YAMAHA YZ450F 2010 Owners Manual

Manufacturer: YAMAHA, Model Year: 2010, Model line: YZ450F, Model: YAMAHA YZ450F 2010Pages: 230, PDF Size: 14.09 MB

Page 101 of 230

4-20

VALVES AND VALVE SPRINGS

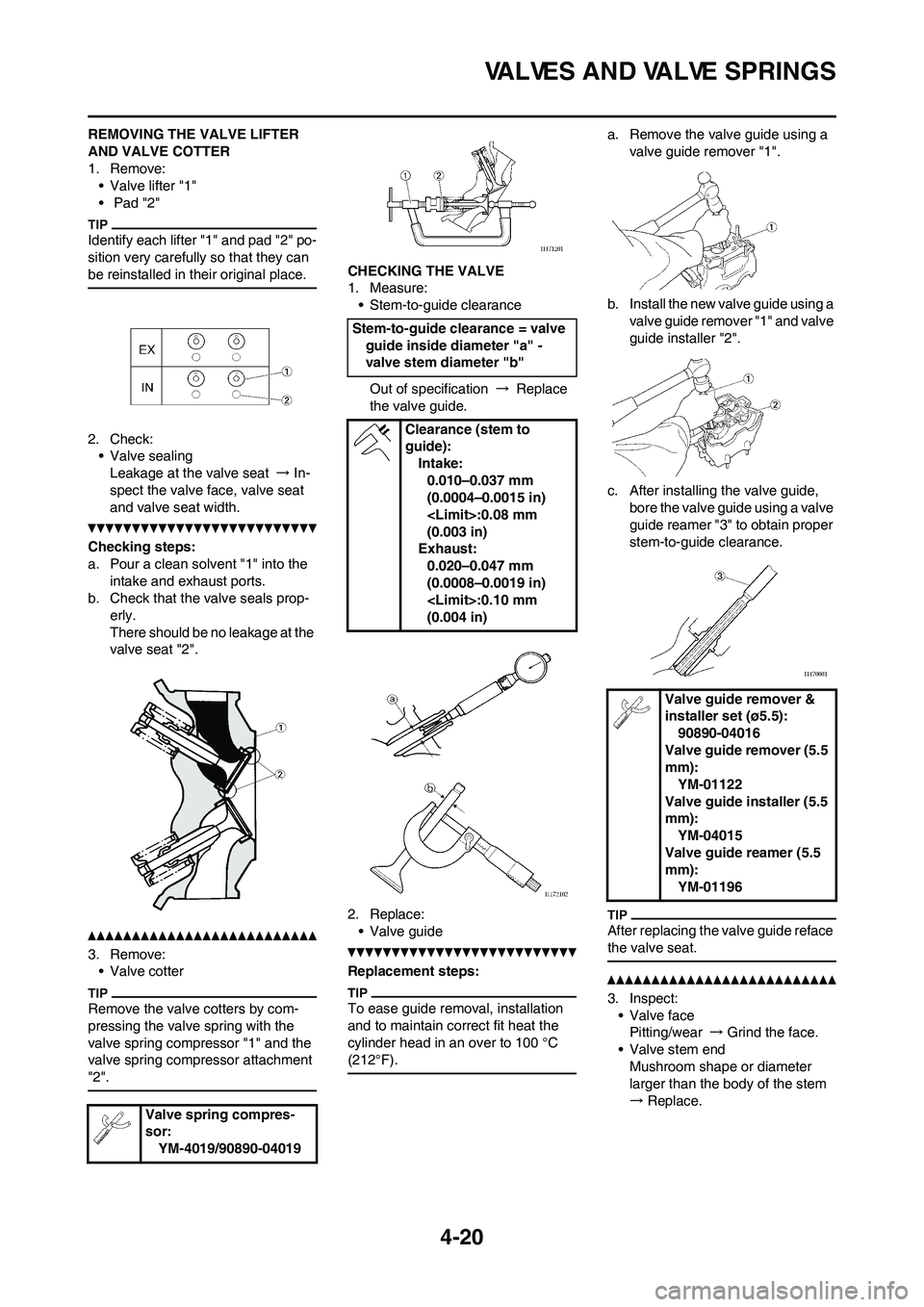

REMOVING THE VALVE LIFTER

AND VALVE COTTER

1. Remove:

• Valve lifter "1"

• Pad "2"

Identify each lifter "1" and pad "2" po-

sition very carefully so that they can

be reinstalled in their original place.

2. Check:

• Valve sealing

Leakage at the valve seat → In-

spect the valve face, valve seat

and valve seat width.

Checking steps:

a. Pour a clean solvent "1" into the

intake and exhaust ports.

b. Check that the valve seals prop-

erly.

There should be no leakage at the

valve seat "2".

3. Remove:

• Valve cotter

Remove the valve cotters by com-

pressing the valve spring with the

valve spring compressor "1" and the

valve spring compressor attachment

"2".

CHECKING THE VALVE

1. Measure:

• Stem-to-guide clearance

Out of specification → Replace

the valve guide.

2. Replace:

• Valve guide

Replacement steps:

To ease guide removal, installation

and to maintain correct fit heat the

cylinder head in an over to 100 °C

(212°F).

a. Remove the valve guide using a

valve guide remover "1".

b. Install the new valve guide using a

valve guide remover "1" and valve

guide installer "2".

c. After installing the valve guide,

bore the valve guide using a valve

guide reamer "3" to obtain proper

stem-to-guide clearance.

After replacing the valve guide reface

the valve seat.

3. Inspect:

• Valve face

Pitting/wear → Grind the face.

• Valve stem end

Mushroom shape or diameter

larger than the body of the stem

→ Replace.

Valve spring compres-

sor:

YM-4019/90890-04019

Stem-to-guide clearance = valve

guide inside diameter "a" -

valve stem diameter "b"

Clearance (stem to

guide):

Intake:

0.010–0.037 mm

(0.0004–0.0015 in)

(0.003 in)

Exhaust:

0.020–0.047 mm

(0.0008–0.0019 in)

(0.004 in)

Valve guide remover &

installer set (ø5.5):

90890-04016

Valve guide remover (5.5

mm):

YM-01122

Valve guide installer (5.5

mm):

YM-04015

Valve guide reamer (5.5

mm):

YM-01196

Page 102 of 230

4-21

VALVES AND VALVE SPRINGS

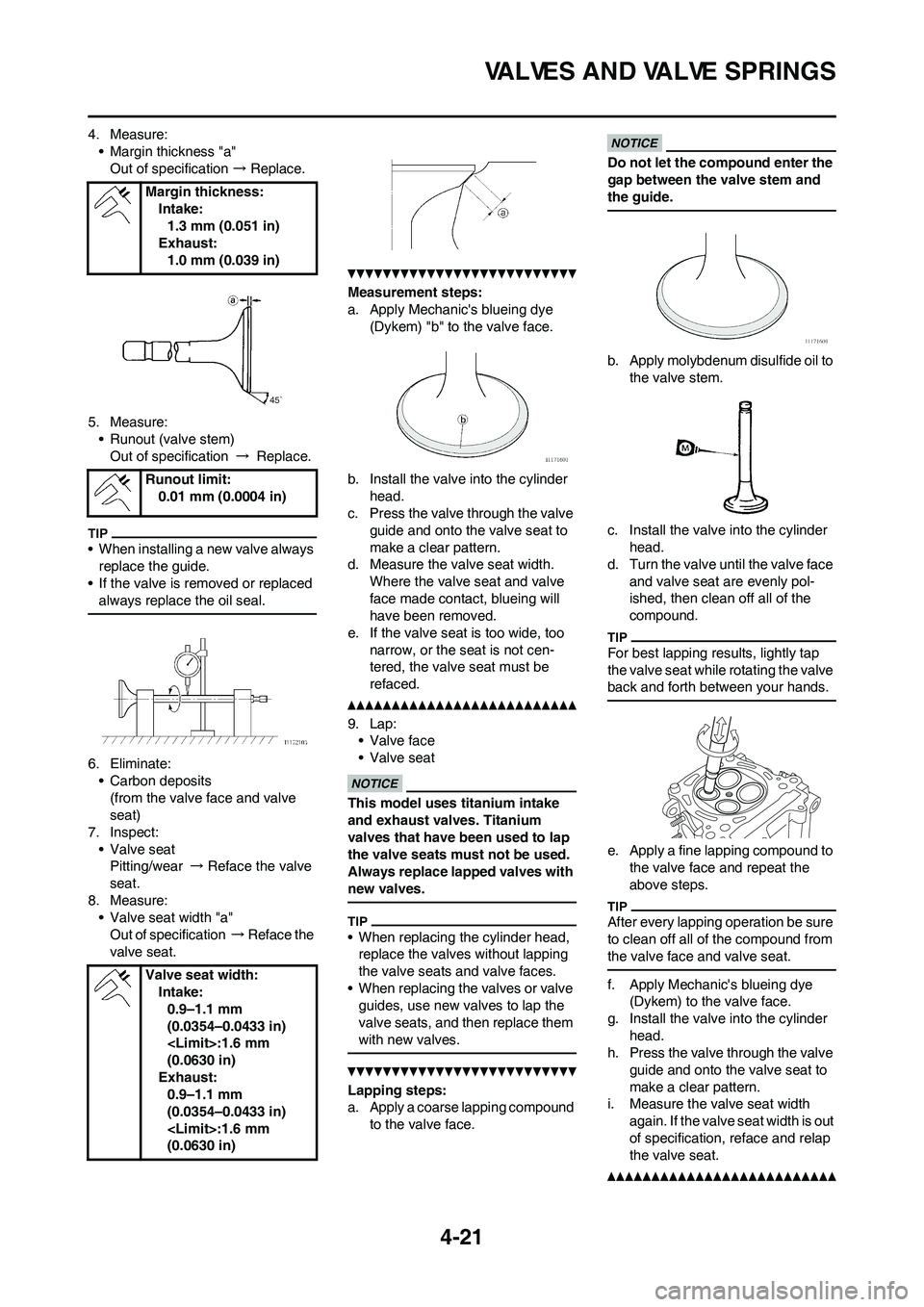

4. Measure:

• Margin thickness "a"

Out of specification → Replace.

5. Measure:

• Runout (valve stem)

Out of specification → Replace.

• When installing a new valve always

replace the guide.

• If the valve is removed or replaced

always replace the oil seal.

6. Eliminate:

• Carbon deposits

(from the valve face and valve

seat)

7. Inspect:

• Valve seat

Pitting/wear → Reface the valve

seat.

8. Measure:

• Valve seat width "a"

Out of specification → Reface the

valve seat.

Measurement steps:

a. Apply Mechanic's blueing dye

(Dykem) "b" to the valve face.

b. Install the valve into the cylinder

head.

c. Press the valve through the valve

guide and onto the valve seat to

make a clear pattern.

d. Measure the valve seat width.

Where the valve seat and valve

face made contact, blueing will

have been removed.

e. If the valve seat is too wide, too

narrow, or the seat is not cen-

tered, the valve seat must be

refaced.

9. Lap:

• Valve face

• Valve seat

This model uses titanium intake

and exhaust valves. Titanium

valves that have been used to lap

the valve seats must not be used.

Always replace lapped valves with

new valves.

• When replacing the cylinder head,

replace the valves without lapping

the valve seats and valve faces.

• When replacing the valves or valve

guides, use new valves to lap the

valve seats, and then replace them

with new valves.

Lapping steps:

a. Apply a coarse lapping compound

to the valve face.

Do not let the compound enter the

gap between the valve stem and

the guide.

b. Apply molybdenum disulfide oil to

the valve stem.

c. Install the valve into the cylinder

head.

d. Turn the valve until the valve face

and valve seat are evenly pol-

ished, then clean off all of the

compound.

For best lapping results, lightly tap

the valve seat while rotating the valve

back and forth between your hands.

e. Apply a fine lapping compound to

the valve face and repeat the

above steps.

After every lapping operation be sure

to clean off all of the compound from

the valve face and valve seat.

f. Apply Mechanic's blueing dye

(Dykem) to the valve face.

g. Install the valve into the cylinder

head.

h. Press the valve through the valve

guide and onto the valve seat to

make a clear pattern.

i. Measure the valve seat width

again. If the valve seat width is out

of specification, reface and relap

the valve seat.

Margin thickness:

Intake:

1.3 mm (0.051 in)

Exhaust:

1.0 mm (0.039 in)

Runout limit:

0.01 mm (0.0004 in)

Valve seat width:

Intake:

0.9–1.1 mm

(0.0354–0.0433 in)

(0.0630 in)

Exhaust:

0.9–1.1 mm

(0.0354–0.0433 in)

(0.0630 in)

Page 103 of 230

4-22

VALVES AND VALVE SPRINGS

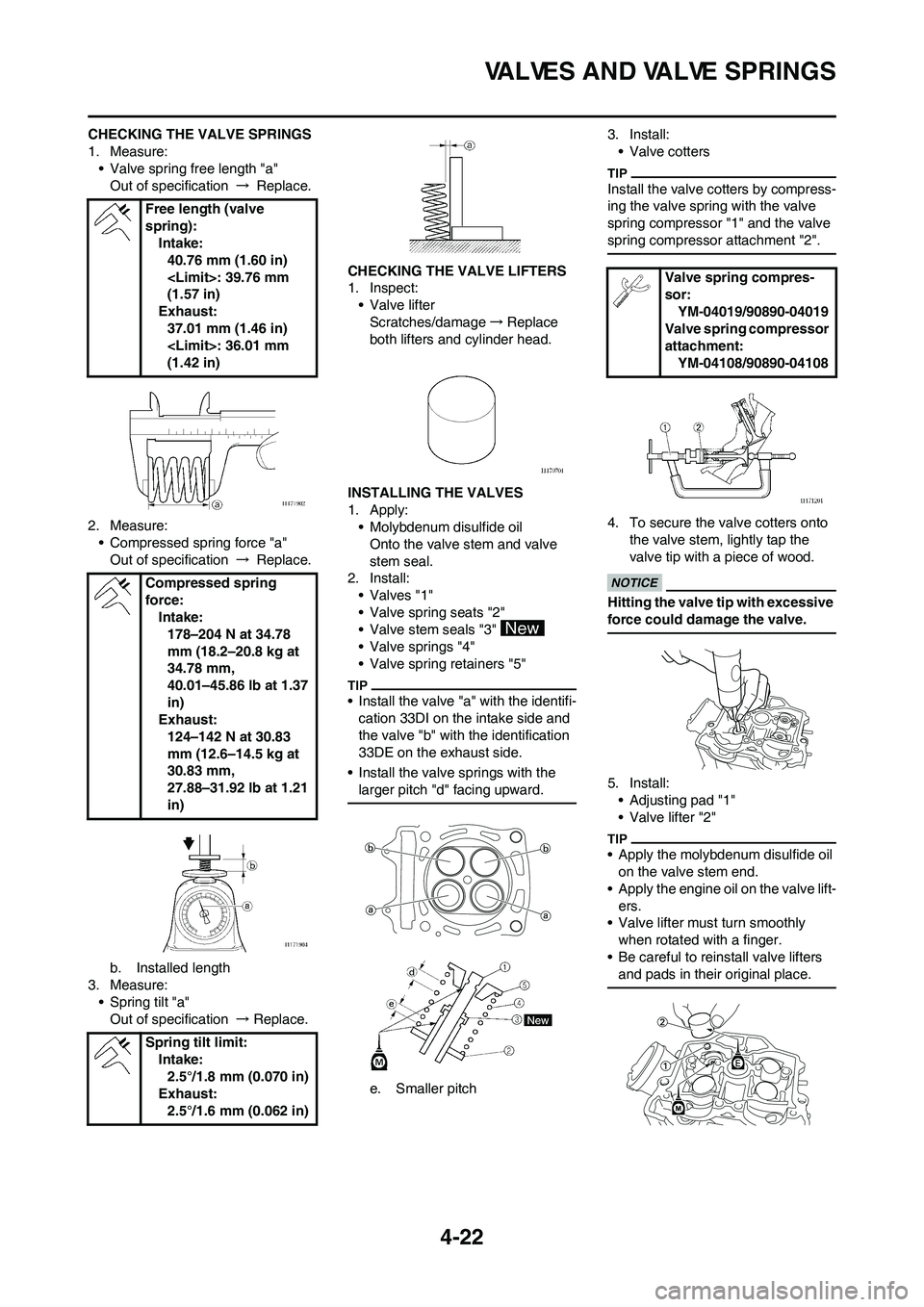

CHECKING THE VALVE SPRINGS

1. Measure:

• Valve spring free length "a"

Out of specification → Replace.

2. Measure:

• Compressed spring force "a"

Out of specification → Replace.

b. Installed length

3. Measure:

• Spring tilt "a"

Out of specification → Replace.CHECKING THE VALVE LIFTERS

1. Inspect:

• Valve lifter

Scratches/damage→Replace

both lifters and cylinder head.

INSTALLING THE VALVES

1. Apply:

• Molybdenum disulfide oil

Onto the valve stem and valve

stem seal.

2. Install:

• Valves "1"

• Valve spring seats "2"

• Valve stem seals "3"

• Valve springs "4"

• Valve spring retainers "5"

• Install the valve "a" with the identifi-

cation 33DI on the intake side and

the valve "b" with the identification

33DE on the exhaust side.

• Install the valve springs with the

larger pitch "d" facing upward.

e. Smaller pitch3. Install:

• Valve cotters

Install the valve cotters by compress-

ing the valve spring with the valve

spring compressor "1" and the valve

spring compressor attachment "2".

4. To secure the valve cotters onto

the valve stem, lightly tap the

valve tip with a piece of wood.

Hitting the valve tip with excessive

force could damage the valve.

5. Install:

• Adjusting pad "1"

• Valve lifter "2"

• Apply the molybdenum disulfide oil

on the valve stem end.

• Apply the engine oil on the valve lift-

ers.

• Valve lifter must turn smoothly

when rotated with a finger.

• Be careful to reinstall valve lifters

and pads in their original place.

Free length (valve

spring):

Intake:

40.76 mm (1.60 in)

(1.57 in)

Exhaust:

37.01 mm (1.46 in)

(1.42 in)

Compressed spring

force:

Intake:

178–204 N at 34.78

mm (18.2–20.8 kg at

34.78 mm,

40.01–45.86 lb at 1.37

in)

Exhaust:

124–142 N at 30.83

mm (12.6–14.5 kg at

30.83 mm,

27.88–31.92 lb at 1.21

in)

Spring tilt limit:

Intake:

2.5°/1.8 mm (0.070 in)

Exhaust:

2.5°/1.6 mm (0.062 in)

Valve spring compres-

sor:

YM-04019/90890-04019

Valve spring compressor

attachment:

YM-04108/90890-04108

Page 104 of 230

4-23

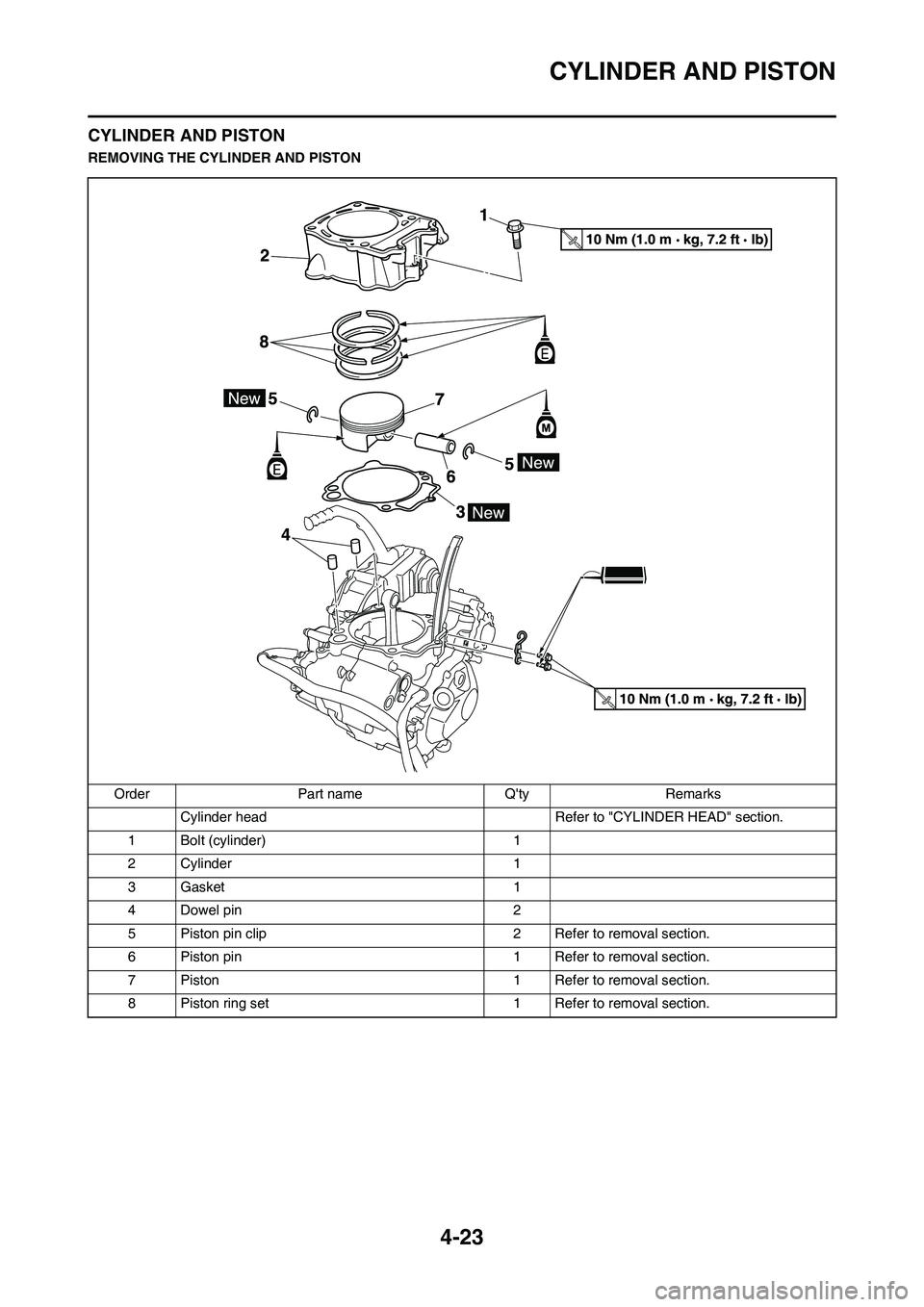

CYLINDER AND PISTON

CYLINDER AND PISTON

REMOVING THE CYLINDER AND PISTON

Order Part name Q'ty Remarks

Cylinder head Refer to "CYLINDER HEAD" section.

1 Bolt (cylinder) 1

2 Cylinder 1

3 Gasket 1

4 Dowel pin 2

5 Piston pin clip 2 Refer to removal section.

6 Piston pin 1 Refer to removal section.

7 Piston 1 Refer to removal section.

8 Piston ring set 1 Refer to removal section.

Page 105 of 230

4-24

CYLINDER AND PISTON

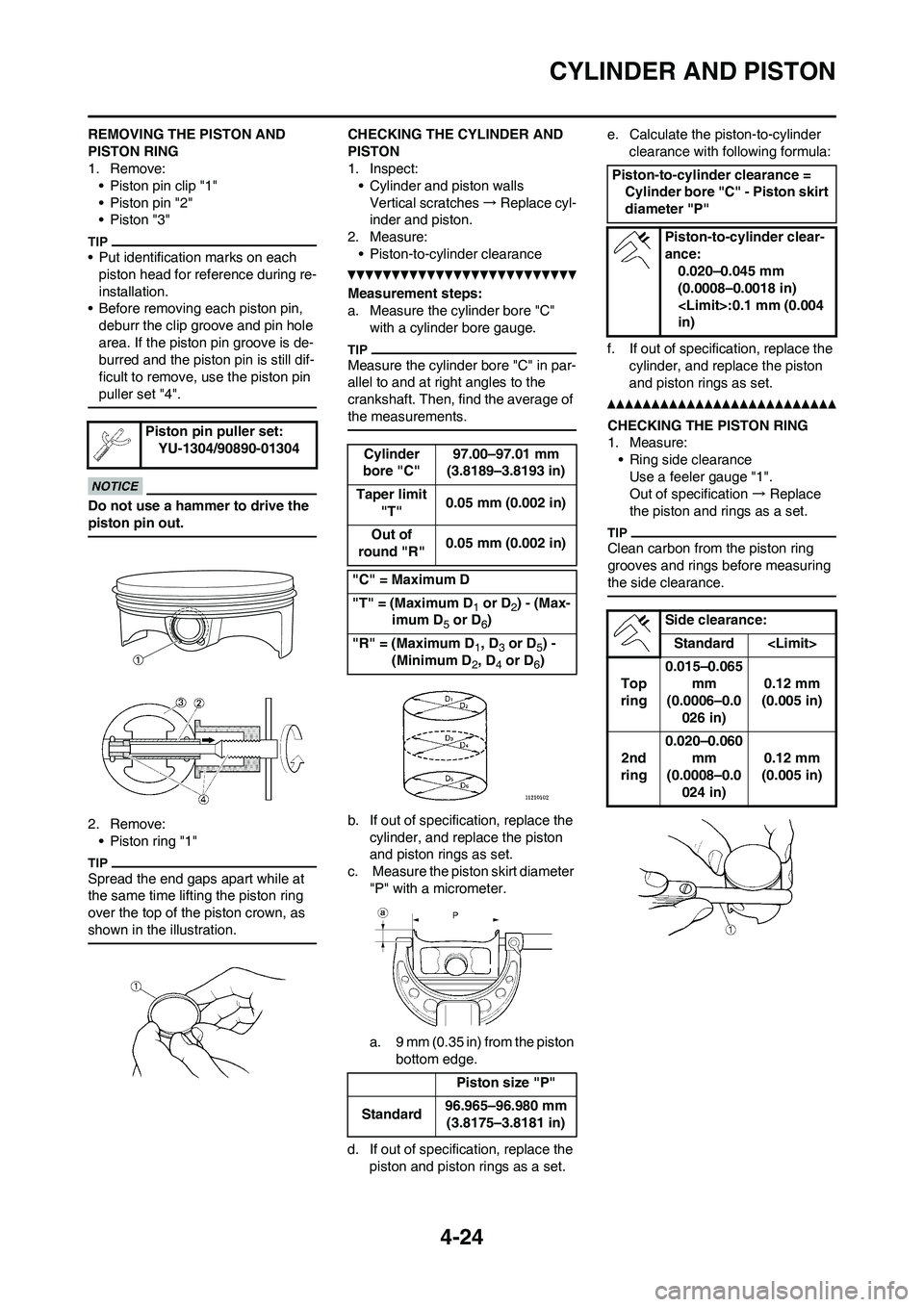

REMOVING THE PISTON AND

PISTON RING

1. Remove:

• Piston pin clip "1"

• Piston pin "2"

• Piston "3"

• Put identification marks on each

piston head for reference during re-

installation.

• Before removing each piston pin,

deburr the clip groove and pin hole

area. If the piston pin groove is de-

burred and the piston pin is still dif-

ficult to remove, use the piston pin

puller set "4".

Do not use a hammer to drive the

piston pin out.

2. Remove:

• Piston ring "1"

Spread the end gaps apart while at

the same time lifting the piston ring

over the top of the piston crown, as

shown in the illustration.

CHECKING THE CYLINDER AND

PISTON

1. Inspect:

• Cylinder and piston walls

Vertical scratches→Replace cyl-

inder and piston.

2. Measure:

• Piston-to-cylinder clearance

Measurement steps:

a. Measure the cylinder bore "C"

with a cylinder bore gauge.

Measure the cylinder bore "C" in par-

allel to and at right angles to the

crankshaft. Then, find the average of

the measurements.

b. If out of specification, replace the

cylinder, and replace the piston

and piston rings as set.

c. Measure the piston skirt diameter

"P" with a micrometer.

a. 9 mm (0.35 in) from the piston

bottom edge.

d. If out of specification, replace the

piston and piston rings as a set.e. Calculate the piston-to-cylinder

clearance with following formula:

f. If out of specification, replace the

cylinder, and replace the piston

and piston rings as set.

CHECKING THE PISTON RING

1. Measure:

• Ring side clearance

Use a feeler gauge "1".

Out of specification → Replace

the piston and rings as a set.

Clean carbon from the piston ring

grooves and rings before measuring

the side clearance.

Piston pin puller set:

YU-1304/90890-01304

Cylinder

bore "C"97.00–97.01 mm

(3.8189–3.8193 in)

Taper limit

"T"0.05 mm (0.002 in)

Out of

round "R"0.05 mm (0.002 in)

"C" = Maximum D

"T" = (Maximum D

1 or D2) - (Max-

imum D

5 or D6)

"R" = (Maximum D

1, D3 or D5) -

(Minimum D

2, D4 or D6)

Piston size "P"

Standard96.965–96.980 mm

(3.8175–3.8181 in)

Piston-to-cylinder clearance =

Cylinder bore "C" - Piston skirt

diameter "P"

Piston-to-cylinder clear-

ance:

0.020–0.045 mm

(0.0008–0.0018 in)

in)

Side clearance:

Standard

Top

ring0.015–0.065

mm

(0.0006–0.0

026 in)0.12 mm

(0.005 in)

2nd

ring0.020–0.060

mm

(0.0008–0.0

024 in)0.12 mm

(0.005 in)

Page 106 of 230

4-25

CYLINDER AND PISTON

2. Position:

• Piston ring

(in cylinder)

Insert a ring into the cylinder and

push it approximately 40mm (1.57 in)

into the cylinder. Push the ring with

the piston crown so that the ring will

be at a right angle to the cylinder

bore.

a. 40 mm (1.57 in)

3. Measure:

• Ring end gap

Out of specification → Replace.

You cannot measure the end gap on

the expander spacer of the oil control

ring. If the oil control ring rails show

excessive gap, replace all three rings.

CHECKING THE PISTON PIN

1. Inspect:

• Piston pin

Blue discoloration/grooves→Re-

place, then inspect the lubrication

system.2. Measure:

• Piston pin-to-piston clearance

Measurement steps:

a. Measure the outside diameter

(piston pin) "a".

If out of specification, replace the

piston pin.

b. Measure the inside diameter (pis-

ton) "b".

c. Calculate the piston pin-to-piston

clearance with the following for-

mula.

d. If out of specification, replace the

piston.

INSTALLING THE PISTON RING

AND PISTON

1. Install:

• Piston ring

Onto the piston.

• Be sure to install the piston rings so

that the manufacturer's marks or

numbers are located on the upper

side of the rings.

• Lubricate the piston and piston

rings liberally with engine oil.

2. Position:

•Top ring

•2nd ring

•Oil ring

Offset the piston ring end gaps as

shown.

a. Top ring end

b. 2nd ring end

c. Oil ring end (upper)

d. Oil ring

e. Oil ring end (lower) End gap:

Standard

Top

ring0.20–0.30

mm

(0.008–0.01

2 in)0.55 mm

(0.022 in)

2nd

ring0.35–0.50

mm

(0.014–0.02

0 in)0.85 mm

(0.033 in)

Oil

ring0.20–0.50

mm

(0.01–0.02

in)—

Outside diameter (piston

pin):

17.991–18.000 mm

(0.7083–0.7087 in)

Inside diameter (piston):

18.004–18.015 mm

(0.7088–0.7093 in)

Piston pin-to-piston clearance =

Inside diameter (piston) "b" -

Outside diameter (piston pin)

"a"

Piston pin-to-piston

clearance:

0.004–0.024 mm

(0.00016–0.00094 in)

in)

2525

2525115

Page 107 of 230

4-26

CYLINDER AND PISTON

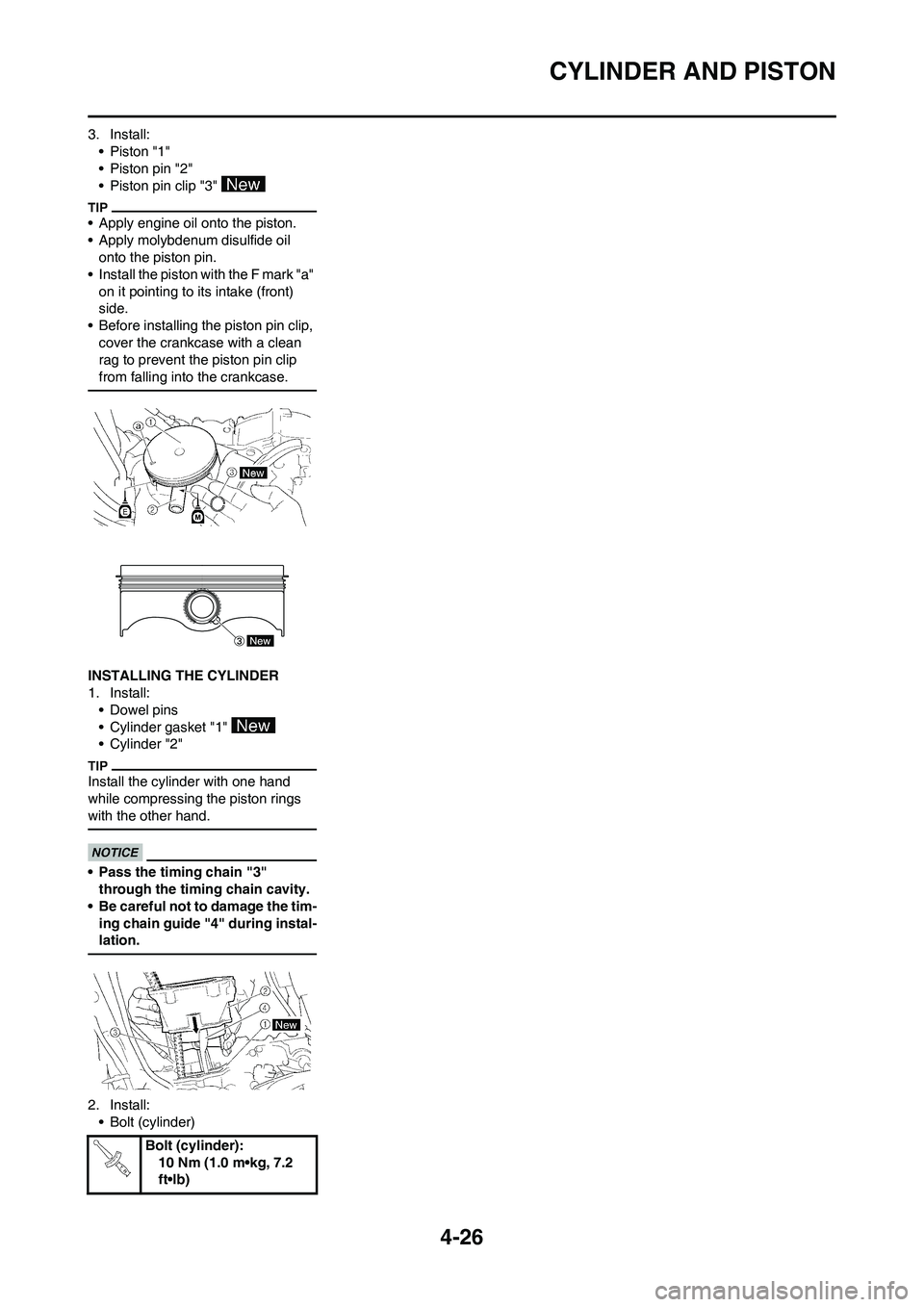

3. Install:

• Piston "1"

• Piston pin "2"

• Piston pin clip "3"

• Apply engine oil onto the piston.

• Apply molybdenum disulfide oil

onto the piston pin.

• Install the piston with the F mark "a"

on it pointing to its intake (front)

side.

• Before installing the piston pin clip,

cover the crankcase with a clean

rag to prevent the piston pin clip

from falling into the crankcase.

INSTALLING THE CYLINDER

1. Install:

• Dowel pins

• Cylinder gasket "1"

• Cylinder "2"

Install the cylinder with one hand

while compressing the piston rings

with the other hand.

• Pass the timing chain "3"

through the timing chain cavity.

• Be careful not to damage the tim-

ing chain guide "4" during instal-

lation.

2. Install:

• Bolt (cylinder)

Bolt (cylinder):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 108 of 230

4-27

CLUTCH

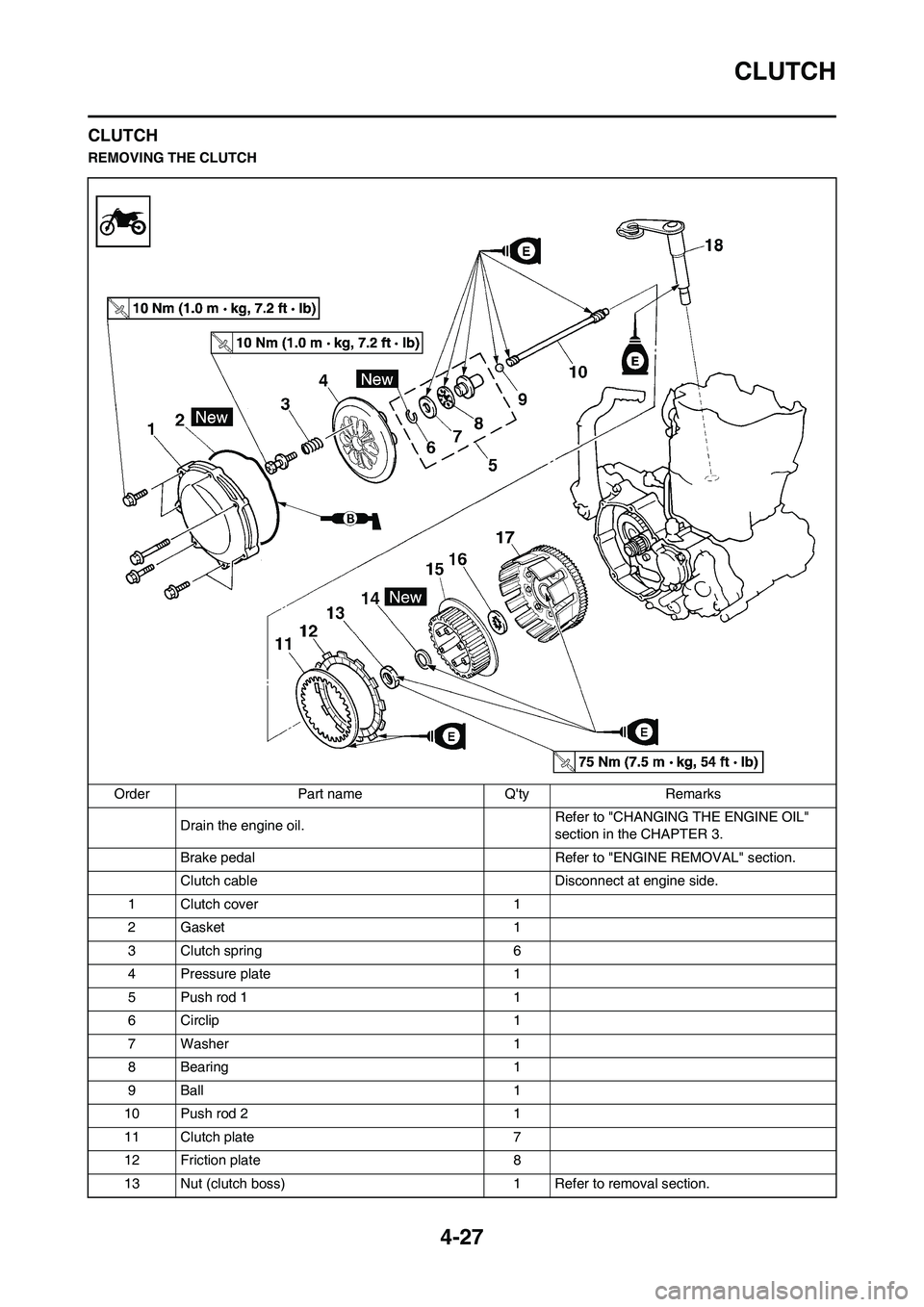

CLUTCH

REMOVING THE CLUTCH

Order Part name Q'ty Remarks

Drain the engine oil. Refer to "CHANGING THE ENGINE OIL"

section in the CHAPTER 3.

Brake pedal Refer to "ENGINE REMOVAL" section.

Clutch cable Disconnect at engine side.

1 Clutch cover 1

2 Gasket 1

3 Clutch spring 6

4 Pressure plate 1

5 Push rod 1 1

6 Circlip 1

7 Washer 1

8 Bearing 1

9Ball 1

10 Push rod 2 1

11 Clutch plate 7

12 Friction plate 8

13 Nut (clutch boss) 1 Refer to removal section.

Page 109 of 230

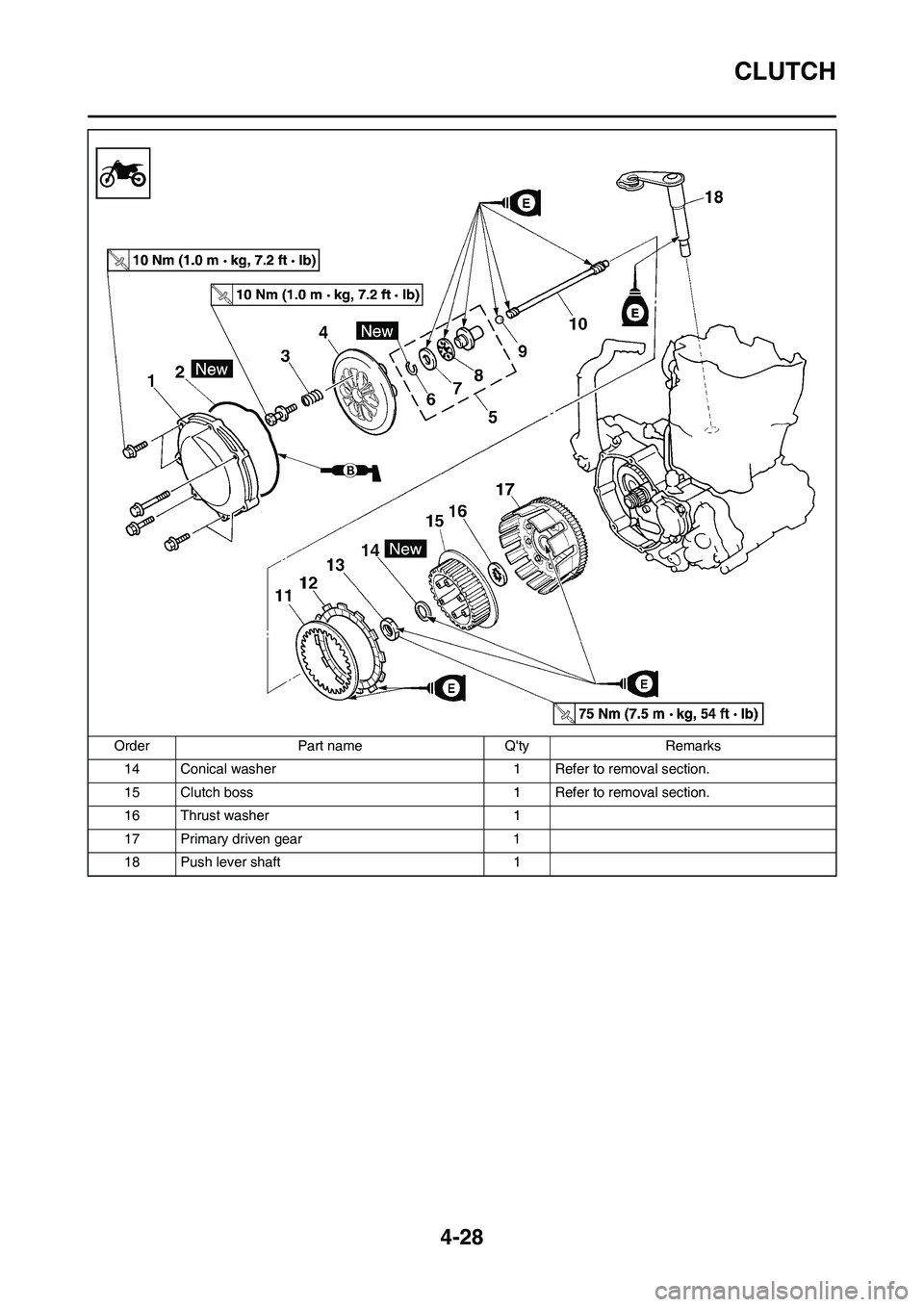

4-28

CLUTCH

14 Conical washer 1 Refer to removal section.

15 Clutch boss 1 Refer to removal section.

16 Thrust washer 1

17 Primary driven gear 1

18 Push lever shaft 1 Order Part name Q'ty Remarks

Page 110 of 230

4-29

CLUTCH

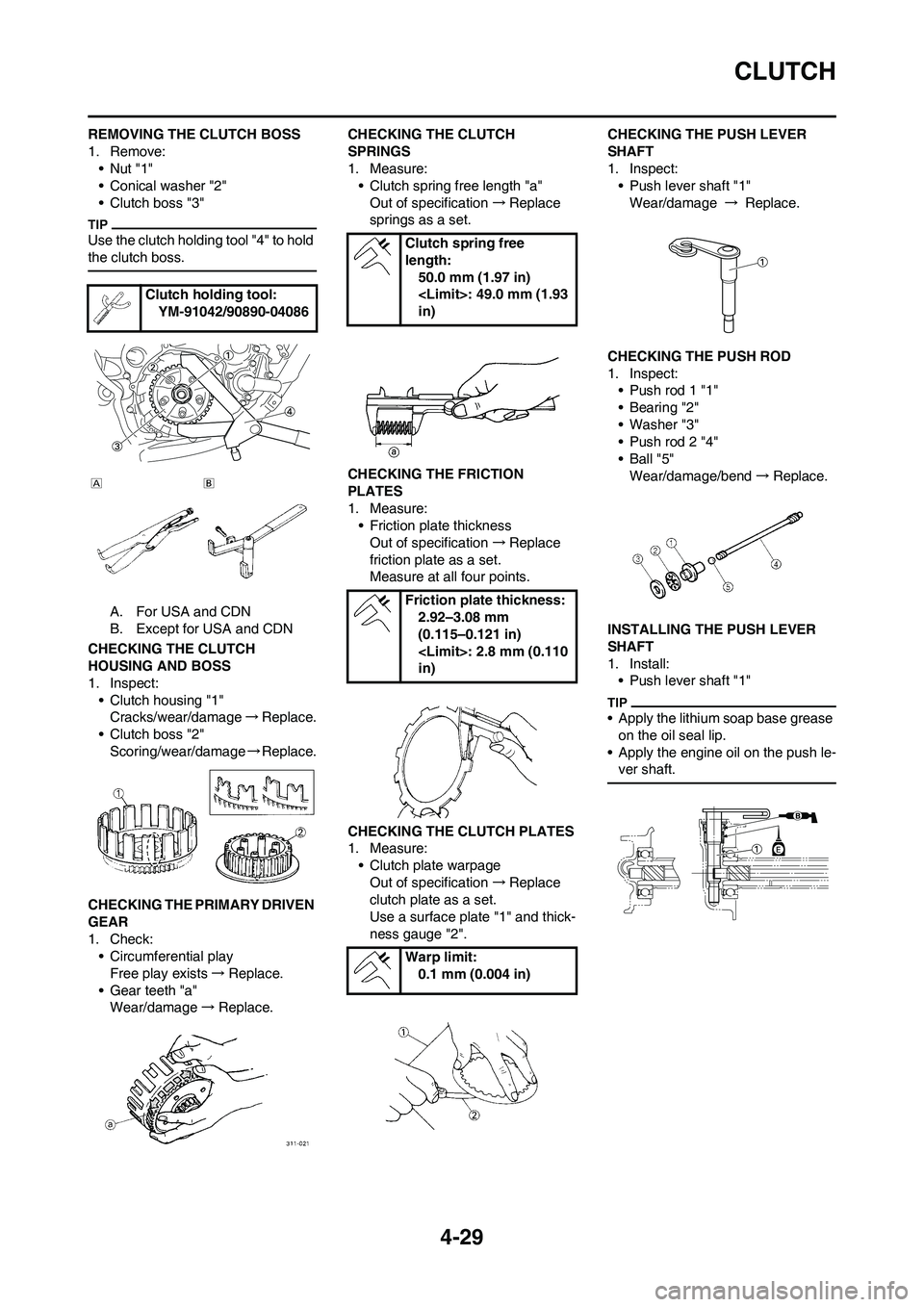

REMOVING THE CLUTCH BOSS

1. Remove:

•Nut "1"

• Conical washer "2"

• Clutch boss "3"

Use the clutch holding tool "4" to hold

the clutch boss.

A. For USA and CDN

B. Except for USA and CDN

CHECKING THE CLUTCH

HOUSING AND BOSS

1. Inspect:

• Clutch housing "1"

Cracks/wear/damage→Replace.

• Clutch boss "2"

Scoring/wear/damage→Replace.

CHECKING THE PRIMARY DRIVEN

GEAR

1. Check:

• Circumferential play

Free play exists→Replace.

• Gear teeth "a"

Wear/damage→Replace.CHECKING THE CLUTCH

SPRINGS

1. Measure:

• Clutch spring free length "a"

Out of specification→Replace

springs as a set.

CHECKING THE FRICTION

PLATES

1. Measure:

• Friction plate thickness

Out of specification→Replace

friction plate as a set.

Measure at all four points.

CHECKING THE CLUTCH PLATES

1. Measure:

• Clutch plate warpage

Out of specification→Replace

clutch plate as a set.

Use a surface plate "1" and thick-

ness gauge "2".CHECKING THE PUSH LEVER

SHAFT

1. Inspect:

• Push lever shaft "1"

Wear/damage → Replace.

CHECKING THE PUSH ROD

1. Inspect:

• Push rod 1 "1"

• Bearing "2"

• Washer "3"

• Push rod 2 "4"

•Ball "5"

Wear/damage/bend→Replace.

INSTALLING THE PUSH LEVER

SHAFT

1. Install:

• Push lever shaft "1"

• Apply the lithium soap base grease

on the oil seal lip.

• Apply the engine oil on the push le-

ver shaft.

Clutch holding tool:

YM-91042/90890-04086

Clutch spring free

length:

50.0 mm (1.97 in)

in)

Friction plate thickness:

2.92–3.08 mm

(0.115–0.121 in)

in)

Warp limit:

0.1 mm (0.004 in)