YAMAHA WR 450F 2016 Owners Manual

Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 201 of 426

FRONT FORK

5-49

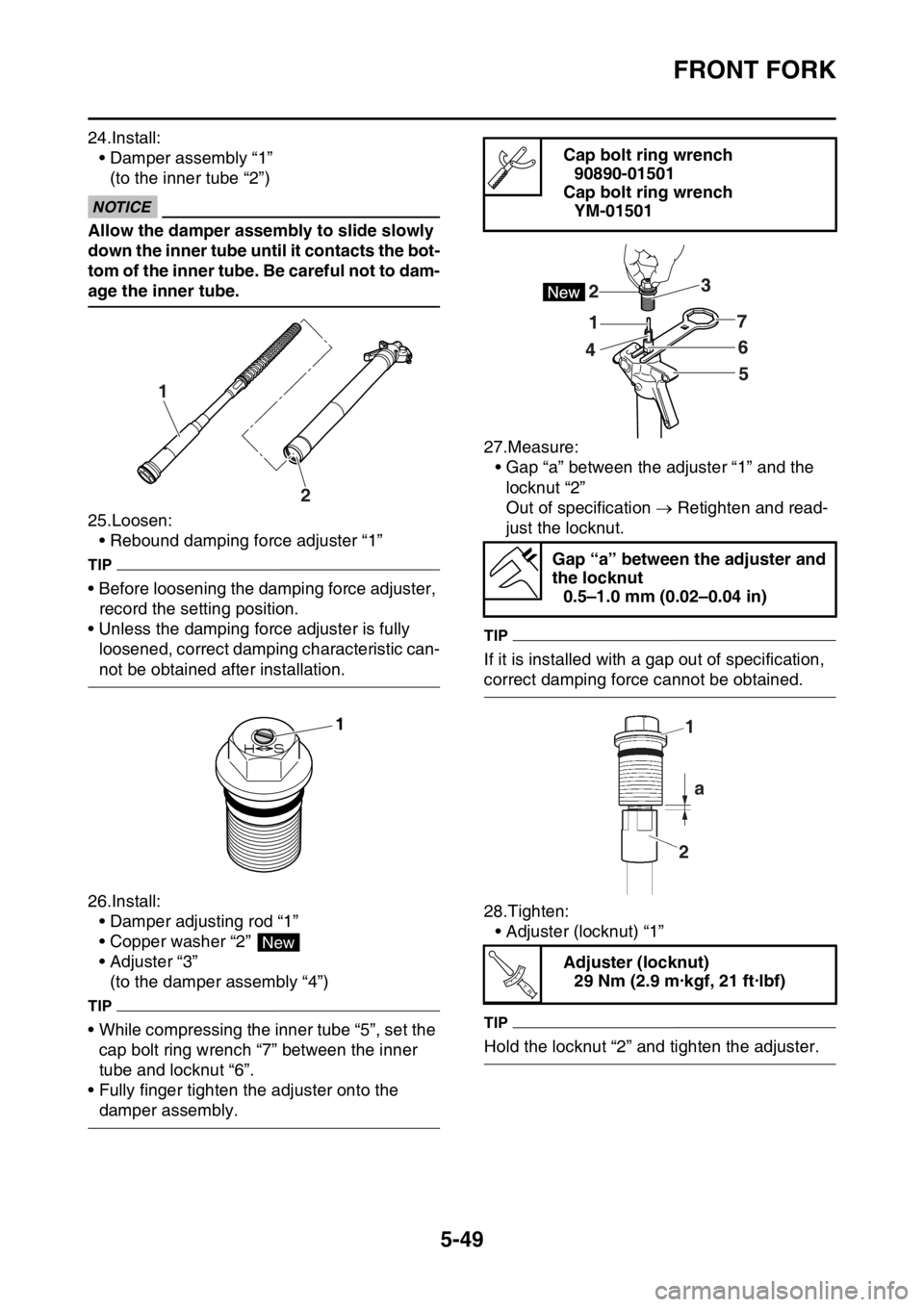

24.Install:• Damper assembly “1”(to the inner tube “2”)

ECA

NOTICE

Allow the damper assembly to slide slowly

down the inner tube until it contacts the bot-

tom of the inner tube. Be careful not to dam-

age the inner tube.

25.Loosen:

• Rebound damping force adjuster “1”

TIP

• Before loosening the damping force adjuster, record the setting position.

• Unless the damping force adjuster is fully loosened, correct damping characteristic can-

not be obtained after installation.

26.Install: • Damper adjusting rod “1”

• Copper washer “2”

• Adjuster “3”(to the damper assembly “4”)

TIP

• While compressing the inner tube “5”, set the cap bolt ring wrench “7” between the inner

tube and locknut “6”.

• Fully finger tighten the adjuster onto the

damper assembly. 27.Measure:

• Gap “a” between the adjuster “1” and the

locknut “2”

Out of specification Retighten and read-

just the locknut.

TIP

If it is installed with a gap out of specification,

correct damping force cannot be obtained.

28.Tighten:

• Adjuster (locknut) “1”

TIP

Hold the locknut “2” and tighten the adjuster.

1

2

1

New

Cap bolt ring wrench90890-01501

Cap bolt ring wrench YM-01501

Gap “a” between the adjuster and

the locknut 0.5–1.0 mm (0.02–0.04 in)

Adjuster (locknut) 29 Nm (2.9 m·kgf, 21 ft·lbf)

1

2 a

T R..

Page 202 of 426

FRONT FORK

5-50

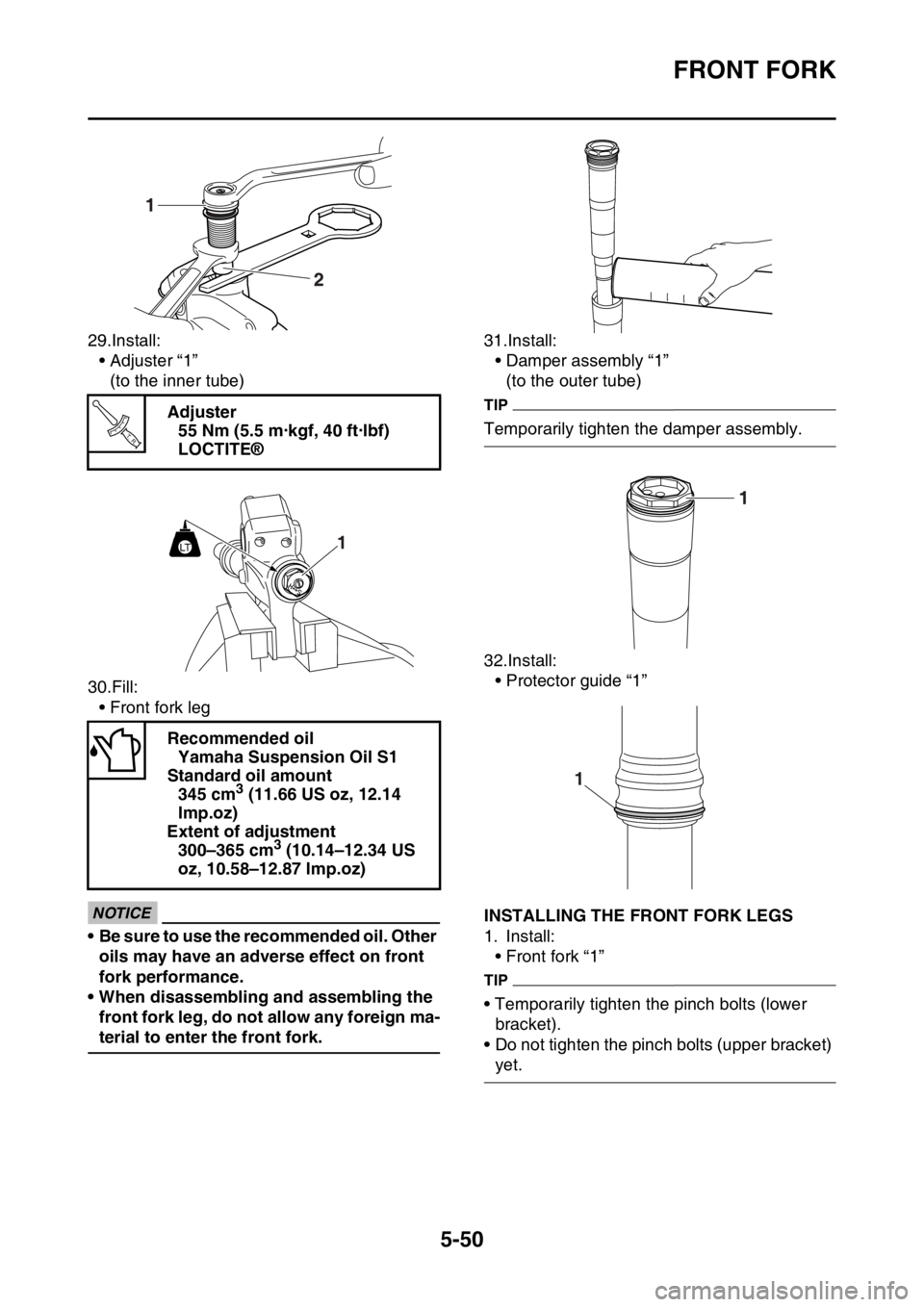

29.Install:• Adjuster “1”

(to the inner tube)

30.Fill: • Front fork leg

ECA

NOTICE

• Be sure to use the recommended oil. Other oils may have an adverse effect on front

fork performance.

• When disassembling and assembling the front fork leg, do not allow any foreign ma-

terial to enter the front fork. 31.Install:

• Damper assembly “1”

(to the outer tube)

TIP

Temporarily tighten the damper assembly.

32.Install:• Protector guide “1”

EAS2GC1202INSTALLING THE FRONT FORK LEGS

1. Install:• Front fork “1”

TIP

• Temporarily tighten the pinch bolts (lower bracket).

• Do not tighten the pinch bolts (upper bracket)

yet.

Adjuster

55 Nm (5.5 m·kgf, 40 ft·lbf)

LOCTITE®

Recommended oil Yamaha Suspension Oil S1

Standard oil amount 345 cm

3 (11.66 US oz, 12.14

lmp.oz)

Extent of adjustment 300–365 cm

3 (10.14–12.34 US

oz, 10.58–12.87 lmp.oz)

T R..

1LT

1

Page 203 of 426

FRONT FORK

5-51

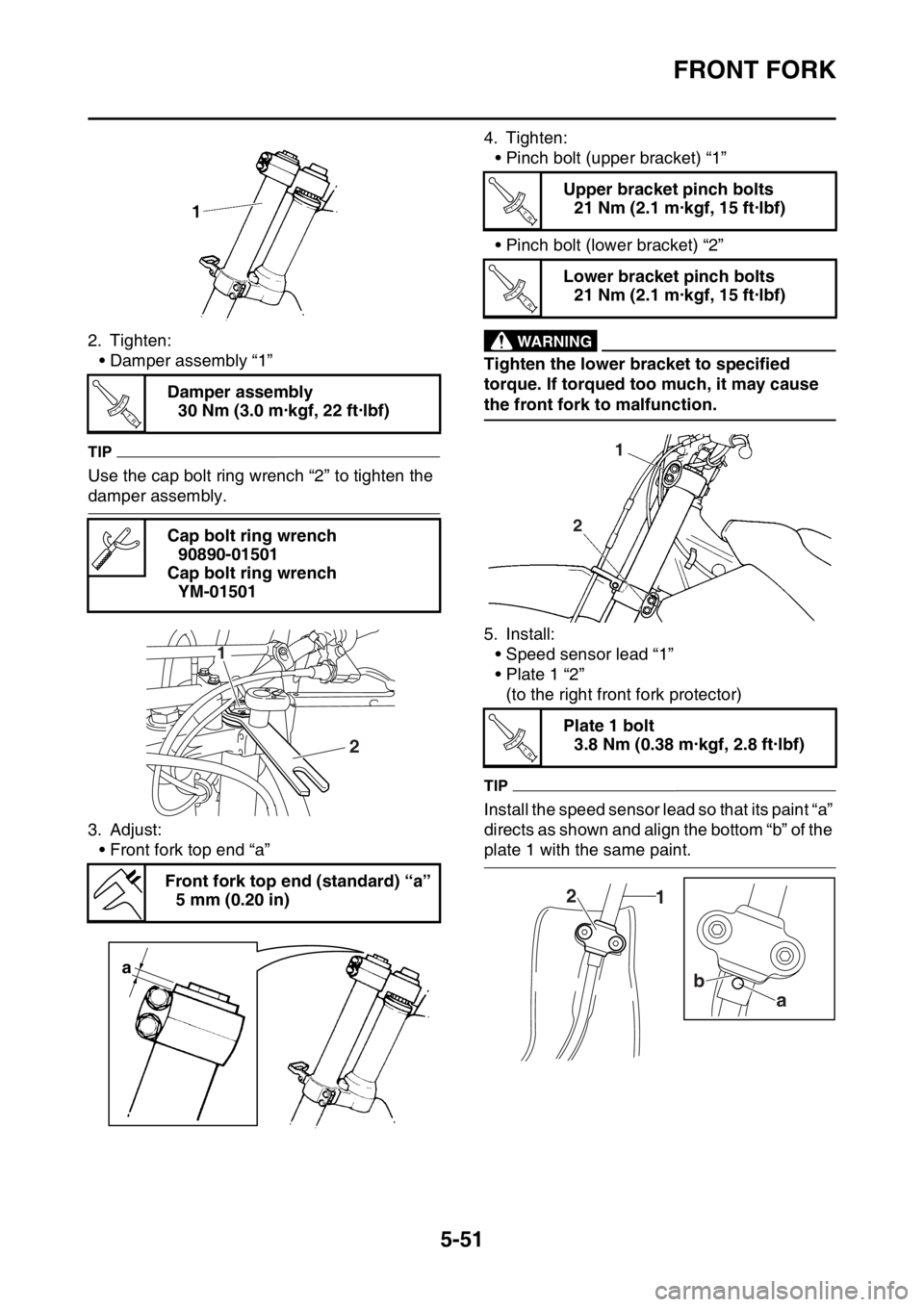

2. Tighten:• Damper assembly “1”

TIP

Use the cap bolt ring wrench “2” to tighten the

damper assembly.

3. Adjust:

• Front fork top end “a” 4. Tighten:

• Pinch bolt (upper bracket) “1”

• Pinch bolt (lower bracket) “2”

EWA

WARNING

Tighten the lower bracket to specified

torque. If torqued too much, it may cause

the front fork to malfunction.

5. Install:• Speed sensor lead “1”

• Plate 1 “2”(to the right front fork protector)

TIP

Install the speed sensor lead so that its paint “a”

directs as shown and align the bottom “b” of the

plate 1 with the same paint.

Damper assembly

30 Nm (3.0 m·kgf, 22 ft·lbf)

Cap bolt ring wrench 90890-01501

Cap bolt ring wrench YM-01501

Front fork top end (standard) “a” 5 mm (0.20 in)

T R..

2

1

a

Upper bracket pinch bolts21 Nm (2.1 m·kgf, 15 ft·lbf)

Lower bracket pinch bolts 21 Nm (2.1 m·kgf, 15 ft·lbf)

Plate 1 bolt 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

T R..

T R..

2 1

T R..

1

2

a

b

Page 204 of 426

FRONT FORK

5-52

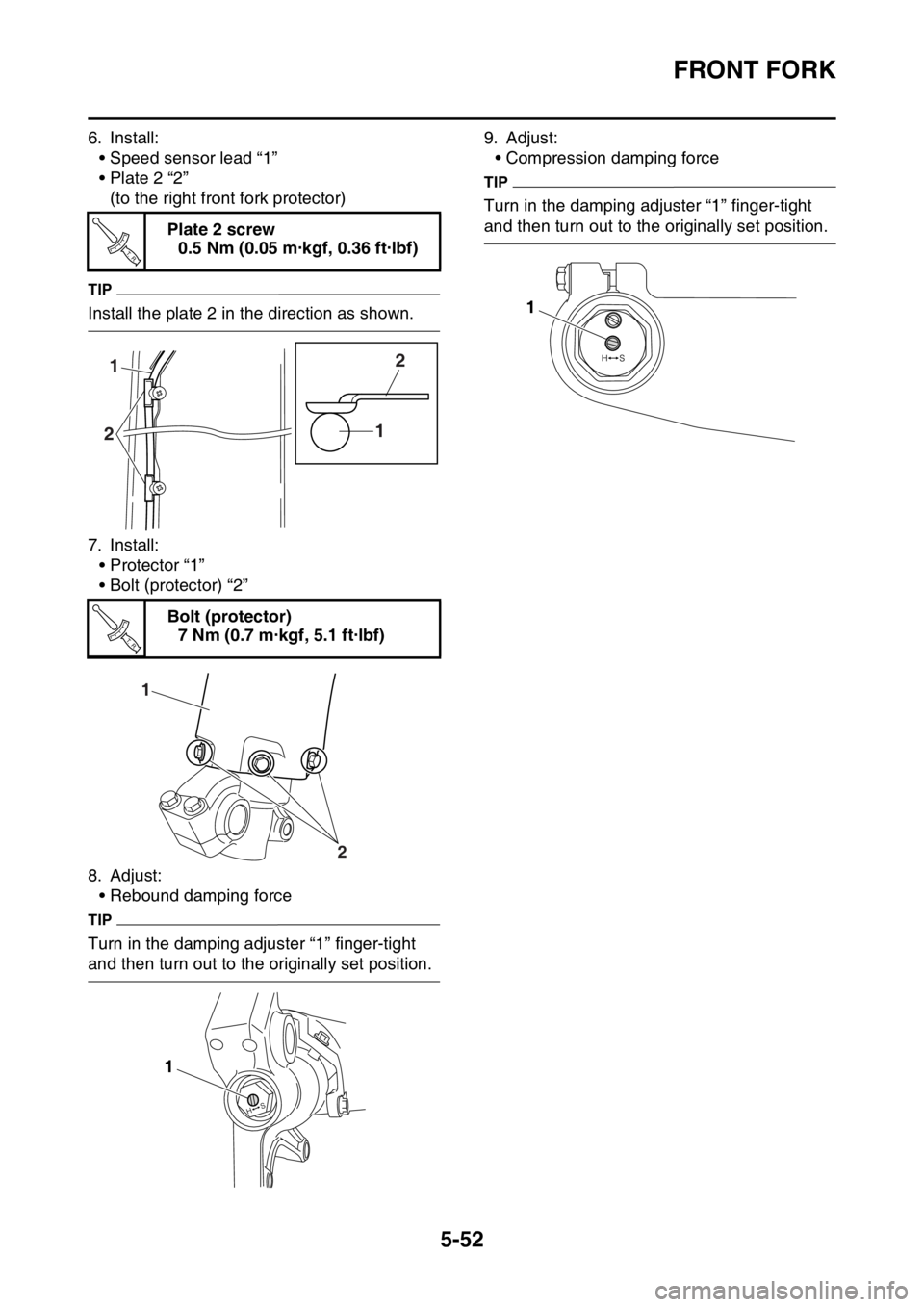

6. Install:• Speed sensor lead “1”

• Plate 2 “2”(to the right front fork protector)

TIP

Install the plate 2 in the direction as shown.

7. Install:• Protector “1”

• Bolt (protector) “2”

8. Adjust: • Rebound damping force

TIP

Turn in the damping adjuster “1” finger-tight

and then turn out to the originally set position. 9. Adjust:

• Compression damping force

TIP

Turn in the damping adjuster “1” finger-tight

and then turn out to the originally set position.

Plate 2 screw

0.5 Nm (0.05 m·kgf, 0.36 ft·lbf)

Bolt (protector) 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

T R..

1

2 12

T R..

1

2

1

1

Page 205 of 426

STEERING HEAD

5-53

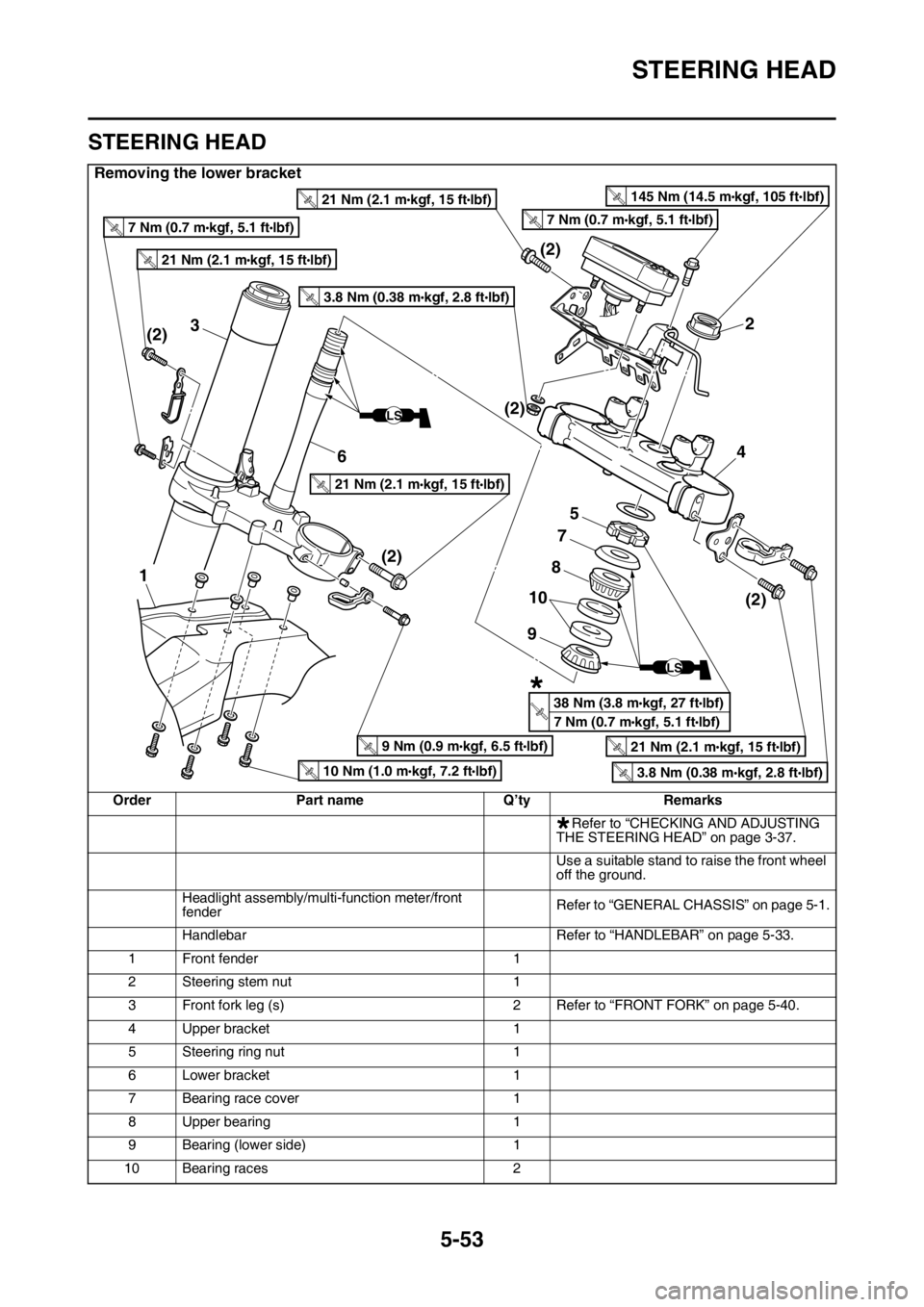

EAS2GC1203

STEERING HEAD

Removing the lower bracket

OrderPart name Q’tyRemarks

Refer to “CHECKING AND ADJUSTING

THE STEERING HEAD” on page 3-37.

Use a suitable stand to raise the front wheel

off the ground.

Headlight assembly/multi -function meter/front

fender Refer to “GENERAL

CHASSIS” on page 5-1.

Handlebar Refer to “HANDLEBAR” on page 5-33.

1 Front fender 1

2 Steering stem nut 1

3 Front fork leg (s) 2 Refer to “FRONT FORK” on page 5-40.

4 Upper bracket 1

5 Steering ring nut 1

6 Lower bracket 1

7 Bearing race cover 1

8 Upper bearing 1

9 Bearing (lower side) 1

10 Bearing races 2

2

4

5

7

3

(2) (2)

(2)

(2)

(2)

1

6

8

9

10

LS

LS

T

.R.21 Nm (2.1 mlbf)

kgf, 15 ft

T

.R.21 Nm (2.1 mlbf)

kgf, 15 ft

T

.R.21 Nm (2.1 mlbf)

kgf, 15 ft

T

.R.21 Nm (2.1 mlbf)

kgf, 15 ft

T

.R.3.8 Nm (0.38 mlbf)

kgf, 2.8 ft

T

.R.3.8 Nm (0.38 mlbf)

kgf, 2.8 ft

T

.R.9 Nm (0.9 mlbf)

kgf, 6.5 ft

T

.R.7 Nm (0.7 mlbf)

kgf, 5.1 ftT

.R.7 Nm (0.7 mlbf)

kgf, 5.1 ft

T

.R.10 Nm (1.0 mlbf)

kgf, 7.2 ft

T

.R.145 Nm (14.5 mlbf)

kgf, 105 ft

T

.R.38 Nm (3.8 mlbf)

kgf, 27 ft

7 Nm (0.7 m

lbf)

kgf, 5.1 ft

*

*

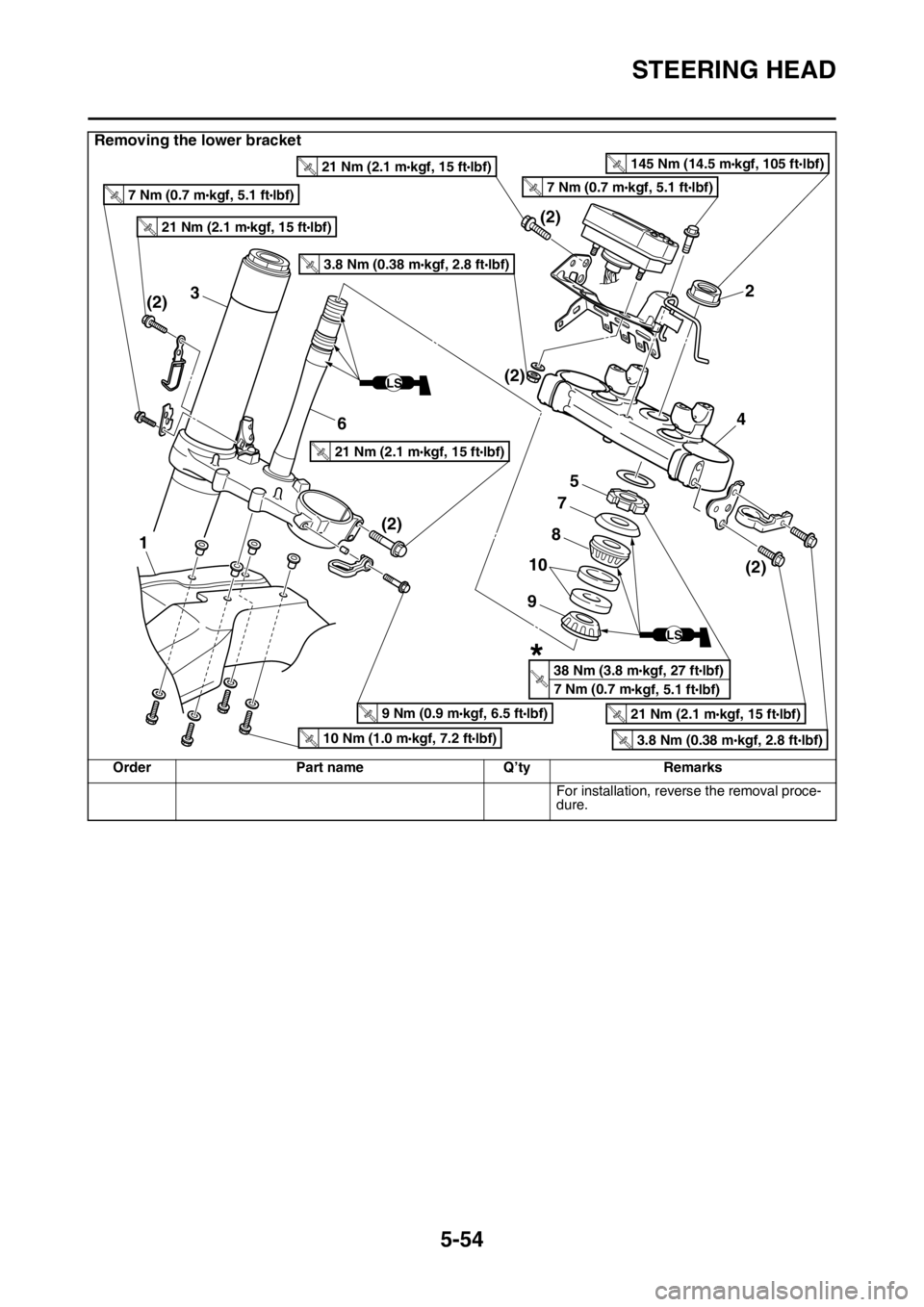

Page 206 of 426

STEERING HEAD

5-54

For installation, reverse the removal proce-

dure.

Removing the lower bracket

OrderPart name Q’tyRemarks

2

4

5

7

3

(2) (2)

(2)

(2)

(2)

1

6

8

9

10

LS

LS

T

.R.21 Nm (2.1 mlbf)

kgf, 15 ft

T

.R.21 Nm (2.1 mlbf)

kgf, 15 ft

T

.R.21 Nm (2.1 mlbf)

kgf, 15 ft

T

.R.21 Nm (2.1 mlbf)

kgf, 15 ft

T

.R.3.8 Nm (0.38 mlbf)

kgf, 2.8 ft

T

.R.3.8 Nm (0.38 mlbf)

kgf, 2.8 ft

T

.R.9 Nm (0.9 mlbf)

kgf, 6.5 ft

T

.R.7 Nm (0.7 mlbf)

kgf, 5.1 ftT

.R.7 Nm (0.7 mlbf)

kgf, 5.1 ft

T

.R.10 Nm (1.0 mlbf)

kgf, 7.2 ft

T

.R.145 Nm (14.5 mlbf)

kgf, 105 ft

T

.R.38 Nm (3.8 mlbf)

kgf, 27 ft

7 Nm (0.7 m

lbf)

kgf, 5.1 ft

*

Page 207 of 426

STEERING HEAD

5-55

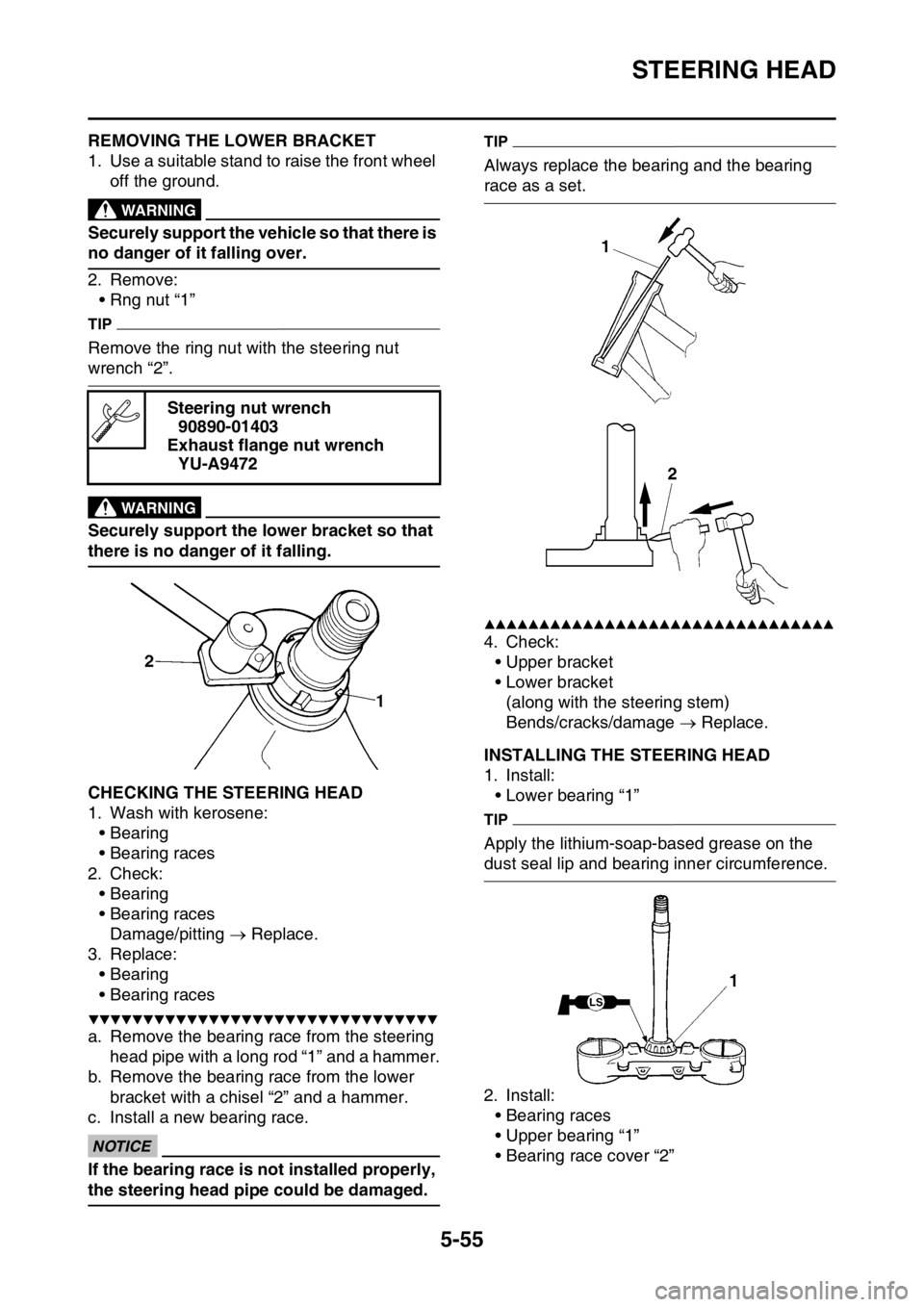

EAS2GC1204REMOVING THE LOWER BRACKET

1. Use a suitable stand to raise the front wheel off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Remove:• Rng nut “1”

TIP

Remove the ring nut with the steering nut

wrench “2”.

EWA

WARNING

Securely support the lower bracket so that

there is no danger of it falling.

EAS2GC1205CHECKING THE STEERING HEAD

1. Wash with kerosene:• Bearing

• Bearing races

2. Check: • Bearing

• Bearing races

Damage/pitting Replace.

3. Replace:

• Bearing

• Bearing races

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the bearing race from the steering head pipe with a long rod “1” and a hammer.

b. Remove the bearing race from the lower bracket with a chisel “2” and a hammer.

c. Install a new bearing race.

ECA

NOTICE

If the bearing race is not installed properly,

the steering head pipe could be damaged.

TIP

Always replace the bearing and the bearing

race as a set.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

4. Check: • Upper bracket

• Lower bracket

(along with the steering stem)

Bends/cracks/damage Replace.

EAS2GC1206INSTALLING THE STEERING HEAD

1. Install:

• Lower bearing “1”

TIP

Apply the lithium-soap-based grease on the

dust seal lip and bearing inner circumference.

2. Install:• Bearing races

• Upper bearing “1”

• Bearing race cover “2”

Steering nut wrench

90890-01403

Exhaust flange nut wrench YU-A9472

Page 208 of 426

STEERING HEAD

5-56

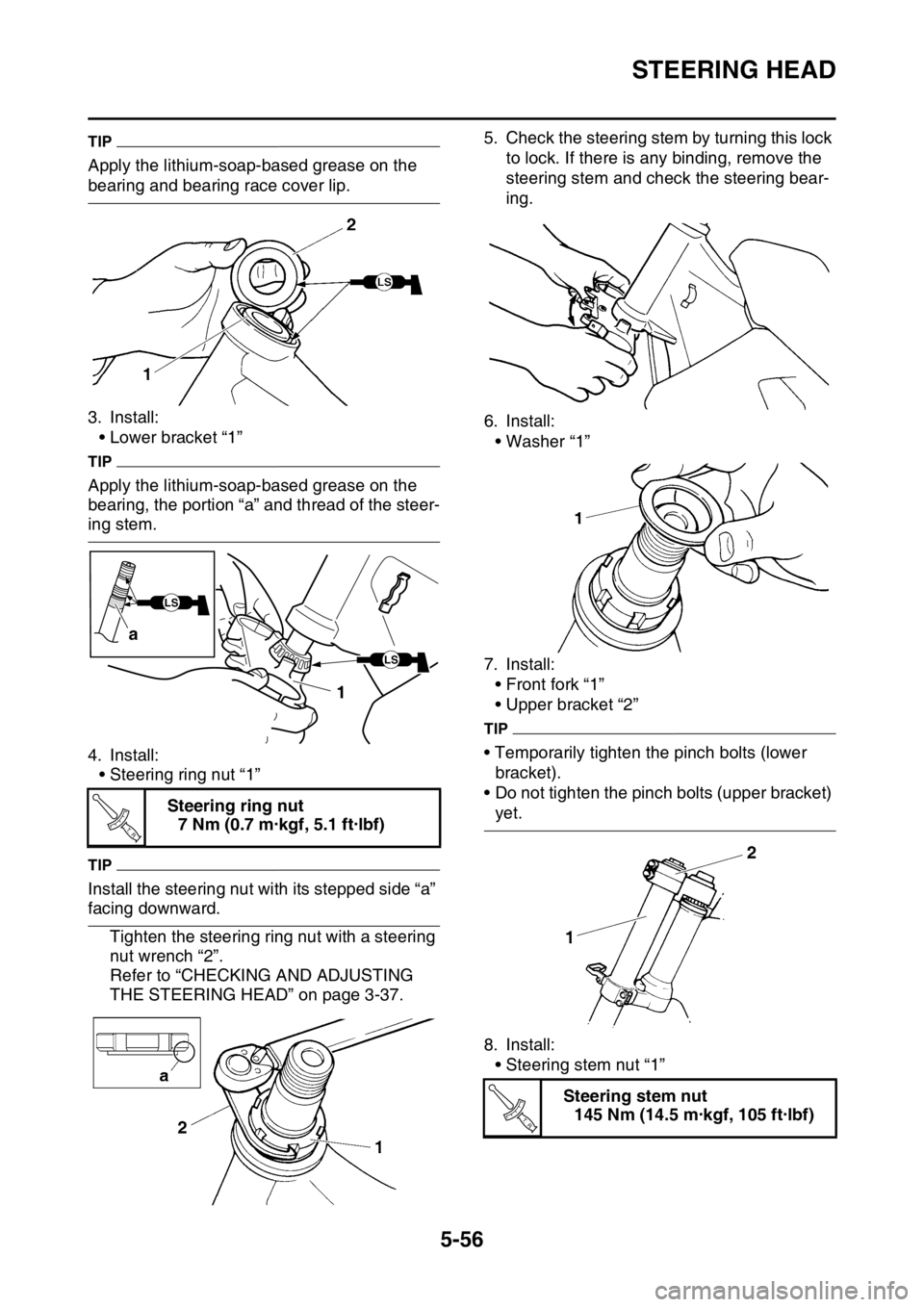

TIP

Apply the lithium-soap-based grease on the

bearing and bearing race cover lip.

3. Install:• Lower bracket “1”

TIP

Apply the lithium-soap-based grease on the

bearing, the portion “a” and thread of the steer-

ing stem.

4. Install:• Steering ring nut “1”

TIP

Install the steering nut with its stepped side “a”

facing downward.

Tighten the steering ring nut with a steering

nut wrench “2”.

Refer to “CHECKING AND ADJUSTING

THE STEERING HEAD” on page 3-37. 5. Check the steering stem by turning this lock

to lock. If there is any binding, remove the

steering stem and check the steering bear-

ing.

6. Install: • Washer “1”

7. Install: • Front fork “1”

• Upper bracket “2”

TIP

• Temporarily tighten the pinch bolts (lower bracket).

• Do not tighten the pinch bolts (upper bracket)

yet.

8. Install: • Steering stem nut “1”

Steering ring nut

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

LS

1

a

LSLS

T R..

Steering stem nut

145 Nm (14.5 m·kgf, 105 ft·lbf)

T R..

Page 209 of 426

STEERING HEAD

5-57

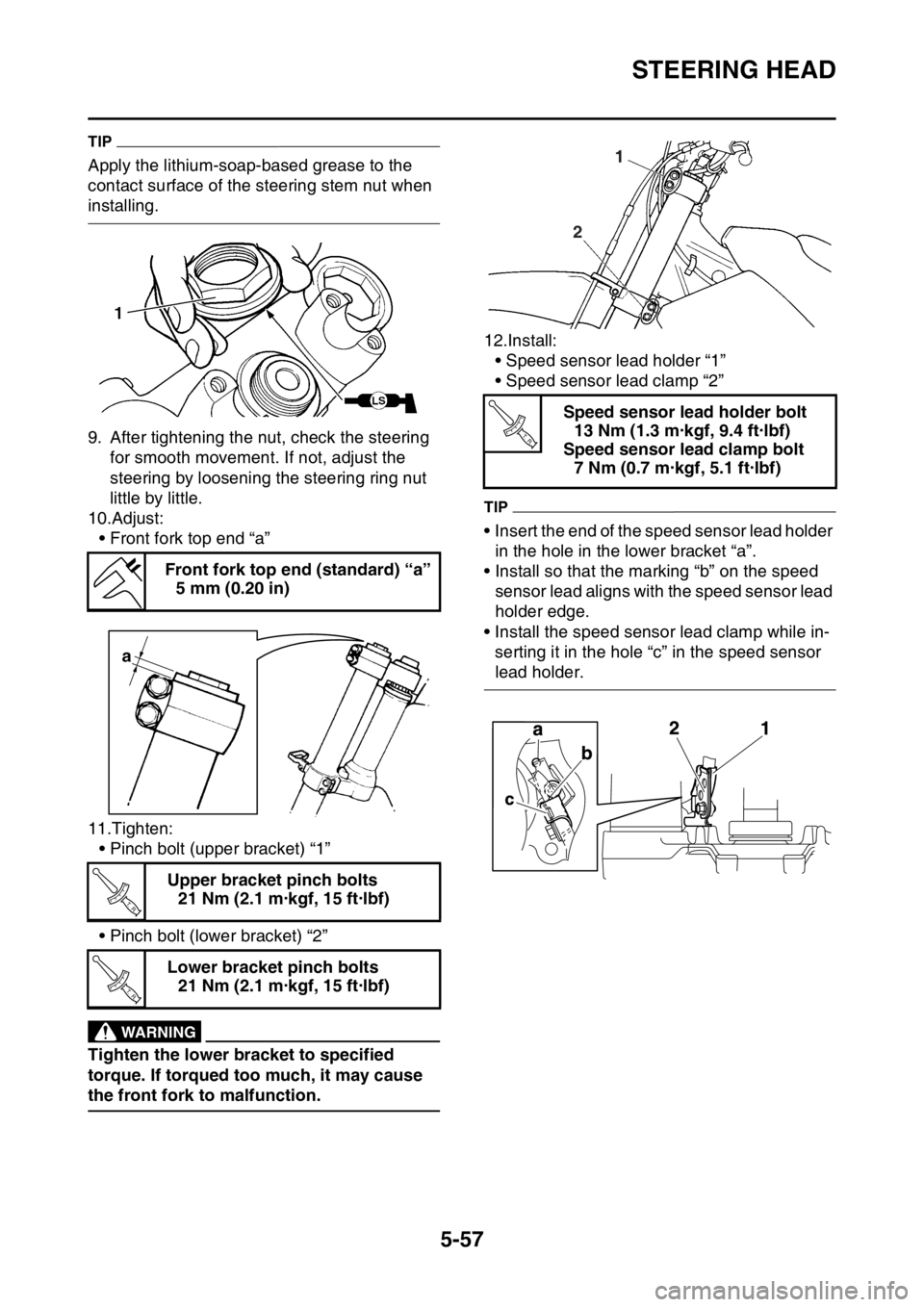

TIP

Apply the lithium-soap-based grease to the

contact surface of the steering stem nut when

installing.

9. After tightening the nut, check the steering for smooth movement. If not, adjust the

steering by loosening the steering ring nut

little by little.

10.Adjust:

• Front fork top end “a”

11.Tighten: • Pinch bolt (upper bracket) “1”

• Pinch bolt (lower bracket) “2”

EWA

WARNING

Tighten the lower bracket to specified

torque. If torqued too much, it may cause

the front fork to malfunction. 12.Install:

• Speed sensor lead holder “1”

• Speed sensor lead clamp “2”

TIP

• Insert the end of the speed sensor lead holder

in the hole in the lower bracket “a”.

• Install so that the marking “b” on the speed sensor lead aligns with the speed sensor lead

holder edge.

• Install the speed sens or lead clamp while in-

serting it in the hole “c” in the speed sensor

lead holder.

Front fork top end (standard) “a”

5 mm (0.20 in)

Upper bracket pinch bolts 21 Nm (2.1 m·kgf, 15 ft·lbf)

Lower bracket pinch bolts 21 Nm (2.1 m·kgf, 15 ft·lbf)

a

T R..

T R..

Speed sensor lead holder bolt13 Nm (1.3 m·kgf, 9.4 ft·lbf)

Speed sensor lead clamp bolt 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

2 1

T R..

Page 210 of 426

REAR SHOCK ABSORBER ASSEMBLY

5-58

EAS2GC1207

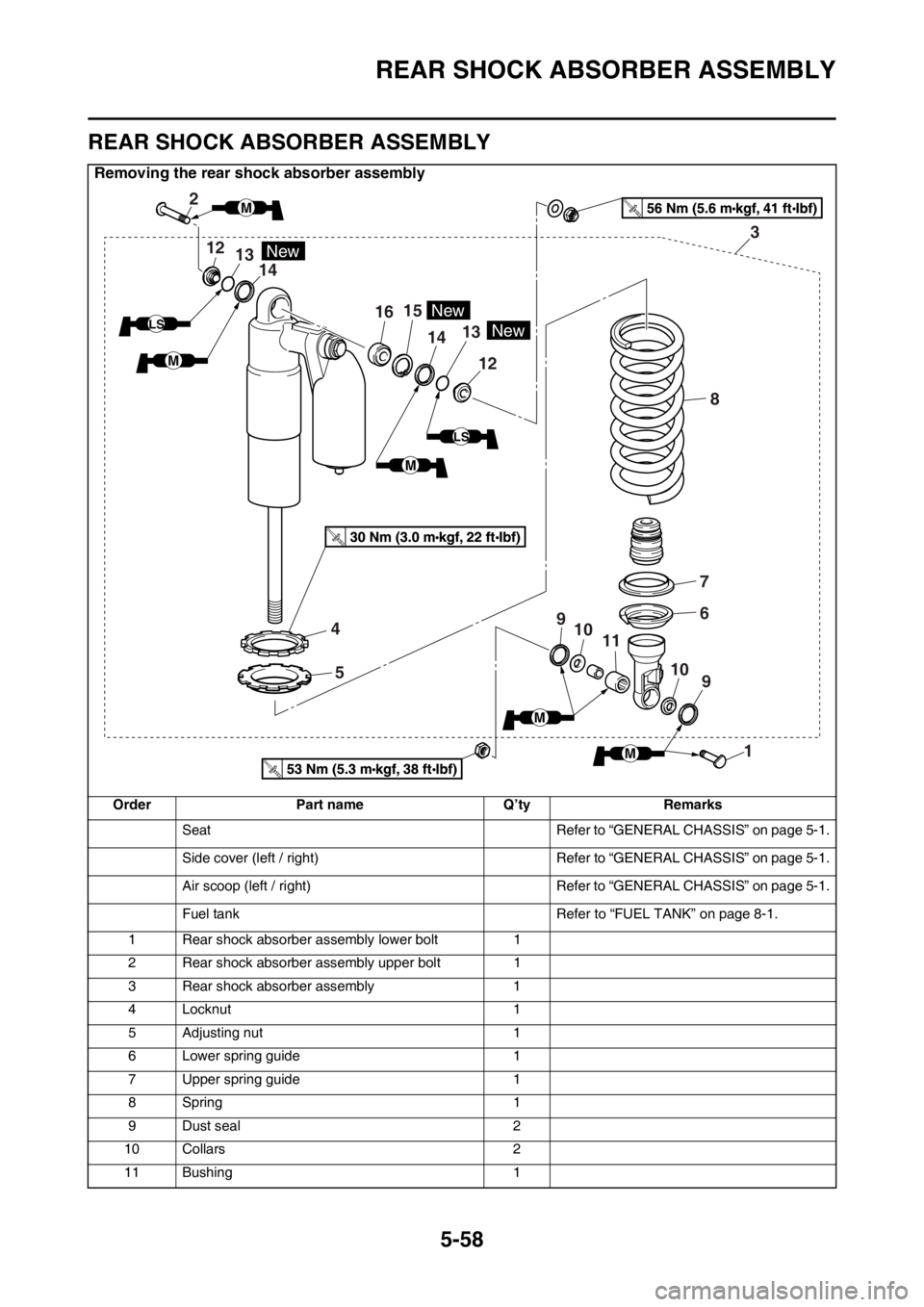

REAR SHOCK ABSORBER ASSEMBLY

Removing the rear shock absorber assembly

OrderPart name Q’tyRemarks

Seat Refer to “GENERAL CHASSIS” on page 5-1.

Side cover (left / right) Refer to “GENERAL CHASSIS” on page 5-1.

Air scoop (left / right) Refer to “GENERAL CHASSIS” on page 5-1.

Fuel tank Refer to “FUEL TANK” on page 8-1.

1 Rear shock absorber assembly lower bolt 1

2 Rear shock absorber assembly upper bolt 1

3 Rear shock absorber assembly 1

4 Locknut 1

5 Adjusting nut 1

6 Lower spring guide 1

7 Upper spring guide 1

8Spring 1

9 Dust seal 2

10 Collars 2

11 Bushing 1

2

12

1615

14 13

12

14

4

5

7

6

8 3

9

9

10

10

11

1

New

New

13New

LS

LS

M

M

M

M

M