engine YAMAHA YZ450F 2005 Manual Online

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: YZ450F, Model: YAMAHA YZ450F 2005Pages: 646, PDF Size: 16.06 MB

Page 402 of 646

4 - 81

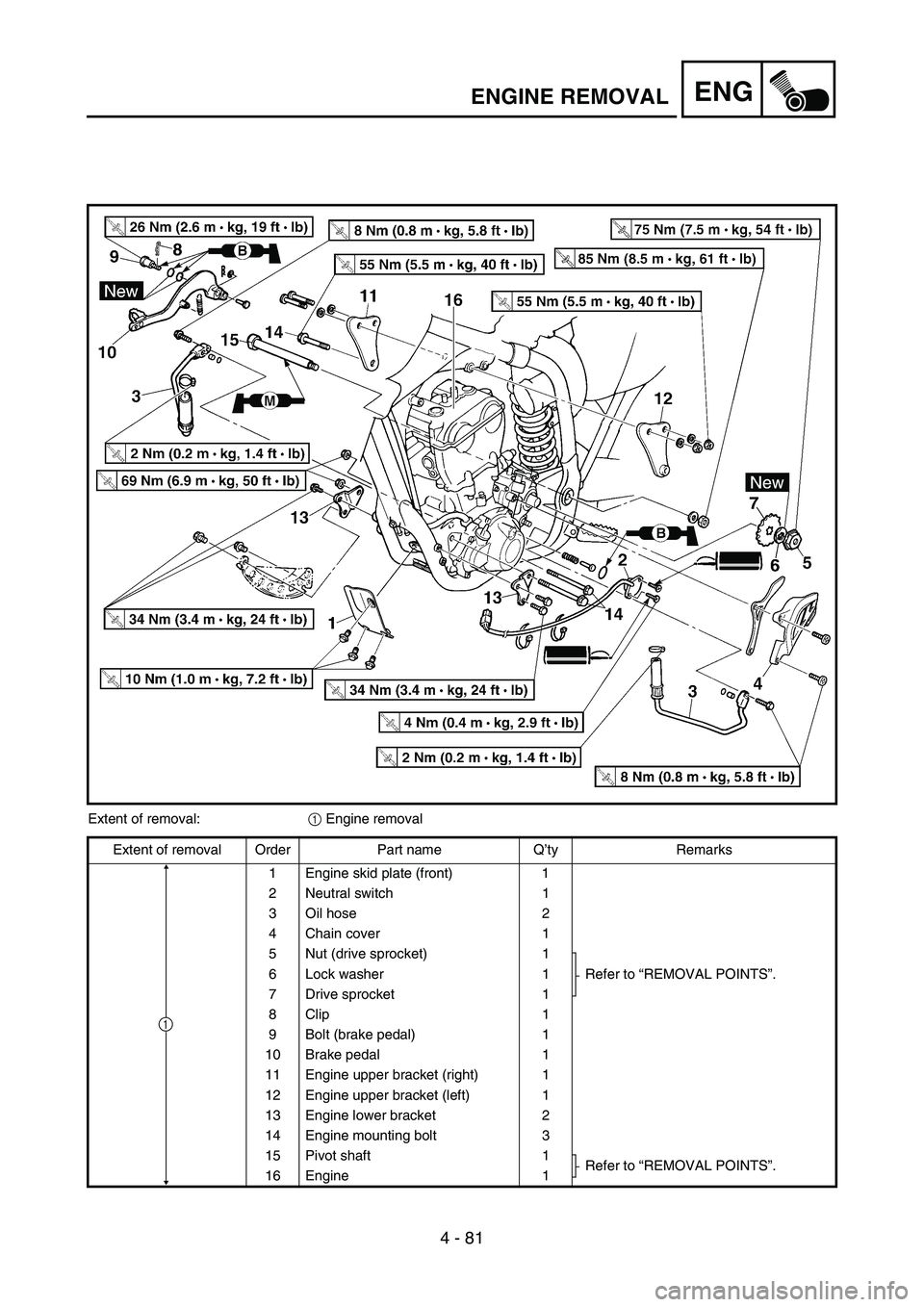

ENGENGINE REMOVAL

Extent of removal:

1 Engine removal

Extent of removal Order Part name Q’ty Remarks

1 Engine skid plate (front) 1

2 Neutral switch 1

3 Oil hose 2

4 Chain cover 1

5 Nut (drive sprocket) 1

Refer to “REMOVAL POINTS”. 6 Lock washer 1

7 Drive sprocket 1

8Clip 1

9 Bolt (brake pedal) 1

10 Brake pedal 1

11 Engine upper bracket (right) 1

12 Engine upper bracket (left) 1

13 Engine lower bracket 2

14 Engine mounting bolt 3

15 Pivot shaft 1

Refer to “REMOVAL POINTS”.

16 Engine 1

1

Page 404 of 646

4 - 82

ENGENGINE REMOVAL

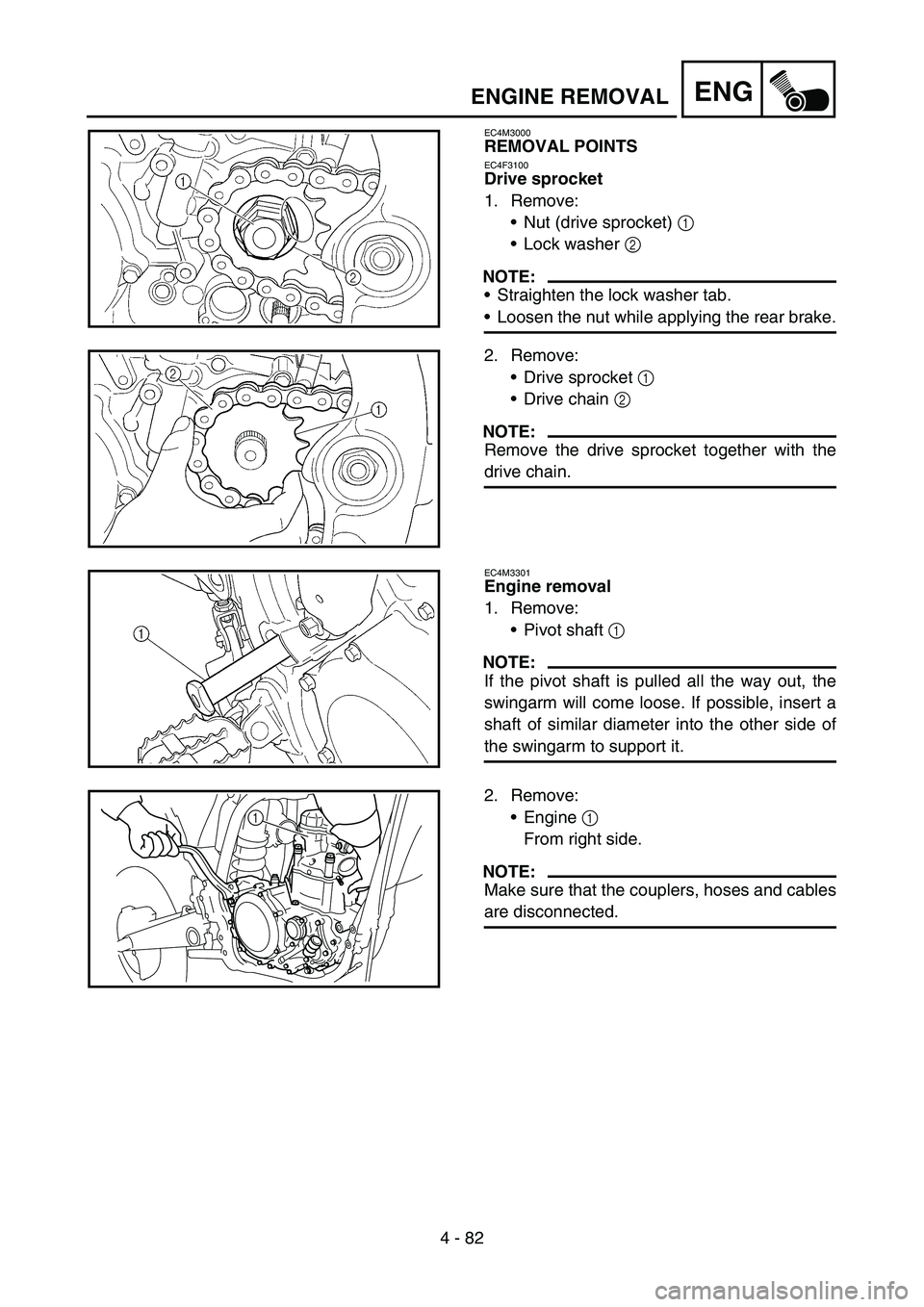

EC4M3000

REMOVAL POINTS

EC4F3100

Drive sprocket

1. Remove:

Nut (drive sprocket) 1

Lock washer 2

NOTE:

Straighten the lock washer tab.

Loosen the nut while applying the rear brake.

2. Remove:

Drive sprocket 1

Drive chain 2

NOTE:

Remove the drive sprocket together with the

drive chain.

EC4M3301

Engine removal

1. Remove:

Pivot shaft 1

NOTE:

If the pivot shaft is pulled all the way out, the

swingarm will come loose. If possible, insert a

shaft of similar diameter into the other side of

the swingarm to support it.

2. Remove:

Engine 1

From right side.

NOTE:

Make sure that the couplers, hoses and cables

are disconnected.

1

Page 406 of 646

4 - 83

ENGENGINE REMOVAL

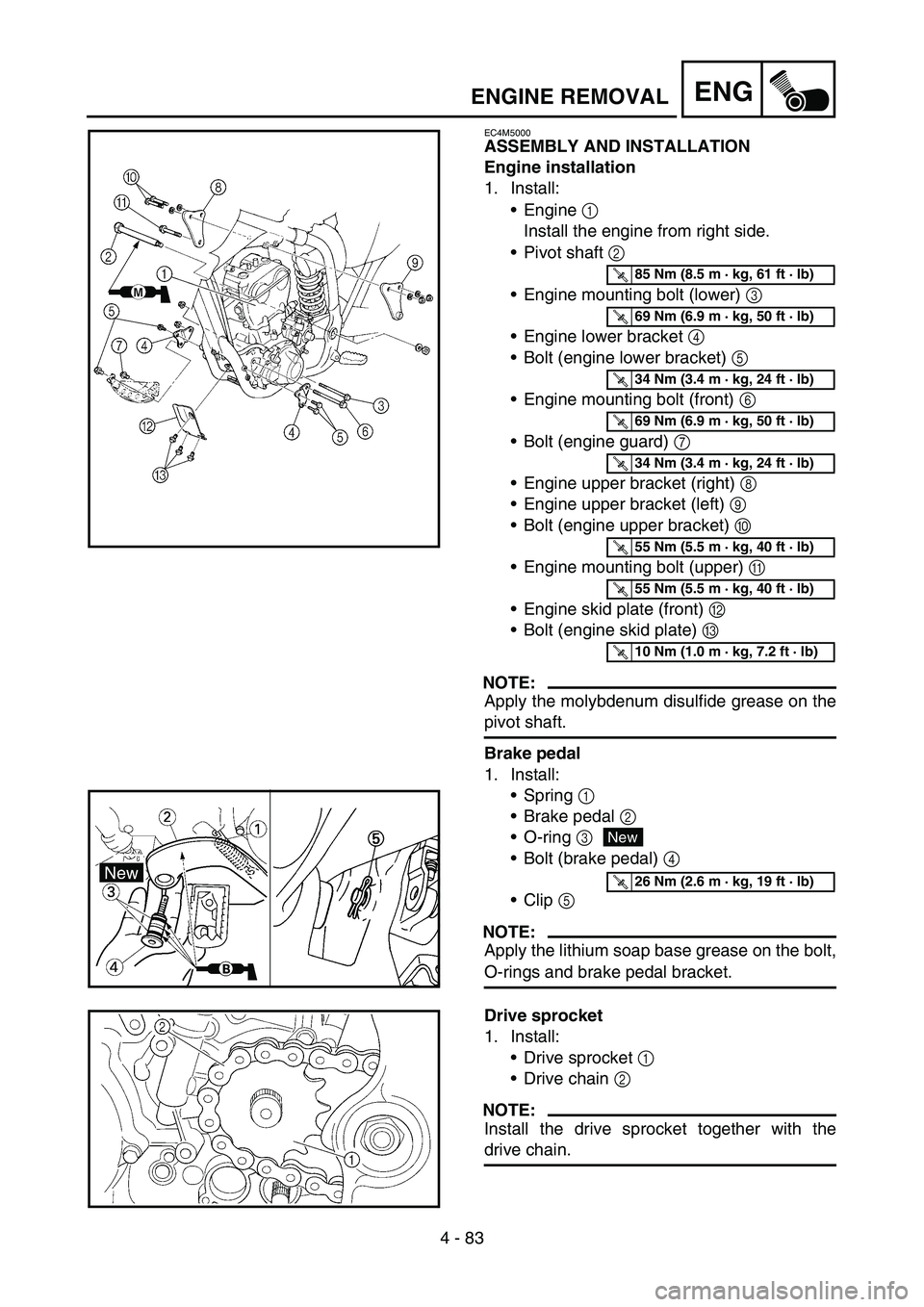

EC4M5000

ASSEMBLY AND INSTALLATION

Engine installation

1. Install:

Engine 1

Install the engine from right side.

Pivot shaft 2

Engine mounting bolt (lower) 3

Engine lower bracket 4

Bolt (engine lower bracket) 5

Engine mounting bolt (front) 6

Bolt (engine guard) 7

Engine upper bracket (right) 8

Engine upper bracket (left) 9

Bolt (engine upper bracket) 0

Engine mounting bolt (upper) A

Engine skid plate (front) B

Bolt (engine skid plate) C

NOTE:

Apply the molybdenum disulfide grease on the

pivot shaft.

Brake pedal

1. Install:

Spring 1

Brake pedal 2

O-ring 3

Bolt (brake pedal) 4

Clip 5

NOTE:

Apply the lithium soap base grease on the bolt,

O-rings and brake pedal bracket.

T R..85 Nm (8.5 m · kg, 61 ft · lb)

T R..69 Nm (6.9 m · kg, 50 ft · lb)

T R..34 Nm (3.4 m · kg, 24 ft · lb)

T R..69 Nm (6.9 m · kg, 50 ft · lb)

T R..34 Nm (3.4 m · kg, 24 ft · lb)

T R..55 Nm (5.5 m · kg, 40 ft · lb)

T R..55 Nm (5.5 m · kg, 40 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

New

T R..26 Nm (2.6 m · kg, 19 ft · lb)

Drive sprocket

1. Install:

Drive sprocket 1

Drive chain 2

NOTE:

Install the drive sprocket together with the

drive chain.

Page 408 of 646

4 - 84

ENGENGINE REMOVAL

2. Install:

Lock washer 1

Nut (drive sprocket) 2

NOTE:

Tighten the nut while applying the rear brake.

New

T R..75 Nm (7.5 m · kg, 54 ft · lb)

3. Bend the lock washer tab to lock the nut.

4. Install:

Chain guide

Chain cover 1

Screw (chain cover) 2

21T R..8 Nm (0.8 m · kg, 5.8 ft · lb)

5. Install:

O-ring 1

Dowel pin 2

Oil hose 3

Bolt (oil hose) 4

NOTE:

Apply the lithium soap base grease on the O-

ring.

6. Install:

Spring 1

Pin 2

O-ring 3

Neutral switch 4

Screw (neutral switch) 5

NOTE:

Apply the lithium soap base grease on the O-

ring.

New

T R..8 Nm (0.8 m · kg, 5.8 ft · lb)

New

T R..4 Nm (0.4 m · kg, 2.9 ft · lb)

Page 410 of 646

4 - 85

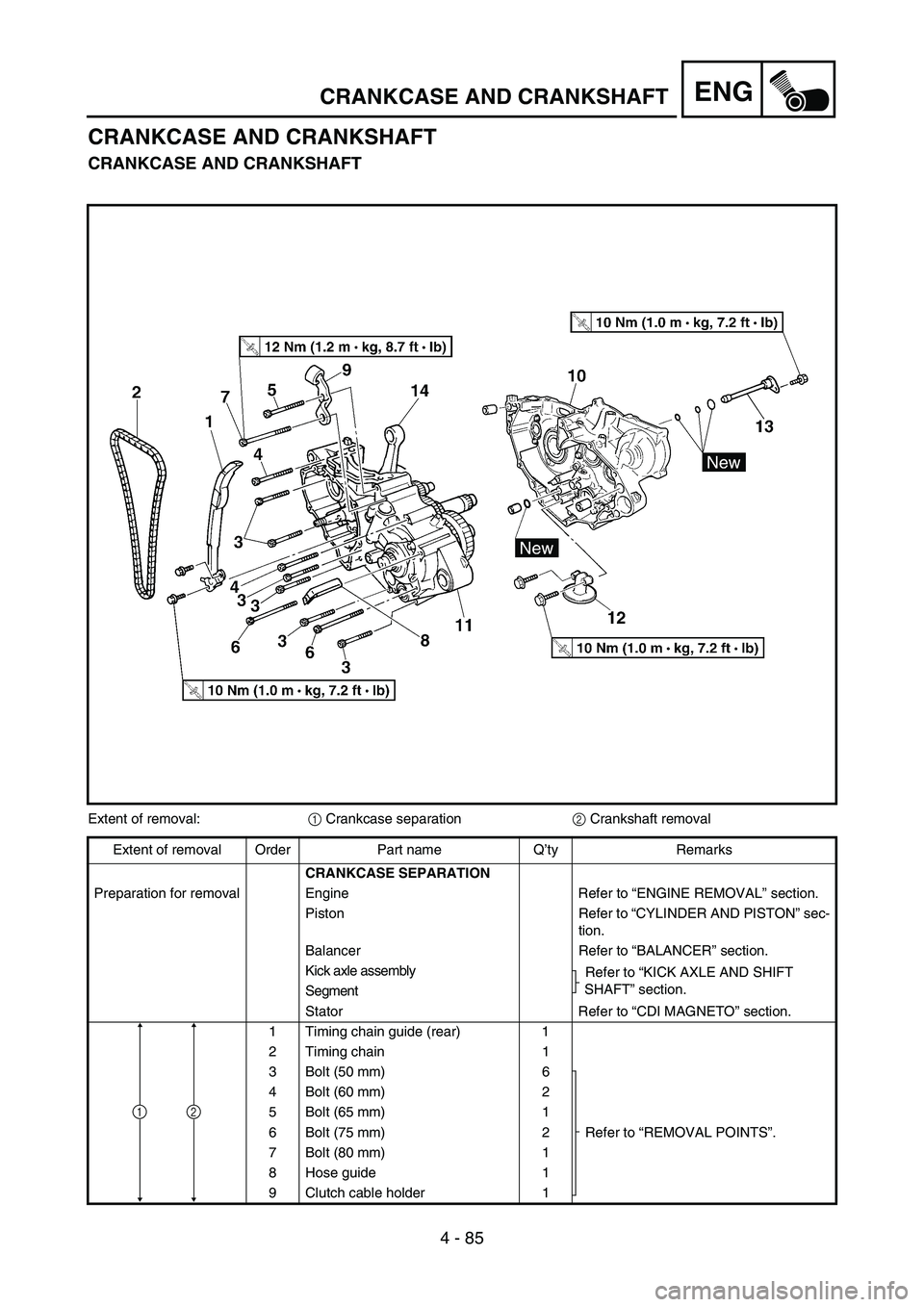

ENGCRANKCASE AND CRANKSHAFT

CRANKCASE AND CRANKSHAFT

CRANKCASE AND CRANKSHAFT

Extent of removal:

1 Crankcase separation

2 Crankshaft removal

Extent of removal Order Part name Q’ty Remarks

CRANKCASE SEPARATION

Preparation for removal Engine Refer to “ENGINE REMOVAL” section.

Piston Refer to “CYLINDER AND PISTON” sec-

tion.

Balancer Refer to “BALANCER” section.

Kick axle assembly

Refer to “KICK AXLE AND SHIFT

SHAFT” section.

Segment

Stator Refer to “CDI MAGNETO” section.

1 Timing chain guide (rear) 1

2 Timing chain 1

3 Bolt (50 mm) 6

Refer to “REMOVAL POINTS”. 4 Bolt (60 mm) 2

5 Bolt (65 mm) 1

6 Bolt (75 mm) 2

7 Bolt (80 mm) 1

8 Hose guide 1

9 Clutch cable holder 1

21

Page 416 of 646

4 - 88

ENGCRANKCASE AND CRANKSHAFT

REMOVAL POINTS

Crankcase

1. Separate:

Crankcase (right)

Crankcase (left)

Separation steps:

Remove the crankcase bolts, hose guide

and clutch cable holder.

NOTE:

Loosen each bolt 1/4 of a turn at a time and

after all the bolts are loosened, remove

them.

Remove the crankcase (right).

NOTE:

Place the crankcase with its left side

downward and split it by inserting a screw-

driver tip into the splitting slit a in the

crankcase.

Lift the crankcase (right) horizontally while

lightly patting the case splitting slit and

engine mounting boss using a soft ham-

mer, and leave the crankshaft and trans-

mission with the crankcase (left).

CAUTION:

Use soft hammer to tap on the case half.

Tap only on reinforced portions of case.

Do not tap on gasket mating surface.

Work slowly and carefully. Make sure the

case halves separate evenly. If one end

“hangs up”, take pressure off the push

screw, realign, and start over. If the

cases do not separate, check for a

remaining case screw or fitting. Do not

force.

Remove the dowel pins and O-ring.

a

Page 418 of 646

4 - 89

ENGCRANKCASE AND CRANKSHAFT

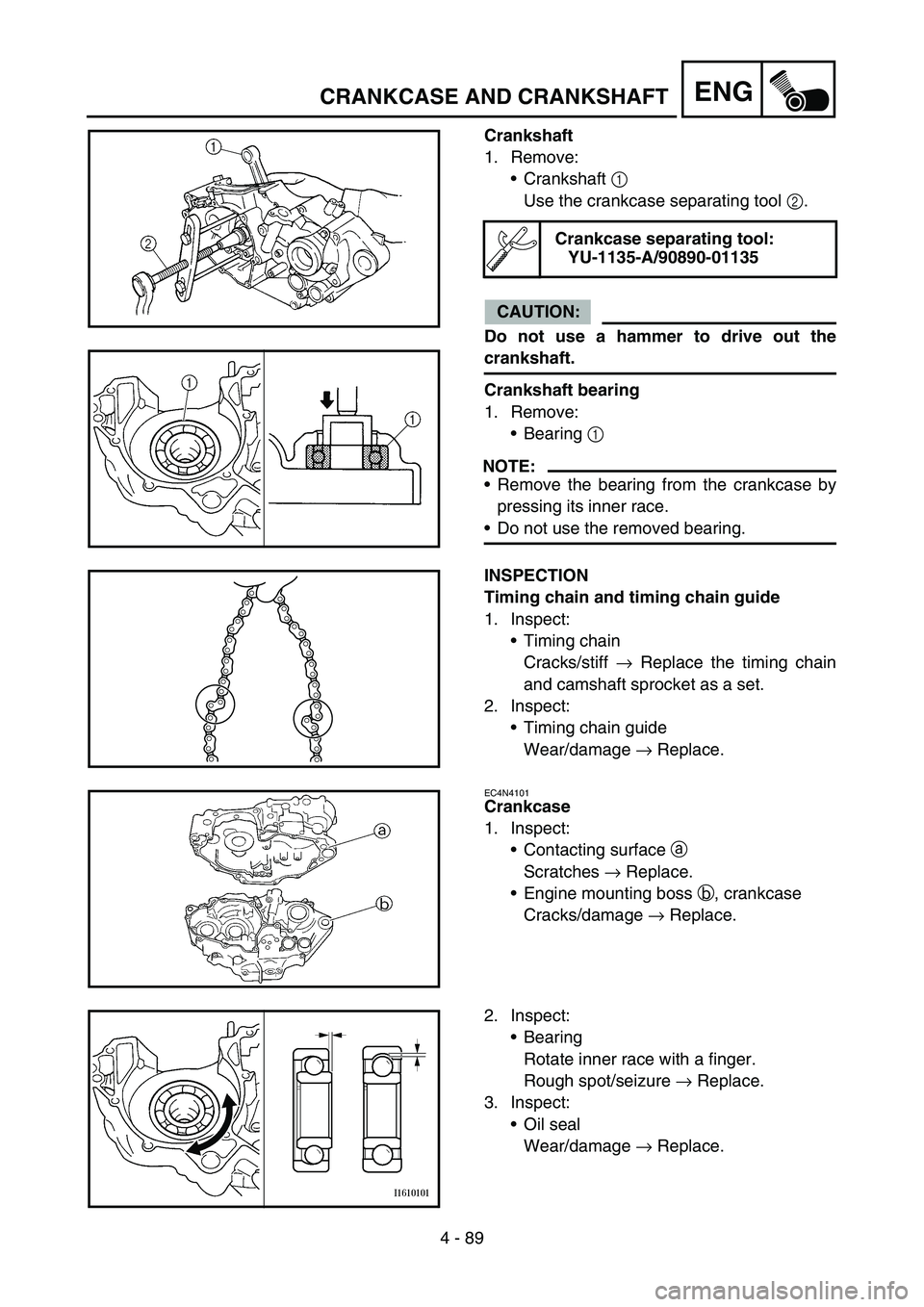

Crankshaft

1. Remove:

Crankshaft 1

Use the crankcase separating tool 2.

CAUTION:

Do not use a hammer to drive out the

crankshaft.

Crankshaft bearing

1. Remove:

Bearing 1

NOTE:

Remove the bearing from the crankcase by

pressing its inner race.

Do not use the removed bearing.

Crankcase separating tool:

YU-1135-A/90890-01135

INSPECTION

Timing chain and timing chain guide

1. Inspect:

Timing chain

Cracks/stiff → Replace the timing chain

and camshaft sprocket as a set.

2. Inspect:

Timing chain guide

Wear/damage → Replace.

EC4N4101

Crankcase

1. Inspect:

Contacting surface a

Scratches → Replace.

Engine mounting boss b, crankcase

Cracks/damage → Replace.

2. Inspect:

Bearing

Rotate inner race with a finger.

Rough spot/seizure → Replace.

3. Inspect:

Oil seal

Wear/damage → Replace.

Page 426 of 646

4 - 93

ENGCRANKCASE AND CRANKSHAFT

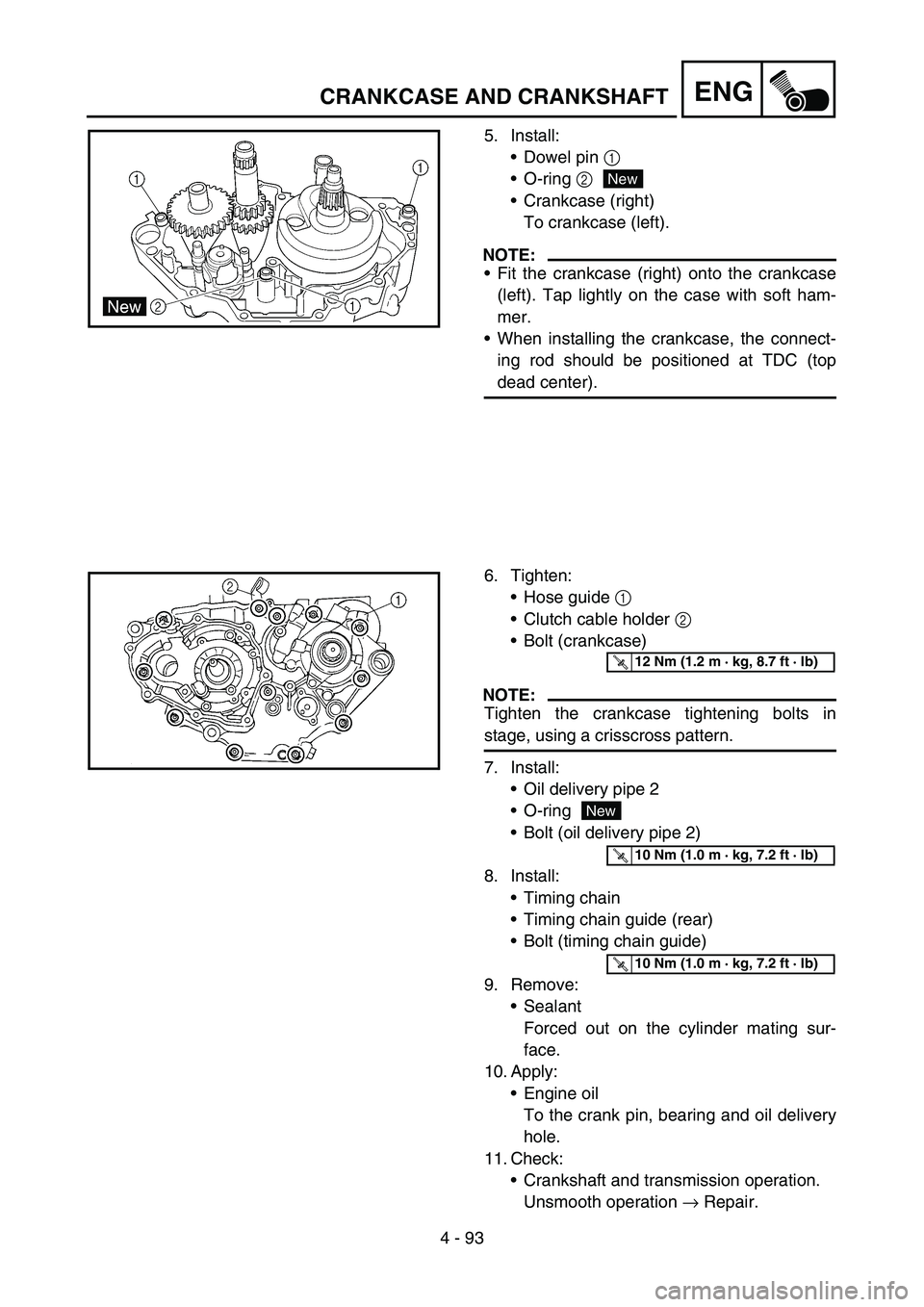

5. Install:

Dowel pin 1

O-ring 2

Crankcase (right)

To crankcase (left).

NOTE:

Fit the crankcase (right) onto the crankcase

(left). Tap lightly on the case with soft ham-

mer.

When installing the crankcase, the connect-

ing rod should be positioned at TDC (top

dead center).

New

6. Tighten:

Hose guide 1

Clutch cable holder 2

Bolt (crankcase)

NOTE:

Tighten the crankcase tightening bolts in

stage, using a crisscross pattern.

7. Install:

Oil delivery pipe 2

O-ring

Bolt (oil delivery pipe 2)

8. Install:

Timing chain

Timing chain guide (rear)

Bolt (timing chain guide)

9. Remove:

Sealant

Forced out on the cylinder mating sur-

face.

10. Apply:

Engine oil

To the crank pin, bearing and oil delivery

hole.

11. Check:

Crankshaft and transmission operation.

Unsmooth operation → Repair.

T R..12 Nm (1.2 m · kg, 8.7 ft · lb)

New

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 428 of 646

4 - 94

ENGTRANSMISSION, SHIFT CAM AND SHIFT FORK

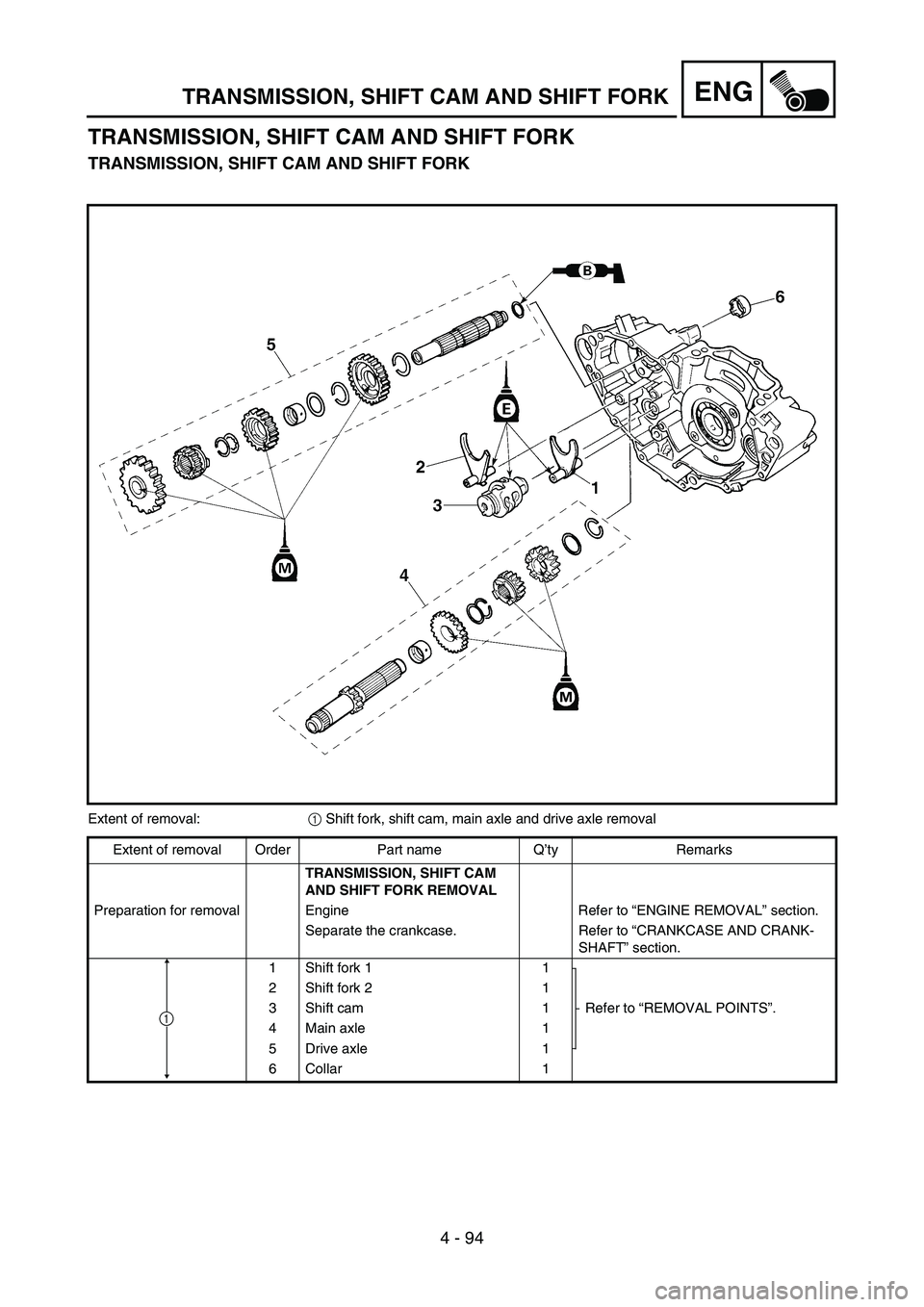

TRANSMISSION, SHIFT CAM AND SHIFT FORK

TRANSMISSION, SHIFT CAM AND SHIFT FORK

Extent of removal:

1 Shift fork, shift cam, main axle and drive axle removal

Extent of removal Order Part name Q’ty Remarks

TRANSMISSION, SHIFT CAM

AND SHIFT FORK REMOVAL

Preparation for removal Engine Refer to “ENGINE REMOVAL” section.

Separate the crankcase. Refer to “CRANKCASE AND CRANK-

SHAFT” section.

1 Shift fork 1 1

Refer to “REMOVAL POINTS”. 2 Shift fork 2 1

3Shift cam 1

4 Main axle 1

5 Drive axle 1

6 Collar 1

1

Page 436 of 646

4 - 98

ENGTRANSMISSION, SHIFT CAM AND SHIFT FORK

5. Install:

Shift fork 1 (L) 1

Shift fork 2 (R) 2

Shift cam 3

To main axle and drive axle.

NOTE:

Apply the molybdenum disulfide oil on the

shift fork grooves.

Mesh the shift fork #1 (L) with the 3rd pinion

gear 4 on the main axle.

Mesh the shift fork #2 (R) with the 4th wheel

gear 5 on the drive axle.

6. Install:

Transmission assembly 1

To crankcase (left) 2.

NOTE:

Apply the engine oil on the bearings and guide

bars.

7. Check:

Shifter operation

Transmission operation

Unsmooth operation → Repair.