YAMAHA XMAX 250 2009 Repair Manual

Manufacturer: YAMAHA, Model Year: 2009, Model line: XMAX 250, Model: YAMAHA XMAX 250 2009Pages: 92, PDF Size: 4.7 MB

Page 61 of 92

EAU22390

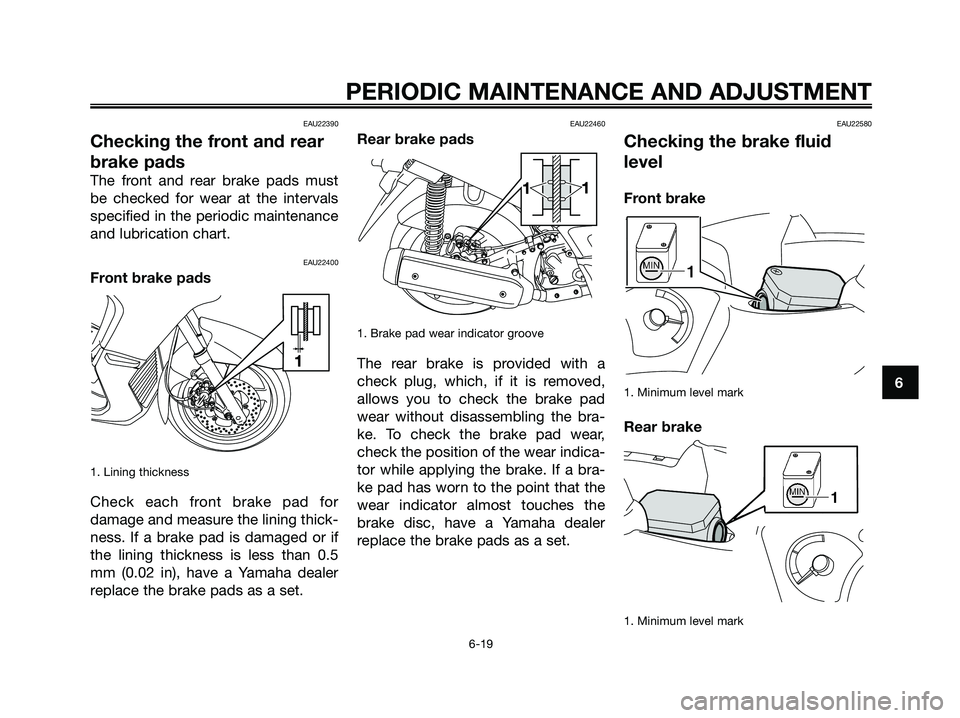

Checking the front and rear

brake pads

The front and rear brake pads must

be checked for wear at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU22400

Front brake pads

1. Lining thickness

Check each front brake pad for

damage and measure the lining thick-

ness. If a brake pad is damaged or if

the lining thickness is less than 0.5

mm (0.02 in), have a Yamaha dealer

replace the brake pads as a set.

EAU22460

Rear brake pads

1. Brake pad wear indicator groove

The rear brake is provided with a

check plug, which, if it is removed,

allows you to check the brake pad

wear without disassembling the bra-

ke. To check the brake pad wear,

check the position of the wear indica-

tor while applying the brake. If a bra-

ke pad has worn to the point that the

wear indicator almost touches the

brake disc, have a Yamaha dealer

replace the brake pads as a set.

EAU22580

Checking the brake fluid

level

Front brake

1. Minimum level mark

Rear brake

1. Minimum level mark

PERIODIC MAINTENANCE AND ADJUSTMENT

6-19

6

1C0-F8199-E5.QXD 3/10/08 05:56 Página 61

Page 62 of 92

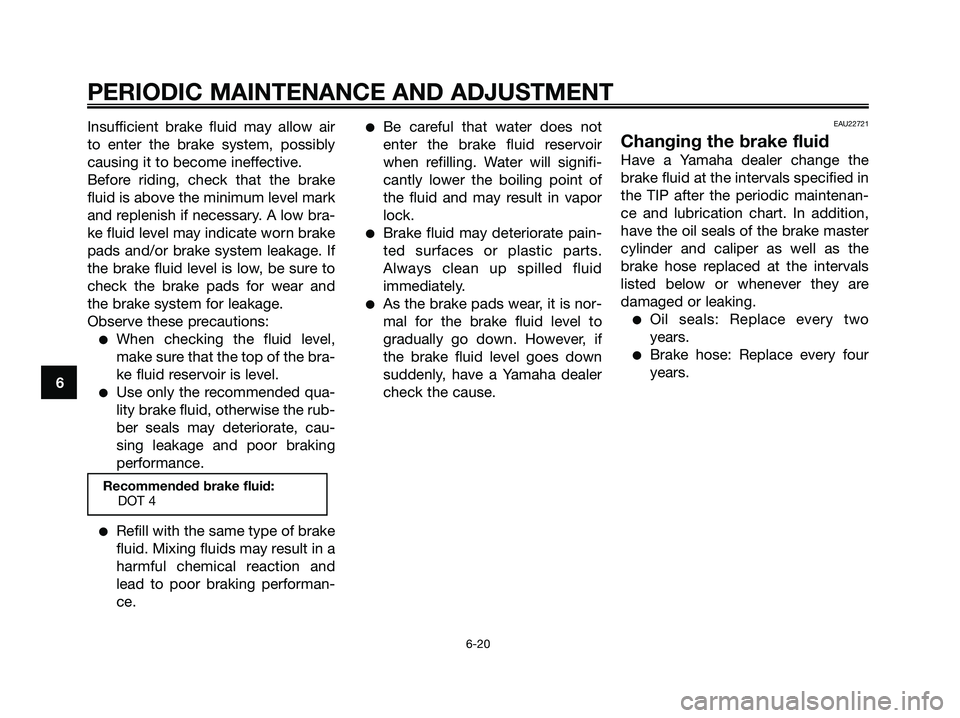

Insufficient brake fluid may allow air

to enter the brake system, possibly

causing it to become ineffective.

Before riding, check that the brake

fluid is above the minimum level mark

and replenish if necessary. A low bra-

ke fluid level may indicate worn brake

pads and/or brake system leakage. If

the brake fluid level is low, be sure to

check the brake pads for wear and

the brake system for leakage.

Observe these precautions:

●When checking the fluid level,

make sure that the top of the bra-

ke fluid reservoir is level.

●Use only the recommended qua-

lity brake fluid, otherwise the rub-

ber seals may deteriorate, cau-

sing leakage and poor braking

performance.

●Refill with the same type of brake

fluid. Mixing fluids may result in a

harmful chemical reaction and

lead to poor braking performan-

ce.

●Be careful that water does not

enter the brake fluid reservoir

when refilling. Water will signifi-

cantly lower the boiling point of

the fluid and may result in vapor

lock.

●Brake fluid may deteriorate pain-

ted surfaces or plastic parts.

Always clean up spilled fluid

immediately.

●As the brake pads wear, it is nor-

mal for the brake fluid level to

gradually go down. However, if

the brake fluid level goes down

suddenly, have a Yamaha dealer

check the cause.

EAU22721

Changing the brake fluid

Have a Yamaha dealer change the

brake fluid at the intervals specified in

the TIP after the periodic maintenan-

ce and lubrication chart. In addition,

have the oil seals of the brake master

cylinder and caliper as well as the

brake hose replaced at the intervals

listed below or whenever they are

damaged or leaking.

●Oil seals: Replace every two

years.

●Brake hose: Replace every four

years.

Recommended brake fluid:

DOT 4

PERIODIC MAINTENANCE AND ADJUSTMENT

6-20

6

1C0-F8199-E5.QXD 3/10/08 05:56 Página 62

Page 63 of 92

EAU23101

Checking and lubricating the

cables

The operation of all control cables

and the condition of the cables

should be checked before each ride,

and the cables and cable ends should

be lubricated if necessary. If a cable is

damaged or does not move smoothly,

have a Yamaha dealer check or repla-

ce it. WARNING! Damage to the

outer sheath may interfere with

proper cable operation and will

cause the inner cable to rust.

Replace a damaged cable as soon

as possible to prevent unsafe con-

ditions.

[EWA10721]EAU23111

Checking and lubricating the

throttle grip and cable

The operation of the throttle grip

should be checked before each ride.

In addition, the cable should be lubri-

cated at the intervals specified in the

periodic maintenance chart.

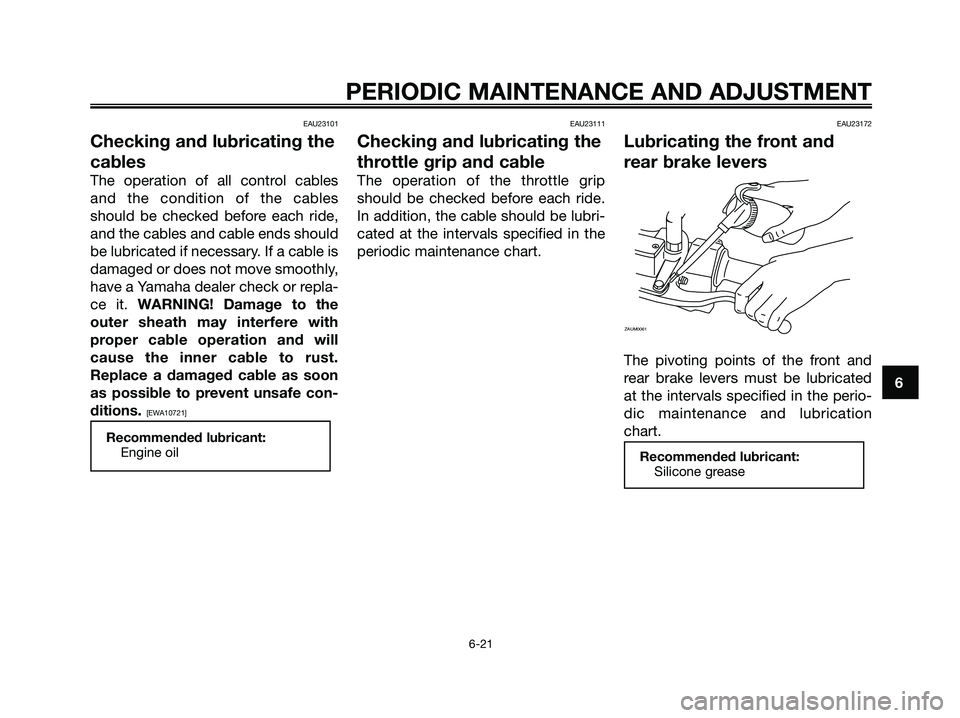

EAU23172

Lubricating the front and

rear brake levers

The pivoting points of the front and

rear brake levers must be lubricated

at the intervals specified in the perio-

dic maintenance and lubrication

chart.

Recommended lubricant:

Silicone grease

ZAUM0061

Recommended lubricant:

Engine oil

PERIODIC MAINTENANCE AND ADJUSTMENT

6-21

6

1C0-F8199-E5.QXD 3/10/08 05:56 Página 63

Page 64 of 92

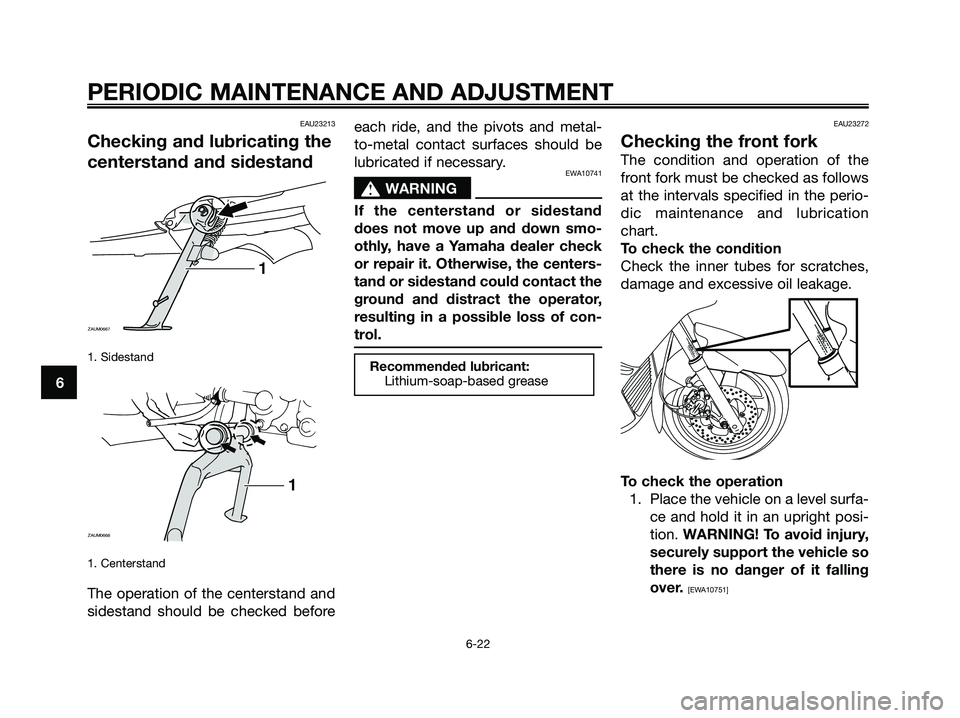

EAU23213

Checking and lubricating the

centerstand and sidestand

1. Sidestand

1. Centerstand

The operation of the centerstand and

sidestand should be checked beforeeach ride, and the pivots and metal-

to-metal contact surfaces should be

lubricated if necessary.

EWA10741

s s

WARNING

If the centerstand or sidestand

does not move up and down smo-

othly, have a Yamaha dealer check

or repair it. Otherwise, the centers-

tand or sidestand could contact the

ground and distract the operator,

resulting in a possible loss of con-

trol.

EAU23272

Checking the front fork

The condition and operation of the

front fork must be checked as follows

at the intervals specified in the perio-

dic maintenance and lubrication

chart.

To check the condition

Check the inner tubes for scratches,

damage and excessive oil leakage.

To check the operation

1. Place the vehicle on a level surfa-

ce and hold it in an upright posi-

tion. WARNING! To avoid injury,

securely support the vehicle so

there is no danger of it falling

over.

[EWA10751]

Recommended lubricant:

Lithium-soap-based grease

1

ZAUM0668

ZAUM0667

1

PERIODIC MAINTENANCE AND ADJUSTMENT

6-22

6

1C0-F8199-E5.QXD 3/10/08 05:56 Página 64

Page 65 of 92

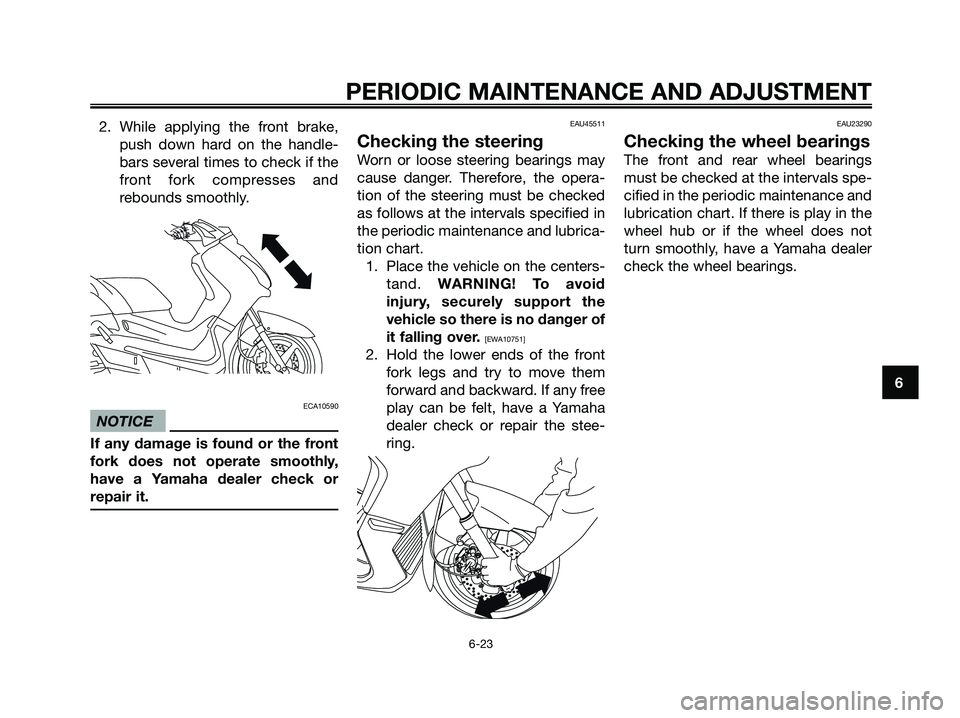

2. While applying the front brake,

push down hard on the handle-

bars several times to check if the

front fork compresses and

rebounds smoothly.

ECA10590

NOTICE

If any damage is found or the front

fork does not operate smoothly,

have a Yamaha dealer check or

repair it.

EAU45511

Checking the steering

Worn or loose steering bearings may

cause danger. Therefore, the opera-

tion of the steering must be checked

as follows at the intervals specified in

the periodic maintenance and lubrica-

tion chart.

1. Place the vehicle on the centers-

tand. WARNING! To avoid

injury, securely support the

vehicle so there is no danger of

it falling over.

[EWA10751]

2. Hold the lower ends of the front

fork legs and try to move them

forward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the stee-

ring.

EAU23290

Checking the wheel bearings

The front and rear wheel bearings

must be checked at the intervals spe-

cified in the periodic maintenance and

lubrication chart. If there is play in the

wheel hub or if the wheel does not

turn smoothly, have a Yamaha dealer

check the wheel bearings.

PERIODIC MAINTENANCE AND ADJUSTMENT

6-23

6

1C0-F8199-E5.QXD 3/10/08 05:56 Página 65

Page 66 of 92

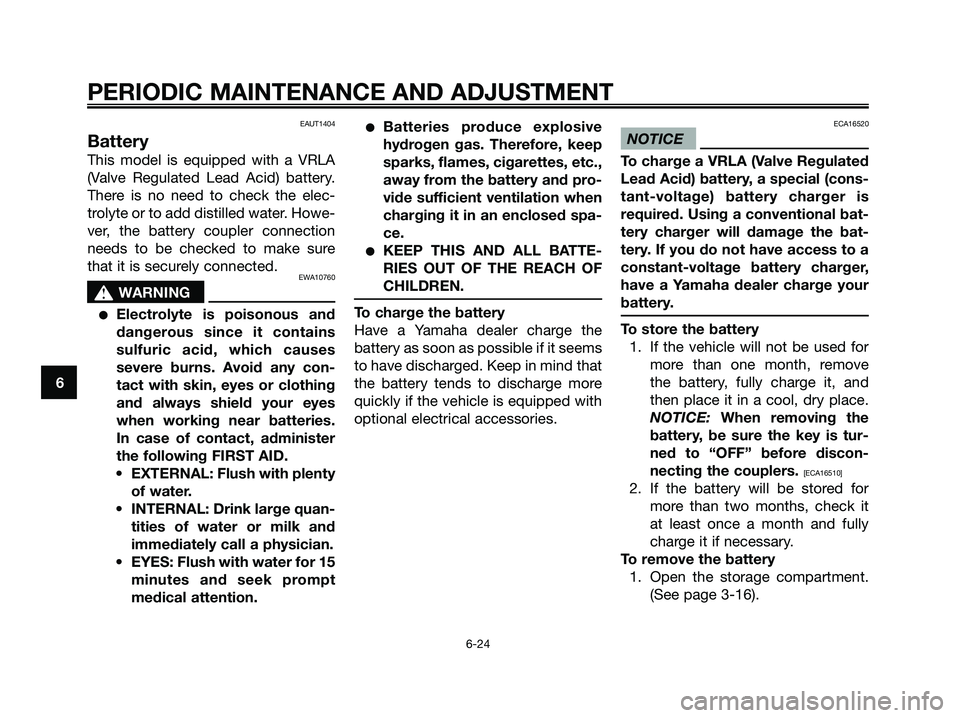

EAUT1404

Battery

This model is equipped with a VRLA

(Valve Regulated Lead Acid) battery.

There is no need to check the elec-

trolyte or to add distilled water. Howe-

ver, the battery coupler connection

needs to be checked to make sure

that it is securely connected.

EWA10760

s s

WARNING

●Electrolyte is poisonous and

dangerous since it contains

sulfuric acid, which causes

severe burns. Avoid any con-

tact with skin, eyes or clothing

and always shield your eyes

when working near batteries.

In case of contact, administer

the following FIRST AID.

• EXTERNAL: Flush with plenty

of water.

• INTERNAL: Drink large quan-

tities of water or milk and

immediately call a physician.

• EYES: Flush with water for 15

minutes and seek prompt

medical attention.

●Batteries produce explosive

hydrogen gas. Therefore, keep

sparks, flames, cigarettes, etc.,

away from the battery and pro-

vide sufficient ventilation when

charging it in an enclosed spa-

ce.

●KEEP THIS AND ALL BATTE-

RIES OUT OF THE REACH OF

CHILDREN.

To charge the battery

Have a Yamaha dealer charge the

battery as soon as possible if it seems

to have discharged. Keep in mind that

the battery tends to discharge more

quickly if the vehicle is equipped with

optional electrical accessories.

ECA16520

NOTICE

To charge a VRLA (Valve Regulated

Lead Acid) battery, a special (cons-

tant-voltage) battery charger is

required. Using a conventional bat-

tery charger will damage the bat-

tery. If you do not have access to a

constant-voltage battery charger,

have a Yamaha dealer charge your

battery.

To store the battery

1. If the vehicle will not be used for

more than one month, remove

the battery, fully charge it, and

then place it in a cool, dry place.

NOTICE:When removing the

battery, be sure the key is tur-

ned to “OFF” before discon-

necting the couplers.

[ECA16510]

2. If the battery will be stored for

more than two months, check it

at least once a month and fully

charge it if necessary.

To remove the battery

1. Open the storage compartment.

(See page 3-16).

PERIODIC MAINTENANCE AND ADJUSTMENT

6-24

6

1C0-F8199-E5.QXD 3/10/08 05:56 Página 66

Page 67 of 92

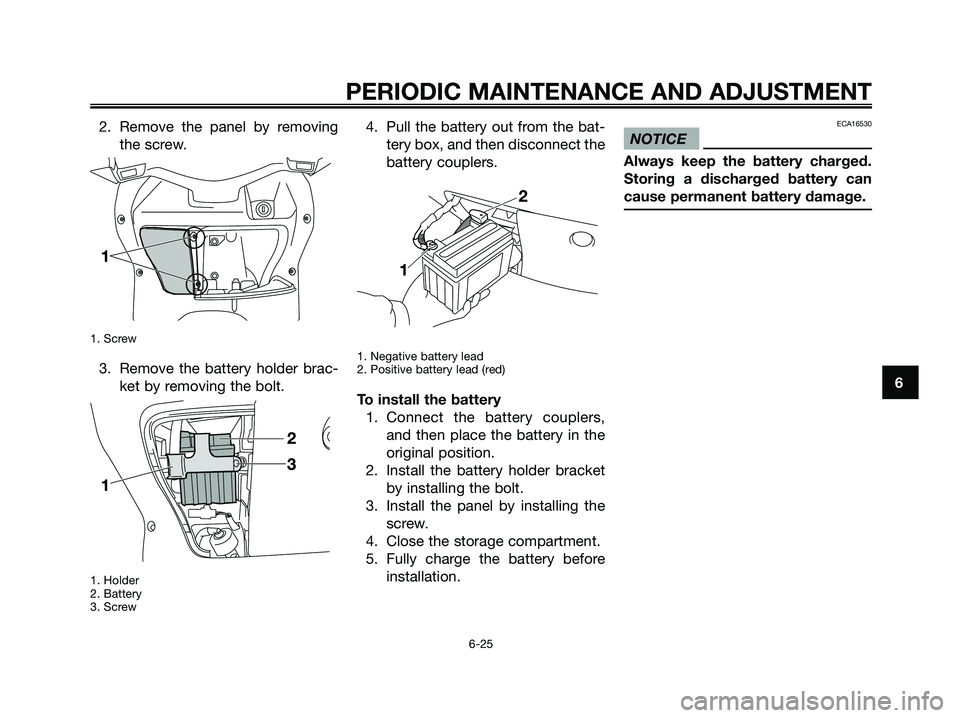

2. Remove the panel by removingthe screw.

1. Screw

3. Remove the battery holder brac-ket by removing the bolt.

1. Holder

2. Battery

3. Screw

4. Pull the battery out from the bat- tery box, and then disconnect the

battery couplers.

1. Negative battery lead

2. Positive battery lead (red)

To install the battery1. Connect the battery couplers, and then place the battery in the

original position.

2. Install the battery holder bracket by installing the bolt.

3. Install the panel by installing the screw.

4. Close the storage compartment.

5. Fully charge the battery before installation.

ECA16530

NOTICE

Always keep the battery charged.

Storing a discharged battery can

cause permanent battery damage.

PERIODIC MAINTENANCE AND ADJUSTMENT

6-25

6

1C0-F8199-E5.QXD 23/10/08 15:32 Página 67

Page 68 of 92

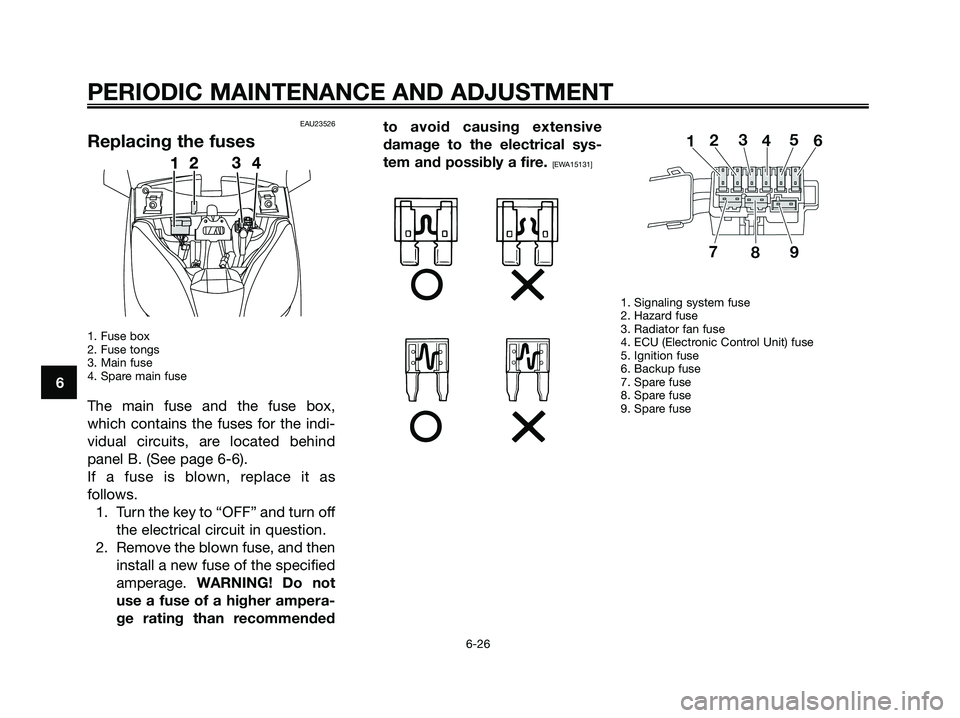

EAU23526

Replacing the fuses

1. Fuse box

2. Fuse tongs

3. Main fuse

4. Spare main fuse

The main fuse and the fuse box,

which contains the fuses for the indi-

vidual circuits, are located behind

panel B. (See page 6-6).

If a fuse is blown, replace it as

follows.

1. Turn the key to “OFF” and turn off

the electrical circuit in question.

2. Remove the blown fuse, and then

install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a higher ampera-

ge rating than recommendedto avoid causing extensive

damage to the electrical sys-

tem and possibly a fire.

[EWA15131]

1. Signaling system fuse

2. Hazard fuse

3. Radiator fan fuse

4. ECU (Electronic Control Unit) fuse

5. Ignition fuse

6. Backup fuse

7. Spare fuse

8. Spare fuse

9. Spare fuse

PERIODIC MAINTENANCE AND ADJUSTMENT

6-26

6

1C0-F8199-E5.QXD 3/10/08 05:56 Página 68

Page 69 of 92

3. Turn the key to “ON” and turn on

the electrical circuit in question to

check if the device operates.

4. If the fuse immediately blows

again, have a Yamaha dealer

check the electrical system.

EAU23911

Replacing a headlight bulb

This model is equipped with quartz

bulb headlights. If a headlight bulb

burns out, replace it as follows.

ECA10660

NOTICE

Do not touch the glass part of the

headlight bulb to keep it free from

oil, otherwise the transparency of

the glass, the luminosity of the

bulb, and the bulb life will be adver-

sely affected. Thoroughly clean off

any dirt and fingerprints on the

headlight bulb using a cloth mois-

tened with alcohol or thinner.

1. Do not touch the glass part of the bulb.

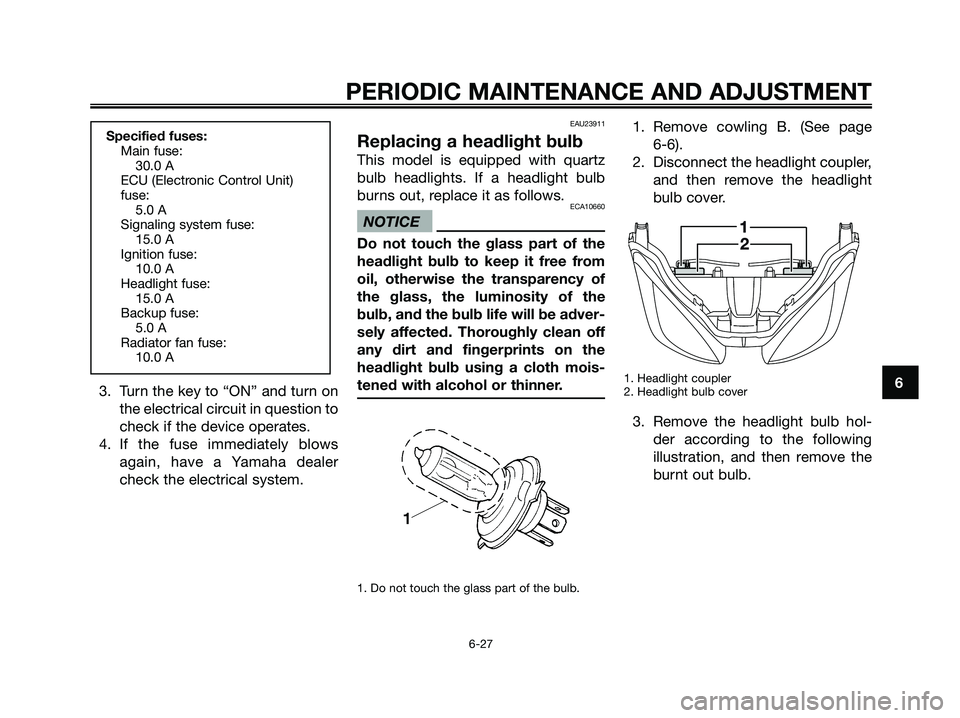

1. Remove cowling B. (See page

6-6).

2. Disconnect the headlight coupler,

and then remove the headlight

bulb cover.

1. Headlight coupler

2. Headlight bulb cover

3. Remove the headlight bulb hol-

der according to the following

illustration, and then remove the

burnt out bulb.

Specified fuses:

Main fuse:

30.0 A

ECU (Electronic Control Unit)

fuse:

5.0 A

Signaling system fuse:

15.0 A

Ignition fuse:

10.0 A

Headlight fuse:

15.0 A

Backup fuse:

5.0 A

Radiator fan fuse:

10.0 A

PERIODIC MAINTENANCE AND ADJUSTMENT

6-27

6

1C0-F8199-E5.QXD 3/10/08 05:56 Página 69

Page 70 of 92

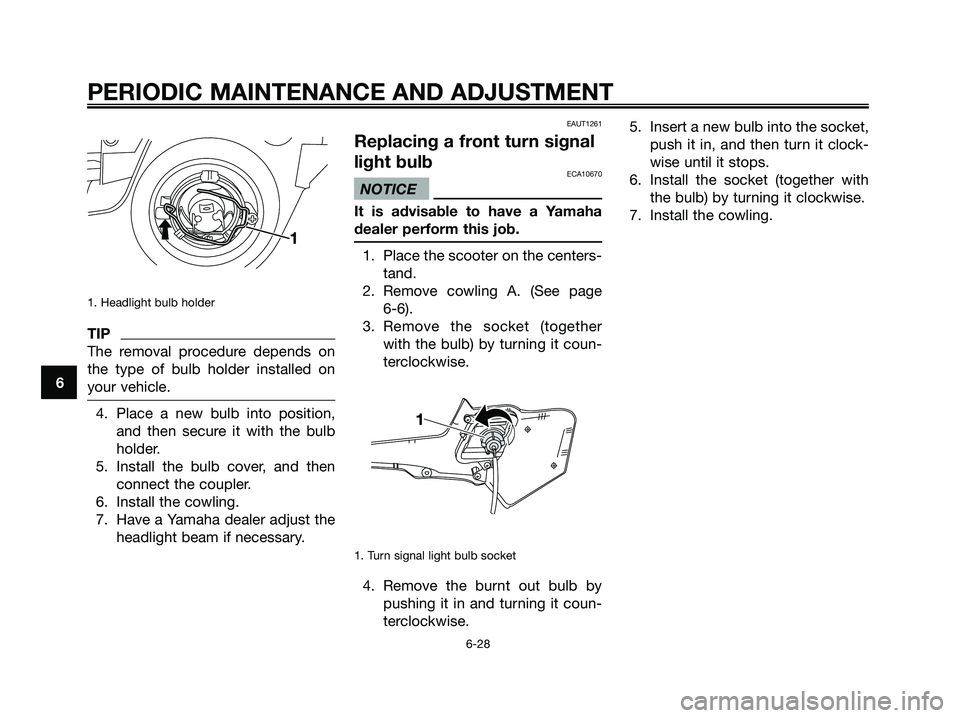

1. Headlight bulb holder

TIP

The removal procedure depends on

the type of bulb holder installed on

your vehicle.

4. Place a new bulb into position,

and then secure it with the bulb

holder.

5. Install the bulb cover, and then

connect the coupler.

6. Install the cowling.

7. Have a Yamaha dealer adjust the

headlight beam if necessary.

EAUT1261

Replacing a front turn signal

light bulb

ECA10670

NOTICE

It is advisable to have a Yamaha

dealer perform this job.

1. Place the scooter on the centers-

tand.

2. Remove cowling A. (See page

6-6).

3. Remove the socket (together

with the bulb) by turning it coun-

terclockwise.

1. Turn signal light bulb socket

4. Remove the burnt out bulb by

pushing it in and turning it coun-

terclockwise.5. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

6. Install the socket (together with

the bulb) by turning it clockwise.

7. Install the cowling.

PERIODIC MAINTENANCE AND ADJUSTMENT

6-28

6

1C0-F8199-E5.QXD 3/10/08 05:56 Página 70