YAMAHA WR 450F 2016 Owners Manual

Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 181 of 426

REAR BRAKE

5-29

EAS2GC1187INSTALLING THE BRAKE CALIPER PISTON

1. Clean:• Brake caliper

• Brake caliper piston seal

• Brake caliper piston dust seal

• Brake caliper pistonUse brake fluid for cleaning.

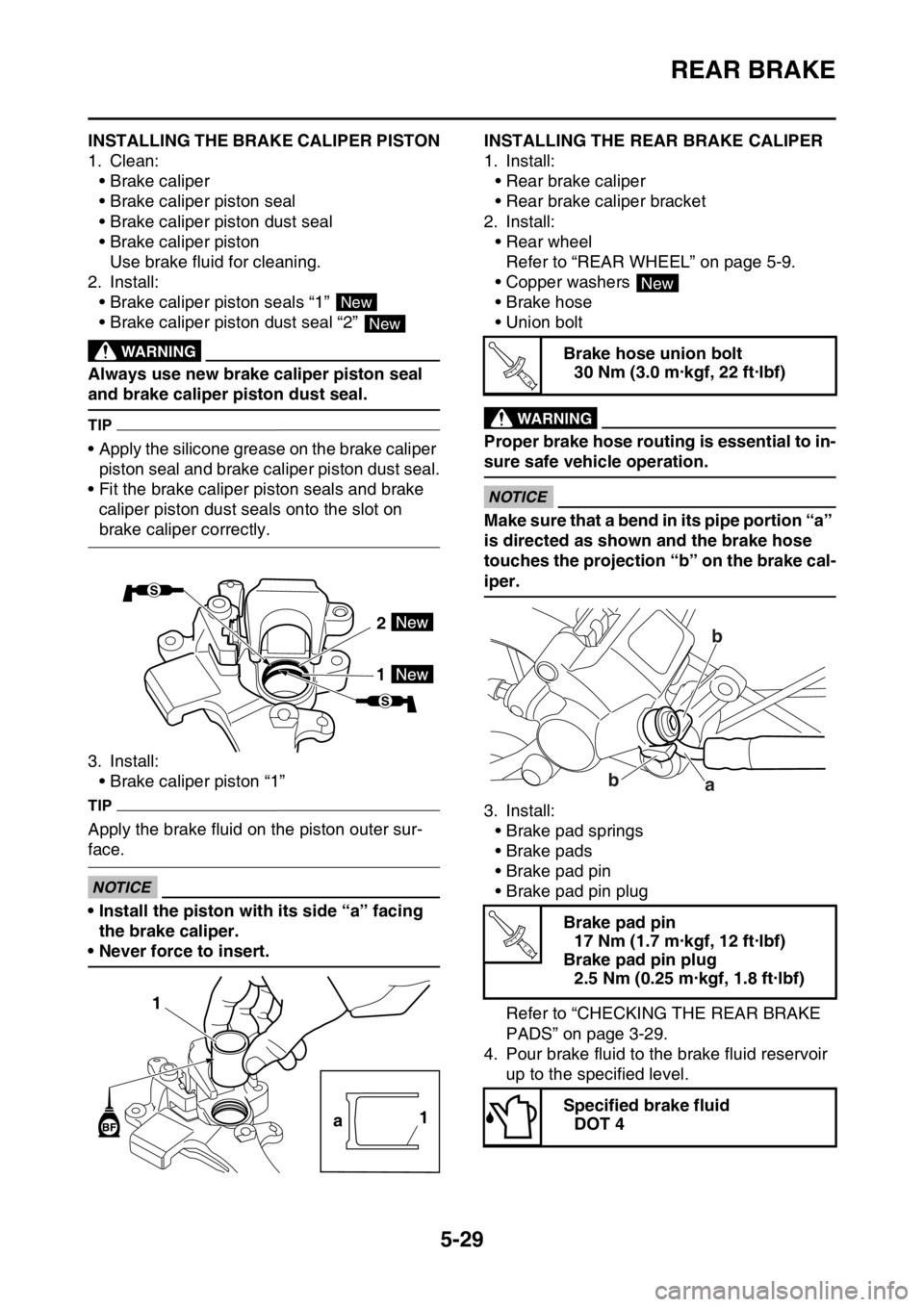

2. Install: • Brake caliper piston seals “1”

• Brake caliper piston dust seal “2”

EWA

WARNING

Always use new brake caliper piston seal

and brake caliper piston dust seal.

TIP

• Apply the silicone grease on the brake caliper

piston seal and brake caliper piston dust seal.

• Fit the brake caliper piston seals and brake caliper piston dust seals onto the slot on

brake caliper correctly.

3. Install: • Brake caliper piston “1”

TIP

Apply the brake fluid on the piston outer sur-

face.

ECA

NOTICE

• Install the piston with its side “a” facing the brake caliper.

• Never force to insert.

EAS2GC1188INSTALLING THE REAR BRAKE CALIPER

1. Install:

• Rear brake caliper

• Rear brake caliper bracket

2. Install: • Rear wheelRefer to “REAR WHEEL” on page 5-9.

• Copper washers

• Brake hose

• Union bolt

EWA

WARNING

Proper brake hose routing is essential to in-

sure safe vehicle operation.

ECA

NOTICE

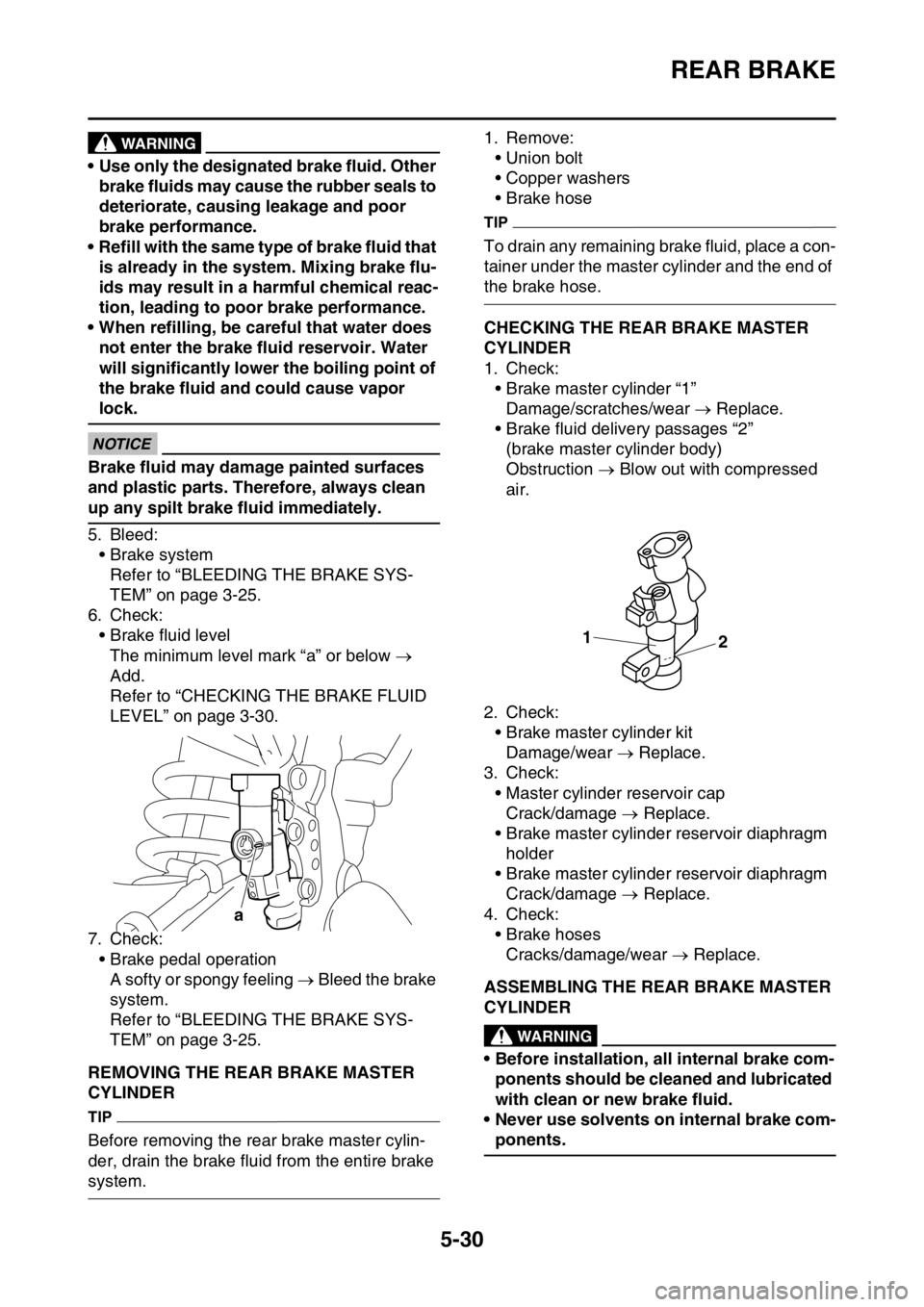

Make sure that a bend in its pipe portion “a”

is directed as shown and the brake hose

touches the projection “b” on the brake cal-

iper.

3. Install: • Brake pad springs

• Brake pads

• Brake pad pin

• Brake pad pin plug

Refer to “CHECKING THE REAR BRAKE

PADS” on page 3-29.

4. Pour brake fluid to the brake fluid reservoir up to the specified level.

EWA

New

New

2

1

1

a1

Brake hose union bolt

30 Nm (3.0 m·kgf, 22 ft·lbf)

Brake pad pin 17 Nm (1.7 m·kgf, 12 ft·lbf)

Brake pad pin plug 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Specified brake fluid DOT 4

New

T R..

b

b a

T R..

Page 182 of 426

REAR BRAKE

5-30

WARNING

• Use only the designated brake fluid. Other brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor

brake performance.

• Refill with the same type of brake fluid that is already in the system. Mixing brake flu-

ids may result in a harmful chemical reac-

tion, leading to poor brake performance.

• When refilling, be careful that water does

not enter the brake fluid reservoir. Water

will significantly lower the boiling point of

the brake fluid and could cause vapor

lock.

ECA

NOTICE

Brake fluid may damage painted surfaces

and plastic parts. Therefore, always clean

up any spilt brake fluid immediately.

5. Bleed:• Brake system

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-25.

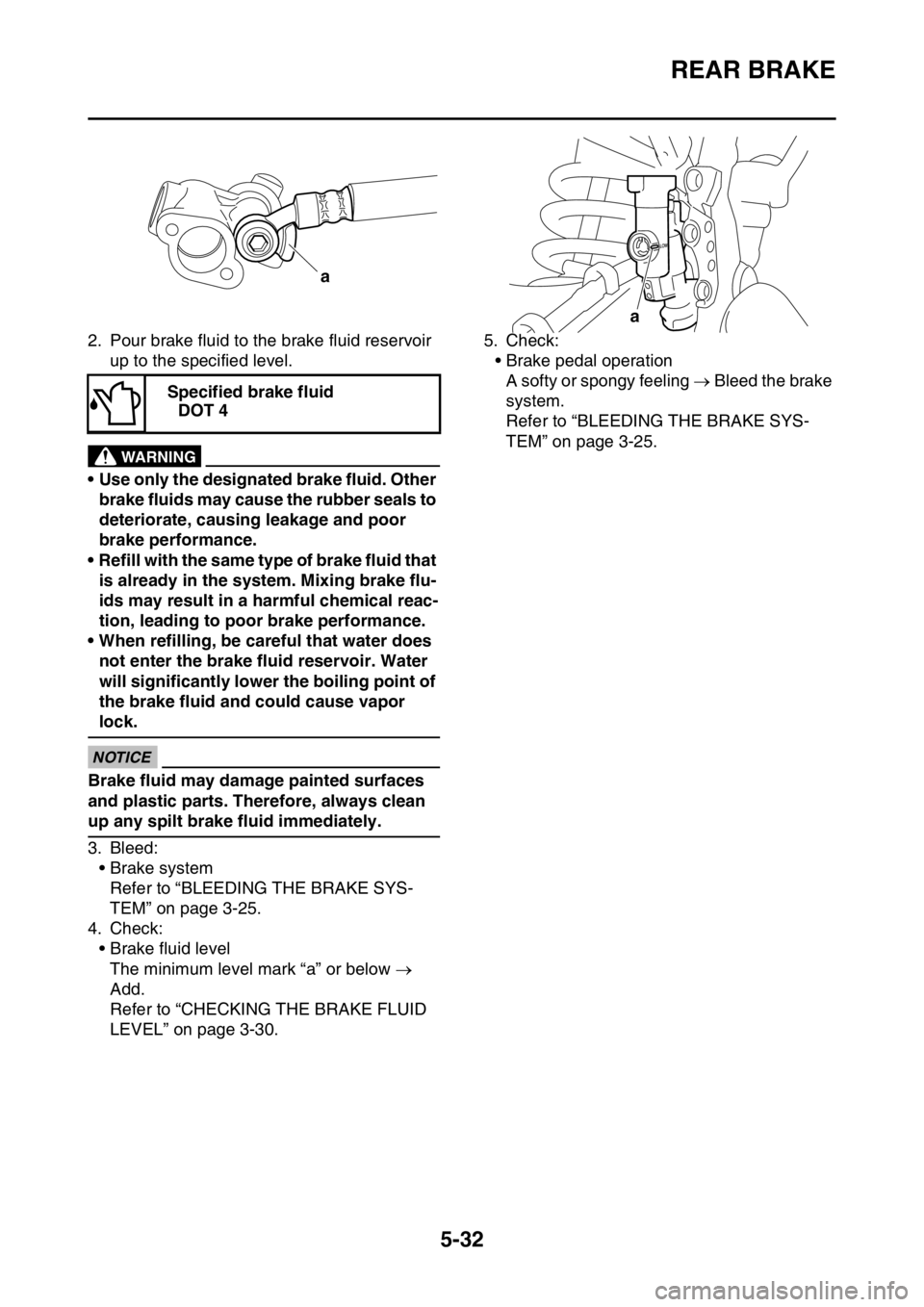

6. Check:

• Brake fluid levelThe minimum level mark “a” or below

Add.

Refer to “CHECKING THE BRAKE FLUID

LEVEL” on page 3-30.

7. Check: • Brake pedal operationA softy or spongy feeling Bleed the brake

system.

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-25.

EAS2GC1189REMOVING THE REAR BRAKE MASTER

CYLINDER

TIP

Before removing the rear brake master cylin-

der, drain the brake fluid from the entire brake

system. 1. Remove:

• Union bolt

• Copper washers

• Brake hose

TIP

To drain any remaining brake fluid, place a con-

tainer under the master cylinder and the end of

the brake hose.

EAS2GC1190CHECKING THE REAR BRAKE MASTER

CYLINDER

1. Check:• Brake master cylinder “1”

Damage/scratches/wear Replace.

• Brake fluid delivery passages “2” (brake master cylinder body)

Obstruction Blow out with compressed

air.

2. Check: • Brake master cylinder kit

Damage/wear Replace.

3. Check: • Master cylinder reservoir capCrack/damage Replace.

• Brake master cylinder reservoir diaphragm holder

• Brake master cylinder reservoir diaphragm

Crack/damage Replace.

4. Check: • Brake hoses

Cracks/damage/wear Replace.

EAS2GC1191ASSEMBLING THE REAR BRAKE MASTER

CYLINDER

EWA

WARNING

• Before installation, all internal brake com-

ponents should be cleaned and lubricated

with clean or new brake fluid.

• Never use solvents on internal brake com-

ponents.

a

1 2

Page 183 of 426

REAR BRAKE

5-31

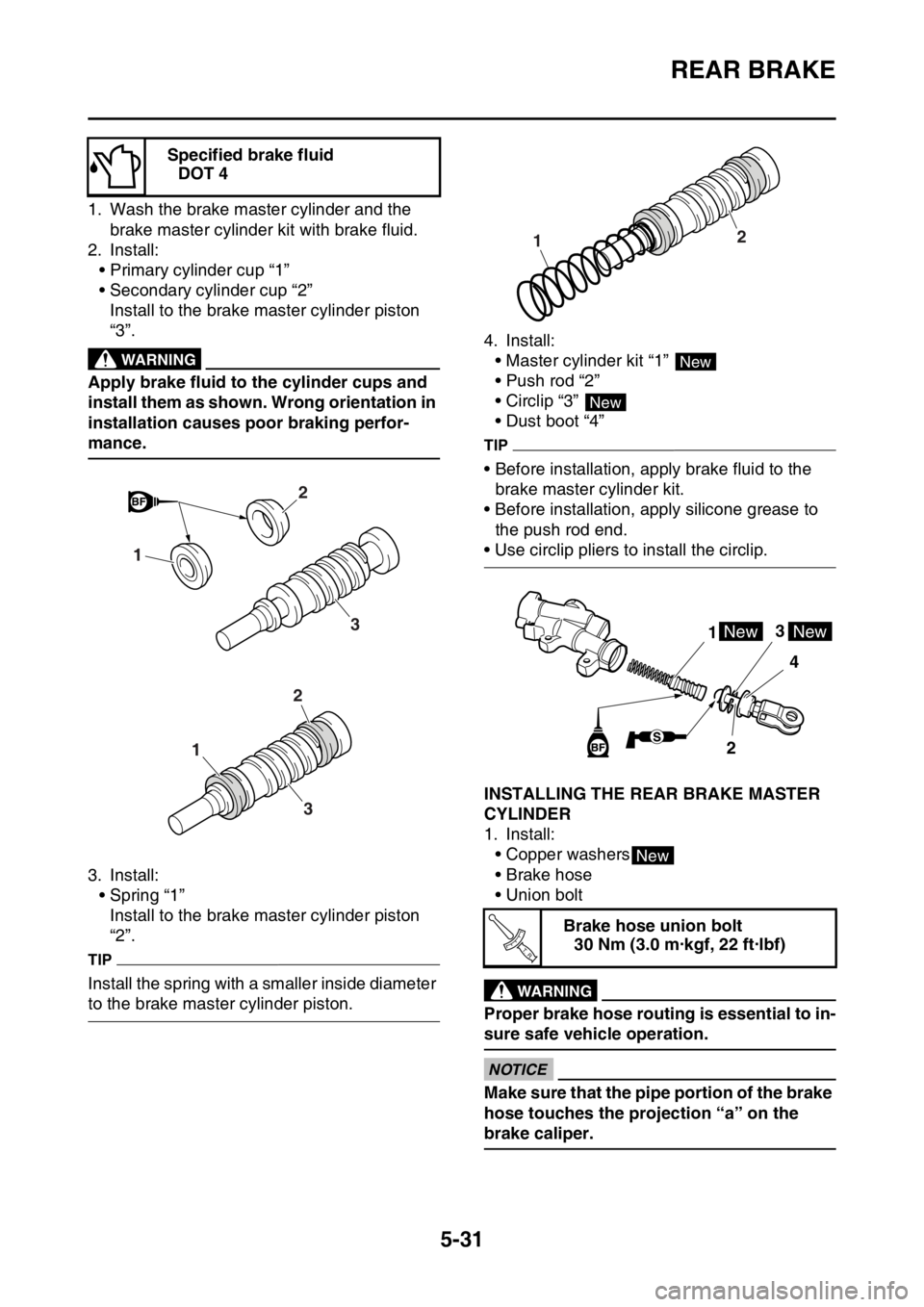

1. Wash the brake master cylinder and the brake master cylinder kit with brake fluid.

2. Install: • Primary cylinder cup “1”

• Secondary cylinder cup “2”

Install to the brake master cylinder piston

“3”.

EWA

WARNING

Apply brake fluid to the cylinder cups and

install them as shown. Wrong orientation in

installation causes poor braking perfor-

mance.

3. Install:• Spring “1”

Install to the brake master cylinder piston

“2”.

TIP

Install the spring with a smaller inside diameter

to the brake master cylinder piston. 4. Install:

• Master cylinder kit “1”

• Push rod “2”

• Circlip “3”

• Dust boot “4”

TIP

• Before installation, apply brake fluid to the brake master cylinder kit.

• Before installation, apply silicone grease to the push rod end.

• Use circlip pliers to install the circlip.

EAS2GC1192INSTALLING THE REAR BRAKE MASTER

CYLINDER

1. Install:• Copper washers

• Brake hose

• Union bolt

EWA

WARNING

Proper brake hose routing is essential to in-

sure safe vehicle operation.

ECA

NOTICE

Make sure that the pipe portion of the brake

hose touches the projection “a” on the

brake caliper.

Specified brake fluid

DOT 4

2

3

1

23

1

Brake hose union bolt 30 Nm (3.0 m·kgf, 22 ft·lbf)

12

New

New

1 3

4

2NewNew

New

T R..

Page 184 of 426

REAR BRAKE

5-32

2. Pour brake fluid to the brake fluid reservoir up to the specified level.

EWA

WARNING

• Use only the designated brake fluid. Other

brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor

brake performance.

• Refill with the same type of brake fluid that is already in the system. Mixing brake flu-

ids may result in a harmful chemical reac-

tion, leading to poor brake performance.

• When refilling, be careful that water does not enter the brake fluid reservoir. Water

will significantly lower the boiling point of

the brake fluid and could cause vapor

lock.

ECA

NOTICE

Brake fluid may damage painted surfaces

and plastic parts. Therefore, always clean

up any spilt brake fluid immediately.

3. Bleed:

• Brake systemRefer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-25.

4. Check: • Brake fluid level

The minimum level mark “a” or below

Add.

Refer to “CHECKING THE BRAKE FLUID

LEVEL” on page 3-30. 5. Check:

• Brake pedal operation

A softy or spongy feeling Bleed the brake

system.

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-25.

Specified brake fluid

DOT 4

a

a

Page 185 of 426

HANDLEBAR

5-33

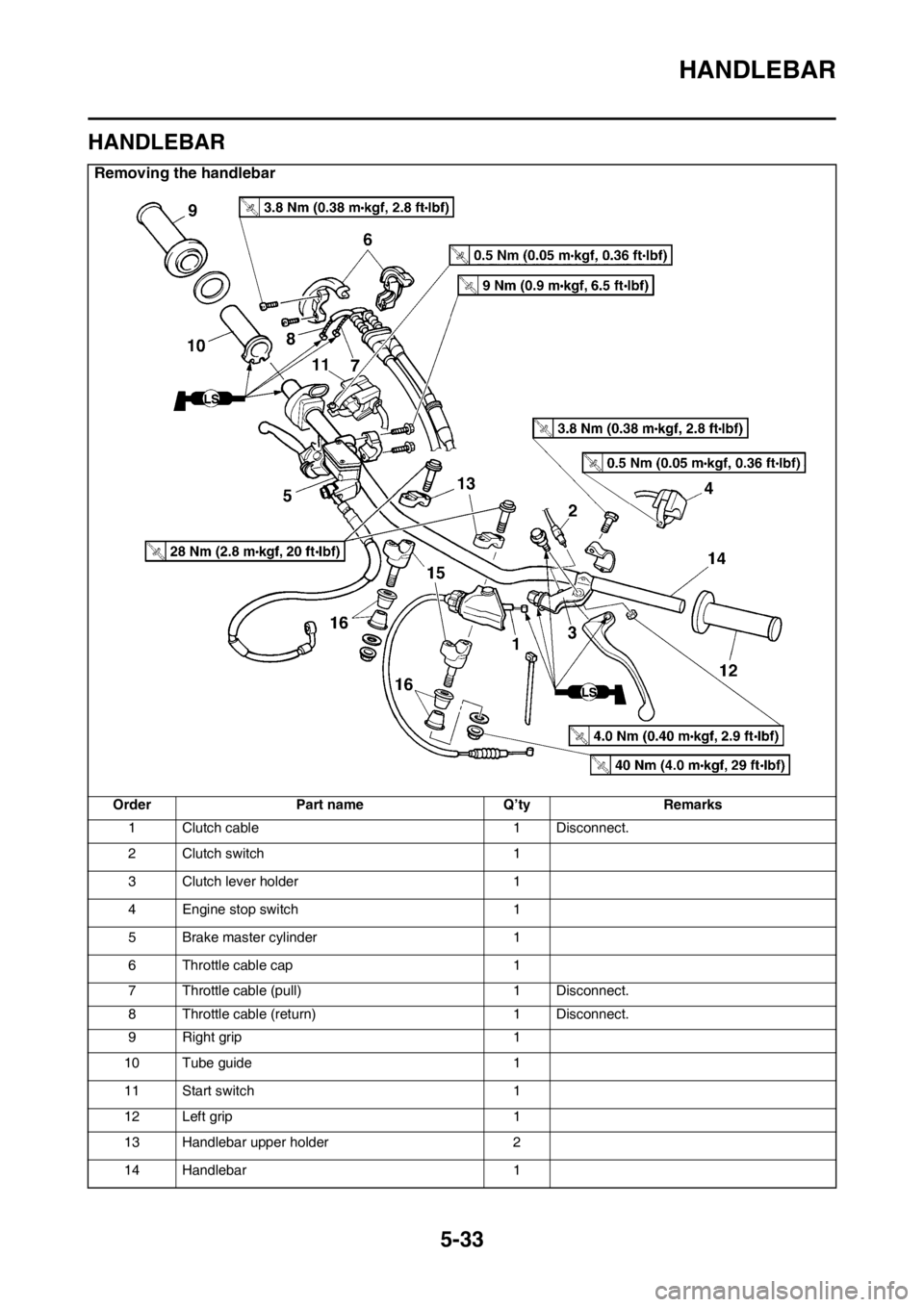

EAS2GC1193

HANDLEBAR

Removing the handlebar

OrderPart name Q’tyRemarks

1 Clutch cable 1 Disconnect.

2 Clutch switch 1

3 Clutch lever holder 1

4 Engine stop switch 1

5 Brake master cylinder 1

6 Throttle cable cap 1

7 Throttle cable (pull) 1 Disconnect.

8 Throttle cable (return) 1 Disconnect.

9 Right grip 1

10 Tube guide 1

11 Start switch 1

12 Left grip 1

13 Handlebar upper holder 2

14 Handlebar 1

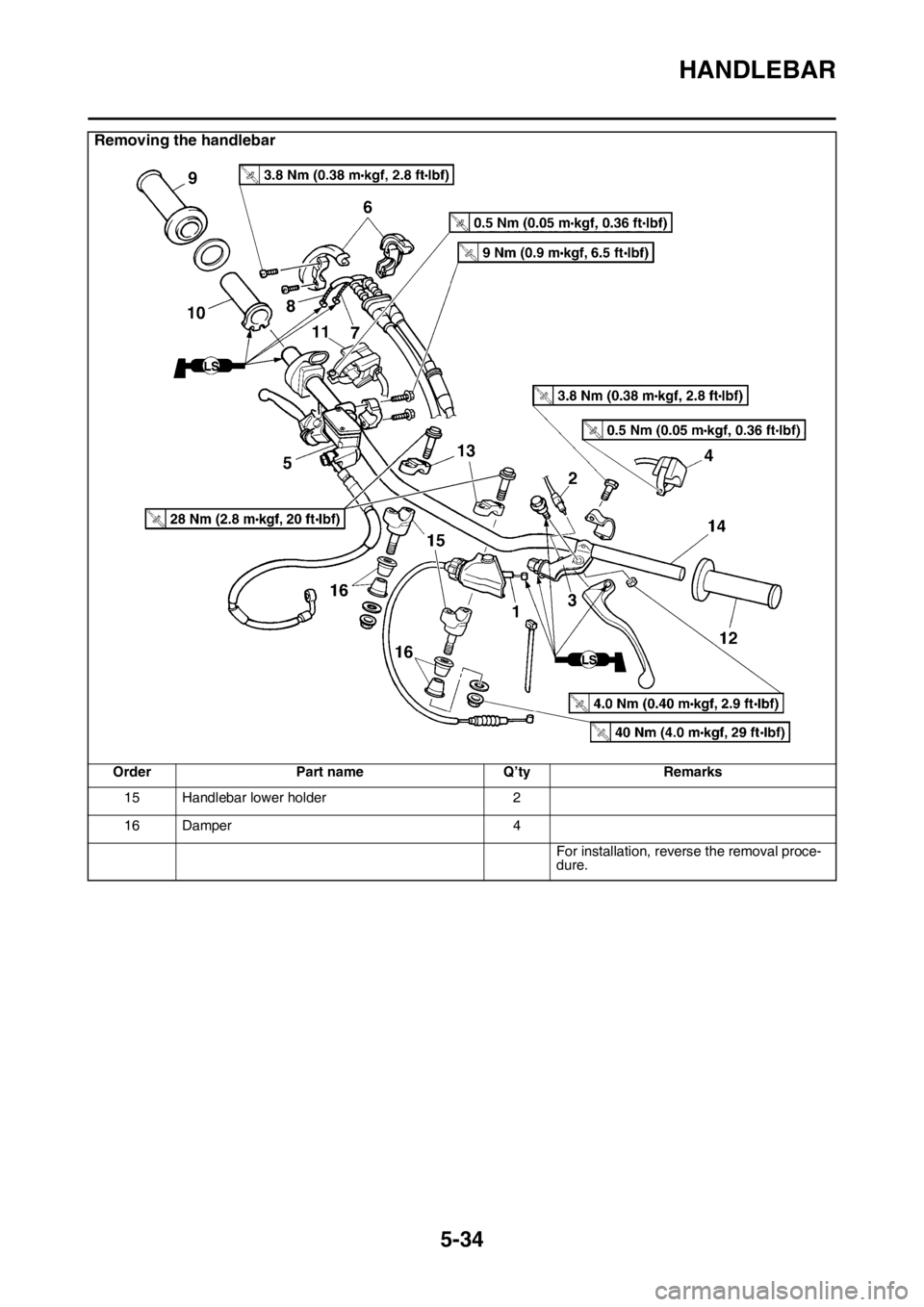

Page 186 of 426

HANDLEBAR

5-34

15 Handlebar lower holder2

16 Damper 4

For installation, reverse the removal proce-

dure.

Removing the handlebar

Order Part name Q’tyRemarks

Page 187 of 426

HANDLEBAR

5-35

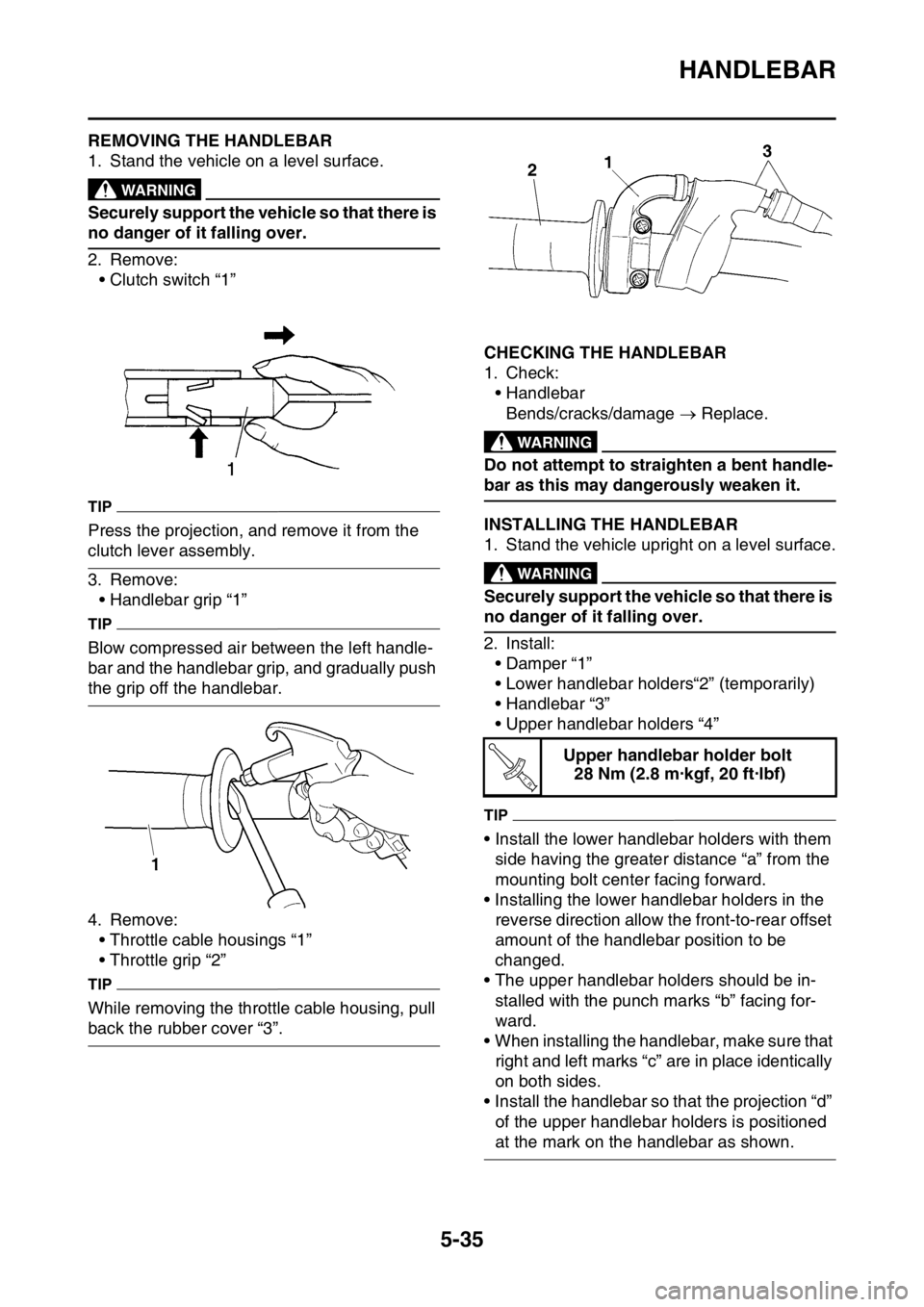

EAS2GC1194REMOVING THE HANDLEBAR

1. Stand the vehicle on a level surface.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Remove:•Clutch switch “1”

TIP

Press the projection, and remove it from the

clutch lever assembly.

3. Remove:• Handlebar grip “1”

TIP

Blow compressed air between the left handle-

bar and the handlebar grip, and gradually push

the grip off the handlebar.

4. Remove:

• Throttle cable housings “1”

• Throttle grip “2”

TIP

While removing the throttle cable housing, pull

back the rubber cover “3”.

EAS2GC1195CHECKING THE HANDLEBAR

1. Check:• Handlebar

Bends/cracks/damage Replace.

EWA

WARNING

Do not attempt to straighten a bent handle-

bar as this may dangerously weaken it.

EAS2GC1196INSTALLING THE HANDLEBAR

1. Stand the vehicle upright on a level surface.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Install:

• Damper “1”

• Lower handlebar holders“2” (temporarily)

• Handlebar “3”

• Upper handlebar holders “4”

TIP

• Install the lower handl ebar holders with them

side having the greater distance “a” from the

mounting bolt center facing forward.

• Installing the lower handlebar holders in the

reverse direction allow the front-to-rear offset

amount of the handlebar position to be

changed.

• The upper handlebar holders should be in- stalled with the punch marks “b” facing for-

ward.

• When installing the handlebar, make sure that right and left marks “c” are in place identically

on both sides.

• Install the handlebar so that the projection “d” of the upper handlebar holders is positioned

at the mark on the handlebar as shown.

ECA

Upper handlebar holder bolt28 Nm (2.8 m·kgf, 20 ft·lbf)

T R..

Page 188 of 426

HANDLEBAR

5-36

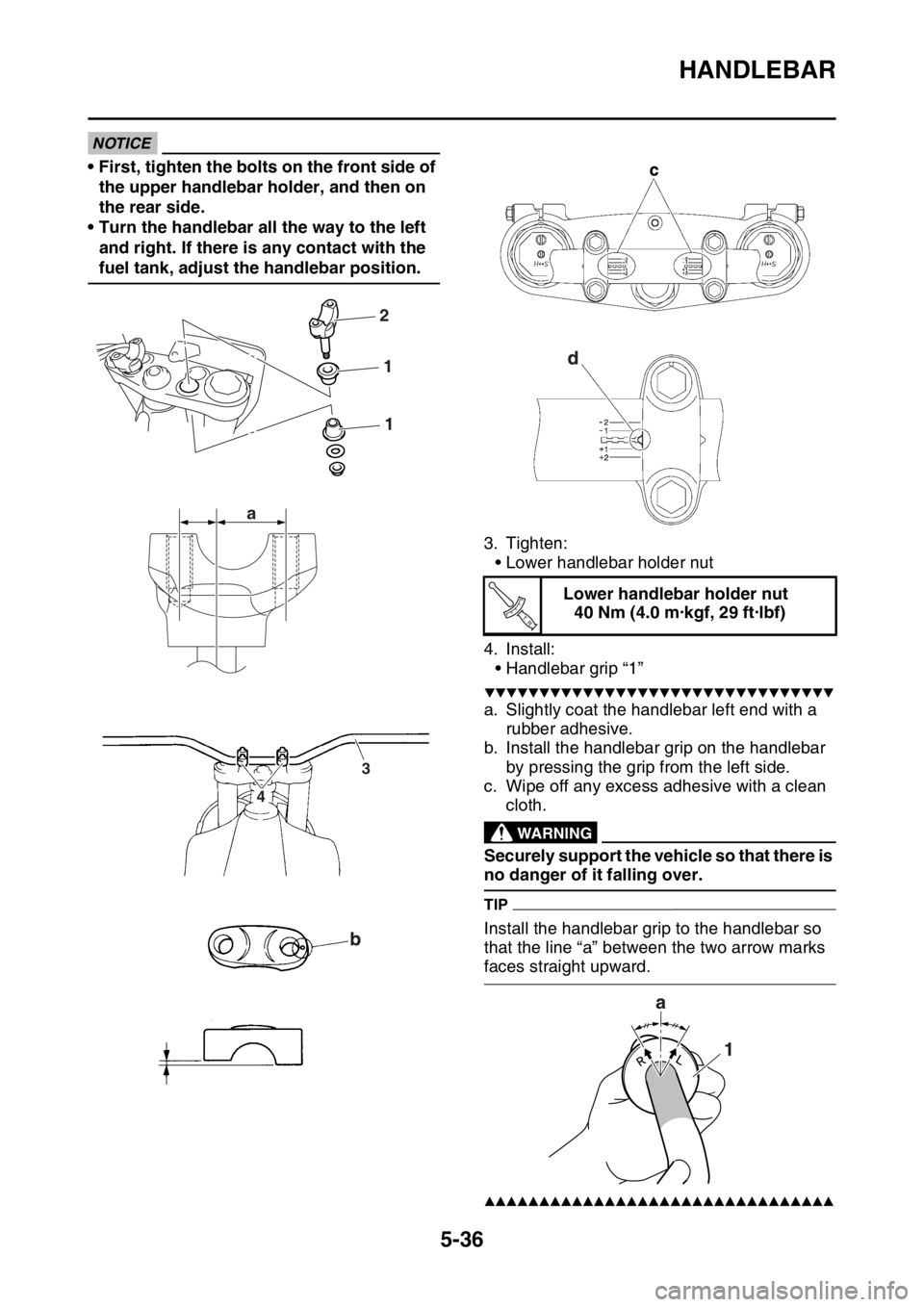

NOTICE

• First, tighten the bolts on the front side of the upper handlebar holder, and then on

the rear side.

• Turn the handlebar all the way to the left and right. If there is any contact with the

fuel tank, adjust the handlebar position.

3. Tighten:• Lower handlebar holder nut

4. Install: • Handlebar grip “1”

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Slightly coat the handlebar left end with a rubber adhesive.

b. Install the handlebar grip on the handlebar by pressing the grip from the left side.

c. Wipe off any excess adhesive with a clean cloth.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

TIP

Install the handlebar grip to the handlebar so

that the line “a” between the two arrow marks

faces straight upward.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

2

1

1

a

3

4

Lower handlebar holder nut40 Nm (4.0 m·kgf, 29 ft·lbf)

T R..

Page 189 of 426

HANDLEBAR

5-37

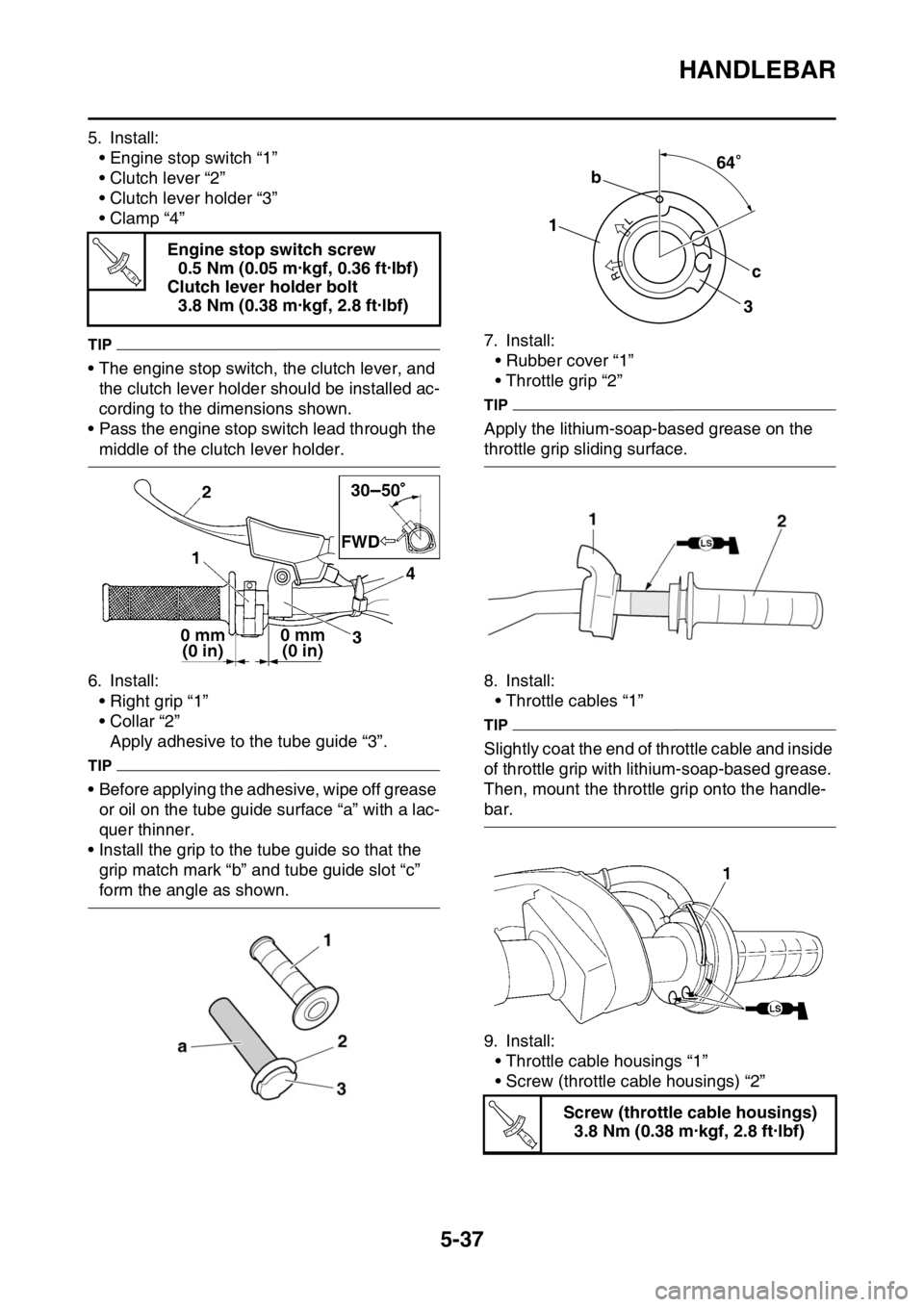

5. Install:• Engine stop switch “1”

• Clutch lever “2”

• Clutch lever holder “3”

•Clamp “4”

TIP

• The engine stop switch, the clutch lever, and the clutch lever holder should be installed ac-

cording to the dimensions shown.

• Pass the engine stop switch lead through the

middle of the clutch lever holder.

6. Install: • Right grip “1”

• Collar “2”Apply adhesive to the tube guide “3”.

TIP

• Before applying the adhesive, wipe off grease or oil on the tube guide surface “a” with a lac-

quer thinner.

• Install the grip to the tube guide so that the grip match mark “b” and tube guide slot “c”

form the angle as shown. 7. Install:

• Rubber cover “1”

• Throttle grip “2”

TIP

Apply the lithium-soap-based grease on the

throttle grip sliding surface.

8. Install:• Throttle cables “1”

TIP

Slightly coat the end of throttle cable and inside

of throttle grip with lithium-soap-based grease.

Then, mount the throttle grip onto the handle-

bar.

9. Install:

• Throttle cable housings “1”

• Screw (throttle cable housings) “2”

EWA

Engine stop switch screw0.5 Nm (0.05 m·kgf, 0.36 ft·lbf)

Clutch lever holder bolt 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

T R..

Screw (throttle cable housings)3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

64

1 b

c

3

64

T R..

Page 190 of 426

HANDLEBAR

5-38

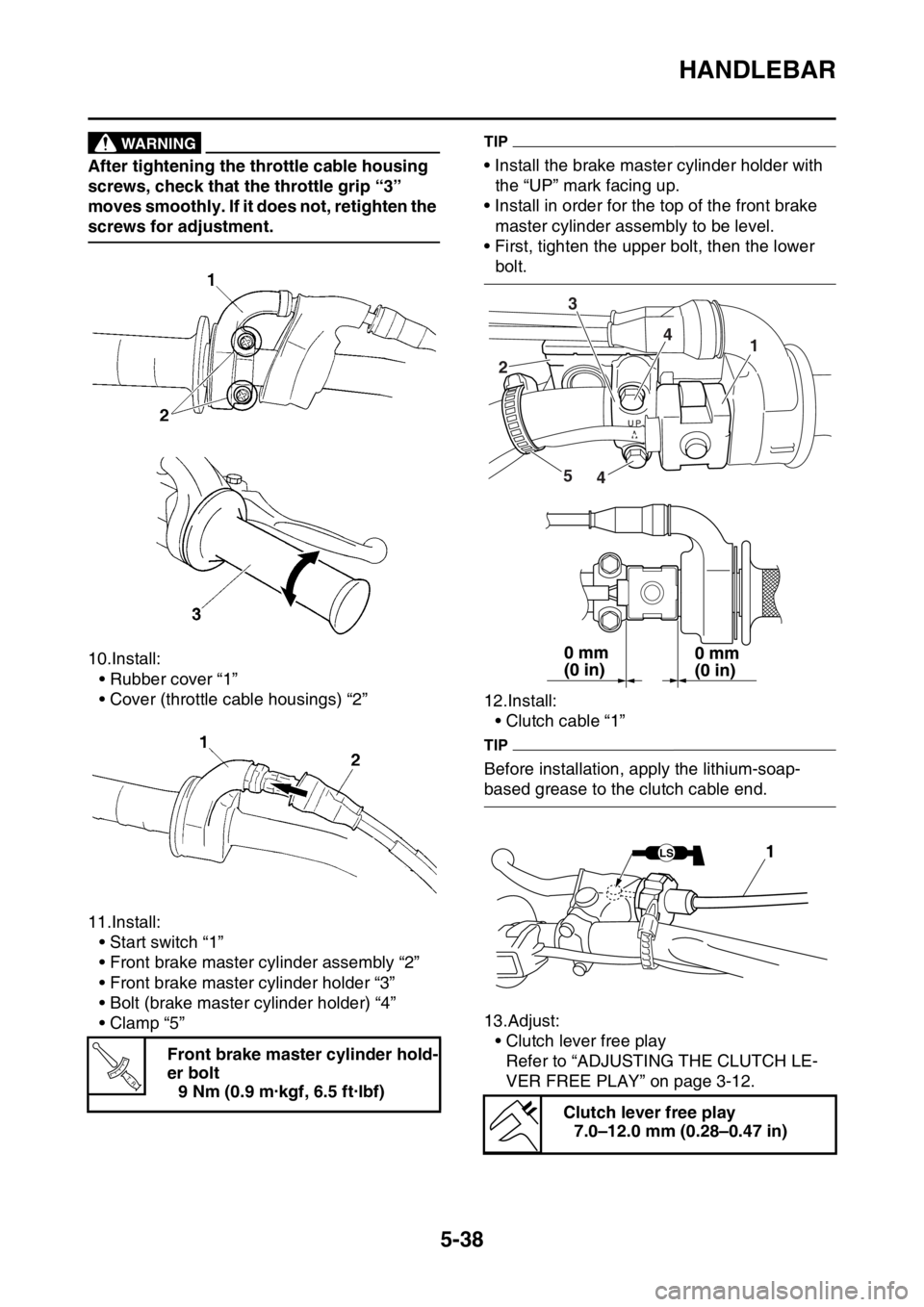

WARNING

After tightening the throttle cable housing

screws, check that the throttle grip “3”

moves smoothly. If it does not, retighten the

screws for adjustment.

10.Install:• Rubber cover “1”

• Cover (throttle cable housings) “2”

11.Install: • Start switch “1”

• Front brake master cylinder assembly “2”

• Front brake master cylinder holder “3”

• Bolt (brake master cylinder holder) “4”

•Clamp “5”

TIP

• Install the brake master cylinder holder with the “UP” mark facing up.

• Install in order for the top of the front brake master cylinder assembly to be level.

• First, tighten the upper bolt, then the lower

bolt.

12.Install: • Clutch cable “1”

TIP

Before installation, apply the lithium-soap-

based grease to the clutch cable end.

13.Adjust:• Clutch lever free play

Refer to “ADJUSTING THE CLUTCH LE-

VER FREE PLAY” on page 3-12.

Front brake master cylinder hold-

er bolt

9 Nm (0.9 m·kgf, 6.5 ft·lbf)

T R..

Clutch lever free play 7.0–12.0 mm (0.28–0.47 in)

2

5

1

4

3

4

1LS