check engine YAMAHA YZ250F 2016 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: YZ250F, Model: YAMAHA YZ250F 2016Pages: 356, PDF Size: 11.25 MB

Page 279 of 356

FUEL TANK

7-4

e. Start the engine.

f. Measure the fuel pressure.

Out of specification Replace the fuel

pump.

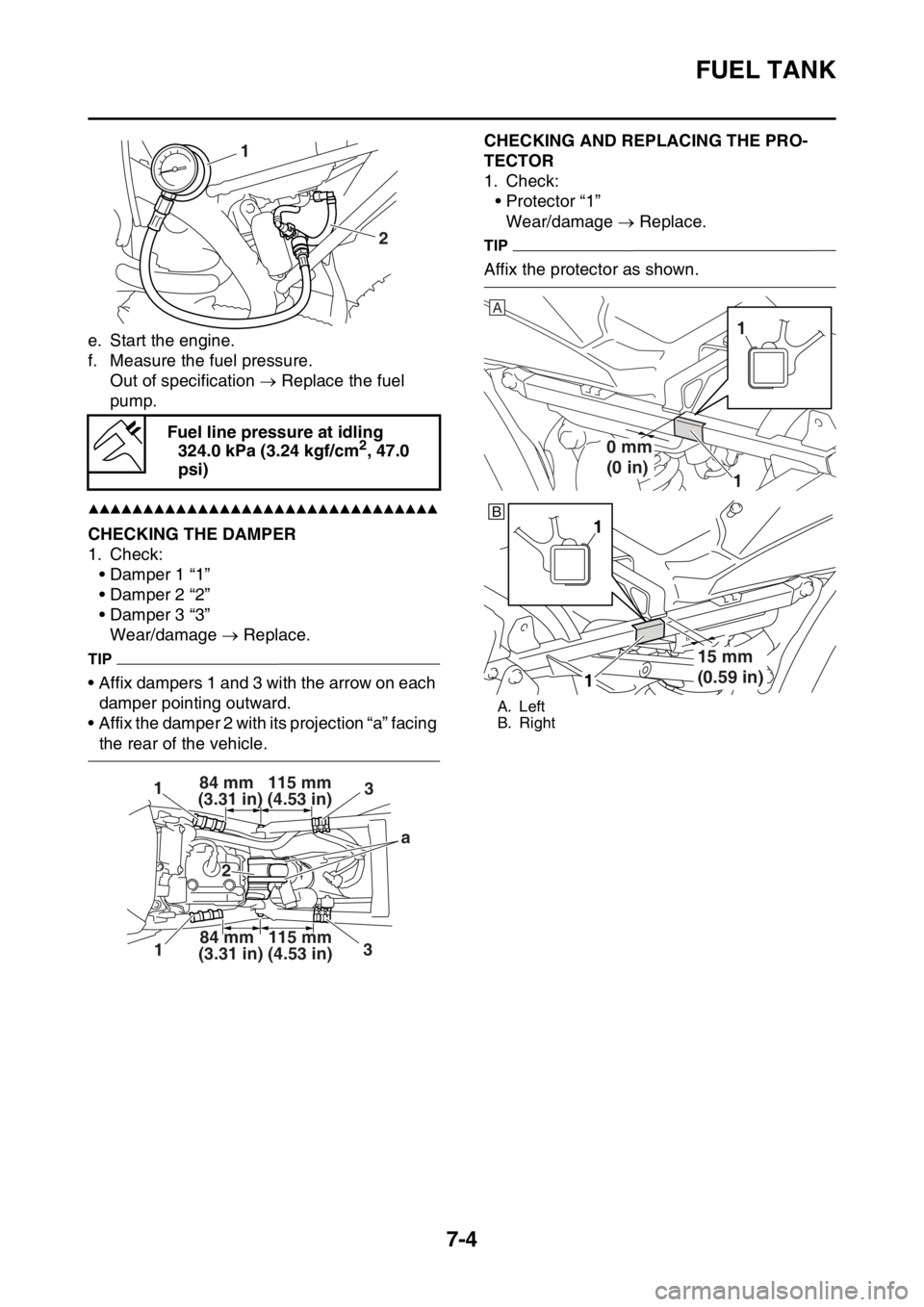

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲EAS1SM9311CHECKING THE DAMPER

1. Check:

• Damper 1 “1”

• Damper 2 “2”

• Damper 3 “3”

Wear/damage Replace.

TIP

• Affix dampers 1 and 3 with the arrow on each

damper pointing outward.

• Affix the damper 2 with its projection “a” facing

the rear of the vehicle.

EAS1SM9312CHECKING AND REPLACING THE PRO-

TECTOR

1. Check:

• Protector “1”

Wear/damage Replace.

TIP

Affix the protector as shown.

Fuel line pressure at idling

324.0 kPa (3.24 kgf/cm

2, 47.0

psi)

1

2

(3.31 in) (4.53 in)

84 mm 115 mm3 1

13a

2

(3.31 in) (4.53 in)84 mm 115 mm

A. Left

B. Right

1

1

A

0 mm

(0 in)

B

1

1

15 mm

(0.59 in)

Page 283 of 356

THROTTLE BODY

7-8

EAS1SM9314CHECKING THE INJECTOR

1. Check:

• Injectors

Obstruction Replace, and check the fuel

pump and the fuel injection system.

Refer to “FUEL INJECTION SYSTEM” on

page 8-10.

Deposits Replace.

Damage Replace.

2. Check:

• Injector resistance

Refer to “CHECKING THE FUEL INJEC-

TOR” on page 8-47.

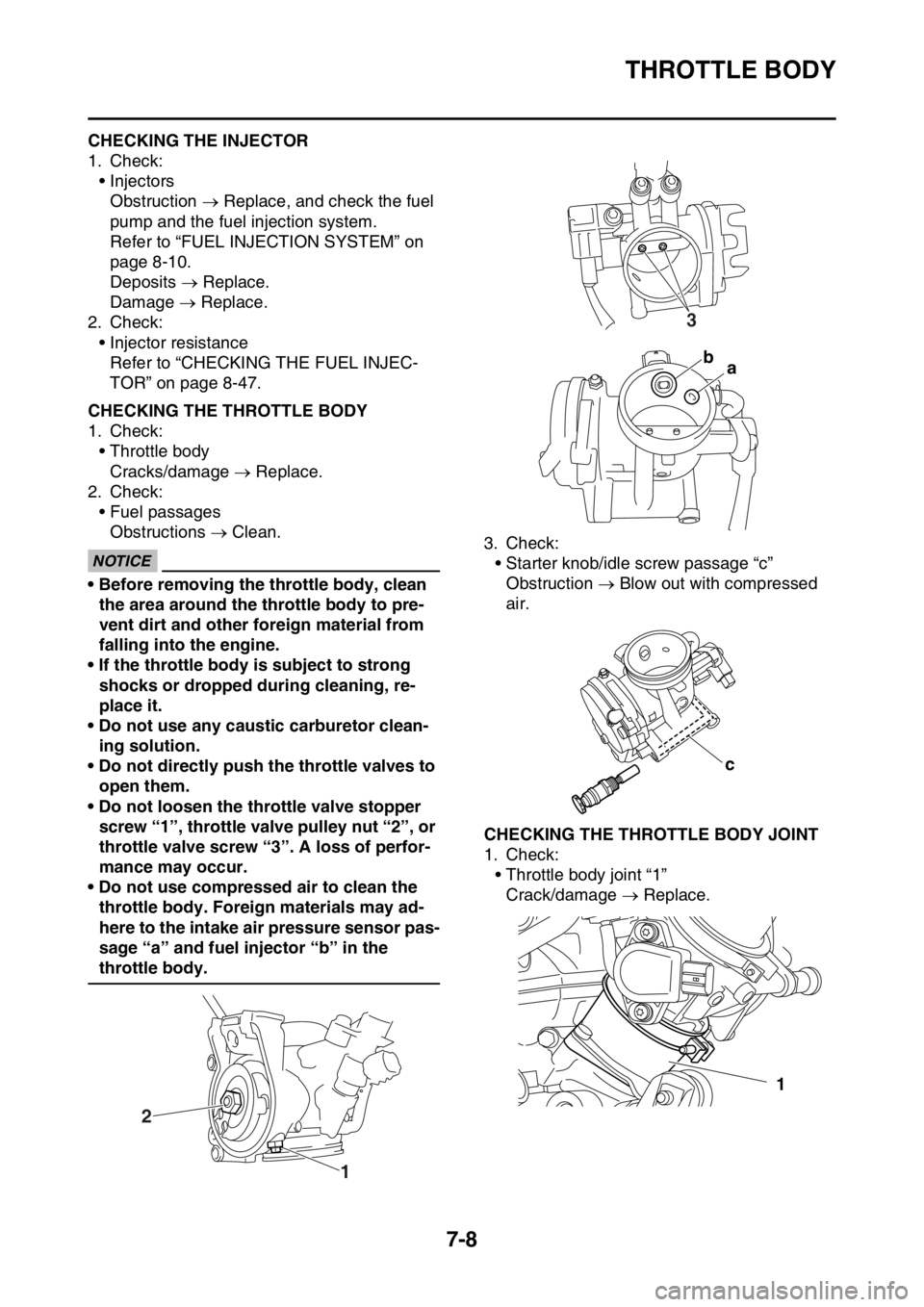

EAS1SM9315CHECKING THE THROTTLE BODY

1. Check:

• Throttle body

Cracks/damage Replace.

2. Check:

• Fuel passages

Obstructions Clean.

ECA

NOTICE

• Before removing the throttle body, clean

the area around the throttle body to pre-

vent dirt and other foreign material from

falling into the engine.

• If the throttle body is subject to strong

shocks or dropped during cleaning, re-

place it.

• Do not use any caustic carburetor clean-

ing solution.

• Do not directly push the throttle valves to

open them.

• Do not loosen the throttle valve stopper

screw “1”, throttle valve pulley nut “2”, or

throttle valve screw “3”. A loss of perfor-

mance may occur.

• Do not use compressed air to clean the

throttle body. Foreign materials may ad-

here to the intake air pressure sensor pas-

sage “a” and fuel injector “b” in the

throttle body.3. Check:

• Starter knob/idle screw passage “c”

Obstruction Blow out with compressed

air.

EAS1SM9316CHECKING THE THROTTLE BODY JOINT

1. Check:

• Throttle body joint “1”

Crack/damage Replace.

1 2

3

ba

c

1

Page 290 of 356

IGNITION SYSTEM

8-4

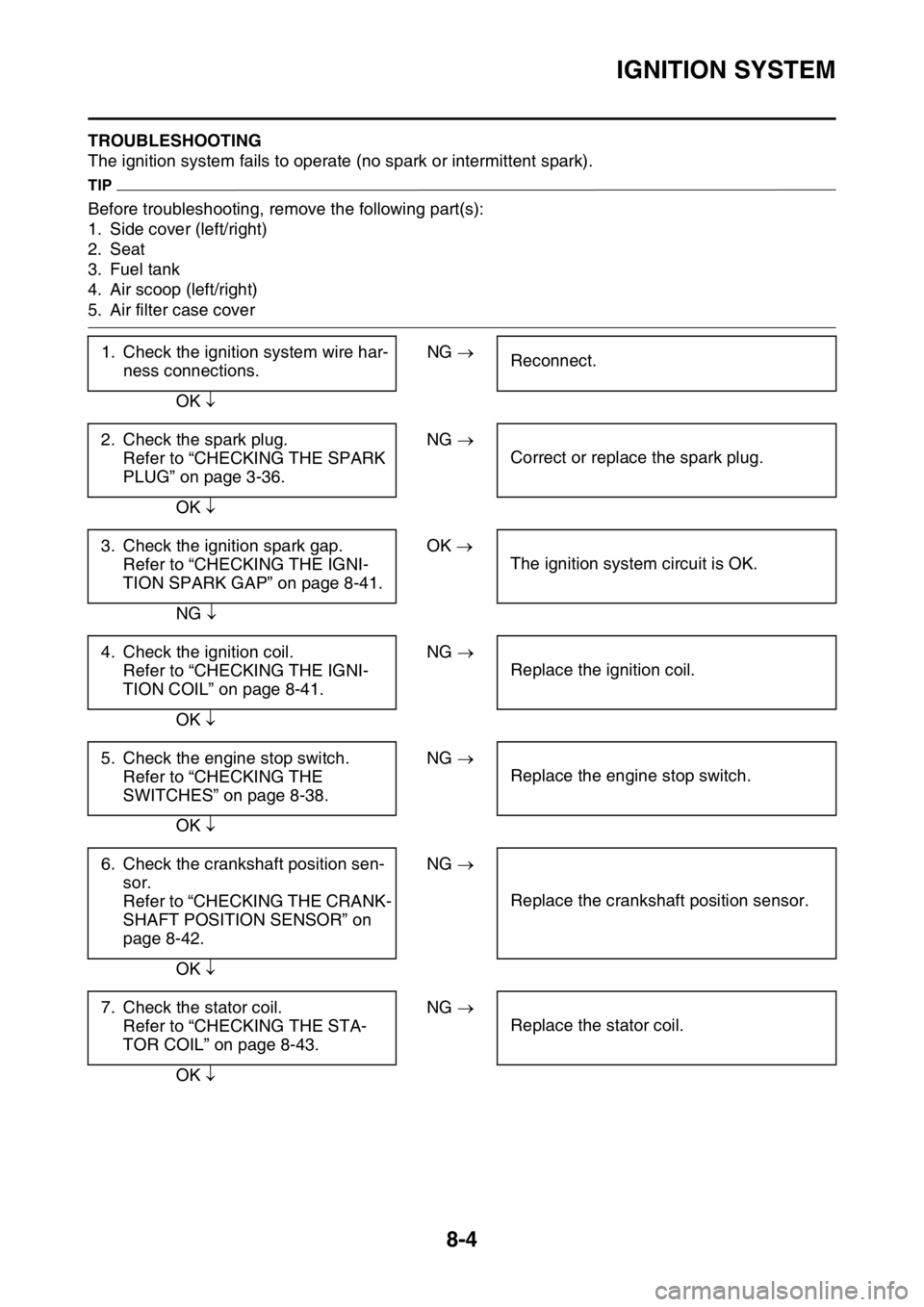

EAS1SM9321TROUBLESHOOTING

The ignition system fails to operate (no spark or intermittent spark).

TIP

Before troubleshooting, remove the following part(s):

1. Side cover (left/right)

2. Seat

3. Fuel tank

4. Air scoop (left/right)

5. Air filter case cover

1. Check the ignition system wire har-

ness connections.NG

Reconnect.

OK

2. Check the spark plug.

Refer to “CHECKING THE SPARK

PLUG” on page 3-36.NG

Correct or replace the spark plug.

OK

3. Check the ignition spark gap.

Refer to “CHECKING THE IGNI-

TION SPARK GAP” on page 8-41.OK

The ignition system circuit is OK.

NG

4. Check the ignition coil.

Refer to “CHECKING THE IGNI-

TION COIL” on page 8-41.NG

Replace the ignition coil.

OK

5. Check the engine stop switch.

Refer to “CHECKING THE

SWITCHES” on page 8-38.NG

Replace the engine stop switch.

OK

6. Check the crankshaft position sen-

sor.

Refer to “CHECKING THE CRANK-

SHAFT POSITION SENSOR” on

page 8-42.NG

Replace the crankshaft position sensor.

OK

7. Check the stator coil.

Refer to “CHECKING THE STA-

TOR COIL” on page 8-43.NG

Replace the stator coil.

OK

Page 299 of 356

FUEL INJECTION SYSTEM

8-13

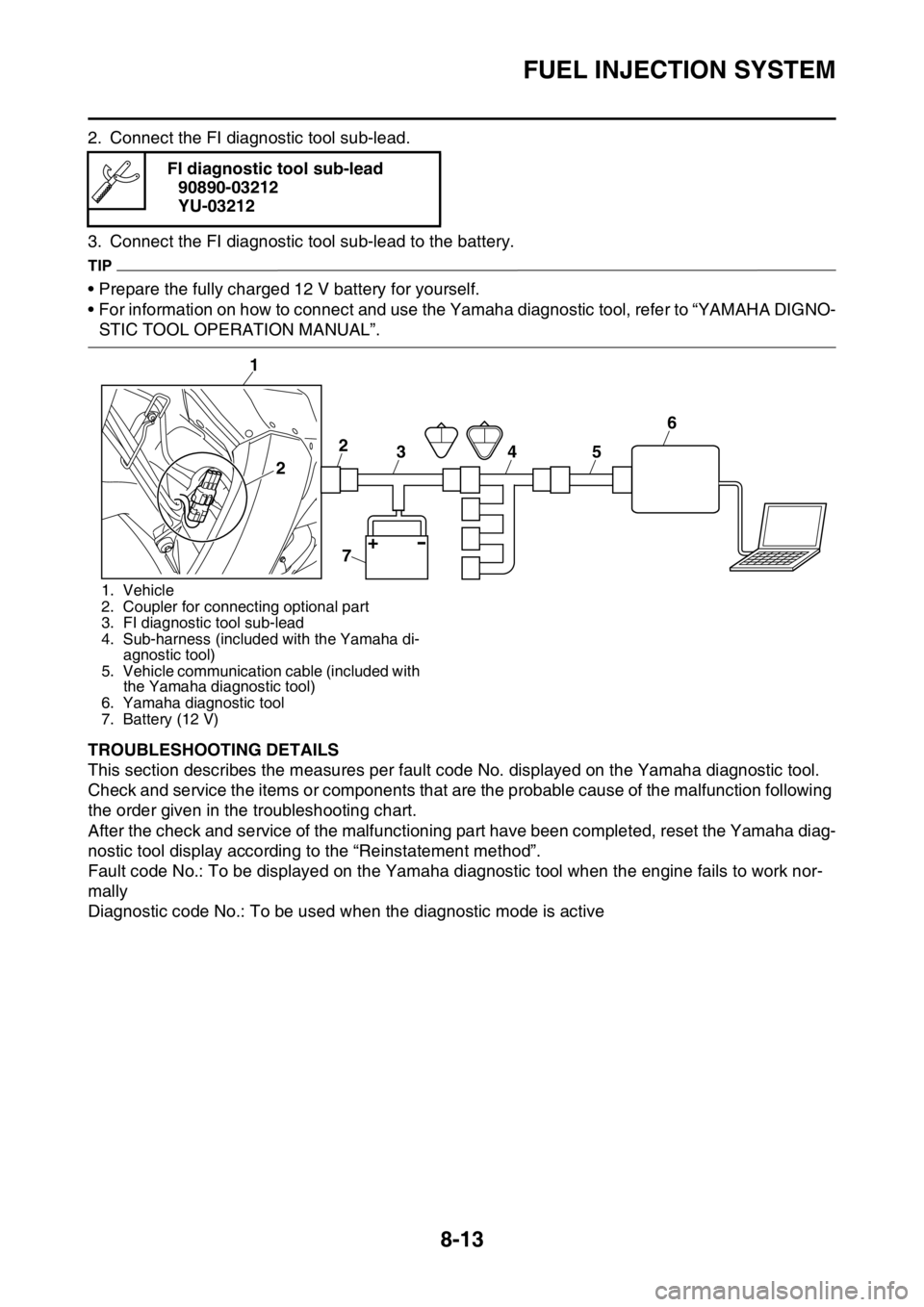

2. Connect the FI diagnostic tool sub-lead.

3. Connect the FI diagnostic tool sub-lead to the battery.

TIP

• Prepare the fully charged 12 V battery for yourself.

• For information on how to connect and use the Yamaha diagnostic tool, refer to “YAMAHA DIGNO-

STIC TOOL OPERATION MANUAL”.

EAS1SM9327TROUBLESHOOTING DETAILS

This section describes the measures per fault code No. displayed on the Yamaha diagnostic tool.

Check and service the items or components that are the probable cause of the malfunction following

the order given in the troubleshooting chart.

After the check and service of the malfunctioning part have been completed, reset the Yamaha diag-

nostic tool display according to the “Reinstatement method”.

Fault code No.: To be displayed on the Yamaha diagnostic tool when the engine fails to work nor-

mally

Diagnostic code No.: To be used when the diagnostic mode is active FI diagnostic tool sub-lead

90890-03212

YU-03212

1. Vehicle

2. Coupler for connecting optional part

3. FI diagnostic tool sub-lead

4. Sub-harness (included with the Yamaha di-

agnostic tool)

5. Vehicle communication cable (included with

the Yamaha diagnostic tool)

6. Yamaha diagnostic tool

7. Battery (12 V)

1

3 2

2456

7

Page 300 of 356

FUEL INJECTION SYSTEM

8-14

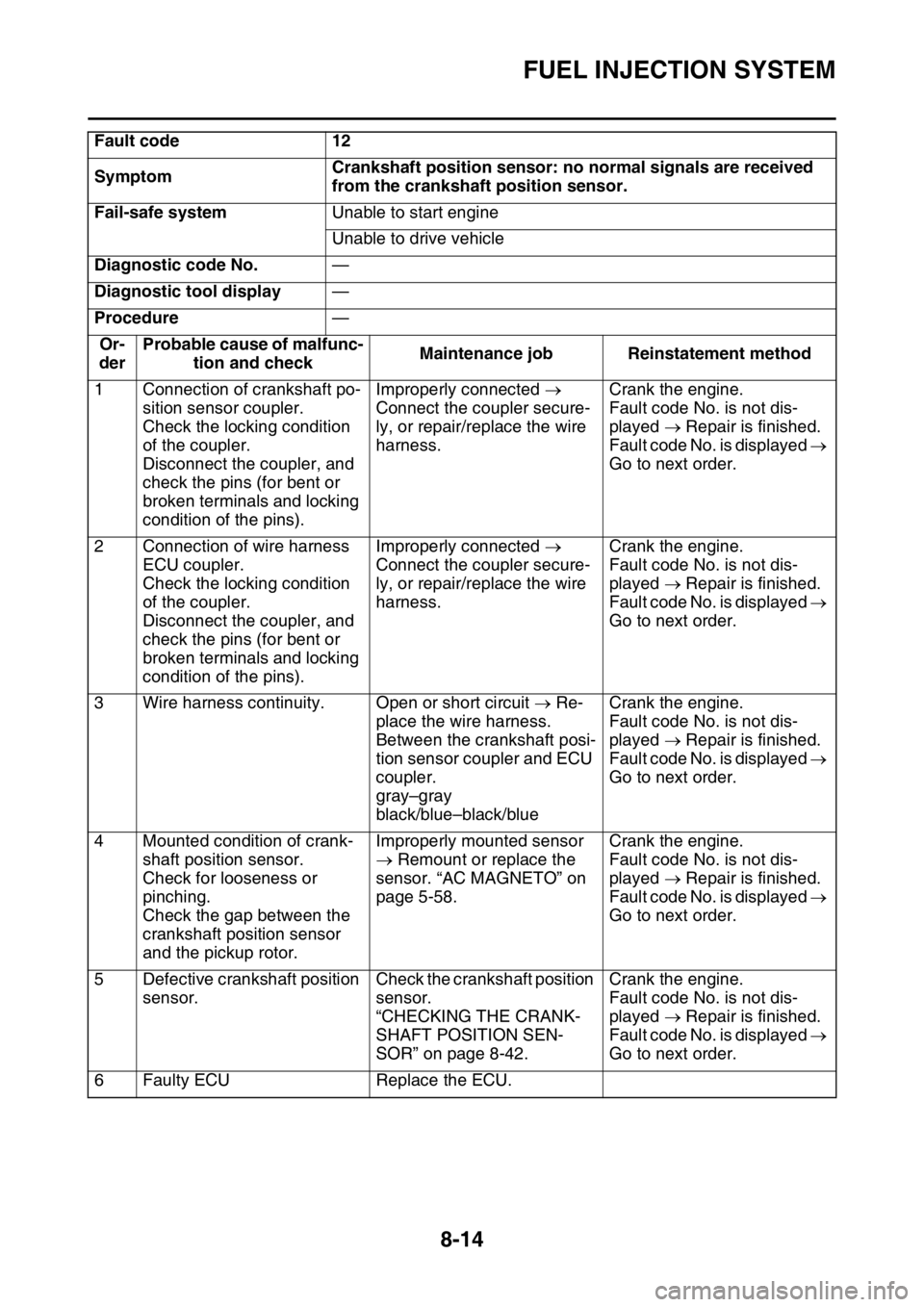

Fault code 12

SymptomCrankshaft position sensor: no normal signals are received

from the crankshaft position sensor.

Fail-safe systemUnable to start engine

Unable to drive vehicle

Diagnostic code No.—

Diagnostic tool display—

Procedure—

Or-

derProbable cause of malfunc-

tion and checkMaintenance job Reinstatement method

1 Connection of crankshaft po-

sition sensor coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).Improperly connected

Connect the coupler secure-

ly, or repair/replace the wire

harness.Crank the engine.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

2 Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).Improperly connected

Connect the coupler secure-

ly, or repair/replace the wire

harness.Crank the engine.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

3 Wire harness continuity. Open or short circuit Re-

place the wire harness.

Between the crankshaft posi-

tion sensor coupler and ECU

coupler.

gray–gray

black/blue–black/blueCrank the engine.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

4 Mounted condition of crank-

shaft position sensor.

Check for looseness or

pinching.

Check the gap between the

crankshaft position sensor

and the pickup rotor.Improperly mounted sensor

Remount or replace the

sensor. “AC MAGNETO” on

page 5-58.Crank the engine.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

5 Defective crankshaft position

sensor.Check the crankshaft position

sensor.

“CHECKING THE CRANK-

SHAFT POSITION SEN-

SOR” on page 8-42.Crank the engine.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

6 Faulty ECU Replace the ECU.

Page 301 of 356

FUEL INJECTION SYSTEM

8-15

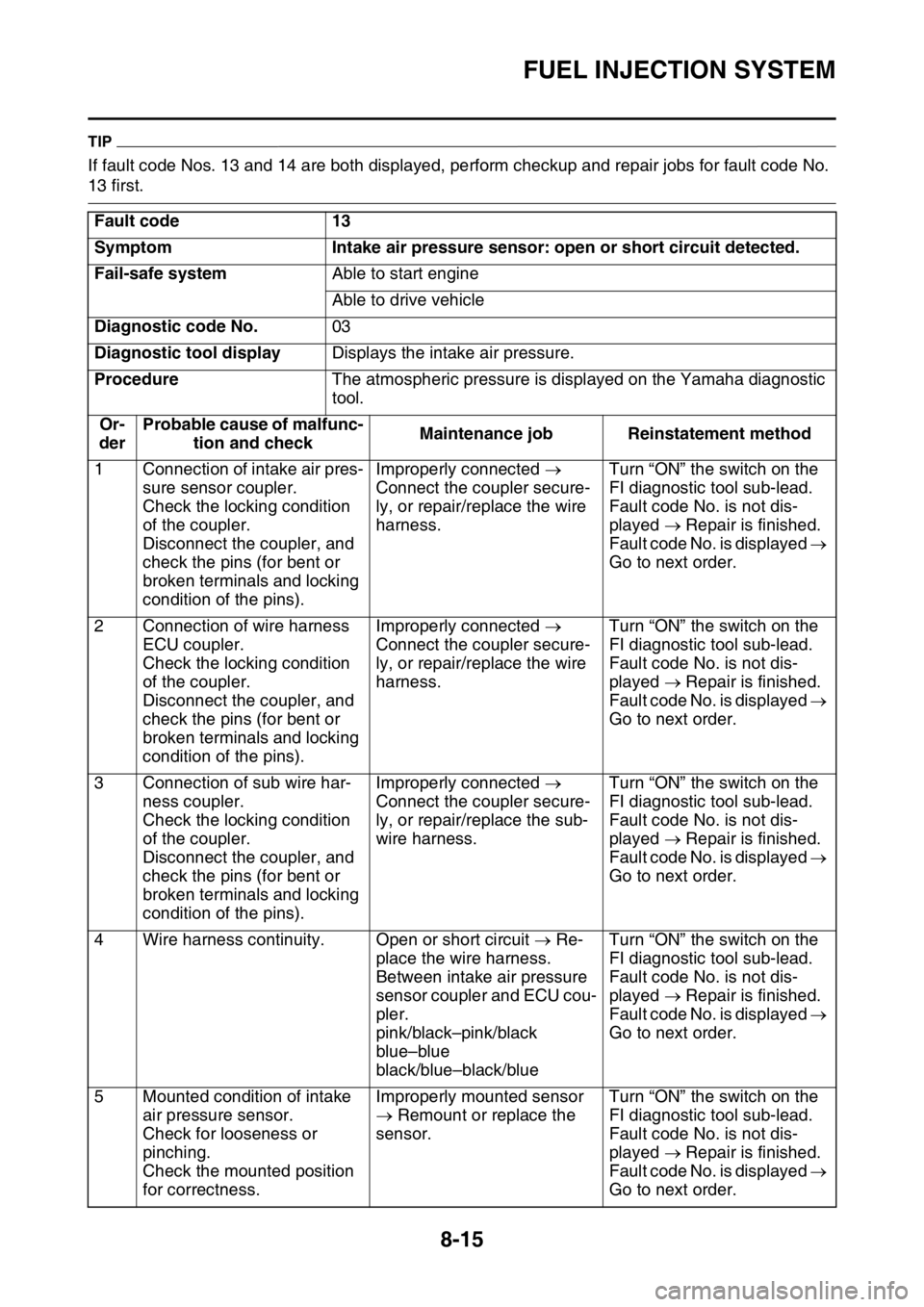

TIP

If fault code Nos. 13 and 14 are both displayed, perform checkup and repair jobs for fault code No.

13 first.

Fault code 13

Symptom Intake air pressure sensor: open or short circuit detected.

Fail-safe systemAble to start engine

Able to drive vehicle

Diagnostic code No.03

Diagnostic tool displayDisplays the intake air pressure.

ProcedureThe atmospheric pressure is displayed on the Yamaha diagnostic

tool.

Or-

derProbable cause of malfunc-

tion and checkMaintenance job Reinstatement method

1 Connection of intake air pres-

sure sensor coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).Improperly connected

Connect the coupler secure-

ly, or repair/replace the wire

harness.Turn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

2 Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).Improperly connected

Connect the coupler secure-

ly, or repair/replace the wire

harness.Turn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

3 Connection of sub wire har-

ness coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).Improperly connected

Connect the coupler secure-

ly, or repair/replace the sub-

wire harness.Turn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

4 Wire harness continuity. Open or short circuit Re-

place the wire harness.

Between intake air pressure

sensor coupler and ECU cou-

pler.

pink/black–pink/black

blue–blue

black/blue–black/blueTurn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

5 Mounted condition of intake

air pressure sensor.

Check for looseness or

pinching.

Check the mounted position

for correctness.Improperly mounted sensor

Remount or replace the

sensor.Turn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

Page 302 of 356

FUEL INJECTION SYSTEM

8-16

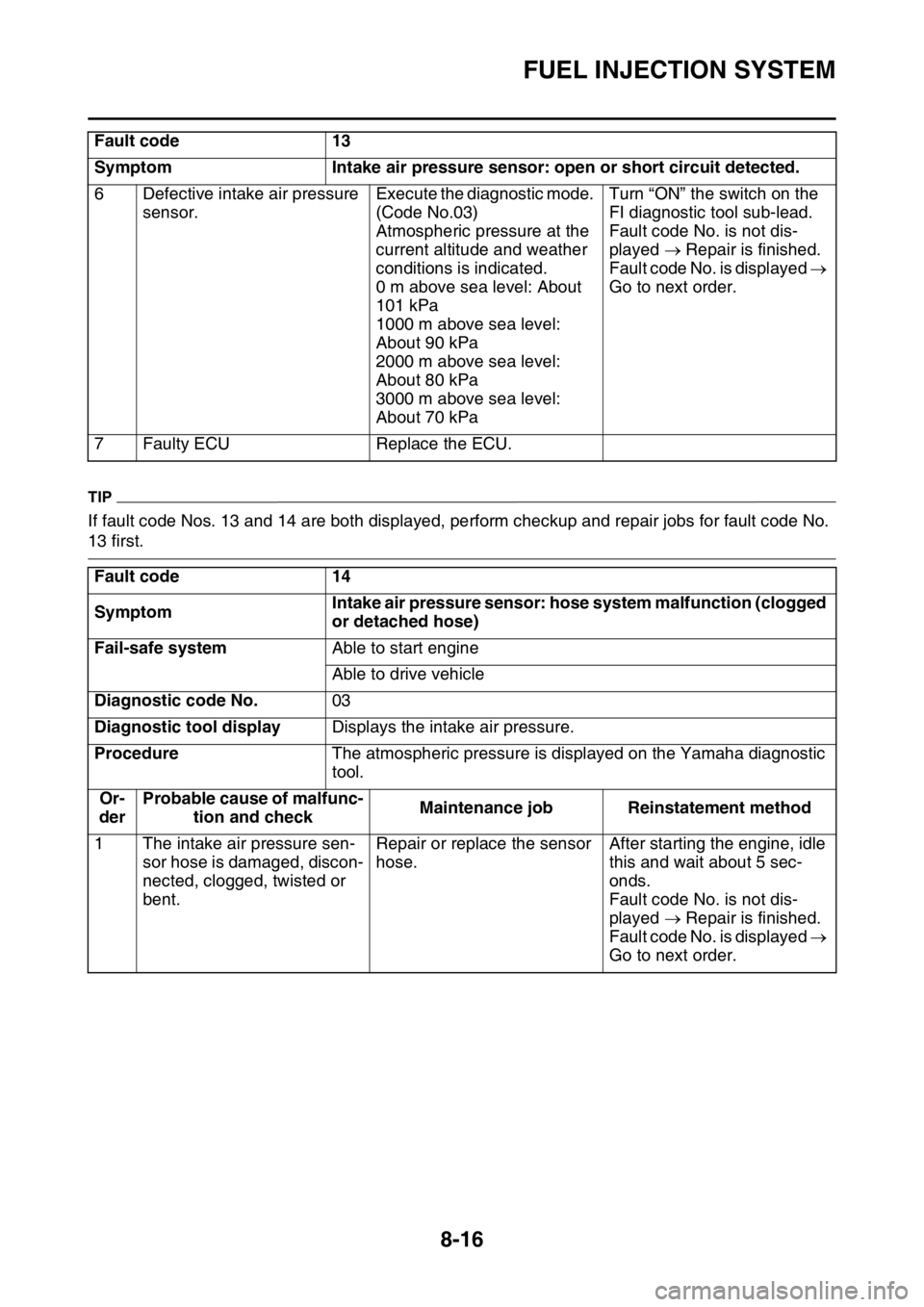

TIP

If fault code Nos. 13 and 14 are both displayed, perform checkup and repair jobs for fault code No.

13 first.6 Defective intake air pressure

sensor.Execute the diagnostic mode.

(Code No.03)

Atmospheric pressure at the

current altitude and weather

conditions is indicated.

0 m above sea level: About

101 kPa

1000 m above sea level:

About 90 kPa

2000 m above sea level:

About 80 kPa

3000 m above sea level:

About 70 kPaTurn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

7 Faulty ECU Replace the ECU.

Fault code 14

SymptomIntake air pressure sensor: hose system malfunction (clogged

or detached hose)

Fail-safe systemAble to start engine

Able to drive vehicle

Diagnostic code No.03

Diagnostic tool displayDisplays the intake air pressure.

ProcedureThe atmospheric pressure is displayed on the Yamaha diagnostic

tool.

Or-

derProbable cause of malfunc-

tion and checkMaintenance job Reinstatement method

1 The intake air pressure sen-

sor hose is damaged, discon-

nected, clogged, twisted or

bent.Repair or replace the sensor

hose.After starting the engine, idle

this and wait about 5 sec-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order. Fault code 13

Symptom Intake air pressure sensor: open or short circuit detected.

Page 303 of 356

FUEL INJECTION SYSTEM

8-17

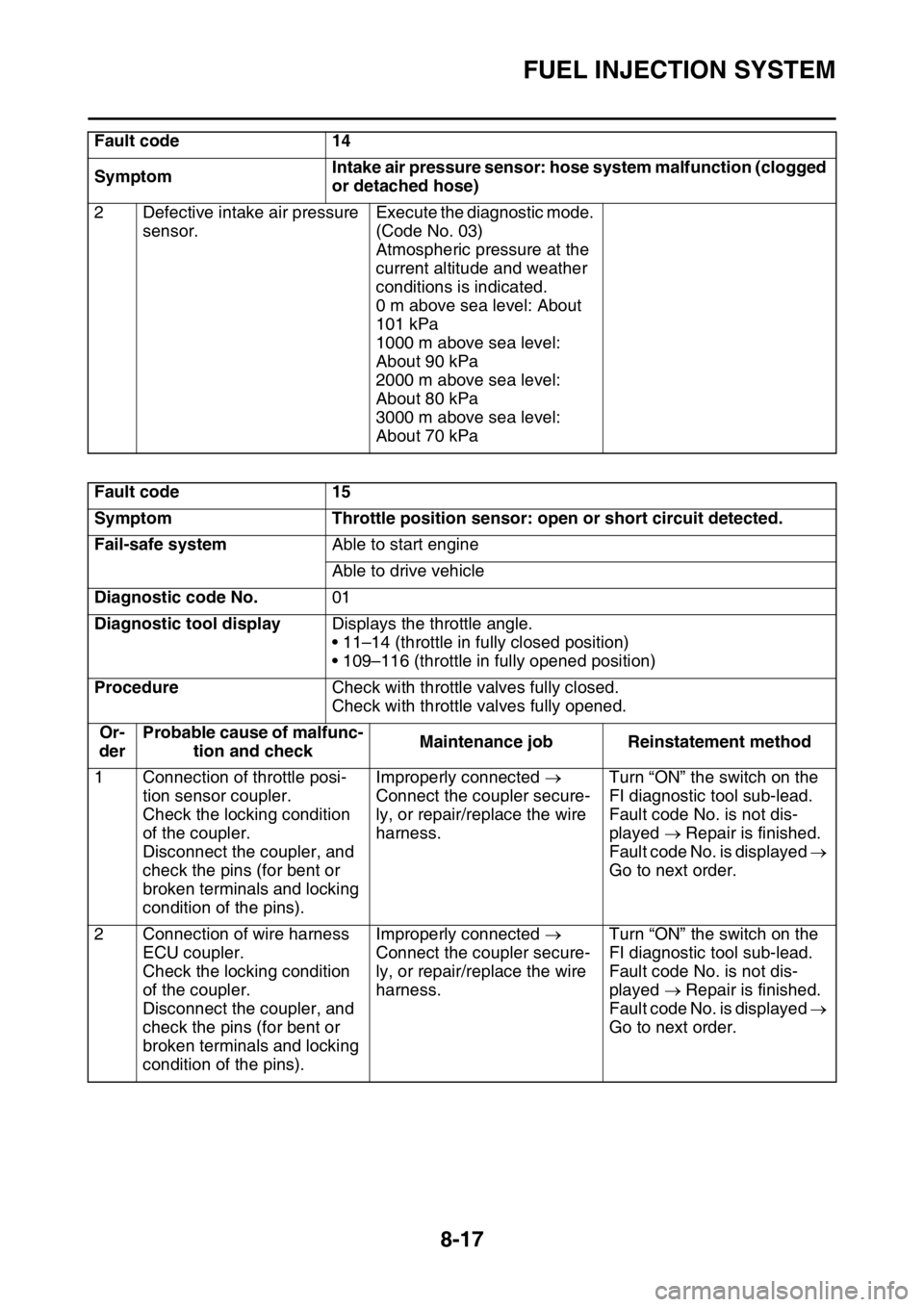

2 Defective intake air pressure

sensor.Execute the diagnostic mode.

(Code No. 03)

Atmospheric pressure at the

current altitude and weather

conditions is indicated.

0 m above sea level: About

101 kPa

1000 m above sea level:

About 90 kPa

2000 m above sea level:

About 80 kPa

3000 m above sea level:

About 70 kPa

Fault code 15

Symptom Throttle position sensor: open or short circuit detected.

Fail-safe systemAble to start engine

Able to drive vehicle

Diagnostic code No.01

Diagnostic tool displayDisplays the throttle angle.

• 11–14 (throttle in fully closed position)

• 109–116 (throttle in fully opened position)

ProcedureCheck with throttle valves fully closed.

Check with throttle valves fully opened.

Or-

derProbable cause of malfunc-

tion and checkMaintenance job Reinstatement method

1 Connection of throttle posi-

tion sensor coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).Improperly connected

Connect the coupler secure-

ly, or repair/replace the wire

harness.Turn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

2 Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).Improperly connected

Connect the coupler secure-

ly, or repair/replace the wire

harness.Turn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order. Fault code 14

SymptomIntake air pressure sensor: hose system malfunction (clogged

or detached hose)

Page 305 of 356

FUEL INJECTION SYSTEM

8-19

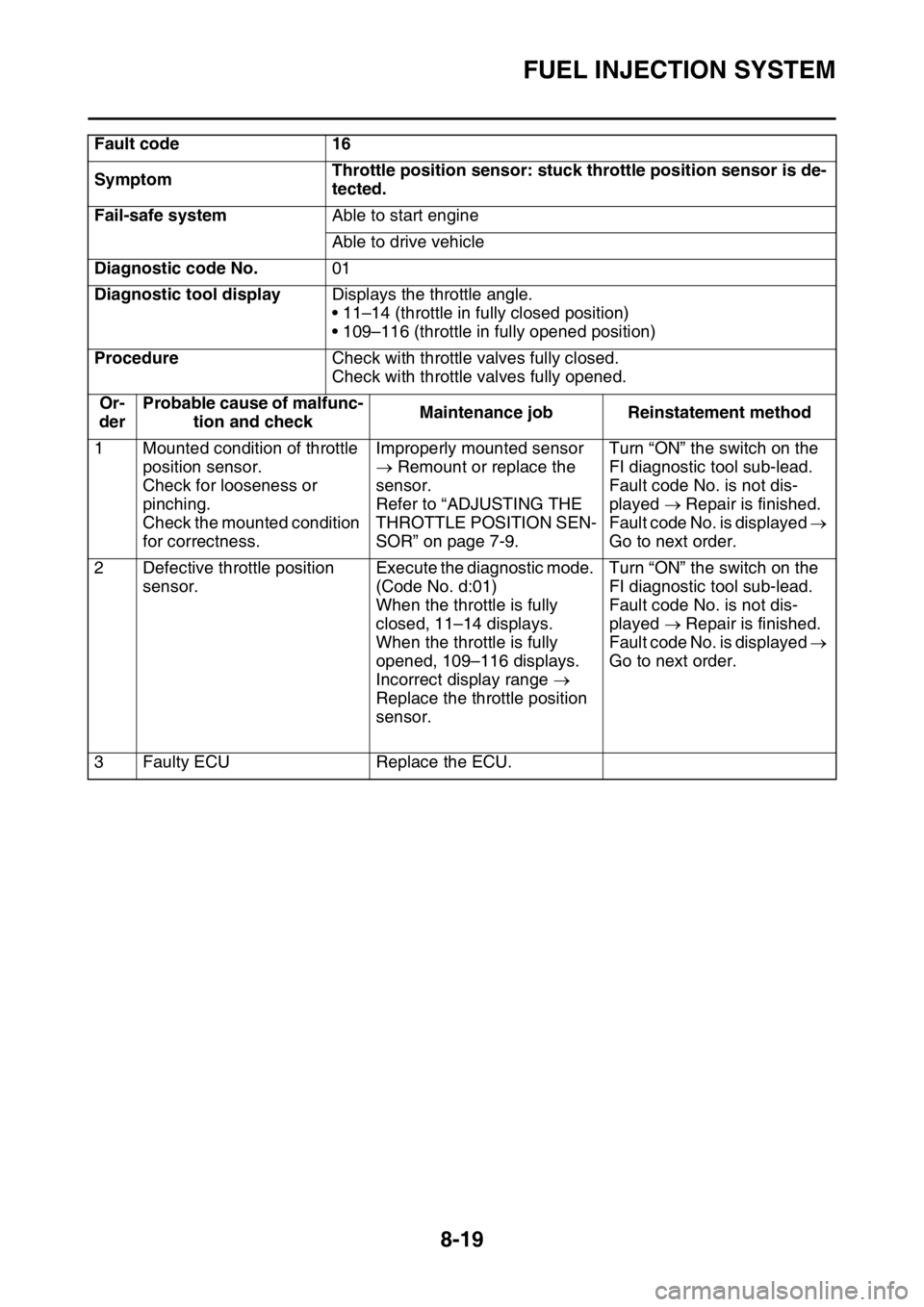

Fault code 16

SymptomThrottle position sensor: stuck throttle position sensor is de-

tected.

Fail-safe systemAble to start engine

Able to drive vehicle

Diagnostic code No.01

Diagnostic tool displayDisplays the throttle angle.

• 11–14 (throttle in fully closed position)

• 109–116 (throttle in fully opened position)

ProcedureCheck with throttle valves fully closed.

Check with throttle valves fully opened.

Or-

derProbable cause of malfunc-

tion and checkMaintenance job Reinstatement method

1 Mounted condition of throttle

position sensor.

Check for looseness or

pinching.

Check the mounted condition

for correctness.Improperly mounted sensor

Remount or replace the

sensor.

Refer to “ADJUSTING THE

THROTTLE POSITION SEN-

SOR” on page 7-9.Turn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

2 Defective throttle position

sensor.Execute the diagnostic mode.

(Code No. d:01)

When the throttle is fully

closed, 11–14 displays.

When the throttle is fully

opened, 109–116 displays.

Incorrect display range

Replace the throttle position

sensor.Turn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

3 Faulty ECU Replace the ECU.

Page 306 of 356

FUEL INJECTION SYSTEM

8-20

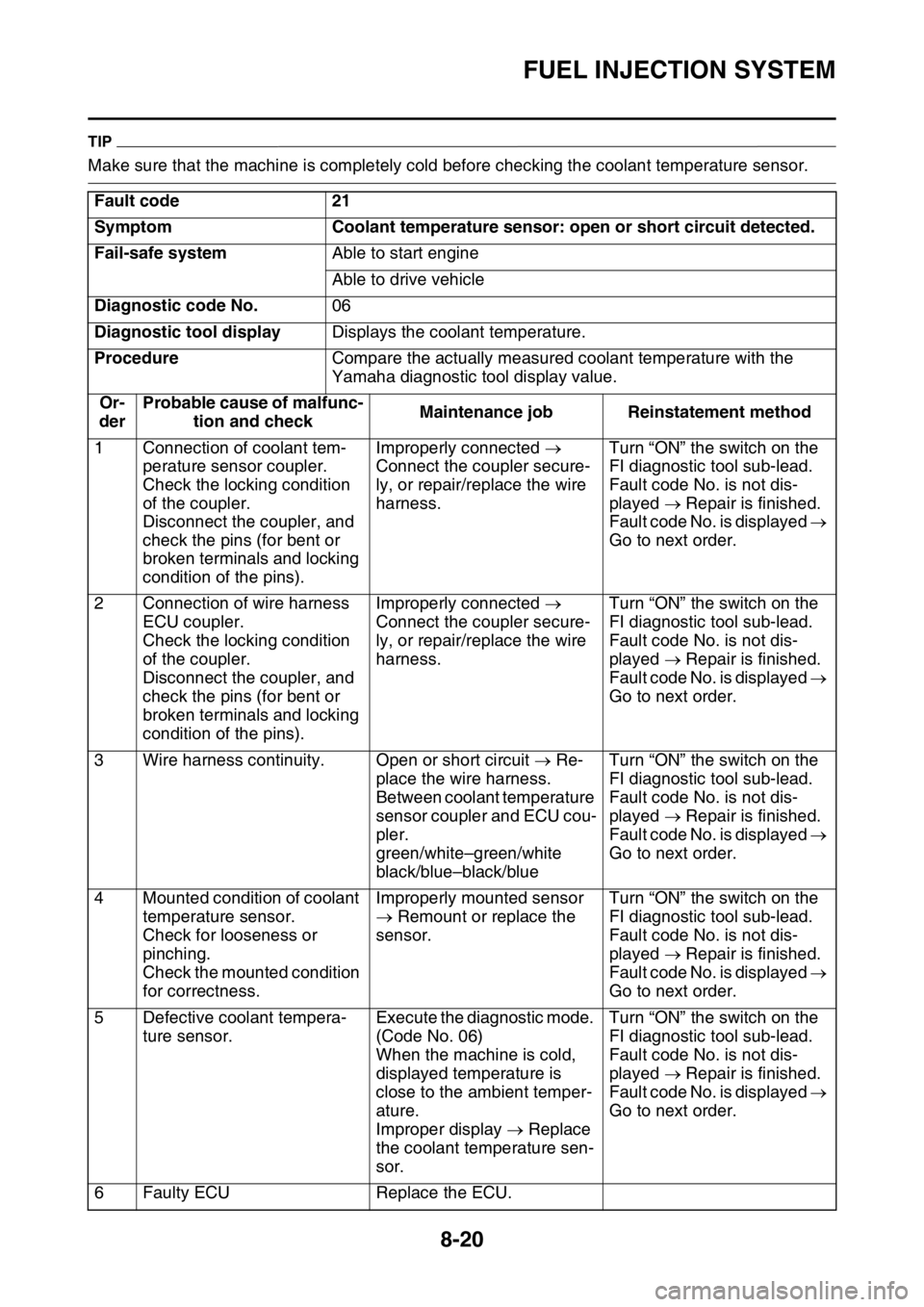

TIP

Make sure that the machine is completely cold before checking the coolant temperature sensor.

Fault code 21

Symptom Coolant temperature sensor: open or short circuit detected.

Fail-safe systemAble to start engine

Able to drive vehicle

Diagnostic code No.06

Diagnostic tool displayDisplays the coolant temperature.

ProcedureCompare the actually measured coolant temperature with the

Yamaha diagnostic tool display value.

Or-

derProbable cause of malfunc-

tion and checkMaintenance job Reinstatement method

1 Connection of coolant tem-

perature sensor coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).Improperly connected

Connect the coupler secure-

ly, or repair/replace the wire

harness.Turn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

2 Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).Improperly connected

Connect the coupler secure-

ly, or repair/replace the wire

harness.Turn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

3 Wire harness continuity. Open or short circuit Re-

place the wire harness.

Between coolant temperature

sensor coupler and ECU cou-

pler.

green/white–green/white

black/blue–black/blueTurn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

4 Mounted condition of coolant

temperature sensor.

Check for looseness or

pinching.

Check the mounted condition

for correctness.Improperly mounted sensor

Remount or replace the

sensor.Turn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

5 Defective coolant tempera-

ture sensor.Execute the diagnostic mode.

(Code No. 06)

When the machine is cold,

displayed temperature is

close to the ambient temper-

ature.

Improper display Replace

the coolant temperature sen-

sor.Turn “ON” the switch on the

FI diagnostic tool sub-lead.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

6 Faulty ECU Replace the ECU.