sensor YAMAHA YZ450F 2008 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: YZ450F, Model: YAMAHA YZ450F 2008Pages: 188, PDF Size: 11.75 MB

Page 40 of 188

2-18

CABLE ROUTING DIAGRAM

CABLE ROUTING DIAGRAM

1. Fuel tank breather hose

2. Radiator hose 1

3. Cylinder head breather hose

4. Hose holder

5. Radiator hose 4

6. Clutch cable

7. Connector cover

8. Fuel hose

9. Throttle position sensor lead10. Hot starter cable

11. Carburetor breather hose

12. Carburetor overflow hose

A. Insert the end of the fuel tank

breather hose into the hole in

the steering stem.B. Pass the cylinder head breather

hose on the outside of the radia-

tor hose 1 and between the radi-

ator hose 4 and frame.

C. Align the paint on the cylinder

head breather hose with the

front edge of the hose holder.

D. Pass the clutch cable through

the cable guide.

Page 41 of 188

2-19

CABLE ROUTING DIAGRAM

E. Pass the clutch cable in front of

the radiator mounting boss.

F. Install the connector cover so

that it does not come in between

the radiator hose 1 and radiator.

G. Pass the fuel hose between the

hot starter cable and throttle po-

sition sensor lead.

H. Pass the carburetor breather

hoses and overflow hose so that

all there hoses do not contact

the rear shock absorber.

Page 42 of 188

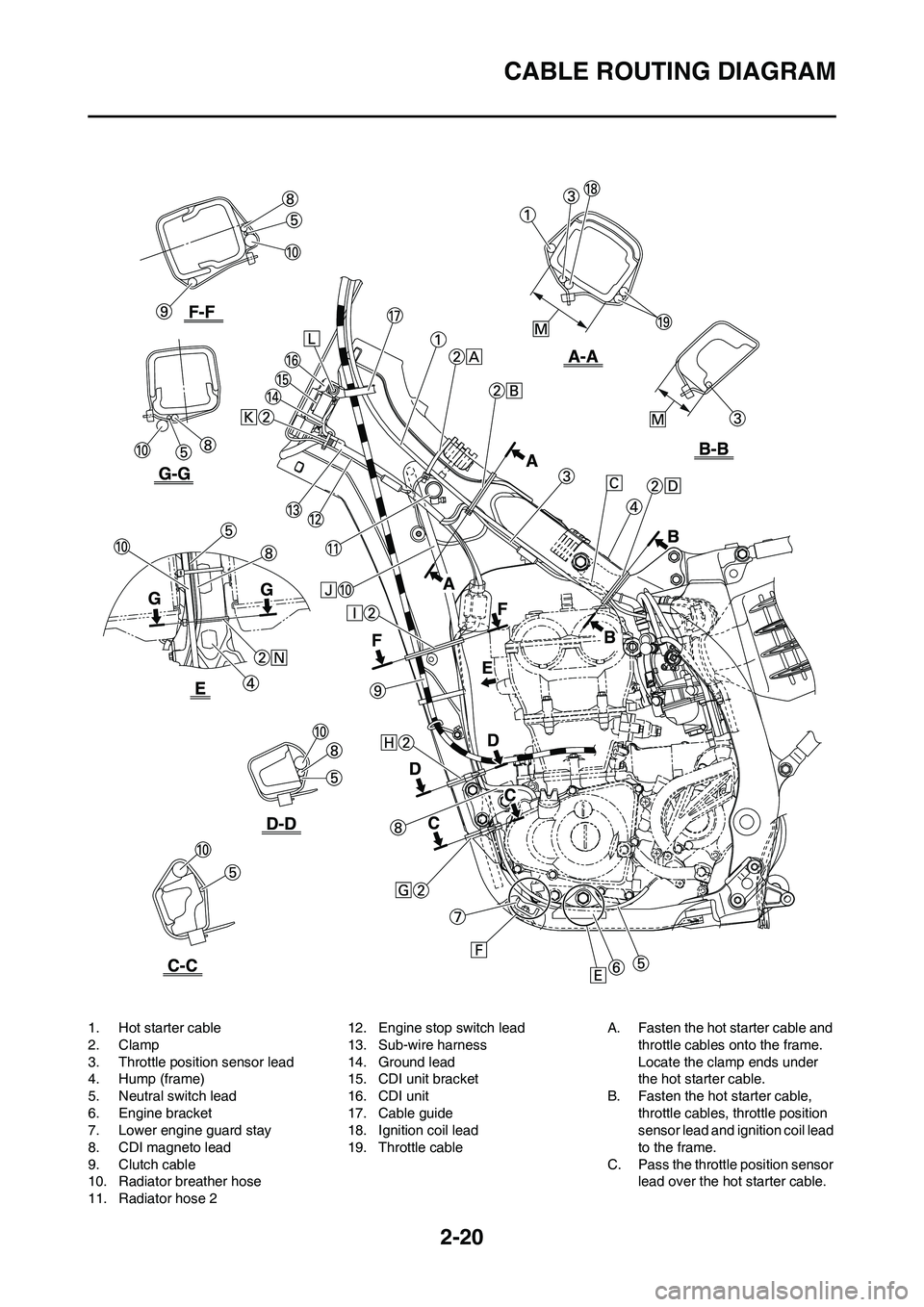

2-20

CABLE ROUTING DIAGRAM

1. Hot starter cable

2. Clamp

3. Throttle position sensor lead

4. Hump (frame)

5. Neutral switch lead

6. Engine bracket

7. Lower engine guard stay

8. CDI magneto lead

9. Clutch cable

10. Radiator breather hose

11. Radiator hose 212. Engine stop switch lead

13. Sub-wire harness

14. Ground lead

15. CDI unit bracket

16. CDI unit

17. Cable guide

18. Ignition coil lead

19. Throttle cableA. Fasten the hot starter cable and

throttle cables onto the frame.

Locate the clamp ends under

the hot starter cable.

B. Fasten the hot starter cable,

throttle cables, throttle position

sensor lead and ignition coil lead

to the frame.

C. Pass the throttle position sensor

lead over the hot starter cable.

Page 75 of 188

4-7

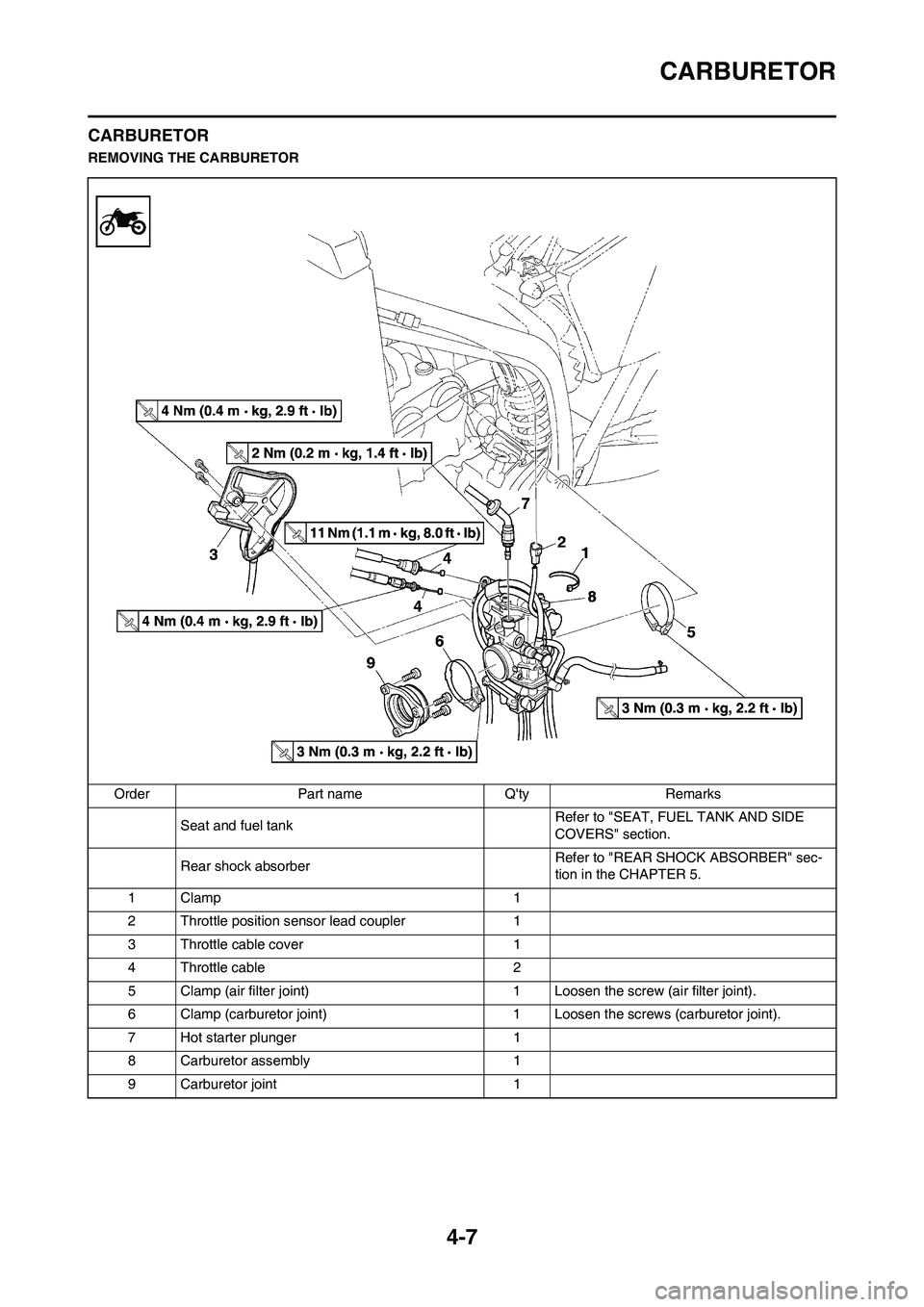

CARBURETOR

CARBURETOR

REMOVING THE CARBURETOR

Order Part name Q'ty Remarks

Seat and fuel tank Refer to "SEAT, FUEL TANK AND SIDE

COVERS" section.

Rear shock absorber Refer to "REAR SHOCK ABSORBER" sec-

tion in the CHAPTER 5.

1Clamp 1

2 Throttle position sensor lead coupler 1

3 Throttle cable cover 1

4 Throttle cable 2

5 Clamp (air filter joint) 1 Loosen the screw (air filter joint).

6 Clamp (carburetor joint) 1 Loosen the screws (carburetor joint).

7 Hot starter plunger 1

8 Carburetor assembly 1

9 Carburetor joint 1

Page 78 of 188

4-10

CARBURETOR

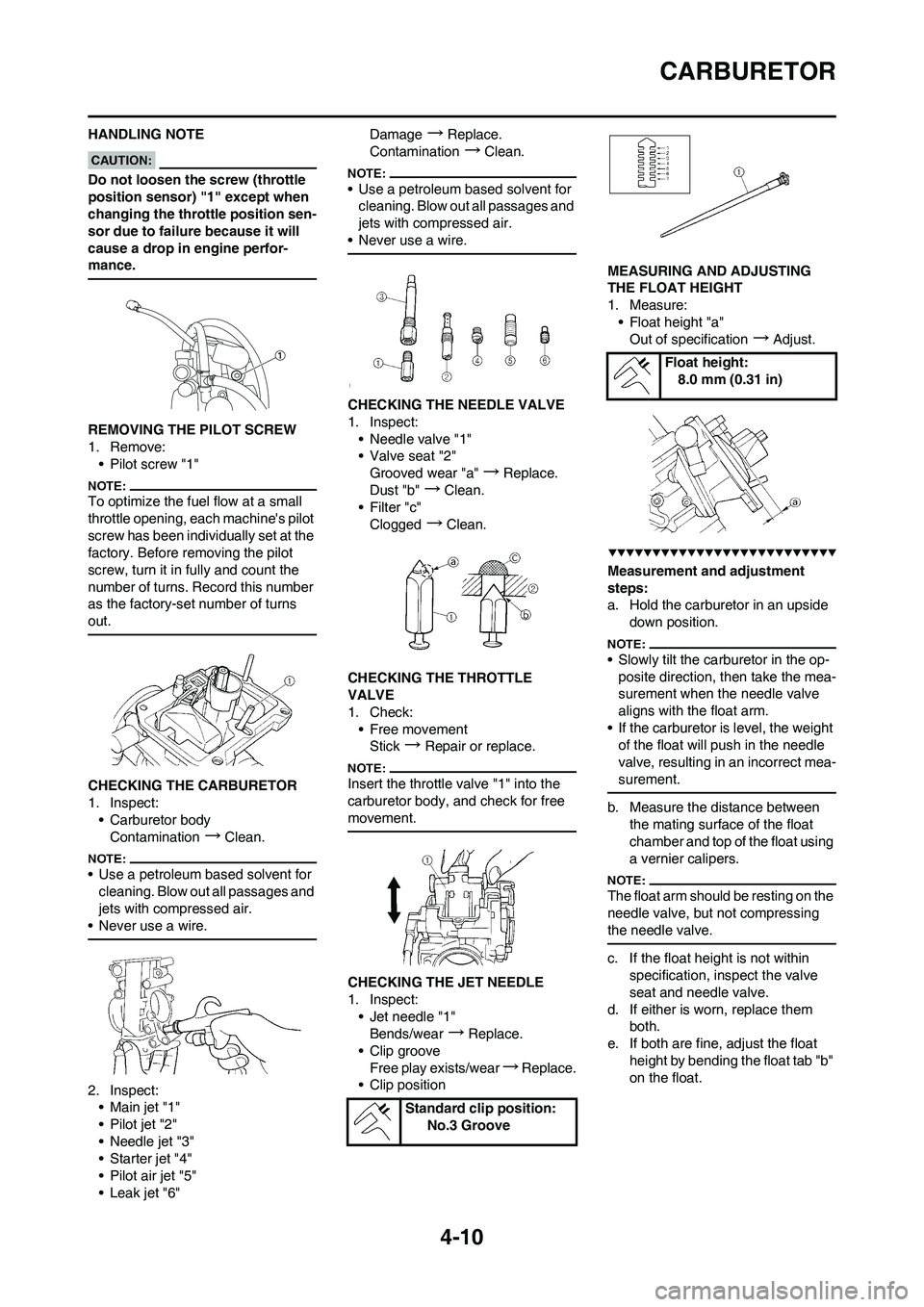

HANDLING NOTE

Do not loosen the screw (throttle

position sensor) "1" except when

changing the throttle position sen-

sor due to failure because it will

cause a drop in engine perfor-

mance.

REMOVING THE PILOT SCREW

1. Remove:

• Pilot screw "1"

To optimize the fuel flow at a small

throttle opening, each machine's pilot

screw has been individually set at the

factory. Before removing the pilot

screw, turn it in fully and count the

number of turns. Record this number

as the factory-set number of turns

out.

CHECKING THE CARBURETOR

1. Inspect:

• Carburetor body

Contamination

→Clean.

• Use a petroleum based solvent for

cleaning. Blow out all passages and

jets with compressed air.

• Never use a wire.

2. Inspect:

•Main jet "1"

• Pilot jet "2"

• Needle jet "3"

• Starter jet "4"

• Pilot air jet "5"

• Leak jet "6"Damage

→Replace.

Contamination

→Clean.

• Use a petroleum based solvent for

cleaning. Blow out all passages and

jets with compressed air.

• Never use a wire.

CHECKING THE NEEDLE VALVE

1. Inspect:

• Needle valve "1"

• Valve seat "2"

Grooved wear "a"

→Replace.

Dust "b"

→Clean.

• Filter "c"

Clogged

→Clean.

CHECKING THE THROTTLE

VALVE

1. Check:

• Free movement

Stick

→Repair or replace.

Insert the throttle valve "1" into the

carburetor body, and check for free

movement.

CHECKING THE JET NEEDLE

1. Inspect:

• Jet needle "1"

Bends/wear

→Replace.

• Clip groove

Free play exists/wear

→Replace.

• Clip positionMEASURING AND ADJUSTING

THE FLOAT HEIGHT

1. Measure:

• Float height "a"

Out of specification

→Adjust.

Measurement and adjustment

steps:

a. Hold the carburetor in an upside

down position.

• Slowly tilt the carburetor in the op-

posite direction, then take the mea-

surement when the needle valve

aligns with the float arm.

• If the carburetor is level, the weight

of the float will push in the needle

valve, resulting in an incorrect mea-

surement.

b. Measure the distance between

the mating surface of the float

chamber and top of the float using

a vernier calipers.

The float arm should be resting on the

needle valve, but not compressing

the needle valve.

c. If the float height is not within

specification, inspect the valve

seat and needle valve.

d. If either is worn, replace them

both.

e. If both are fine, adjust the float

height by bending the float tab "b"

on the float.

Standard clip position:

No.3 Groove

Float height:

8.0 mm (0.31 in)

Page 79 of 188

4-11

CARBURETOR

f. Recheck the float height.

CHECKING THE FLOAT

1. Inspect:

• Float "1"

Damage

→Replace.

CHECKING THE STARTER

PLUNGER

1. Inspect:

• Cold starter plunger "1"

• Hot starter plunger "2"

Wear/damage

→Replace.

CHECKING THE ACCELERATOR

PUMP

1. Inspect:

• Diaphragm (accelerator pump)

"1"

• Spring (accelerator pump) "2"

• Accelerator pump cover "3"

• O-ring "4"

• Push rod "5"

Tears (diaphragm)/damage

→

Replace.

Dirt

→Clean.

2. Inspect:

• Throttle shaft "1"

• Spring "2"

• Lever 1 "3"

• Spring 1 "4"

• Lever 2 "5"• Spring 2 "6"

Dirt

→Clean.

ASSEMBLING THE CARBURETOR

1. Install:

• Cold starter plunger "1"

2. Install:

•Pilot air jet "1"

3. Install:

• Spring 1 "1"

• Lever 1 "2"

To lever 2 "3".

Make sure the spring 1 fits on the

stopper "a" of the lever 2.

4. Install:

• Spring 2 "1"

To lever 2 "2".

5. Install:

• Push rod link lever assembly "1"

Make sure the stopper "a" of the

spring 2 fits into the recess "b" in the carburetor.

6. Install:

• Washer "1"

• Circlip "2"

7. Install:

• Spring "1"

To throttle shaft "2".

Install the bigger hook "a" of the

spring fits on the stopper "b" of the

throttle shaft pulley.

8. Install:

• Throttle shaft assembly "1"

• Washer (metal) "2"

• Washer (resin) "3"

• Valve lever "4"

• Apply the fluorochemical grease on

the bearings.

• Fit the projection "a" on the throttle

shaft assembly into the slot "b" in

the throttle position sensor.

• Make sure the stopper "c" of the

spring fits into the recess in the car-

buretor.

• Turn the throttle shaft assembly left

while holding down the lever 1 "5"

and fit the throttle stop screw tip "d"

to the stopper "e" of the throttle

shaft assembly pulley.

Page 81 of 188

4-13

CARBURETOR

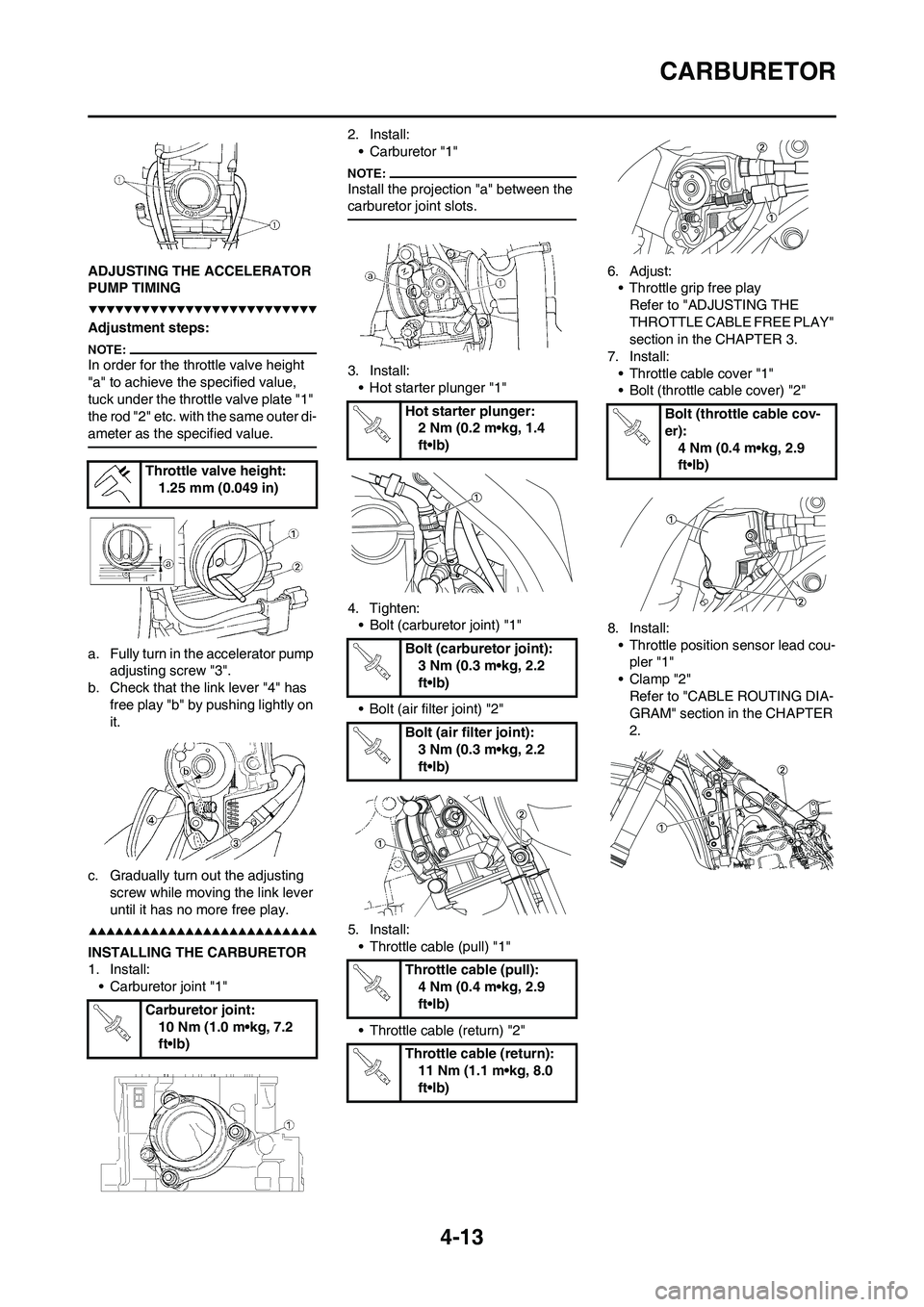

ADJUSTING THE ACCELERATOR

PUMP TIMING

Adjustment steps:

In order for the throttle valve height

"a" to achieve the specified value,

tuck under the throttle valve plate "1"

the rod "2" etc. with the same outer di-

ameter as the specified value.

a. Fully turn in the accelerator pump

adjusting screw "3".

b. Check that the link lever "4" has

free play "b" by pushing lightly on

it.

c. Gradually turn out the adjusting

screw while moving the link lever

until it has no more free play.

INSTALLING THE CARBURETOR

1. Install:

• Carburetor joint "1"2. Install:

• Carburetor "1"

Install the projection "a" between the

carburetor joint slots.

3. Install:

• Hot starter plunger "1"

4. Tighten:

• Bolt (carburetor joint) "1"

• Bolt (air filter joint) "2"

5. Install:

• Throttle cable (pull) "1"

• Throttle cable (return) "2"6. Adjust:

• Throttle grip free play

Refer to "ADJUSTING THE

THROTTLE CABLE FREE PLAY"

section in the CHAPTER 3.

7. Install:

• Throttle cable cover "1"

• Bolt (throttle cable cover) "2"

8. Install:

• Throttle position sensor lead cou-

pler "1"

• Clamp "2"

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2. Throttle valve height:

1.25 mm (0.049 in)

Carburetor joint:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Hot starter plunger:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Bolt (carburetor joint):

3 Nm (0.3 m•kg, 2.2

ft•lb)

Bolt (air filter joint):

3 Nm (0.3 m•kg, 2.2

ft•lb)

Throttle cable (pull):

4 Nm (0.4 m•kg, 2.9

ft•lb)

Throttle cable (return):

11 Nm (1.1 m•kg, 8.0

ft•lb)Bolt (throttle cable cov-

er):

4 Nm (0.4 m•kg, 2.9

ft•lb)

Page 171 of 188

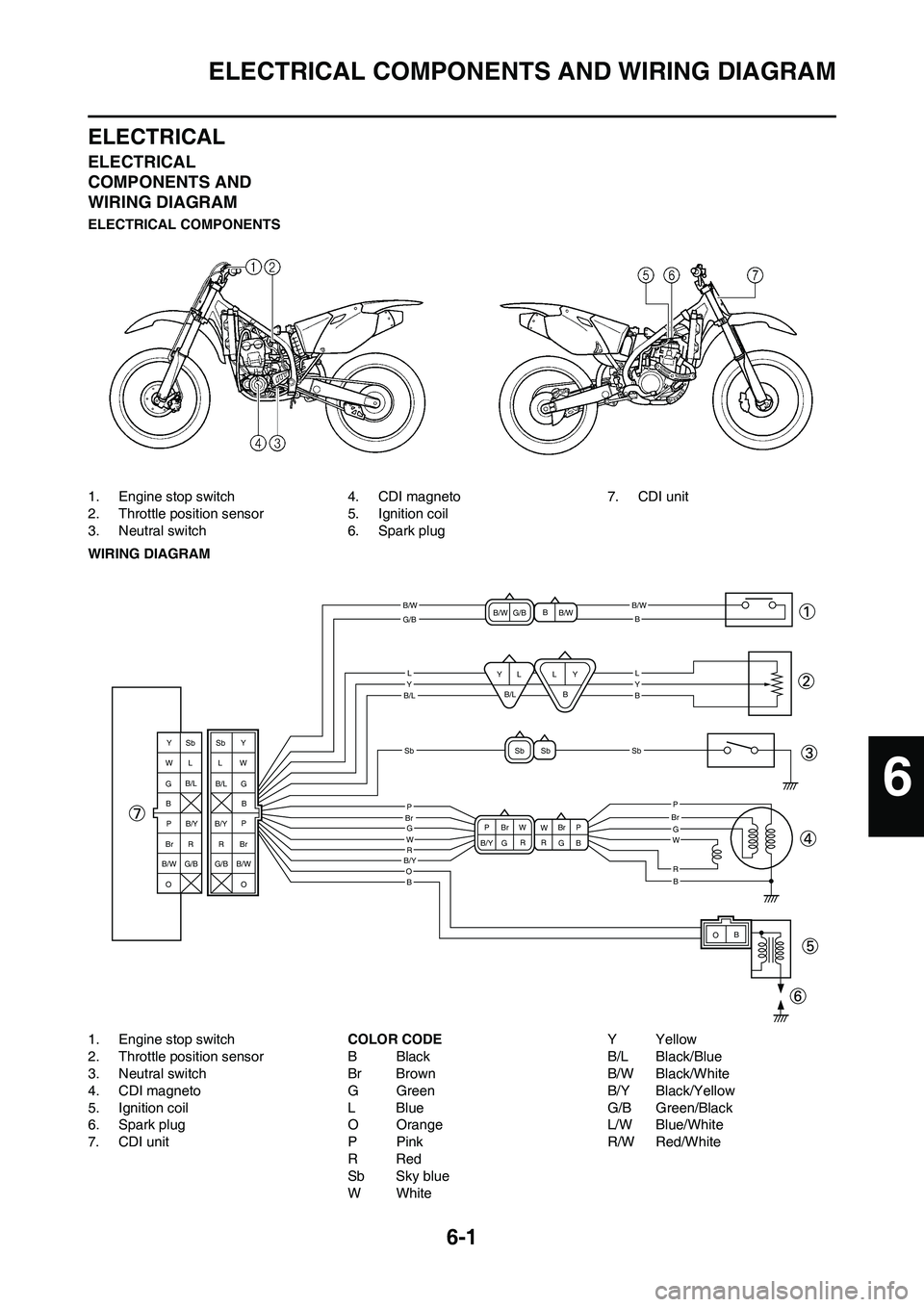

6-1

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

ELECTRICAL

ELECTRICAL

COMPONENTS AND

WIRING DIAGRAM

ELECTRICAL COMPONENTS

1. Engine stop switch

2. Throttle position sensor

3. Neutral switch4. CDI magneto

5. Ignition coil

6. Spark plug7. CDI unit

WIRING DIAGRAM

1. Engine stop switch

2. Throttle position sensor

3. Neutral switch

4. CDI magneto

5. Ignition coil

6. Spark plug

7. CDI unitCOLOR CODE

BBlack

Br Brown

GGreen

LBlue

O Orange

PPink

RRed

Sb Sky blue

WWhiteY Yellow

B/L Black/Blue

B/W Black/White

B/Y Black/Yellow

G/B Green/Black

L/W Blue/White

R/W Red/White

B/WB/W

B/L

B/Y

SbSb

G/B

LYLY

P

B

B

B

B

G

O

WR

P

GW

R P

B Br W

W

B/Y GBr

G RR

OB Sb Sb Y

Y

WY

W

GG

B

PP

Br BrR R

OL

B SbY LL

B/L B/W B/WG/B

B B

B/L L Sb

B/L

G/B

G/BB/Y

B/Y

B/W

O B/W

BrBrP

6

Page 175 of 188

6-5

THROTTLE POSITION SENSOR SYSTEM

THROTTLE POSITION SENSOR SYSTEM

INSPECTION STEPS

If the throttle position sensor will not operate, use the following inspection steps.

*marked: Refer to "IGNITION SYSTEM" section.

Use the following special tools in this inspection.

Check entire ignition system for connection. No good→Repair or replace.

OK

↓

Check throttle position sensor. (Throttle position

sensor coil)No good→Replace.

OK

↓

*Check CDI magneto. (Charging coil) No good→Replace.

OK

↓

Check CDI unit. (Throttle position sensor input

voltage)No good→Replace.

Pocket tester:

YU-3112-C/90890-03112

Page 176 of 188

6-6

THROTTLE POSITION SENSOR SYSTEM

HANDLING NOTE

Do not loosen the screw (throttle

position sensor) "1" except when

changing the throttle position sen-

sor due to failure because it will

cause a drop in engine perfor-

mance.

CHECKING THE COUPLERS AND

LEADS CONNECTION

1. Check:

• Couplers and leads connection

Rust/dust/looseness/short-circuit

→Repair or replace.

CHECKING THE THROTTLE

POSITION SENSOR COIL

1. Inspect:

• Throttle position sensor coil resis-

tance

Out of specification

→Replace.

2. Loosen:

• Throttle stop screw "1"

Turn out the throttle stop screw until

the throttle shaft is in the full close po-

sition.

3. Inspect:

• Throttle position sensor coil vari-

able resistance

Check that the resistance in in-

creased as the throttle grip is

moved from the full close position

to the full open position.

Out of specification

→Replace.

CHANGING AND ADJUSTING THE

THROTTLE POSITION SENSOR

1. Remove:

• Throttle position sensor coupler

• Carburetor

2. Remove:

• Screw (throttle position sensor)

"1"

• Throttle position sensor "2"

Loosen the screw (throttle position

sensor) using the T25 bit.

3. Replace:

• Throttle position sensor

4. Install:

• Throttle position sensor "1"

• Screw (throttle position sensor)

"2"

• Align the slot "a" in the throttle posi-

tion sensor with the projection "b"

on the carburetor.• Temporarily tighten the screw

(throttle position sensor).

5. Install:

•Carburetor

• Throttle position sensor coupler

6. Adjust:

• Engine idling speed

Refer to "ADJUSTING THE EN-

GINE IDLING SPEED" section in

the CHAPTER 3.

7. Insert the thin electric conductors

"2" (lead) into the throttle position

sensor coupler "1", as shown, and

connect the tester to them.

• Do not insert the electric conduc-

tors more than required because

it may reduce the waterproof

function of the coupler.

�ŒMake sure that a short-circuit

does not develop between the

terminals because it may cause

damage to electrical compo-

nents.

8. Start the engine.

9. Adjust:

• Throttle position sensor output

voltage

Adjustment steps:

a. Adjust the installation angle of the

throttle position sensor "1" to ob-

tain the specified output voltage.

Measure the output voltage accurate-

ly with a digital electronic voltmeter

that gives an easy reading of a small

voltage.

Tester (+) lead→Blue lead "1"

Tester (-) lead

→Black lead "2"

Throttle po-

sition sen-

sor coil

resistanceTester se-

lector posi-

tion

4–6 k

Ω at

20°C (68 °F) kΩ×1

Tester (+) lead→Yellow lead "1"

Tester (-) lead

→Black lead "2"

Throttle position

sensor coil vari-

able resistanceTester

selec-

tor po-

sition

Full

closedFull

opened

k

Ω×1 Zero –2

kΩat

20°C

(68 °F)4–6

kΩat

20 °C

(68 °F)

Tester (+) lead→Yellow lead "3"

Tester (-) lead

→Black lead "4"