ABS YAMAHA YZ250F 2008 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: YZ250F, Model: YAMAHA YZ250F 2008Pages: 192, PDF Size: 7.03 MB

Page 65 of 192

3-19

CHASSIS

ADJUSTING THE REAR SHOCK

ABSORBER SPRING PRELOAD

1. Elevate the rear wheel by placing the suitable stand under the en-

gine.

2. Remove: • Rear frame

3. Loosen: • Locknut "1"

4. Adjust:

• Spring preloadBy turning the adjuster "2".

•Be sure to remove all dirt and mud

from around the locknut and adjust-

er before adjustment.

• The length of the spring (installed) changes 1.5 mm (0.06 in) per turn of the adjuster.

• The I.D. mark "b" is marked at the end of the spring.

• The standard length and extent of

adjustment vary according to the

quantity of I.D. marks.

Never attempt to turn the adjuster

beyond the maximum or minimum

setting.

5. Tighten:• Locknut

6. Install: • Rear frame (upper)

• Rear frame (lower)

ADJUSTING THE REAR SHOCK

ABSORBER REBOUND DAMPING

FORCE

1. Adjust: • Rebound damping forceBy turning the adjuster "1". • STANDARD POSITION:

This is the position which is back

by the specific number of clicks

from the fully turned-in position.

(Which align the punch mark "a"

on the adjuster with the punch

mark "b" on the bracket.)

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

ADJUSTING THE REAR SHOCK

ABSORBER LOW COMPRESSION

DAMPING FORCE

1. Adjust:• Low compression damping forceBy turning the adjuster "1".

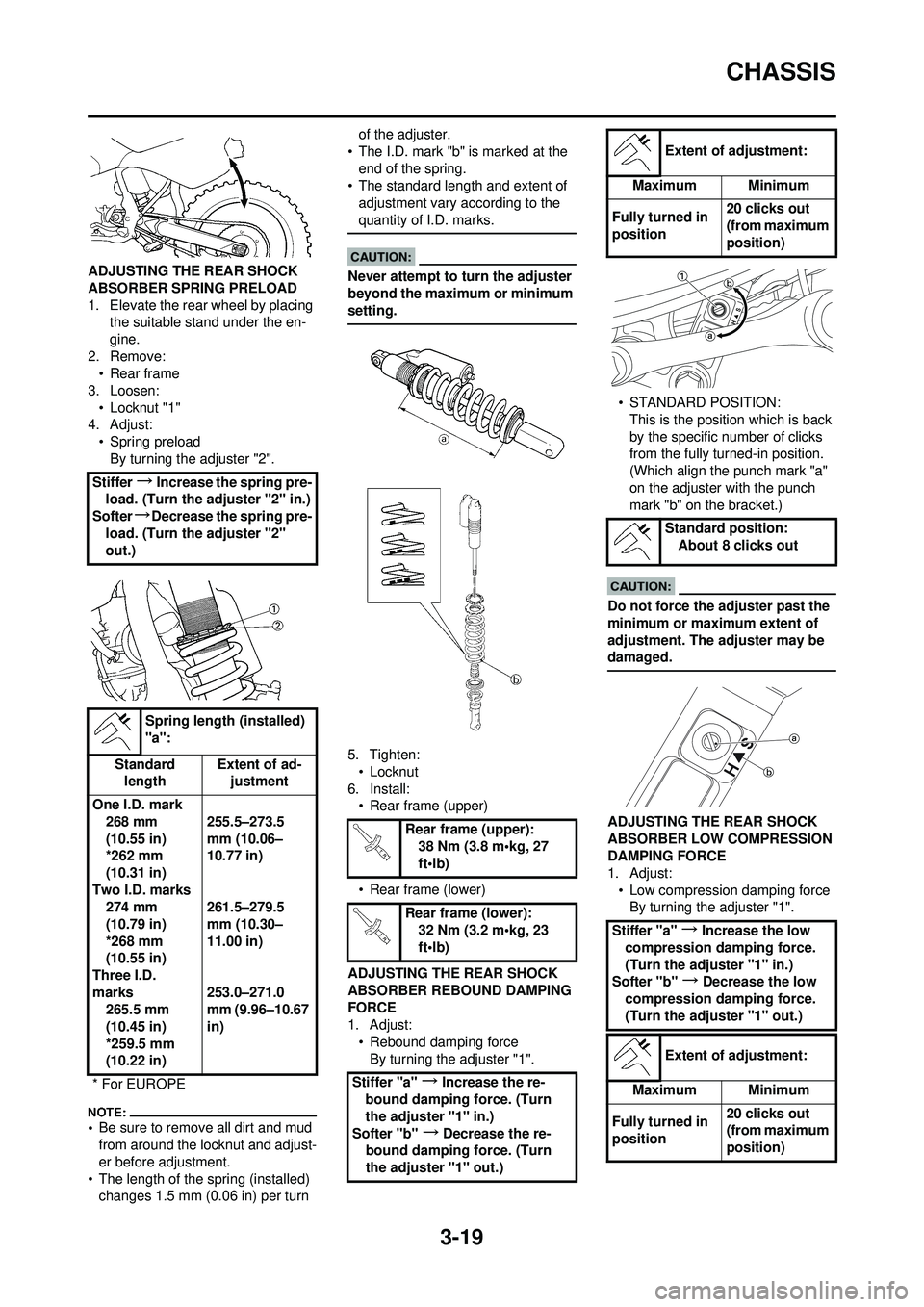

Stiffer

→Increase the spring pre-

load. (Turn the adjuster "2" in.)

Softer

→Decrease the spring pre-

load. (Turn the adjuster "2"

out.)

Spring length (installed)

"a":

Standard length Extent of ad-

justment

One I.D. mark 268 mm

(10.55 in)

*262 mm

(10.31 in)

Two I.D. marks 274 mm

(10.79 in)

*268 mm

(10.55 in)

Three I.D.

marks 265.5 mm

(10.45 in)

*259.5 mm

(10.22 in) 255.5–273.5

mm (10.06–

10.77 in)

261.5–279.5

mm (10.30–

11.00 in)

253.0–271.0

mm (9.96–10.67

in)

* For EUROPE

Rear frame (upper): 38 Nm (3.8 m•kg, 27

ft•lb)

Rear frame (lower): 32 Nm (3.2 m•kg, 23

ft•lb)

Stiffer "a"

→Increase the re-

bound damping force. (Turn

the adjuster "1" in.)

Softer "b"

→Decrease the re-

bound damping force. (Turn

the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position 20 clicks out

(from maximum

position)

Standard position: About 8 clicks out

Stiffer "a"

→Increase the low

compression damping force.

(Turn the adjuster "1" in.)

Softer "b"

→Decrease the low

compression damping force.

(Turn the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position 20 clicks out

(from maximum

position)

Page 66 of 192

3-20

CHASSIS

• STANDARD POSITION:This is the position which is back

by the specific number of clicks

from the fully turned-in position.

(Which align the punch mark "a"

on the adjuster with the punch

mark "b" on the high compression

damping adjuster.)

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

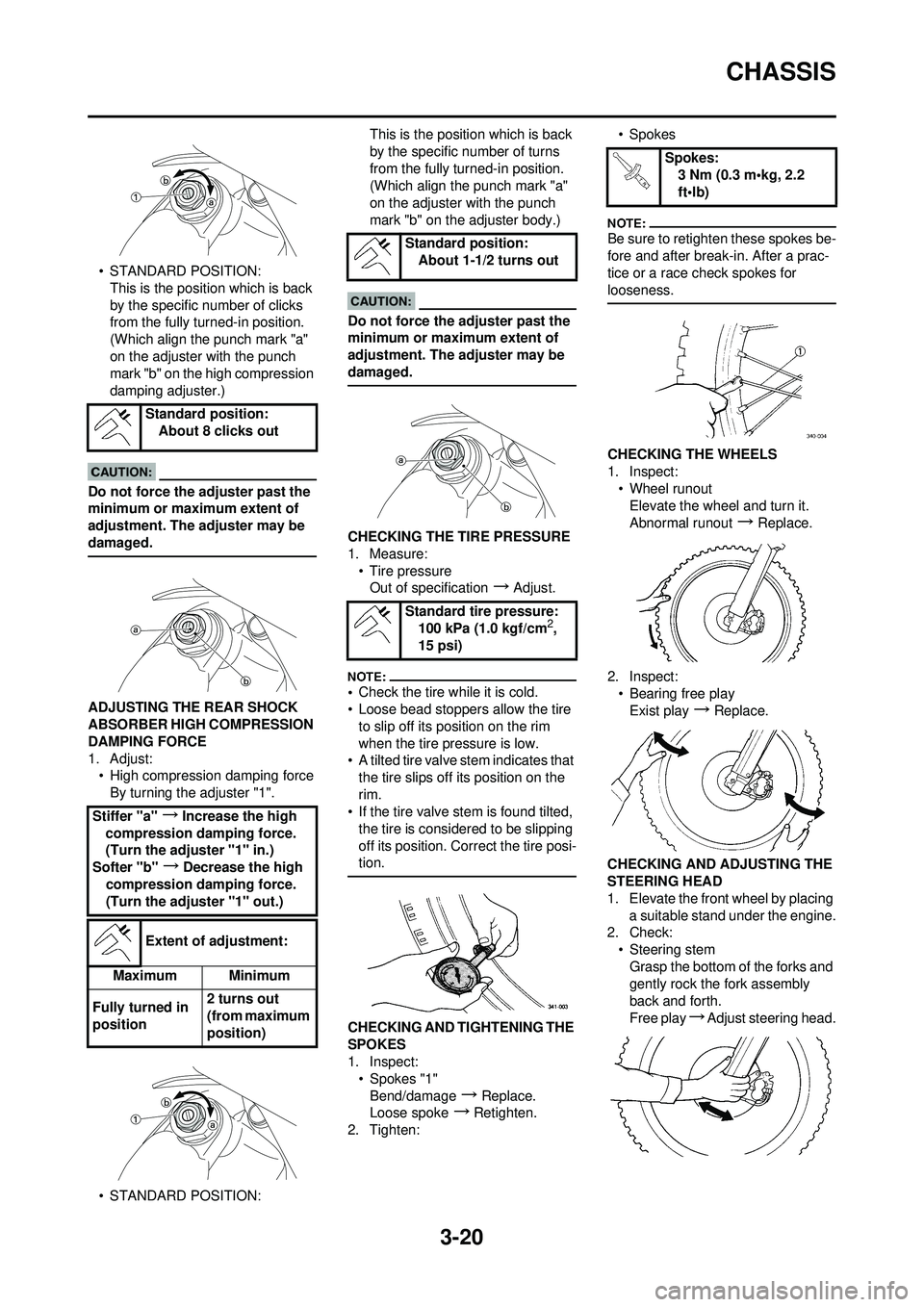

ADJUSTING THE REAR SHOCK

ABSORBER HIGH COMPRESSION

DAMPING FORCE

1. Adjust:• High compression damping force

By turning the adjuster "1".

• STANDARD POSITION: This is the position which is back

by the specific number of turns

from the fully turned-in position.

(Which align the punch mark "a"

on the adjuster with the punch

mark "b" on the adjuster body.)

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

CHECKING THE TIRE PRESSURE

1. Measure:

• Tire pressureOut of specification

→Adjust.

•Check the tire while it is cold.

• Loose bead stoppers allow the tire

to slip off its position on the rim

when the tire pressure is low.

• A tilted tire valve stem indicates that

the tire slips off its position on the

rim.

• If the tire valve stem is found tilted,

the tire is considered to be slipping

off its position. Correct the tire posi-

tion.

CHECKING AND TIGHTENING THE

SPOKES

1. Inspect:• Spokes "1"Bend/damage

→Replace.

Loose spoke

→Retighten.

2. Tighten: •Spokes

Be sure to retighten these spokes be-

fore and after break-in. After a prac-

tice or a race check spokes for

looseness.

CHECKING THE WHEELS

1. Inspect:

• Wheel runoutElevate the wheel and turn it.

Abnormal runout

→ Replace.

2. Inspect: • Bearing free play

Exist play

→Replace.

CHECKING AND ADJUSTING THE

STEERING HEAD

1. Elevate the front wheel by placing a suitable stand under the engine.

2. Check:

• Steering stemGrasp the bottom of the forks and

gently rock the fork assembly

back and forth.

Free play

→Adjust steering head.

Standard position:

About 8 clicks out

Stiffer "a"

→Increase the high

compression damping force.

(Turn the adjuster "1" in.)

Softer "b"

→Decrease the high

compression damping force.

(Turn the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position 2 turns out

(from maximum

position)

Standard position:

About 1-1/2 turns out

Standard tire pressure: 100 kPa (1.0 kgf/cm

2,

15 psi)

Spokes: 3 Nm (0.3 m•kg, 2.2

ft•lb)

Page 76 of 192

4-7

CARBURETOR

CARBURETOR

REMOVING THE CARBURETOROrder Part name Q'ty Remarks Seat and fuel tank Refer to "SEAT, FUEL TANK AND SIDE

COVERS" section.

Rear shock absorber Refer to "REAR SHOCK ABSORBER" sec-

tion in the CHAPTER 5.

1Clamp 1

2 Throttle position sensor lead coupler 1

3 Throttle cable cover 1

4 Throttle cable 2

5 Clamp (air filter joint) 1 Loosen the screw (air filter joint).

6 Clamp (carburetor joint) 1 Loosen the screws (carburetor joint).

7 Hot starter plunger 1

8 Carburetor assembly 1

9 Carburetor joint 1

4 Nm (0.4 m kg, 2.9 ft lb)

4 Nm (0.4 m kg, 2.9 ft lb)

2 Nm (0.2 m kg, 1.4 ft lb)

3 Nm (0.3 m kg, 2.2 ft lb)

3 Nm (0.3 m kg, 2.2 ft lb)

11 Nm (1.1 m kg, 8.0 ft lb)

10 Nm (1.0 m kg, 7.2 ft lb)

Page 146 of 192

5-14

FRONT BRAKE AND REAR BRAKE

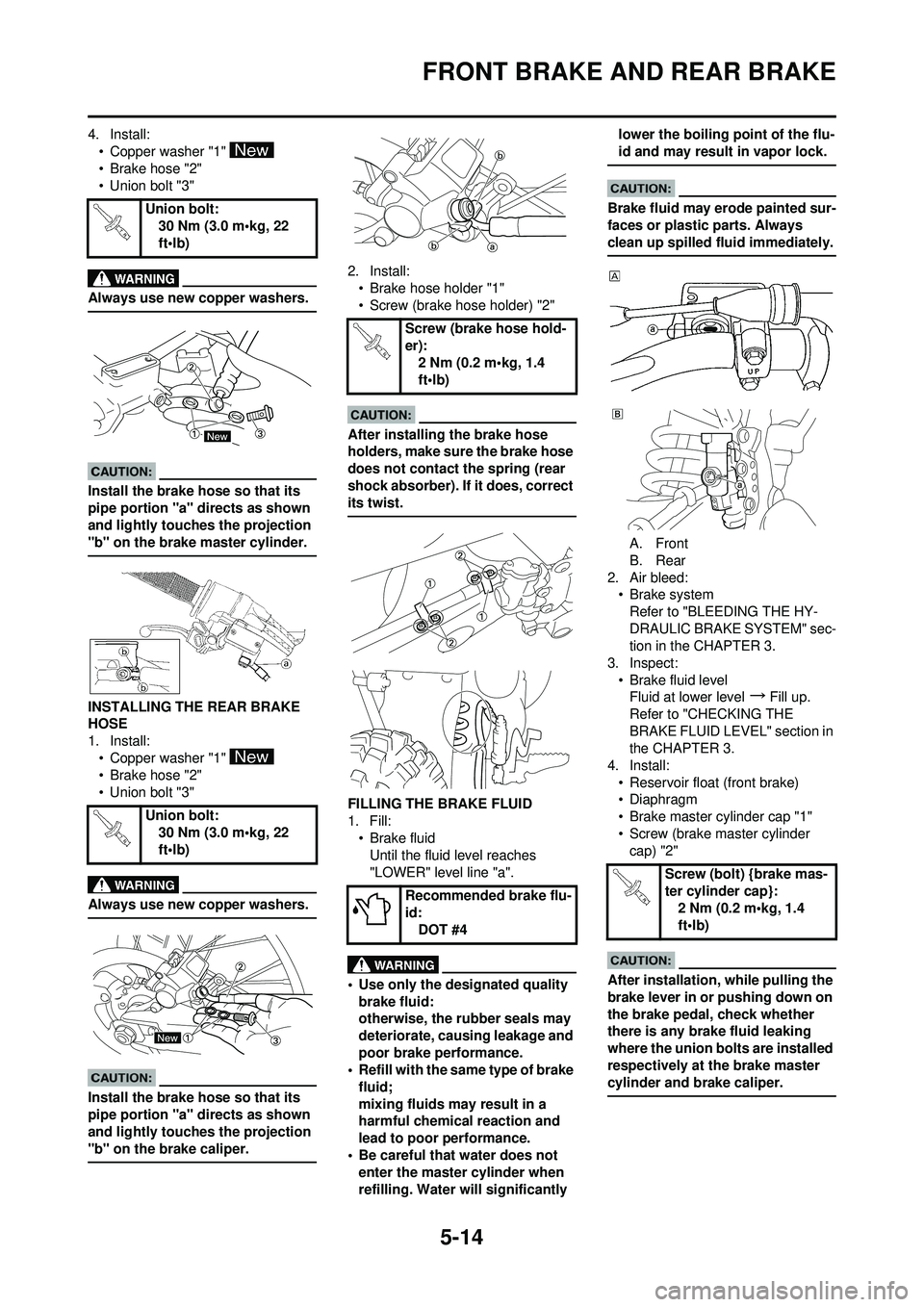

4. Install:• Copper washer "1"

•Brake hose "2"

• Union bolt "3"

Always use new copper washers.

Install the brake hose so that its

pipe portion "a" directs as shown

and lightly touches the projection

"b" on the brake master cylinder.

INSTALLING THE REAR BRAKE

HOSE

1. Install:• Copper washer "1"

•Brake hose "2"

• Union bolt "3"

Always use new copper washers.

Install the brake hose so that its

pipe portion "a" directs as shown

and lightly touches the projection

"b" on the brake caliper.

2. Install:• Brake hose holder "1"

• Screw (brake hose holder) "2"

After installing the brake hose

holders, make sure the brake hose

does not contact the spring (rear

shock absorber). If it does, correct

its twist.

FILLING THE BRAKE FLUID

1. Fill:•Brake fluid

Until the fluid level reaches

"LOWER" level line "a".

• Use only the designated quality brake fluid:

otherwise, the rubber seals may

deteriorate, causing leakage and

poor brake performance.

• Refill with the same type of brake

fluid;

mixing fluids may result in a

harmful chemical reaction and

lead to poor performance.

• Be careful that water does not enter the master cylinder when

refilling. Water will significantly lower the boiling point of the flu-

id and may result in vapor lock.

Brake fluid may erode painted sur-

faces or plastic parts. Always

clean up spilled fluid immediately.

A. Front

B. Rear

2. Air bleed: • Brake system

Refer to "BLEEDING THE HY-

DRAULIC BRAKE SYSTEM" sec-

tion in the CHAPTER 3.

3. Inspect: • Brake fluid levelFluid at lower level

→Fill up.

Refer to "CHECKING THE

BRAKE FLUID LEVEL" section in

the CHAPTER 3.

4. Install: • Reservoir float (front brake)

• Diaphragm

• Brake master cylinder cap "1"

• Screw (brake master cylinder cap) "2"

After installation, while pulling the

brake lever in or pushing down on

the brake pedal, check whether

there is any brake fluid leaking

where the union bolts are installed

respectively at the brake master

cylinder and brake caliper.

Union bolt:

30 Nm (3.0 m•kg, 22

ft•lb)

Union bolt: 30 Nm (3.0 m•kg, 22

ft•lb)

Screw (brake hose hold-

er):2 Nm (0.2 m•kg, 1.4

ft•lb)

Recommended brake flu-

id: DOT #4

Screw (bolt) {brake mas-

ter cylinder cap}:2 Nm (0.2 m•kg, 1.4

ft•lb)

Page 164 of 192

5-32

SWINGARM

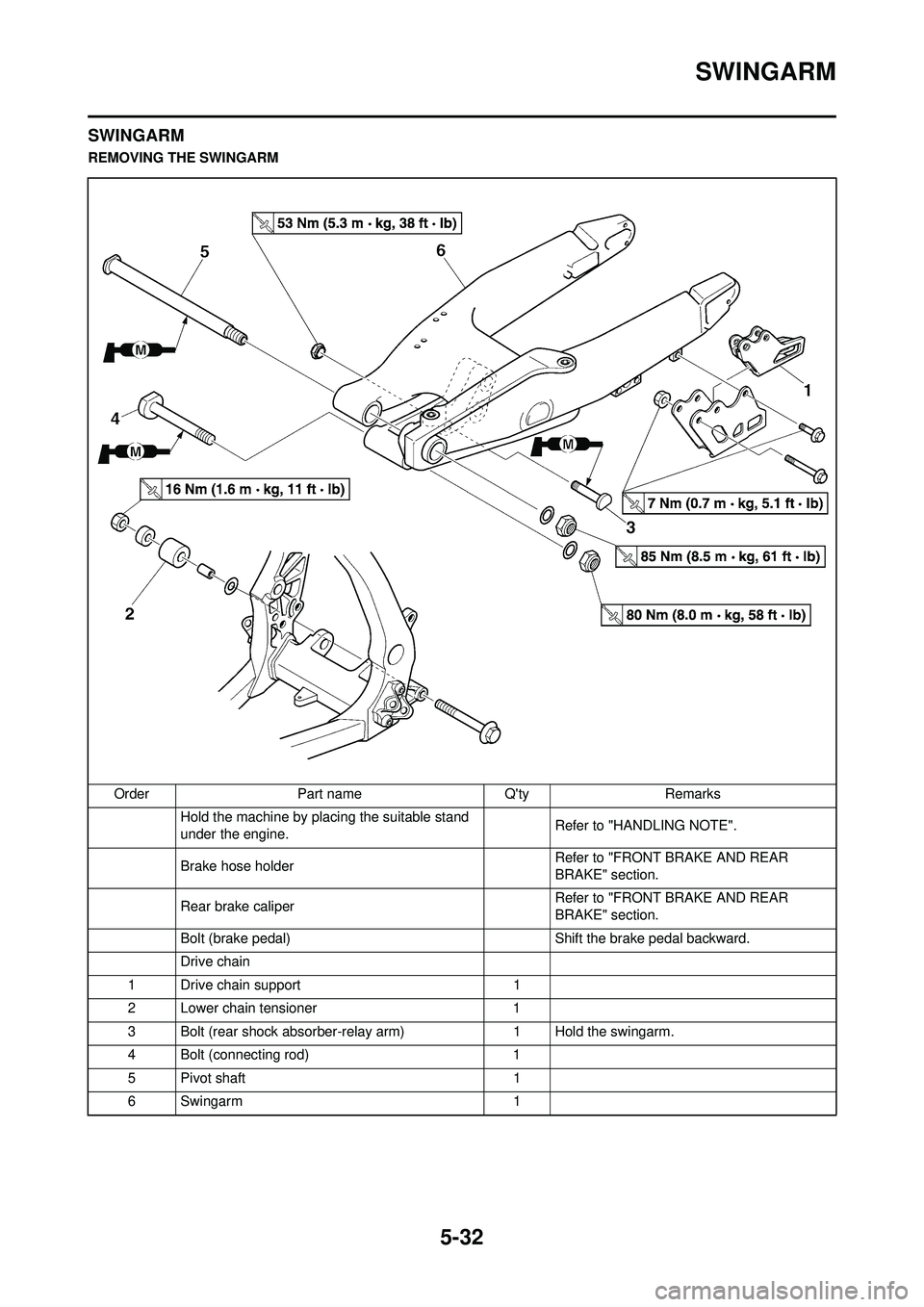

SWINGARM

REMOVING THE SWINGARMOrder Part name Q'ty Remarks Hold the machine by placing the suitable stand

under the engine. Refer to "HANDLING NOTE".

Brake hose holder Refer to "FRONT BRAKE AND REAR

BRAKE" section.

Rear brake caliper Refer to "FRONT BRAKE AND REAR

BRAKE" section.

Bolt (brake pedal) Shift the brake pedal backward.

Drive chain

1 Drive chain support 1

2 Lower chain tensioner 1

3 Bolt (rear shock absorber-relay arm) 1 Hold the swingarm.

4 Bolt (connecting rod) 1

5Pivot shaft 1

6 Swingarm 1

Page 167 of 192

5-35

SWINGARM

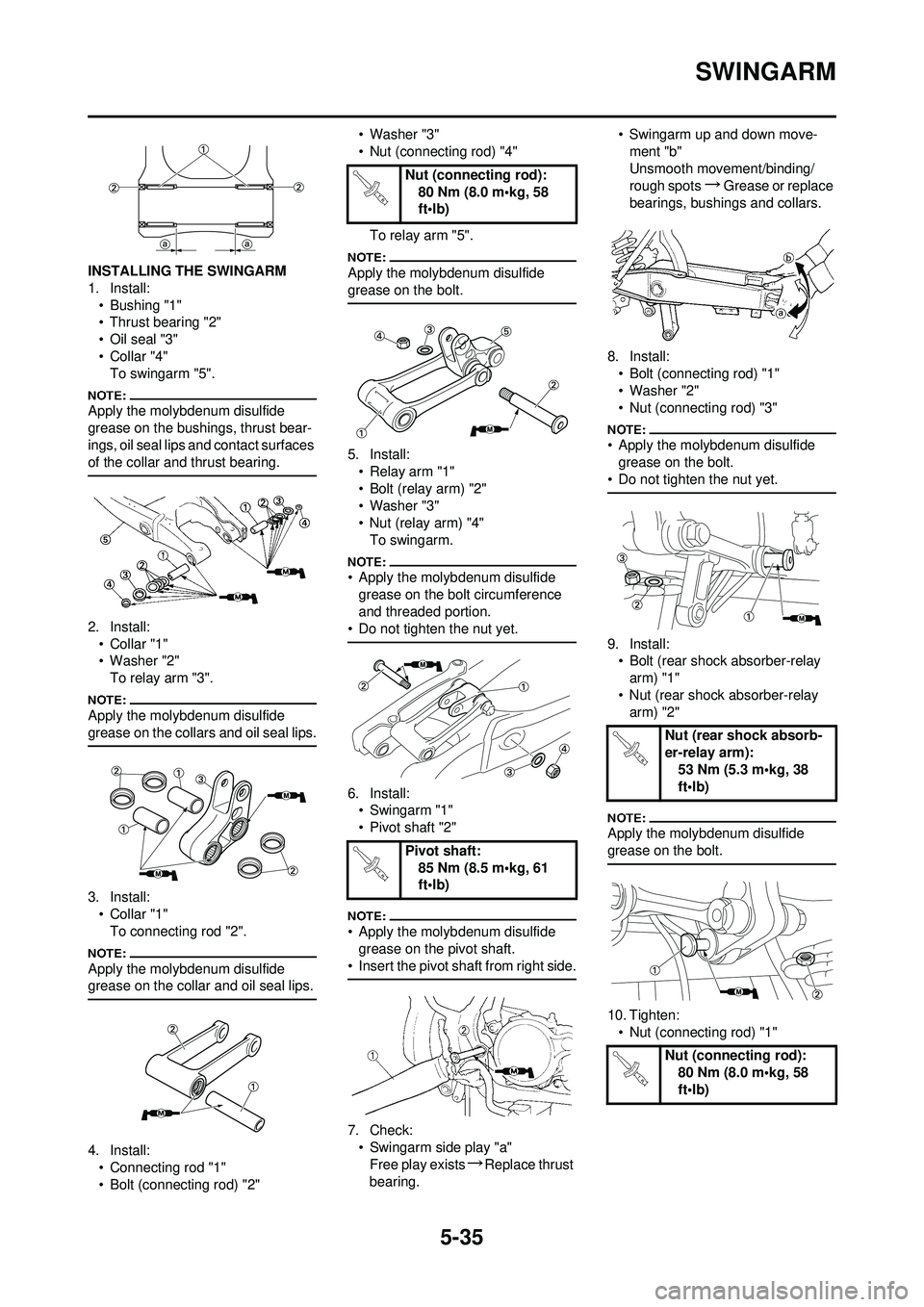

INSTALLING THE SWINGARM

1. Install:• Bushing "1"

• Thrust bearing "2"

•Oil seal "3"

•Collar "4"To swingarm "5".

Apply the molybdenum disulfide

grease on the bushings, thrust bear-

ings, oil seal lips and contact surfaces

of the collar and thrust bearing.

2. Install:

•Collar "1"

• Washer "2"To relay arm "3".

Apply the molybdenum disulfide

grease on the collars and oil seal lips.

3. Install:•Collar "1"To connecting rod "2".

Apply the molybdenum disulfide

grease on the collar and oil seal lips.

4. Install:• Connecting rod "1"

• Bolt (connecting rod) "2" •Washer "3"

• Nut (connecting rod) "4"

To relay arm "5".

Apply the molybdenum disulfide

grease on the bolt.

5. Install:• Relay arm "1"

• Bolt (relay arm) "2"

•Washer "3"

• Nut (relay arm) "4"To swingarm.

• Apply the molybdenum disulfide grease on the bolt circumference

and threaded portion.

• Do not tighten the nut yet.

6. Install: • Swingarm "1"

• Pivot shaft "2"

• Apply the molybdenum disulfide

grease on the pivot shaft.

• Insert the pivot shaft from right side.

7. Check: • Swingarm side play "a"Free play exists

→Replace thrust

bearing. • Swingarm up and down move-

ment "b"

Unsmooth movement/binding/

rough spots

→Grease or replace

bearings, bushings and collars.

8. Install: • Bolt (connecting rod) "1"

• Washer "2"

• Nut (connecting rod) "3"

• Apply the molybdenum disulfide grease on the bolt.

• Do not tighten the nut yet.

9. Install: • Bolt (rear shock absorber-relay

arm) "1"

• Nut (rear shock absorber-relay arm) "2"

Apply the molybdenum disulfide

grease on the bolt.

10. Tighten:• Nut (connecting rod) "1"

Nut (connecting rod):

80 Nm (8.0 m•kg, 58

ft•lb)

Pivot shaft: 85 Nm (8.5 m•kg, 61

ft•lb)

Nut (rear shock absorb-

er-relay arm):53 Nm (5.3 m•kg, 38

ft•lb)

Nut (connecting rod): 80 Nm (8.0 m•kg, 58

ft•lb)

Page 169 of 192

5-37

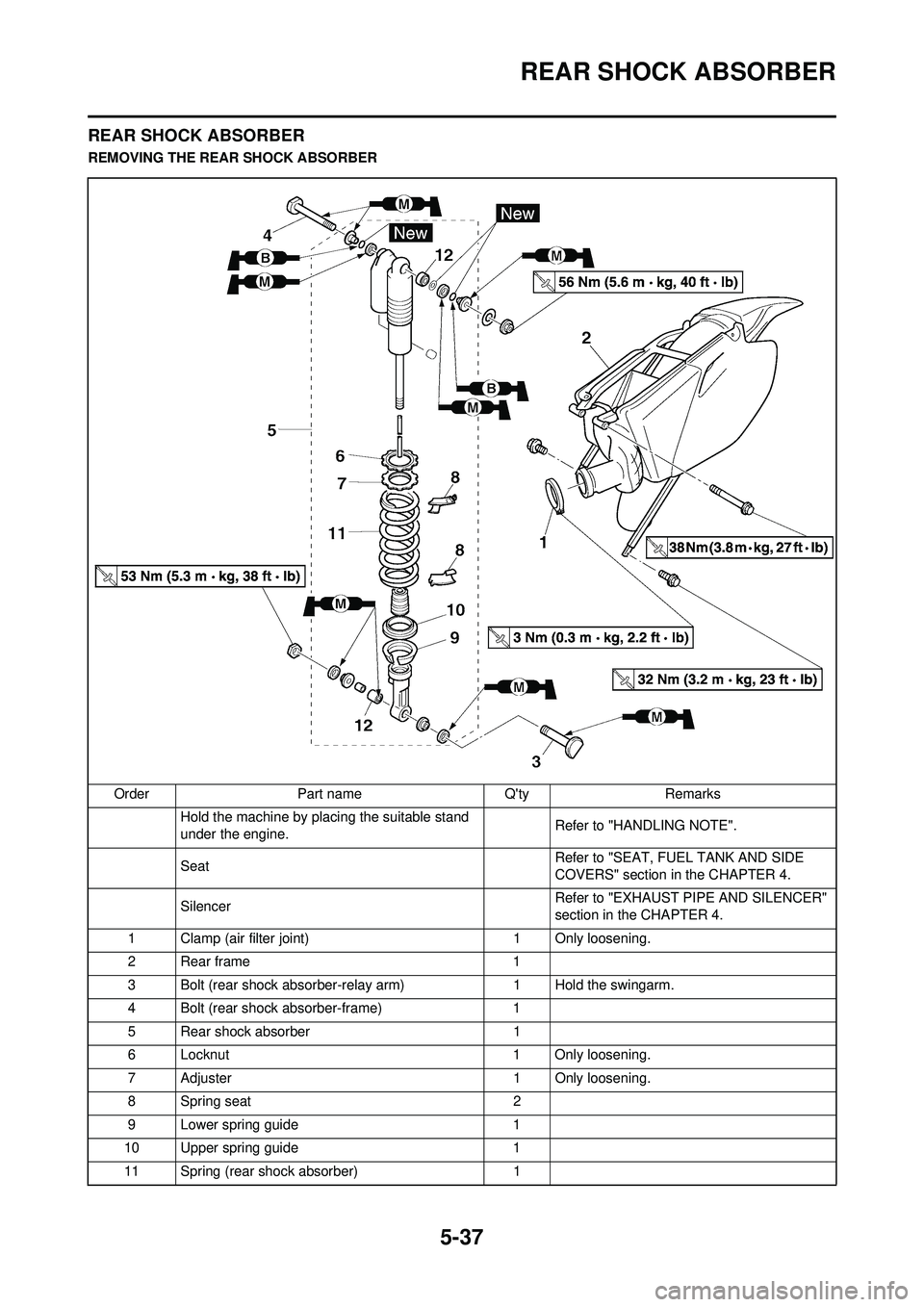

REAR SHOCK ABSORBER

REAR SHOCK ABSORBER

REMOVING THE REAR SHOCK ABSORBEROrder Part name Q'ty Remarks Hold the machine by placing the suitable stand

under the engine. Refer to "HANDLING NOTE".

Seat Refer to "SEAT, FUEL TANK AND SIDE

COVERS" section in the CHAPTER 4.

Silencer Refer to "EXHAUST PIPE AND SILENCER"

section in the CHAPTER 4.

1 Clamp (air filter joint) 1 Only loosening.

2 Rear frame 1

3 Bolt (rear shock absorber-relay arm) 1 Hold the swingarm.

4 Bolt (rear shock absorber-frame) 1

5 Rear shock absorber 1

6 Locknut 1 Only loosening.

7 Adjuster 1 Only loosening.

8 Spring seat 2

9 Lower spring guide 1

10 Upper spring guide 1

11 Spring (rear shock absorber) 1

Page 170 of 192

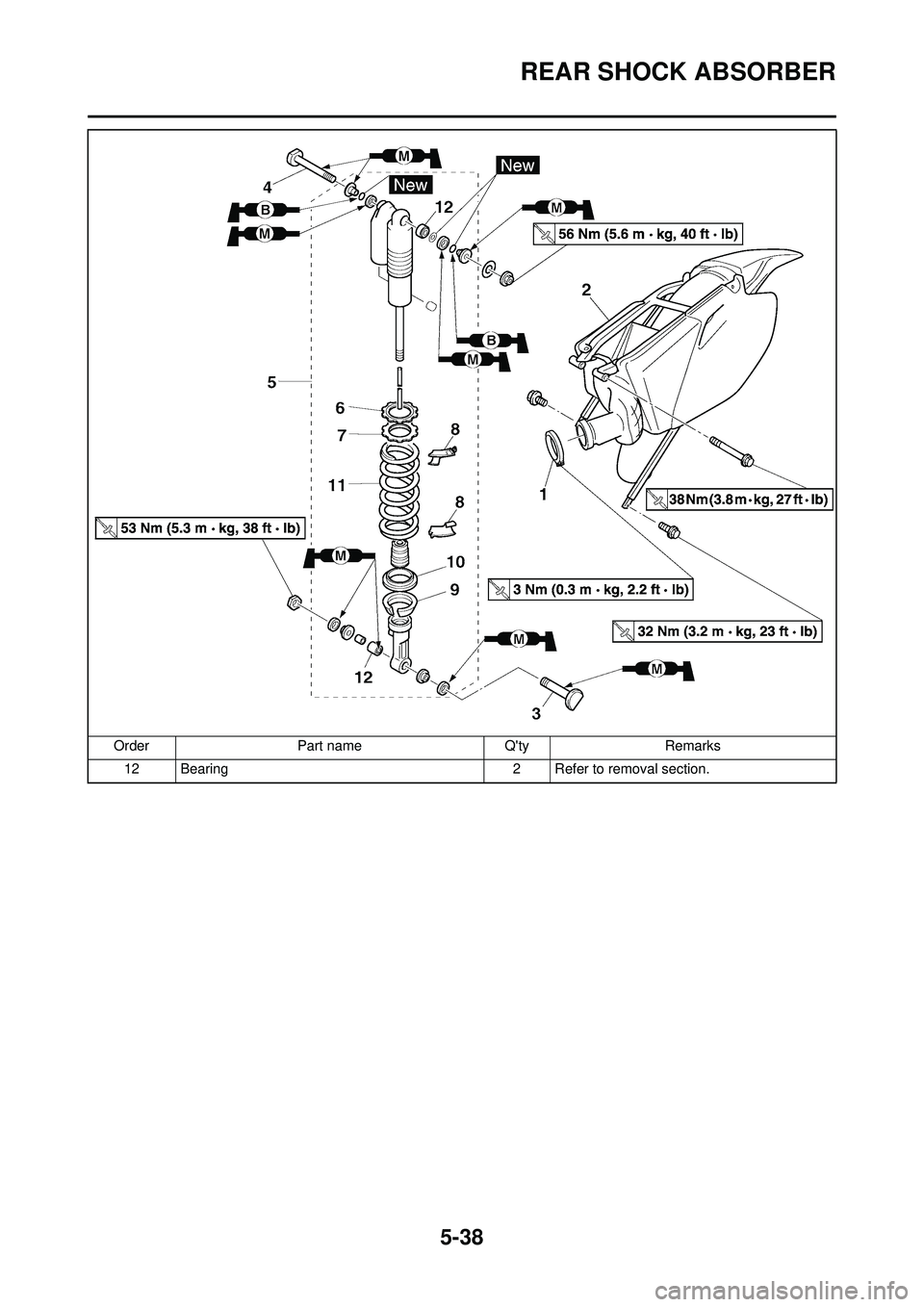

5-38

REAR SHOCK ABSORBER

12 Bearing2 Refer to removal section.

Order

Part name Q'tyRemarks

Page 171 of 192

5-39

REAR SHOCK ABSORBER

HANDLING NOTE

• Support the machine securely so there is no danger of it falling

over.

• This rear shock absorber is pro-

vided with a separate type tank

filled with high-pressure nitro-

gen gas. To prevent the danger

of explosion, read and under-

stand the following information

before handling the shock ab-

sorber. The manufacturer can

not be held responsible for prop-

erty damage or personal injury

that may result from improper

handling.

• Never tamper or attempt to dis-assemble the cylinder or the

tank.

• Never throw the rear shock ab-

sorber into an open flame or

other high heat. The rear shock

absorber may explode as a re-

sult of nitrogen gas expansion

and/ or damage to the hose.

• Be careful not to damage any

part of the gas tank. A damaged

gas tank will impair the damp-

ing performance or cause a

malfunction.

• Take care not to scratch the contact surface of the piston

rod with the cylinder; or oil

could leak out.

• Never attempt to remove the plug at the bottom of the nitro-

gen gas tank. It is very danger-

ous to remove the plug.

• When scrapping the rear shock

absorber, follow the instruc-

tions on disposal.

NOTES ON DISPOSAL (YAMAHA

DEALERS ONLY)

Before disposing the rear shock ab-

sorber, be sure to extract the nitrogen

gas from valve "1". Wear eye protec-

tion to prevent eye damage from es-

caping gas and/or metal chips.

To dispose of a damaged or worn-

out rear shock absorber, take the

unit to your Yamaha dealer for this

disposal procedure.

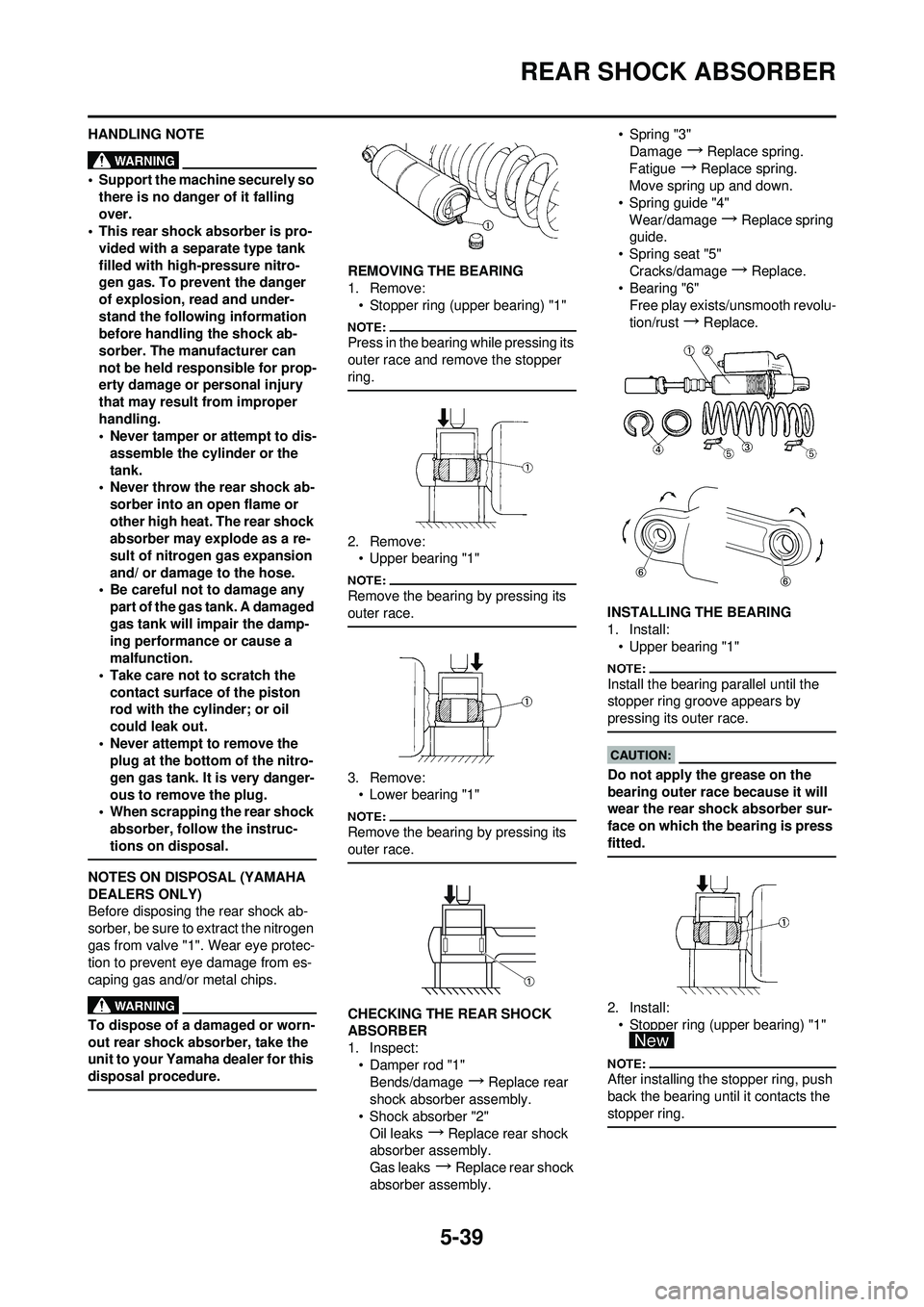

REMOVING THE BEARING

1. Remove:• Stopper ring (upper bearing) "1"

Press in the bearing while pressing its

outer race and remove the stopper

ring.

2. Remove:• Upper bearing "1"

Remove the bearing by pressing its

outer race.

3. Remove:• Lower bearing "1"

Remove the bearing by pressing its

outer race.

CHECKING THE REAR SHOCK

ABSORBER

1. Inspect:

• Damper rod "1"Bends/damage

→Replace rear

shock absorber assembly.

• Shock absorber "2" Oil leaks

→Replace rear shock

absorber assembly.

Gas leaks

→Replace rear shock

absorber assembly. • Spring "3"

Damage

→Replace spring.

Fatigue

→Replace spring.

Move spring up and down.

• Spring guide "4" Wear/damage

→Replace spring

guide.

• Spring seat "5" Cracks/damage

→Replace.

• Bearing "6"

Free play exists/unsmooth revolu-

tion/rust

→Replace.

INSTALLING THE BEARING

1. Install: • Upper bearing "1"

Install the bearing parallel until the

stopper ring groove appears by

pressing its outer race.

Do not apply the grease on the

bearing outer race because it will

wear the rear shock absorber sur-

face on which the bearing is press

fitted.

2. Install:• Stopper ring (upper bearing) "1"

After installing the stopper ring, push

back the bearing until it contacts the

stopper ring.

Page 172 of 192

5-40

REAR SHOCK ABSORBER

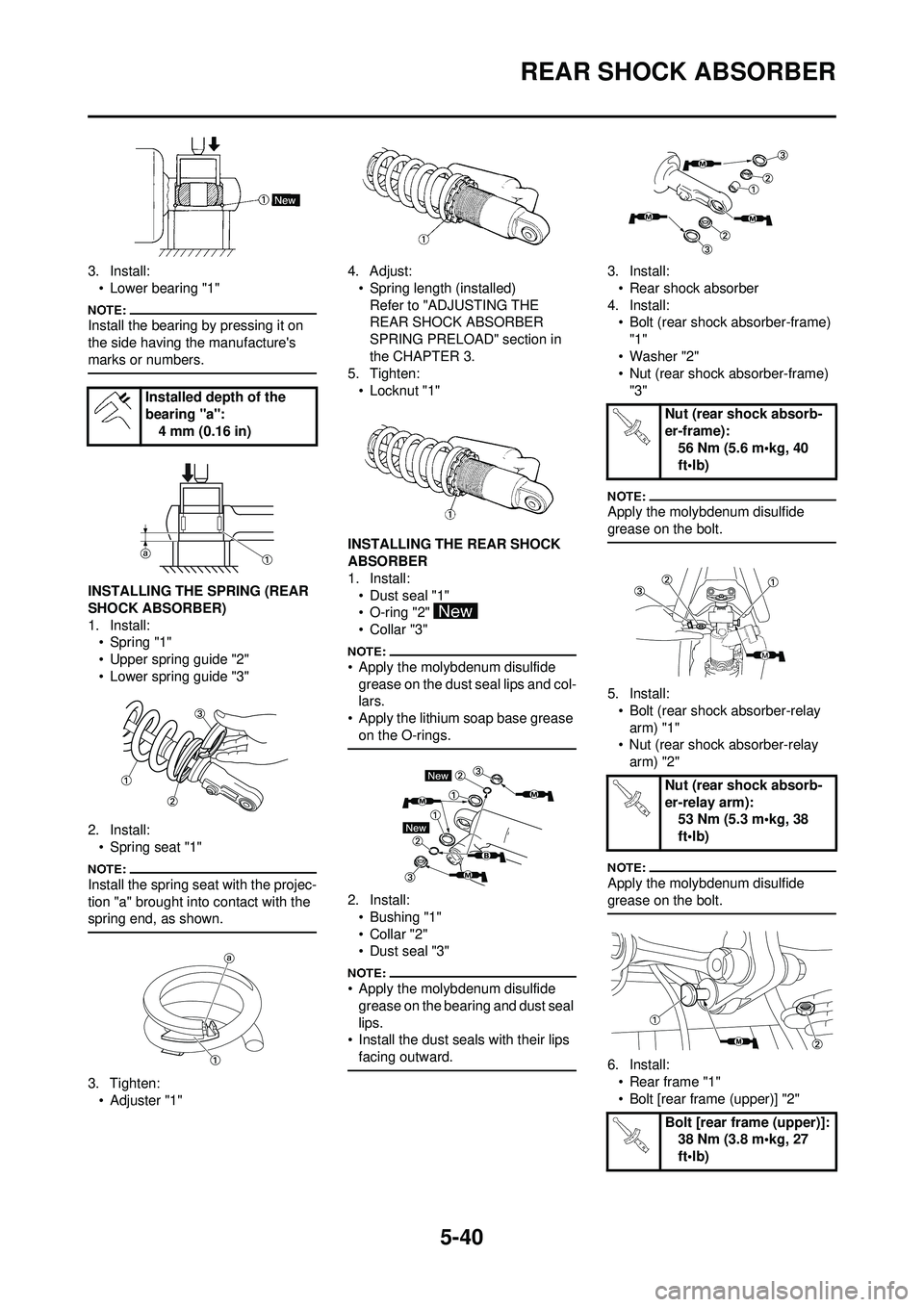

3. Install:• Lower bearing "1"

Install the bearing by pressing it on

the side having the manufacture's

marks or numbers.

INSTALLING THE SPRING (REAR

SHOCK ABSORBER)

1. Install:• Spring "1"

• Upper spring guide "2"

• Lower spring guide "3"

2. Install: • Spring seat "1"

Install the spring seat with the projec-

tion "a" brought into contact with the

spring end, as shown.

3. Tighten:•Adjuster "1" 4. Adjust:

• Spring length (installed)Refer to "ADJUSTING THE

REAR SHOCK ABSORBER

SPRING PRELOAD" section in

the CHAPTER 3.

5. Tighten:

• Locknut "1"

INSTALLING THE REAR SHOCK

ABSORBER

1. Install: • Dust seal "1"

• O-ring "2"

•Collar "3"

• Apply the molybdenum disulfide grease on the dust seal lips and col-

lars.

• Apply the lithium soap base grease on the O-rings.

2. Install:• Bushing "1"

•Collar "2"

• Dust seal "3"

• Apply the molybdenum disulfide grease on the bearing and dust seal

lips.

• Install the dust seals with their lips

facing outward.

3. Install:• Rear shock absorber

4. Install: • Bolt (rear shock absorber-frame)

"1"

• Washer "2"

• Nut (rear shock absorber-frame) "3"

Apply the molybdenum disulfide

grease on the bolt.

5. Install:• Bolt (rear shock absorber-relay arm) "1"

• Nut (rear shock absorber-relay

arm) "2"

Apply the molybdenum disulfide

grease on the bolt.

6. Install:• Rear frame "1"

• Bolt [rear frame (upper)] "2"

Installed depth of the

bearing "a":

4 mm (0.16 in)

Nut (rear shock absorb-

er-frame):56 Nm (5.6 m•kg, 40

ft•lb)

Nut (rear shock absorb-

er-relay arm): 53 Nm (5.3 m•kg, 38

ft•lb)

Bolt [rear frame (upper)]: 38 Nm (3.8 m•kg, 27

ft•lb)