check engine YAMAHA YZ250F 2016 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: YZ250F, Model: YAMAHA YZ250F 2016Pages: 356, PDF Size: 11.25 MB

Page 189 of 356

CHAIN DRIVE

4-65

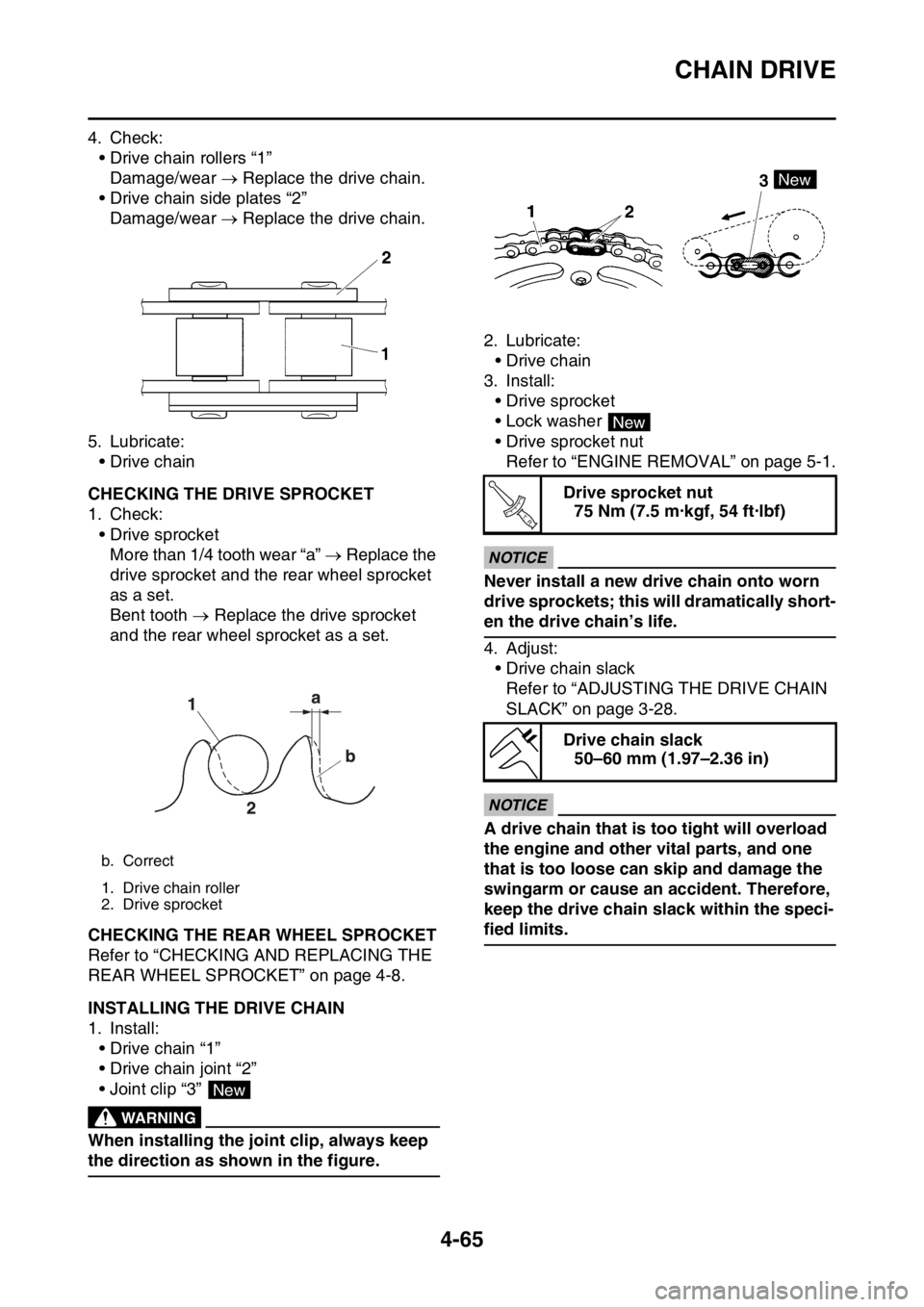

4. Check:

• Drive chain rollers “1”

Damage/wear Replace the drive chain.

• Drive chain side plates “2”

Damage/wear Replace the drive chain.

5. Lubricate:

•Drive chain

EAS1SM9190CHECKING THE DRIVE SPROCKET

1. Check:

• Drive sprocket

More than 1/4 tooth wear “a” Replace the

drive sprocket and the rear wheel sprocket

as a set.

Bent tooth Replace the drive sprocket

and the rear wheel sprocket as a set.

EAS1SM9191CHECKING THE REAR WHEEL SPROCKET

Refer to “CHECKING AND REPLACING THE

REAR WHEEL SPROCKET” on page 4-8.

EAS1SM9192INSTALLING THE DRIVE CHAIN

1. Install:

• Drive chain “1”

• Drive chain joint “2”

• Joint clip “3”

EWA

WARNING

When installing the joint clip, always keep

the direction as shown in the figure.2. Lubricate:

•Drive chain

3. Install:

• Drive sprocket

• Lock washer

• Drive sprocket nut

Refer to “ENGINE REMOVAL” on page 5-1.

ECA1DX1014

NOTICE

Never install a new drive chain onto worn

drive sprockets; this will dramatically short-

en the drive chain’s life.

4. Adjust:

• Drive chain slack

Refer to “ADJUSTING THE DRIVE CHAIN

SLACK” on page 3-28.

ECA13550

NOTICE

A drive chain that is too tight will overload

the engine and other vital parts, and one

that is too loose can skip and damage the

swingarm or cause an accident. Therefore,

keep the drive chain slack within the speci-

fied limits.

b. Correct

1. Drive chain roller

2. Drive sprocket

New

Drive sprocket nut

75 Nm (7.5 m·kgf, 54 ft·lbf)

Drive chain slack

50–60 mm (1.97–2.36 in)

New

T R..

Page 191 of 356

5

ENGINE

ENGINE REMOVAL......................................................................................... 5-1

REMOVING THE SILENCER ..................................................................... 5-6

REMOVING THE EXHAUST PIPE 2.......................................................... 5-6

REMOVING THE DRIVE SPROCKET ....................................................... 5-6

REMOVING THE ENGINE ......................................................................... 5-7

CHECKING THE SILENCER AND EXHAUST PIPE.................................. 5-7

CHANGING THE SILENCER FIBER ......................................................... 5-7

INSTALLING THE ENGINE........................................................................ 5-8

INSTALLING THE BRAKE PEDAL ............................................................ 5-9

INSTALLING THE DRIVE SPROCKET...................................................... 5-9

INSTALLING THE EXHAUST PIPE AND MUFFLER............................... 5-10

CAMSHAFT.................................................................................................... 5-11

REMOVING THE CAMSHAFT ................................................................. 5-13

CHECKING THE CAMSHAFT.................................................................. 5-14

CHECKING THE TIMING CHAIN AND CAMSHAFT SPROCKET .......... 5-15

CHECKING THE TIMING CHAIN TENSIONERS .................................... 5-15

CHECKING THE DECOMPRESSION SYSTEM...................................... 5-16

INSTALLING THE CAMSHAFTS ............................................................. 5-16

CYLINDER HEAD........................................................................................... 5-18

REMOVING THE CYLINDER HEAD........................................................ 5-20

CHECKING THE TIMING CHAIN GUIDE (INTAKE SIDE) ...................... 5-20

CHECKING THE CYLINDER HEAD ........................................................ 5-20

INSTALLING THE CYLINDER HEAD ...................................................... 5-21

VALVES AND VALVE SPRINGS................................................................... 5-22

REMOVING THE VALVES ....................................................................... 5-23

CHECKING THE VALVES AND VALVE GUIDES ................................... 5-24

CHECKING THE VALVE SEATS ............................................................. 5-25

CHECKING THE VALVE SPRINGS......................................................... 5-27

CHECKING THE VALVE LIFTERS .......................................................... 5-28

INSTALLING THE VALVES ..................................................................... 5-28

CYLINDER AND PISTON............................................................................... 5-30

REMOVING THE PISTON ....................................................................... 5-31

CHECKING THE CYLINDER AND PISTON ............................................ 5-31

CHECKING THE PISTON RINGS............................................................ 5-32

CHECKING THE PISTON PIN ................................................................. 5-33

INSTALLING THE PISTON AND CYLINDER .......................................... 5-33

Page 200 of 356

ENGINE REMOVAL

5-7

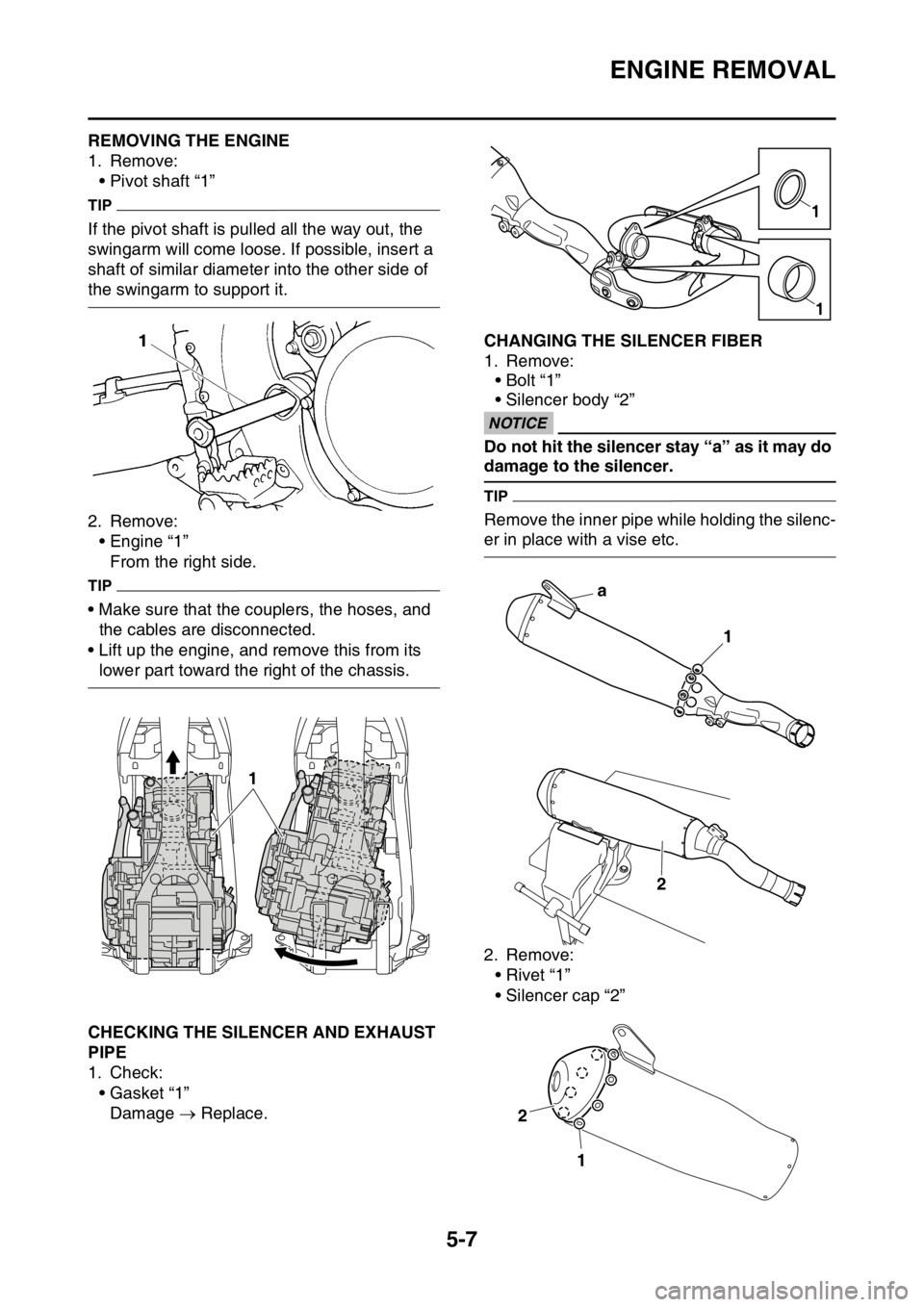

EAS1SM9198REMOVING THE ENGINE

1. Remove:

• Pivot shaft “1”

TIP

If the pivot shaft is pulled all the way out, the

swingarm will come loose. If possible, insert a

shaft of similar diameter into the other side of

the swingarm to support it.

2. Remove:

• Engine “1”

From the right side.

TIP

• Make sure that the couplers, the hoses, and

the cables are disconnected.

• Lift up the engine, and remove this from its

lower part toward the right of the chassis.

EAS1SM9199CHECKING THE SILENCER AND EXHAUST

PIPE

1. Check:

•Gasket “1”

Damage Replace.

EAS1SM9200CHANGING THE SILENCER FIBER

1. Remove:

•Bolt “1”

• Silencer body “2”

ECANOTICE

Do not hit the silencer stay “a” as it may do

damage to the silencer.

TIP

Remove the inner pipe while holding the silenc-

er in place with a vise etc.

2. Remove:

•Rivet “1”

• Silencer cap “2”

1

1

1

a

1

2

2

1

Page 203 of 356

ENGINE REMOVAL

5-10

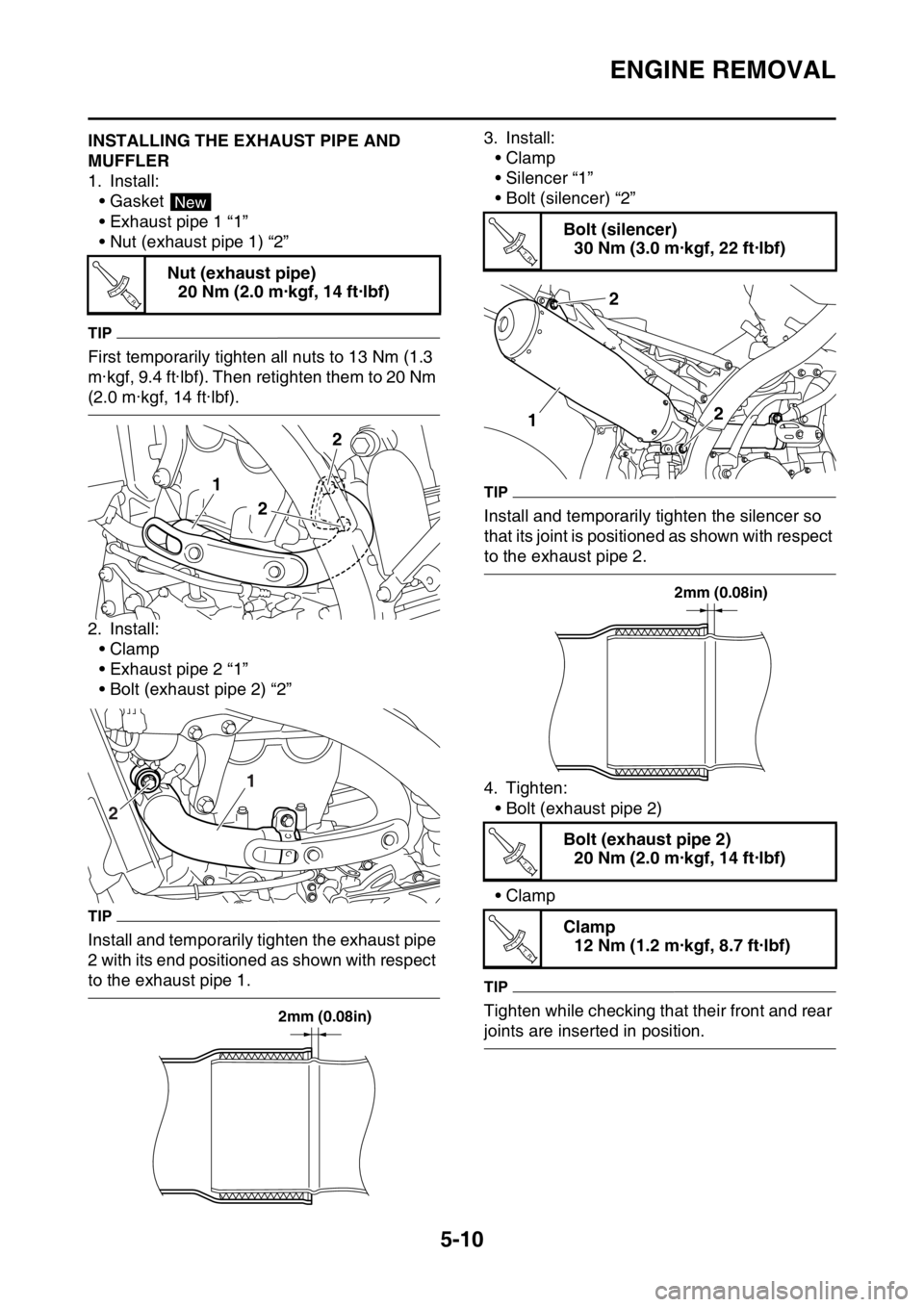

EAS1SM9204INSTALLING THE EXHAUST PIPE AND

MUFFLER

1. Install:

•Gasket

• Exhaust pipe 1 “1”

• Nut (exhaust pipe 1) “2”

TIP

First temporarily tighten all nuts to 13 Nm (1.3

m·kgf, 9.4 ft·lbf). Then retighten them to 20 Nm

(2.0 m·kgf, 14 ft·lbf).

2. Install:

•Clamp

• Exhaust pipe 2 “1”

• Bolt (exhaust pipe 2) “2”

TIP

Install and temporarily tighten the exhaust pipe

2 with its end positioned as shown with respect

to the exhaust pipe 1.3. Install:

•Clamp

• Silencer “1”

• Bolt (silencer) “2”

TIP

Install and temporarily tighten the silencer so

that its joint is positioned as shown with respect

to the exhaust pipe 2.

4. Tighten:

• Bolt (exhaust pipe 2)

•Clamp

TIP

Tighten while checking that their front and rear

joints are inserted in position. Nut (exhaust pipe)

20 Nm (2.0 m·kgf, 14 ft·lbf)

New

T R..

1

22

1

2

2mm (0.08in)

Bolt (silencer)

30 Nm (3.0 m·kgf, 22 ft·lbf)

Bolt (exhaust pipe 2)

20 Nm (2.0 m·kgf, 14 ft·lbf)

Clamp

12 Nm (1.2 m·kgf, 8.7 ft·lbf)

T R..

2

2

1

2mm (0.08in)

T R..

T R..

Page 209 of 356

CAMSHAFT

5-16

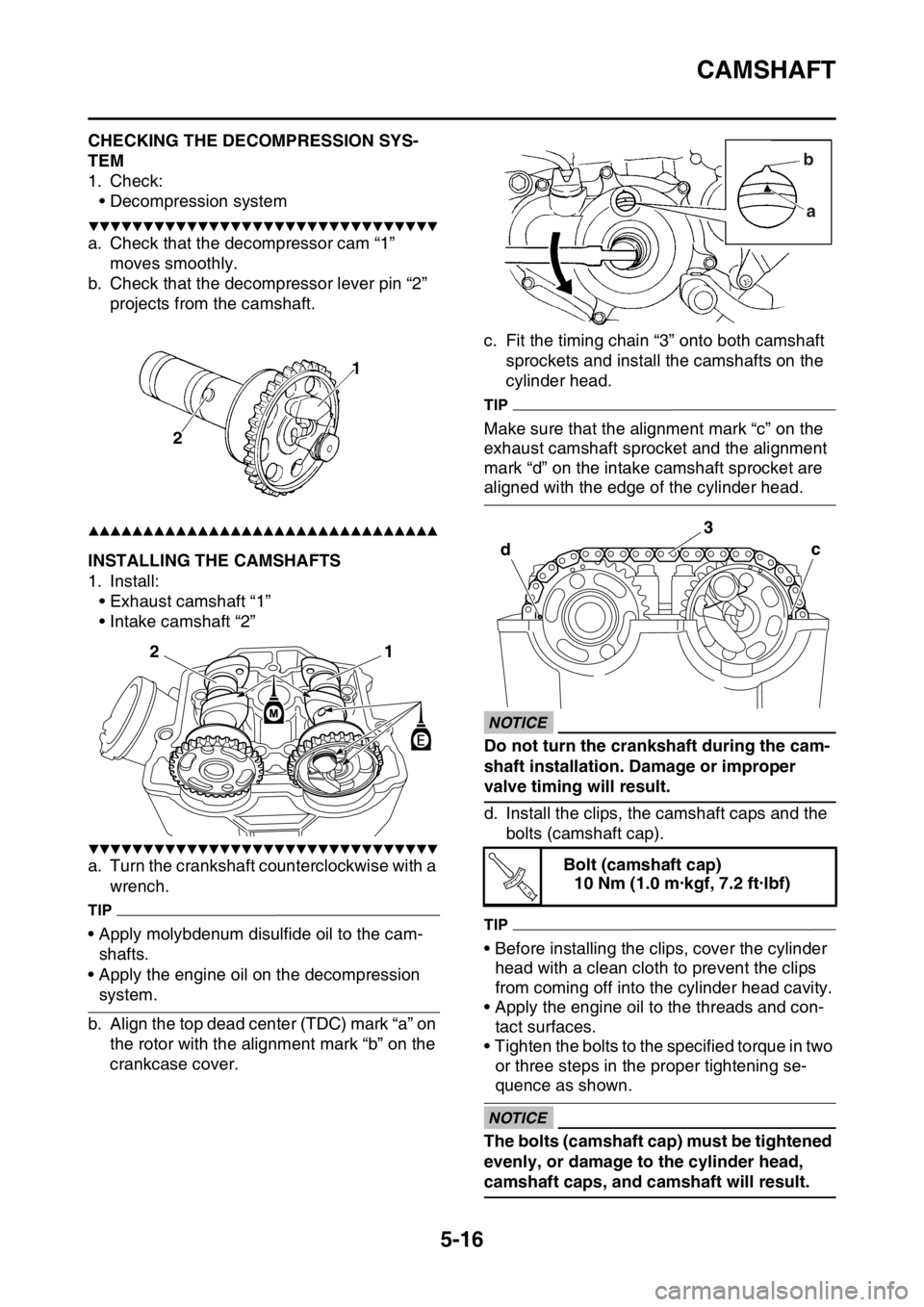

EAS1SM9210CHECKING THE DECOMPRESSION SYS-

TEM

1. Check:

• Decompression system

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Check that the decompressor cam “1”

moves smoothly.

b. Check that the decompressor lever pin “2”

projects from the camshaft.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SM9211INSTALLING THE CAMSHAFTS

1. Install:

• Exhaust camshaft “1”

• Intake camshaft “2”

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the crankshaft counterclockwise with a

wrench.

TIP

• Apply molybdenum disulfide oil to the cam-

shafts.

• Apply the engine oil on the decompression

system.

b. Align the top dead center (TDC) mark “a” on

the rotor with the alignment mark “b” on the

crankcase cover.c. Fit the timing chain “3” onto both camshaft

sprockets and install the camshafts on the

cylinder head.

TIP

Make sure that the alignment mark “c” on the

exhaust camshaft sprocket and the alignment

mark “d” on the intake camshaft sprocket are

aligned with the edge of the cylinder head.

ECA33DD029NOTICE

Do not turn the crankshaft during the cam-

shaft installation. Damage or improper

valve timing will result.

d. Install the clips, the camshaft caps and the

bolts (camshaft cap).

TIP

• Before installing the clips, cover the cylinder

head with a clean cloth to prevent the clips

from coming off into the cylinder head cavity.

• Apply the engine oil to the threads and con-

tact surfaces.

• Tighten the bolts to the specified torque in two

or three steps in the proper tightening se-

quence as shown.

ECA33DD030NOTICE

The bolts (camshaft cap) must be tightened

evenly, or damage to the cylinder head,

camshaft caps, and camshaft will result.

1

2

Bolt (camshaft cap)

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

b

a

dc

3

T R..

Page 233 of 356

CLUTCH

5-40

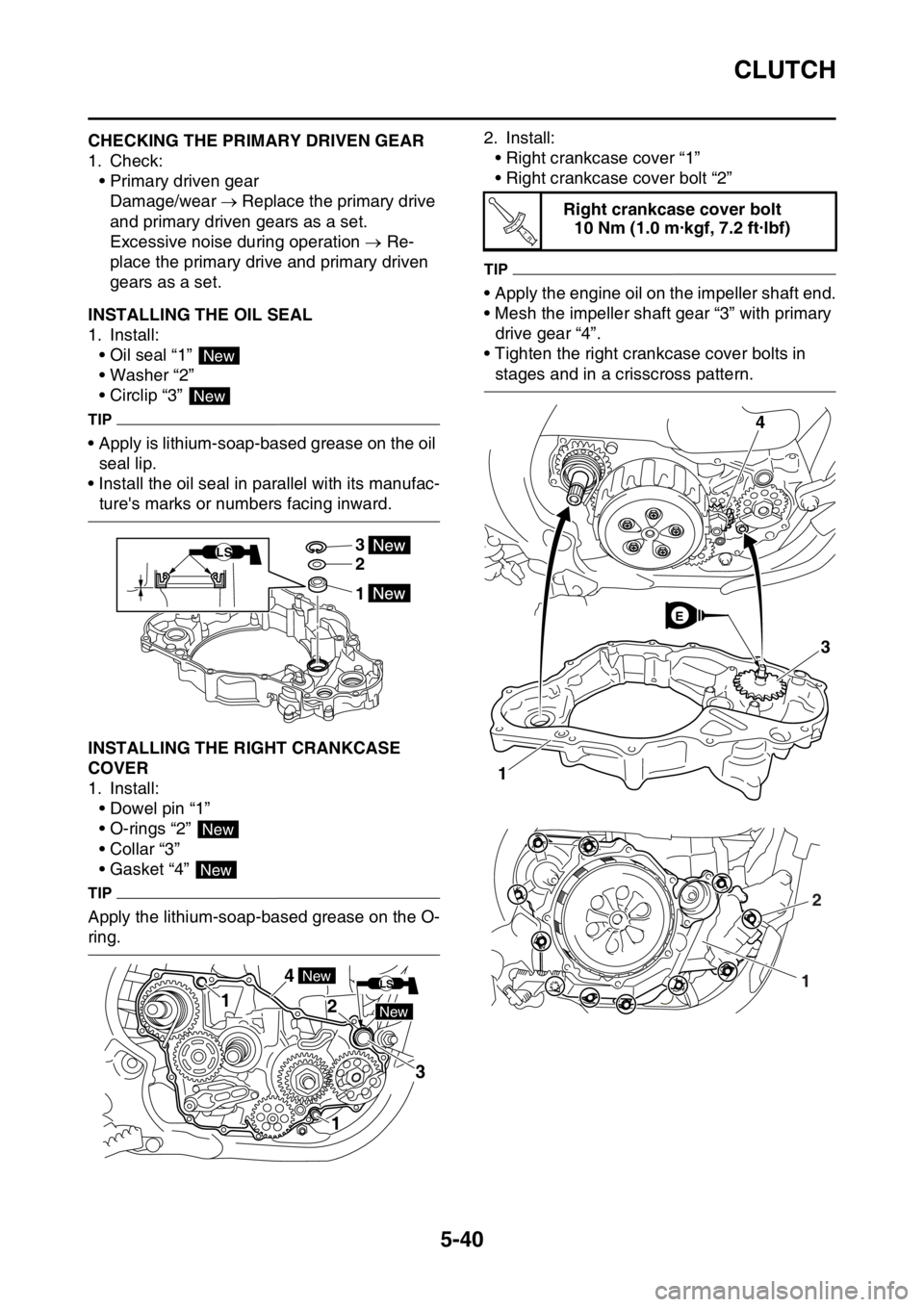

EAS1SM9241CHECKING THE PRIMARY DRIVEN GEAR

1. Check:

• Primary driven gear

Damage/wear Replace the primary drive

and primary driven gears as a set.

Excessive noise during operation Re-

place the primary drive and primary driven

gears as a set.

EAS1SM9242INSTALLING THE OIL SEAL

1. Install:

• Oil seal “1”

• Washer “2”

• Circlip “3”

TIP

• Apply is lithium-soap-based grease on the oil

seal lip.

• Install the oil seal in parallel with its manufac-

ture's marks or numbers facing inward.

EAS1SM9243INSTALLING THE RIGHT CRANKCASE

COVER

1. Install:

• Dowel pin “1”

• O-rings “2”

• Collar “3”

• Gasket “4”

TIP

Apply the lithium-soap-based grease on the O-

ring.2. Install:

• Right crankcase cover “1”

• Right crankcase cover bolt “2”

TIP

• Apply the engine oil on the impeller shaft end.

• Mesh the impeller shaft gear “3” with primary

drive gear “4”.

• Tighten the right crankcase cover bolts in

stages and in a crisscross pattern.

New

New

3

2

1

LS

New

New

1

1 4

2

New

New

3

LS

Right crankcase cover bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

T R..

3

1

4

E

12

Page 248 of 356

OIL PUMP AND BALANCER GEAR

5-55

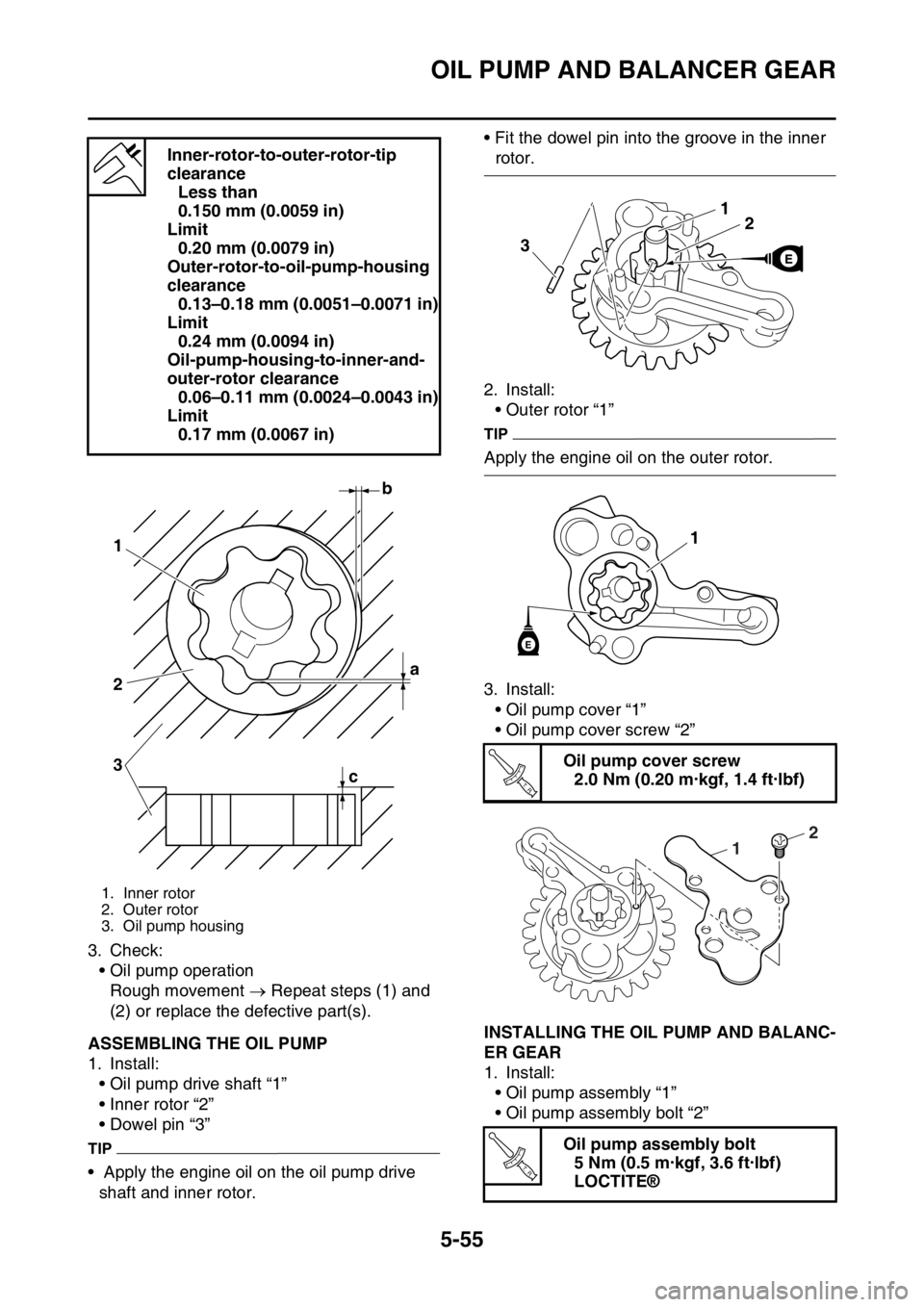

3. Check:

• Oil pump operation

Rough movement Repeat steps (1) and

(2) or replace the defective part(s).

EAS1SM9268ASSEMBLING THE OIL PUMP

1. Install:

• Oil pump drive shaft “1”

• Inner rotor “2”

• Dowel pin “3”

TIP

• Apply the engine oil on the oil pump drive

shaft and inner rotor.• Fit the dowel pin into the groove in the inner

rotor.

2. Install:

• Outer rotor “1”

TIP

Apply the engine oil on the outer rotor.

3. Install:

• Oil pump cover “1”

• Oil pump cover screw “2”

EAS1SM9269INSTALLING THE OIL PUMP AND BALANC-

ER GEAR

1. Install:

• Oil pump assembly “1”

• Oil pump assembly bolt “2” Inner-rotor-to-outer-rotor-tip

clearance

Less than

0.150 mm (0.0059 in)

Limit

0.20 mm (0.0079 in)

Outer-rotor-to-oil-pump-housing

clearance

0.13–0.18 mm (0.0051–0.0071 in)

Limit

0.24 mm (0.0094 in)

Oil-pump-housing-to-inner-and-

outer-rotor clearance

0.06–0.11 mm (0.0024–0.0043 in)

Limit

0.17 mm (0.0067 in)

1. Inner rotor

2. Outer rotor

3. Oil pump housing

b

a 1

2

3

c

Oil pump cover screw

2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

Oil pump assembly bolt

5 Nm (0.5 m·kgf, 3.6 ft·lbf)

LOCTITE®

21

3

1

E

T R..

2

1

T R..

Page 257 of 356

CRANKCASE

5-64

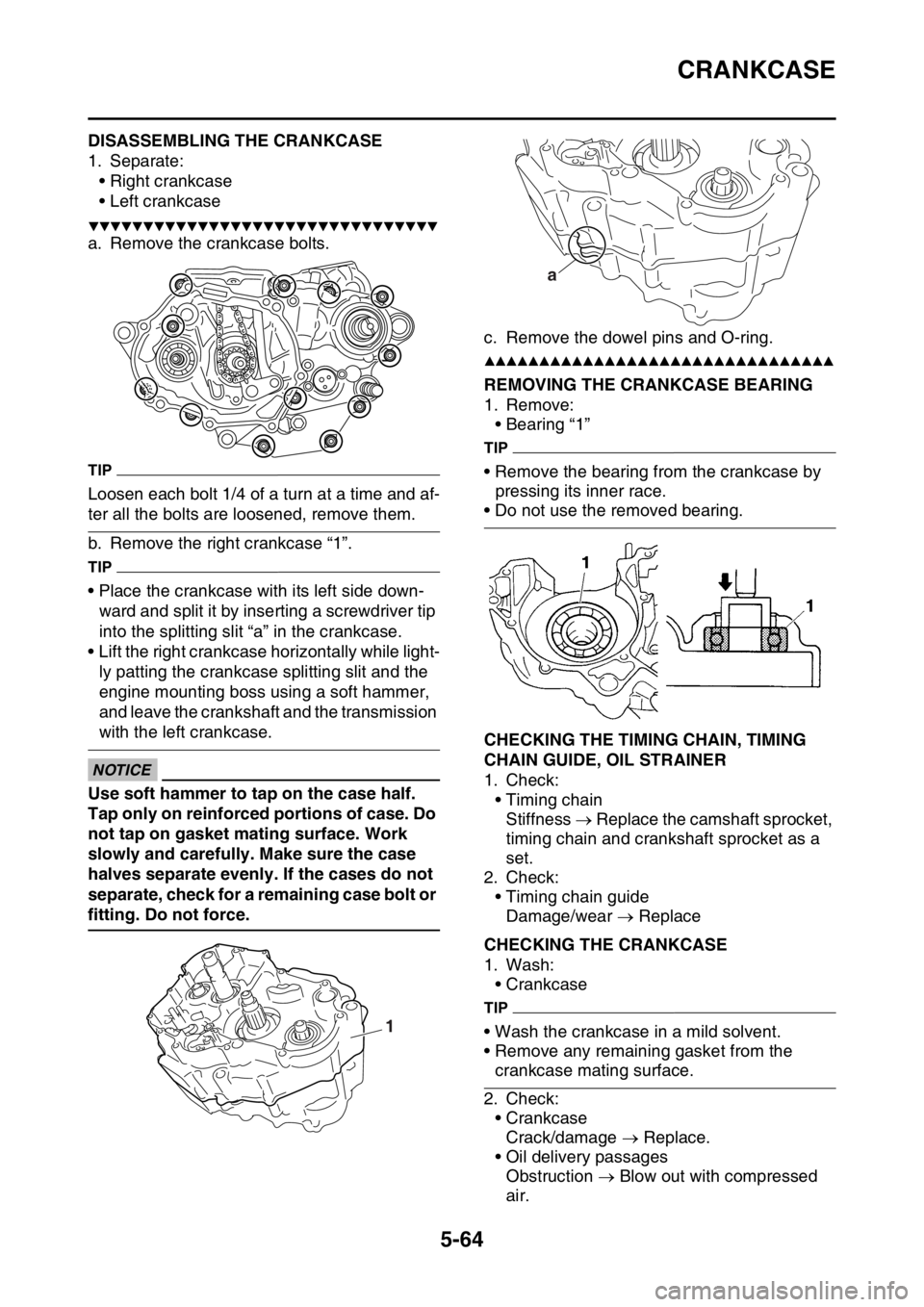

EAS1SM9276DISASSEMBLING THE CRANKCASE

1. Separate:

• Right crankcase

• Left crankcase

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the crankcase bolts.

TIP

Loosen each bolt 1/4 of a turn at a time and af-

ter all the bolts are loosened, remove them.

b. Remove the right crankcase “1”.

TIP

• Place the crankcase with its left side down-

ward and split it by inserting a screwdriver tip

into the splitting slit “a” in the crankcase.

• Lift the right crankcase horizontally while light-

ly patting the crankcase splitting slit and the

engine mounting boss using a soft hammer,

and leave the crankshaft and the transmission

with the left crankcase.

ECA

NOTICE

Use soft hammer to tap on the case half.

Tap only on reinforced portions of case. Do

not tap on gasket mating surface. Work

slowly and carefully. Make sure the case

halves separate evenly. If the cases do not

separate, check for a remaining case bolt or

fitting. Do not force.c. Remove the dowel pins and O-ring.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲EAS1SM9277REMOVING THE CRANKCASE BEARING

1. Remove:

• Bearing “1”

TIP

• Remove the bearing from the crankcase by

pressing its inner race.

• Do not use the removed bearing.

EAS1SM9278CHECKING THE TIMING CHAIN, TIMING

CHAIN GUIDE, OIL STRAINER

1. Check:

• Timing chain

Stiffness Replace the camshaft sprocket,

timing chain and crankshaft sprocket as a

set.

2. Check:

• Timing chain guide

Damage/wear Replace

EAS1SM9279CHECKING THE CRANKCASE

1. Wash:

• Crankcase

TIP

• Wash the crankcase in a mild solvent.

• Remove any remaining gasket from the

crankcase mating surface.

2. Check:

• Crankcase

Crack/damage Replace.

• Oil delivery passages

Obstruction Blow out with compressed

air.

1

a

Page 266 of 356

TRANSMISSION

5-73

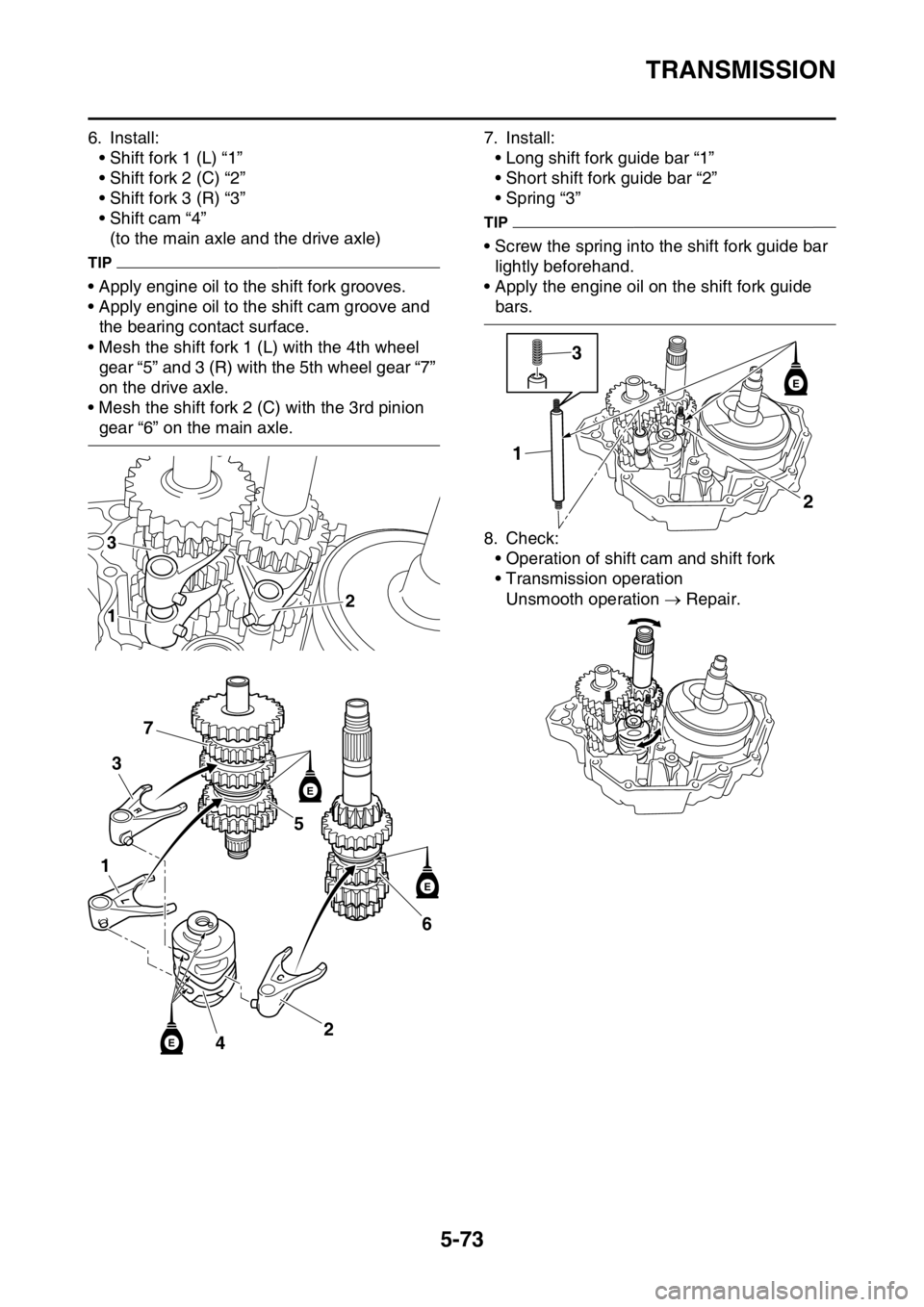

6. Install:

• Shift fork 1 (L) “1”

• Shift fork 2 (C) “2”

• Shift fork 3 (R) “3”

• Shift cam “4”

(to the main axle and the drive axle)

TIP

• Apply engine oil to the shift fork grooves.

• Apply engine oil to the shift cam groove and

the bearing contact surface.

• Mesh the shift fork 1 (L) with the 4th wheel

gear “5” and 3 (R) with the 5th wheel gear “7”

on the drive axle.

• Mesh the shift fork 2 (C) with the 3rd pinion

gear “6” on the main axle.7. Install:

• Long shift fork guide bar “1”

• Short shift fork guide bar “2”

• Spring “3”

TIP

• Screw the spring into the shift fork guide bar

lightly beforehand.

• Apply the engine oil on the shift fork guide

bars.

8. Check:

• Operation of shift cam and shift fork

• Transmission operation

Unsmooth operation Repair.

3

12

6

24

5

3

7

1

E

E

E

2 13

E

Page 273 of 356

WATER PUMP

6-6

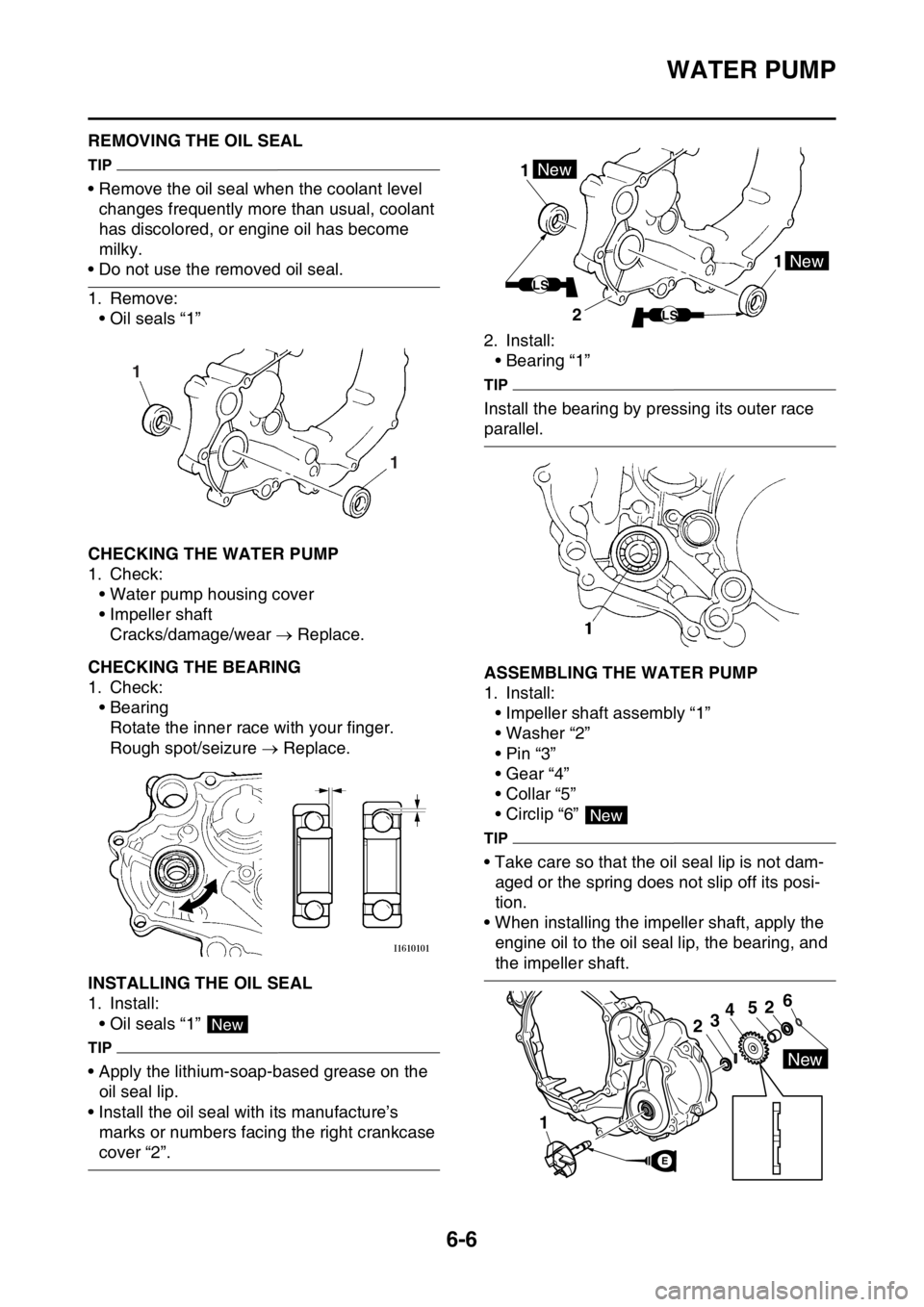

EAS1SM9298REMOVING THE OIL SEAL

TIP

• Remove the oil seal when the coolant level

changes frequently more than usual, coolant

has discolored, or engine oil has become

milky.

• Do not use the removed oil seal.

1. Remove:

• Oil seals “1”

EAS1SM9299CHECKING THE WATER PUMP

1. Check:

• Water pump housing cover

• Impeller shaft

Cracks/damage/wear Replace.

EAS1SM9300CHECKING THE BEARING

1. Check:

• Bearing

Rotate the inner race with your finger.

Rough spot/seizure Replace.

EAS1SM9301INSTALLING THE OIL SEAL

1. Install:

• Oil seals “1”

TIP

• Apply the lithium-soap-based grease on the

oil seal lip.

• Install the oil seal with its manufacture’s

marks or numbers facing the right crankcase

cover “2”.2. Install:

• Bearing “1”

TIP

Install the bearing by pressing its outer race

parallel.

EAS1SM9302ASSEMBLING THE WATER PUMP

1. Install:

• Impeller shaft assembly “1”

• Washer “2”

•Pin “3”

• Gear “4”

• Collar “5”

• Circlip “6”

TIP

• Take care so that the oil seal lip is not dam-

aged or the spring does not slip off its posi-

tion.

• When installing the impeller shaft, apply the

engine oil to the oil seal lip, the bearing, and

the impeller shaft.

1 1

New

1 1New

New

LS

LS2

New

1

2

52346

New

E