engine YAMAHA YZ450F 2005 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: YZ450F, Model: YAMAHA YZ450F 2005Pages: 646, PDF Size: 16.06 MB

Page 28 of 646

1 - 2

GEN

INFO

MACHINE IDENTIFICATION

EC120001

MACHINE IDENTIFICATION

There are two significant reasons for knowing

the serial number of your machine:

1. When ordering parts, you can give the

number to your Yamaha dealer for positive

identification of the model you own.

2. If your machine is stolen, the authorities will

need the number to search for and identify

your machine.

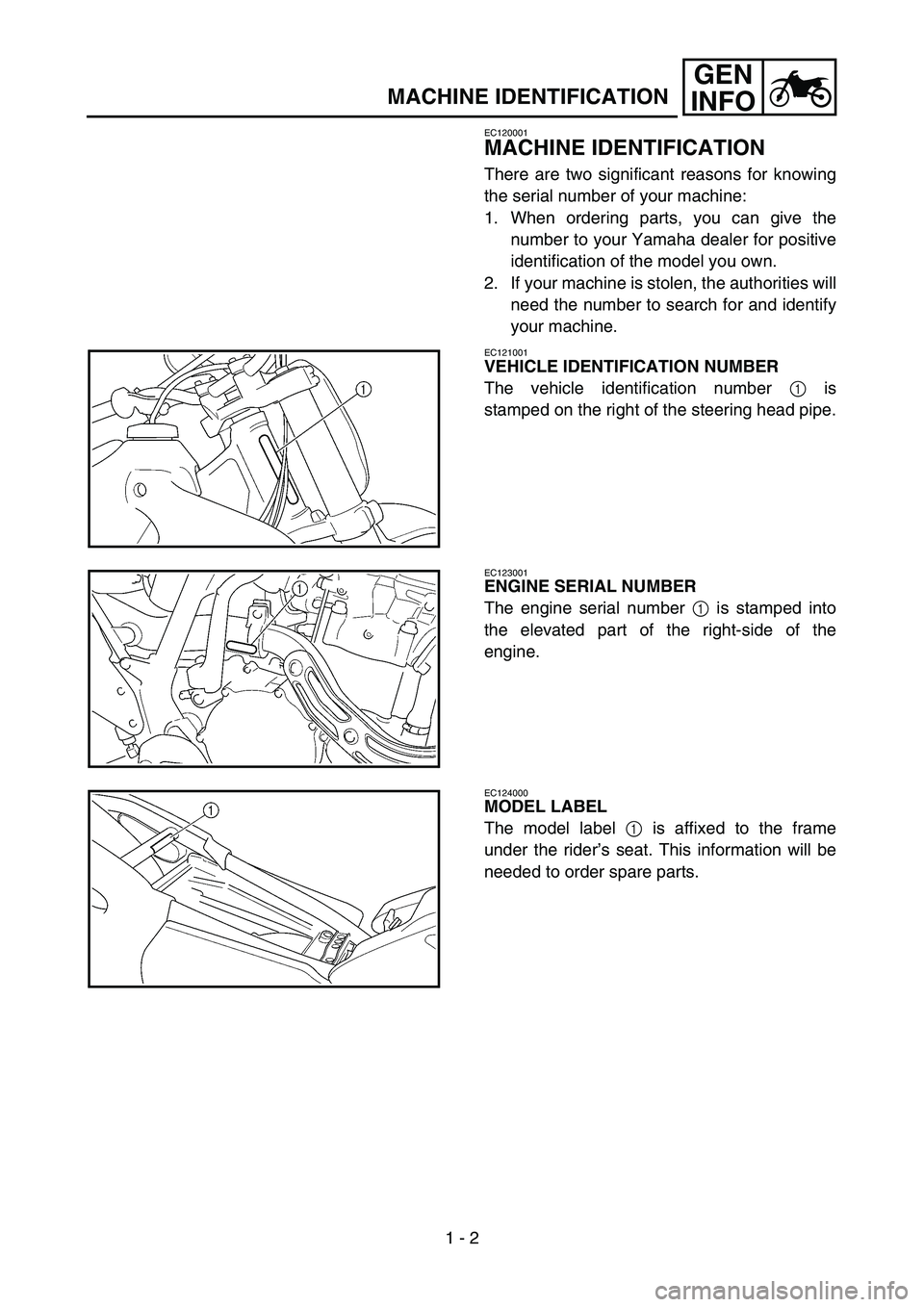

EC121001

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number 1 is

stamped on the right of the steering head pipe.

EC123001

ENGINE SERIAL NUMBER

The engine serial number 1 is stamped into

the elevated part of the right-side of the

engine.

EC124000

MODEL LABEL

The model label 1 is affixed to the frame

under the rider’s seat. This information will be

needed to order spare parts.

Page 32 of 646

1 - 4

GEN

INFO

IMPORTANT INFORMATION

EC132000

ALL REPLACEMENT PARTS

1. We recommend to use Yamaha genuine

parts for all replacements. Use oil and/or

grease recommended by Yamaha for

assembly and adjustment.

EC133000

GASKETS, OIL SEALS AND O-RINGS

1. All gaskets, oil seals, and O-rings should

be replaced when an engine is overhauled.

All gasket surfaces, oil seal lips, and O-

rings must be cleaned.

2. Properly oil all mating parts and bearings

during reassembly. Apply grease to the oil

seal lips.

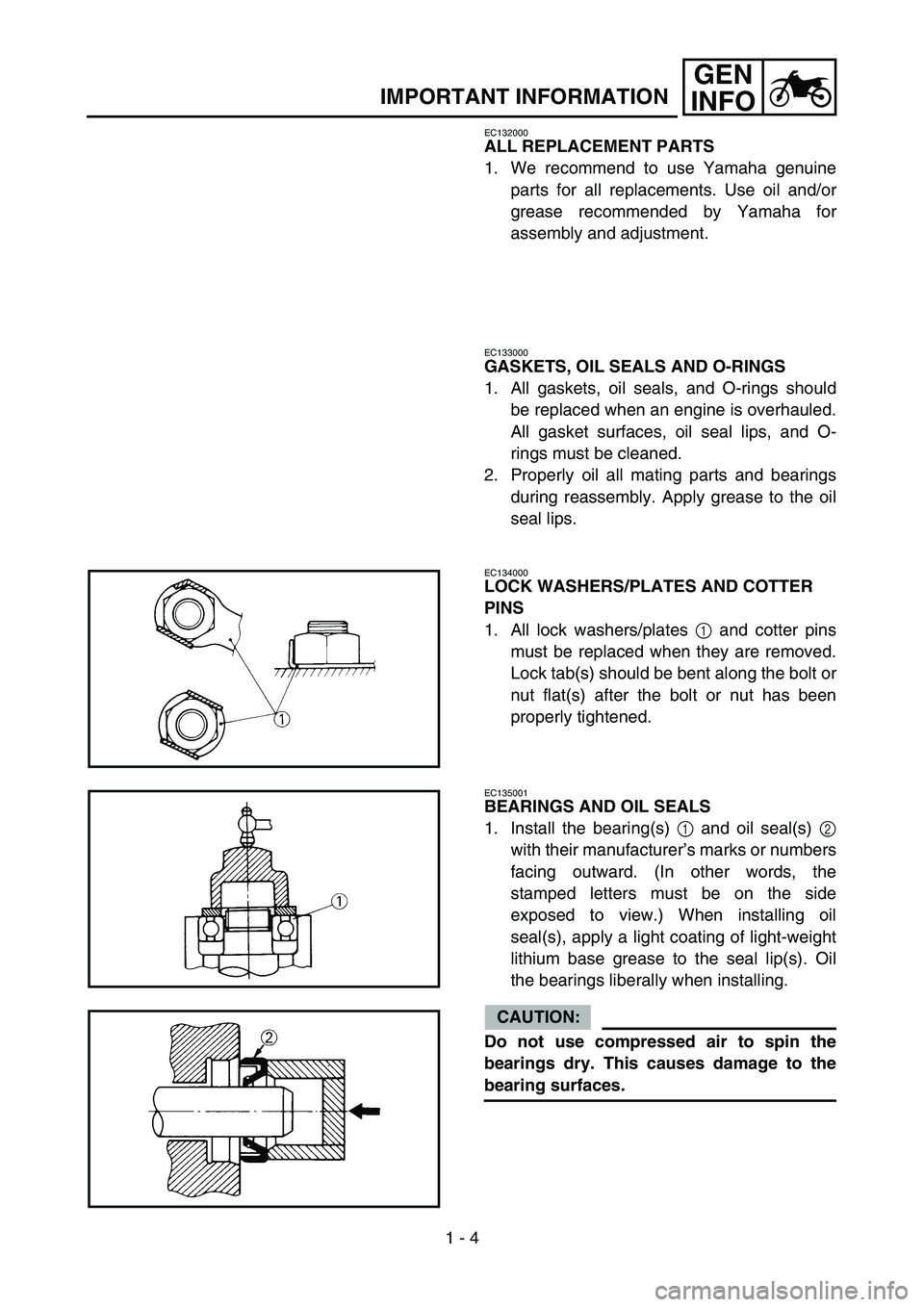

EC134000

LOCK WASHERS/PLATES AND COTTER

PINS

1. All lock washers/plates 1 and cotter pins

must be replaced when they are removed.

Lock tab(s) should be bent along the bolt or

nut flat(s) after the bolt or nut has been

properly tightened.

EC135001

BEARINGS AND OIL SEALS

1. Install the bearing(s) 1 and oil seal(s) 2

with their manufacturer’s marks or numbers

facing outward. (In other words, the

stamped letters must be on the side

exposed to view.) When installing oil

seal(s), apply a light coating of light-weight

lithium base grease to the seal lip(s). Oil

the bearings liberally when installing.

CAUTION:

Do not use compressed air to spin the

bearings dry. This causes damage to the

bearing surfaces.

Page 48 of 646

1 - 10

GEN

INFO

CONTROL FUNCTIONS

EC150000

CONTROL FUNCTIONS

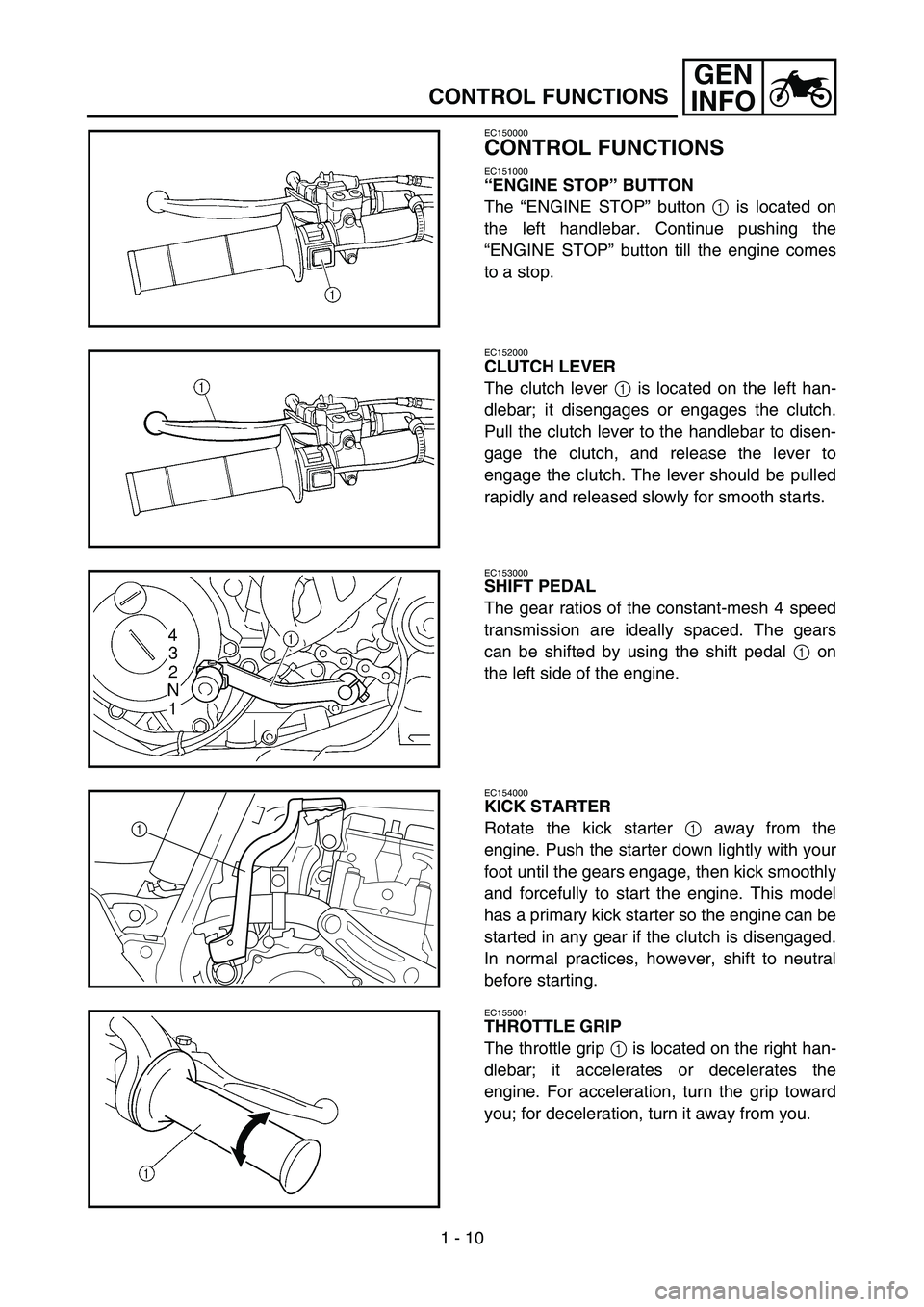

EC151000

“ENGINE STOP” BUTTON

The “ENGINE STOP” button 1 is located on

the left handlebar. Continue pushing the

“ENGINE STOP” button till the engine comes

to a stop.

EC152000

CLUTCH LEVER

The clutch lever 1 is located on the left han-

dlebar; it disengages or engages the clutch.

Pull the clutch lever to the handlebar to disen-

gage the clutch, and release the lever to

engage the clutch. The lever should be pulled

rapidly and released slowly for smooth starts.

EC153000

SHIFT PEDAL

The gear ratios of the constant-mesh 4 speed

transmission are ideally spaced. The gears

can be shifted by using the shift pedal 1 on

the left side of the engine.

EC154000

KICK STARTER

Rotate the kick starter 1 away from the

engine. Push the starter down lightly with your

foot until the gears engage, then kick smoothly

and forcefully to start the engine. This model

has a primary kick starter so the engine can be

started in any gear if the clutch is disengaged.

In normal practices, however, shift to neutral

before starting.

1

EC155001

THROTTLE GRIP

The throttle grip 1 is located on the right han-

dlebar; it accelerates or decelerates the

engine. For acceleration, turn the grip toward

you; for deceleration, turn it away from you.

Page 49 of 646

GEN

INFO

BEDIENUNGSELEMENTE UND

DEREN FUNKTION

MOTORSTOPPSCHALTER “ENGINE STOP”

Der Motorstoppschalter “ENGINE STOP” 1

befindet sich links am Lenker. Den Motor-

stoppschalter “ENGINE STOP” gedrückt hal-

ten, bis der Motor stoppt.

KUPPLUNGSHEBEL

Der Kupplungshebel 1 befindet sich links am

Lenker. Zum Auskuppeln den Kupplungshe-

bel zügig ziehen, beim Einkuppeln gefühlvoll

loslassen. Dies gewährleistet ein weiches Aus-

und Einrücken der Kupplung.

FUSSCHALTHEBEL

Das 4-Gang-Getriebe dieses Motorrads ist

ideal abgestuft. Die Gänge werden über den

Fußschalthebel 1 links am Motor geschaltet.

KICKSTARTERHEBEL

Den Kickstarterhebel 1 ausklappen. Zum Anlas-

sen des Motors den Kickstarterhebel langsam

niedertreten, bis deutlicher Widerstand spürbar

wird; anschließend den Kickstarter kräftig durch-

treten. Da dieses Modell mit einem Primärkick-

starter ausgerüstet ist, kann der Motor bei

eingelegtem Gang und gezogener Kupplung

gestartet werden. Es ist jedoch ratsam, den Motor

in der Leerlaufstellung des Getriebes anzulassen.

GASDREHGRIFF

Der Gasdrehgriff 1 befindet sich rechts am

Lenker. Zum Gasgeben den Drehgriff öffnen;

zum Gaswegnehmen den Drehgriff schließen.

FONCTIONS DES COMMANDES

BEDIENUNGSELEMENTE UND DEREN FUNKTION

FONCTIONS DES COMMANDES

BOUTON “ENGINE STOP”

Le bouton “ENGINE STOP” 1 est situé sur la par-

tie gauche du guidon. Garder ce bouton enfoncé

jusqu’à ce que le moteur s’arrête.

LEVIER D’EMBRAYAGE

Le levier d’embrayage 1 est situé sur la partie gau-

che du guidon et permet d’embrayer ou de

débrayer. Tirer le levier d’embrayage vers le gui-

don pour débrayer et le relâcher pour embrayer.

Pour un démarrage en douceur, le levier doit être

tiré rapidement et relâché lentement.

SELECTEUR

Les 4 rapports de la boîte de vitesses à prise cons-

tante sont idéalement échelonnés. Le changement

de vitesse est commandé par le sélecteur 1 situé

sur le côté gauche du moteur.

KICK

Déployer le kick 1. Appuyer légèrement sur la

pédale pour mettre les pignons en prise, puis

l’actionner vigoureusement mais en souplesse pour

mettre le moteur en marche. Ce modèle est équipé

d’un kick primaire, de sorte qu’il est possible de

démarrer dans n’importe quel rapport à condition

de débrayer. Normalement, toutefois, on repassera

au point mort avant de démarrer.

POIGNEE DES GAZ

La poignée des gaz 1 est située sur la partie droite

du guidon et permet d’accélérer ou de décélérer.

Pour accélérer, tourner la poignée vers soi; pour

décélérer, la tourner dans l’autre sens.

1 - 10

Page 50 of 646

1 - 11

GEN

INFO

CONTROL FUNCTIONS

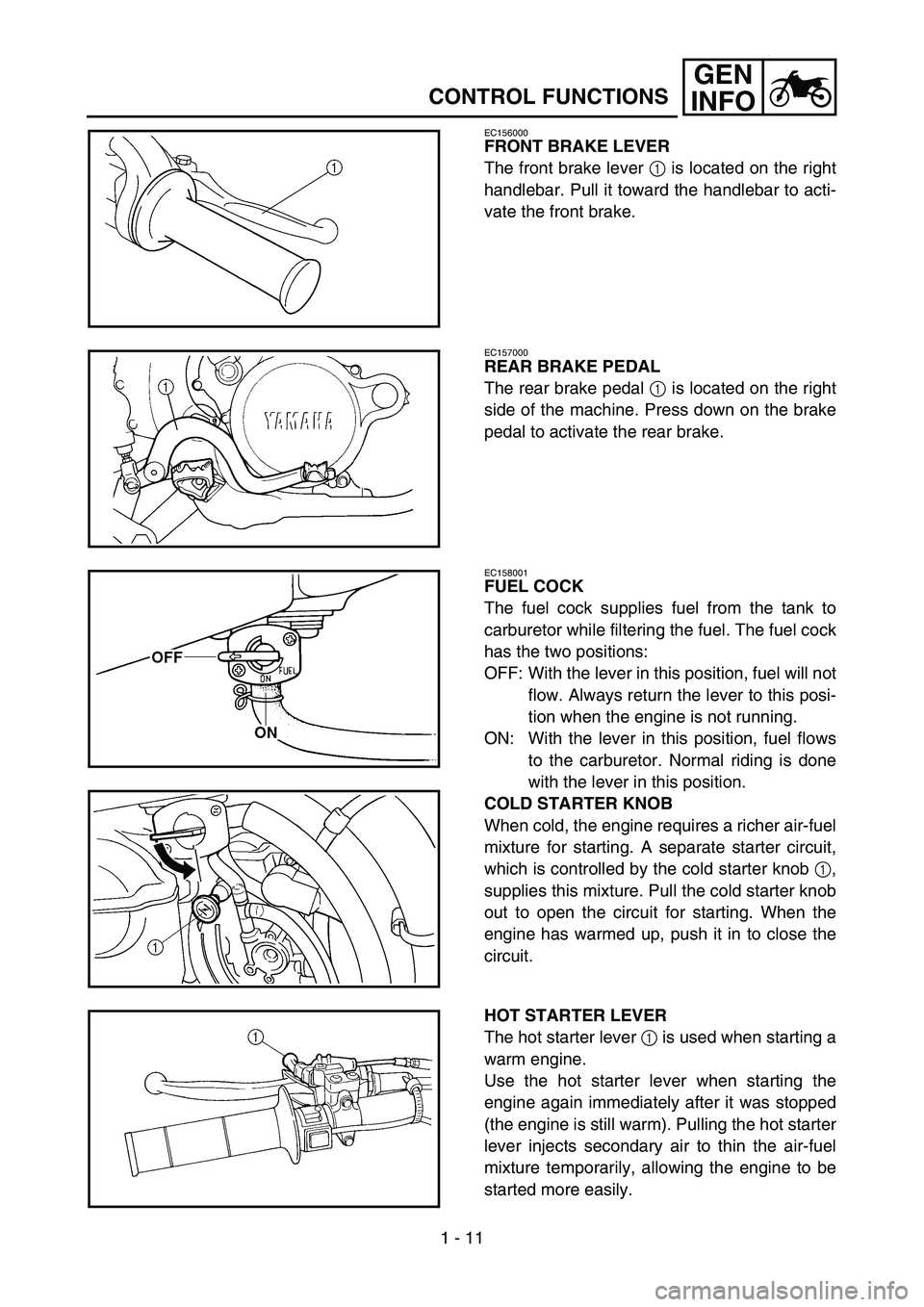

EC156000

FRONT BRAKE LEVER

The front brake lever 1 is located on the right

handlebar. Pull it toward the handlebar to acti-

vate the front brake.

EC157000

REAR BRAKE PEDAL

The rear brake pedal 1 is located on the right

side of the machine. Press down on the brake

pedal to activate the rear brake.

EC158001

FUEL COCK

The fuel cock supplies fuel from the tank to

carburetor while filtering the fuel. The fuel cock

has the two positions:

OFF: With the lever in this position, fuel will not

flow. Always return the lever to this posi-

tion when the engine is not running.

ON: With the lever in this position, fuel flows

to the carburetor. Normal riding is done

with the lever in this position.

COLD STARTER KNOB

When cold, the engine requires a richer air-fuel

mixture for starting. A separate starter circuit,

which is controlled by the cold starter knob 1,

supplies this mixture. Pull the cold starter knob

out to open the circuit for starting. When the

engine has warmed up, push it in to close the

circuit.

HOT STARTER LEVER

The hot starter lever 1 is used when starting a

warm engine.

Use the hot starter lever when starting the

engine again immediately after it was stopped

(the engine is still warm). Pulling the hot starter

lever injects secondary air to thin the air-fuel

mixture temporarily, allowing the engine to be

started more easily.

Page 54 of 646

1 - 13

GEN

INFO

FUEL

Always use the recommended fuel as stated

below. Also, be sure to use new gasoline the

day of a race.

CAUTION:

Use only unleaded gasoline. The use of

leaded gasoline will cause severe damage

to the engine internal parts such as valves,

piston rings, and exhaust system, etc.

NOTE:

If knocking or pinging occurs, use a different

brand of gasoline or higher octane grade.

WARNING

For refueling, be sure to stop the engine

and use enough care not to spill any fuel.

Also be sure to avoid refueling close to a

fire.

Refuel after the engine, exhaust pipe, etc.

have cooled off.

Recommended fuel:

Premium unleaded gasoline

only with a research octane

number of 95 or higher.

FUEL

Page 56 of 646

1 - 14

GEN

INFO

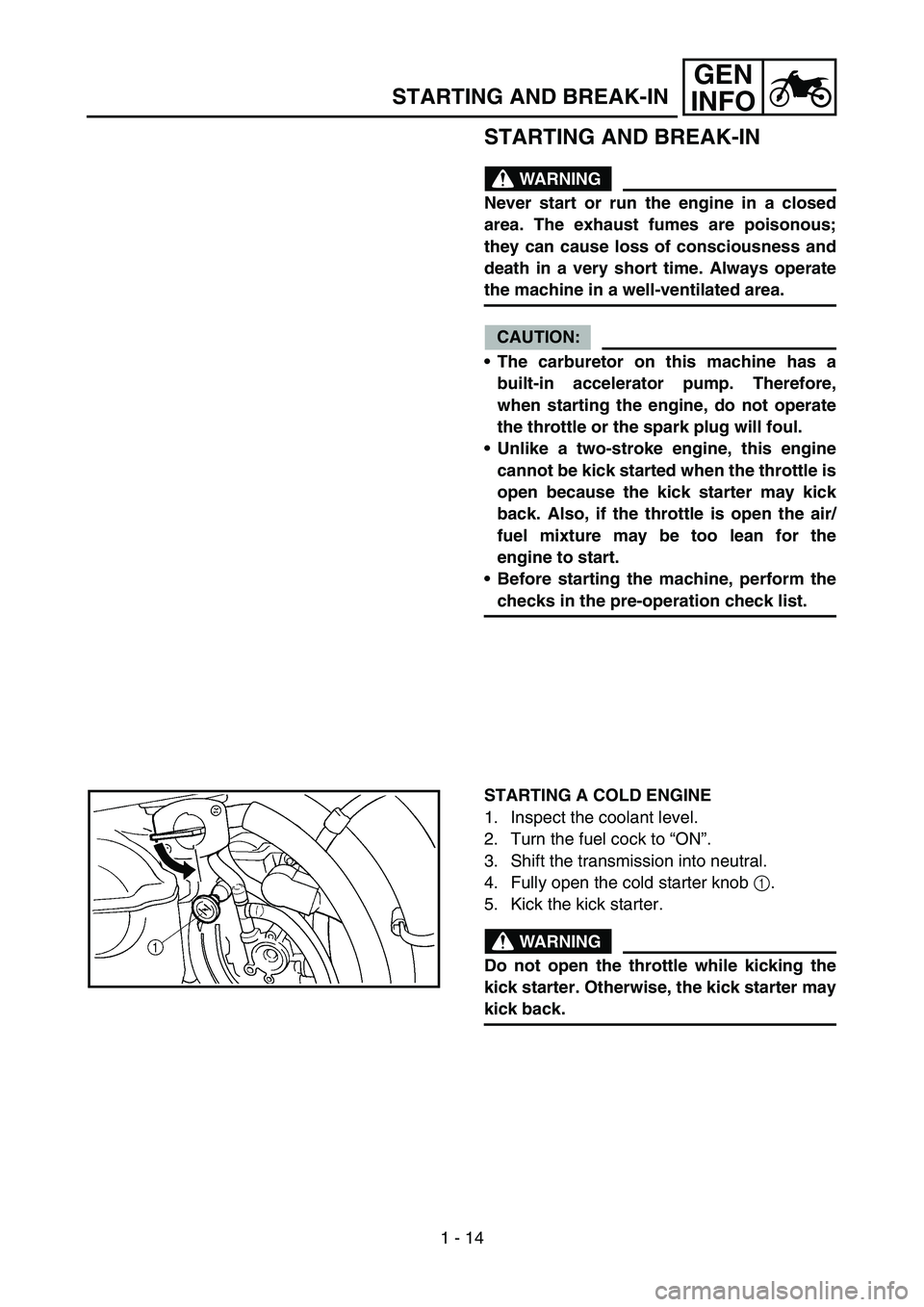

STARTING AND BREAK-IN

STARTING AND BREAK-IN

WARNING

Never start or run the engine in a closed

area. The exhaust fumes are poisonous;

they can cause loss of consciousness and

death in a very short time. Always operate

the machine in a well-ventilated area.

CAUTION:

The carburetor on this machine has a

built-in accelerator pump. Therefore,

when starting the engine, do not operate

the throttle or the spark plug will foul.

Unlike a two-stroke engine, this engine

cannot be kick started when the throttle is

open because the kick starter may kick

back. Also, if the throttle is open the air/

fuel mixture may be too lean for the

engine to start.

Before starting the machine, perform the

checks in the pre-operation check list.

STARTING A COLD ENGINE

1. Inspect the coolant level.

2. Turn the fuel cock to “ON”.

3. Shift the transmission into neutral.

4. Fully open the cold starter knob 1.

5. Kick the kick starter.

WARNING

Do not open the throttle while kicking the

kick starter. Otherwise, the kick starter may

kick back.

Page 58 of 646

1 - 15

GEN

INFO

STARTING AND BREAK-IN

6. Return the cold starter knob to its original

position and run the engine at 3,000 ~

5,000 r/min for 1 or 2 minutes.

NOTE:

Since this model is equipped with an accelera-

tor pump, if the engine is raced (the throttle

opened and closed), the air/fuel mixture will be

too rich and the engine may stall. Also unlike a

two-stroke engine, this model can idle.

CAUTION:

Do not warm up the engine for extended

periods of time.

Page 60 of 646

1 - 16

GEN

INFO

STARTING AND BREAK-IN

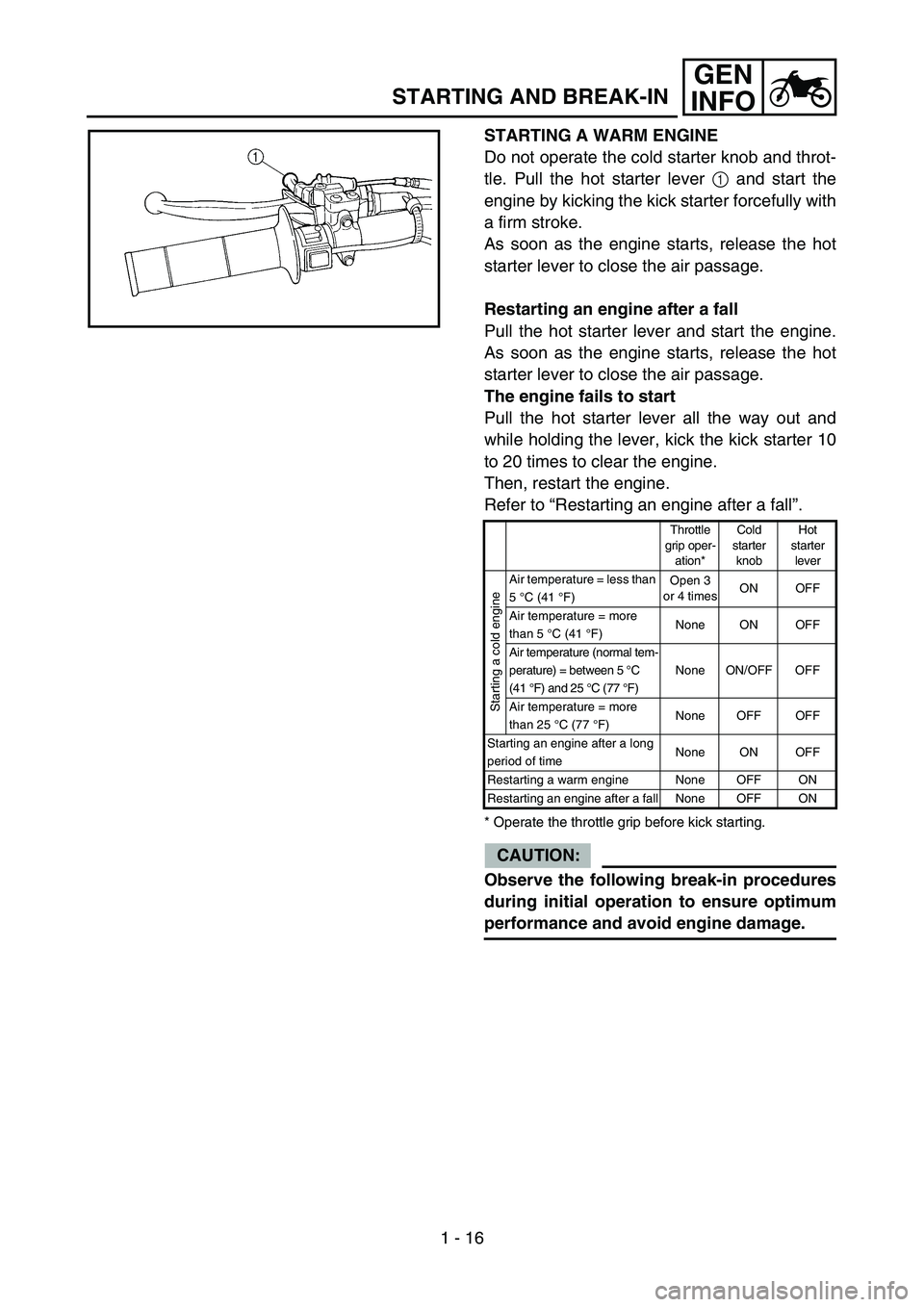

STARTING A WARM ENGINE

Do not operate the cold starter knob and throt-

tle. Pull the hot starter lever 1 and start the

engine by kicking the kick starter forcefully with

a firm stroke.

As soon as the engine starts, release the hot

starter lever to close the air passage.

Restarting an engine after a fall

Pull the hot starter lever and start the engine.

As soon as the engine starts, release the hot

starter lever to close the air passage.

The engine fails to start

Pull the hot starter lever all the way out and

while holding the lever, kick the kick starter 10

to 20 times to clear the engine.

Then, restart the engine.

Refer to “Restarting an engine after a fall”.

* Operate the throttle grip before kick starting.

CAUTION:

Observe the following break-in procedures

during initial operation to ensure optimum

performance and avoid engine damage.

Throttle

grip oper-

ation*Cold

starter

knobHot

starter

lever

Starting a cold engine

Air temperature = less than

5 °C (41 °F)Open 3

or 4 timesON OFF

Air temperature = more

than 5 °C (41 °F)None ON OFF

Air temperature (normal tem-

perature) = between 5°C

(41°F) and 25 °C (77°F)None ON/OFF OFF

Air temperature = more

than 25 °C (77 °F)None OFF OFF

Starting an engine after a long

period of timeNone ON OFF

Restarting a warm engine None OFF ON

Restarting an engine after a fall None OFF ON

Page 62 of 646

1 - 17

GEN

INFO

BREAK-IN PROCEDURES

1. Before starting the engine, fill the fuel tank

with the fuel.

2. Perform the pre-operation checks on the

machine.

3. Start and warm up the engine. Check the

idle speed, and check the operation of the

controls and the “ENGINE STOP” button.

Then, restart the engine and check its

operation within no more than 5 minutes

after it is restarted.

4. Operate the machine in the lower gears at

moderate throttle openings for five to eight

minutes.

5. Check how the engine runs when the

machine is ridden with the throttle 1/4 to 1/

2 open (low to medium speed) for about

one hour.

6. Restart the engine and check the operation

of the machine throughout its entire operat-

ing range. Restart the machine and oper-

ate it for about 10 to 15 more minutes. The

machine will now be ready to race.

CAUTION:

After the break-in or before each race,

you must check the entire machine for

loose fittings and fasteners as per

“TORQUE-CHECK POINTS”.

Tighten all such fasteners as required.

When any of the following parts have

been replaced, they must be broken in.

CYLINDER AND CRANKSHAFT:

About one hour of break-in operation is

necessary.

PISTON, RING, VALVES, CAMSHAFTS

AND GEARS:

These parts require about 30 minutes of

break-in operation at half-throttle or less.

Observe the condition of the engine care-

fully during operation.

STARTING AND BREAK-IN