check engine YAMAHA YZ250F 2016 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: YZ250F, Model: YAMAHA YZ250F 2016Pages: 356, PDF Size: 11.25 MB

Page 96 of 356

ENGINE

3-12

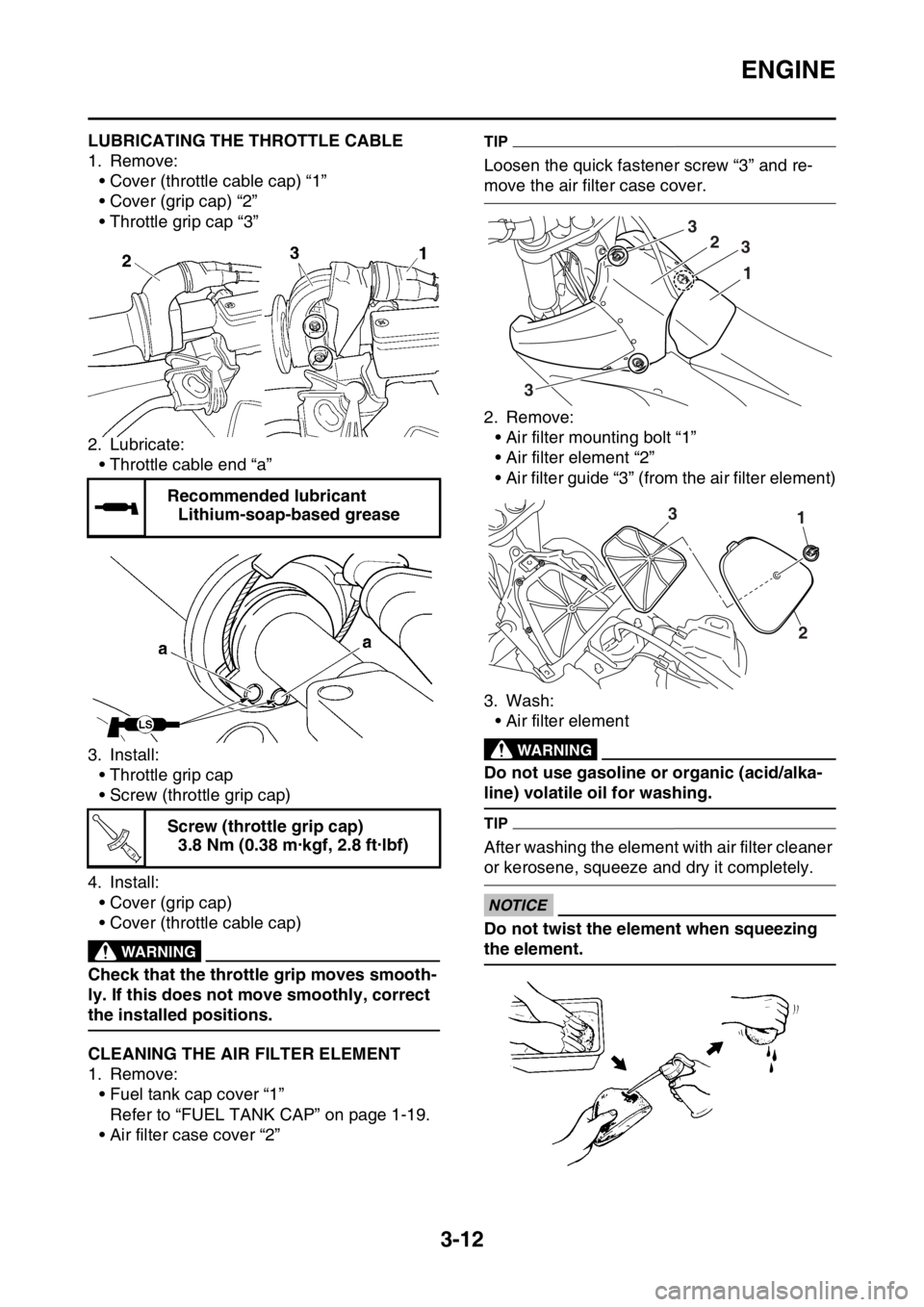

EAS1SM9077LUBRICATING THE THROTTLE CABLE

1. Remove:

• Cover (throttle cable cap) “1”

• Cover (grip cap) “2”

• Throttle grip cap “3”

2. Lubricate:

• Throttle cable end “a”

3. Install:

• Throttle grip cap

• Screw (throttle grip cap)

4. Install:

• Cover (grip cap)

• Cover (throttle cable cap)

EWA

WARNING

Check that the throttle grip moves smooth-

ly. If this does not move smoothly, correct

the installed positions.

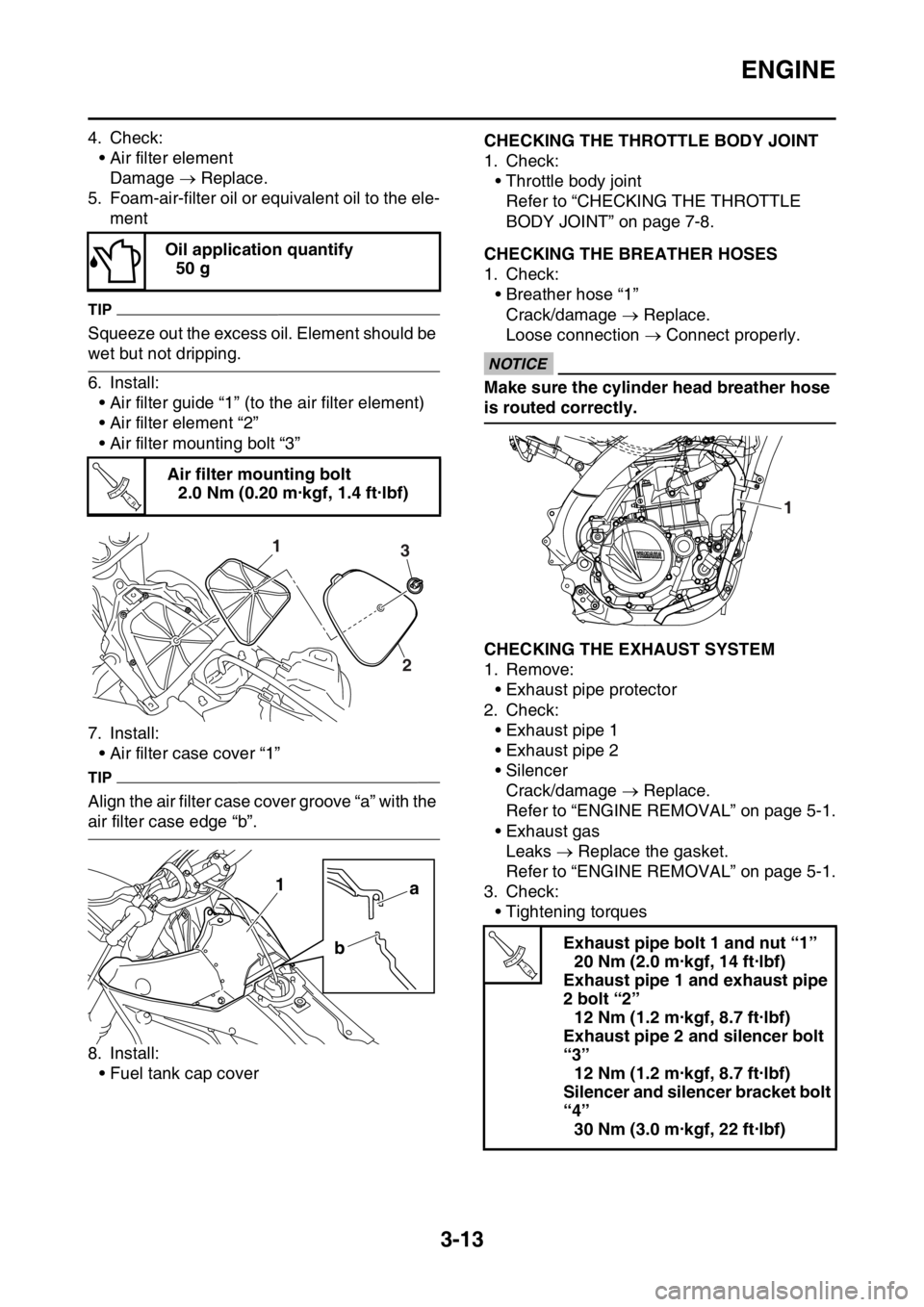

EAS1SM9078CLEANING THE AIR FILTER ELEMENT

1. Remove:

• Fuel tank cap cover “1”

Refer to “FUEL TANK CAP” on page 1-19.

• Air filter case cover “2”

TIP

Loosen the quick fastener screw “3” and re-

move the air filter case cover.

2. Remove:

• Air filter mounting bolt “1”

• Air filter element “2”

• Air filter guide “3” (from the air filter element)

3. Wash:

• Air filter element

EWA

WARNING

Do not use gasoline or organic (acid/alka-

line) volatile oil for washing.

TIP

After washing the element with air filter cleaner

or kerosene, squeeze and dry it completely.

ECA

NOTICE

Do not twist the element when squeezing

the element. Recommended lubricant

Lithium-soap-based grease

Screw (throttle grip cap)

3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

T R..

1

2

3

3

3

13

2

Page 97 of 356

ENGINE

3-13

4. Check:

• Air filter element

Damage Replace.

5. Foam-air-filter oil or equivalent oil to the ele-

ment

TIP

Squeeze out the excess oil. Element should be

wet but not dripping.

6. Install:

• Air filter guide “1” (to the air filter element)

• Air filter element “2”

• Air filter mounting bolt “3”

7. Install:

• Air filter case cover “1”

TIP

Align the air filter case cover groove “a” with the

air filter case edge “b”.

8. Install:

• Fuel tank cap cover

EAS1SM9079CHECKING THE THROTTLE BODY JOINT

1. Check:

• Throttle body joint

Refer to “CHECKING THE THROTTLE

BODY JOINT” on page 7-8.

EAS1SM9080CHECKING THE BREATHER HOSES

1. Check:

• Breather hose “1”

Crack/damage Replace.

Loose connection Connect properly.

ECA14920

NOTICE

Make sure the cylinder head breather hose

is routed correctly.

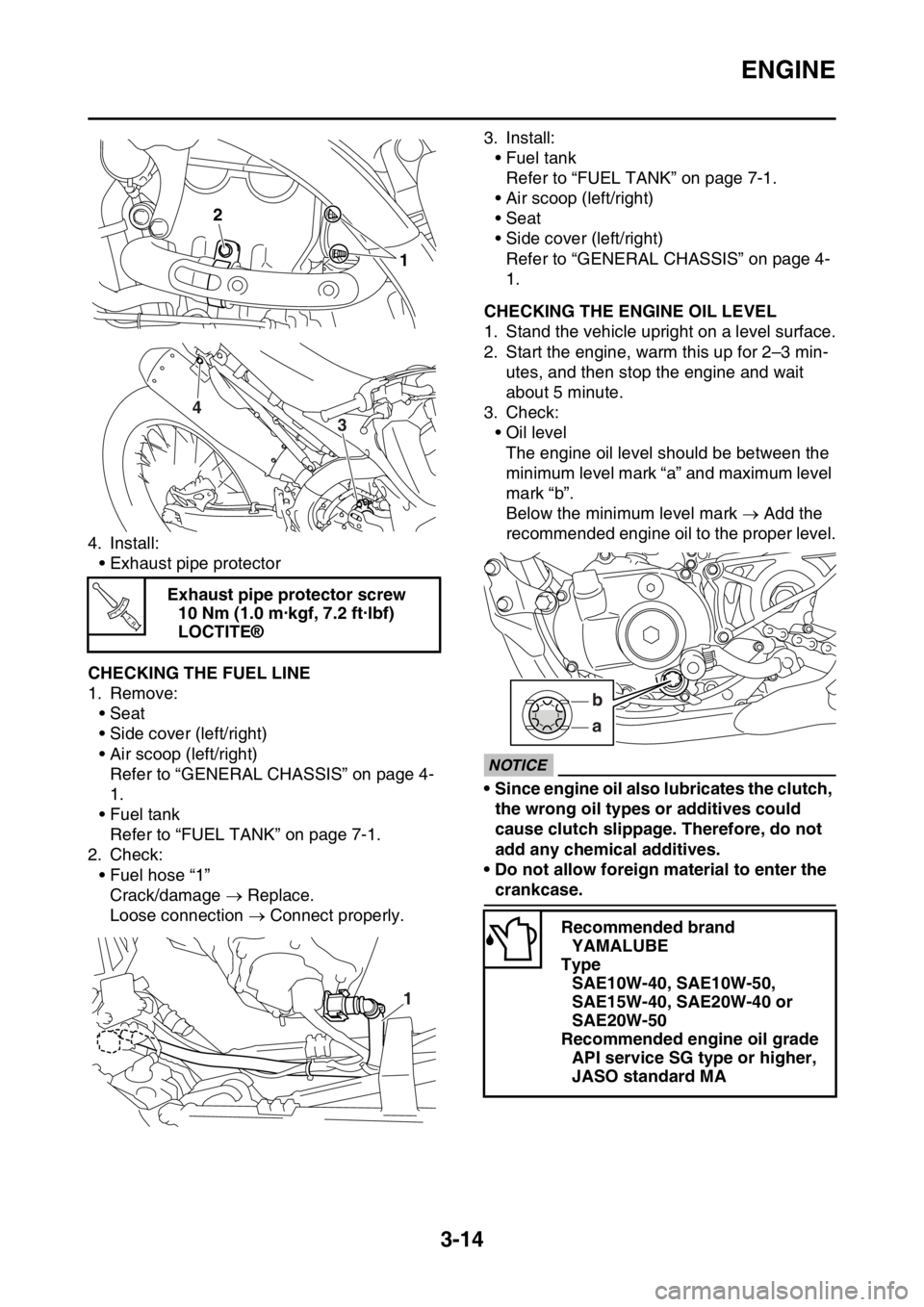

EAS1SM9081CHECKING THE EXHAUST SYSTEM

1. Remove:

• Exhaust pipe protector

2. Check:

• Exhaust pipe 1

• Exhaust pipe 2

• Silencer

Crack/damage Replace.

Refer to “ENGINE REMOVAL” on page 5-1.

• Exhaust gas

Leaks Replace the gasket.

Refer to “ENGINE REMOVAL” on page 5-1.

3. Check:

• Tightening torques Oil application quantify

50 g

Air filter mounting bolt

2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

T R..

31

2

a

b 1

Exhaust pipe bolt 1 and nut “1”

20 Nm (2.0 m·kgf, 14 ft·lbf)

Exhaust pipe 1 and exhaust pipe

2 bolt “2”

12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Exhaust pipe 2 and silencer bolt

“3”

12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Silencer and silencer bracket bolt

“4”

30 Nm (3.0 m·kgf, 22 ft·lbf)

1

T R..

Page 98 of 356

ENGINE

3-14

4. Install:

• Exhaust pipe protector

EAS1SM9082CHECKING THE FUEL LINE

1. Remove:

• Seat

• Side cover (left/right)

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

2. Check:

• Fuel hose “1”

Crack/damage Replace.

Loose connection Connect properly.3. Install:

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

EAS1SM9083CHECKING THE ENGINE OIL LEVEL

1. Stand the vehicle upright on a level surface.

2. Start the engine, warm this up for 2–3 min-

utes, and then stop the engine and wait

about 5 minute.

3. Check:

• Oil level

The engine oil level should be between the

minimum level mark “a” and maximum level

mark “b”.

Below the minimum level mark Add the

recommended engine oil to the proper level.

ECA33DD018

NOTICE

• Since engine oil also lubricates the clutch,

the wrong oil types or additives could

cause clutch slippage. Therefore, do not

add any chemical additives.

• Do not allow foreign material to enter the

crankcase. Exhaust pipe protector screw

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

LOCTITE®

2

1

4

3

T R..

1

Recommended brand

YAMALUBE

Type

SAE10W-40, SAE10W-50,

SAE15W-40, SAE20W-40 or

SAE20W-50

Recommended engine oil grade

API service SG type or higher,

JASO standard MA

a b

Page 99 of 356

ENGINE

3-15

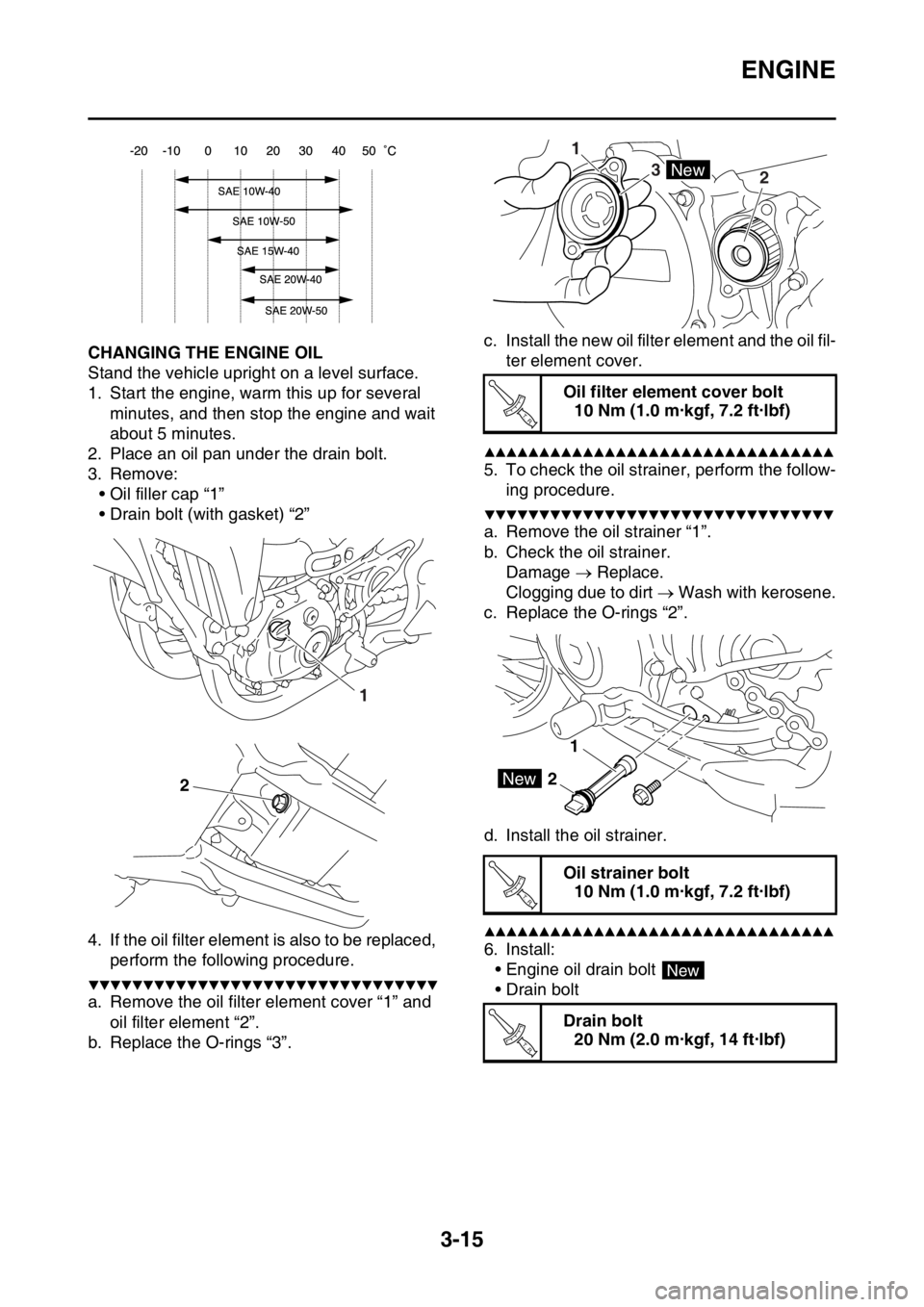

EAS1SM9084CHANGING THE ENGINE OIL

Stand the vehicle upright on a level surface.

1. Start the engine, warm this up for several

minutes, and then stop the engine and wait

about 5 minutes.

2. Place an oil pan under the drain bolt.

3. Remove:

• Oil filler cap “1”

• Drain bolt (with gasket) “2”

4. If the oil filter element is also to be replaced,

perform the following procedure.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the oil filter element cover “1” and

oil filter element “2”.

b. Replace the O-rings “3”.c. Install the new oil filter element and the oil fil-

ter element cover.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. To check the oil strainer, perform the follow-

ing procedure.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the oil strainer “1”.

b. Check the oil strainer.

Damage Replace.

Clogging due to dirt Wash with kerosene.

c. Replace the O-rings “2”.

d. Install the oil strainer.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

6. Install:

• Engine oil drain bolt

• Drain bolt

1

2

Oil filter element cover bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil strainer bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Drain bolt

20 Nm (2.0 m·kgf, 14 ft·lbf)

1

3

2

New

T R..

1

2New

T R..

New

T R..

Page 100 of 356

ENGINE

3-16

7. Pour the specified amount of engine oil into

the oil filler cap hole.

8. Install:

• Oil filler cap

9. Check:

• Oil level

Refer to “CHECKING THE ENGINE OIL

LEVEL” on page 3-14.

10.Check:

• Engine oil pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Slightly loosen the oil pressure check bolt

“1”.

EWA

WARNING

When the engine is started with the check

bolt removed, oil will spout; therefore, al-

ways loosen it before the checkup.

Start the engine and keep it idling until oil

starts to seep from the oil pressure check

bolt.

EWA

WARNING

Always keep the engine idling speed during

the checkup without increasing the engine

speed.

ECA

NOTICE

If no engine oil seeps out after one minute,

immediately turn the engine off so it will not

seize.

b. If no engine oil seeps out, check the engine

oil for leaks, and the engine oil passage and

the oil pump for damage.

c. Check the oil pressure again.

d. Tighten the oil pressure check bolt.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SM9085ADJUSTING THE ENGINE IDLING SPEED

TIP

• Because the air pressure is lower at high alti-

tudes, the air-fuel mixture will become richer.

If the idling speed is low, turn the starter knob/

idle screw a few clicks counterclockwise to in-

crease the speed before the adjustment.

• Before adjusting the engine idling speed,

make sure that the air filter element is not

clogged, the engine compression is proper,

and the throttle grip free play is proper.

• Adjust the engine idling speed with the starter

knob/idle screw pushed in completely.

1. Start the engine, and warm this up until the

oil has reached the specified temperature.

2. Attach the pocket tester with temperature

probe “1” to the oil drain bolt. Engine oil quantity

Without oil filter element replace-

ment

0.71 L (0.75 US qt, 0.62 Imp.qt)

With oil filter element replace-

ment

0.73 L (0.77 US qt, 0.64 Imp.qt)

Quantity (disassembled)

0.90 L (0.95 US qt, 0.79 Imp.qt)

1

Oil pressure check bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil temperature

55–65 °C (131–149 °F)

T R..

1

Page 101 of 356

ENGINE

3-17

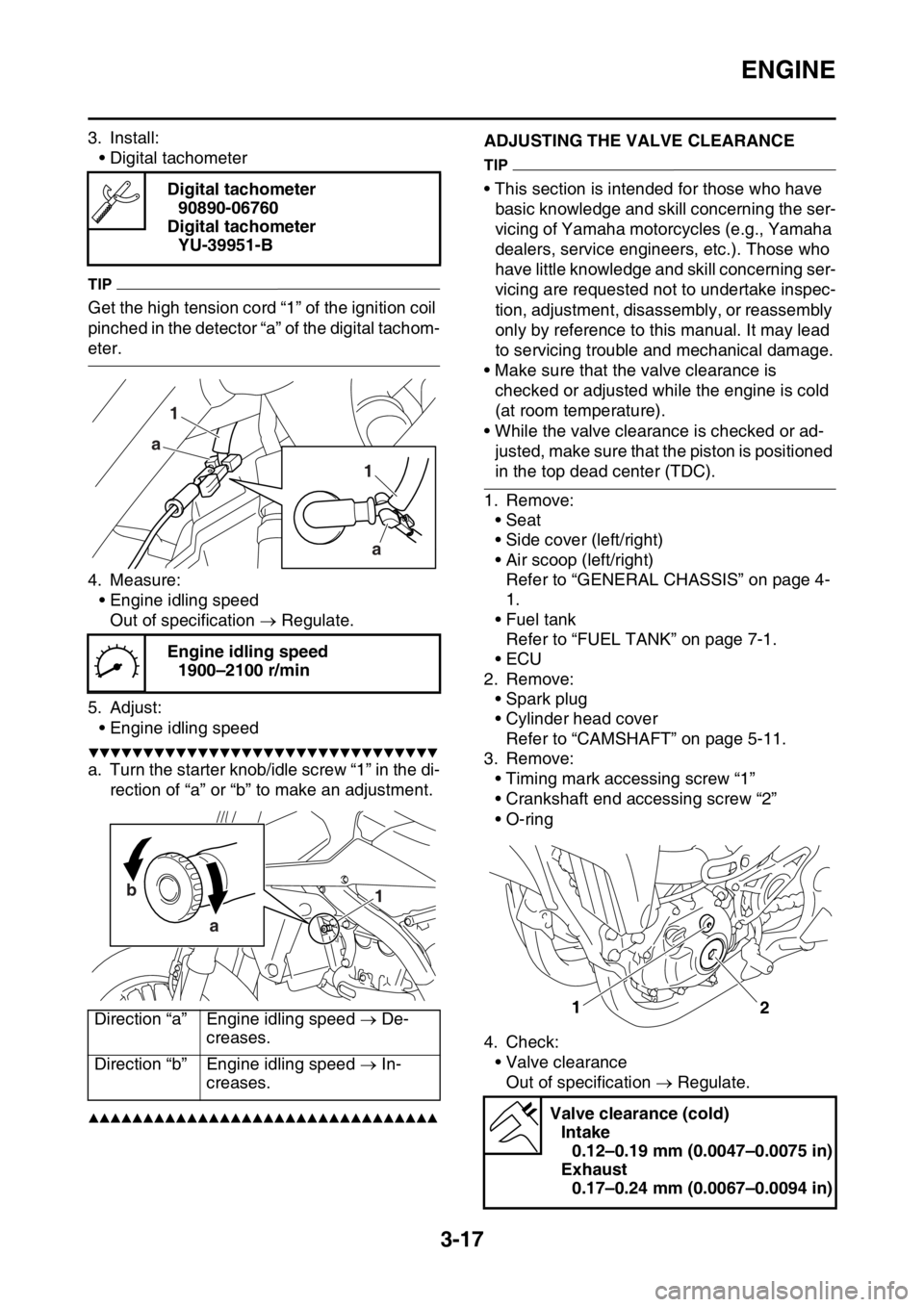

3. Install:

• Digital tachometer

TIP

Get the high tension cord “1” of the ignition coil

pinched in the detector “a” of the digital tachom-

eter.

4. Measure:

• Engine idling speed

Out of specification Regulate.

5. Adjust:

• Engine idling speed

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the starter knob/idle screw “1” in the di-

rection of “a” or “b” to make an adjustment.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

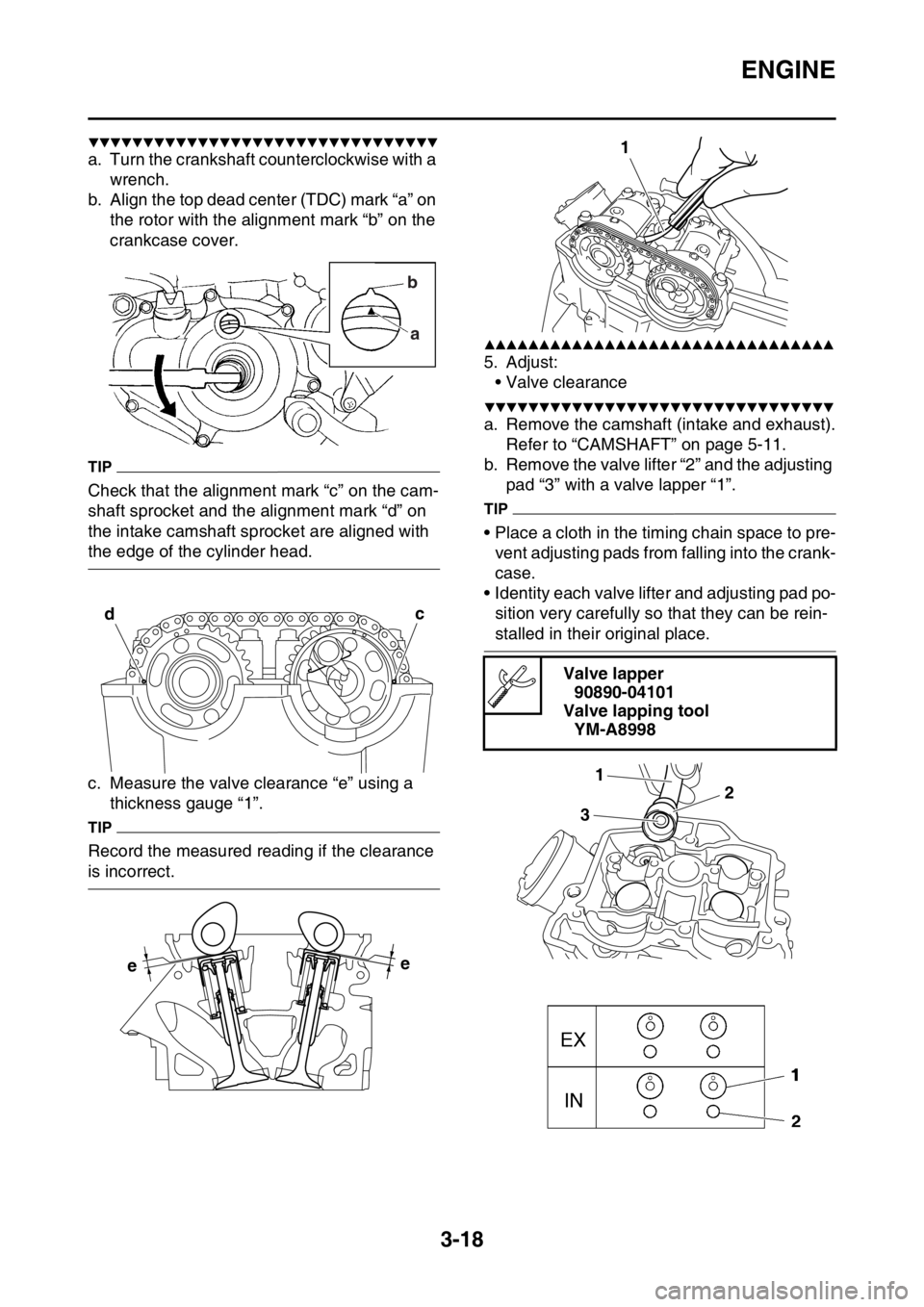

EAS1SM9086ADJUSTING THE VALVE CLEARANCE

TIP

• This section is intended for those who have

basic knowledge and skill concerning the ser-

vicing of Yamaha motorcycles (e.g., Yamaha

dealers, service engineers, etc.). Those who

have little knowledge and skill concerning ser-

vicing are requested not to undertake inspec-

tion, adjustment, disassembly, or reassembly

only by reference to this manual. It may lead

to servicing trouble and mechanical damage.

• Make sure that the valve clearance is

checked or adjusted while the engine is cold

(at room temperature).

• While the valve clearance is checked or ad-

justed, make sure that the piston is positioned

in the top dead center (TDC).

1. Remove:

• Seat

• Side cover (left/right)

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

•ECU

2. Remove:

• Spark plug

• Cylinder head cover

Refer to “CAMSHAFT” on page 5-11.

3. Remove:

• Timing mark accessing screw “1”

• Crankshaft end accessing screw “2”

• O-ring

4. Check:

• Valve clearance

Out of specification Regulate. Digital tachometer

90890-06760

Digital tachometer

YU-39951-B

Engine idling speed

1900–2100 r/min

Direction “a” Engine idling speed De-

creases.

Direction “b” Engine idling speed In-

creases.1 1

a a

1 b

a

Valve clearance (cold)

Intake

0.12–0.19 mm (0.0047–0.0075 in)

Exhaust

0.17–0.24 mm (0.0067–0.0094 in)

1

2

Page 102 of 356

ENGINE

3-18

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the crankshaft counterclockwise with a

wrench.

b. Align the top dead center (TDC) mark “a” on

the rotor with the alignment mark “b” on the

crankcase cover.

TIP

Check that the alignment mark “c” on the cam-

shaft sprocket and the alignment mark “d” on

the intake camshaft sprocket are aligned with

the edge of the cylinder head.

c. Measure the valve clearance “e” using a

thickness gauge “1”.

TIP

Record the measured reading if the clearance

is incorrect.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. Adjust:

• Valve clearance

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the camshaft (intake and exhaust).

Refer to “CAMSHAFT” on page 5-11.

b. Remove the valve lifter “2” and the adjusting

pad “3” with a valve lapper “1”.

TIP

• Place a cloth in the timing chain space to pre-

vent adjusting pads from falling into the crank-

case.

• Identity each valve lifter and adjusting pad po-

sition very carefully so that they can be rein-

stalled in their original place.

b

a

dc

ee

Valve lapper

90890-04101

Valve lapping tool

YM-A8998

1

1

32

Page 103 of 356

ENGINE

3-19

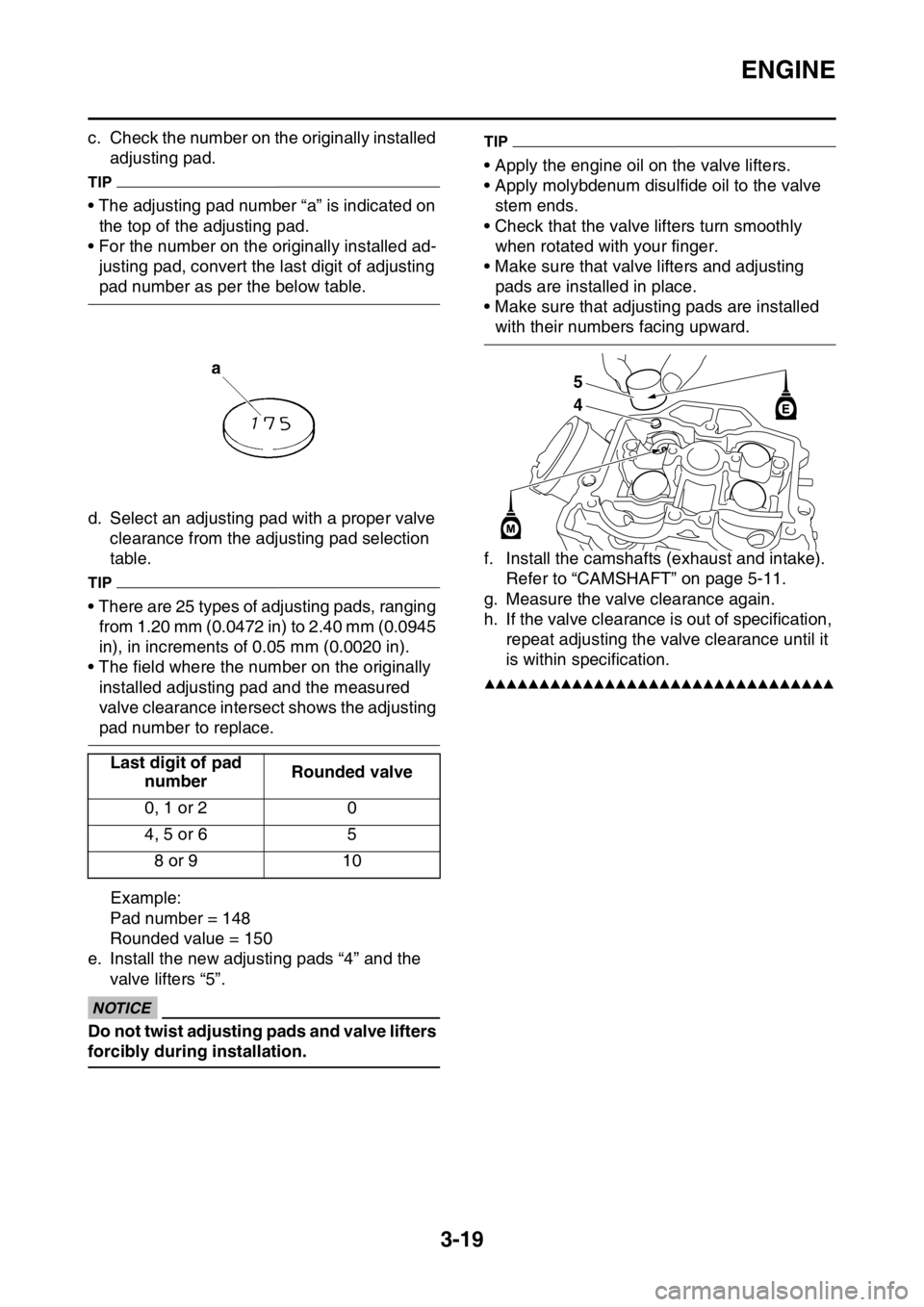

c. Check the number on the originally installed

adjusting pad.

TIP

• The adjusting pad number “a” is indicated on

the top of the adjusting pad.

• For the number on the originally installed ad-

justing pad, convert the last digit of adjusting

pad number as per the below table.

d. Select an adjusting pad with a proper valve

clearance from the adjusting pad selection

table.

TIP

• There are 25 types of adjusting pads, ranging

from 1.20 mm (0.0472 in) to 2.40 mm (0.0945

in), in increments of 0.05 mm (0.0020 in).

• The field where the number on the originally

installed adjusting pad and the measured

valve clearance intersect shows the adjusting

pad number to replace.

Example:

Pad number = 148

Rounded value = 150

e. Install the new adjusting pads “4” and the

valve lifters “5”.

ECA@

NOTICE

Do not twist adjusting pads and valve lifters

forcibly during installation.

TIP

• Apply the engine oil on the valve lifters.

• Apply molybdenum disulfide oil to the valve

stem ends.

• Check that the valve lifters turn smoothly

when rotated with your finger.

• Make sure that valve lifters and adjusting

pads are installed in place.

• Make sure that adjusting pads are installed

with their numbers facing upward.

f. Install the camshafts (exhaust and intake).

Refer to “CAMSHAFT” on page 5-11.

g. Measure the valve clearance again.

h. If the valve clearance is out of specification,

repeat adjusting the valve clearance until it

is within specification.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Last digit of pad

numberRounded valve

0, 1 or 2 0

4, 5 or 6 5

8 or 9 10

4 5

Page 112 of 356

CHASSIS

3-28

WARNING

• Use only the designated brake fluid. Other

brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor

brake performance.

• Refill with the same type of brake fluid that

is already in the system. Mixing brake flu-

ids may result in a harmful chemical reac-

tion, leading to poor brake performance.

• When refilling, be careful that water does

not enter the brake fluid reservoir. Water

will significantly lower the boiling point of

the brake fluid and could cause vapor

lock.

ECA

NOTICE

Brake fluid may damage painted surfaces

and plastic parts. Therefore, always clean

up any spilt brake fluid immediately.

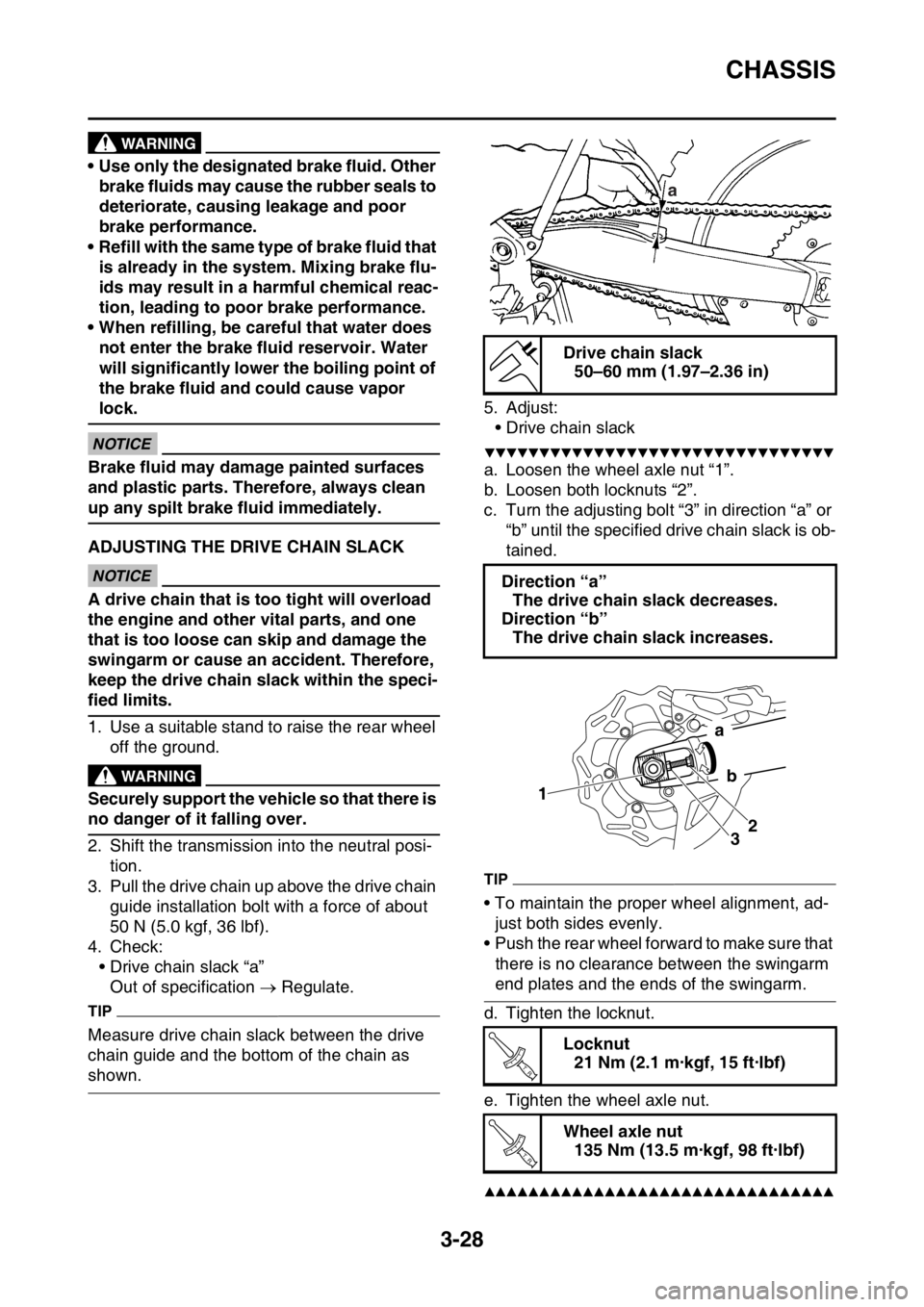

EAS1SM9096ADJUSTING THE DRIVE CHAIN SLACKECA13550

NOTICE

A drive chain that is too tight will overload

the engine and other vital parts, and one

that is too loose can skip and damage the

swingarm or cause an accident. Therefore,

keep the drive chain slack within the speci-

fied limits.

1. Use a suitable stand to raise the rear wheel

off the ground.

EWA13120

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Shift the transmission into the neutral posi-

tion.

3. Pull the drive chain up above the drive chain

guide installation bolt with a force of about

50 N (5.0 kgf, 36 lbf).

4. Check:

• Drive chain slack “a”

Out of specification Regulate.

TIP

Measure drive chain slack between the drive

chain guide and the bottom of the chain as

shown.5. Adjust:

• Drive chain slack

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the wheel axle nut “1”.

b. Loosen both locknuts “2”.

c. Turn the adjusting bolt “3” in direction “a” or

“b” until the specified drive chain slack is ob-

tained.

TIP

• To maintain the proper wheel alignment, ad-

just both sides evenly.

• Push the rear wheel forward to make sure that

there is no clearance between the swingarm

end plates and the ends of the swingarm.

d. Tighten the locknut.

e. Tighten the wheel axle nut.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Drive chain slack

50–60 mm (1.97–2.36 in)

Direction “a”

The drive chain slack decreases.

Direction “b”

The drive chain slack increases.

Locknut

21 Nm (2.1 m·kgf, 15 ft·lbf)

Wheel axle nut

135 Nm (13.5 m·kgf, 98 ft·lbf)

a

1

32

a

b

T R..

T R..

Page 121 of 356

ELECTRICAL SYSTEM

3-37

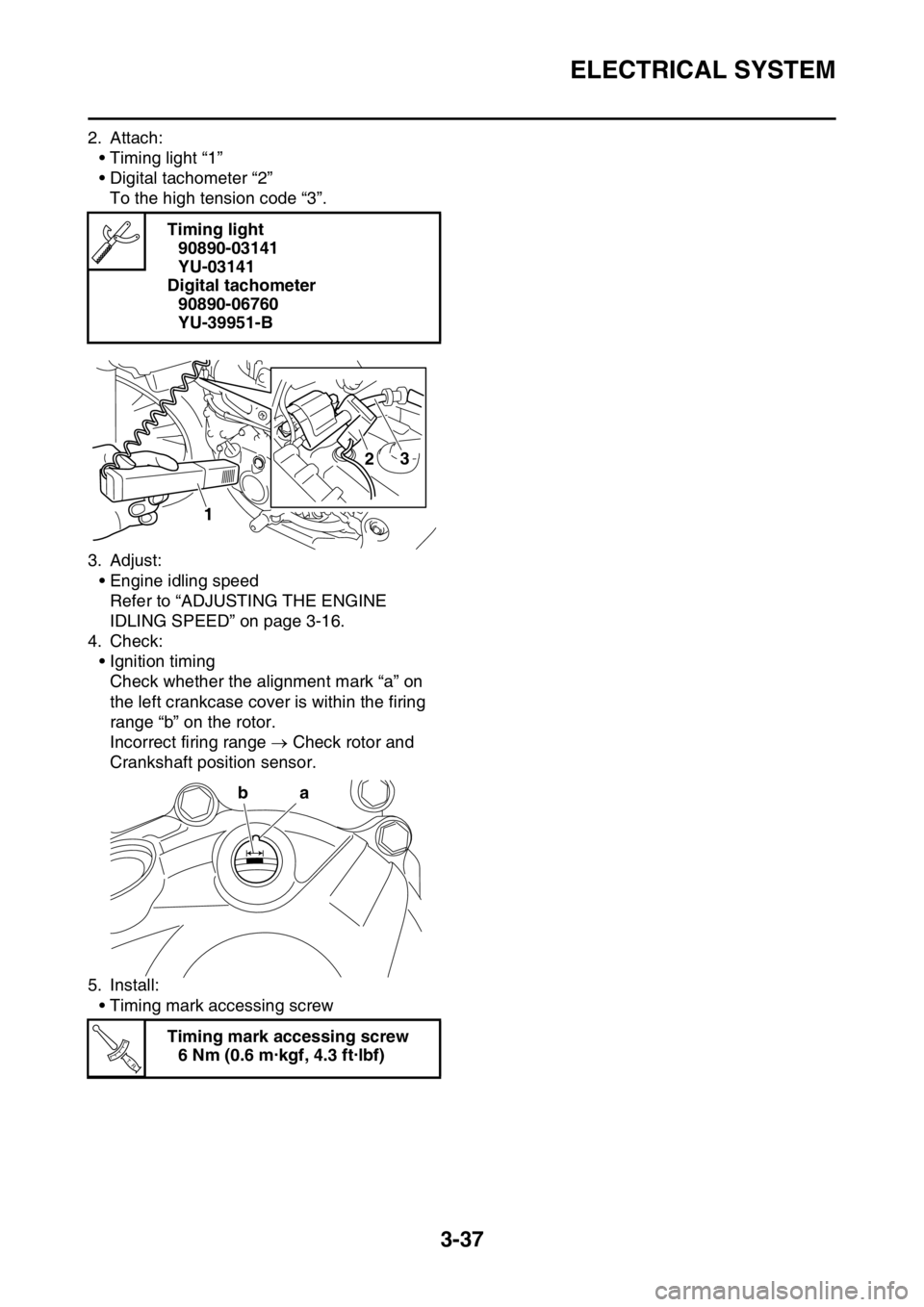

2. Attach:

• Timing light “1”

• Digital tachometer “2”

To the high tension code “3”.

3. Adjust:

• Engine idling speed

Refer to “ADJUSTING THE ENGINE

IDLING SPEED” on page 3-16.

4. Check:

• Ignition timing

Check whether the alignment mark “a” on

the left crankcase cover is within the firing

range “b” on the rotor.

Incorrect firing range Check rotor and

Crankshaft position sensor.

5. Install:

• Timing mark accessing screwTiming light

90890-03141

YU-03141

Digital tachometer

90890-06760

YU-39951-B

Timing mark accessing screw

6 Nm (0.6 m·kgf, 4.3 ft·lbf)

2

1

3

a

b

T R..