YAMAHA XSR 900 2020 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2020, Model line: XSR 900, Model: YAMAHA XSR 900 2020Pages: 102, PDF Size: 7.74 MB

Page 51 of 102

6-1

1

2

3

4

567

8

9

10

11

12

Periodic maintenance and adjustment

EAU17246

Periodic inspection, adjustment, and lu-

brication will keep your vehicle in the

safest and most efficient condition pos-

sible. Safety is an obligation of the vehi-

cle owner/operator. The most important

points of vehicle inspection, adjust-

ment, and lubrication are explained on

the following pages.

The intervals given in the periodic

maintenance charts should be simply

considered as a general guide under

normal riding conditions. However, de-

pending on the weather, terrain, geo-

graphical location, and individual use,

the maintenance intervals may need to

be shortened.

WARNING

EWA10322

Failure to properly maintain the ve-

hicle or performing maintenance ac-

tivities incorrectly may increase

your risk of injury or death during

service or while using the vehicle. If

you are not familiar with vehicle ser-

vice, have a Yamaha dealer performservice.

WARNING

EWA15123

Turn off the engine when performing

maintenance unless otherwise

specified.

A running engine has moving

parts that can catch on body

parts or clothing and electrical

parts that can cause shocks or

fires.

Running the engine while ser-

vicing can lead to eye injury,

burns, fire, or carbon monoxide

poisoning – possibly leading to

death. See page 1-2 for more in-

formation about carbon monox-ide.WARNING

EWA15461

Brake discs, calipers, drums, and

linings can become very hot during

use. To avoid possible burns, let

brake components cool beforetouching them.

EAU17303

Emission controls not only function to

ensure cleaner air, but are also vital to

proper engine operation and maximum

performance. In the following periodic

maintenance charts, the services relat-

ed to emissions control are grouped

separately. These services require

specialized data, knowledge, and

equipment. Maintenance, replacement,

or repair of the emission control devic-

es and systems may be performed by

any repair establishment or individual

that is certified (if applicable). Yamaha

dealers are trained and equipped to

perform these particular services.

BAE-28199-E1.book 1 ページ 2019年8月23日 金曜日 午後3時56分

Page 52 of 102

Periodic maintenance and adjustment

6-2

1

2

3

4

56

7

8

9

10

11

12

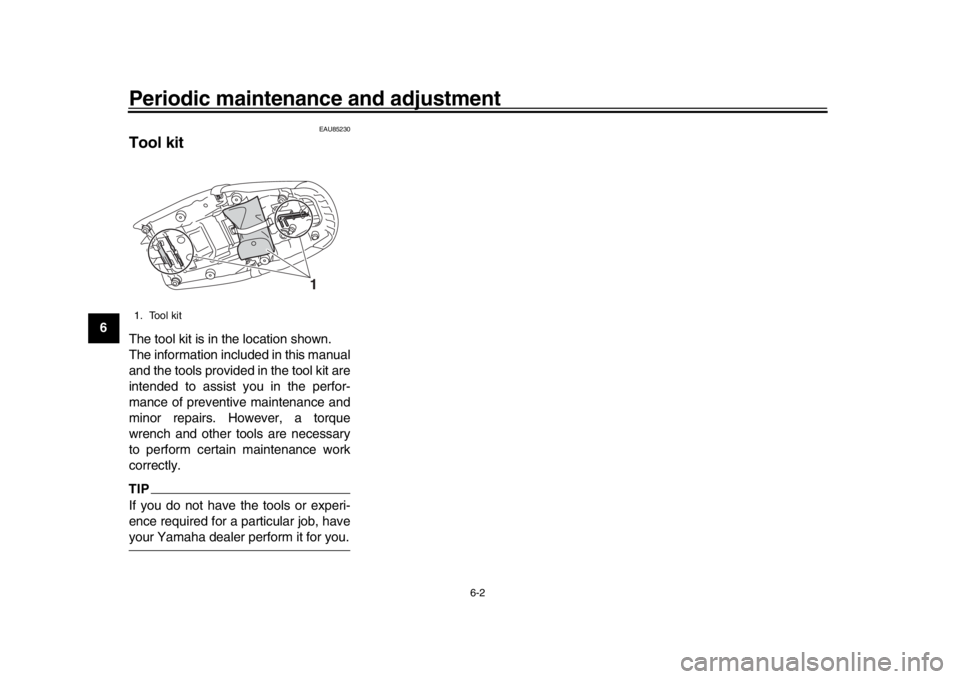

EAU85230

Tool kitThe tool kit is in the location shown.

The information included in this manual

and the tools provided in the tool kit are

intended to assist you in the perfor-

mance of preventive maintenance and

minor repairs. However, a torque

wrench and other tools are necessary

to perform certain maintenance work

correctly.TIPIf you do not have the tools or experi-

ence required for a particular job, haveyour Yamaha dealer perform it for you.1. Tool kit

1

BAE-28199-E1.book 2 ページ 2019年8月23日 金曜日 午後3時56分

Page 53 of 102

Periodic maintenance and adjustment

6-3

1

2

3

4

567

8

9

10

11

12

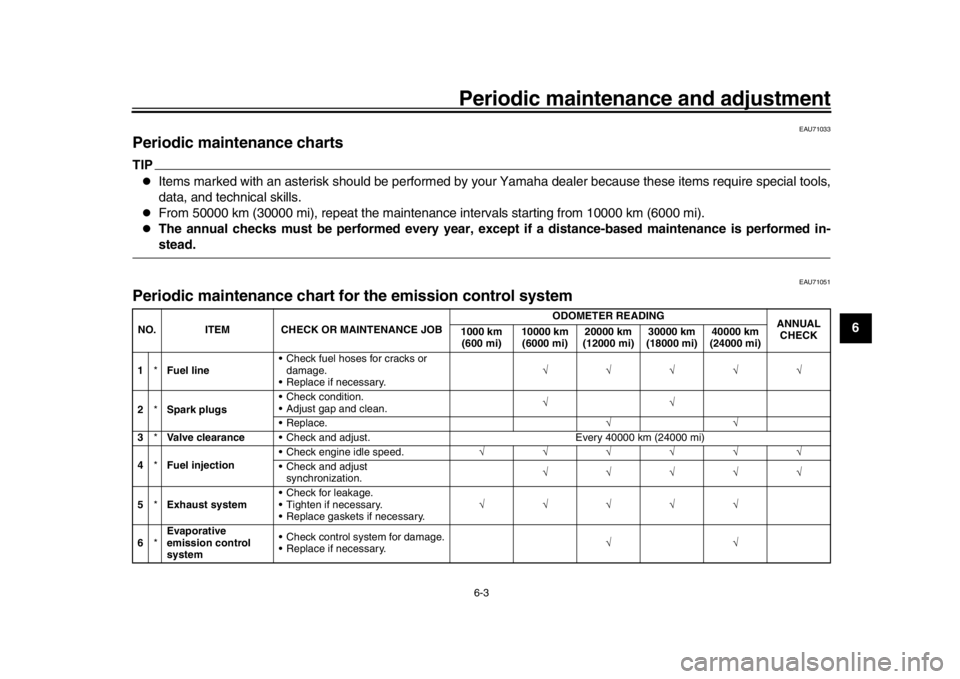

EAU71033

Periodic maintenance chartsTIP

Items marked with an asteri sk should be performed by your Yamaha dealer because these items require special tools,

data, and technical skills.

From 50000 km (30000 mi), repeat the maintenance intervals starting from 10000 km (6000 mi).

The annual checks must be performed every year, except if a distance-based maintenance is performed in-stead.

EAU71051

Periodic maintenance chart fo r the emission control systemNO. ITEM CHECK OR MAINTENANCE JOB ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

1 *Fuel line Check fuel hoses for cracks or

damage.

Replace if necessary.

2 *Spark plugs Check condition.

Adjust gap and clean.

Replace.

3 *Valve clearance Check and adjust. Every 40000 km (24000 mi)

4 *Fuel injection Check engine idle speed.

Check and adjust synchronization.

5 *Exhaust system Check for leakage.

Tighten if necessary.

Replace gaskets if necessary.

6 *Evaporative

emission control

system Check control system for damage.

Replace if necessary.

BAE-28199-E1.book 3 ページ 2019年8月23日 金曜日 午後3時56分

Page 54 of 102

Periodic maintenance and adjustment

6-4

1

2

3

4

56

7

8

9

10

11

12

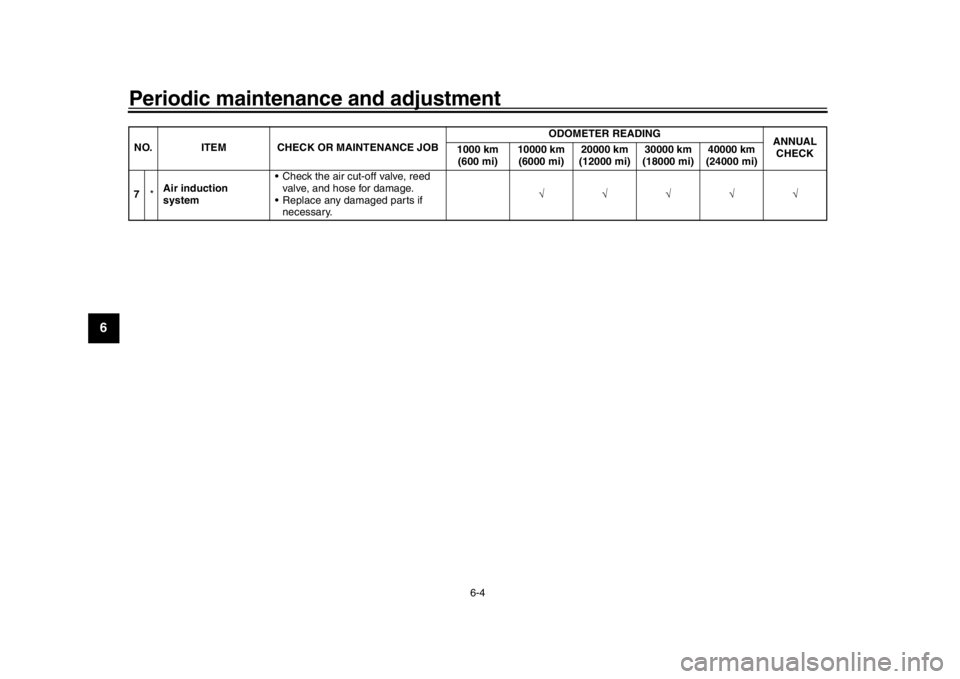

7 *Air induction

system Check the air cut-off valve, reed

valve, and hose for damage.

Replace any damaged parts if necessary.

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

BAE-28199-E1.book 4 ページ 2019年8月23日 金曜日 午後3時56分

Page 55 of 102

Periodic maintenance and adjustment

6-5

1

2

3

4

567

8

9

10

11

12

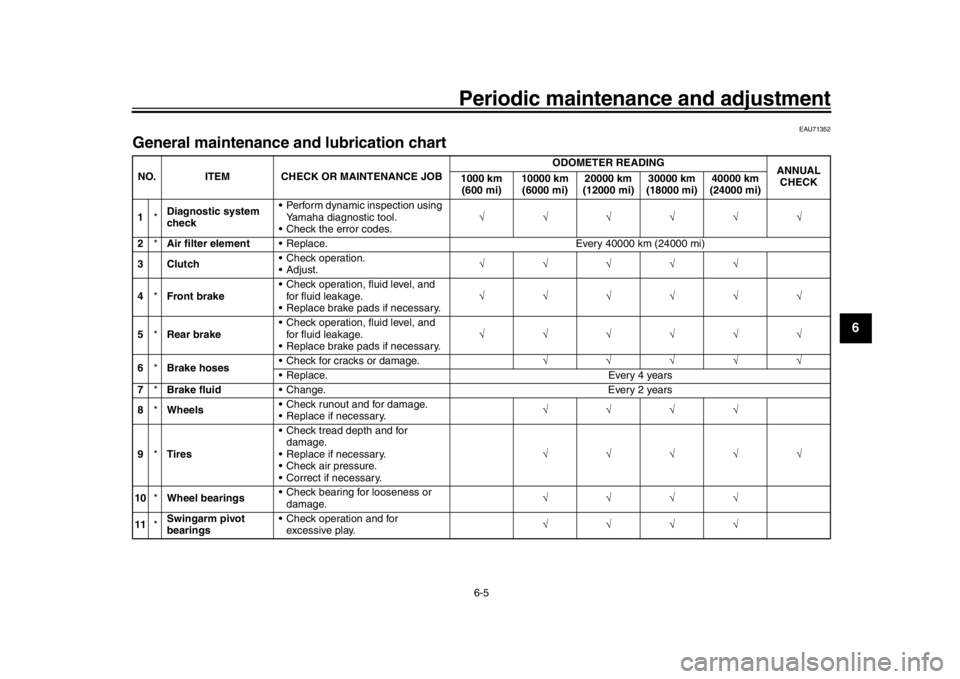

EAU71352

General maintenance an d lubrication chartNO. ITEM CHECK OR MAINTENANCE JOB ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

1 *Diagnostic system

check Perform dynamic inspection using

Yamaha diagnostic tool.

Check the error codes.

2 *Air filter element Replace. Every 40000 km (24000 mi)

3Clutch Check operation.

Adjust.

4 *Front brake Check operation, fluid level, and

for fluid leakage.

Replace brake pads if necessary.

5 *Rear brake Check operation, fluid level, and

for fluid leakage.

Replace brake pads if necessary.

6 *Brake hoses Check for cracks or damage.

Replace. Every 4 years

7 *Brake fluid Change. Every 2 years

8 *Wheels Check runout and for damage.

Replace if necessary.

9 *Tires Check tread depth and for

damage.

Replace if necessary.

Check air pressure.

Correct if necessary.

10 *Wheel bearings Check bearing for looseness or

damage.

11 *Swingarm pivot

bearings Check operation and for

excessive play.

BAE-28199-E1.book 5 ページ 2019年8月23日 金曜日 午後3時56分

Page 56 of 102

Periodic maintenance and adjustment

6-6

1

2

3

4

56

7

8

9

10

11

12

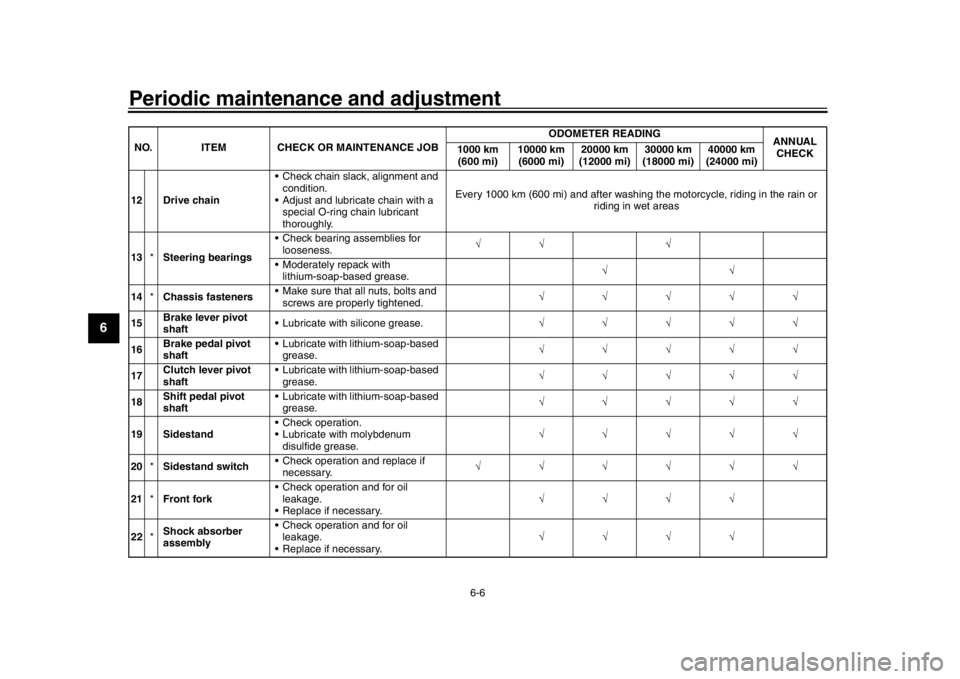

12 Drive chain Check chain slack, alignment and

condition.

Adjust and lubricate chain with a special O-ring chain lubricant

thoroughly. Every 1000 km (600 mi) and after washing the motorcycle, riding in the rain or

riding in wet areas

13 *Steering bearings Check bearing assemblies for

looseness.

Moderately repack with lithium-soap-based grease.

14 *Chassis fasteners Make sure that all nuts, bolts and

screws are properly tightened.

15 Brake lever pivot

shaft Lubricate with silicone grease.

16 Brake pedal pivot

shaft Lubricate with lithium-soap-based

grease.

17 Clutch lever pivot

shaft Lubricate with lithium-soap-based

grease.

18 Shift pedal pivot

shaft Lubricate with lithium-soap-based

grease.

19 Sidestand Check operation.

Lubricate with molybdenum

disulfide grease.

20 *Sidestand switch Check operation and replace if

necessary.

21 *Front fork Check operation and for oil

leakage.

Replace if necessary.

22 *Shock absorber

assembly Check operation and for oil

leakage.

Replace if necessary.

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)BAE-28199-E1.book 6 ページ 2019年8月23日 金曜日 午後3時56分

Page 57 of 102

Periodic maintenance and adjustment

6-7

1

2

3

4

567

8

9

10

11

12

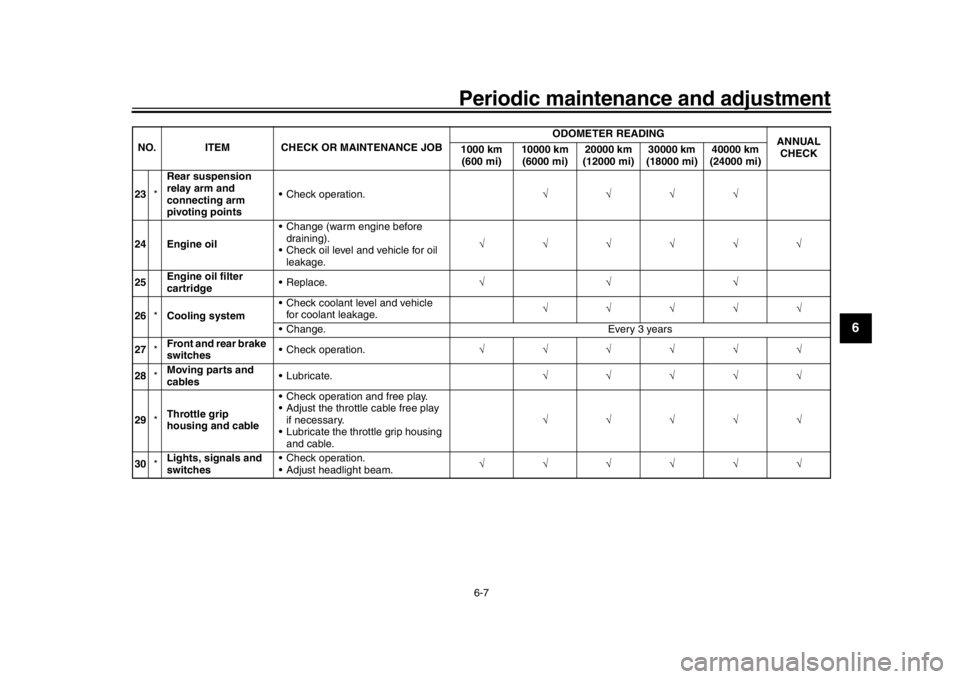

23 *Rear suspension

relay arm and

connecting arm

pivoting points Check operation.

24 Engine oil Change (warm engine before

draining).

Check oil level and vehicle for oil leakage.

25 Engine oil filter

cartridge Replace.

26 *Cooling system Check coolant level and vehicle

for coolant leakage.

Change. Every 3 years

27 *Front and rear brake

switches Check operation.

28 *Moving parts and

cables Lubricate.

29 *Throttle grip

housing and cable Check operation and free play.

Adjust the throttle cable free play

if necessary.

Lubricate the throttle grip housing and cable.

30 *Lights, signals and

switches Check operation.

Adjust headlight beam.

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

BAE-28199-E1.book 7 ページ 2019年8月23日 金曜日 午後3時56分

Page 58 of 102

Periodic maintenance and adjustment

6-8

1

2

3

4

56

7

8

9

10

11

12

EAU72800

TIP

Air filter

This model’s air filter is equipped wi th a disposable oil-coated paper elemen t, which must not be cleaned with com-

pressed air to avoid damaging it.

The air filter element needs to be replaced more fr equently when riding in unusually wet or dusty areas.

Hydraulic brake service

Regularly check and, if necessary, correct the brake fluid level.

Every two years replace the internal components of t he brake master cylinders and calipers, and change the brake

fluid. Replace the brake hoses every four years and if cracked or damaged.

BAE-28199-E1.book 8 ページ 2019年8月23日 金曜日 午後3時56分

Page 59 of 102

Periodic maintenance and adjustment

6-9

1

2

3

4

567

8

9

10

11

12

EAU19653

Checking the spark plugsThe spark plugs are important engine

components, which should be checked

periodically, preferably by a Yamaha

dealer. Since heat and deposits will

cause any spark plug to slowly erode,

they should be removed and checked

in accordance with the periodic mainte-

nance and lubrication chart. In addition,

the condition of the spark plugs can re-

veal the condition of the engine.

The porcelain insulator around the cen-

ter electrode of each spark plug should

be a medium-to-light tan (the ideal color

when the vehicle is ridden normally),

and all spark plugs installed in the en-

gine should have the same color. If any

spark plug shows a distinctly different

color, the engine could be operating im-

properly. Do not attempt to diagnose

such problems yourself. Instead, have

a Yamaha dealer check the vehicle.

If a spark plug shows signs of electrode

erosion and excessive carbon or other

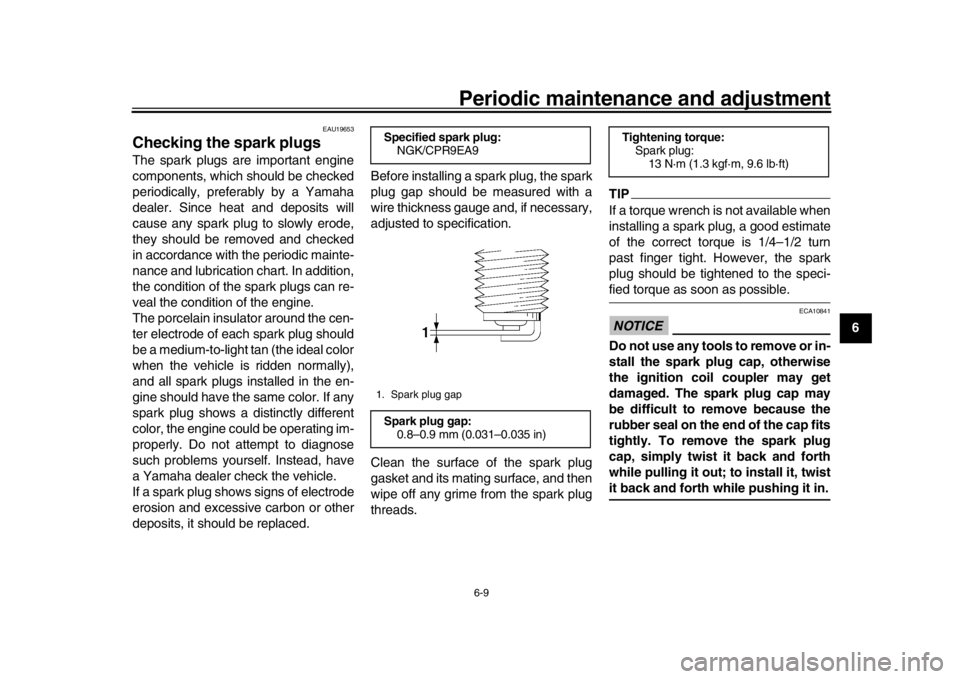

deposits, it should be replaced. Before installing a spark plug, the spark

plug gap should be measured with a

wire thickness gauge and, if necessary,

adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and then

wipe off any grime from the spark plug

threads.

TIPIf a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4–1/2 turn

past finger tight. However, the spark

plug should be tightened to the speci-fied torque as soon as possible.NOTICE

ECA10841

Do not use any tools to remove or in-

stall the spark plug cap, otherwise

the ignition coil coupler may get

damaged. The spark plug cap may

be difficult to remove because the

rubber seal on the end of the cap fits

tightly. To remove the spark plug

cap, simply twist it back and forth

while pulling it out; to install it, twistit back and forth while pushing it in.

Specified spark plug:

NGK/CPR9EA91. Spark plug gapSpark plug gap:0.8–0.9 mm (0.031–0.035 in)

Tightening torque:Spark plug:13 N·m (1.3 kgf·m, 9.6 lb·ft)

BAE-28199-E1.book 9 ページ 2019年8月23日 金曜日 午後3時56分

Page 60 of 102

Periodic maintenance and adjustment

6-10

1

2

3

4

56

7

8

9

10

11

12

EAU36112

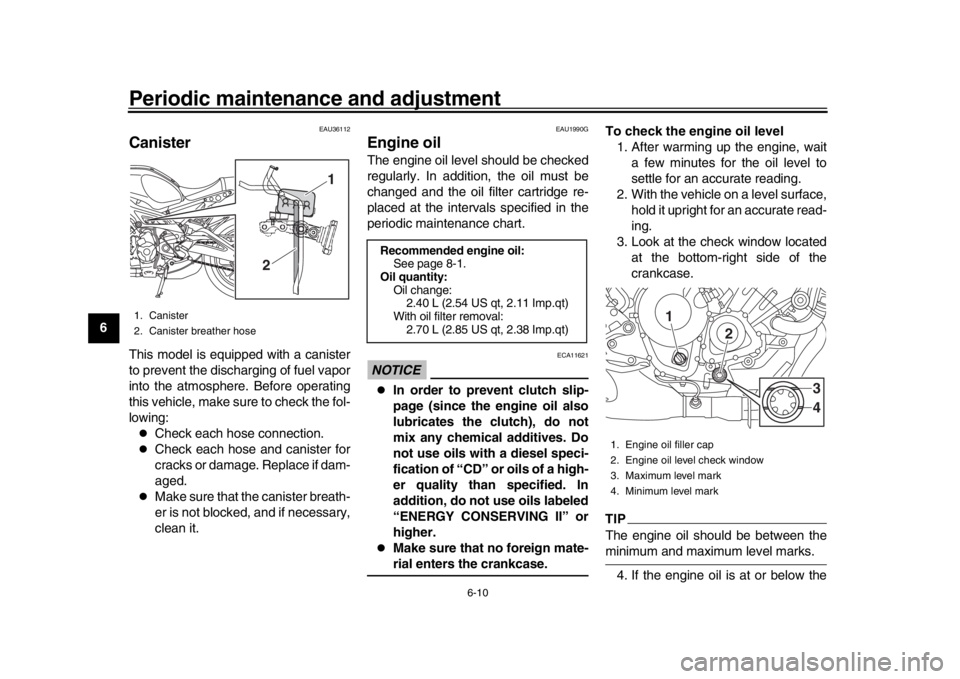

CanisterThis model is equipped with a canister

to prevent the discharging of fuel vapor

into the atmosphere. Before operating

this vehicle, make sure to check the fol-

lowing:

Check each hose connection.

Check each hose and canister for

cracks or damage. Replace if dam-

aged.

Make sure that the canister breath-

er is not blocked, and if necessary,

clean it.

EAU1990G

Engine oilThe engine oil level should be checked

regularly. In addition, the oil must be

changed and the oil filter cartridge re-

placed at the intervals specified in the

periodic maintenance chart.NOTICE

ECA11621

In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a high-

er quality than specified. In

addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

Make sure that no foreign mate-rial enters the crankcase. To check the engine oil level

1. After warming up the engine, wait a few minutes for the oil level to

settle for an accurate reading.

2. With the vehicle on a level surface, hold it upright for an accurate read-

ing.

3. Look at the check window located at the bottom-right side of the

crankcase.

TIPThe engine oil should be between theminimum and maximum level marks.

4. If the engine oil is at or below the

1. Canister

2. Canister breather hose

1

2

Recommended engine oil: See page 8-1.

Oil quantity: Oil change:2.40 L (2.54 US qt, 2.11 Imp.qt)

With oil filter removal: 2.70 L (2.85 US qt, 2.38 Imp.qt)

1. Engine oil filler cap

2. Engine oil level check window

3. Maximum level mark

4. Minimum level mark

1

2

34

BAE-28199-E1.book 10 ページ 2019年8月23日 金曜日 午後3時56分