YAMAHA XJR 1300 2016 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2016, Model line: XJR 1300, Model: YAMAHA XJR 1300 2016Pages: 98, PDF Size: 2.59 MB

Page 51 of 98

Periodic maintenance an d a djustment

6-6

6

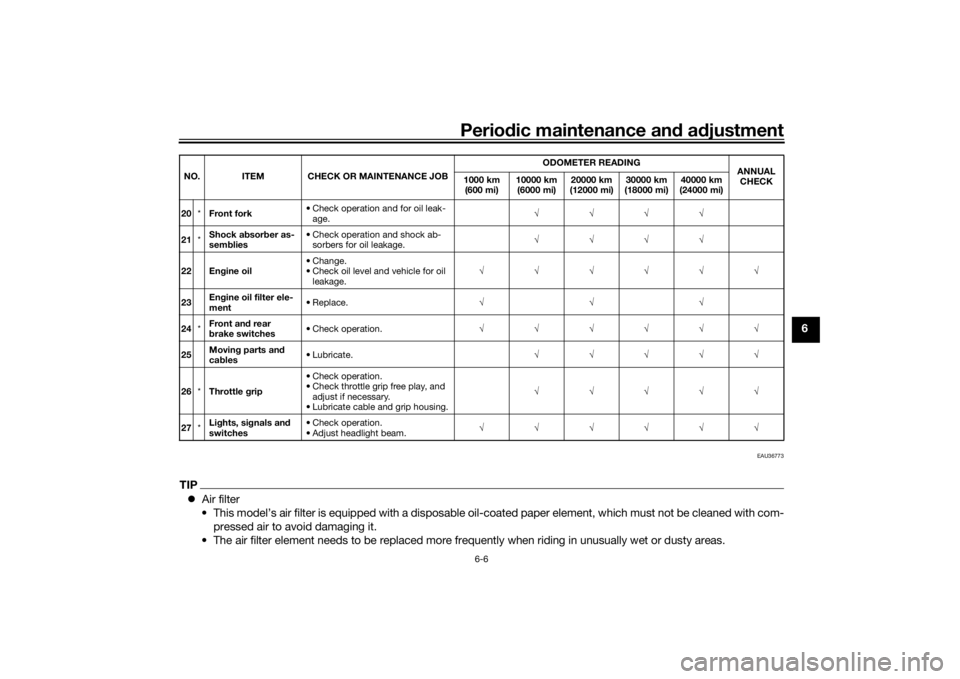

EAU36773

TIP Air filter

• This model’s air filter is equipped with a disposable oil-coated paper element, which must not be cleaned with com- pressed air to avoid damaging it.

• The air filter element needs to be replaced more frequently when riding in unusually wet or dusty areas.20 *Front fork • Check operation and for oil leak-

age. √√√√

21 *Shock a

bsor ber as-

sem blies • Check operation and shock ab-

sorbers for oil leakage. √√√√

22 En gine oil • Change.

• Check oil level and vehicle for oil

leakage. √√√√√√

23 En

gine oil filter ele-

ment •Replace.

√√√

24 *Front an

d rear

b rake switches • Check operation.

√√√√√√

25 Movin

g parts an d

ca bles • Lubricate.

√√√√√

26 *Throttle g rip • Check operation.

• Check throttle grip free play, and

adjust if necessary.

• Lubricate cable and grip housing. √√√√√

27 *Li

ghts, si gnals an d

switches • Check operation.

• Adjust headlight beam.

√√√√√√

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

U2PNE1E0.book Page 6 Monday, December 28, 2015 11:03 AM

Page 52 of 98

Periodic maintenance an d a djustment

6-7

6

Hydraulic brake and clutch service

• Regularly check and, if necessary, correct the brake fluid and clutch fluid levels.

• Every two years replace the internal components of the brake master cylinders and calipers as well as clutch master and release cylinders, and change the brake and clutch fluids.

• Replace the brake and clutch hoses every four years and if cracked or damaged.

U2PNE1E0.book Page 7 Monday, December 28, 2015 11:03 AM

Page 53 of 98

Periodic maintenance an d a djustment

6-8

6

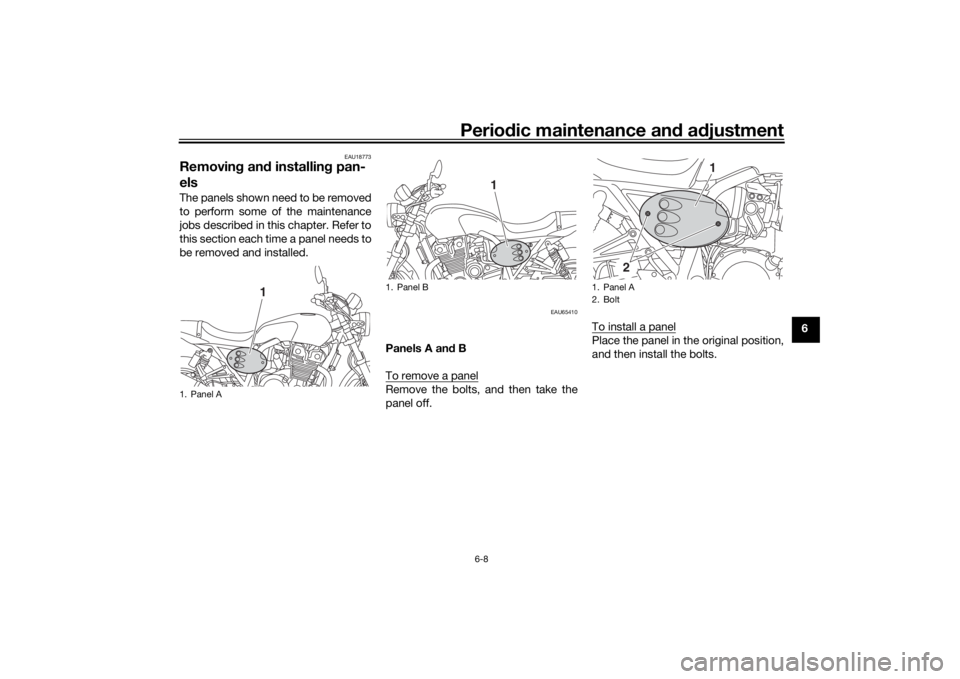

EAU18773

Removin g an d installin g pan-

elsThe panels shown need to be removed

to perform some of the maintenance

jobs described in this chapter. Refer to

this section each time a panel needs to

be removed and installed.

EAU65410

Panels A an d B

To remove a panelRemove the bolts, and then take the

panel off. To install a panel

Place the panel in the original position,

and then install the bolts.

1. Panel A

1

1. Panel B

1

1. Panel A

2. Bolt

1

2

U2PNE1E0.book Page 8 Monday, December 28, 2015 11:03 AM

Page 54 of 98

Periodic maintenance an d a djustment

6-9

6

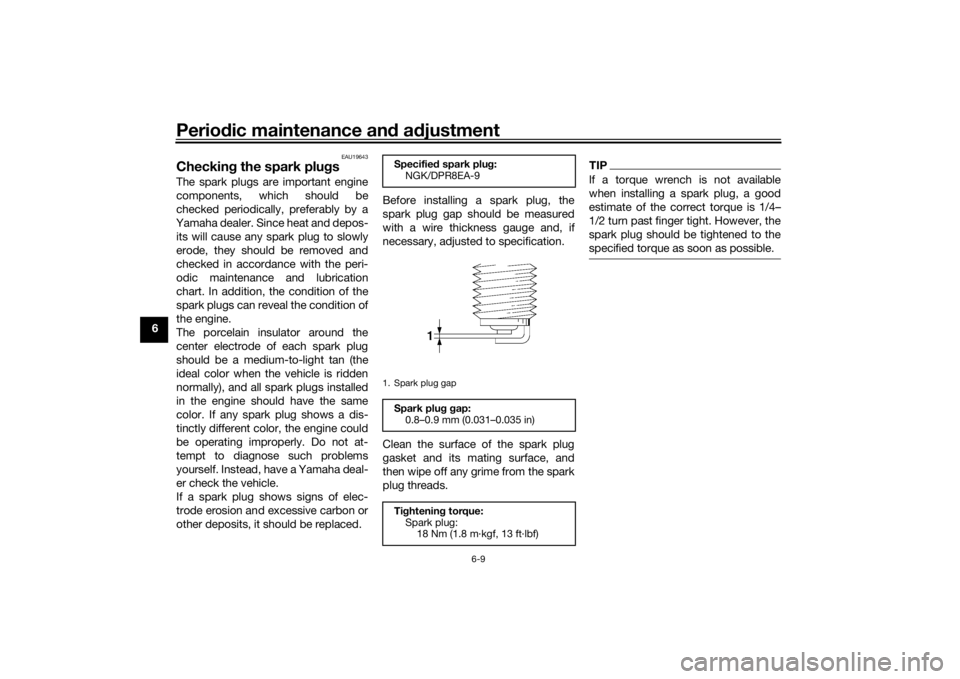

EAU19643

Checkin g the spark plu gsThe spark plugs are important engine

components, which should be

checked periodically, preferably by a

Yamaha dealer. Since heat and depos- its will cause any spark plug to slowly

erode, they should be removed and

checked in accordance with the peri-

odic maintenance and lubrication

chart. In addition, the condition of the

spark plugs can reveal the condition of

the engine.

The porcelain insulator around the

center electrode of each spark plug

should be a medium-to-light tan (the

ideal color when the vehicle is ridden

normally), and all spark plugs installed

in the engine should have the same

color. If any spark plug shows a dis-

tinctly different color, the engine could

be operating improperly. Do not at-

tempt to diagnose such problems

yourself. Instead, have a Yamaha deal-

er check the vehicle.

If a spark plug shows signs of elec-

trode erosion and excessive carbon or

other deposits, it should be replaced. Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the spark

plug threads.

TIPIf a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4–

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.

Specifie

d spark plu g:

NGK/DPR8EA-91. Spark plug gapSpark plu g g ap:

0.8–0.9 mm (0.031–0.035 in)

Ti ghtenin g torque:

Spark plug: 18 Nm (1.8 m·kgf, 13 ft·lbf)

U2PNE1E0.book Page 9 Monday, December 28, 2015 11:03 AM

Page 55 of 98

Periodic maintenance an d a djustment

6-10

6

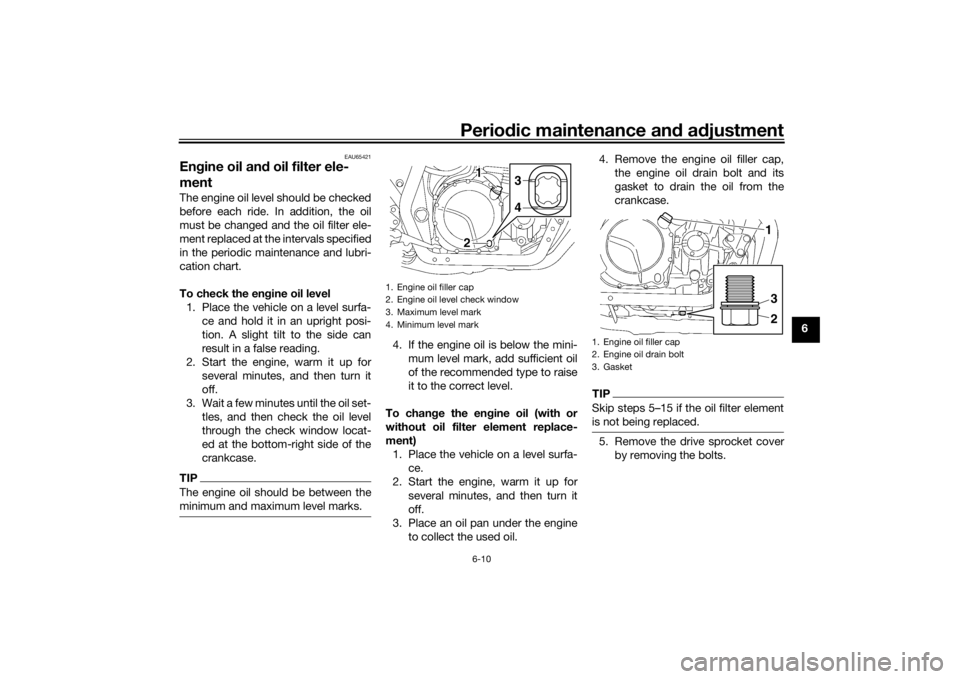

EAU65421

En gine oil an d oil filter ele-

mentThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter ele-

ment replaced at the intervals specified

in the periodic maintenance and lubri-

cation chart.

To check the en gine oil level

1. Place the vehicle on a level surfa- ce and hold it in an upright posi-

tion. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Wait a few minutes until the oil set- tles, and then check the oil level

through the check window locat-

ed at the bottom-right side of the

crankcase.TIPThe engine oil should be between the

minimum and maximum level marks.

4. If the engine oil is below the mini-mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

To chan ge the en gine oil (with or

without oil filter element replace-

ment) 1. Place the vehicle on a level surfa- ce.

2. Start the engine, warm it up for several minutes, and then turn it

off.

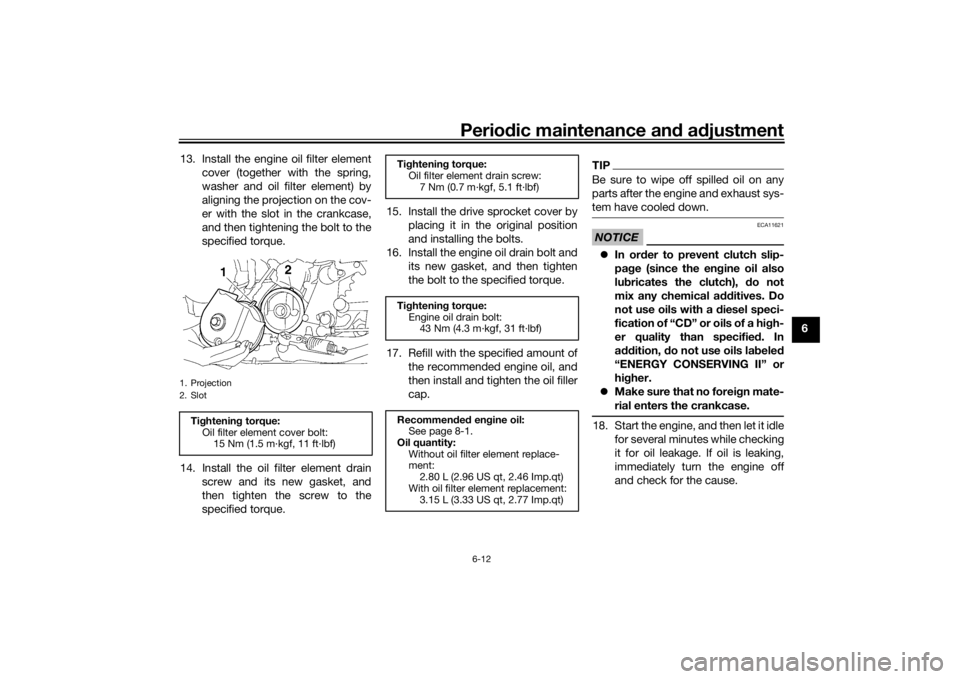

3. Place an oil pan under the engine to collect the used oil. 4. Remove the engine oil filler cap,

the engine oil drain bolt and its

gasket to drain the oil from the

crankcase.

TIPSkip steps 5–15 if the oil filter element

is not being replaced.5. Remove the drive sprocket coverby removing the bolts.

1. Engine oil filler cap

2. Engine oil level check window

3. Maximum level mark

4. Minimum level mark

3

4

1. Engine oil filler cap

2. Engine oil drain bolt

3. Gasket

231

U2PNE1E0.book Page 10 Monday, December 28, 2015 11:03 AM

Page 56 of 98

Periodic maintenance an d a djustment

6-11

6 6. Remove the oil filter element drain

screw and its gasket to drain the

oil from the oil filter element.

7. Remove the oil filter element cover by removing the oil filter element

cover bolt. 8. Remove the oil filter element and

O-rings.

TIPTake care not to lose the compression

spring and washer.

9. Install new O-rings onto the ele-ment cover bolt and element cov-

er.

10. Apply a thin coat of clean engine oil to the O-rings.

11. Insert the element cover bolt into the element cover.

12. Fit the spring, washer and a new oil filter element over the bolt.TIPMake sure the O-rings are properly

seated.

1. Drive sprocket cover

2. Bolt

2

1

1. Oil filter element drain screw

2. Gasket

3. Oil filter element cover bolt

4. Oil filter element cover

1

2

43

1. O-ring

2. Oil filter element cover bolt

3. Oil filter element cover

4. Compression spring

5. Washer

6. Oil filter element

2

3

4

5

6

1

U2PNE1E0.book Page 11 Monday, December 28, 2015 11:03 AM

Page 57 of 98

Periodic maintenance an d a djustment

6-12

6

13. Install the engine oil filter element

cover (together with the spring,

washer and oil filter element) by

aligning the projection on the cov-

er with the slot in the crankcase,

and then tightening the bolt to the

specified torque.

14. Install the oil filter element drain screw and its new gasket, and

then tighten the screw to the

specified torque. 15. Install the drive sprocket cover by

placing it in the original position

and installing the bolts.

16. Install the engine oil drain bolt and its new gasket, and then tighten

the bolt to the specified torque.

17. Refill with the specified amount of the recommended engine oil, and

then install and tighten the oil filler

cap.

TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.NOTICE

ECA11621

In or der to prevent clutch slip-

pa ge (since the en gine oil also

lu bricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a hi gh-

er quality than specifie d. In

a dd ition, do not use oils la bele d

“ENERGY CONSERVING II” or

hi gher.

Make sure that no forei gn mate-

rial enters the crankcase.18. Start the engine, and then let it idle for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

1. Projection

2. SlotTightenin g torque:

Oil filter element cover bolt: 15 Nm (1.5 m·kgf, 11 ft·lbf)

Tightenin g torque:

Oil filter element drain screw:

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Ti ghtenin g torque:

Engine oil drain bolt: 43 Nm (4.3 m·kgf, 31 ft·lbf)

Recommen ded en gine oil:

See page 8-1.

Oil quantity: Without oil filter element replace-

ment:

2.80 L (2.96 US qt, 2.46 Imp.qt)

With oil filter element replacement: 3.15 L (3.33 US qt, 2.77 Imp.qt)

U2PNE1E0.book Page 12 Monday, December 28, 2015 11:03 AM

Page 58 of 98

Periodic maintenance an d a djustment

6-13

6

TIPAfter the engine is started, the engine

oil level warning light should go off if

the oil level is sufficient.NOTICE

ECA10402

If the oil level warnin g lig ht flickers

or remains on even if the oil level is

correct, imme diately turn the en gine

off an d have a Yamaha d ealer check

the vehicle.19. Turn the engine off, and then check the oil level and correct it if

necessary.

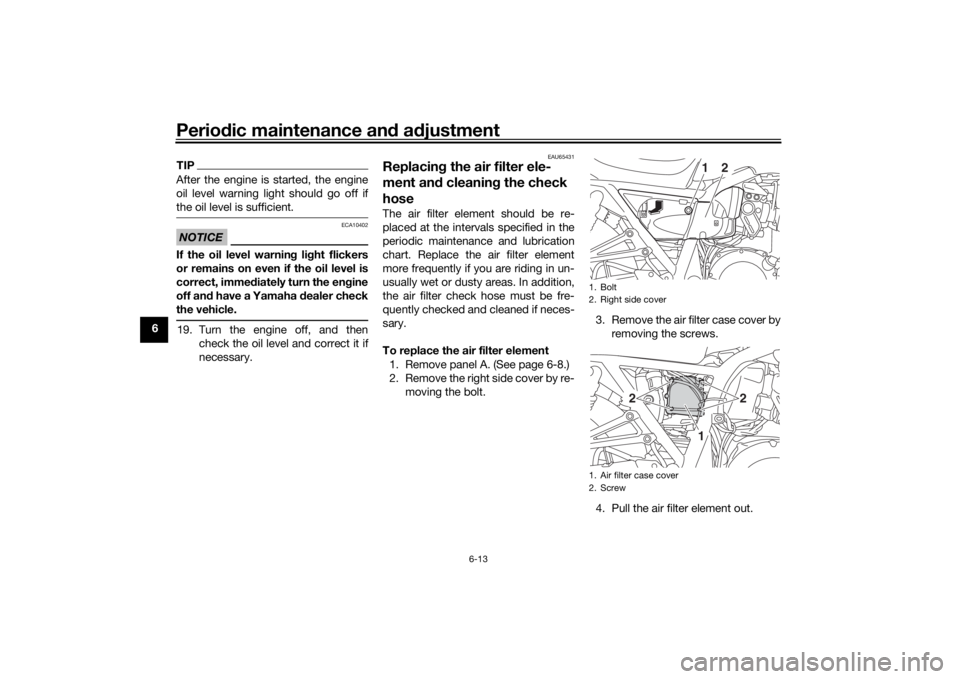

EAU65431

Replacin g the air filter ele-

ment an d cleanin g the check

hoseThe air filter element should be re-

placed at the intervals specified in the

periodic maintenance and lubrication

chart. Replace the air filter element

more frequently if you are riding in un-

usually wet or dusty areas. In addition,

the air filter check hose must be fre-

quently checked and cleaned if neces-

sary.

To replace the air filter element

1. Remove panel A. (See page 6-8.)

2. Remove the right side cover by re- moving the bolt. 3. Remove the air filter case cover by

removing the screws.

4. Pull the air filter element out.

1. Bolt

2. Right side cover

1. Air filter case cover

2. Screw

1

2

2

2

1

U2PNE1E0.book Page 13 Monday, December 28, 2015 11:03 AM

Page 59 of 98

Periodic maintenance an d a djustment

6-14

6

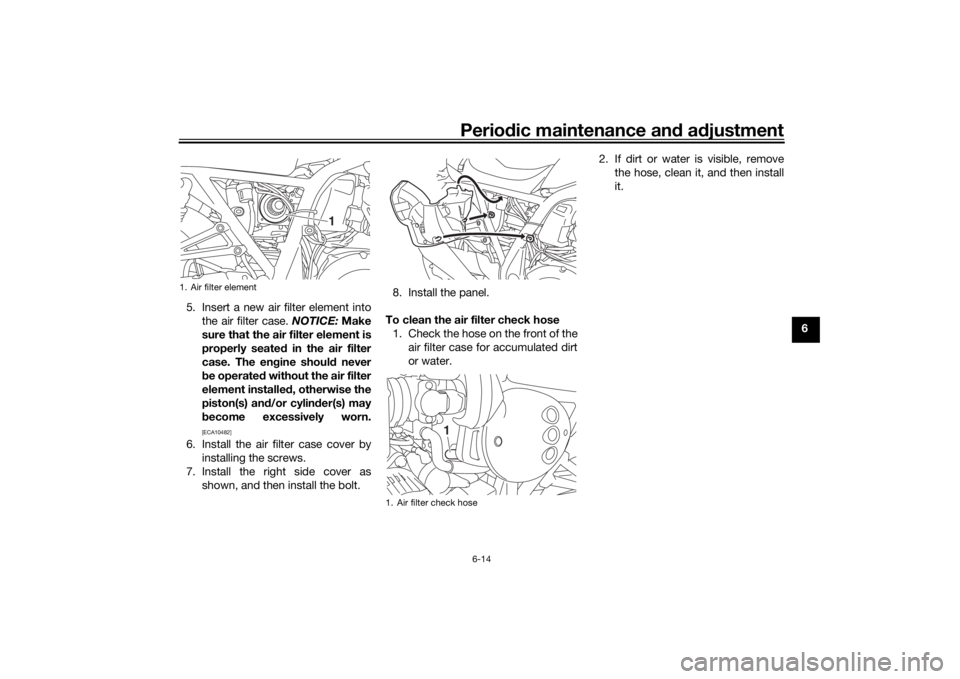

5. Insert a new air filter element into

the air filter case. NOTICE: Make

sure that the air filter element is

properly seate d in the air filter

case. The en gine should never

b e operated without the air filter

element installed , otherwise the

piston(s) an d/or cylin der(s) may

b ecome excessively worn.

[ECA10482]

6. Install the air filter case cover by

installing the screws.

7. Install the right side cover as shown, and then install the bolt. 8. Install the panel.

To clean the air filter check hose 1. Check the hose on the front of the air filter case for accumulated dirt

or water. 2. If dirt or water is visible, remove

the hose, clean it, and then install

it.1. Air filter element

1

1. Air filter check hose

1

U2PNE1E0.book Page 14 Monday, December 28, 2015 11:03 AM

Page 60 of 98

Periodic maintenance an d a djustment

6-15

6

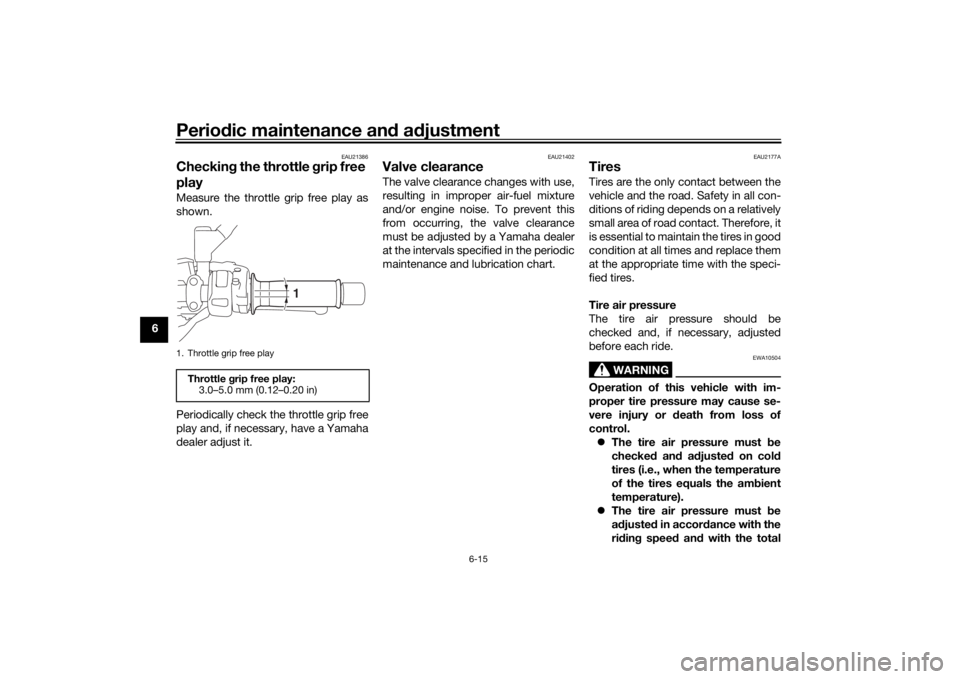

EAU21386

Checkin g the throttle grip free

playMeasure the throttle grip free play as

shown.

Periodically check the throttle grip free

play and, if necessary, have a Yamaha

dealer adjust it.

EAU21402

Valve clearanceThe valve clearance changes with use,

resulting in improper air-fuel mixture

and/or engine noise. To prevent this

from occurring, the valve clearance

must be adjusted by a Yamaha dealer

at the intervals specified in the periodic

maintenance and lubrication chart.

EAU2177A

TiresTires are the only contact between the

vehicle and the road. Safety in all con-

ditions of riding depends on a relatively

small area of road contact. Therefore, it

is essential to maintain the tires in good

condition at all times and replace them

at the appropriate time with the speci-

fied tires.

Tire air pressure

The tire air pressure should be

checked and, if necessary, adjusted

before each ride.

WARNING

EWA10504

Operation of this vehicle with im-

proper tire pressure may cause se-

vere injury or death from loss of

control. The tire air pressure must be

checked and a djuste d on col d

tires (i.e., when the temperature

of the tires equals the amb ient

temperature).

The tire air pressure must be

a d juste d in accor dance with the

ri din g speed and with the total

1. Throttle grip free playThrottle g rip free play:

3.0–5.0 mm (0.12–0.20 in)

1

U2PNE1E0.book Page 15 Monday, December 28, 2015 11:03 AM