YAMAHA XMAX 300 2022 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2022, Model line: XMAX 300, Model: YAMAHA XMAX 300 2022Pages: 116, PDF Size: 4.64 MB

Page 51 of 116

Instrument and control functions

4-21

4

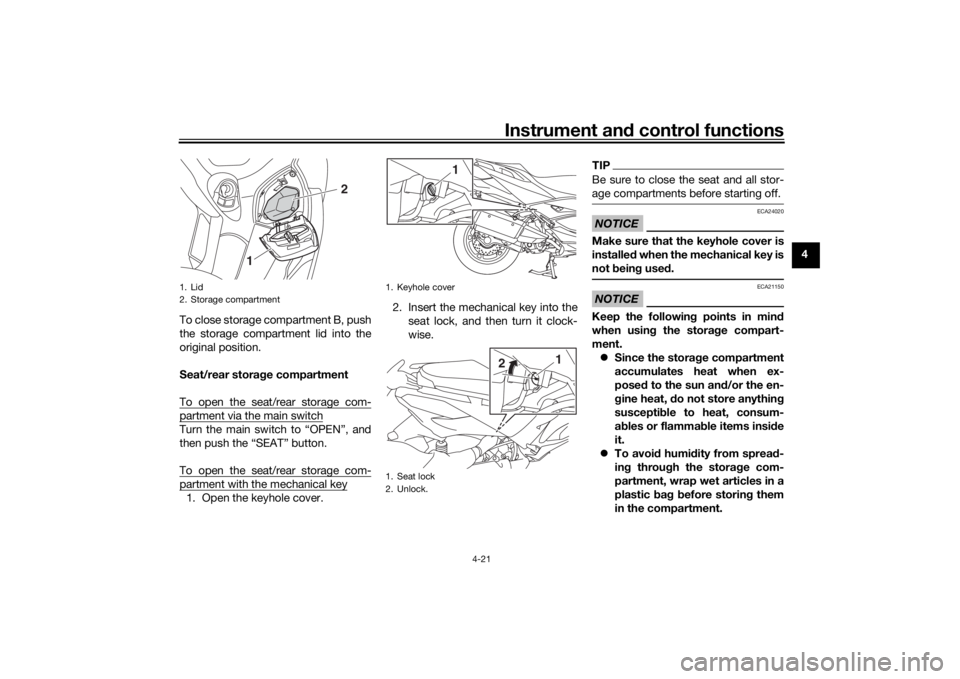

To close storage compartment B, push

the storage compartment lid into the

original position.

Seat/rear stora ge compartment

To open the seat/rear storage com-

partment via the main switchTurn the main switch to “OPEN”, and

then push the “SEAT” button.

To open the seat/rear storage com-partment with the mechanical key1. Open the keyhole cover. 2. Insert the mechanical key into the

seat lock, and then turn it clock-

wise.

TIPBe sure to close the seat and all stor-

age compartments before starting off.NOTICE

ECA24020

Make sure that the keyhole cover is

installe d when the mechanical key is

not bein g use d.NOTICE

ECA21150

Keep the followin g points in min d

when usin g the stora ge compart-

ment. Since the storag e compartment

accumulates heat when ex-

pose d to the sun an d/or the en-

g ine heat, d o not store anythin g

suscepti ble to heat, consum-

a b les or flamma ble items insi de

it.

To avoi d humi dity from sprea d-

in g throu gh the stora ge com-

partment, wrap wet articles in a

plastic bag b efore storin g them

in the compartment.

1. Lid

2. Storage compartment

1 2

1. Keyhole cover

1. Seat lock

2. Unlock.

1

1

2

UBBAE1E0.book Page 21 Monday, October 4, 2021 4:51 PM

Page 52 of 116

Instrument and control functions

4-22

4

Since the stora ge compartment

may get wet while the vehicle is

b ein g washe d, wrap any articles

store d in the compartment in a

plastic bag .

Do not keep anythin g valua ble

or breakab le in the stora ge

compartment.

WARNING

EWA18950

Do not exceed the load limit of 1

k g (2.2 l b) for stora ge compart-

ment A.

Do not exceed the load limit of

0.5 k g (1.1 l b) for stora ge com-

partment B.

Do not exceed the load limit of 5

k g (11 l b) for the rear storag e

compartment.

Do not exceed the maximum

loa d of 161 k g (355 l b) for the ve-

hicle.

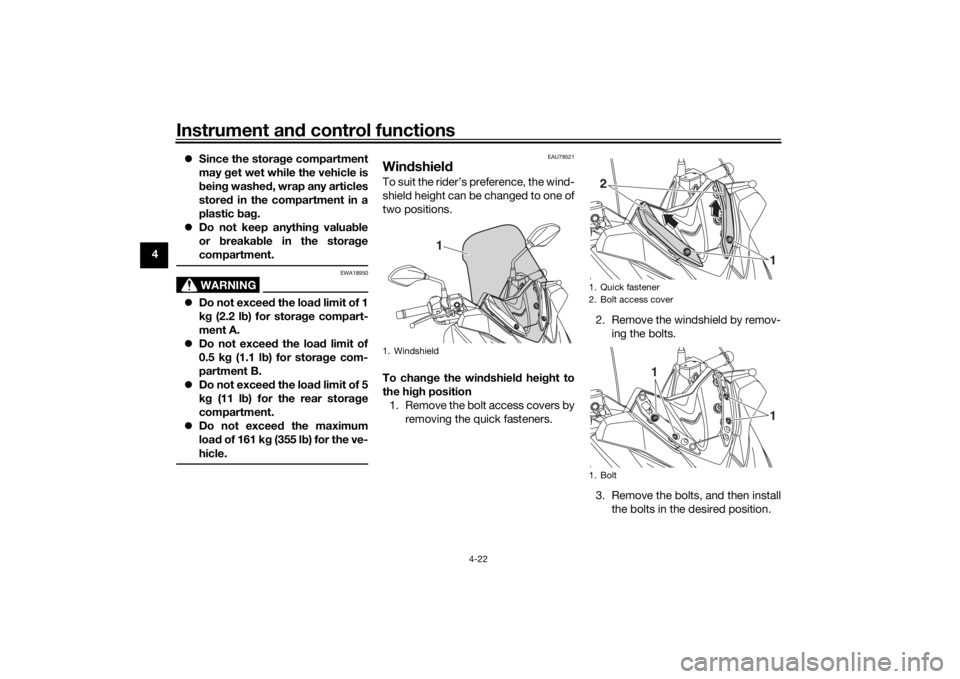

EAU78521

Win dshiel dTo suit the rider’s preference, the wind-

shield height can be changed to one of

two positions.

To chan ge the win dshiel d hei ght to

the hi gh position

1. Remove the bolt access covers by removing the quick fasteners. 2. Remove the windshield by remov-

ing the bolts.

3. Remove the bolts, and then install the bolts in the desired position.1. Windshield

1

1. Quick fastener

2. Bolt access cover

1. Bolt2

1

1

1

UBBAE1E0.book Page 22 Monday, October 4, 2021 4:51 PM

Page 53 of 116

Instrument and control functions

4-23

4

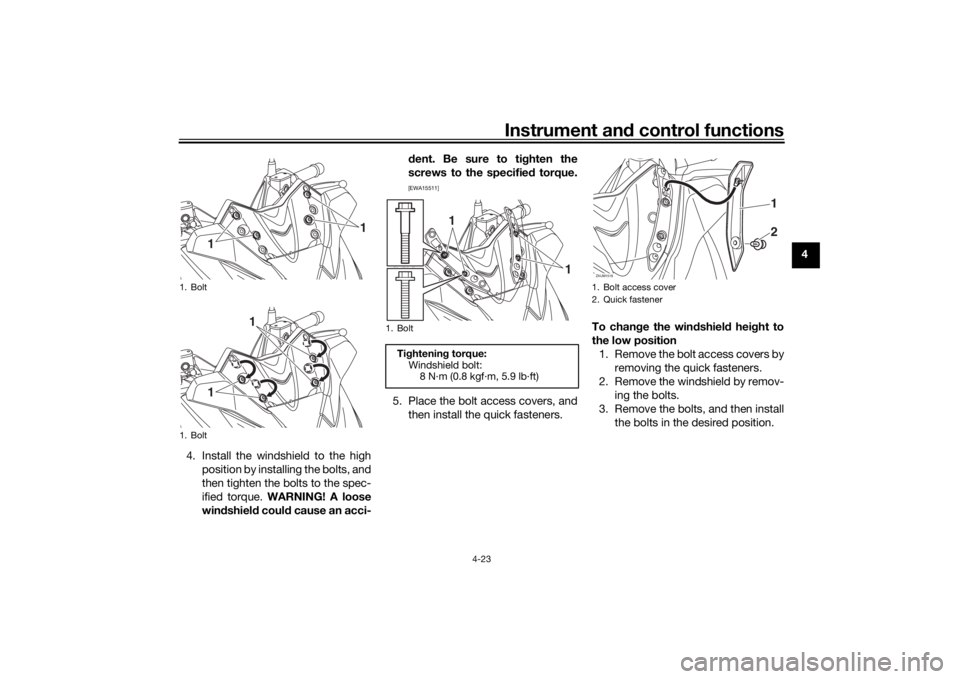

4. Install the windshield to the high position by installing the bolts, and

then tighten the bolts to the spec-

ified torque. WARNING! A loose

win dshiel d coul d cause an acci- d

ent. Be sure to ti ghten the

screws to the specifie d torque.

[EWA15511]

5. Place the bolt access covers, and

then install the quick fasteners. To chan

ge the win dshiel d hei ght to

the low position 1. Remove the bolt access covers by removing the quick fasteners.

2. Remove the windshield by remov- ing the bolts.

3. Remove the bolts, and then install the bolts in the desired position.

1. Bolt

1. Bolt

1

1

1

1

1. Bolt

Tightenin g torque:

Windshield bolt: 8 N·m (0.8 kgf·m, 5.9 lb·ft)

1

1

1. Bolt access cover

2. Quick fastenerZAUM1518

12

UBBAE1E0.book Page 23 Monday, October 4, 2021 4:51 PM

Page 54 of 116

Instrument and control functions

4-24

4

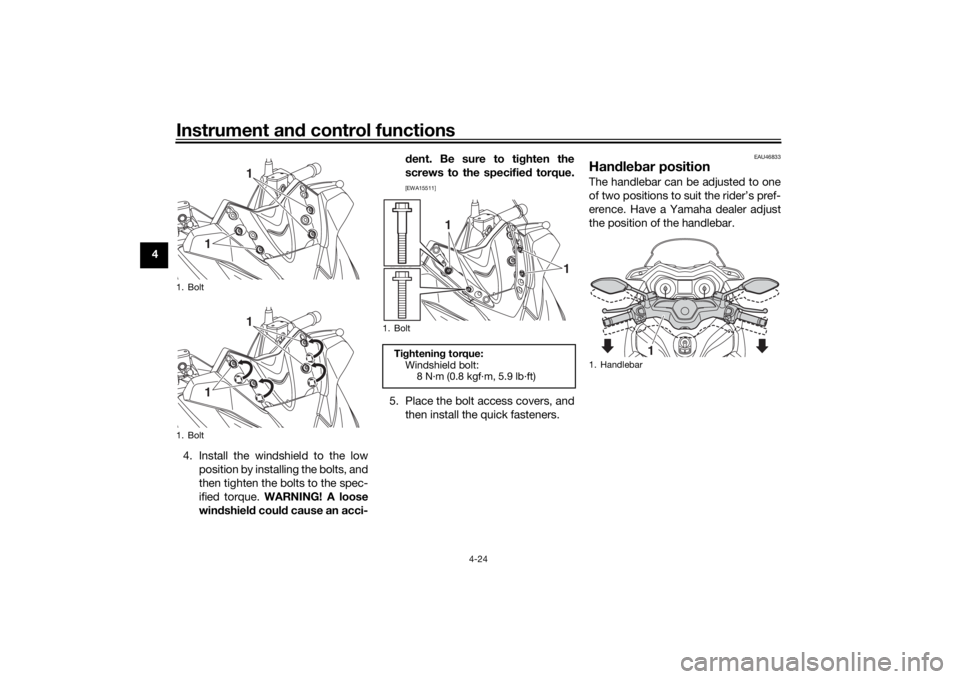

4. Install the windshield to the lowposition by installing the bolts, and

then tighten the bolts to the spec-

ified torque. WARNING! A loose

win dshield could cause an acci- d

ent. Be sure to ti ghten the

screws to the specifie d torque.

[EWA15511]

5. Place the bolt access covers, and

then install the quick fasteners.

EAU46833

Han dle bar position The handlebar can be adjusted to one

of two positions to suit the rider’s pref-

erence. Have a Yamaha dealer adjust

the position of the handlebar.

1. Bolt

1. Bolt

1

11

1

1. BoltTi ghtenin g torque:

Windshield bolt: 8 N·m (0.8 kgf·m, 5.9 lb·ft)

1

1

1. Handlebar

1

UBBAE1E0.book Page 24 Monday, October 4, 2021 4:51 PM

Page 55 of 116

Instrument and control functions

4-25

4

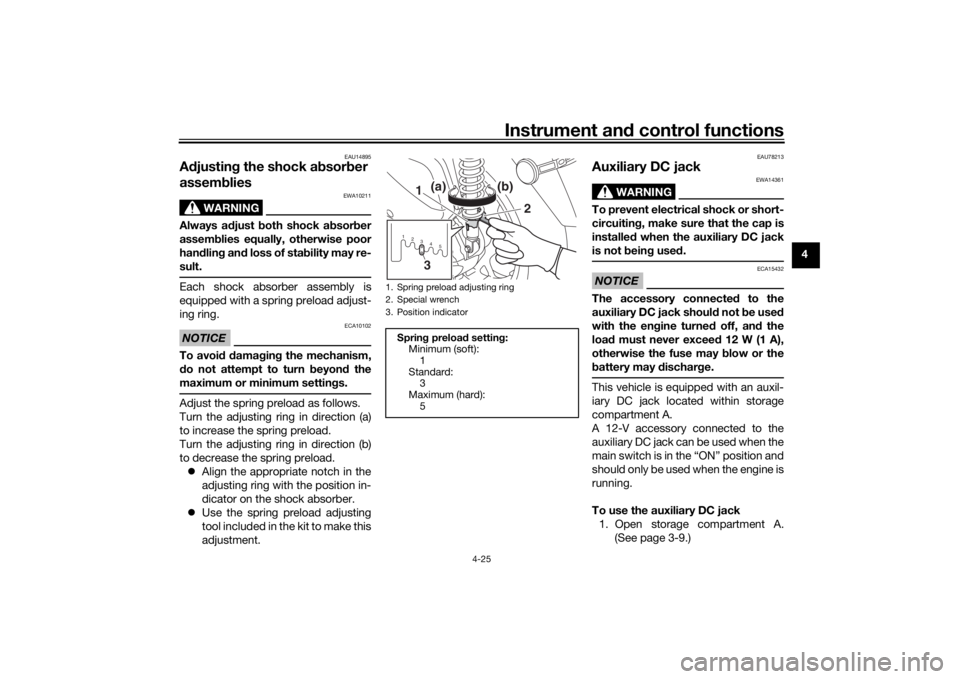

EAU14895

A djustin g the shock a bsor ber

assem blies

WARNING

EWA10211

Always a djust both shock a bsor ber

assem blies equally, otherwise poor

han dlin g an d loss of sta bility may re-

sult.Each shock absorber assembly is

equipped with a spring preload adjust-

ing ring.NOTICE

ECA10102

To avoi d d amag ing the mechanism,

d o not attempt to turn b eyond the

maximum or minimum settin gs.Adjust the spring preload as follows.

Turn the adjusting ring in direction (a)

to increase the spring preload.

Turn the adjusting ring in direction (b)

to decrease the spring preload.

Align the appropriate notch in the

adjusting ring with the position in-

dicator on the shock absorber.

Use the spring preload adjusting

tool included in the kit to make this

adjustment.

EAU78213

Auxiliary DC jack

WARNING

EWA14361

To prevent electrical shock or short-

circuitin g, make sure that the cap is

installe d when the auxiliary DC jack

is not b eing use d.NOTICE

ECA15432

The accessory connecte d to the

auxiliary DC jack shoul d not b e used

with the en gine turne d off, an d the

loa d must never excee d 12 W (1 A),

otherwise the fuse may blow or the

b attery may dischar ge.This vehicle is equipped with an auxil-

iary DC jack located within storage

compartment A.

A 12-V accessory connected to the

auxiliary DC jack can be used when the

main switch is in the “ON” position and

should only be used when the engine is

running.

To use the auxiliary DC jack

1. Open storage compartment A. (See page 3-9.)

1. Spring preload adjusting ring

2. Special wrench

3. Position indicator

Sprin g preloa d settin g:

Minimum (soft):

1

Standard: 3

Maximum (hard): 51 2345

2

1

(a)

(b)

3

UBBAE1E0.book Page 25 Monday, October 4, 2021 4:51 PM

Page 56 of 116

Instrument and control functions

4-26

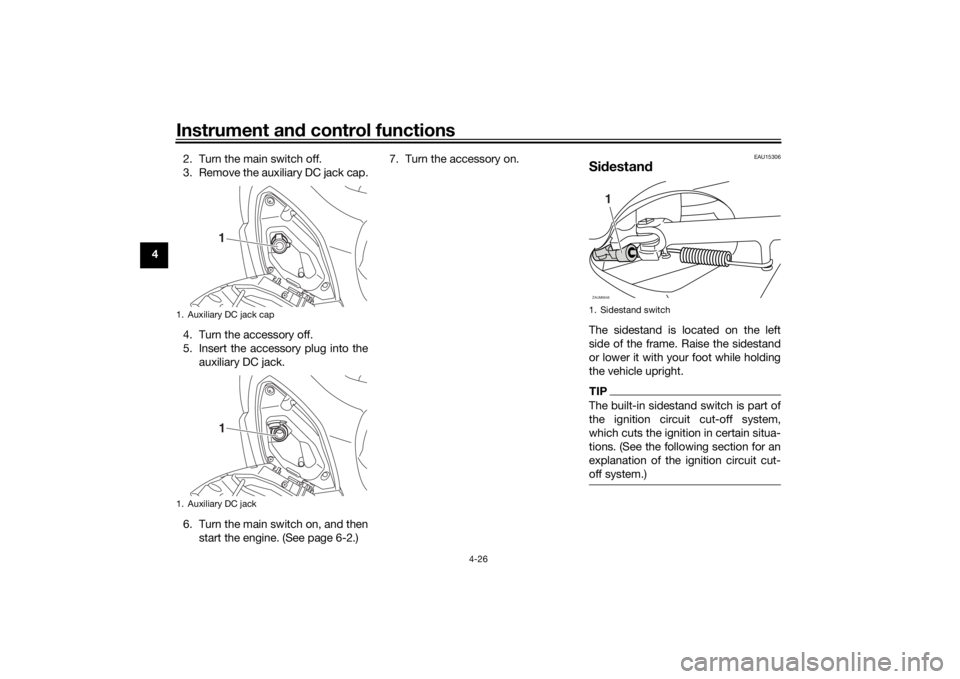

4 2. Turn the main switch off.

3. Remove the auxiliary DC jack cap.

4. Turn the accessory off.

5. Insert the accessory plug into the

auxiliary DC jack.

6. Turn the main switch on, and then start the engine. (See page 6-2.) 7. Turn the accessory on.

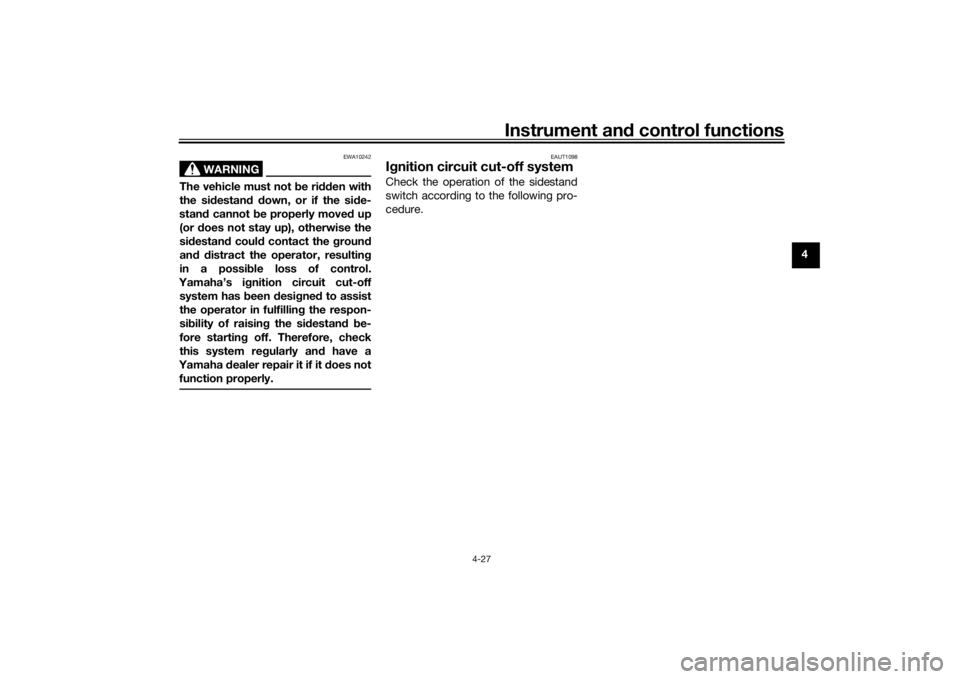

EAU15306

Si

destan dThe sidestand is located on the left

side of the frame. Raise the sidestand

or lower it with your foot while holding

the vehicle upright.TIPThe built-in sidestand switch is part of

the ignition circuit cut-off system,

which cuts the ignition in certain situa-

tions. (See the following section for an

explanation of the ignition circuit cut-

off system.)

1. Auxiliary DC jack cap

1. Auxiliary DC jack

11

1. Sidestand switchZAUM0648

1

UBBAE1E0.book Page 26 Monday, October 4, 2021 4:51 PM

Page 57 of 116

Instrument and control functions

4-27

4

WARNING

EWA10242

The vehicle must not b e ridden with

the si destan d d own, or if the si de-

stan d cannot b e properly move d up

(or does not stay up), otherwise the

si destan d coul d contact the groun d

an d d istract the operator, resultin g

in a possi ble loss of control.

Yamaha’s i gnition circuit cut-off

system has been desi gne d to assist

the operator in fulfilling the respon-

si bility of raisin g the si destan d b e-

fore startin g off. Therefore, check

this system re gularly an d have a

Yamaha dealer repair it if it does not

function properly.

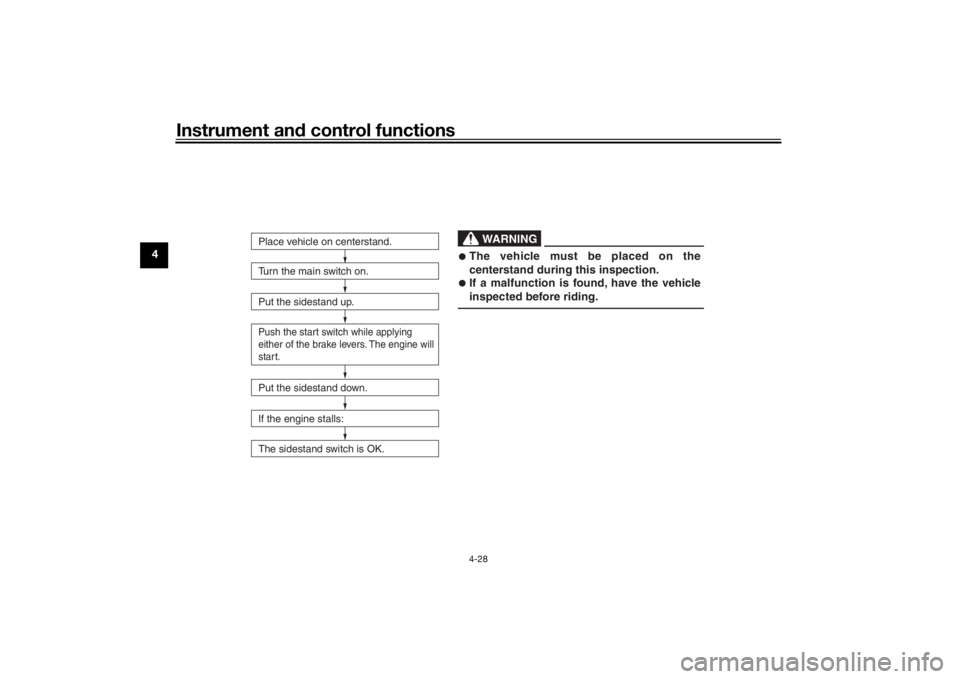

EAUT1098

I g nition circuit cut-off systemCheck the operation of the sidestand

switch according to the following pro-

cedure.

UBBAE1E0.book Page 27 Monday, October 4, 2021 4:51 PM

Page 58 of 116

Instrument and control functions

4-28

4

Turn the main switch on.

Put the sidestand up.Push the start switch while applying

either of the brake levers. The engine will

start.Put the sidestand down.

If the engine stalls:

The sidestand switch is OK.Place vehicle on centerstand.

WARNING

The vehicle must be placed on the

centerstand during this inspection.

If a malfunction is found, have the vehicle

inspected before riding.

UBBAE1E0.book Page 28 Monday, October 4, 2021 4:51 PM

Page 59 of 116

For your safety – pre-operation checks

5-1

5

EAU1559B

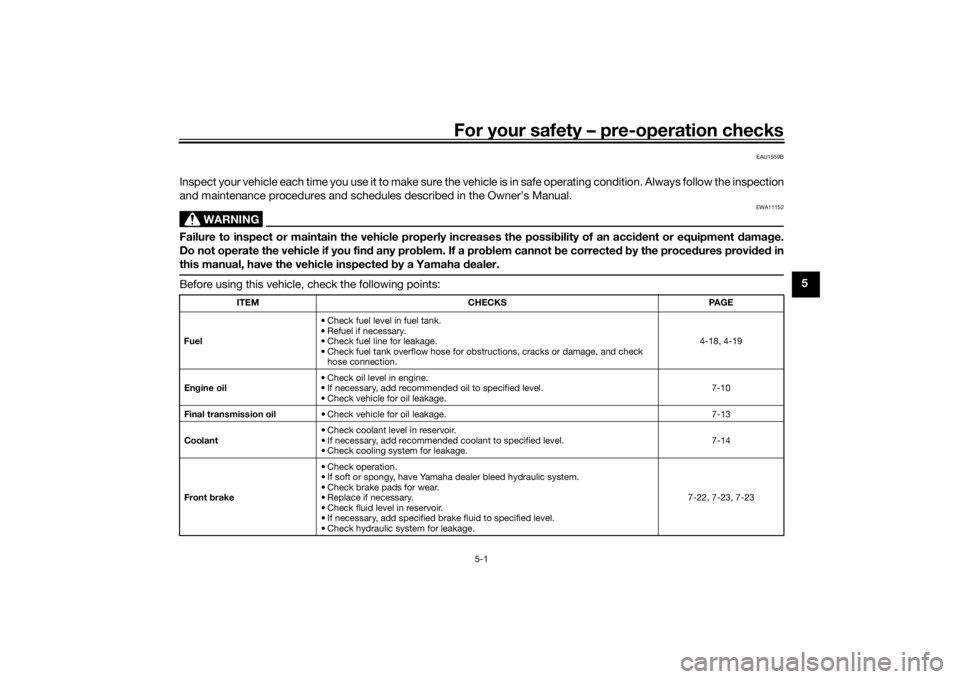

Inspect your vehicle each time you use it to make sure the vehicle is in safe operating condition. Always follow the inspection

and maintenance procedures and schedules described in the Owner’s Manual.

WARNING

EWA11152

Failure to inspect or maintain the vehicle properly increases the possibility of an acci dent or equipment damag e.

Do not operate the vehicle if you fin d any pro blem. If a pro blem cannot be corrected b y the proce dures provi ded in

this manual, have the vehicle inspecte d b y a Yamaha dealer.Before using this vehicle, check the following points:

ITEM CHECKS PAGE

Fuel • Check fuel level in fuel tank.

• Refuel if necessary.

• Check fuel line for leakage.

• Check fuel tank overflow hose for obstructions, cracks or damage, and check

hose connection. 4-18, 4-19

En gine oil • Check oil level in engine.

• If necessary, add recommended oil to specified level.

• Check vehicle for oil leakage. 7-10

Final transmission oil • Check vehicle for oil leakage. 7-13

Coolant • Check coolant level in reservoir.

• If necessary, add recommended coolant to specified level.

• Check cooling system for leakage. 7-14

Front brake • Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic system.

• Check brake pads for wear.

• Replace if necessary.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage. 7-22, 7-23, 7-23

UBBAE1E0.book Page 1 Monday, October 4, 2021 4:51 PM

Page 60 of 116

For your safety – pre-operation checks

5-2

5

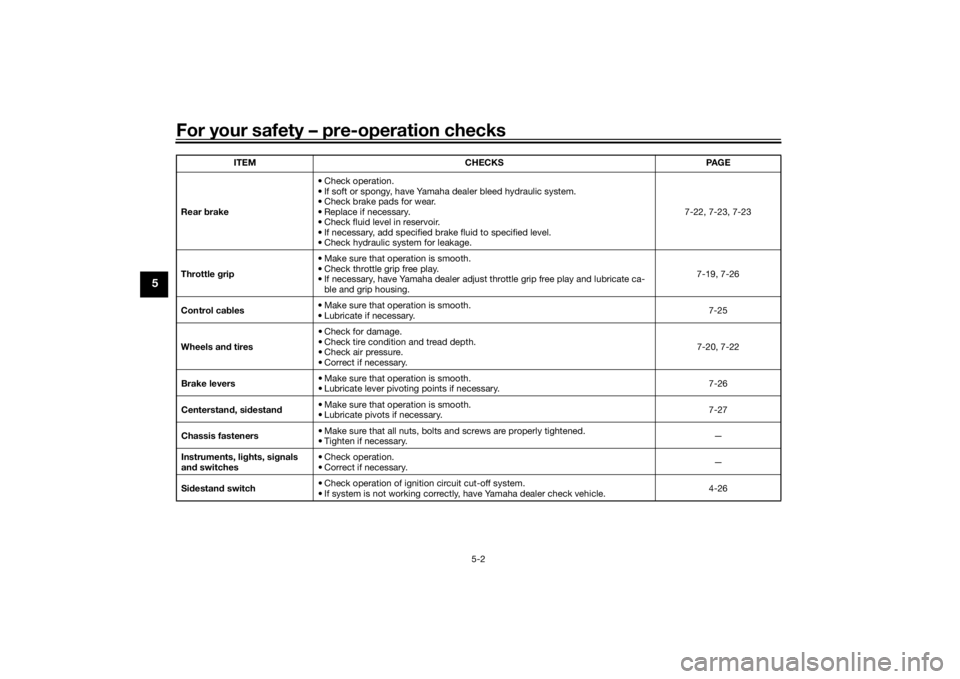

Rear brake • Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic system.

• Check brake pads for wear.

• Replace if necessary.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage. 7-22, 7-23, 7-23

Throttle g rip • Make sure that operation is smooth.

• Check throttle grip free play.

• If necessary, have Yamaha dealer adjust throttle grip free play and lubricate ca-

ble and grip housing. 7-19, 7-26

Control ca bles • Make sure that operation is smooth.

• Lubricate if necessary. 7-25

Wheels an d tires •Check for damage.

• Check tire condition and tread depth.

• Check air pressure.

• Correct if necessary. 7-20, 7-22

Brake levers • Make sure that operation is smooth.

• Lubricate lever pivoting points if necessary.

7-26

Centerstan d, si destan d • Make sure that operation is smooth.

• Lubricate pivots if necessary.

7-27

Chassis fasteners • Make sure that all nuts, bolts and screws are properly tightened.

• Tighten if necessary. —

Instruments, li ghts, si gnals

an d switches • Check operation.

• Correct if necessary.

—

Si destan d switch • Check operation of ignition circuit cut-off system.

• If system is not working correctly, have Yamaha dealer check vehicle.

4-26

ITEM

CHECKS PAGE

UBBAE1E0.book Page 2 Monday, October 4, 2021 4:51 PM