment, ad-just both sides evenly.

• Push the rear wheel forward to make sure that

there is no clearance between the swingarm

end plates and the ends of the swingarm.

d. Tighten the locknut.

e. Tighten the wheel axle nut.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GC1111CHECKING THE FRONT FORK LEGS

1. Stand the vehicle upright on a level surface.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Check: • Inner tubeDamage/scratches Replace.

• Front fork leg (s) Oil leaks between inner tube and outer tube

Replace the oil seal.

Drive chain slack (on a suitable

stand)

50.0–60.0 mm (1.97–2.36 in)

a

Direction “a”The drive chain slack decreases.

Direction “b” The drive chain slack increases.

Locknut21 Nm (2.1 m·kgf, 15 ft·lbf)

Wheel axle nut 125 Nm (12.5 m·kgf, 90 ft·lbf)

1

32

a

b

T R..

T R..

Page 130 of 426

CHASSIS

3-32

3. Hold the vehicle upright and apply the front brake.

4. Check:

• Front fork operationPush down hard on the handlebar several

times and check if the front fork rebounds

smoothly.

Unsmooth operation Correct or replace.

Refer to “FRONT FORK” on page 5-40.

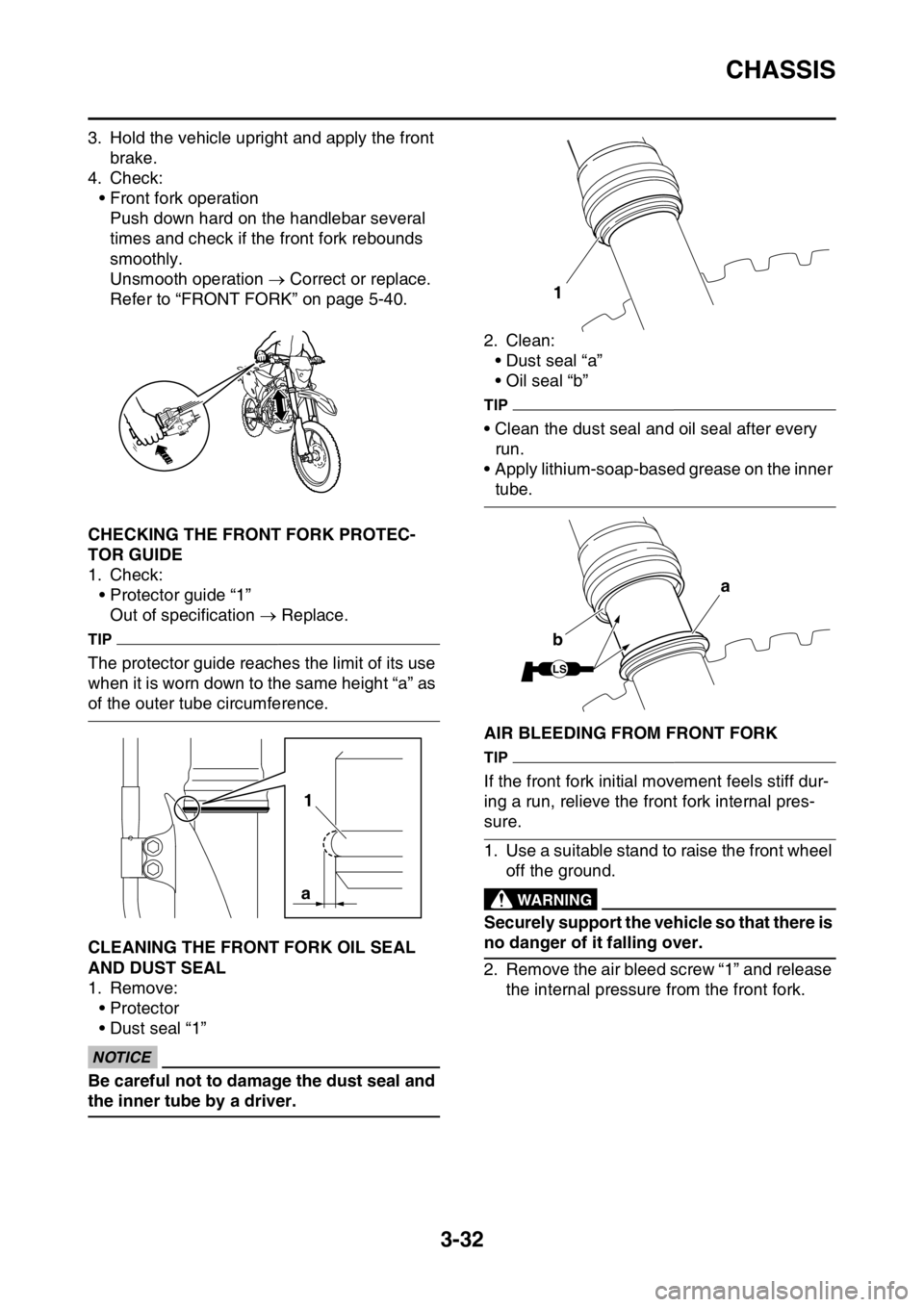

EAS2GC1112CHECKING THE FRONT FORK PROTEC-

TOR GUIDE

1. Check:

• Protector guide “1”Out of specification Replace.

TIP

The protector guide reaches the limit of its use

when it is worn down to the same height “a” as

of the outer tube circumference.

EAS2GC1113CLEANING THE FRONT FORK OIL SEAL

AND DUST SEAL

1. Remove:

•Protector

• Dust seal “1”

ECA

NOTICE

Be careful not to damage the dust seal and

the inner tube by a driver. 2. Clean:

• Dust seal “a”

• Oil seal “b”

TIP

• Clean the dust seal and oil seal after every

run.

• Apply lithium-soap-based grease on the inner

tube.

EAS2GC1114AIR BLEEDING FROM FRONT FORK

TIP

If the front fork initial movement feels stiff dur-

ing a run, relieve the front fork internal pres-

sure.

1. Use a suitable stand to raise the front wheel off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Remove the air bleed screw “1” and release the internal pressure from the front fork.

1

a

1

LS

a

b