check engine YAMAHA YZ250F 2016 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: YZ250F, Model: YAMAHA YZ250F 2016Pages: 356, PDF Size: 11.25 MB

Page 56 of 356

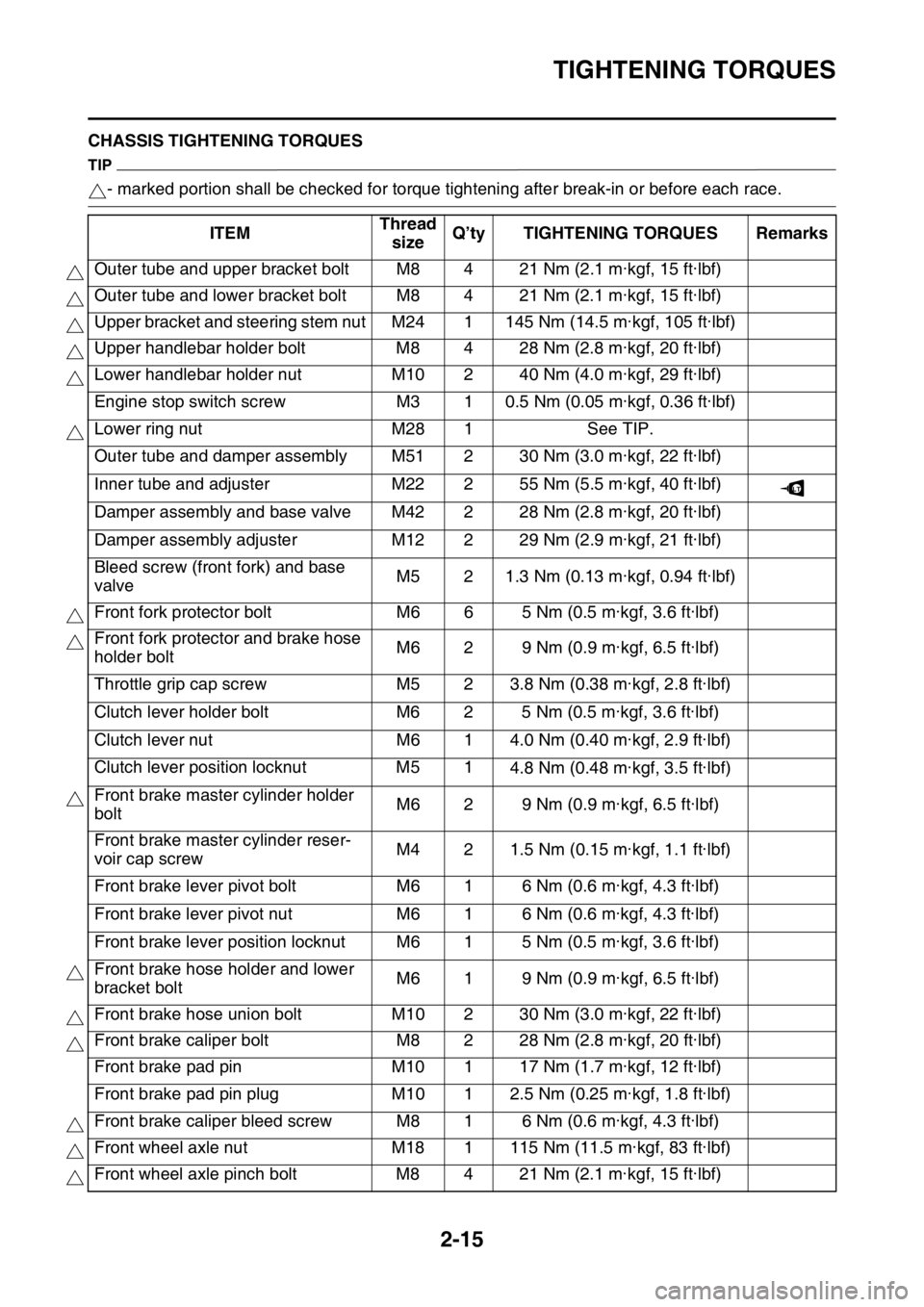

TIGHTENING TORQUES

2-15

EAS1SM9056CHASSIS TIGHTENING TORQUES

TIP

- marked portion shall be checked for torque tightening after break-in or before each race.

ITEMThread

sizeQ’ty TIGHTENING TORQUES Remarks

Outer tube and upper bracket bolt M8 4 21 Nm (2.1 m·kgf, 15 ft·lbf)

Outer tube and lower bracket bolt M8 4 21 Nm (2.1 m·kgf, 15 ft·lbf)

Upper bracket and steering stem nut M24 1 145 Nm (14.5 m·kgf, 105 ft·lbf)

Upper handlebar holder bolt M8 4 28 Nm (2.8 m·kgf, 20 ft·lbf)

Lower handlebar holder nut M10 2 40 Nm (4.0 m·kgf, 29 ft·lbf)

Engine stop switch screw M3 1 0.5 Nm (0.05 m·kgf, 0.36 ft·lbf)

Lower ring nut M28 1 See TIP.

Outer tube and damper assembly M51 2 30 Nm (3.0 m·kgf, 22 ft·lbf)

Inner tube and adjuster M22 2 55 Nm (5.5 m·kgf, 40 ft·lbf)

Damper assembly and base valve M42 2 28 Nm (2.8 m·kgf, 20 ft·lbf)

Damper assembly adjuster M12 2 29 Nm (2.9 m·kgf, 21 ft·lbf)

Bleed screw (front fork) and base

valveM5 2 1.3 Nm (0.13 m·kgf, 0.94 ft·lbf)

Front fork protector bolt M6 6 5 Nm (0.5 m·kgf, 3.6 ft·lbf)

Front fork protector and brake hose

holder boltM6 2 9 Nm (0.9 m·kgf, 6.5 ft·lbf)

Throttle grip cap screw M5 2 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

Clutch lever holder bolt M6 2 5 Nm (0.5 m·kgf, 3.6 ft·lbf)

Clutch lever nut M6 1 4.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

Clutch lever position locknut M5 1

4.8 Nm (0.48 m·kgf, 3.5 ft·lbf)

Front brake master cylinder holder

boltM6 2 9 Nm (0.9 m·kgf, 6.5 ft·lbf)

Front brake master cylinder reser-

voir cap screwM4 2 1.5 Nm (0.15 m·kgf, 1.1 ft·lbf)

Front brake lever pivot bolt M6 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Front brake lever pivot nut M6 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Front brake lever position locknut M6 1 5 Nm (0.5 m·kgf, 3.6 ft·lbf)

Front brake hose holder and lower

bracket boltM6 1 9 Nm (0.9 m·kgf, 6.5 ft·lbf)

Front brake hose union bolt M10 2 30 Nm (3.0 m·kgf, 22 ft·lbf)

Front brake caliper bolt M8 2 28 Nm (2.8 m·kgf, 20 ft·lbf)

Front brake pad pin M10 1 17 Nm (1.7 m·kgf, 12 ft·lbf)

Front brake pad pin plug M10 1 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Front brake caliper bleed screw M8 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Front wheel axle nut M18 1 115 Nm (11.5 m·kgf, 83 ft·lbf)

Front wheel axle pinch bolt M8 4 21 Nm (2.1 m·kgf, 15 ft·lbf)

LT

Page 83 of 356

3

PERIODIC CHECKS AND ADJUSTMENTS

MAINTENANCE INTERVALS.......................................................................... 3-1

MAINTENANCE INTERVALS .................................................................... 3-1

PRE-OPERATION INSPECTION AND MAINTENANCE................................. 3-7

GENERAL INSPECTION AND MAINTENANCE........................................ 3-7

ENGINE............................................................................................................ 3-8

CHECKING THE COOLANT LEVEL .......................................................... 3-8

CHECKING THE COOLING SYSTEM ....................................................... 3-8

CHANGING THE COOLANT...................................................................... 3-8

CHECKING THE RADIATOR CAP ............................................................ 3-9

CHECKING THE RADIATOR CAP VALVE OPENING PRESSURE ......... 3-9

CHECKING THE COOLANT CIRCULATORY SYSTEM FOR LEAKS .... 3-10

ADJUSTING THE CLUTCH LEVER POSITION ...................................... 3-10

ADJUSTING THE CLUTCH LEVER FREE PLAY .................................... 3-10

ADJUSTING THE THROTTLE GRIP FREE PLAY .................................. 3-11

LUBRICATING THE THROTTLE CABLE ................................................ 3-12

CLEANING THE AIR FILTER ELEMENT................................................. 3-12

CHECKING THE THROTTLE BODY JOINT ............................................ 3-13

CHECKING THE BREATHER HOSES .................................................... 3-13

CHECKING THE EXHAUST SYSTEM..................................................... 3-13

CHECKING THE FUEL LINE ................................................................... 3-14

CHECKING THE ENGINE OIL LEVEL..................................................... 3-14

CHANGING THE ENGINE OIL ................................................................ 3-15

ADJUSTING THE ENGINE IDLING SPEED ............................................ 3-16

ADJUSTING THE VALVE CLEARANCE ................................................. 3-17

CHASSIS........................................................................................................ 3-22

BLEEDING THE BRAKE SYSTEM .......................................................... 3-22

CHECKING THE BRAKE HOSE .............................................................. 3-23

ADJUSTING THE FRONT BRAKE .......................................................... 3-23

ADJUSTING THE REAR BRAKE ............................................................. 3-24

CHECKING THE FRONT BRAKE PADS ................................................. 3-24

CHECKING THE REAR BRAKE PADS ................................................... 3-26

CHECKING THE REAR BRAKE PAD INSULATOR ................................ 3-27

CHECKING THE BRAKE FLUID LEVEL.................................................. 3-27

ADJUSTING THE DRIVE CHAIN SLACK ................................................ 3-28

CHECKING THE FRONT FORK LEGS ................................................... 3-29

CHECKING THE FRONT FORK PROTECTOR GUIDE .......................... 3-29

CLEANING THE FRONT FORK OIL SEAL AND DUST SEAL ................ 3-29

AIR BLEEDING FROM FRONT FORK .................................................... 3-29

ADJUSTING THE FRONT FORK LEGS .................................................. 3-30

CHECKING THE SWINGARM OPERATION ........................................... 3-31

CHECKING THE REAR SUSPENSION ................................................... 3-31

ADJUSTING THE REAR SHOCK ABSORBER ASSEMBLY ................... 3-31

CHECKING THE TIRES ........................................................................... 3-33

CHECKING AND TIGHTENING THE SPOKES ....................................... 3-33

CHECKING THE WHEELS ...................................................................... 3-34

Page 85 of 356

MAINTENANCE INTERVALS

3-1

EAS1SM9063

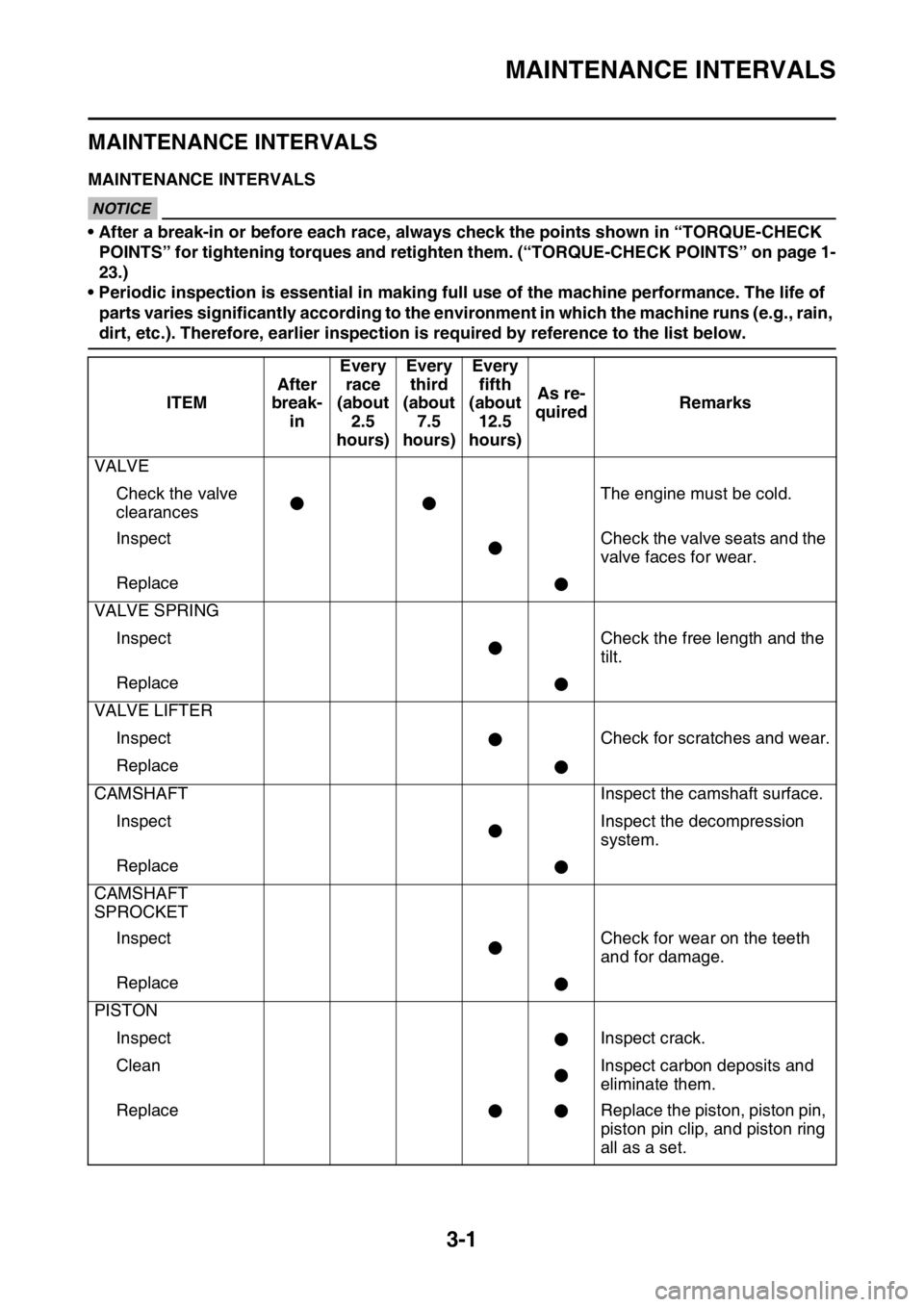

MAINTENANCE INTERVALS

EAS1SM9064MAINTENANCE INTERVALSECA@

NOTICE

• After a break-in or before each race, always check the points shown in “TORQUE-CHECK

POINTS” for tightening torques and retighten them. (“TORQUE-CHECK POINTS” on page 1-

23.)

• Periodic inspection is essential in making full use of the machine performance. The life of

parts varies significantly according to the environment in which the machine runs (e.g., rain,

dirt, etc.). Therefore, earlier inspection is required by reference to the list below.

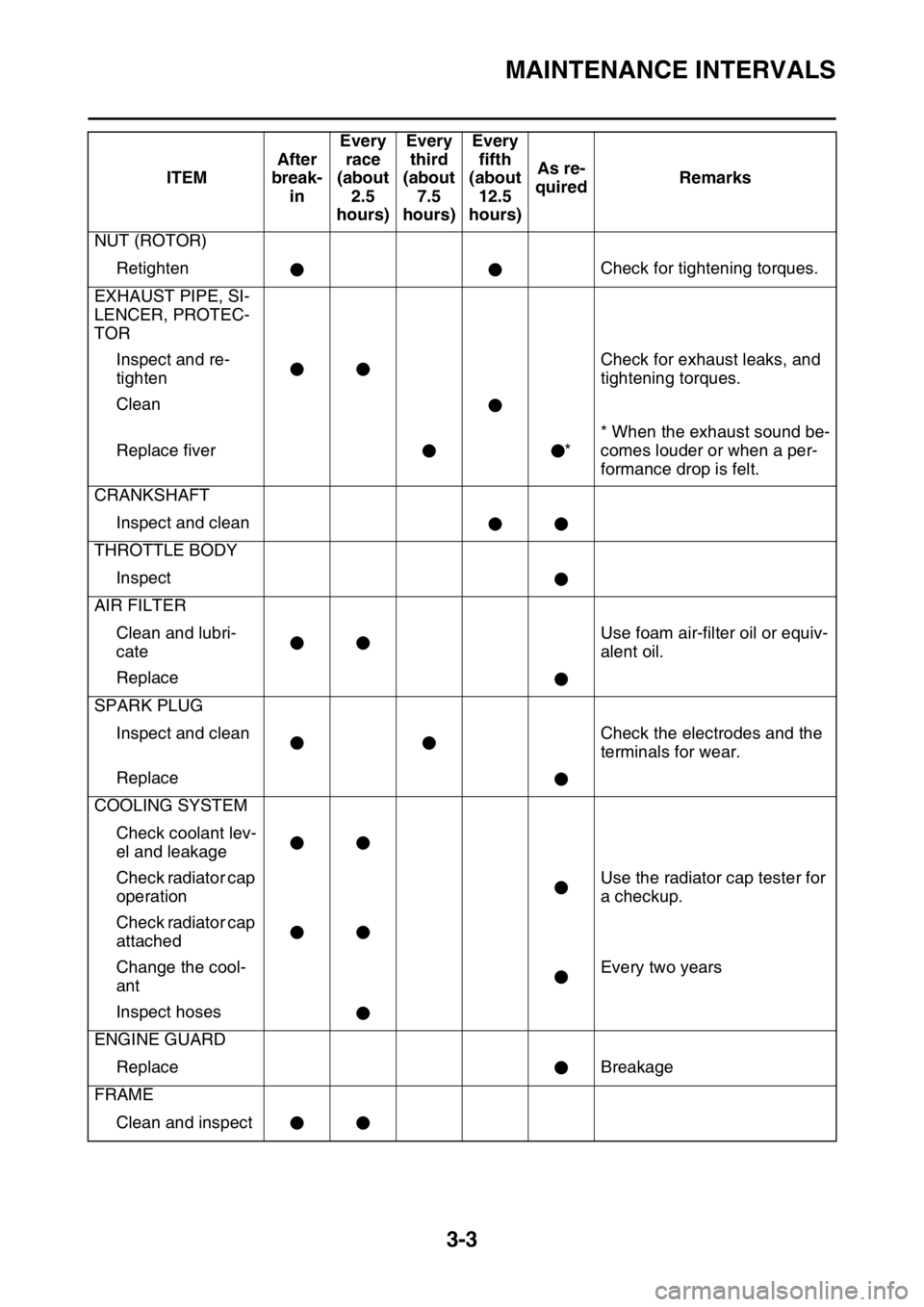

ITEMAfter

break-

inEvery

race

(about

2.5

hours)Every

third

(about

7.5

hours)Every

fifth

(about

12.5

hours)As re-

quiredRemarks

VALVE

Check the valve

clearancesThe engine must be cold.

Inspect Check the valve seats and the

valve faces for wear.

Replace

VALVE SPRING

Inspect Check the free length and the

tilt.

Replace

VALVE LIFTER

Inspect Check for scratches and wear.

Replace

CAMSHAFT Inspect the camshaft surface.

Inspect Inspect the decompression

system.

Replace

CAMSHAFT

SPROCKET

Inspect Check for wear on the teeth

and for damage.

Replace

PISTON

Inspect Inspect crack.

Clean Inspect carbon deposits and

eliminate them.

Replace Replace the piston, piston pin,

piston pin clip, and piston ring

all as a set.

Page 86 of 356

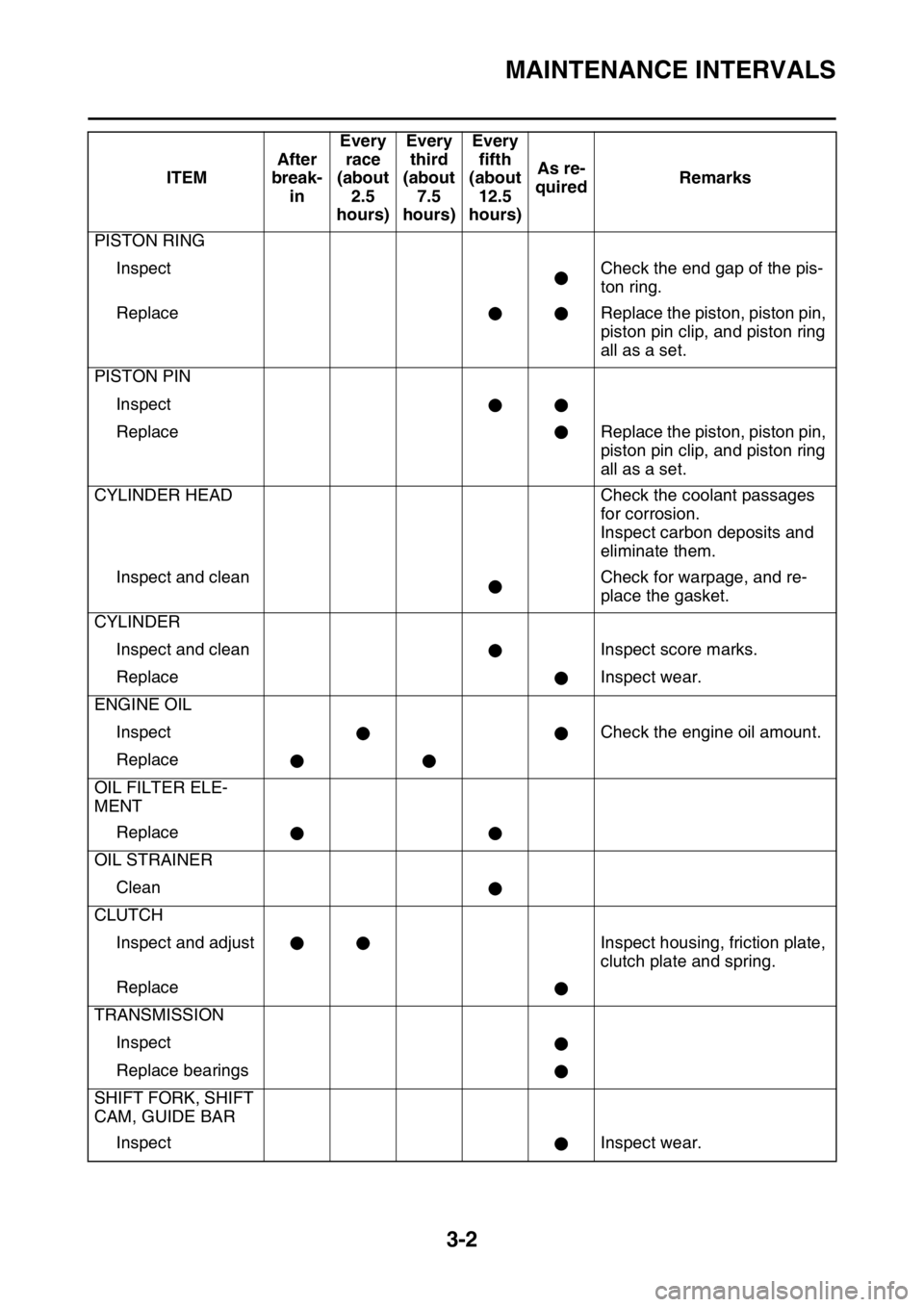

MAINTENANCE INTERVALS

3-2

PISTON RING

Inspect Check the end gap of the pis-

ton ring.

Replace Replace the piston, piston pin,

piston pin clip, and piston ring

all as a set.

PISTON PIN

Inspect

Replace Replace the piston, piston pin,

piston pin clip, and piston ring

all as a set.

CYLINDER HEAD Check the coolant passages

for corrosion.

Inspect carbon deposits and

eliminate them.

Inspect and clean Check for warpage, and re-

place the gasket.

CYLINDER

Inspect and clean Inspect score marks.

Replace Inspect wear.

ENGINE OIL

Inspect Check the engine oil amount.

Replace

OIL FILTER ELE-

MENT

Replace

OIL STRAINER

Clean

CLUTCH

Inspect and adjust Inspect housing, friction plate,

clutch plate and spring.

Replace

TRANSMISSION

Inspect

Replace bearings

SHIFT FORK, SHIFT

CAM, GUIDE BAR

Inspect Inspect wear.ITEMAfter

break-

inEvery

race

(about

2.5

hours)Every

third

(about

7.5

hours)Every

fifth

(about

12.5

hours)As re-

quiredRemarks

Page 87 of 356

MAINTENANCE INTERVALS

3-3

NUT (ROTOR)

Retighten Check for tightening torques.

EXHAUST PIPE, SI-

LENCER, PROTEC-

TOR

Inspect and re-

tightenCheck for exhaust leaks, and

tightening torques.

Clean

Replace fiver ** When the exhaust sound be-

comes louder or when a per-

formance drop is felt.

CRANKSHAFT

Inspect and clean

THROTTLE BODY

Inspect

AIR FILTER

Clean and lubri-

cateUse foam air-filter oil or equiv-

alent oil.

Replace

SPARK PLUG

Inspect and clean Check the electrodes and the

terminals for wear.

Replace

COOLING SYSTEM

Check coolant lev-

el and leakage

Check radiator cap

operationUse the radiator cap tester for

a checkup.

Check radiator cap

attached

Change the cool-

antEvery two years

Inspect hoses

ENGINE GUARD

Replace Breakage

FRAME

Clean and inspectITEMAfter

break-

inEvery

race

(about

2.5

hours)Every

third

(about

7.5

hours)Every

fifth

(about

12.5

hours)As re-

quiredRemarks

Page 91 of 356

PRE-OPERATION INSPECTION AND MAINTENANCE

3-7

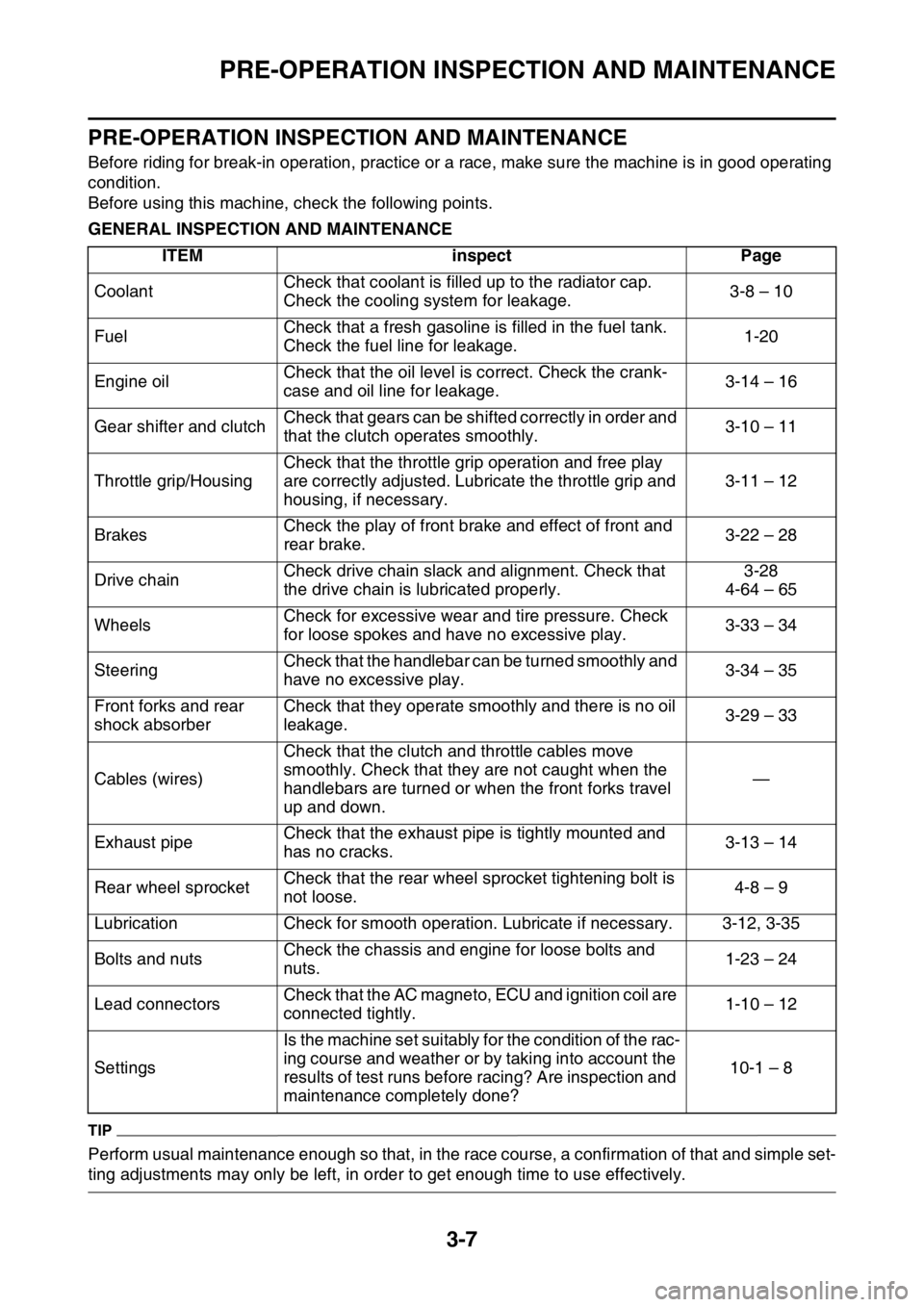

EAS1SM9065PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

EAS1SM9066GENERAL INSPECTION AND MAINTENANCE

TIP

Perform usual maintenance enough so that, in the race course, a confirmation of that and simple set-

ting adjustments may only be left, in order to get enough time to use effectively.ITEM inspect Page

CoolantCheck that coolant is filled up to the radiator cap.

Check the cooling system for leakage.3-8 – 10

FuelCheck that a fresh gasoline is filled in the fuel tank.

Check the fuel line for leakage.1-20

Engine oilCheck that the oil level is correct. Check the crank-

case and oil line for leakage.3-14 – 16

Gear shifter and clutchCheck that gears can be shifted correctly in order and

that the clutch operates smoothly.3-10 – 11

Throttle grip/HousingCheck that the throttle grip operation and free play

are correctly adjusted. Lubricate the throttle grip and

housing, if necessary.3-11 – 12

BrakesCheck the play of front brake and effect of front and

rear brake.3-22 – 28

Drive chainCheck drive chain slack and alignment. Check that

the drive chain is lubricated properly.3-28

4-64 – 65

WheelsCheck for excessive wear and tire pressure. Check

for loose spokes and have no excessive play.3-33 – 34

SteeringCheck that the handlebar can be turned smoothly and

have no excessive play.3-34 – 35

Front forks and rear

shock absorberCheck that they operate smoothly and there is no oil

leakage.3-29 – 33

Cables (wires)Check that the clutch and throttle cables move

smoothly. Check that they are not caught when the

handlebars are turned or when the front forks travel

up and down.—

Exhaust pipeCheck that the exhaust pipe is tightly mounted and

has no cracks.3-13 – 14

Rear wheel sprocketCheck that the rear wheel sprocket tightening bolt is

not loose.4-8 – 9

Lubrication Check for smooth operation. Lubricate if necessary. 3-12, 3-35

Bolts and nutsCheck the chassis and engine for loose bolts and

nuts.1-23 – 24

Lead connectorsCheck that the AC magneto, ECU and ignition coil are

connected tightly.1-10 – 12

SettingsIs the machine set suitably for the condition of the rac-

ing course and weather or by taking into account the

results of test runs before racing? Are inspection and

maintenance completely done?10-1 – 8

Page 92 of 356

ENGINE

3-8

EAS1SM9067

ENGINE

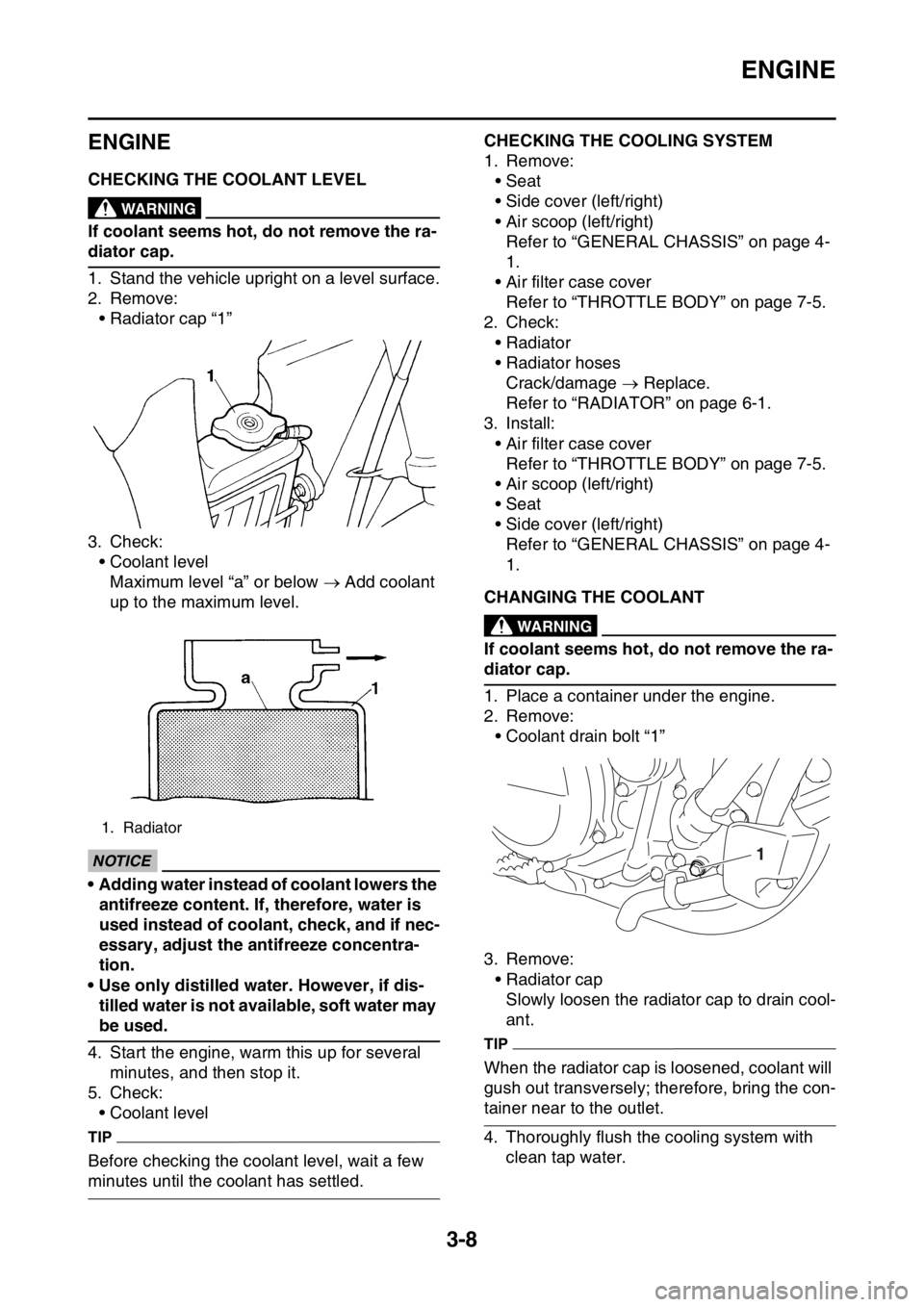

EAS1SM9068CHECKING THE COOLANT LEVELEWA1DX1003

WARNING

If coolant seems hot, do not remove the ra-

diator cap.

1. Stand the vehicle upright on a level surface.

2. Remove:

• Radiator cap “1”

3. Check:

• Coolant level

Maximum level “a” or below Add coolant

up to the maximum level.

ECA1DX1004

NOTICE

• Adding water instead of coolant lowers the

antifreeze content. If, therefore, water is

used instead of coolant, check, and if nec-

essary, adjust the antifreeze concentra-

tion.

• Use only distilled water. However, if dis-

tilled water is not available, soft water may

be used.

4. Start the engine, warm this up for several

minutes, and then stop it.

5. Check:

• Coolant level

TIP

Before checking the coolant level, wait a few

minutes until the coolant has settled.

EAS1SM9069CHECKING THE COOLING SYSTEM

1. Remove:

• Seat

• Side cover (left/right)

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

• Air filter case cover

Refer to “THROTTLE BODY” on page 7-5.

2. Check:

• Radiator

• Radiator hoses

Crack/damage Replace.

Refer to “RADIATOR” on page 6-1.

3. Install:

• Air filter case cover

Refer to “THROTTLE BODY” on page 7-5.

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

EAS1SM9070CHANGING THE COOLANTEWA1DX1004

WARNING

If coolant seems hot, do not remove the ra-

diator cap.

1. Place a container under the engine.

2. Remove:

• Coolant drain bolt “1”

3. Remove:

• Radiator cap

Slowly loosen the radiator cap to drain cool-

ant.

TIP

When the radiator cap is loosened, coolant will

gush out transversely; therefore, bring the con-

tainer near to the outlet.

4. Thoroughly flush the cooling system with

clean tap water.

1. Radiator

1

Page 93 of 356

ENGINE

3-9

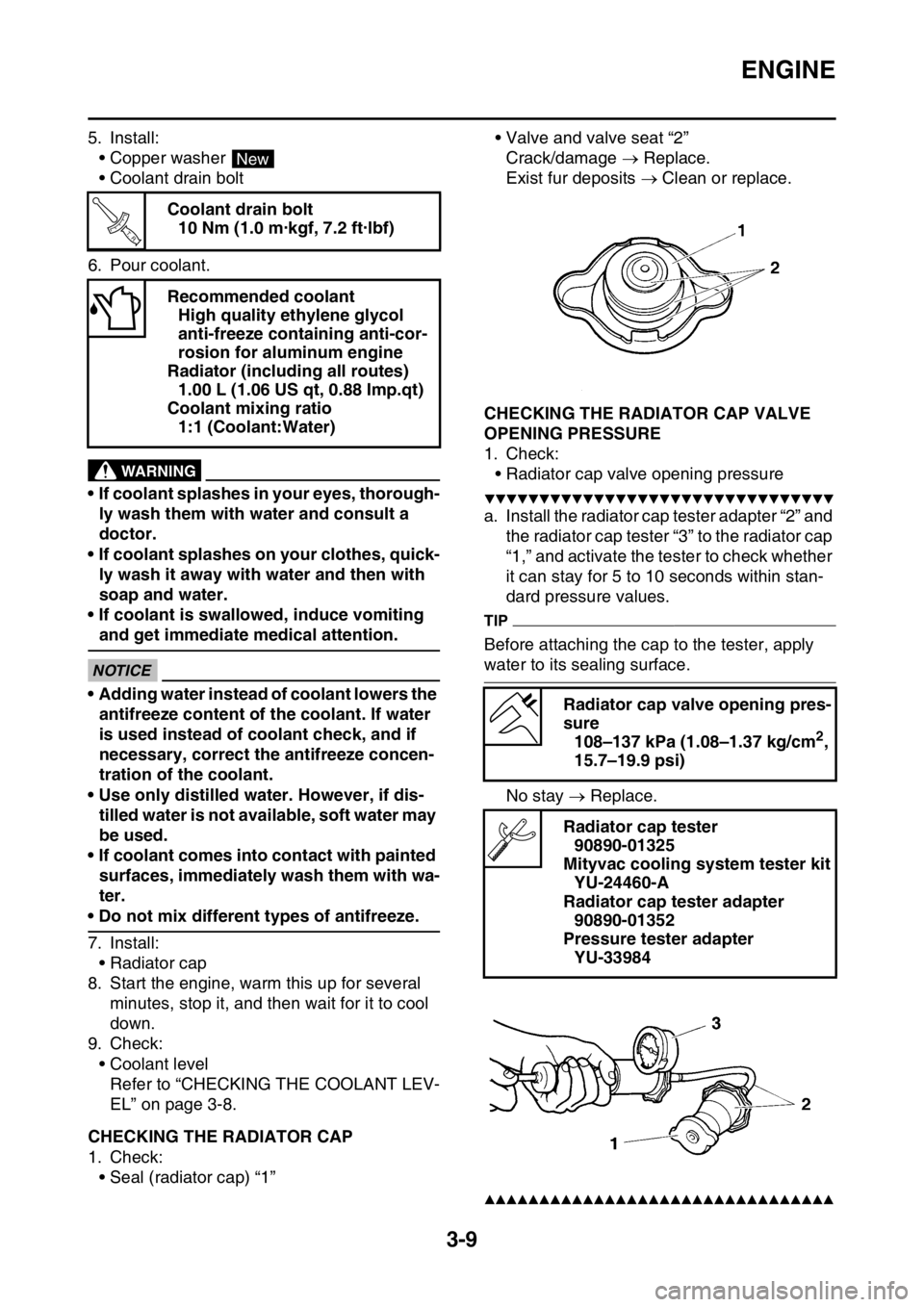

5. Install:

• Copper washer

• Coolant drain bolt

6. Pour coolant.

EWA13040

WARNING

• If coolant splashes in your eyes, thorough-

ly wash them with water and consult a

doctor.

• If coolant splashes on your clothes, quick-

ly wash it away with water and then with

soap and water.

• If coolant is swallowed, induce vomiting

and get immediate medical attention.

ECA13480

NOTICE

• Adding water instead of coolant lowers the

antifreeze content of the coolant. If water

is used instead of coolant check, and if

necessary, correct the antifreeze concen-

tration of the coolant.

• Use only distilled water. However, if dis-

tilled water is not available, soft water may

be used.

• If coolant comes into contact with painted

surfaces, immediately wash them with wa-

ter.

• Do not mix different types of antifreeze.

7. Install:

• Radiator cap

8. Start the engine, warm this up for several

minutes, stop it, and then wait for it to cool

down.

9. Check:

• Coolant level

Refer to “CHECKING THE COOLANT LEV-

EL” on page 3-8.

EAS1SM9071CHECKING THE RADIATOR CAP

1. Check:

• Seal (radiator cap) “1”• Valve and valve seat “2”

Crack/damage Replace.

Exist fur deposits Clean or replace.

EAS1SM9072CHECKING THE RADIATOR CAP VALVE

OPENING PRESSURE

1. Check:

• Radiator cap valve opening pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Install the radiator cap tester adapter “2” and

the radiator cap tester “3” to the radiator cap

“1,” and activate the tester to check whether

it can stay for 5 to 10 seconds within stan-

dard pressure values.

TIP

Before attaching the cap to the tester, apply

water to its sealing surface.

No stay Replace.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Coolant drain bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Recommended coolant

High quality ethylene glycol

anti-freeze containing anti-cor-

rosion for aluminum engine

Radiator (including all routes)

1.00 L (1.06 US qt, 0.88 Imp.qt)

Coolant mixing ratio

1:1 (Coolant:Water)

New

T R..

Radiator cap valve opening pres-

sure

108–137 kPa (1.08–1.37 kg/cm

2,

15.7–19.9 psi)

Radiator cap tester

90890-01325

Mityvac cooling system tester kit

YU-24460-A

Radiator cap tester adapter

90890-01352

Pressure tester adapter

YU-33984

Page 94 of 356

ENGINE

3-10

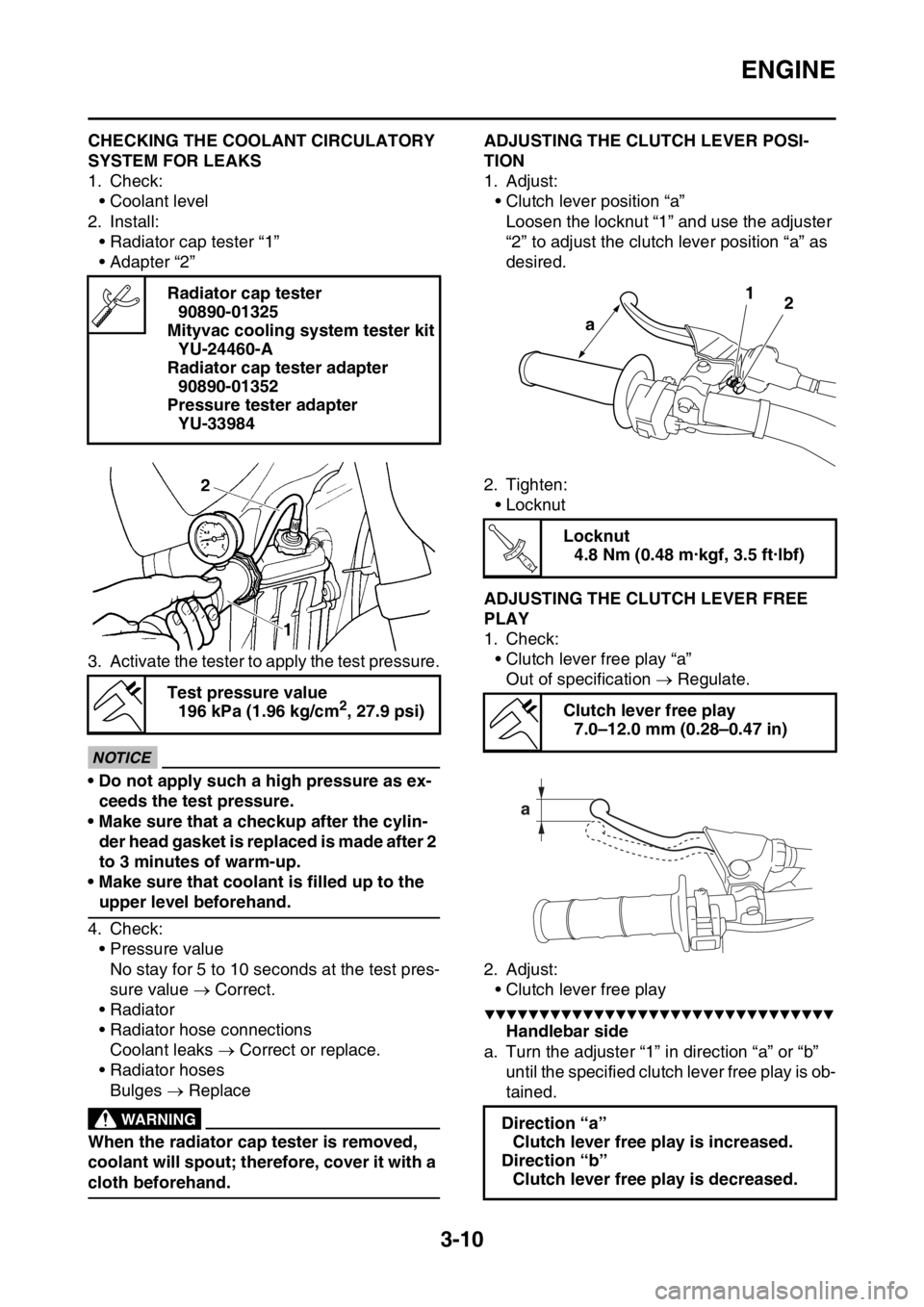

EAS1SM9073CHECKING THE COOLANT CIRCULATORY

SYSTEM FOR LEAKS

1. Check:

• Coolant level

2. Install:

• Radiator cap tester “1”

• Adapter “2”

3. Activate the tester to apply the test pressure.

ECA@

NOTICE

• Do not apply such a high pressure as ex-

ceeds the test pressure.

• Make sure that a checkup after the cylin-

der head gasket is replaced is made after 2

to 3 minutes of warm-up.

• Make sure that coolant is filled up to the

upper level beforehand.

4. Check:

• Pressure value

No stay for 5 to 10 seconds at the test pres-

sure value Correct.

• Radiator

• Radiator hose connections

Coolant leaks Correct or replace.

• Radiator hoses

Bulges Replace

EWA@

WARNING

When the radiator cap tester is removed,

coolant will spout; therefore, cover it with a

cloth beforehand.

EAS1SM9074ADJUSTING THE CLUTCH LEVER POSI-

TION

1. Adjust:

• Clutch lever position “a”

Loosen the locknut “1” and use the adjuster

“2” to adjust the clutch lever position “a” as

desired.

2. Tighten:

• Locknut

EAS1SM9075ADJUSTING THE CLUTCH LEVER FREE

PLAY

1. Check:

• Clutch lever free play “a”

Out of specification Regulate.

2. Adjust:

• Clutch lever free play

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Handlebar side

a. Turn the adjuster “1” in direction “a” or “b”

until the specified clutch lever free play is ob-

tained. Radiator cap tester

90890-01325

Mityvac cooling system tester kit

YU-24460-A

Radiator cap tester adapter

90890-01352

Pressure tester adapter

YU-33984

Test pressure value

196 kPa (1.96 kg/cm

2, 27.9 psi)

Locknut

4.8 Nm (0.48 m·kgf, 3.5 ft·lbf)

Clutch lever free play

7.0–12.0 mm (0.28–0.47 in)

Direction “a”

Clutch lever free play is increased.

Direction “b”

Clutch lever free play is decreased.

1

2

a

T R..

Page 95 of 356

ENGINE

3-11

TIP

If the clutch lever free play cannot be obtained

on the handlebar side, use the adjuster on the

clutch cable side.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Clutch cable side

a. Slide the clutch cable cover.

b. Loosen the locknut “1”.

c. Turn the adjuster “2” in direction “a” or “b”

until the specified clutch lever free play is ob-

tained.

d. Tighten the locknut “1”.

e. Return the clutch cable cover to its original

position.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SM9076ADJUSTING THE THROTTLE GRIP FREE

PLAY

TIP

Prior to adjusting throttle grip free play, the en-

gine idling speed should be adjusted.

1. Check:

• Throttle grip free play “a”

Out of specification Regulate.

2. Adjust:

• Throttle grip free play

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the locknut “1”.

b. Turn the adjuster “2” until the specified free

play is obtained.

c. Tighten the locknut.

EWA

WARNING

After adjusting the throttle grip free play,

turn the handlebar to the right and to the left

to ensure that this does not cause the en-

gine idling speed to change.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Direction “a”

Clutch lever free play is increased.

Direction “b”

Clutch lever free play is decreased.

Locknut

4.3 Nm (0.43 m·kgf, 3.1 ft·lbf)

a b

1

T R..

1a

b

2

b

Throttle grip free play

3.0–5.0 mm (0.12–0.20 in)

Direction “a”

Throttle grip free play is increased.

Direction “b”

Throttle grip free play is decreased.

1 2

b

a