Specification YAMAHA YZ250F 2007 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: YZ250F, Model: YAMAHA YZ250F 2007Pages: 676, PDF Size: 21.24 MB

Page 85 of 676

SPEC

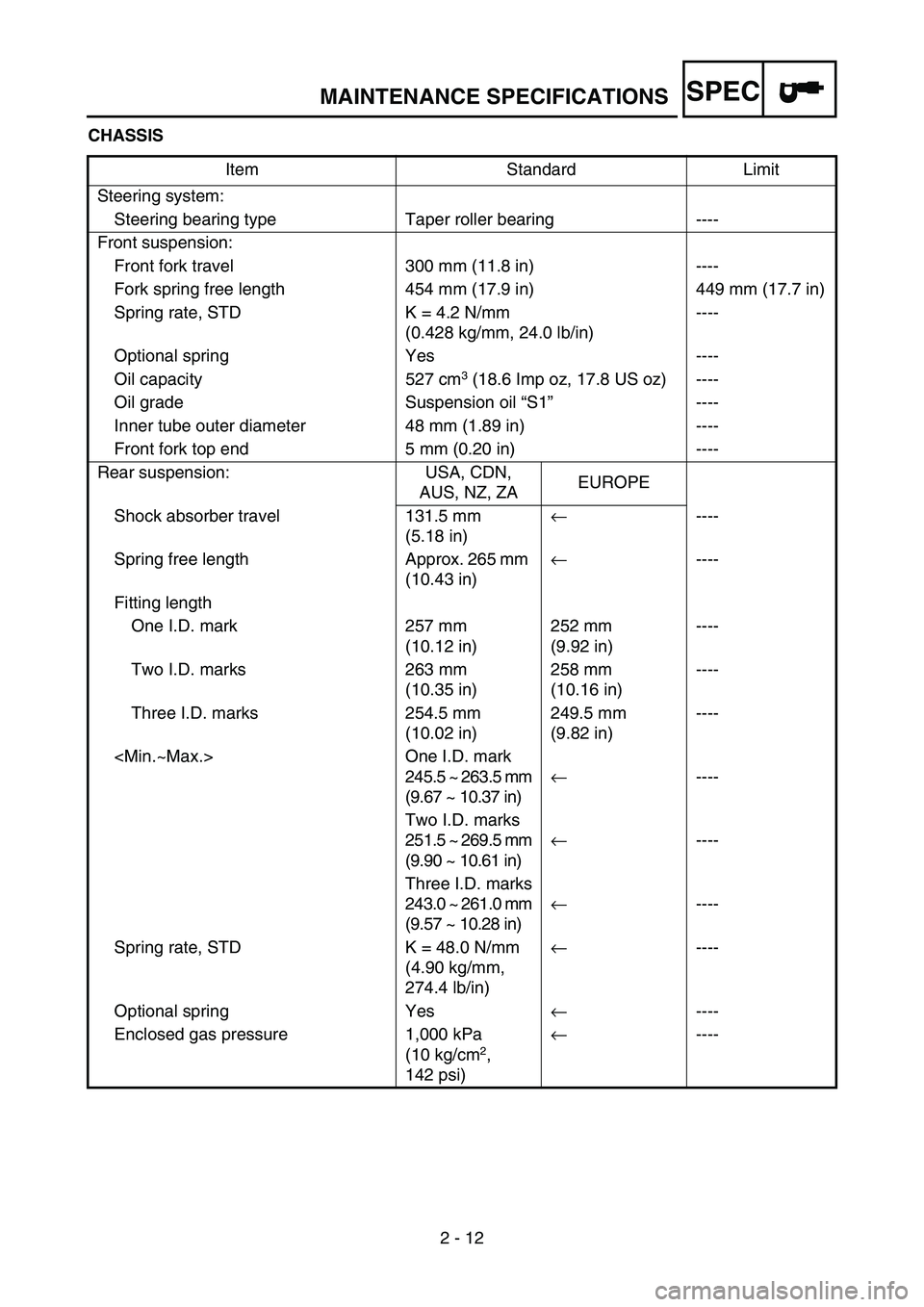

2 - 12 CHASSIS

Item Standard Limit

Steering system:

Steering bearing type Taper roller bearing ----

Front suspension:

Front fork travel 300 mm (11.8 in) ----

Fork spring free length 454 mm (17.9 in) 449 mm (17.7 in)

Spring rate, STD K = 4.2 N/mm

(0.428 kg/mm, 24.0 lb/in)----

Optional spring Yes ----

Oil capacity 527 cm

3 (18.6 Imp oz, 17.8 US oz) ----

Oil grade Suspension oil “S1”----

Inner tube outer diameter 48 mm (1.89 in) ----

Front fork top end 5 mm (0.20 in) ----

Rear suspension: USA, CDN,

AUS, NZ, ZAEUROPE

Shock absorber travel 131.5 mm

(5.18 in)← ----

Spring free length Approx. 265 mm

(10.43 in)← ----

Fitting length

One I.D. mark 257 mm

(10.12 in)252 mm

(9.92 in)----

Two I.D. marks 263 mm

(10.35 in)258 mm

(10.16 in)----

Three I.D. marks 254.5 mm

(10.02 in)249.5 mm

(9.82 in)----

245.5 ~ 263.5 mm

(9.67 ~ 10.37 in)←----

Two I.D. marks

251.5 ~ 269.5 mm

(9.90 ~ 10.61 in)←----

Three I.D. marks

243.0 ~ 261.0 mm

(9.57 ~ 10.28 in)←----

Spring rate, STD K = 48.0 N/mm

(4.90 kg/mm,

274.4 lb/in)←----

Optional spring Yes← ----

Enclosed gas pressure 1,000 kPa

(10 kg/cm

2,

142 psi)← ----

MAINTENANCE SPECIFICATIONS

Page 86 of 676

SPEC

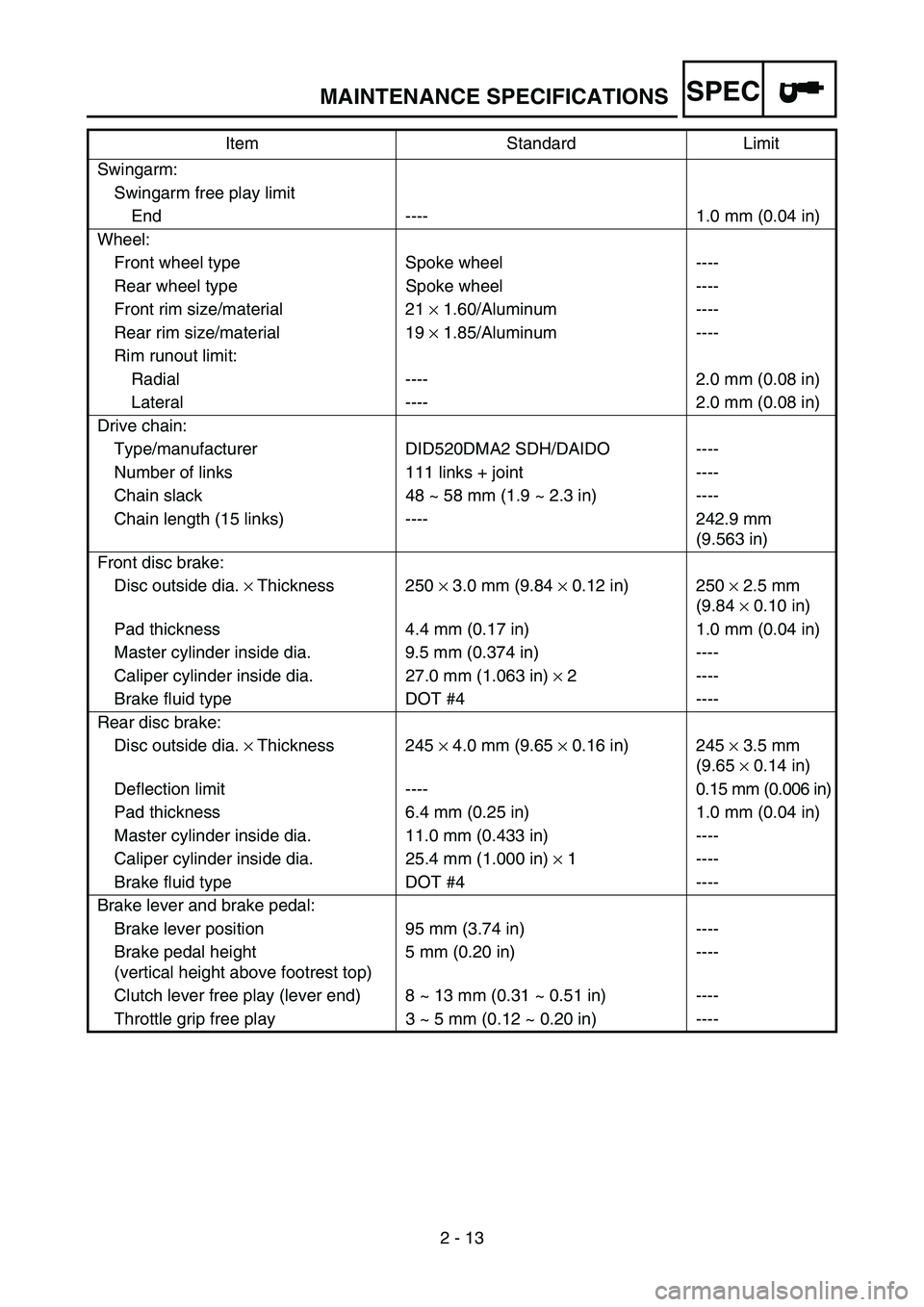

2 - 13 Swingarm:

Swingarm free play limit

End ---- 1.0 mm (0.04 in)

Wheel:

Front wheel type Spoke wheel ----

Rear wheel type Spoke wheel ----

Front rim size/material 21 × 1.60/Aluminum ----

Rear rim size/material 19 × 1.85/Aluminum ----

Rim runout limit:

Radial ---- 2.0 mm (0.08 in)

Lateral ---- 2.0 mm (0.08 in)

Drive chain:

Type/manufacturer DID520DMA2 SDH/DAIDO ----

Number of links 111 links + joint ----

Chain slack 48 ~ 58 mm (1.9 ~ 2.3 in) ----

Chain length (15 links) ---- 242.9 mm

(9.563 in)

Front disc brake:

Disc outside dia. × Thickness 250 × 3.0 mm (9.84 × 0.12 in) 250 × 2.5 mm

(9.84 × 0.10 in)

Pad thickness 4.4 mm (0.17 in) 1.0 mm (0.04 in)

Master cylinder inside dia. 9.5 mm (0.374 in) ----

Caliper cylinder inside dia. 27.0 mm (1.063 in) × 2 ----

Brake fluid type DOT #4 ----

Rear disc brake:

Disc outside dia. × Thickness 245 × 4.0 mm (9.65 × 0.16 in) 245 × 3.5 mm

(9.65 × 0.14 in)

Deflection limit ---- 0.15 mm (0.006 in)

Pad thickness 6.4 mm (0.25 in) 1.0 mm (0.04 in)

Master cylinder inside dia. 11.0 mm (0.433 in) ----

Caliper cylinder inside dia. 25.4 mm (1.000 in) × 1 ----

Brake fluid type DOT #4 ----

Brake lever and brake pedal:

Brake lever position 95 mm (3.74 in) ----

Brake pedal height

(vertical height above footrest top)5 mm (0.20 in) ----

Clutch lever free play (lever end) 8 ~ 13 mm (0.31 ~ 0.51 in) ----

Throttle grip free play 3 ~ 5 mm (0.12 ~ 0.20 in) ----Item Standard Limit

MAINTENANCE SPECIFICATIONS

Page 87 of 676

SPEC

2 - 14

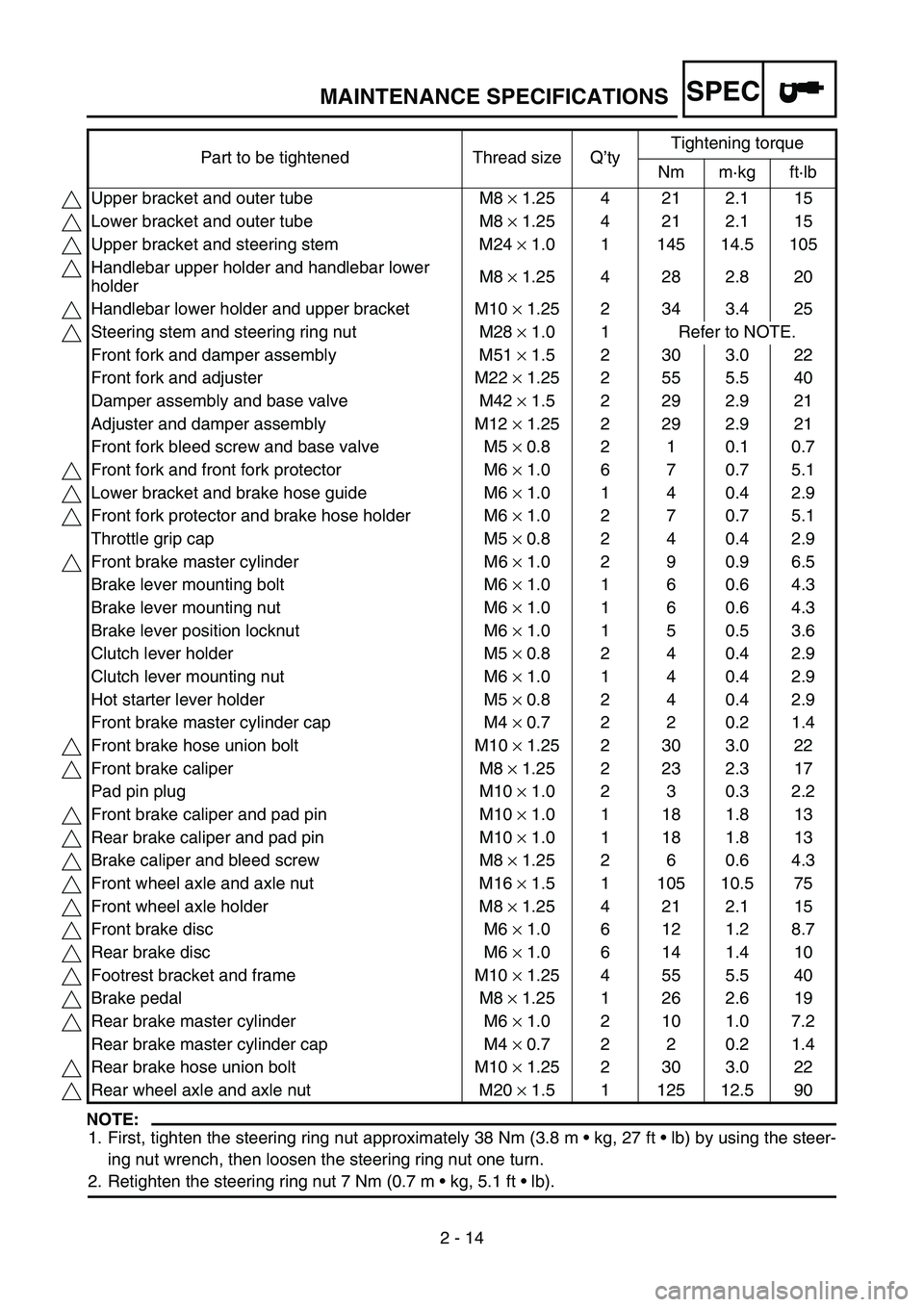

NOTE:

1. First, tighten the steering ring nut approximately 38 Nm (3.8 m kg, 27 ft lb) by using the steer-

ing nut wrench, then loosen the steering ring nut one turn.

2. Retighten the steering ring nut 7 Nm (0.7 m kg, 5.1 ft lb). Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Upper bracket and outer tube M8 × 1.25 4 21 2.1 15

Lower bracket and outer tube M8 × 1.25 4 21 2.1 15

Upper bracket and steering stem M24 × 1.0 1 145 14.5 105

Handlebar upper holder and handlebar lower

holderM8 × 1.25 4 28 2.8 20

Handlebar lower holder and upper bracket M10 × 1.25 2 34 3.4 25

Steering stem and steering ring nut M28 × 1.0 1 Refer to NOTE.

Front fork and damper assembly M51 × 1.5 2 30 3.0 22

Front fork and adjuster M22 × 1.25 2 55 5.5 40

Damper assembly and base valve M42 × 1.5 2 29 2.9 21

Adjuster and damper assembly M12 × 1.25 2 29 2.9 21

Front fork bleed screw and base valve M5 × 0.8 2 1 0.1 0.7

Front fork and front fork protector M6 × 1.0 6 7 0.7 5.1

Lower bracket and brake hose guide M6 × 1.0 1 4 0.4 2.9

Front fork protector and brake hose holder M6 × 1.0 2 7 0.7 5.1

Throttle grip cap M5 × 0.8 2 4 0.4 2.9

Front brake master cylinder M6 × 1.0 2 9 0.9 6.5

Brake lever mounting bolt M6 × 1.0 1 6 0.6 4.3

Brake lever mounting nut M6 × 1.0 1 6 0.6 4.3

Brake lever position locknut M6 × 1.0 1 5 0.5 3.6

Clutch lever holder M5 × 0.8 2 4 0.4 2.9

Clutch lever mounting nut M6 × 1.0 1 4 0.4 2.9

Hot starter lever holder M5 × 0.8 2 4 0.4 2.9

Front brake master cylinder cap M4 × 0.7 2 2 0.2 1.4

Front brake hose union bolt M10 × 1.25 2 30 3.0 22

Front brake caliper M8 × 1.25 2 23 2.3 17

Pad pin plug M10 × 1.0 2 3 0.3 2.2

Front brake caliper and pad pin M10 × 1.0 1 18 1.8 13

Rear brake caliper and pad pin M10 × 1.0 1 18 1.8 13

Brake caliper and bleed screw M8 × 1.25 2 6 0.6 4.3

Front wheel axle and axle nut M16 × 1.5 1 105 10.5 75

Front wheel axle holder M8 × 1.25 4 21 2.1 15

Front brake disc M6 × 1.0 6 12 1.2 8.7

Rear brake disc M6 × 1.0 6 14 1.4 10

Footrest bracket and frame M10 × 1.25 4 55 5.5 40

Brake pedal M8 × 1.25 1 26 2.6 19

Rear brake master cylinder M6 × 1.0 2 10 1.0 7.2

Rear brake master cylinder cap M4 × 0.7 2 2 0.2 1.4

Rear brake hose union bolt M10 × 1.25 2 30 3.0 22

Rear wheel axle and axle nut M20 × 1.5 1 125 12.5 90

MAINTENANCE SPECIFICATIONS

Page 88 of 676

SPEC

2 - 15

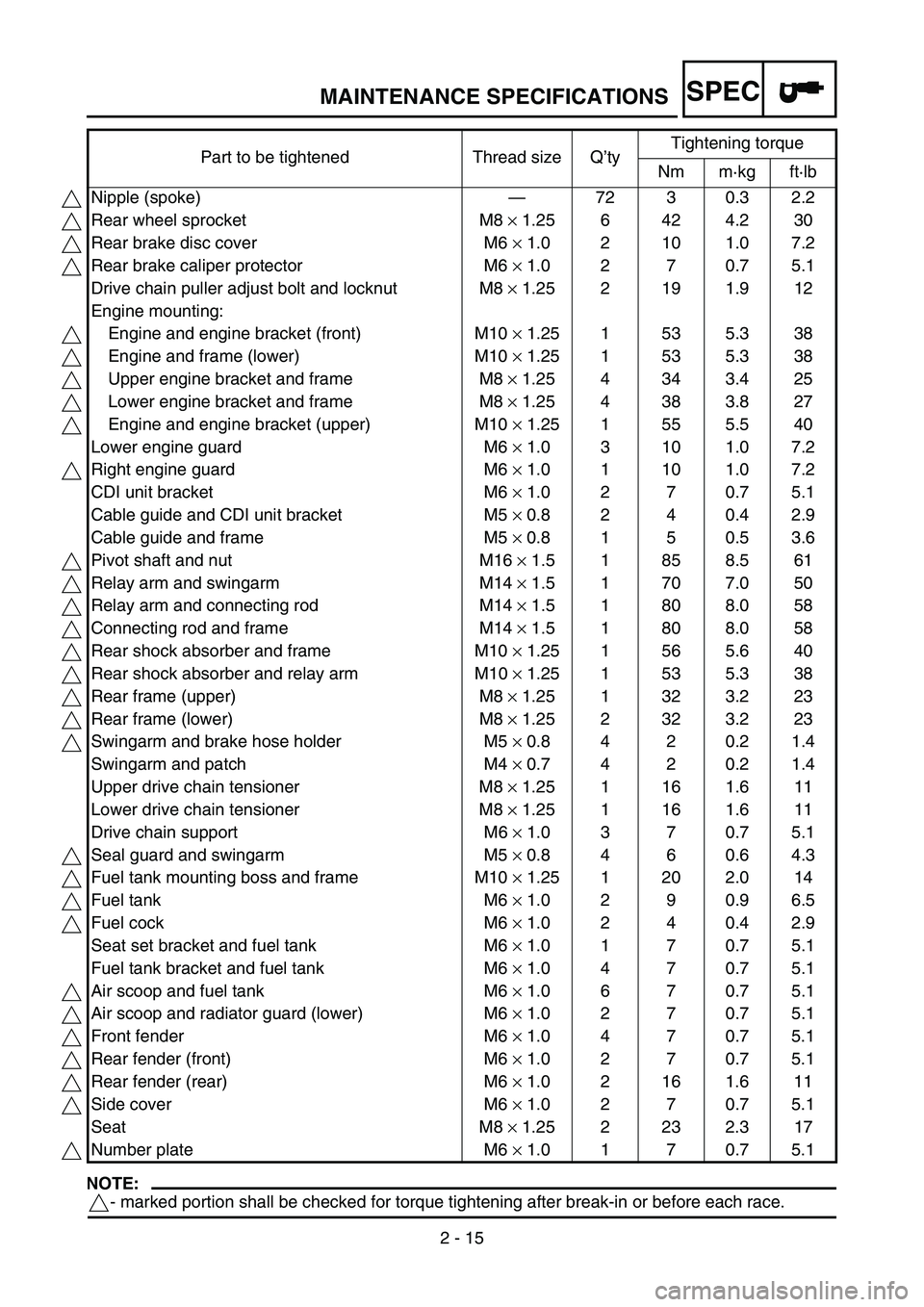

NOTE:

- marked portion shall be checked for torque tightening after break-in or before each race.Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Nipple (spoke)—72 3 0.3 2.2

Rear wheel sprocket M8 × 1.25 6 42 4.2 30

Rear brake disc cover M6 × 1.0 2 10 1.0 7.2

Rear brake caliper protector M6 × 1.0 2 7 0.7 5.1

Drive chain puller adjust bolt and locknut M8 × 1.25 2 19 1.9 12

Engine mounting:

Engine and engine bracket (front) M10 × 1.25 1 53 5.3 38

Engine and frame (lower) M10 × 1.25 1 53 5.3 38

Upper engine bracket and frame M8 × 1.25 4 34 3.4 25

Lower engine bracket and frame M8 × 1.25 4 38 3.8 27

Engine and engine bracket (upper) M10 × 1.25 1 55 5.5 40

Lower engine guard M6 × 1.0 3 10 1.0 7.2

Right engine guard M6 × 1.0 1 10 1.0 7.2

CDI unit bracket M6 × 1.0 2 7 0.7 5.1

Cable guide and CDI unit bracket M5 × 0.8 2 4 0.4 2.9

Cable guide and frame M5 × 0.8 1 5 0.5 3.6

Pivot shaft and nut M16 × 1.5 1 85 8.5 61

Relay arm and swingarm M14 × 1.5 1 70 7.0 50

Relay arm and connecting rod M14 × 1.5 1 80 8.0 58

Connecting rod and frame M14 × 1.5 1 80 8.0 58

Rear shock absorber and frame M10 × 1.25 1 56 5.6 40

Rear shock absorber and relay arm M10 × 1.25 1 53 5.3 38

Rear frame (upper) M8 × 1.25 1 32 3.2 23

Rear frame (lower) M8 × 1.25 2 32 3.2 23

Swingarm and brake hose holder M5 × 0.8 4 2 0.2 1.4

Swingarm and patch M4 × 0.7 4 2 0.2 1.4

Upper drive chain tensioner M8 × 1.25 1 16 1.6 11

Lower drive chain tensioner M8 × 1.25 1 16 1.6 11

Drive chain support M6 × 1.0 3 7 0.7 5.1

Seal guard and swingarm M5 × 0.8 4 6 0.6 4.3

Fuel tank mounting boss and frame M10 × 1.25 1 20 2.0 14

Fuel tank M6 × 1.0 2 9 0.9 6.5

Fuel cock M6 × 1.0 2 4 0.4 2.9

Seat set bracket and fuel tank M6 × 1.0 1 7 0.7 5.1

Fuel tank bracket and fuel tank M6 × 1.0 4 7 0.7 5.1

Air scoop and fuel tank M6 × 1.0 6 7 0.7 5.1

Air scoop and radiator guard (lower) M6 × 1.0 2 7 0.7 5.1

Front fender M6 × 1.0 4 7 0.7 5.1

Rear fender (front) M6 × 1.0 2 7 0.7 5.1

Rear fender (rear) M6 × 1.0 2 16 1.6 11

Side cover M6 × 1.0 2 7 0.7 5.1

Seat M8 × 1.25 2 23 2.3 17

Number plate M6 × 1.0 1 7 0.7 5.1

MAINTENANCE SPECIFICATIONS

Page 89 of 676

SPEC

2 - 16

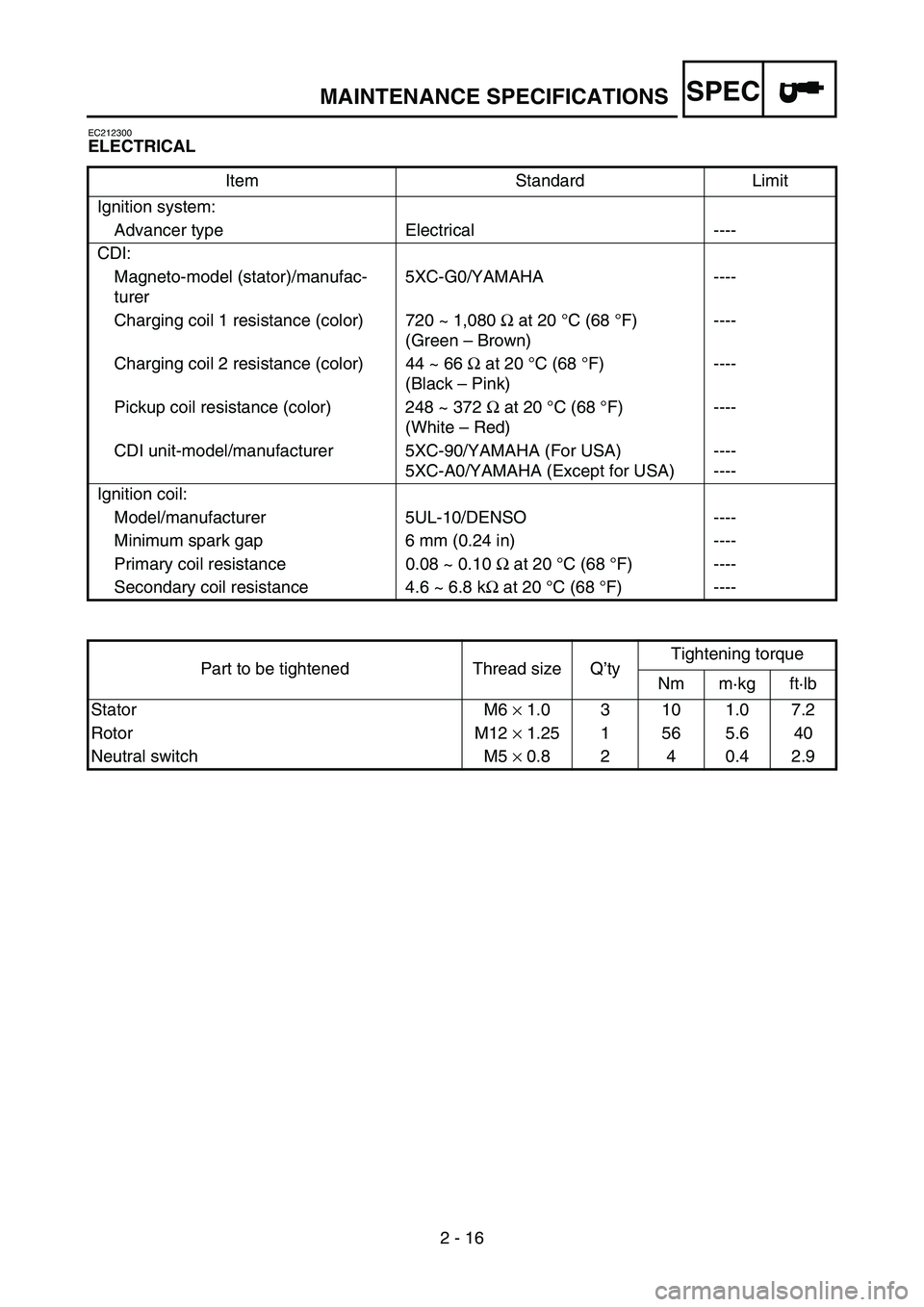

EC212300

ELECTRICAL

Item Standard Limit

Ignition system:

Advancer type Electrical ----

CDI:

Magneto-model (stator)/manufac-

turer5XC-G0/YAMAHA ----

Charging coil 1 resistance (color) 720 ~ 1,080 Ω at 20 °C (68 °F)

(Green – Brown)----

Charging coil 2 resistance (color) 44 ~ 66 Ω at 20°C (68 °F)

(Black – Pink)----

Pickup coil resistance (color) 248 ~ 372 Ω at 20°C (68 °F)

(White – Red)----

CDI unit-model/manufacturer 5XC-90/YAMAHA (For USA)

5XC-A0/YAMAHA (Except for USA)----

----

Ignition coil:

Model/manufacturer 5UL-10/DENSO ----

Minimum spark gap 6 mm (0.24 in) ----

Primary coil resistance 0.08 ~ 0.10 Ω at 20 °C (68 °F) ----

Secondary coil resistance 4.6 ~ 6.8 kΩ at 20 °C (68 °F) ----

Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Stator M6 × 1.0 3 10 1.0 7.2

Rotor M12 × 1.25 1 56 5.6 40

Neutral switch M5 × 0.8 2 4 0.4 2.9

MAINTENANCE SPECIFICATIONS

Page 90 of 676

SPEC

2 - 17

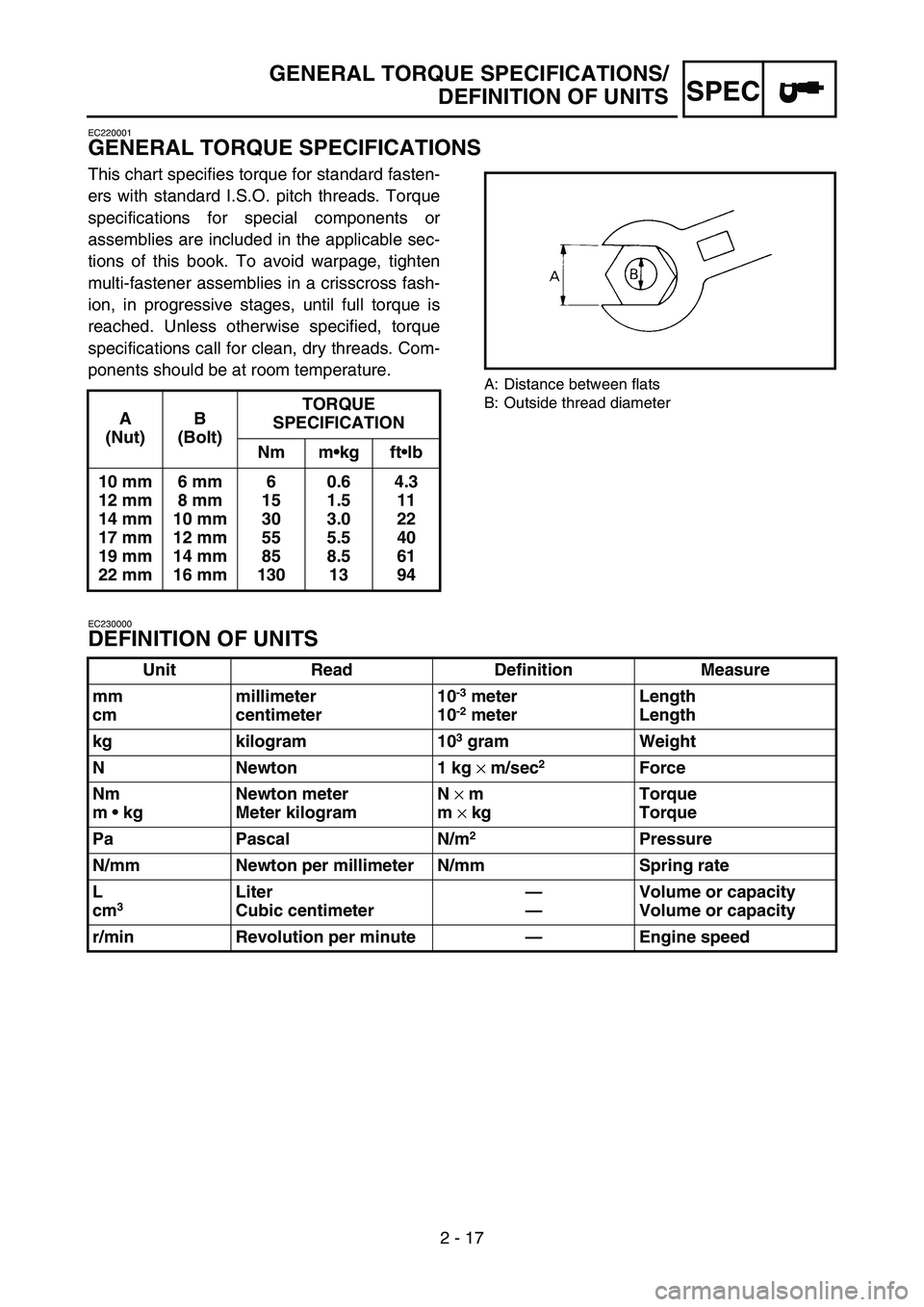

EC220001

GENERAL TORQUE SPECIFICATIONS

This chart specifies torque for standard fasten-

ers with standard I.S.O. pitch threads. Torque

specifications for special components or

assemblies are included in the applicable sec-

tions of this book. To avoid warpage, tighten

multi-fastener assemblies in a crisscross fash-

ion, in progressive stages, until full torque is

reached. Unless otherwise specified, torque

specifications call for clean, dry threads. Com-

ponents should be at room temperature.

A: Distance between flats

B: Outside thread diameter

EC230000

DEFINITION OF UNITS

A

(Nut)B

(Bolt)TORQUE

SPECIFICATION

Nm mkg ftlb

10 mm

12 mm

14 mm

17 mm

19 mm

22 mm6 mm

8 mm

10 mm

12 mm

14 mm

16 mm6

15

30

55

85

1300.6

1.5

3.0

5.5

8.5

134.3

11

22

40

61

94

Unit Read Definition Measure

mm

cmmillimeter

centimeter10

-3 meter

10-2 meterLength

Length

kg kilogram 10

3 gram Weight

N Newton 1 kg

× m/sec

2 Force

Nm

m kgNewton meter

Meter kilogramN

× m

m

× kgTorque

Torque

Pa Pascal N/m

2Pressure

N/mm Newton per millimeter N/mm Spring rate

L

cm

3 Liter

Cubic centimeter—

—Volume or capacity

Volume or capacity

r/min Revolution per minute—Engine speed

GENERAL TORQUE SPECIFICATIONS/

DEFINITION OF UNITS

Page 107 of 676

SPEC

2 - 17

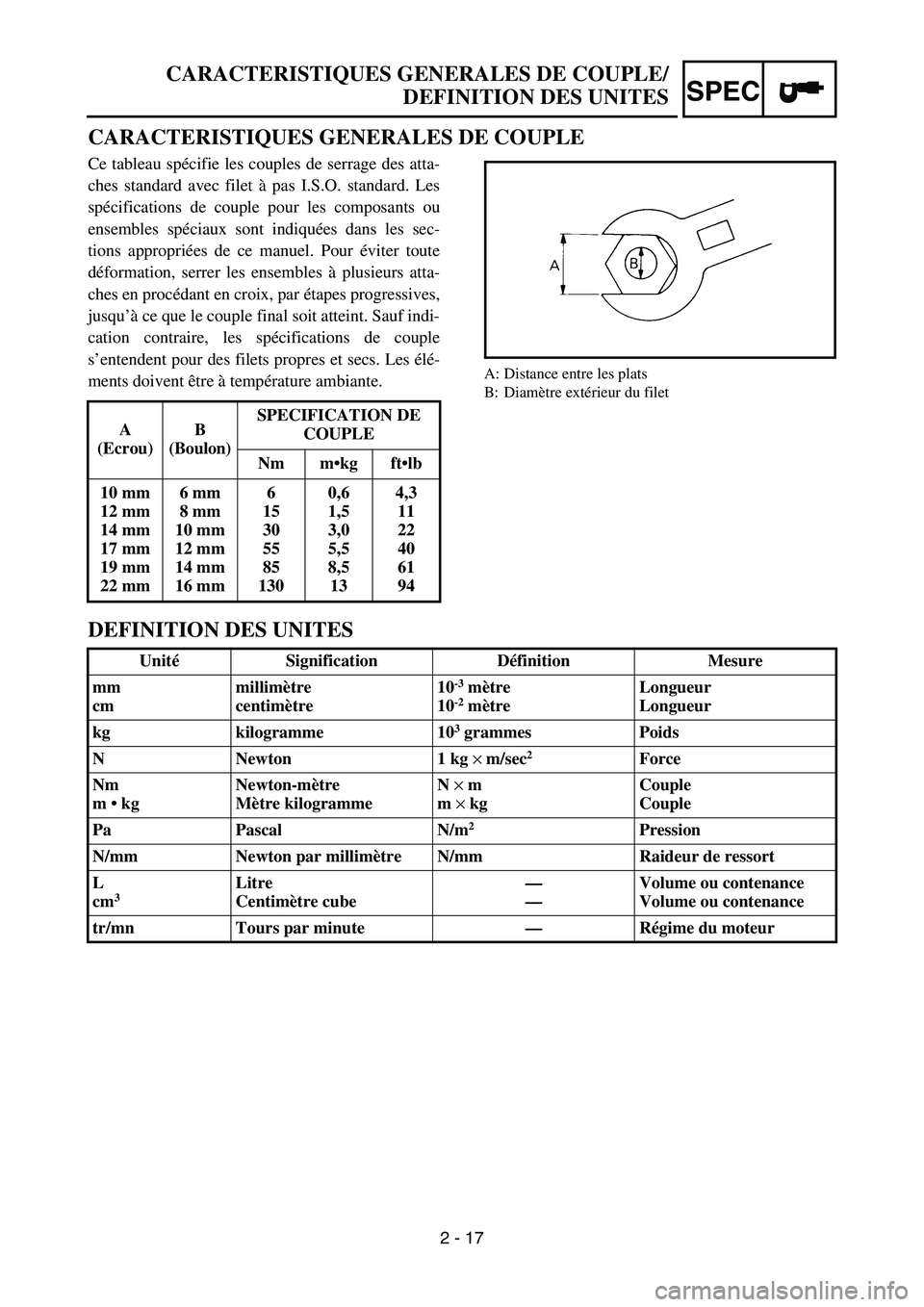

CARACTERISTIQUES GENERALES DE COUPLE

Ce tableau spécifie les couples de serrage des atta-

ches standard avec filet à pas I.S.O. standard. Les

spécifications de couple pour les composants ou

ensembles spéciaux sont indiquées dans les sec-

tions appropriées de ce manuel. Pour éviter toute

déformation, serrer les ensembles à plusieurs atta-

ches en procédant en croix, par étapes progressives,

jusqu’à ce que le couple final soit atteint. Sauf indi-

cation contraire, les spécifications de couple

s’entendent pour des filets propres et secs. Les élé-

ments doivent être à température ambiante.

A: Distance entre les plats

B: Diamètre extérieur du filet

DEFINITION DES UNITES

A

(Ecrou)B

(Boulon)SPECIFICATION DE

COUPLE

Nm mkg ftlb

10 mm

12 mm

14 mm

17 mm

19 mm

22 mm6 mm

8 mm

10 mm

12 mm

14 mm

16 mm6

15

30

55

85

1300,6

1,5

3,0

5,5

8,5

134,3

11

22

40

61

94

UnitéSignification Définition Mesure

mm

cmmillimètre

centimètre10

-3 mètre

10-2 mètreLongueur

Longueur

kg kilogramme 10

3 grammes Poids

N Newton 1 kg ×

m/sec

2Force

Nm

m kgNewton-mètre

Mètre kilogrammeN ×

m

m ×

kgCouple

Couple

Pa Pascal N/m

2Pression

N/mm Newton par millimètre N/mm Raideur de ressort

L

cm

3 Litre

Centimètre cube—

—Volume ou contenance

Volume ou contenance

tr/mn Tours par minute—Régime du moteur

CARACTERISTIQUES GENERALES DE COUPLE/

DEFINITION DES UNITES

Page 184 of 676

3 - 9

INSP

ADJ

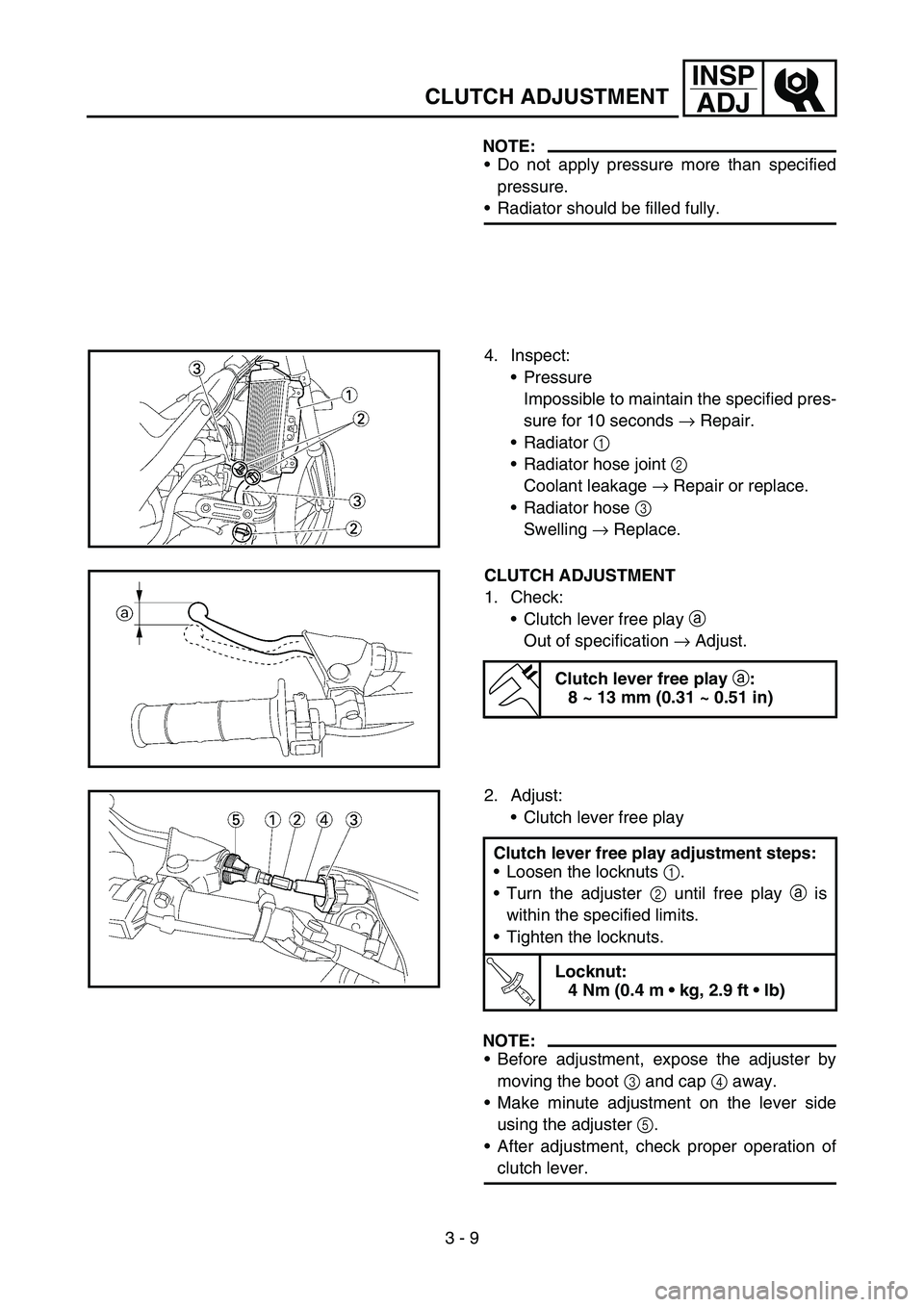

CLUTCH ADJUSTMENT

NOTE:

Do not apply pressure more than specified

pressure.

Radiator should be filled fully.

4. Inspect:

Pressure

Impossible to maintain the specified pres-

sure for 10 seconds → Repair.

Radiator 1

Radiator hose joint 2

Coolant leakage → Repair or replace.

Radiator hose 3

Swelling → Replace.

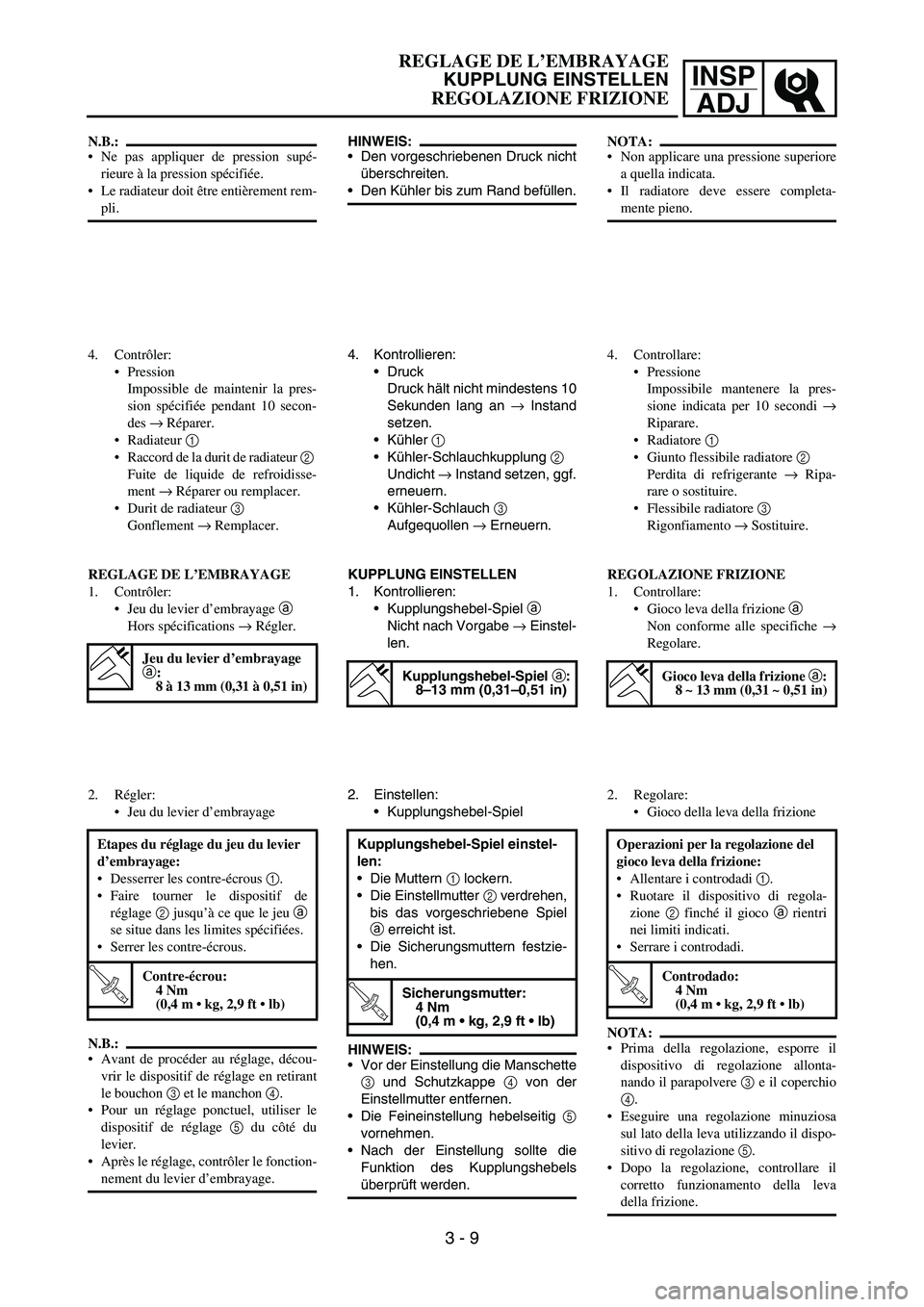

CLUTCH ADJUSTMENT

1. Check:

Clutch lever free play a

Out of specification → Adjust.

Clutch lever free play

a:

8 ~ 13 mm (0.31 ~ 0.51 in)

2. Adjust:

Clutch lever free play

NOTE:

Before adjustment, expose the adjuster by

moving the boot 3 and cap 4 away.

Make minute adjustment on the lever side

using the adjuster 5.

After adjustment, check proper operation of

clutch lever. Clutch lever free play adjustment steps:

Loosen the locknuts 1.

Turn the adjuster 2 until free play a is

within the specified limits.

Tighten the locknuts.

T R..

Locknut:

4 Nm (0.4 m kg, 2.9 ft lb)

Page 185 of 676

INSP

ADJ

HINWEIS:

Den vorgeschriebenen Druck nicht

überschreiten.

Den Kühler bis zum Rand befüllen.

4. Kontrollieren:

Druck

Druck hält nicht mindestens 10

Sekunden lang an → Instand

setzen.

Kühler 1

Kühler-Schlauchkupplung 2

Undicht → Instand setzen, ggf.

erneuern.

Kühler-Schlauch 3

Aufgequollen → Erneuern.

KUPPLUNG EINSTELLEN

1. Kontrollieren:

Kupplungshebel-Spiel a

Nicht nach Vorgabe → Einstel-

len.

Kupplungshebel-Spiel a:

8–13 mm (0,31–0,51 in)

2. Einstellen:

Kupplungshebel-Spiel

HINWEIS:

Vor der Einstellung die Manschette

3 und Schutzkappe 4 von der

Einstellmutter entfernen.

Die Feineinstellung hebelseitig 5

vornehmen.

Nach der Einstellung sollte die

Funktion des Kupplungshebels

überprüft werden. Kupplungshebel-Spiel einstel-

len:

Die Muttern 1 lockern.

Die Einstellmutter 2 verdrehen,

bis das vorgeschriebene Spiel

a erreicht ist.

Die Sicherungsmuttern festzie-

hen.

T R..

Sicherungsmutter:

4 Nm

(0,4 m kg, 2,9 ft lb)

N.B.:

Ne pas appliquer de pression supé-

rieure à la pression spécifiée.

Le radiateur doit être entièrement rem-

pli.

4. Contrôler:

Pression

Impossible de maintenir la pres-

sion spécifiée pendant 10 secon-

des → Réparer.

Radiateur 1

Raccord de la durit de radiateur 2

Fuite de liquide de refroidisse-

ment → Réparer ou remplacer.

Durit de radiateur 3

Gonflement → Remplacer.

REGLAGE DE L’EMBRAYAGE

1. Contrôler:

Jeu du levier d’embrayage a

Hors spécifications → Régler.

Jeu du levier d’embrayage

a:

8 à 13 mm (0,31 à 0,51 in)

2. Régler:

Jeu du levier d’embrayage

N.B.:

Avant de procéder au réglage, décou-

vrir le dispositif de réglage en retirant

le bouchon 3 et le manchon 4.

Pour un réglage ponctuel, utiliser le

dispositif de réglage 5 du côté du

levier.

Après le réglage, contrôler le fonction-

nement du levier d’embrayage. Etapes du réglage du jeu du levier

d’embrayage:

Desserrer les contre-écrous 1.

Faire tourner le dispositif de

réglage 2 jusqu’à ce que le jeu a

se situe dans les limites spécifiées.

Serrer les contre-écrous.

T R..

Contre-écrou:

4 Nm

(0,4 m kg, 2,9 ft lb)

NOTA:

Non applicare una pressione superiore

a quella indicata.

Il radiatore deve essere completa-

mente pieno.

4. Controllare:

Pressione

Impossibile mantenere la pres-

sione indicata per 10 secondi →

Riparare.

Radiatore 1

Giunto flessibile radiatore 2

Perdita di refrigerante → Ripa-

rare o sostituire.

Flessibile radiatore 3

Rigonfiamento → Sostituire.

REGOLAZIONE FRIZIONE

1. Controllare:

Gioco leva della frizione a

Non conforme alle specifiche →

Regolare.

Gioco leva della frizione a:

8 ~ 13 mm (0,31 ~ 0,51 in)

2. Regolare:

Gioco della leva della frizione

NOTA:

Prima della regolazione, esporre il

dispositivo di regolazione allonta-

nando il parapolvere 3 e il coperchio

4.

Eseguire una regolazione minuziosa

sul lato della leva utilizzando il dispo-

sitivo di regolazione 5.

Dopo la regolazione, controllare il

corretto funzionamento della leva

della frizione. Operazioni per la regolazione del

gioco leva della frizione:

Allentare i controdadi 1.

Ruotare il dispositivo di regola-

zione 2 finché il gioco a rientri

nei limiti indicati.

Serrare i controdadi.

T R..

Controdado:

4 Nm

(0,4 m kg, 2,9 ft lb)

REGLAGE DE L’EMBRAYAGE

KUPPLUNG EINSTELLEN

REGOLAZIONE FRIZIONE

3 - 9

Page 186 of 676

3 - 10

INSP

ADJTHROTTLE CABLE ADJUSTMENT/

THROTTLE LUBRICATION

3. Install:

Cap 1

Boot 2

NOTE:

Place the tip a of the cap in the boot.

THROTTLE CABLE ADJUSTMENT

1. Check:

Throttle grip free play a

Out of specification → Adjust.

2. Adjust:

Throttle grip free play

Throttle grip free play

a:

3 ~ 5 mm (0.12 ~ 0.20 in)

Throttle grip free play adjustment steps:

Slide the adjuster cover.

Loosen the locknut 1.

Turn the adjuster 2 until the specified free

play is obtained.

Tighten the locknut.

T R..

Locknut:

4 Nm (0.4 m kg, 2.9 ft lb)

NOTE:

Before adjusting the throttle cable free play,

the engine idle speed should be adjusted.

WARNING

After adjusting, turn the handlebar to

right and left and make sure that the

engine idling does not run faster.

1 2

THROTTLE LUBRICATION

1. Remove:

Cover (throttle cable cap) 1

Cover (grip cap) 2

Throttle grip cap 3