engine YAMAHA YZ450F 2014 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ450F, Model: YAMAHA YZ450F 2014Pages: 360, PDF Size: 11.76 MB

Page 96 of 360

ENGINE

3-8

EAS1SL1069

ENGINE

EAS1SL1070CHECKING THE COOLANT LEVELEWA1DX1003

WARNING

If coolant seems hot, do not remove the ra-

diator cap.

1. Stand the vehicle upright on a level surface.

2. Remove:

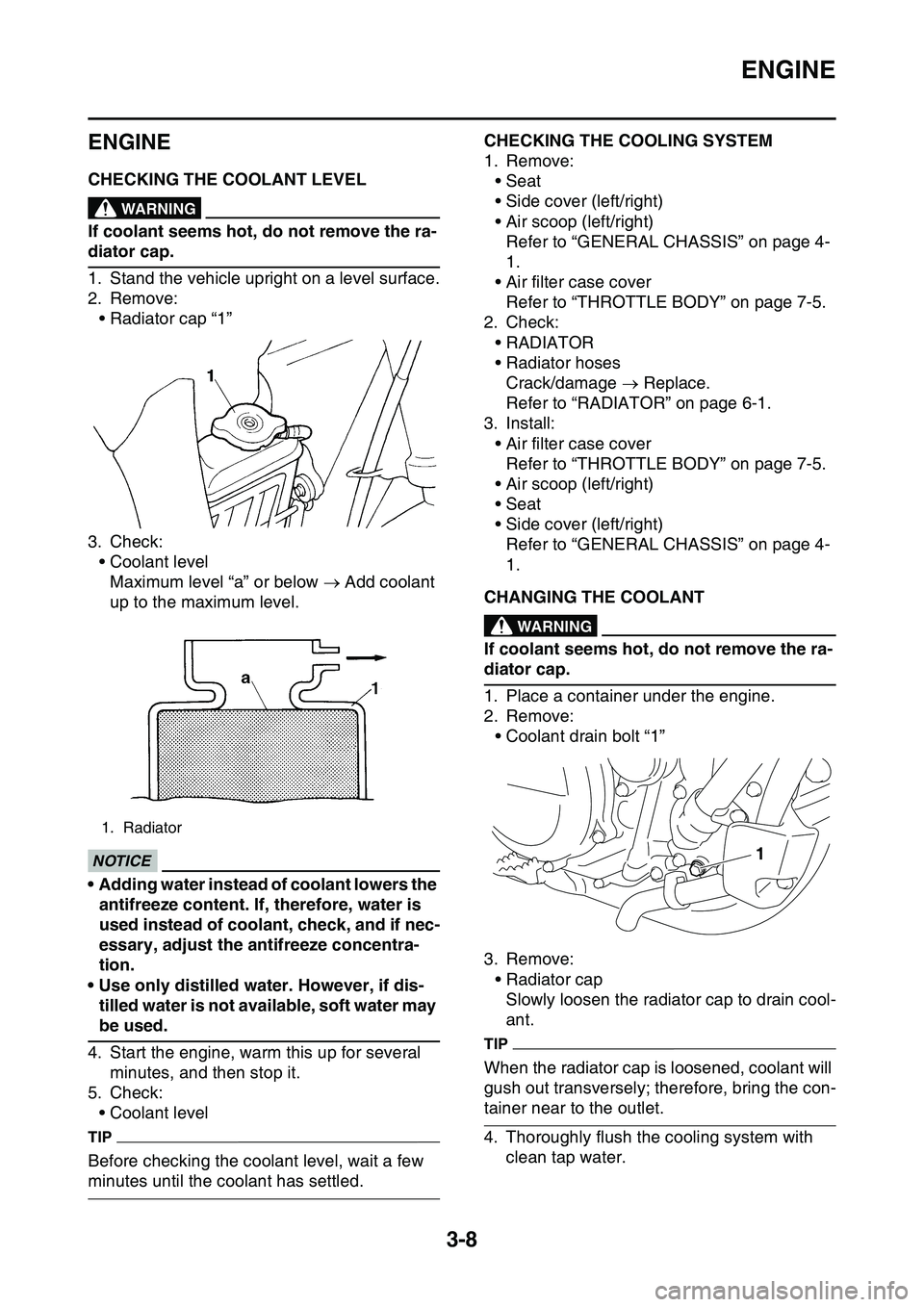

• Radiator cap “1”

3. Check:

• Coolant level

Maximum level “a” or below Add coolant

up to the maximum level.

ECA1DX1004

NOTICE

• Adding water instead of coolant lowers the

antifreeze content. If, therefore, water is

used instead of coolant, check, and if nec

-

essary, adjust the antifreeze concentra-

tion.

• Use only distilled water. However, if dis-

tilled water is not available, soft water may

be used.

4. Start the engine, warm this up for several

minutes, and then stop it.

5. Check:

• Coolant level

TIP

Before checking the coolant level, wait a few

minutes until the coolant has settled.

EAS1SL1071CHECKING THE COOLING SYSTEM

1. Remove:

• Seat

• Side cover (left/right)

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

• Air filter case cover

Refer to “THROTTLE BODY” on page 7-5.

2. Check:

•RADIATOR

• Radiator hoses

Crack/damage Replace.

Refer to “RADIATOR” on page 6-1.

3. Install:

• Air filter case cover

Refer to “THROTTLE BODY” on page 7-5.

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

EAS1SL1072CHANGING THE COOLANTEWA1DX1004

WARNING

If coolant seems hot, do not remove the ra-

diator cap.

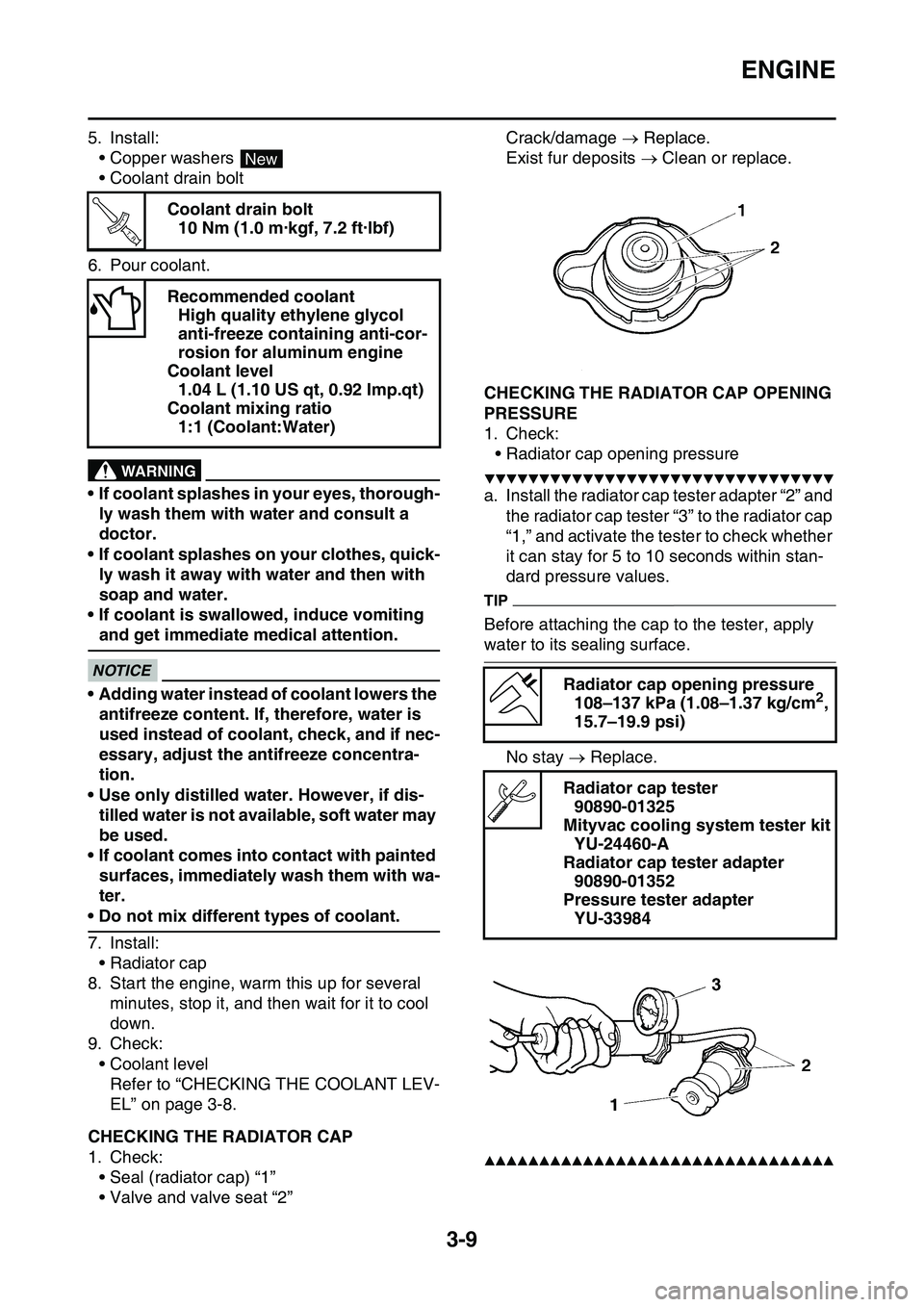

1. Place a container under the engine.

2. Remove:

• Coolant drain bolt “1”

3. Remove:

• Radiator cap

Slowly loosen the radiator cap to drain cool-

ant.

TIP

When the radiator cap is loosened, coolant will

gush out transversely; therefore, bring the con

-

tainer near to the outlet.

4. Thoroughly flush the cooling system with

clean tap water.

1. Radiator

1

Page 97 of 360

ENGINE

3-9

5. Install:

• Copper washers

• Coolant drain bolt

6. Pour coolant.

EWA13040

WARNING

• If coolant splashes in your eyes, thorough-

ly wash them with water and consult a

doctor.

• If coolant splashes on your clothes, quick-

ly wash it away with water and then with

soap and water.

• If coolant is swallowed, induce vomiting

and get immediate medical attention.

ECA13480

NOTICE

• Adding water instead of coolant lowers the

antifreeze content. If, therefore, water is

used instead of coolant, check, and if nec

-

essary, adjust the antifreeze concentra-

tion.

• Use only distilled water. However, if dis-

tilled water is not available, soft water may

be used.

• If coolant comes into contact with painted

surfaces, immediately wash them with wa

-

ter.

• Do not mix different types of coolant.

7. Install:

• Radiator cap

8. Start the engine, warm this up for several

minutes, stop it, and then wait for it to cool

down.

9. Check:

• Coolant level

Refer to “CHECKING THE COOLANT LEV-

EL” on page 3-8.

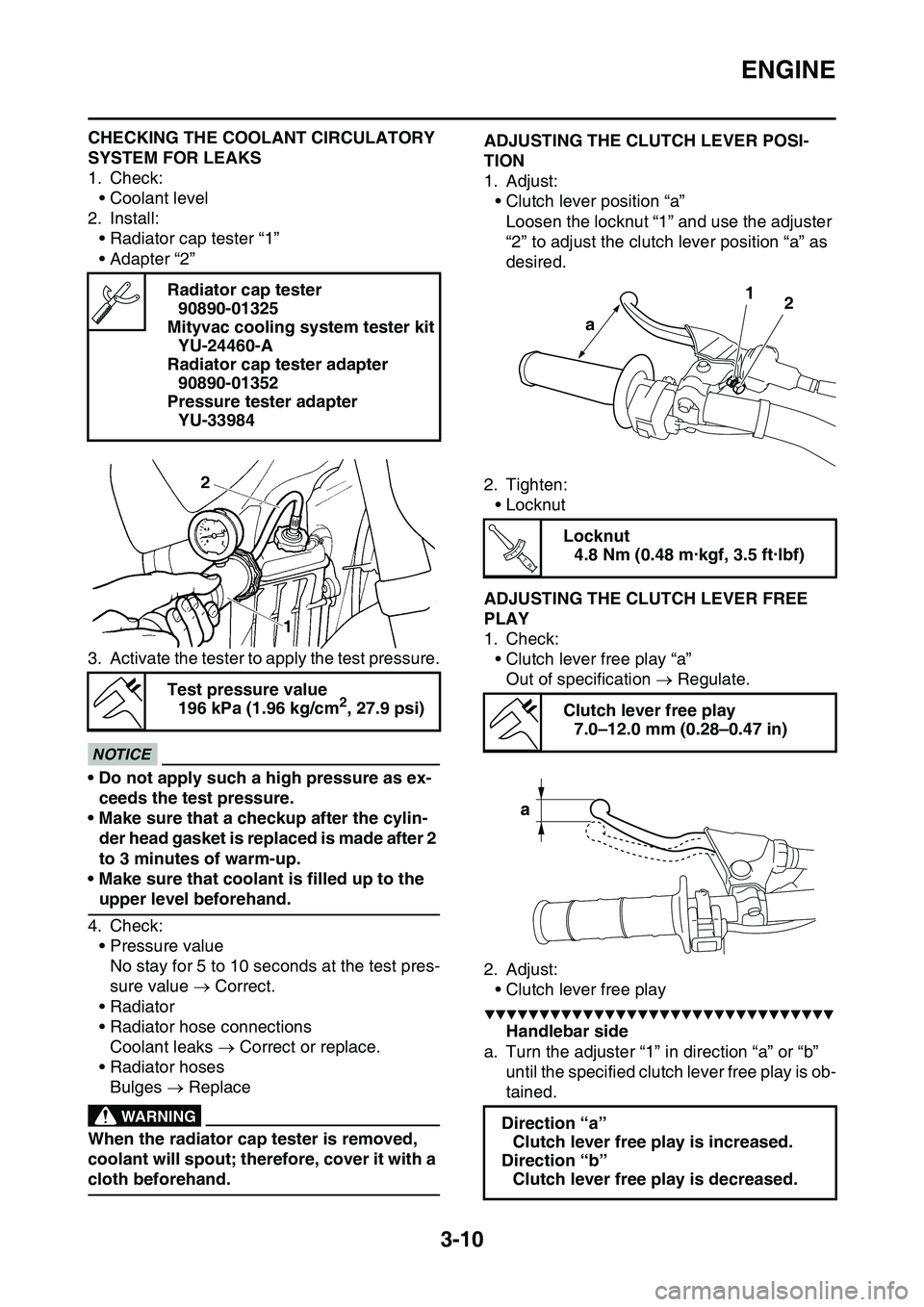

EAS1SL1073CHECKING THE RADIATOR CAP

1. Check:

• Seal (radiator cap) “1”

• Valve and valve seat “2”

Crack/damage Replace.

Exist fur deposits Clean or replace.

EAS1SL1074CHECKING THE RADIATOR CAP OPENING

PRESSURE

1. Check:

• Radiator cap opening pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Install the radiator cap tester adapter “2” and

the radiator cap tester “3” to the radiator cap

“1,” and activate the tester to check whether

it can stay for 5 to 10 seconds within stan

-

dard pressure values.

TIP

Before attaching the cap to the tester, apply

water to its sealing surface.

No stay Replace.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1075

Coolant drain bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Recommended coolant

High quality ethylene glycol

anti-freeze containing anti-cor

-

rosion for aluminum engine

Coolant level

1.04 L (1.10 US qt, 0.92 Imp.qt)

Coolant mixing ratio

1:1 (Coolant:Water)

New

T R..

Radiator cap opening pressure

108–137 kPa (1.08–1.37 kg/cm2,

15.7–19.9 psi)

Radiator cap tester

90890-01325

Mityvac cooling system tester kit

YU-24460-A

Radiator cap tester adapter

90890-01352

Pressure tester adapter

YU-33984

Page 98 of 360

ENGINE

3-10

CHECKING THE COOLANT CIRCULATORY

SYSTEM FOR LEAKS

1. Check:

• Coolant level

2. Install:

• Radiator cap tester “1”

• Adapter “2”

3. Activate the tester to apply the test pressure.

ECA@

NOTICE

• Do not apply such a high pressure as ex-

ceeds the test pressure.

• Make sure that a checkup after the cylin-

der head gasket is replaced is made after 2

to 3 minutes of warm-up.

• Make sure that coolant is filled up to the

upper level beforehand.

4. Check:

• Pressure value

No stay for 5 to 10 seconds at the test pres-

sure value Correct.

• Radiator

• Radiator hose connections

Coolant leaks Correct or replace.

• Radiator hoses

Bulges ReplaceEWA@

WARNING

When the radiator cap tester is removed,

coolant will spout; therefore, cover it with a

cloth beforehand.

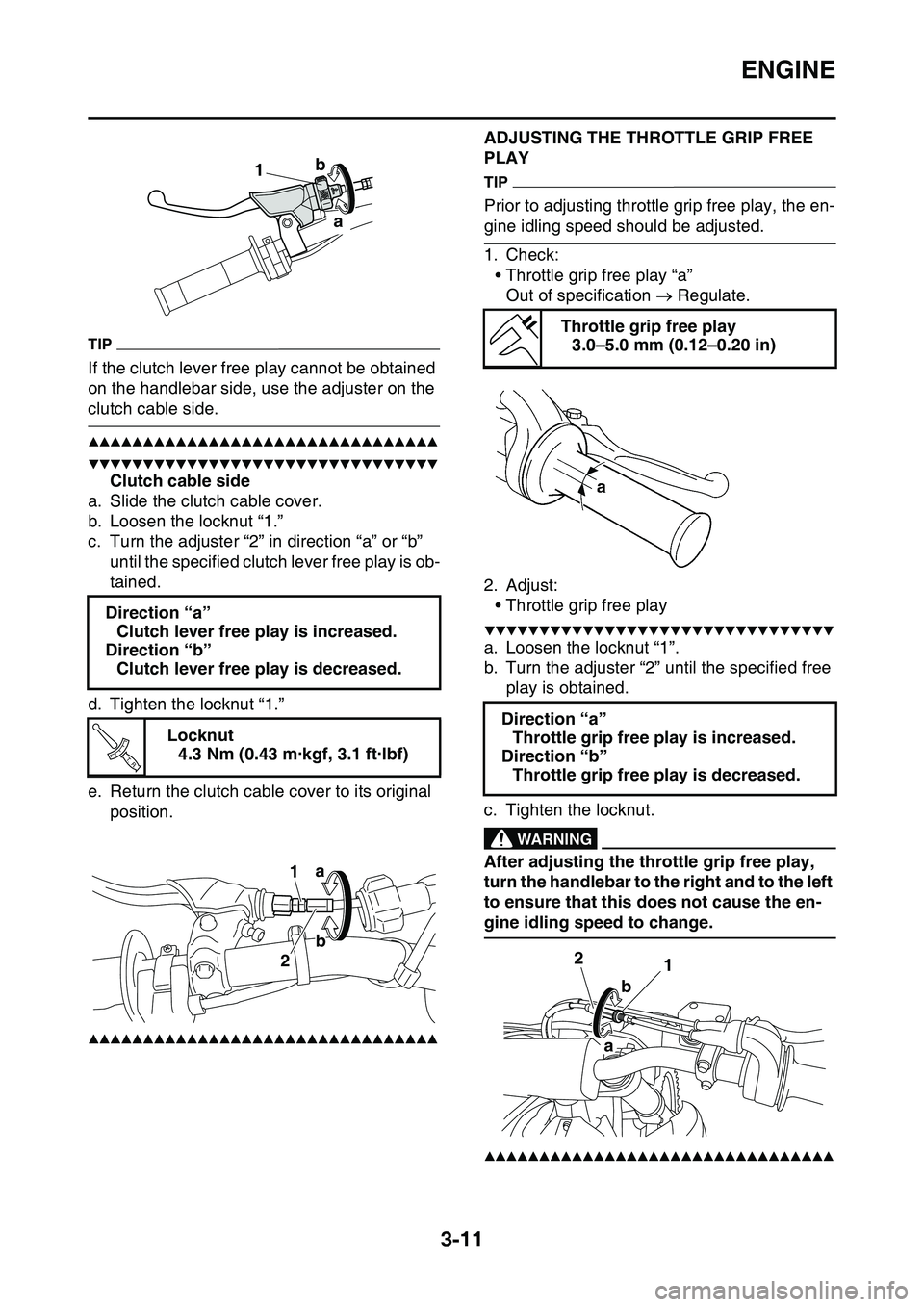

EAS1SL1076ADJUSTING THE CLUTCH LEVER POSI-

TION

1. Adjust:

• Clutch lever position “a”

Loosen the locknut “1” and use the adjuster

“2” to adjust the clutch lever position “a” as

desired.

2. Tighten:

• Locknut

EAS1SL1077ADJUSTING THE CLUTCH LEVER FREE

PLAY

1. Check:

• Clutch lever free play “a”

Out of specification Regulate.

2. Adjust:

• Clutch lever free play

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Handlebar side

a. Turn the adjuster “1” in direction “a” or “b”

until the specified clutch lever free play is ob

-

tained.

Radiator cap tester

90890-01325

Mityvac cooling system tester kit

YU-24460-A

Radiator cap tester adapter

90890-01352

Pressure tester adapter

YU-33984

Test pressure value

196 kPa (1.96 kg/cm2, 27.9 psi)

Locknut

4.8 Nm (0.48 m·kgf, 3.5 ft·lbf)

Clutch lever free play

7.0–12.0 mm (0.28–0.47 in)

Direction “a”

Clutch lever free play is increased.

Direction “b”

Clutch lever free play is decreased.

1

2

a

T R..

Page 99 of 360

ENGINE

3-11

TIP

If the clutch lever free play cannot be obtained

on the handlebar side, use the adjuster on the

clutch cable side.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Clutch cable side

a. Slide the clutch cable cover.

b. Loosen the locknut “1.”

c. Turn the adjuster “2” in direction “a” or “b”

until the specified clutch lever free play is ob

-

tained.

d. Tighten the locknut “1.”

e. Return the clutch cable cover to its original

position.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1078

ADJUSTING THE THROTTLE GRIP FREE

PLAY

TIP

Prior to adjusting throttle grip free play, the en-

gine idling speed should be adjusted.

1. Check:

• Throttle grip free play “a”

Out of specification Regulate.

2. Adjust:

• Throttle grip free play

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the locknut “1”.

b. Turn the adjuster “2” until the specified free

play is obtained.

c. Tighten the locknut.EWA33DD008

WARNING

After adjusting the throttle grip free play,

turn the handlebar to the right and to the left

to ensure that this does not cause the en

-

gine idling speed to change.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1079

Direction “a”

Clutch lever free play is increased.

Direction “b”

Clutch lever free play is decreased.

Locknut

4.3 Nm (0.43 m·kgf, 3.1 ft·lbf)

a b

1

T R..

1a

b

2

b

Throttle grip free play

3.0–5.0 mm (0.12–0.20 in)

Direction “a”

Throttle grip free play is increased.

Direction “b”

Throttle grip free play is decreased.

1 2

b

a

Page 100 of 360

ENGINE

3-12

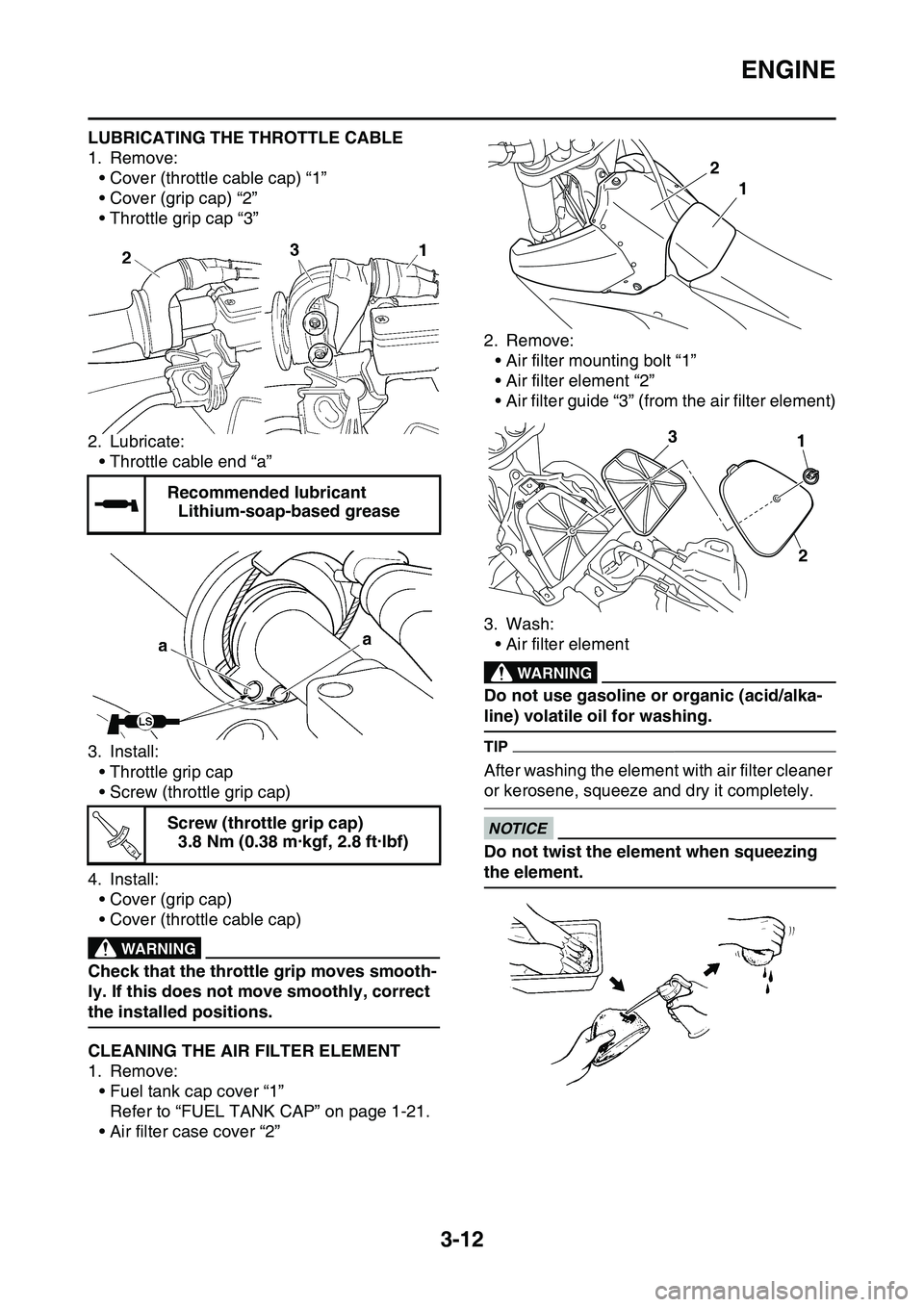

LUBRICATING THE THROTTLE CABLE

1. Remove:• Cover (throttle cable cap) “1”

• Cover (grip cap) “2”

• Throttle grip cap “3”

2. Lubricate: • Throttle cable end “a”

3. Install: • Throttle grip cap

• Screw (throttle grip cap)

4. Install: • Cover (grip cap)

• Cover (throttle cable cap)

EWA

WARNING

Check that the throttle grip moves smooth-

ly. If this does not move smoothly, correct

the installed positions.

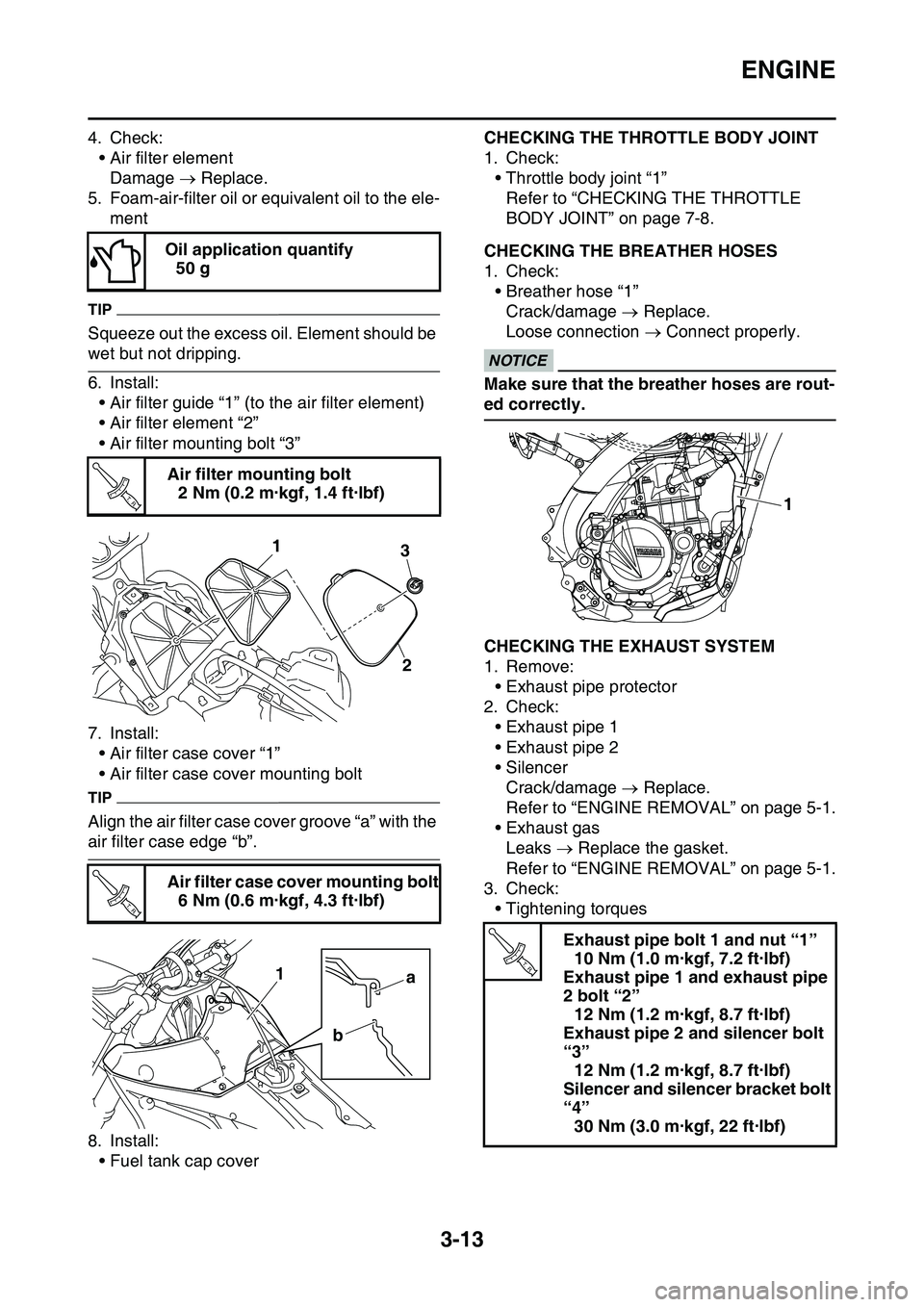

EAS1SL1080CLEANING THE AIR FILTER ELEMENT

1. Remove:• Fuel tank cap cover “1”Refer to “FUEL TANK CAP” on page 1-21.

• Air filter case cover “2” 2. Remove:

• Air filter mounting bolt “1”

• Air filter element “2”

• Air filter guide “3” (from the air filter element)

3. Wash: • Air filter element

EWA

WARNING

Do not use gasoline or organic (acid/alka-

line) volatile oil for washing.

TIP

After washing the element with air filter cleaner

or kerosene, squeeze and dry it completely.

ECA33DD016

NOTICE

Do not twist the element when squeezing

the element.

Recommended lubricant

Lithium-soap-based grease

Screw (throttle grip cap) 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

T R..

1

2

13

2

Page 101 of 360

ENGINE

3-13

4. Check:• Air filter elementDamage Replace.

5. Foam-air-filter oil or equivalent oil to the ele- ment

TIP

Squeeze out the excess oil. Element should be

wet but not dripping.

6. Install:• Air filter guide “1” (to the air filter element)

• Air filter element “2”

• Air filter mounting bolt “3”

7. Install: • Air filter case cover “1”

• Air filter case cover mounting bolt

TIP

Align the air filter case cover groove “a” with the

air filter case edge “b”.

8. Install:• Fuel tank cap cover

EAS1SL1081

CHECKING THE THROTTLE BODY JOINT

1. Check:• Throttle body joint “1”

Refer to “CHECKING THE THROTTLE

BODY JOINT” on page 7-8.

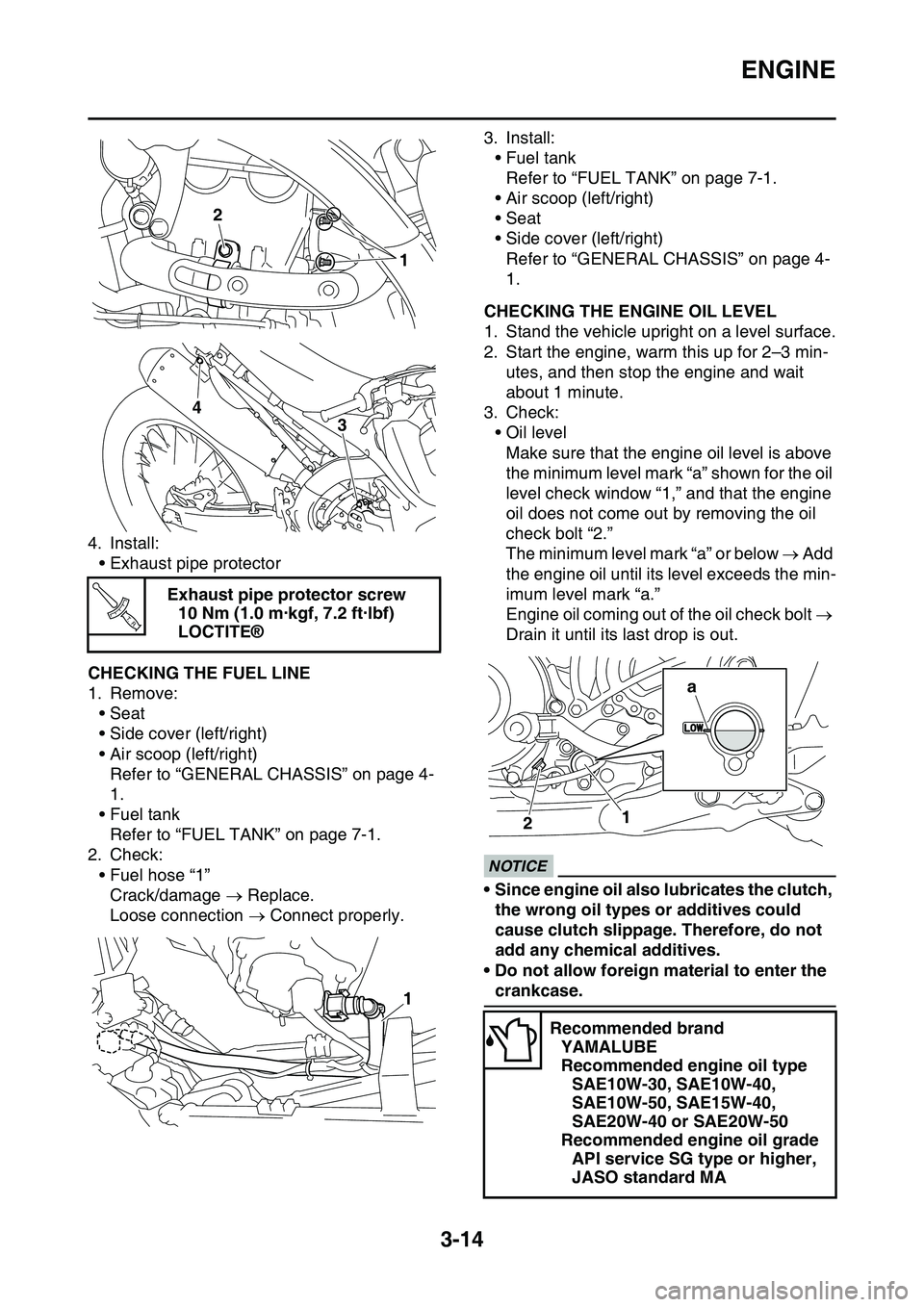

EAS1SL1082CHECKING THE BREATHER HOSES

1. Check:• Breather hose “1”Crack/damage Replace.

Loose connection Connect properly.

ECA14920

NOTICE

Make sure that the breather hoses are rout-

ed correctly.

EAS1SL1083CHECKING THE EXHAUST SYSTEM

1. Remove:

• Exhaust pipe protector

2. Check:

• Exhaust pipe 1

• Exhaust pipe 2

• SilencerCrack/damage Replace.

Refer to “ENGINE REMOVAL” on page 5-1.

• Exhaust gas

Leaks Replace the gasket.

Refer to “ENGINE REMOVAL” on page 5-1.

3. Check:

• Tightening torques

Oil application quantify

50 g

Air filter mounting bolt 2 Nm (0.2 m·kgf, 1.4 ft·lbf)

Air filter case cover mounting bolt 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

T R..

31

2

T R..

a

b

1

Exhaust pipe bolt 1 and nut “1”

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Exhaust pipe 1 and exhaust pipe

2 bolt “2” 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Exhaust pipe 2 and silencer bolt

“3” 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Silencer and silencer bracket bolt

“4” 30 Nm (3.0 m·kgf, 22 ft·lbf)

1

T R..

Page 102 of 360

ENGINE

3-14

4. Install:

• Exhaust pipe protector

EAS1SL1084CHECKING THE FUEL LINE

1. Remove:

• Seat

• Side cover (left/right)

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

2. Check:

• Fuel hose “1”

Crack/damage Replace.

Loose connection Connect properly.

3. Install:

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

EAS1SL1085CHECKING THE ENGINE OIL LEVEL

1. Stand the vehicle upright on a level surface.

2. Start the engine, warm this up for 2–3 min-

utes, and then stop the engine and wait

about 1 minute.

3. Check:

• Oil level

Make sure that the engine oil level is above

the minimum level mark “a” shown for the oil

level check window “1,” and that the engine

oil does not come out by removing the oil

check bolt “2.”

The minimum level mark “a” or below Add

the engine oil until its level exceeds the min

-

imum level mark “a.”

Engine oil coming out of the oil check bolt

Drain it until its last drop is out.

ECA33DD018

NOTICE

• Since engine oil also lubricates the clutch,

the wrong oil types or additives could

cause clutch slippage. Therefore, do not

add any chemical additives.

• Do not allow foreign material to enter the

crankcase.

Exhaust pipe protector screw

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

LOCTITE®

2

1

4

3

T R..

1

Recommended brand

YAMALUBE

Recommended engine oil type

SAE10W-30, SAE10W-40,

SAE10W-50, SAE15W-40,

SAE20W-40 or SAE20W-50

Recommended engine oil grade

API service SG type or higher,

JASO standard MA

12

a

Page 103 of 360

ENGINE

3-15

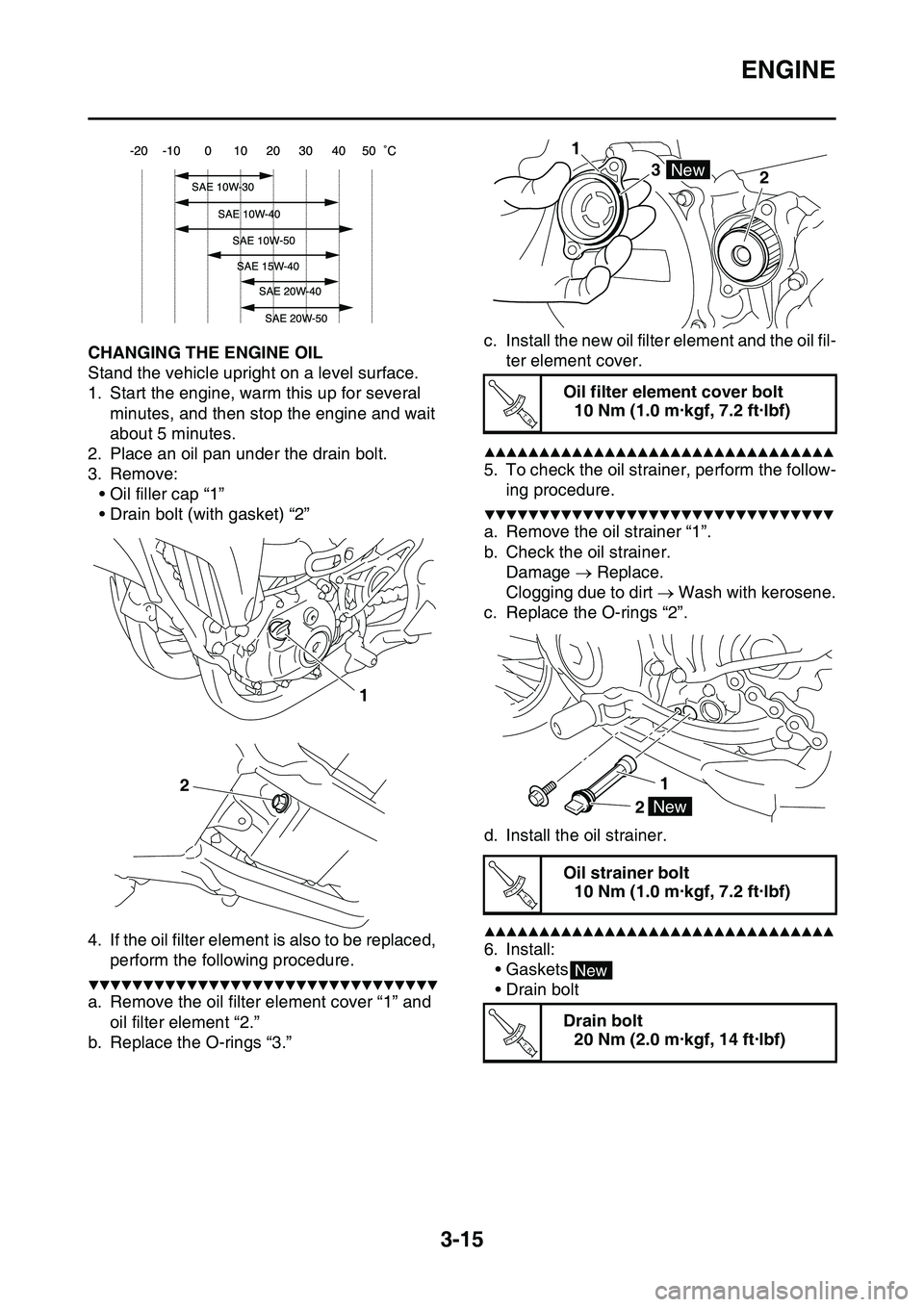

EAS1SL1086CHANGING THE ENGINE OIL

Stand the vehicle upright on a level surface.

1. Start the engine, warm this up for several

minutes, and then stop the engine and wait

about 5 minutes.

2. Place an oil pan under the drain bolt.

3. Remove:

• Oil filler cap “1”

• Drain bolt (with gasket) “2”

4. If the oil filter element is also to be replaced,

perform the following procedure.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the oil filter element cover “1” and

oil filter element “2.”

b. Replace the O-rings “3.”

c. Install the new oil filter element and the oil fil-

ter element cover.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. To check the oil strainer, perform the follow-

ing procedure.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the oil strainer “1”.

b. Check the oil strainer.

Damage Replace.

Clogging due to dirt Wash with kerosene.

c. Replace the O-rings “2”.

d. Install the oil strainer.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

6. Install:

•Gaskets

• Drain bolt

1

2

Oil filter element cover bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil strainer bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Drain bolt

20 Nm (2.0 m·kgf, 14 ft·lbf)

1

3

2

New

T R..

1

2New

T R..

New

T R..

Page 104 of 360

ENGINE

3-16

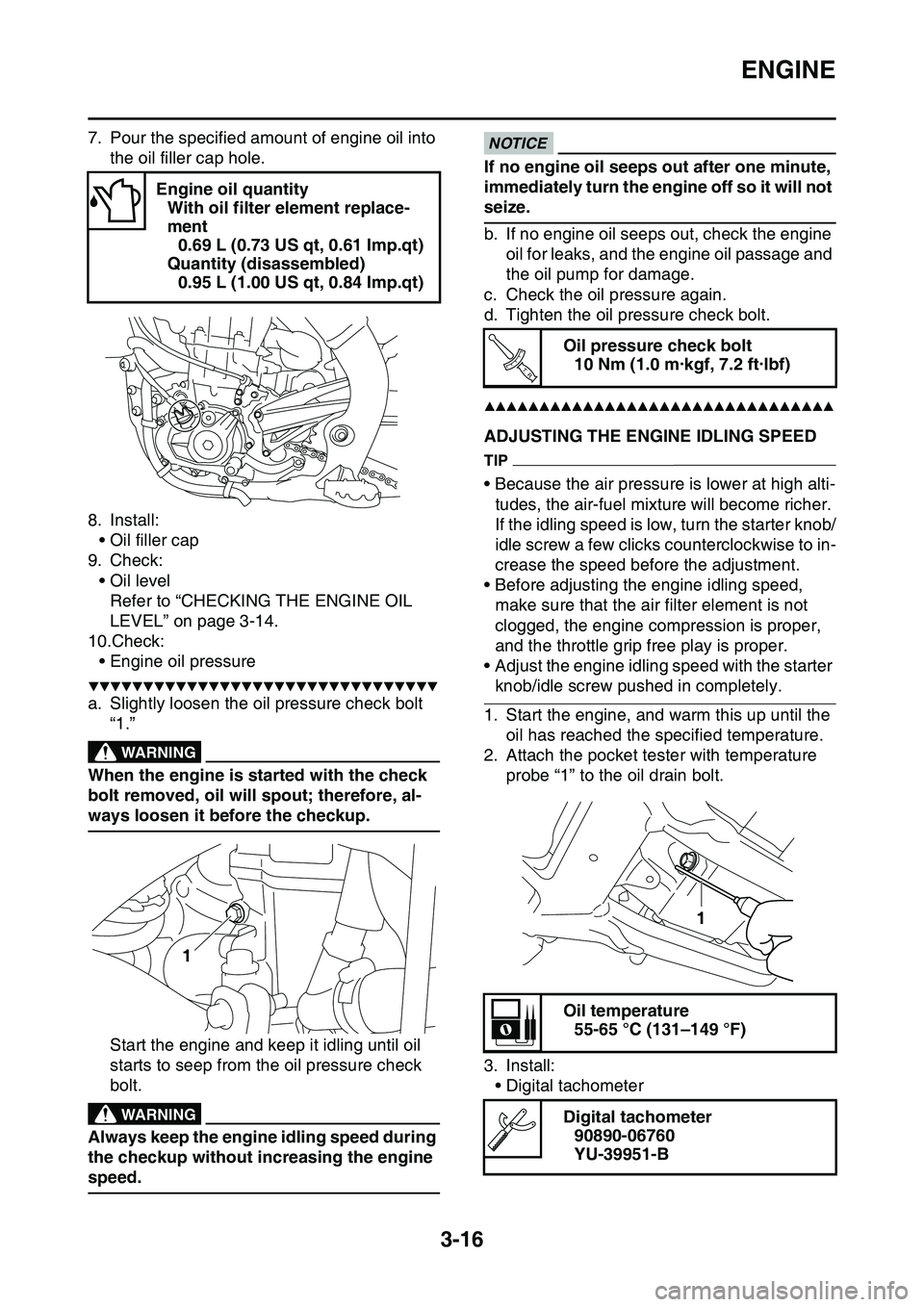

7. Pour the specified amount of engine oil into

the oil filler cap hole.

8. Install:

• Oil filler cap

9. Check:

• Oil level

Refer to “CHECKING THE ENGINE OIL

LEVEL” on page 3-14.

10.Check:

• Engine oil pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Slightly loosen the oil pressure check bolt

“1.”

EWA

WARNING

When the engine is started with the check

bolt removed, oil will spout; therefore, al

-

ways loosen it before the checkup.

Start the engine and keep it idling until oil

starts to seep from the oil pressure check

bolt.

EWA

WARNING

Always keep the engine idling speed during

the checkup without increasing the engine

speed.

ECA

NOTICE

If no engine oil seeps out after one minute,

immediately turn the engine off so it will not

seize.

b. If no engine oil seeps out, check the engine

oil for leaks, and the engine oil passage and

the oil pump for damage.

c. Check the oil pressure again.

d. Tighten the oil pressure check bolt.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1087ADJUSTING THE ENGINE IDLING SPEED

TIP

• Because the air pressure is lower at high alti-

tudes, the air-fuel mixture will become richer.

If the idling speed is low, turn the starter knob/

idle screw a few clicks counterclockwise to in

-

crease the speed before the adjustment.

• Before adjusting the engine idling speed,

make sure that the air filter element is not

clogged, the engine compression is proper,

and the throttle grip free play is proper.

• Adjust the engine idling speed with the starter

knob/idle screw pushed in completely.

1. Start the engine, and warm this up until the

oil has reached the specified temperature.

2. Attach the pocket tester with temperature

probe “1” to the oil drain bolt.

3. Install:

• Digital tachometer

Engine oil quantity

With oil filter element replace-

ment

0.69 L (0.73 US qt, 0.61 Imp.qt)

Quantity (disassembled)

0.95 L (1.00 US qt, 0.84 Imp.qt)

1

Oil pressure check bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil temperature

55-65 °C (131–149 °F)

Digital tachometer

90890-06760

YU-39951-B

T R..

1

Page 105 of 360

ENGINE

3-17

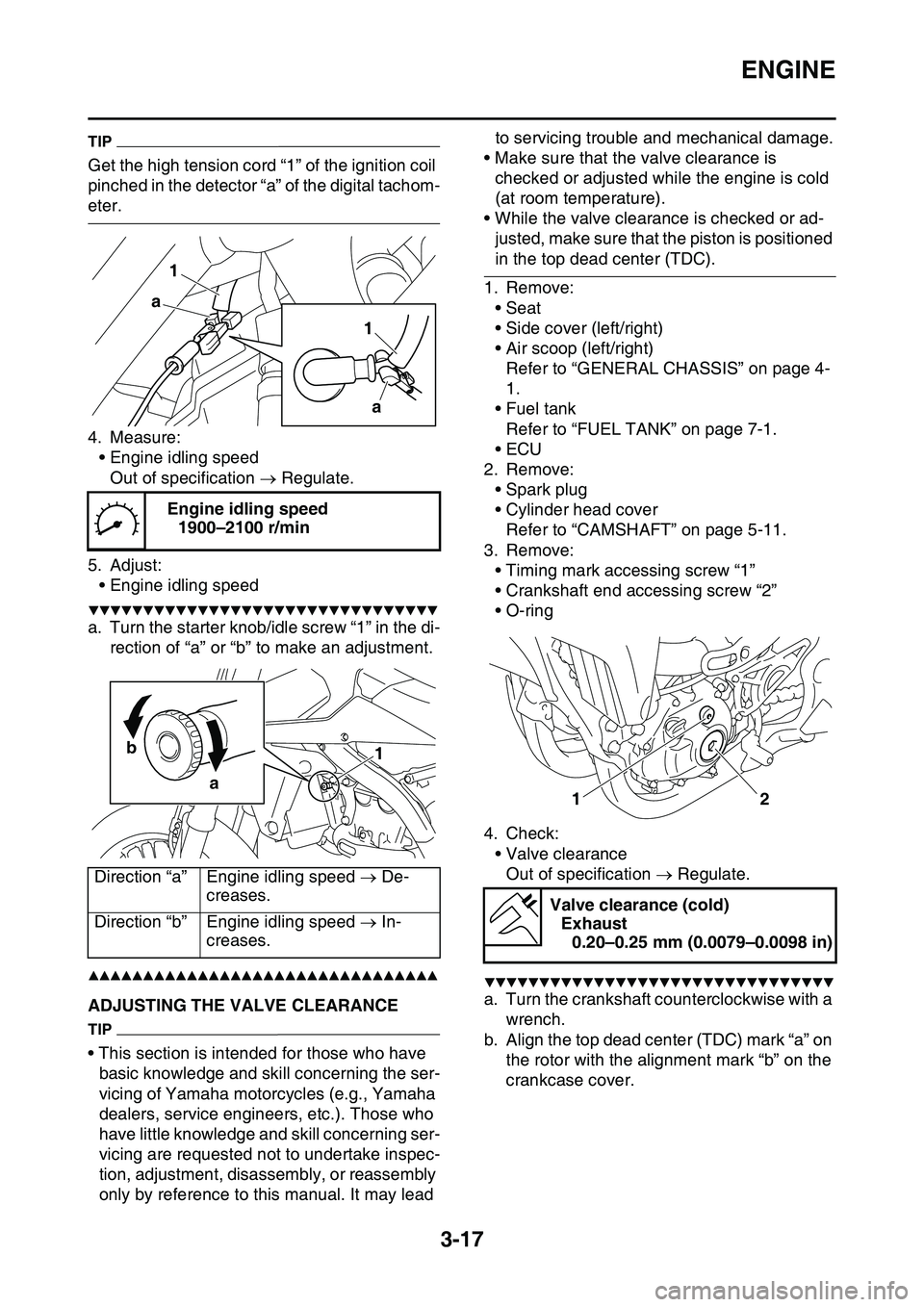

TIP

Get the high tension cord “1” of the ignition coil

pinched in the detector “a” of the digital tachom

-

eter.

4. Measure:

• Engine idling speed

Out of specification Regulate.

5. Adjust:

• Engine idling speed

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the starter knob/idle screw “1” in the di-

rection of “a” or “b” to make an adjustment.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SL1088ADJUSTING THE VALVE CLEARANCE

TIP

• This section is intended for those who have

basic knowledge and skill concerning the ser

-

vicing of Yamaha motorcycles (e.g., Yamaha

dealers, service engineers, etc.). Those who

have little knowledge and skill concerning ser

-

vicing are requested not to undertake inspec-

tion, adjustment, disassembly, or reassembly

only by reference to this manual. It may lead to servicing trouble and mechanical damage.

• Make sure that the valve clearance is

checked or adjusted while the engine is cold

(at room temperature).

• While the valve clearance is checked or ad-

justed, make sure that the piston is positioned

in the top dead center (TDC).

1. Remove:

• Seat

• Side cover (left/right)

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

•ECU

2. Remove:

• Spark plug

• Cylinder head cover

Refer to “CAMSHAFT” on page 5-11.

3. Remove:

• Timing mark accessing screw “1”

• Crankshaft end accessing screw “2”

• O-ring

4. Check:

• Valve clearance

Out of specification Regulate.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the crankshaft counterclockwise with a

wrench.

b. Align the top dead center (TDC) mark “a” on

the rotor with the alignment mark “b” on the

crankcase cover.

Engine idling speed

1900–2100 r/min

Direction “a”Engine idling speed De-

creases.

Direction “b”Engine idling speed In-

creases.

1 1

a a

1 b

a

Valve clearance (cold)

Exhaust

0.20–0.25 mm (0.0079–0.0098 in)

1

2