engine YAMAHA YZ450F 2005 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: YZ450F, Model: YAMAHA YZ450F 2005Pages: 646, PDF Size: 16.06 MB

Page 63 of 646

GEN

INFO

EINFAHRVORSCHRIFTEN

1. Vor dem Starten volltanken.

2. Die “Routinekontrolle vor Fahrtbeginn” aus-

führen.

3. Den Motor anlassen und einige Minuten

lang betreiben. Die Leerlaufdrehzahl und

die Funktion der Bedienelemente ein-

schließlich des Motorstoppschalters

“ENGINE STOP” kontrollieren. Den Motor

erneut anlassen und innerhalb 5 Minuten

dessen Funktion kontrollieren.

4. Die Maschine 5–8 Minuten lang mit mäßi-

gem Gas im unteren Gangbereich betrei-

ben.

5. Den Motorbetrieb bei 1/4 bis 1/2 geöffne-

tem Gasdrehgriff (niedriger bis mäßiger

Geschwindigkeit) etwa eine Stunde lang

überwachen.

6. Den Motor erneut starten und den gesam-

ten Betriebsbereich kontrollieren. Den

Motor erneut starten und weiter 10–15

Minuten lang betreiben. Die Maschine ist

nun rennfertig.

ACHTUNG:

Entsprechend dem Abschnitt “ANZUGS-

DREHMOMENTE KONTROLLIEREN”,

nach dem Einfahren sowie vor jedem

Rennen sämtliche Befestigungselemente

kontrollieren.

Befestigungselemente ggf. vorschrifts-

mäßig festziehen.

Folgende Bauteile müssen nach dem

Auswechseln eingefahren werden.

ZYLINDER UND KURBELWELLE:

Eine einstündige Einfahrzeit einlegen.

KOLBEN, KOLBENRINGE, VENTILE,

NOCKLENWELLEN UND RITZEL:

Eine halbstündige Einfahrzeit mit maxi-

mal halb geöffnetem Gasdrehgriff einle-

gen. Den Motorbetrieb gründlich

überwachen.

MISE EN MARCHE ET RODAGE

STARTEN UND EINFAHREN

PROCEDURE DE RODAGE

1. Avant de démarrer le moteur, faire le plein du

réservoir de carburant.

2. Effectuer les contrôles avant utilisation.

3. Mettre le moteur en marche et le laisser chauf-

fer. Contrôler le régime de ralenti et le bon

fonctionnement des commandes et du bouton

“ENGINE STOP”. Redémarrer ensuite le

moteur et contrôler son fonctionnement dans

les 5 minutes maximum qui suivent son redé-

marrage.

4. Rouler pendant cinq à huit minutes sur les rap-

ports inférieurs et à régime modéré.

5. Contrôler le fonctionnement du moteur lorsque

la moto est utilisée pendant une heure environ

aux régimes bas à moyens (ouverture des gaz

1/4 à 1/2).

6. Remettre le moteur en marche et vérifier le

fonctionnement de la moto à toutes les vitesses.

Redémarrer la moto et rouler pendant 10 à 15

minutes environ. La moto est maintenant prête

pour la course.

ATTENTION:

Après le rodage ou avant chaque course, il est

indispensable de contrôler le bon serrage des

raccords et des fixations conformément aux

instructions de la section “POINTS DE VERI-

FICATION DES COUPLES DE SERRAGE”.

Resserrer au couple requis tout élément des-

serré.

Si l’une quelconque des pièces suivantes a été

remplacée, un nouveau rodage est nécessaire.

CYLINDRE ET VILEBREQUIN:

Roder pendant environ une heure.

PISTON, SEGMENT, SOUPAPES, ARBRES

A CAMES ET PIGNONS:

Ces pièces nécessitent un rodage d’environ 30

minutes à une ouverture des gaz de 1/2 au

maximum. Surveiller attentivement l’état du

moteur pendant le rodage.

1 - 17

Page 64 of 646

GEN

INFO

1 - 18

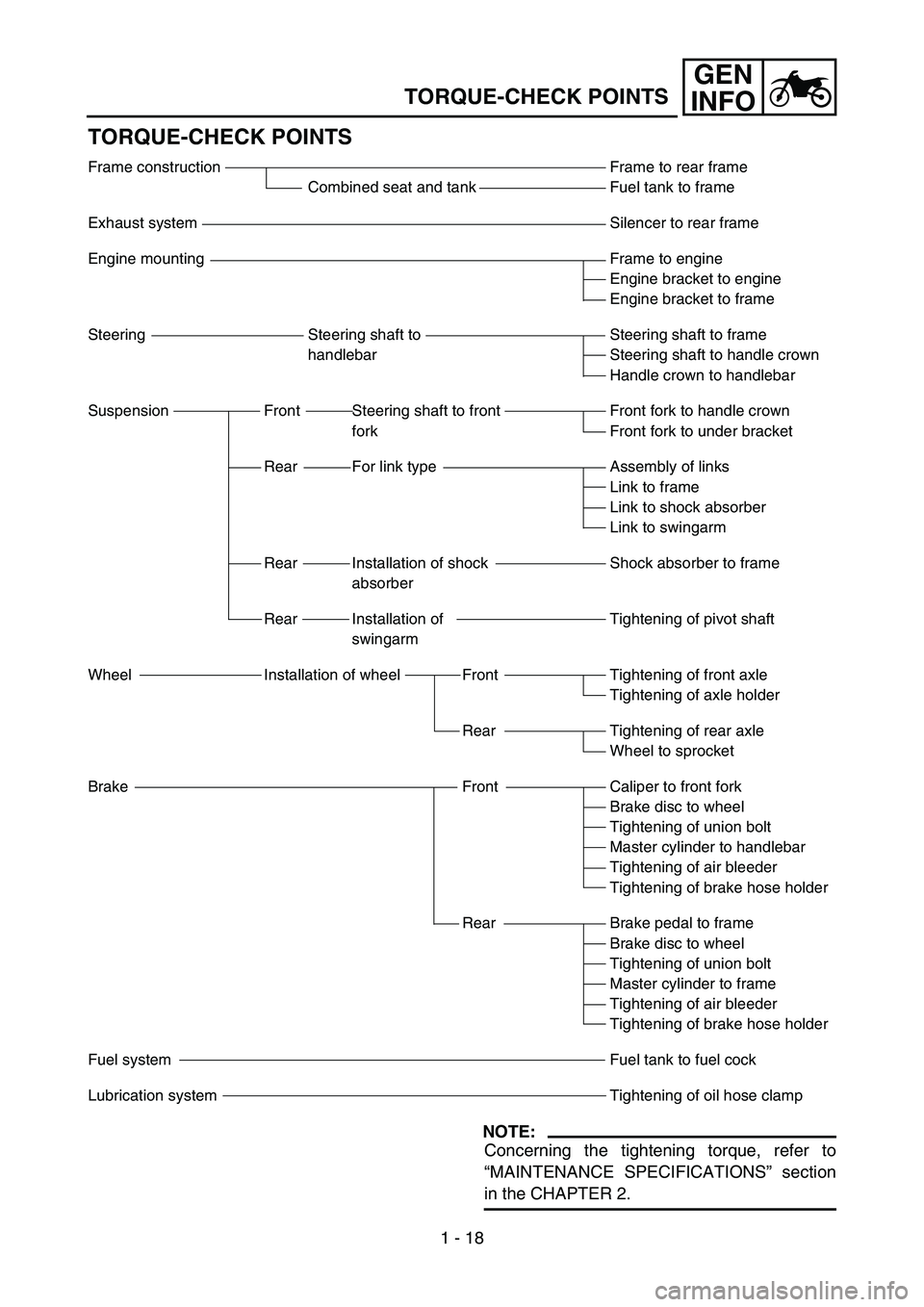

TORQUE-CHECK POINTS

TORQUE-CHECK POINTS

NOTE:

Concerning the tightening torque, refer to

“MAINTENANCE SPECIFICATIONS” section

in the CHAPTER 2.

Frame to rear frame

Fuel tank to frame

Silencer to rear frame

Frame to engine

Engine bracket to engine

Engine bracket to frame

Steering shaft to frame

Steering shaft to handle crown

Handle crown to handlebar

Front fork to handle crown

Front fork to under bracket

Assembly of links

Link to frame

Link to shock absorber

Link to swingarm

Shock absorber to frame

Tightening of pivot shaft

Tightening of front axle

Tightening of axle holder

Tightening of rear axle

Wheel to sprocket

Caliper to front fork

Brake disc to wheel

Tightening of union bolt

Master cylinder to handlebar

Tightening of air bleeder

Tightening of brake hose holder

Brake pedal to frame

Brake disc to wheel

Tightening of union bolt

Master cylinder to frame

Tightening of air bleeder

Tightening of brake hose holder

Fuel tank to fuel cock

Tightening of oil hose clamp Frame construction

Combined seat and tank

Exhaust system

Engine mounting

Steering Steering shaft to

handlebar

Suspension Front Steering shaft to front

fork

Rear For link type

Rear Installation of shock

absorber

Rear Installation of

swingarm

Wheel Installation of wheel Front

Rear

Brake Front

Rear

Fuel system

Lubrication system

Page 68 of 646

1 - 19

GEN

INFO

CLEANING AND STORAGE

EC1B0000

CLEANING AND STORAGE

EC1B1000

CLEANING

Frequent cleaning of your machine will

enhance its appearance, maintain good overall

performance, and extend the life of many com-

ponents.

1. Before washing the machine, block off the

end of the exhaust pipe to prevent water

from entering. A plastic bag secured with a

rubber band may be used for this purpose.

2. If the engine is excessively greasy, apply

some degreaser to it with a paint brush. Do

not apply degreaser to the chain, sprock-

ets, or wheel axles.

3. Rinse the dirt and degreaser off with a gar-

den hose; use only enough pressure to do

the job.

CAUTION:

Excessive hose pressure may cause water

seepage and contamination of wheel bear-

ings, front forks, brakes and transmission

seals. Many expensive repair bills have

resulted from improper high pressure

detergent applications such as those avail-

able in coin-operated car washers.

4. After the majority of the dirt has been

hosed off, wash all surfaces with warm

water and a mild detergent. Use an old

toothbrush to clean hard-to-reach places.

5. Rinse the machine off immediately with

clean water, and dry all surfaces with a soft

towel or cloth.

6. Immediately after washing, remove excess

water from the chain with a paper towel

and lubricate the chain to prevent rust.

7. Clean the seat with a vinyl upholstery

cleaner to keep the cover pliable and

glossy.

Page 70 of 646

1 - 20

GEN

INFO

CLEANING AND STORAGE

8. Automotive wax may be applied to all

painted or chromed surfaces. Avoid combi-

nation cleaner-waxes, as they may contain

abrasives.

9. After completing the above, start the

engine and allow it to idle for several min-

utes.

EC1B2001

STORAGE

If your machine is to be stored for 60 days or

more, some preventive measures must be

taken to avoid deterioration. After cleaning the

machine thoroughly, prepare it for storage as

follows:

1. Drain the fuel tank, fuel lines, and the car-

buretor float bowl.

2. Remove the spark plug, pour a tablespoon

of SAE 10W-30 motor oil in the spark plug

hole, and reinstall the plug. With the engine

stop switch pushed in, kick the engine over

several times to coat the cylinder walls with

oil.

3. Remove the drive chain, clean it thoroughly

with solvent, and lubricate it. Reinstall the

chain or store it in a plastic bag tied to the

frame.

4. Lubricate all control cables.

5. Block the frame up to raise the wheels off

the ground.

6. Tie a plastic bag over the exhaust pipe out-

let to prevent moisture from entering.

7. If the machine is to be stored in a humid or

salt-air environment, coat all exposed

metal surfaces with a film of light oil. Do not

apply oil to rubber parts or the seat cover.

NOTE:

Make any necessary repairs before the

machine is stored.

Page 72 of 646

SPEC

2 - 1

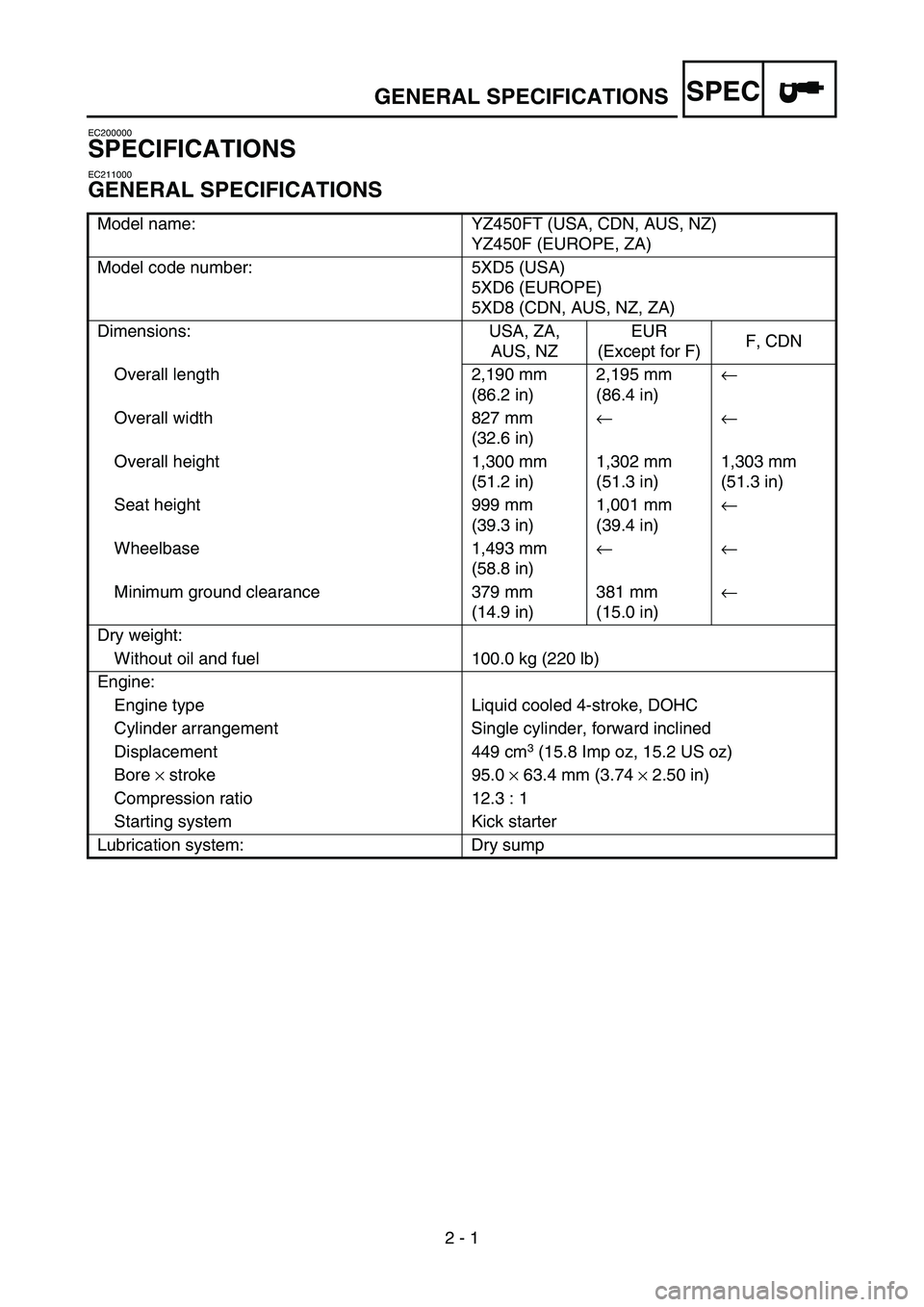

EC200000

SPECIFICATIONS

EC211000

GENERAL SPECIFICATIONS

Model name: YZ450FT (USA, CDN, AUS, NZ)

YZ450F (EUROPE, ZA)

Model code number: 5XD5 (USA)

5XD6 (EUROPE)

5XD8 (CDN, AUS, NZ, ZA)

Dimensions: USA, ZA,

AUS, NZEUR

(Except for F)F, CDN

Overall length 2,190 mm

(86.2 in)2,195 mm

(86.4 in)←

Overall width 827 mm

(32.6 in)← ←

Overall height 1,300 mm

(51.2 in)1,302 mm

(51.3 in)1,303 mm

(51.3 in)

Seat height 999 mm

(39.3 in)1,001 mm

(39.4 in)←

Wheelbase 1,493 mm

(58.8 in)← ←

Minimum ground clearance 379 mm

(14.9 in)381 mm

(15.0 in)←

Dry weight:

Without oil and fuel 100.0 kg (220 lb)

Engine:

Engine type Liquid cooled 4-stroke, DOHC

Cylinder arrangement Single cylinder, forward inclined

Displacement 449 cm

3 (15.8 Imp oz, 15.2 US oz)

Bore × stroke 95.0 × 63.4 mm (3.74 × 2.50 in)

Compression ratio 12.3 : 1

Starting system Kick starter

Lubrication system: Dry sump

GENERAL SPECIFICATIONS

Page 73 of 646

SPEC

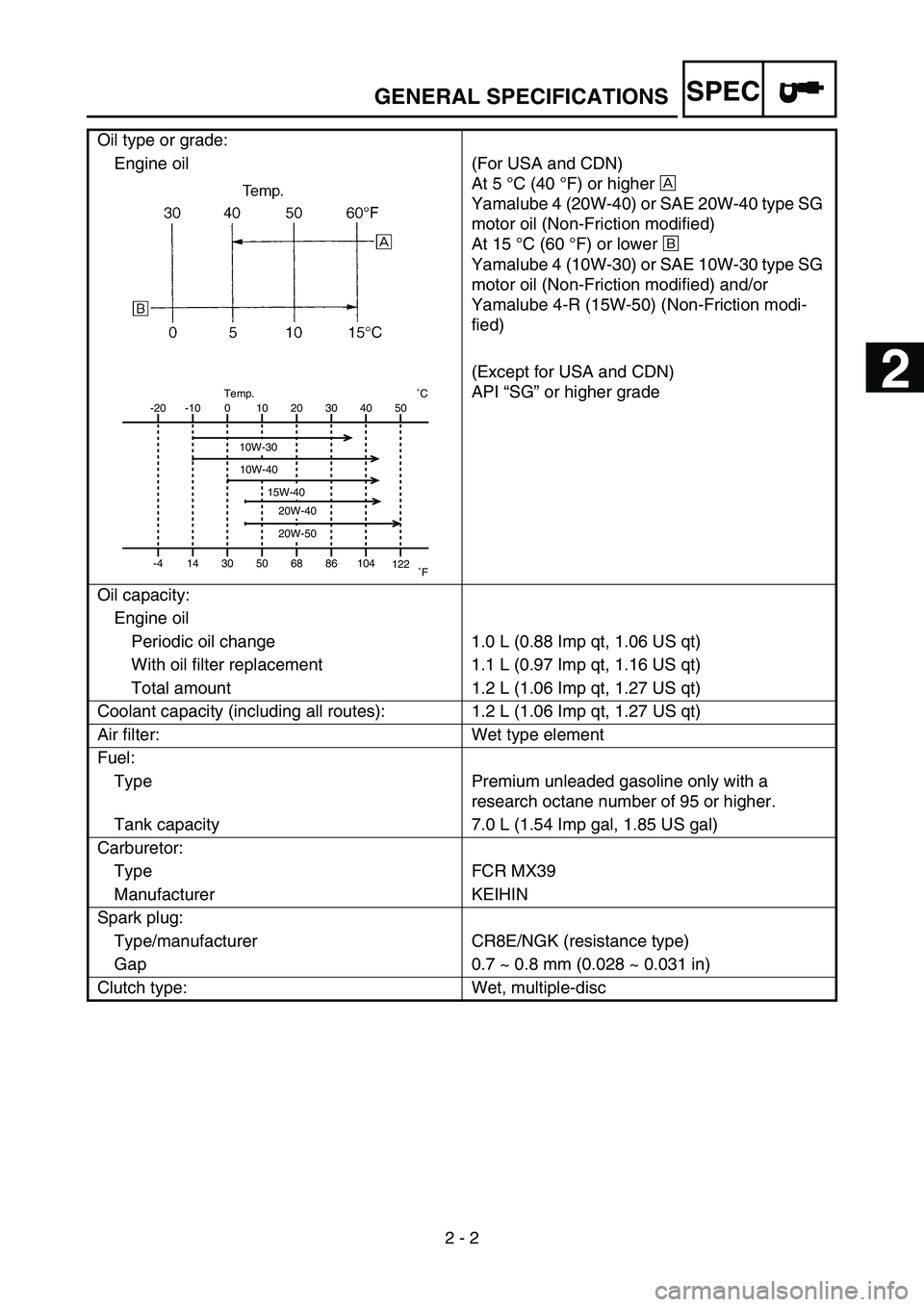

2 - 2 Oil type or grade:

Engine oil (For USA and CDN)

At 5 °C (40 °F) or higher È

Yamalube 4 (20W-40) or SAE 20W-40 type SG

motor oil (Non-Friction modified)

At 15 °C (60 °F) or lower É

Yamalube 4 (10W-30) or SAE 10W-30 type SG

motor oil (Non-Friction modified) and/or

Yamalube 4-R (15W-50) (Non-Friction modi-

fied)

(Except for USA and CDN)

API “SG” or higher grade

Oil capacity:

Engine oil

Periodic oil change 1.0 L (0.88 Imp qt, 1.06 US qt)

With oil filter replacement 1.1 L (0.97 Imp qt, 1.16 US qt)

Total amount 1.2 L (1.06 Imp qt, 1.27 US qt)

Coolant capacity (including all routes): 1.2 L (1.06 Imp qt, 1.27 US qt)

Air filter: Wet type element

Fuel:

Type Premium unleaded gasoline only with a

research octane number of 95 or higher.

Tank capacity 7.0 L (1.54 Imp gal, 1.85 US gal)

Carburetor:

Type FCR MX39

Manufacturer KEIHIN

Spark plug:

Type/manufacturer CR8E/NGK (resistance type)

Gap 0.7 ~ 0.8 mm (0.028 ~ 0.031 in)

Clutch type: Wet, multiple-disc

-20

-4-10

140

3010

5020

6830

8640 50

104

122 ˚CTemp.

˚F

10W-30

10W-40

20W-40

20W-50

15W-40

GENERAL SPECIFICATIONS

2

Page 75 of 646

SPEC

2 - 4

MAINTENANCE SPECIFICATIONS

ENGINE

Item Standard Limit

Cylinder head:

Warp limit ---- 0.05 mm

(0.002 in)

Cylinder:

Bore size 95.00 ~ 95.01 mm

(3.7402 ~ 3.7406 in)----

Out of round limit ---- 0.05 mm

(0.002 in)

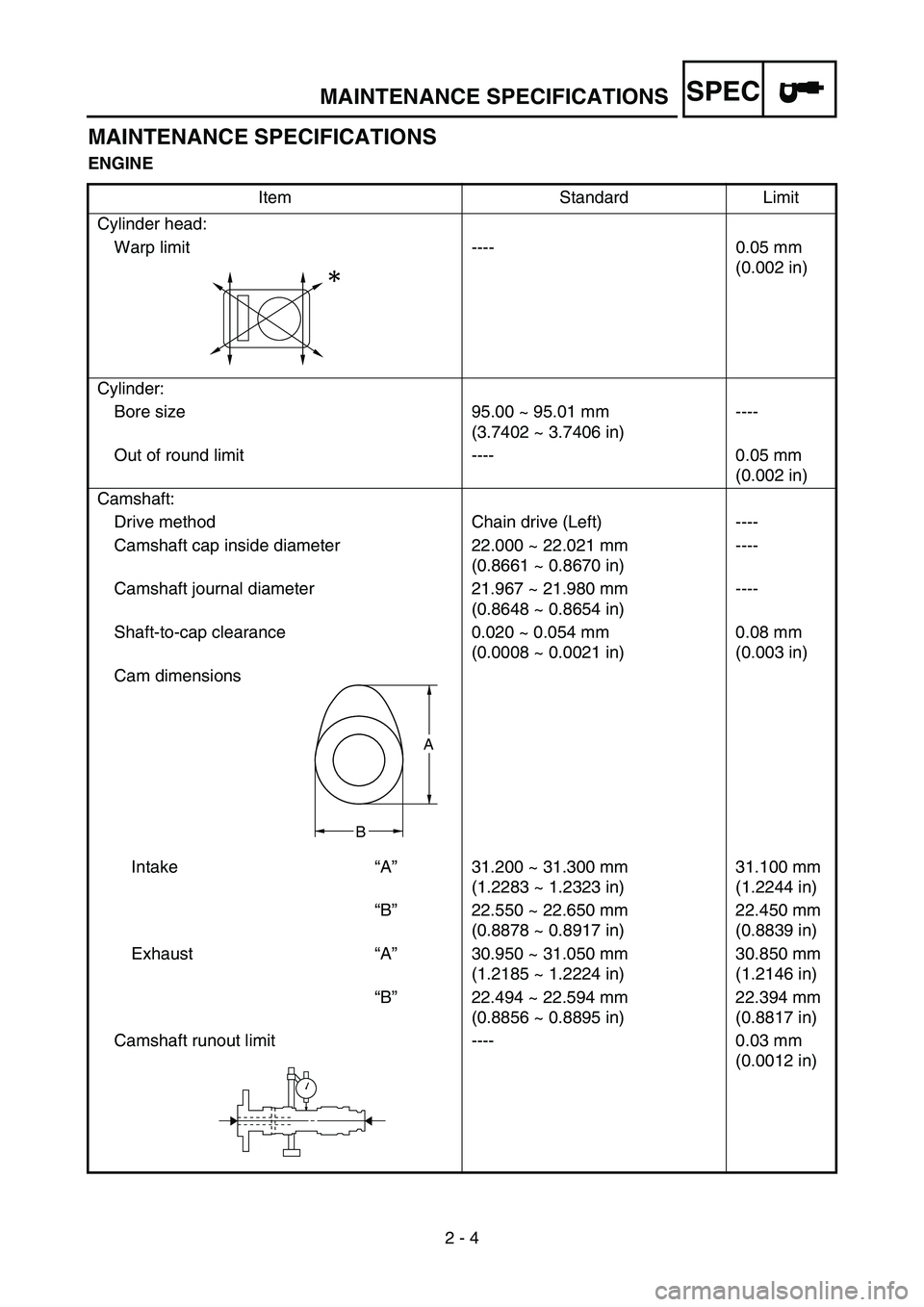

Camshaft:

Drive method Chain drive (Left) ----

Camshaft cap inside diameter 22.000 ~ 22.021 mm

(0.8661 ~ 0.8670 in)----

Camshaft journal diameter 21.967 ~ 21.980 mm

(0.8648 ~ 0.8654 in)----

Shaft-to-cap clearance 0.020 ~ 0.054 mm

(0.0008 ~ 0.0021 in)0.08 mm

(0.003 in)

Cam dimensions

Intake“A”31.200 ~ 31.300 mm

(1.2283 ~ 1.2323 in)31.100 mm

(1.2244 in)

“B”22.550 ~ 22.650 mm

(0.8878 ~ 0.8917 in)22.450 mm

(0.8839 in)

Exhaust“A”30.950 ~ 31.050 mm

(1.2185 ~ 1.2224 in)30.850 mm

(1.2146 in)

“B”22.494 ~ 22.594 mm

(0.8856 ~ 0.8895 in)22.394 mm

(0.8817 in)

Camshaft runout limit ---- 0.03 mm

(0.0012 in)

A

B

MAINTENANCE SPECIFICATIONS

Page 79 of 646

SPEC

2 - 8 Clutch:

Friction plate thickness 2.92 ~ 3.08 mm

(0.115 ~ 0.121 in)2.8 mm

(0.110 in)

Quantity 9 ----

Clutch plate thickness 1.1 ~ 1.3 mm (0.043 ~ 0.051 in) ----

Quantity 8 ----

Warp limit ---- 0.1 mm

(0.004 in)

Clutch spring free length 47.8 mm (1.88 in) 46.8 mm

(1.84 in)

Quantity 6 ----

Clutch housing thrust clearance 0.10 ~ 0.35 mm

(0.0039 ~ 0.0138 in)----

Clutch housing radial clearance 0.010 ~ 0.044 mm

(0.0004 ~ 0.0017 in)----

Clutch release method Inner push, cam push ----

Shifter:

Shifter type Cam drum and guide bar ----

Guide bar bending limit ---- 0.05 mm

(0.002 in)

Kick starter:

Type Ratchet type ----

Carburetor:

I.D. mark 5XD5 50 ----

Main jet (M.J) #165 ----

Main air jet (M.A.J)ø2.0 ----

Jet needle - clip position (J.N) NFLR-4 ----

Cutaway (C.A) 1.5 ----

Pilot jet (P.J) #45 ----

Pilot air jet (P.A.J) #100 ----

Pilot outlet (P.O)ø0.9 ----

Pilot screw (example) (P.S) 1-3/4 ----

Bypass (B.P)ø1.0 ----

Valve seat size (V.S)ø3.8 ----

Starter jet (G.S) #72 ----

Leak jet (Acc. P) #40 ----

Float height (F.H) 8 mm (0.31 in) ----

Engine idle speed 1,900 ~ 2,100 r/min ----

Intake vacuum 28.0 ~ 33.3 kPa

(210 ~ 250 mmHg,

8.27 ~ 9.84 inHg)----

Hot starter lever free play 3 ~ 6 mm (0.12 ~ 0.24 in) ----Item Standard Limit

MAINTENANCE SPECIFICATIONS

Page 82 of 646

SPEC

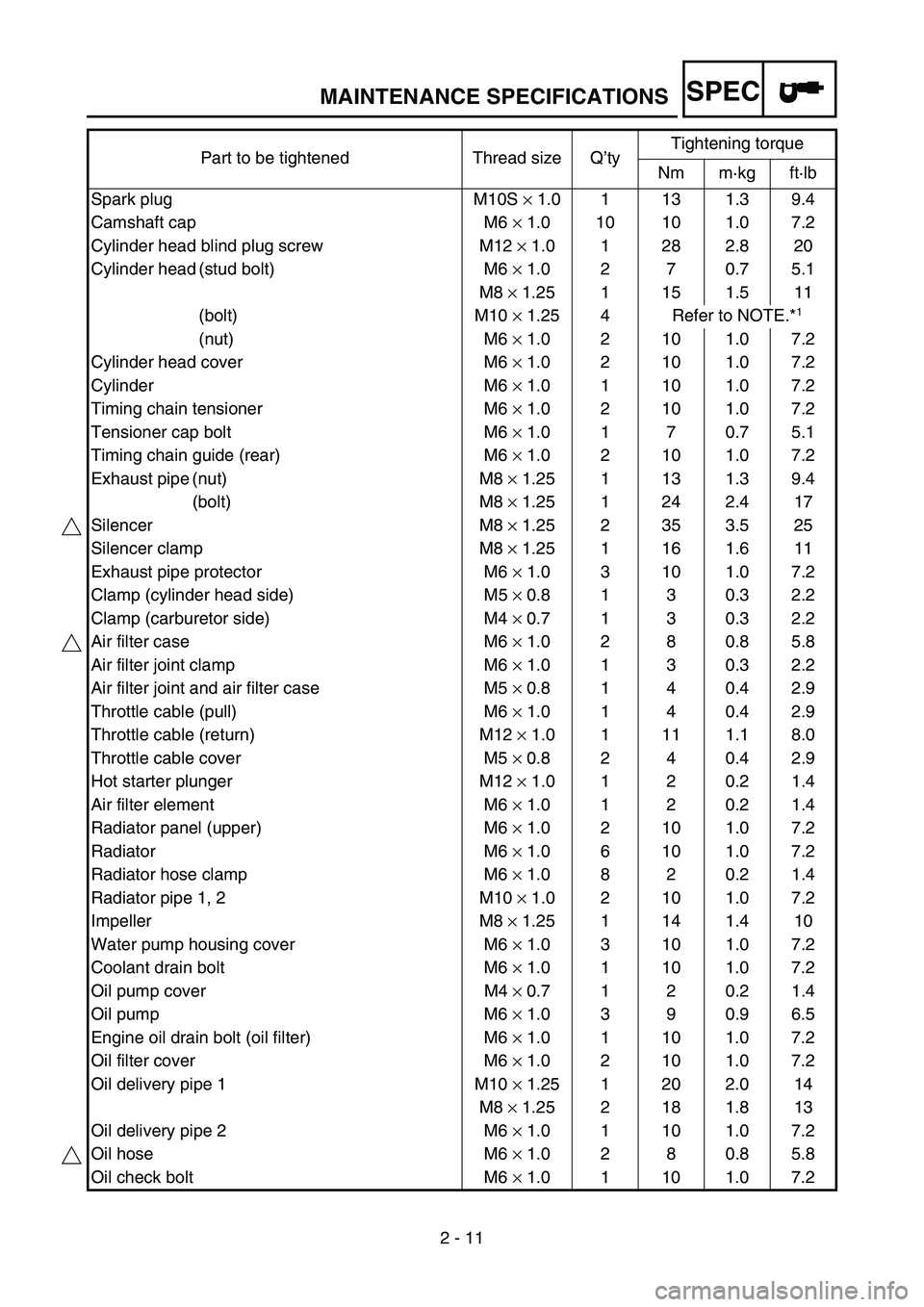

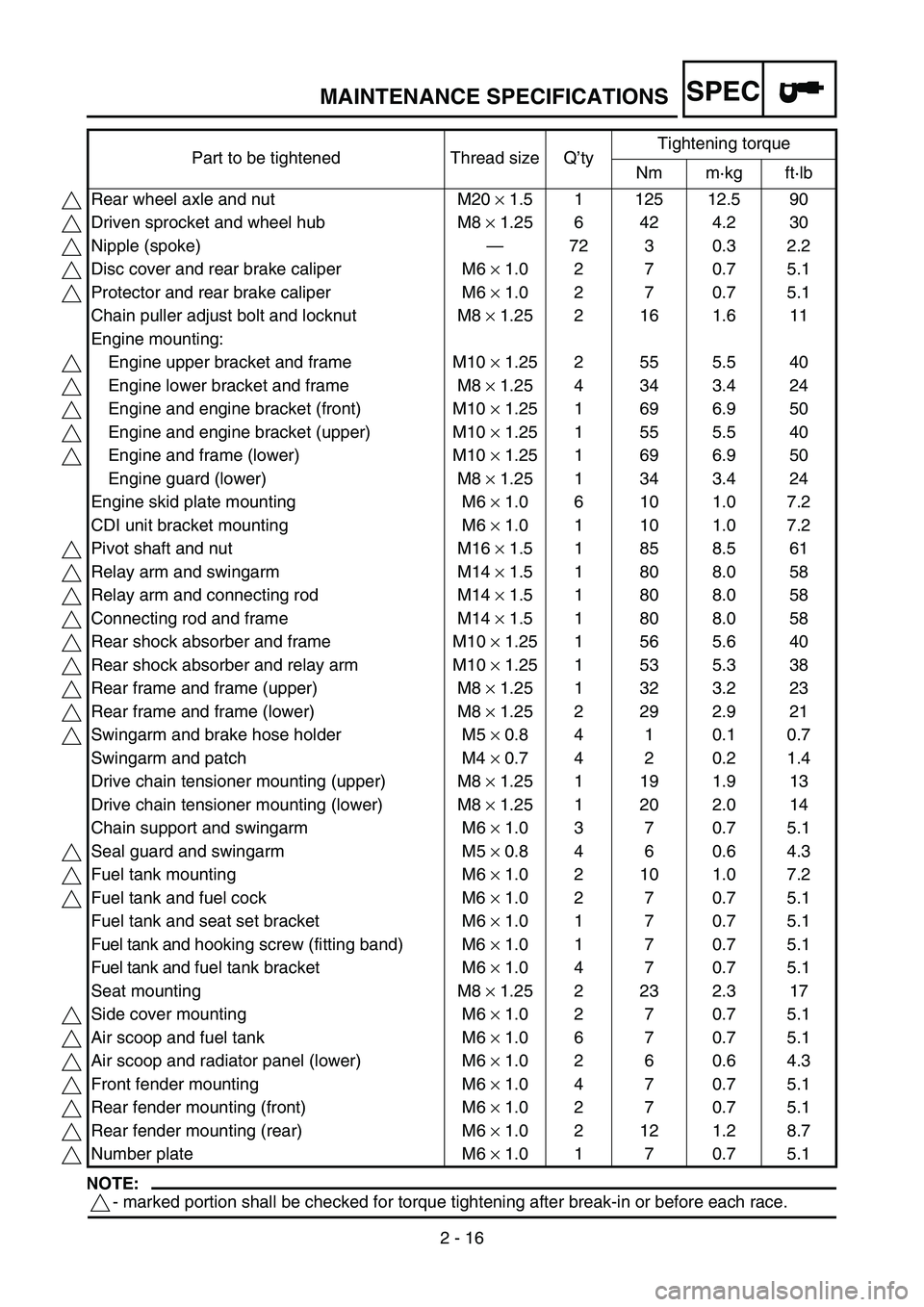

2 - 11 Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Spark plug M10S × 1.0 1 13 1.3 9.4

Camshaft cap M6 × 1.0 10 10 1.0 7.2

Cylinder head blind plug screw M12 × 1.0 1 28 2.8 20

Cylinder head (stud bolt) M6 × 1.0 2 7 0.7 5.1

M8 × 1.25 1 15 1.5 11

(bolt) M10 × 1.25 4 Refer to NOTE.*

1

(nut) M6 × 1.0 2 10 1.0 7.2

Cylinder head cover M6 × 1.0 2 10 1.0 7.2

Cylinder M6 × 1.0 1 10 1.0 7.2

Timing chain tensioner M6 × 1.0 2 10 1.0 7.2

Tensioner cap bolt M6 × 1.0 1 7 0.7 5.1

Timing chain guide (rear) M6 × 1.0 2 10 1.0 7.2

Exhaust pipe (nut) M8 × 1.25 1 13 1.3 9.4

(bolt) M8 × 1.25 1 24 2.4 17

Silencer M8 × 1.25 2 35 3.5 25

Silencer clamp M8 × 1.25 1 16 1.6 11

Exhaust pipe protector M6 × 1.0 3 10 1.0 7.2

Clamp (cylinder head side) M5 × 0.8 1 3 0.3 2.2

Clamp (carburetor side) M4 × 0.7 1 3 0.3 2.2

Air filter case M6 × 1.0 2 8 0.8 5.8

Air filter joint clamp M6 × 1.0 1 3 0.3 2.2

Air filter joint and air filter case M5 × 0.8 1 4 0.4 2.9

Throttle cable (pull) M6 × 1.0 1 4 0.4 2.9

Throttle cable (return) M12 × 1.0 1 11 1.1 8.0

Throttle cable cover M5 × 0.8 2 4 0.4 2.9

Hot starter plunger M12 × 1.0 1 2 0.2 1.4

Air filter element M6 × 1.0 1 2 0.2 1.4

Radiator panel (upper) M6 × 1.0 2 10 1.0 7.2

Radiator M6 × 1.0 6 10 1.0 7.2

Radiator hose clamp M6 × 1.0 8 2 0.2 1.4

Radiator pipe 1, 2 M10 × 1.0 2 10 1.0 7.2

Impeller M8 × 1.25 1 14 1.4 10

Water pump housing cover M6 × 1.0 3 10 1.0 7.2

Coolant drain bolt M6 × 1.0 1 10 1.0 7.2

Oil pump cover M4 × 0.7 1 2 0.2 1.4

Oil pump M6 × 1.0 3 9 0.9 6.5

Engine oil drain bolt (oil filter) M6 × 1.0 1 10 1.0 7.2

Oil filter cover M6 × 1.0 2 10 1.0 7.2

Oil delivery pipe 1 M10 × 1.25 1 20 2.0 14

M8 × 1.25 2 18 1.8 13

Oil delivery pipe 2 M6 × 1.0 1 10 1.0 7.2

Oil hose M6 × 1.0 2 8 0.8 5.8

Oil check bolt M6 × 1.0 1 10 1.0 7.2

MAINTENANCE SPECIFICATIONS

Page 87 of 646

SPEC

2 - 16

NOTE:

- marked portion shall be checked for torque tightening after break-in or before each race.Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Rear wheel axle and nut M20 × 1.5 1 125 12.5 90

Driven sprocket and wheel hub M8 × 1.25 6 42 4.2 30

Nipple (spoke)—72 3 0.3 2.2

Disc cover and rear brake caliper M6 × 1.0 2 7 0.7 5.1

Protector and rear brake caliper M6 × 1.0 2 7 0.7 5.1

Chain puller adjust bolt and locknut M8 × 1.25 2 16 1.6 11

Engine mounting:

Engine upper bracket and frame M10 × 1.25 2 55 5.5 40

Engine lower bracket and frame M8 × 1.25 4 34 3.4 24

Engine and engine bracket (front) M10 × 1.25 1 69 6.9 50

Engine and engine bracket (upper) M10 × 1.25 1 55 5.5 40

Engine and frame (lower) M10 × 1.25 1 69 6.9 50

Engine guard (lower) M8 × 1.25 1 34 3.4 24

Engine skid plate mounting M6 × 1.0 6 10 1.0 7.2

CDI unit bracket mounting M6 × 1.0 1 10 1.0 7.2

Pivot shaft and nut M16 × 1.5 1 85 8.5 61

Relay arm and swingarm M14 × 1.5 1 80 8.0 58

Relay arm and connecting rod M14 × 1.5 1 80 8.0 58

Connecting rod and frame M14 × 1.5 1 80 8.0 58

Rear shock absorber and frame M10 × 1.25 1 56 5.6 40

Rear shock absorber and relay arm M10 × 1.25 1 53 5.3 38

Rear frame and frame (upper) M8 × 1.25 1 32 3.2 23

Rear frame and frame (lower) M8 × 1.25 2 29 2.9 21

Swingarm and brake hose holder M5 × 0.8 4 1 0.1 0.7

Swingarm and patch M4 × 0.7 4 2 0.2 1.4

Drive chain tensioner mounting (upper) M8 × 1.25 1 19 1.9 13

Drive chain tensioner mounting (lower) M8 × 1.25 1 20 2.0 14

Chain support and swingarm M6 × 1.0 3 7 0.7 5.1

Seal guard and swingarm M5 × 0.8 4 6 0.6 4.3

Fuel tank mounting M6 × 1.0 2 10 1.0 7.2

Fuel tank and fuel cock M6 × 1.0 2 7 0.7 5.1

Fuel tank and seat set bracket M6 × 1.0 1 7 0.7 5.1

Fuel tank and hooking screw (fitting band) M6 × 1.0 1 7 0.7 5.1

Fuel tank and fuel tank bracket M6 × 1.0 4 7 0.7 5.1

Seat mounting M8 × 1.25 2 23 2.3 17

Side cover mounting M6 × 1.0 2 7 0.7 5.1

Air scoop and fuel tank M6 × 1.0 6 7 0.7 5.1

Air scoop and radiator panel (lower) M6 × 1.0 2 6 0.6 4.3

Front fender mounting M6 × 1.0 4 7 0.7 5.1

Rear fender mounting (front) M6 × 1.0 2 7 0.7 5.1

Rear fender mounting (rear) M6 × 1.0 2 12 1.2 8.7

Number plate M6 × 1.0 1 7 0.7 5.1

MAINTENANCE SPECIFICATIONS