engine YAMAHA YZ450F 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ450F, Model: YAMAHA YZ450F 2014Pages: 360, PDF Size: 11.76 MB

Page 25 of 360

IMPORTANT INFORMATION

1-11

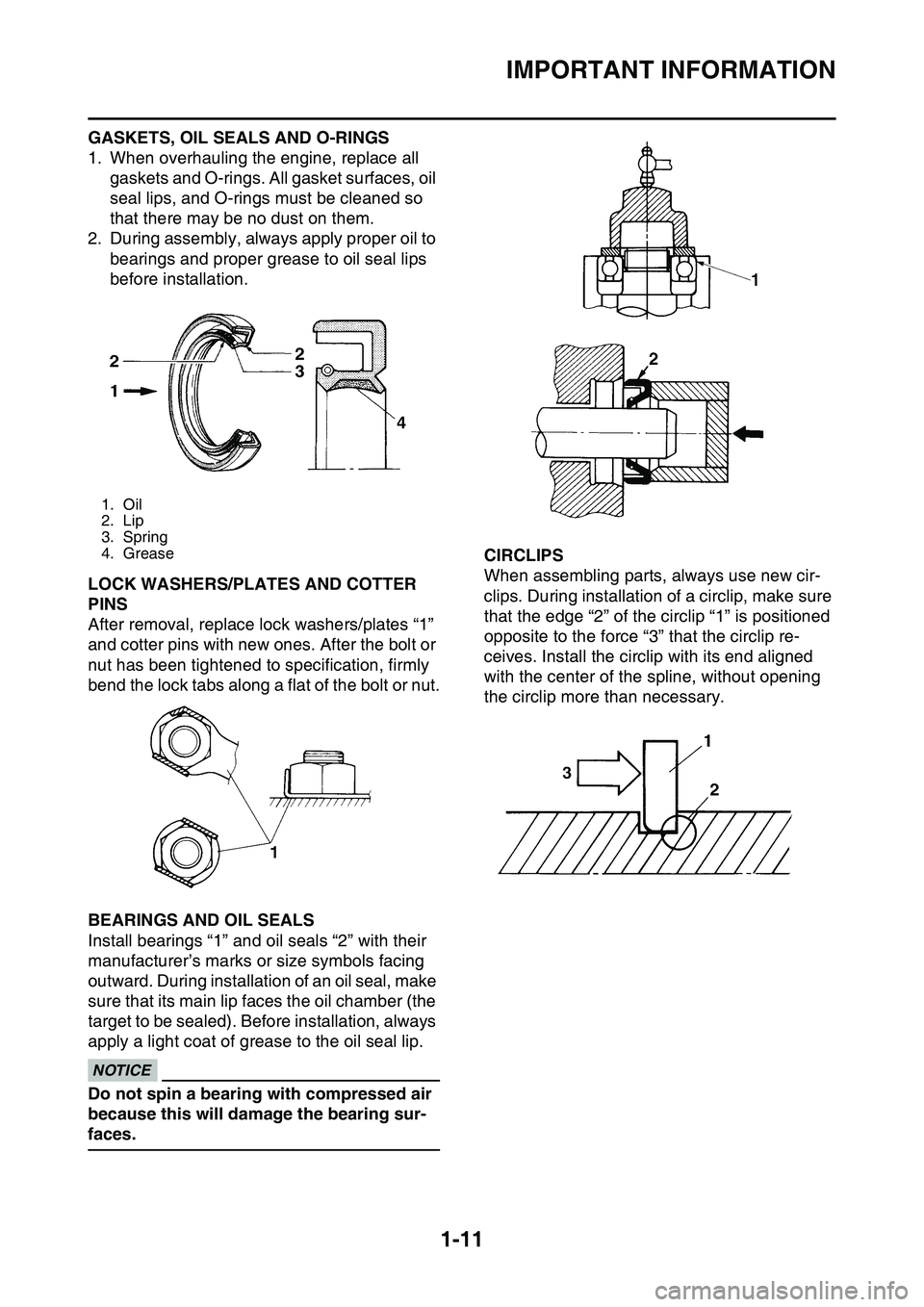

GASKETS, OIL SEALS AND O-RINGS

1. When overhauling the engine, replace all

gaskets and O-rings. All gasket surfaces, oil

seal lips, and O-rings must be cleaned so

that there may be no dust on them.

2. During assembly, always apply proper oil to

bearings and proper grease to oil seal lips

before installation.

EAS1SL1026LOCK WASHERS/PLATES AND COTTER

PINS

After removal, replace lock washers/plates “1”

and cotter pins with new ones. After the bolt or

nut has been tightened to specification, firmly

bend the lock tabs along a flat of the bolt or nut.

EAS1SL1027BEARINGS AND OIL SEALS

Install bearings “1” and oil seals “2” with their

manufacturer’s marks or size symbols facing

outward. During installation of an oil seal, make

sure that its main lip faces the oil chamber (the

target to be sealed). Before installation, always

apply a light coat of grease to the oil seal lip.

ECA13300

NOTICE

Do not spin a bearing with compressed air

because this will damage the bearing sur

-

faces.

EAS1SL1028CIRCLIPS

When assembling parts, always use new cir-

clips. During installation of a circlip, make sure

that the edge “2” of the circlip “1” is positioned

opposite to the force “3” that the circlip re

-

ceives. Install the circlip with its end aligned

with the center of the spline, without opening

the circlip more than necessary.

1. Oil

2. Lip

3. Spring

4. Grease

Page 33 of 360

SPECIAL TOOLS

1-19

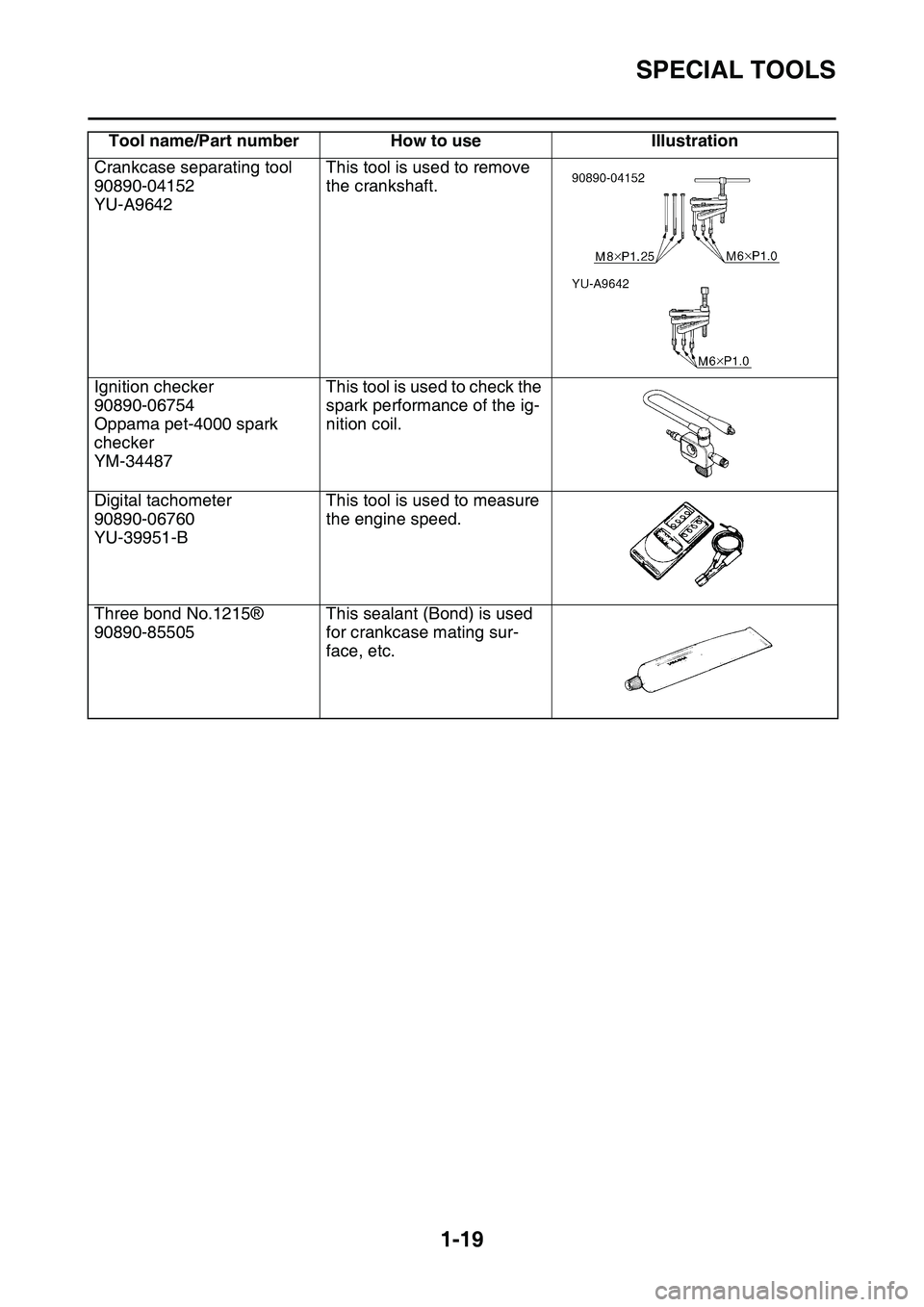

Crankcase separating tool

90890-04152

YU-A9642

This tool is used to remove

the crankshaft.

Ignition checker

90890-06754

Oppama pet-4000 spark

checker

YM-34487

This tool is used to check the

spark performance of the ig

-

nition coil.

Digital tachometer

90890-06760

YU-39951-B

This tool is used to measure

the engine speed.

Three bond No.1215®

90890-85505

This sealant (Bond) is used

for crankcase mating sur

-

face, etc.

Tool name/Part number How to use Illustration

Page 34 of 360

CONTROL FUNCTIONS

1-20

EAS1SL1032

CONTROL FUNCTIONS

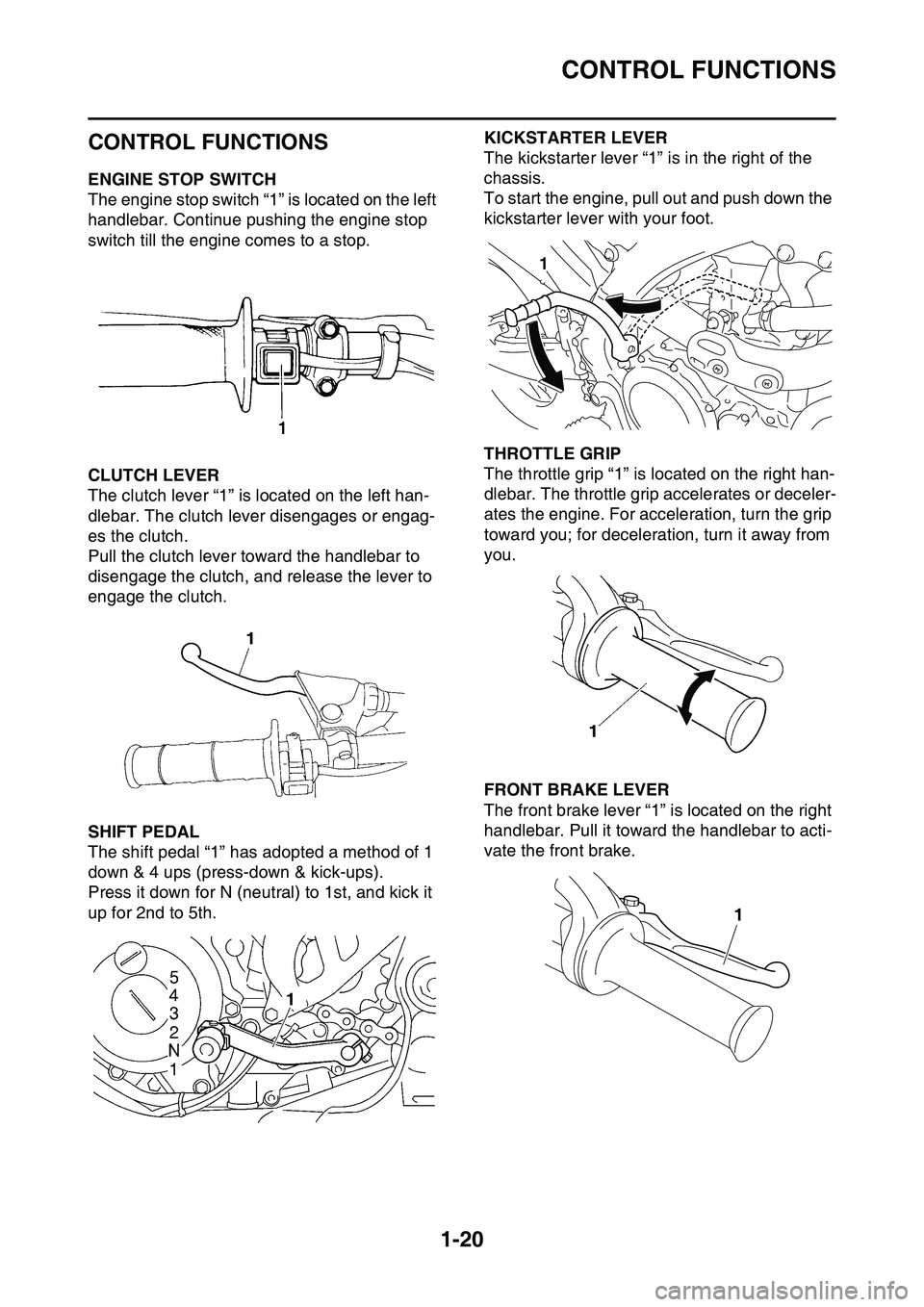

EAS1SL1033ENGINE STOP SWITCH

The engine stop switch “1” is located on the left

handlebar. Continue pushing the engine stop

switch till the engine comes to a stop.

EAS1SL1034CLUTCH LEVER

The clutch lever “1” is located on the left han-

dlebar. The clutch lever disengages or engag-

es the clutch.

Pull the clutch lever toward the handlebar to

disengage the clutch, and release the lever to

engage the clutch.

EAS1SL1035SHIFT PEDAL

The shift pedal “1” has adopted a method of 1

down & 4 ups (press-down & kick-ups).

Press it down for N (neutral) to 1st, and kick it

up for 2nd to 5th.

EAS1SL1036

KICKSTARTER LEVER

The kickstarter lever “1” is in the right of the

chassis.

To start the engine, pull out and push down the

kickstarter lever with your foot.

EAS1SL1037THROTTLE GRIP

The throttle grip “1” is located on the right han-

dlebar. The throttle grip accelerates or deceler-

ates the engine. For acceleration, turn the grip

toward you; for deceleration, turn it away from

you.

EAS1SL1038FRONT BRAKE LEVER

The front brake lever “1” is located on the right

handlebar. Pull it toward the handlebar to acti

-

vate the front brake.

EAS1SL1039

1

1

Page 35 of 360

CONTROL FUNCTIONS

1-21

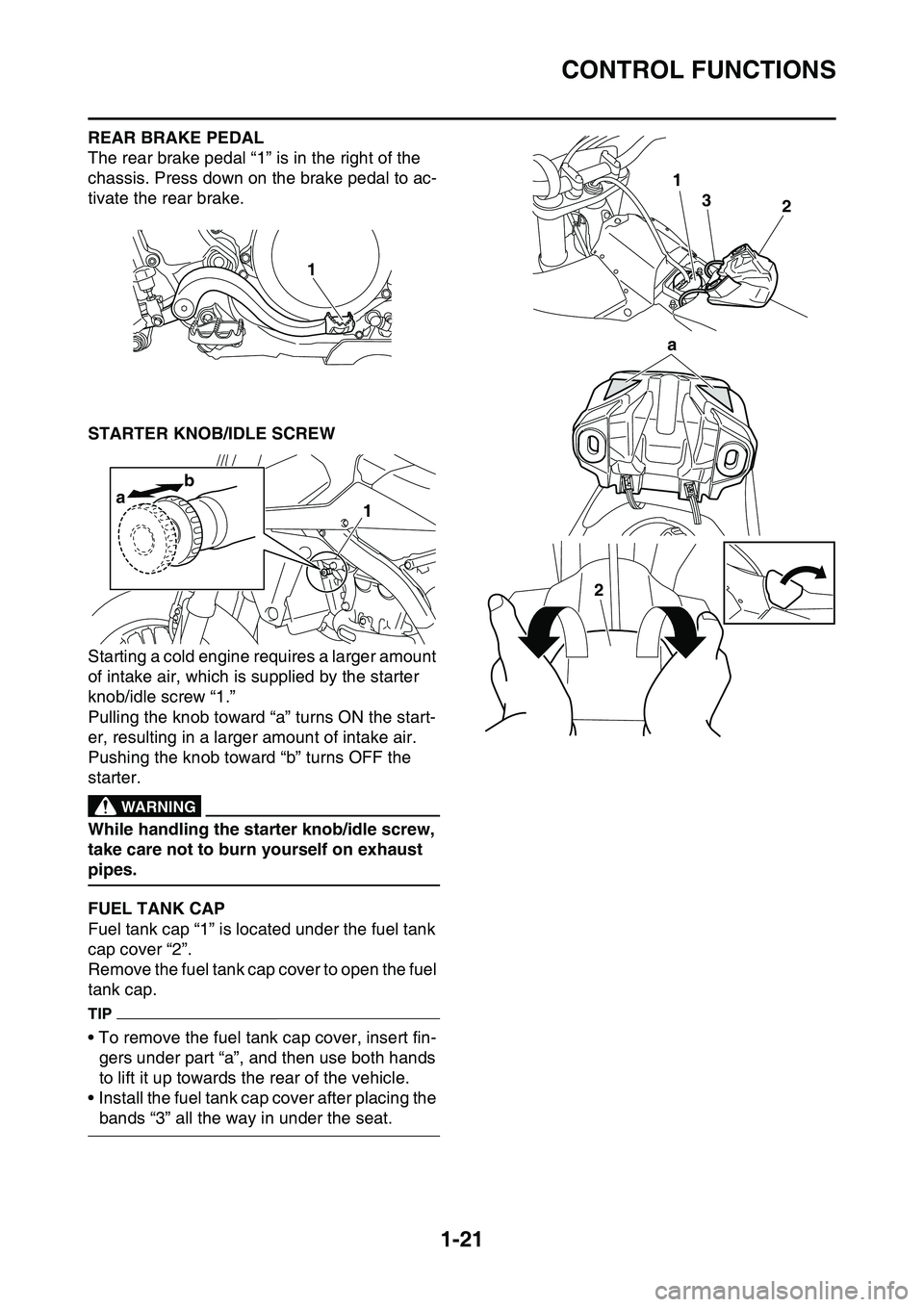

REAR BRAKE PEDAL

The rear brake pedal “1” is in the right of the

chassis. Press down on the brake pedal to ac-

tivate the rear brake.

EAS1SL1040STARTER KNOB/IDLE SCREW

Starting a cold engine requires a larger amount

of intake air, which is supplied by the starter

knob/idle screw “1.”

Pulling the knob toward “a” turns ON the start-

er, resulting in a larger amount of intake air.

Pushing the knob toward “b” turns OFF the

starter.

EWA@

WARNING

While handling the starter knob/idle screw,

take care not to burn yourself on exhaust

pipes.

EAS1SL1040FUEL TANK CAP

Fuel tank cap “1” is located under the fuel tank

cap cover “2”.

Remove the fuel tank cap cover to open the fuel

tank cap.

TIP

• To remove the fuel tank cap cover, insert fin-gers under part “a”, and then use both hands

to lift it up towards the rear of the vehicle.

• Install the fuel tank cap cover after placing the

bands “3” all the way in under the seat.

1

a b1

1

23

a

2

Page 36 of 360

STARTING AND BREAK-IN

1-22

EAS1SL1041

STARTING AND BREAK-IN

EAS1SL1042FUEL

Always use the recommended fuel as stated

below. Also, be sure to use new gasoline the

day of a race.

JCA

NOTICE

Use only unleaded gasoline. The use of

leaded gasoline will cause severe damage

to the engine internal parts such as valves,

piston rings, and exhaust system, etc.

TIP

Your Yamaha engine has been designed to use

premium unleaded gasoline with a pump oc

-

tane number [(R+M)/2] of 91 or higher, or a re-

search octane number of 95 or higher. If

knocking (or pinging) occurs, use a gasoline of

a different brand.

JWA

WARNING

• For refueling, be sure to stop the engine

and use enough care not to spill any fuel.

Also be sure to avoid refueling close to a

fire.

• Refuel after the engine, exhaust pipe, etc.

have cooled off.

Gasohol (For USA and Canada)

There are two types of gasohol: gasohol con-

taining ethanol and that containing methanol.

Gasohol containing ethanol can be used if the

ethanol content does not exceed 10%. Gasohol

containing methanol is not recommended by

Yamaha because it can cause damage to the

fuel system or vehicle performance problems.

EAS1SL1043STARTING A COLD ENGINE

1. Press the shift pedal to neutral.

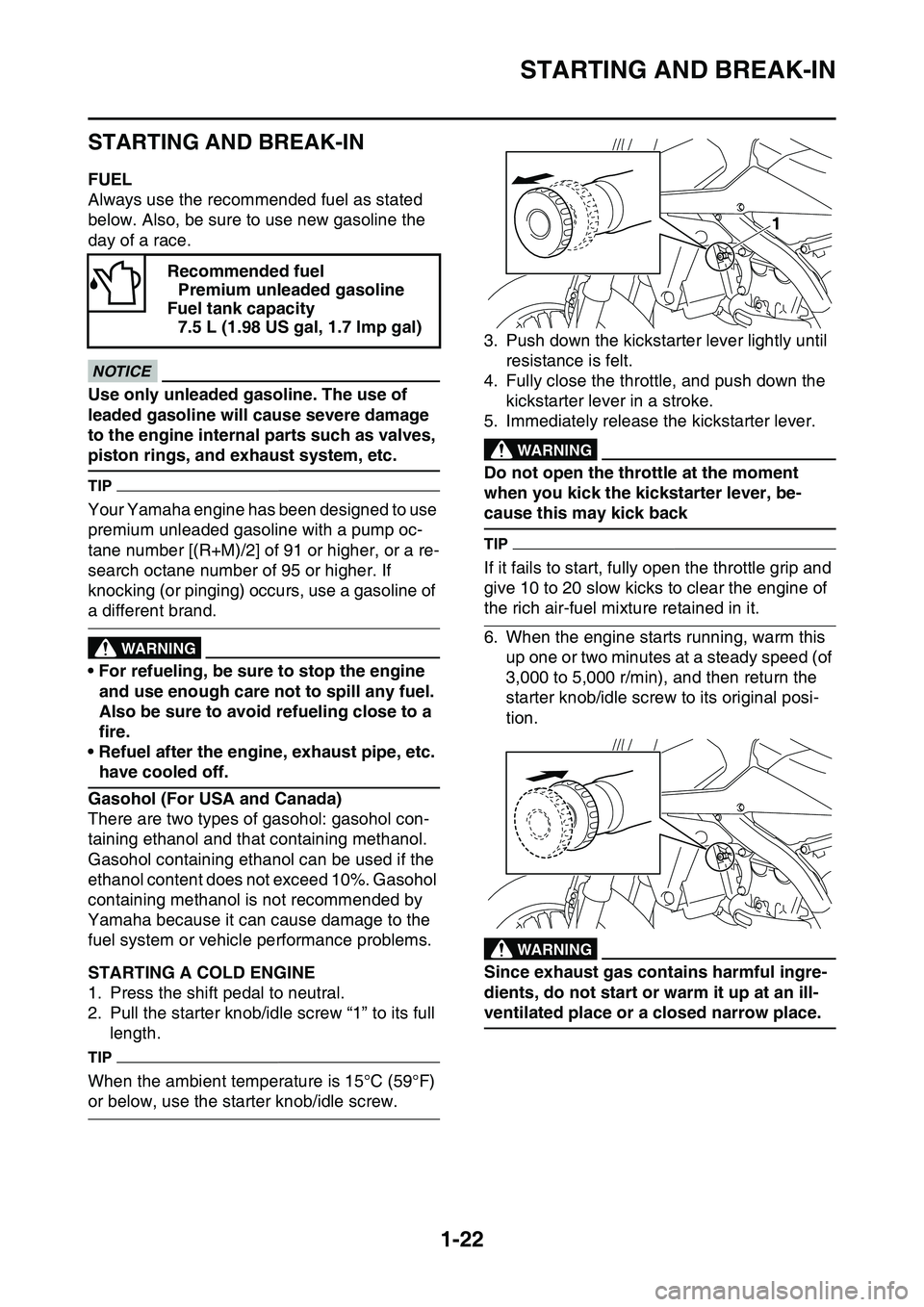

2. Pull the starter knob/idle screw “1” to its full

length.

TIP

When the ambient temperature is 15°C (59°F)

or below, use the starter knob/idle screw.

3. Push down the kickstarter lever lightly until

resistance is felt.

4. Fully close the throttle, and push down the

kickstarter lever in a stroke.

5. Immediately release the kickstarter lever.EWA

WARNING

Do not open the throttle at the moment

when you kick the kickstarter lever, be

-

cause this may kick back

TIP

If it fails to start, fully open the throttle grip and

give 10 to 20 slow kicks to clear the engine of

the rich air-fuel mixture retained in it.

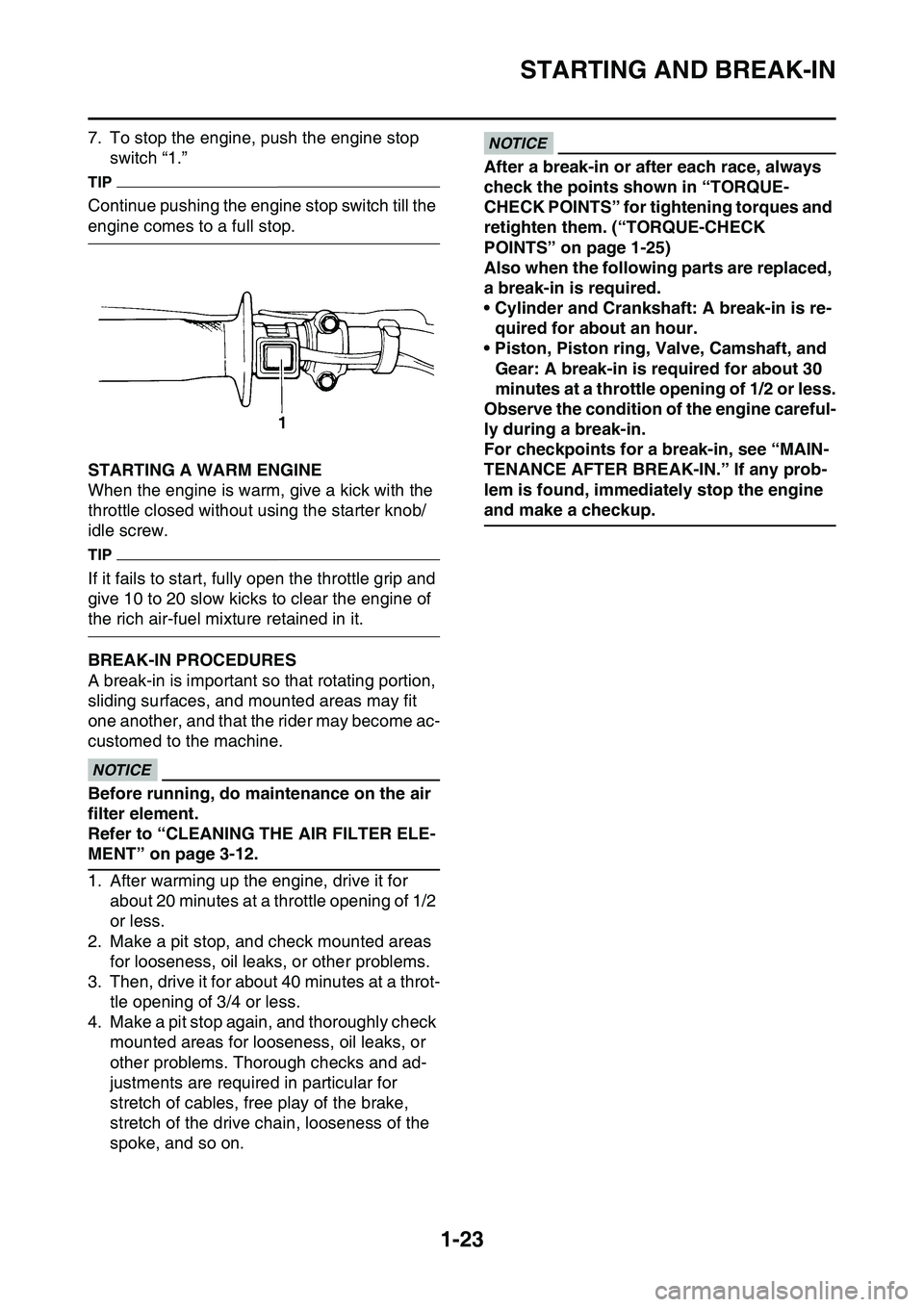

6. When the engine starts running, warm this

up one or two minutes at a steady speed (of

3,000 to 5,000 r/min), and then return the

starter knob/idle screw to its original posi

-

tion.

EWA

WARNING

Since exhaust gas contains harmful ingre-

dients, do not start or warm it up at an ill-

ventilated place or a closed narrow place.

Recommended fuel

Premium unleaded gasoline

Fuel tank capacity

7.5 L (1.98 US gal, 1.7 lmp gal)

1

Page 37 of 360

STARTING AND BREAK-IN

1-23

7. To stop the engine, push the engine stop

switch “1.”

TIP

Continue pushing the engine stop switch till the

engine comes to a full stop.

EAS1SL1044STARTING A WARM ENGINE

When the engine is warm, give a kick with the

throttle closed without using the starter knob/

idle screw.

TIP

If it fails to start, fully open the throttle grip and

give 10 to 20 slow kicks to clear the engine of

the rich air-fuel mixture retained in it.

EAS1SL1045BREAK-IN PROCEDURES

A break-in is important so that rotating portion,

sliding surfaces, and mounted areas may fit

one another, and that the rider may become ac

-

customed to the machine.ECA

NOTICE

Before running, do maintenance on the air

filter element.

Refer to “CLEANING THE AIR FILTER ELE-

MENT” on page 3-12.

1. After warming up the engine, drive it for

about 20 minutes at a throttle opening of 1/2

or less.

2. Make a pit stop, and check mounted areas

for looseness, oil leaks, or other problems.

3. Then, drive it for about 40 minutes at a throt-

tle opening of 3/4 or less.

4. Make a pit stop again, and thoroughly check

mounted areas for looseness, oil leaks, or

other problems. Thorough checks and ad

-

justments are required in particular for

stretch of cables, free play of the brake,

stretch of the drive chain, looseness of the

spoke, and so on.

ECA

NOTICE

After a break-in or after each race, always

check the points shown in “TORQUE-

CHECK POINTS” for tightening torques and

retighten them. (

“TORQUE-CHECK

POINTS” on page 1-25)

Also when the following parts are replaced,

a break-in is required.

• Cylinder and Crankshaft: A break-in is re-

quired for about an hour.

• Piston, Piston ring, Valve, Camshaft, and

Gear: A break-in is required for about 30

minutes at a throttle opening of 1/2 or less.

Observe the condition of the engine careful-

ly during a break-in.

For checkpoints for a break-in, see “MAIN-

TENANCE AFTER BREAK-IN.” If any prob-

lem is found, immediately stop the engine

and make a checkup.

EAS1SL1046

Page 38 of 360

MAINTENANCE AFTER BREAK-IN

1-24

MAINTENANCE AFTER BREAK-IN

After a break-in, perform careful maintenance

to get ready for the next practice or race.

Refer to “PRE-OPERATION INSPECTION

AND MAINTENANCE” on page 3-7.

EAS1SL1047MAJOR MAINTENANCE

1. For the engine

• Leaks around the engine

Check for pressure leaks from the cylinder

head or the cylinder, oil leaks from the

crankcase or the case cover, leaks from the

coolant system, and other leaks.

• Check that the valve, the cylinder head, the

cylinder, the piston, and the piston ring fit

one another, and that contact between the

valve and the cylinder head, and that be

-

tween the cylinder and the piston are cor-

rect.

• Engine oil change

Drain the oil, and check for dirt and foreign

materials such as metal chips. (If any foreign

material is mixed, disassemble and check

the crankcase.)

Pour the specified amount of the recom-

mended oil.

• AC magneto

Check for looseness in mounted areas of

the rotor and the stator.

Check that the connector is not being dis-

connected.

• Silencer

Check the main body and stay for cracks.

Check for leaks.

• Mounting bolts and nuts

Check for looseness in mounted areas of

parts, as well as engine mounting bolts and

engine brackets.

2. For the chassis

• Check welds and mounted areas of the

frame, the swingarm, the link, the bracket,

and so on, for looseness and cracks.

• Wheel (s)

Check the wheel for runout. Check the

spoke for looseness.

• Brake(s)

Check the brake disc mounting bolt for

looseness.

Check that the reservoir contains the speci-

fied amount of brake fluid. Check for leaks.

• Cable

Grease and adjust cables.

•Drive chain

Lubricate the drive chain and adjust its ten-

sion.

• Fuel tank

Clean the inside of the fuel tank. Check for

leaks.

• Suspension

Check for oil leaks in the front fork or the rear

shock absorber. Check that the mounted

conditions are good.

• Sprocket

Check for looseness in the sprocket mount-

ed on the rear wheel.

• Mounting bolts and nuts

Check mounted areas for looseness.JCA1SL1001

NOTICE

After a break-in or before each race, always

check the points shown in “TORQUE-

CHECK POINTS” for tightening torques and

retighten them. (Refer to

“TORQUE-CHECK

POINTS”.)

• Greasing and oiling

Always grease or oil the specified points.

Page 39 of 360

TORQUE-CHECK POINTS

1-25

EAS1SL1048

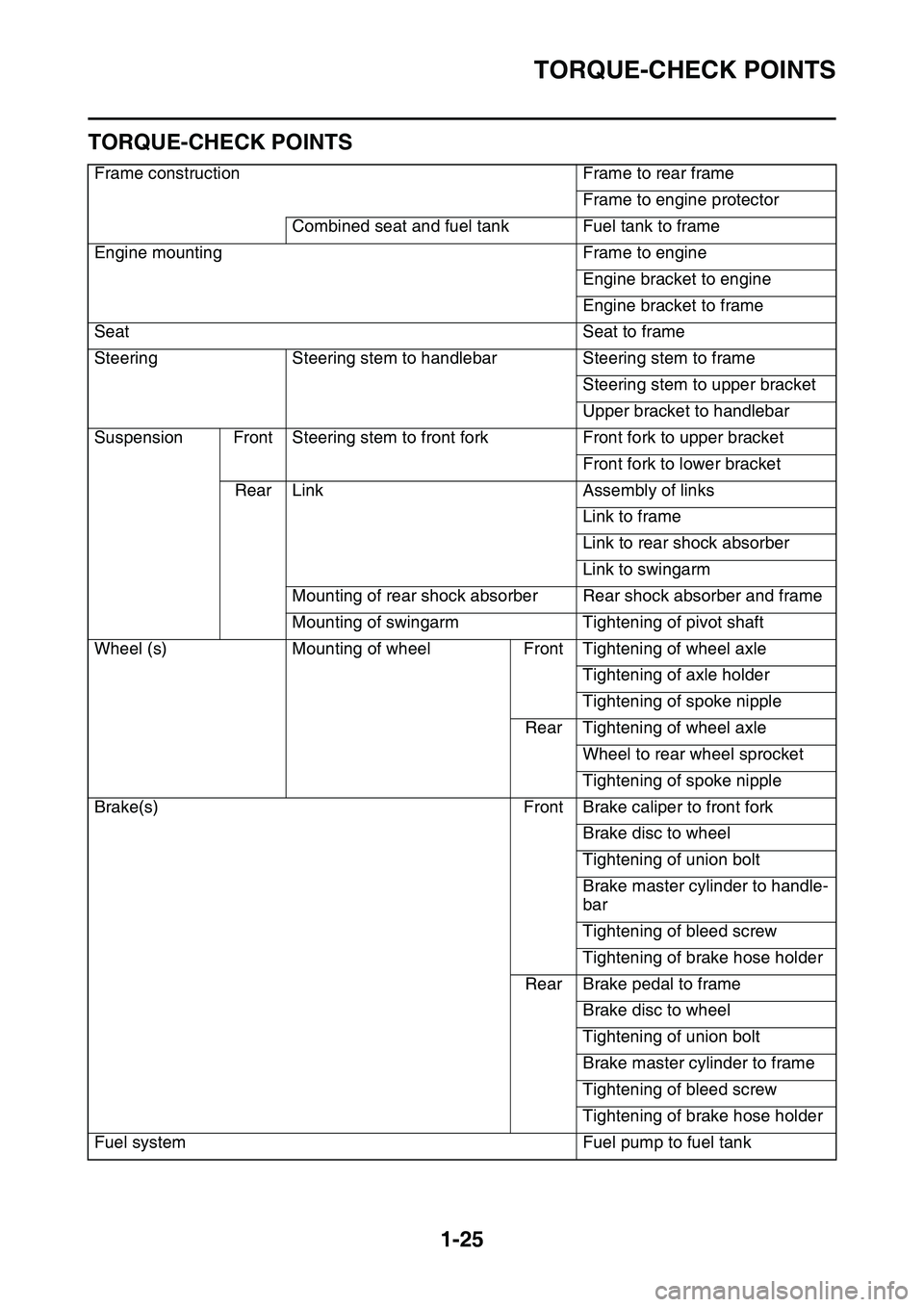

TORQUE-CHECK POINTS

Frame constructionFrame to rear frame

Frame to engine protector

Combined seat and fuel tankFuel tank to frame

Engine mountingFrame to engine

Engine bracket to engine

Engine bracket to frame

SeatSeat to frame

SteeringSteering stem to handlebarSteering stem to frame

Steering stem to upper bracket

Upper bracket to handlebar

SuspensionFrontSteering stem to front forkFront fork to upper bracket

Front fork to lower bracket

RearLinkAssembly of links

Link to frame

Link to rear shock absorber

Link to swingarm

Mounting of rear shock absorberRear shock absorber and frame

Mounting of swingarmTightening of pivot shaft

Wheel (s)Mounting of wheelFrontTightening of wheel axle

Tightening of axle holder

Tightening of spoke nipple

RearTightening of wheel axle

Wheel to rear wheel sprocket

Tightening of spoke nipple

Brake(s)FrontBrake caliper to front fork

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to handle-

bar

Tightening of bleed screw

Tightening of brake hose holder

RearBrake pedal to frame

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to frame

Tightening of bleed screw

Tightening of brake hose holder

Fuel systemFuel pump to fuel tank

Page 41 of 360

CLEANING AND STORAGE

1-27

EAS1SL1049

CLEANING AND STORAGE

EAS1SL1050CLEANING

Frequent cleaning of your vehicle will enhance

its appearance, maintain performance, and ex

-

tend the life of parts.

1. Before cleaning, block the silencer outlet to

prevent water from entering. A plastic bag

secured with a rubber band may be used for

this purpose.

2. If the engine is contaminated with oil, apply

some degreaser to it with a brush. Do not

apply degreaser to the drive chain, the

sprockets, or the wheel axles.

3. Hose off dirt. Use only enough water pres-

sure to do the job.ECA

NOTICE

Do not use high-pressure washers or steam

cleaners. Otherwise, these may cause a fail

-

ure because of the entry of water.

4. After hosing off the dirt, wash all surfaces

with a mild detergent and warm water. Use

a toothbrush to clean hard-to-reach places.

5. Rinse the detergent with clean water, and

dry the surfaces with a soft towel or a cloth.

6. Immediately after cleaning, remove any wa-

ter from the drive chain with a paper towel,

and lubricate it to prevent rust.

7. Clean the seat with a vinyl upholstery clean-

er to keep the cover pliable and glossy.

8. Automotive wax may be applied to all paint-

ed or chromed surfaces. Avoid using such

wax as contains abrasives, because it may

scratch surfaces.

9. After completing the above, start the engine

and allow it to warm up for several minutes.

EAS1SL1051STORAGE

If your vehicle is to be stored for 60 days or

more, some preventive measures must be tak

-

en to avoid deterioration. After cleaning the ve-

hicle thoroughly, prepare it for storage as

follows:

1. Fill the fuel tank with gasoline.

2. Remove the spark plug, pour a spoonful of

engine oil (SAE 10W-40) into the spark plug

hole, and reinstall the plug. With the engine

stop switch pushed in, by pushing down the

kickstarter lever, crank the engine to coat

the cylinder walls with oil.

3. Remove the drive chain, clean it thoroughly

with solvent, and lubricate it Reinstall the

drive chain or store it in a plastic bag tied to

the frame.

4. Lubricate all cables.

5. Lift up the frame of the vehicle to keep the

wheels off the ground.

6. Tie a plastic bag over the muffler outlet to

prevent moisture from entering.

7. If the vehicle is to be stored in a place that is

humid or exposed to the sea breeze, apply a

light coat of oil to metal surfaces. Do not ap

-

ply oil to the seat or rubber parts.

TIP

Make any necessary repairs before the vehicle

is stored.

Page 43 of 360

2

SPECIFICATIONS

GENERAL SPECIFICATIONS......................................................................... 2-1

ENGINE SPECIFICATIONS............................................................................. 2-2

CHASSIS SPECIFICATIONS........................................................................... 2-8

ELECTRICAL SPECIFICATIONS.................................................................. 2-12

TIGHTENING TORQUES............................................................................... 2-13

GENERAL TIGHTENING TORQUE SPECIFICATIONS .......................... 2-13

ENGINE TIGHTENING TORQUES .......................................................... 2-14

CHASSIS TIGHTENING TORQUES ........................................................ 2-18

LUBRICATION POINTS AND LUBRICANT TYPES..................................... 2-21

ENGINE .................................................................................................... 2-21

CHASSIS .................................................................................................. 2-23

LUBRICATION SYSTEM CHART AND DIAGRAMS..................................... 2-25

LUBRICATION DIAGRAMS ..................................................................... 2-25

CABLE ROUTING DIAGRAM........................................................................ 2-33