YAMAHA YZ85 2014 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ85, Model: YAMAHA YZ85 2014Pages: 88, PDF Size: 1.8 MB

Page 51 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-6

7

EAU42012

TIP’ü¼Hydraulic brake service

ŌĆó Regularly check and, if necessary, correct the brake fluid levels.

ŌłÜ

ŌłÜŌłÜ

ŌłÜ

24

*Drive chain roller and

support guide

Replace if necessary. Check for wear or damage.

ŌłÜ

25 *Rear suspension Check operation and tighten if necessary.

Lubricate with

lithium-soap-based grease

.

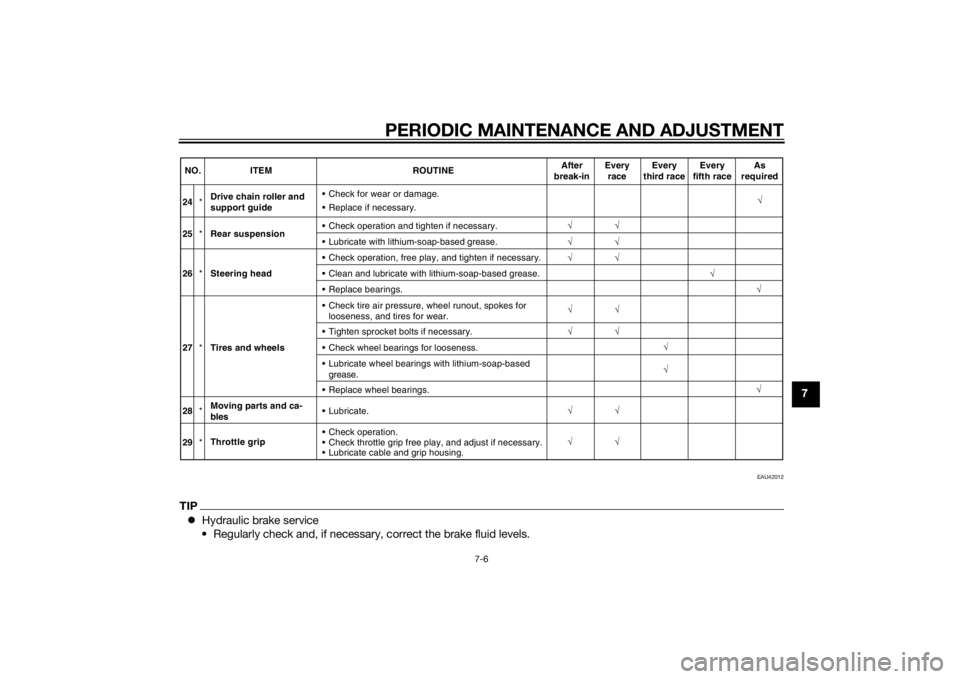

NO.

ITEM ROUTINEAfter

break-in Every

race Every

third race Every

fifth race As

required

ŌłÜ ŌłÜŌłÜ

ŌłÜ

ŌłÜ ŌłÜ

ŌłÜ

ŌłÜ ŌłÜ

ŌłÜ

ŌłÜ

ŌłÜ ŌłÜ

ŌłÜ

ŌłÜ

26

*Steering head Check operation, free play, and tighten if necessary.

Clean and lubricate with lithium-soap-based grease.

Replace bearings.

27 *Tires and wheels Check tire air pressure, wheel runout, spokes for

looseness, and tires for wear.

Tighten sprocket bolts if necessary.

Check wheel bearings for looseness.

Lubricate wheel bearings with lithium-soap-based grease.

Replace wheel bearings.

28 *Moving parts and ca-

bles Lubricate.

29 *Throttle grip Check operation.

Check throttle grip free play, and adjust if necessary.

Lubricate cable and grip housing.

U1SN82E0.book Page 6 Friday, June 7, 2013 3:51 PM

Page 52 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-7

7ŌĆó Every two years replace the internal components of the brake master cylinders and calipers, and change the brake

fluid.

ŌĆó Replace the brake hoses every four years and if cracked or damaged.

U1SN82E0.book Page 7 Friday, June 7, 2013 3:51 PM

Page 53 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-8

7

EAU19614

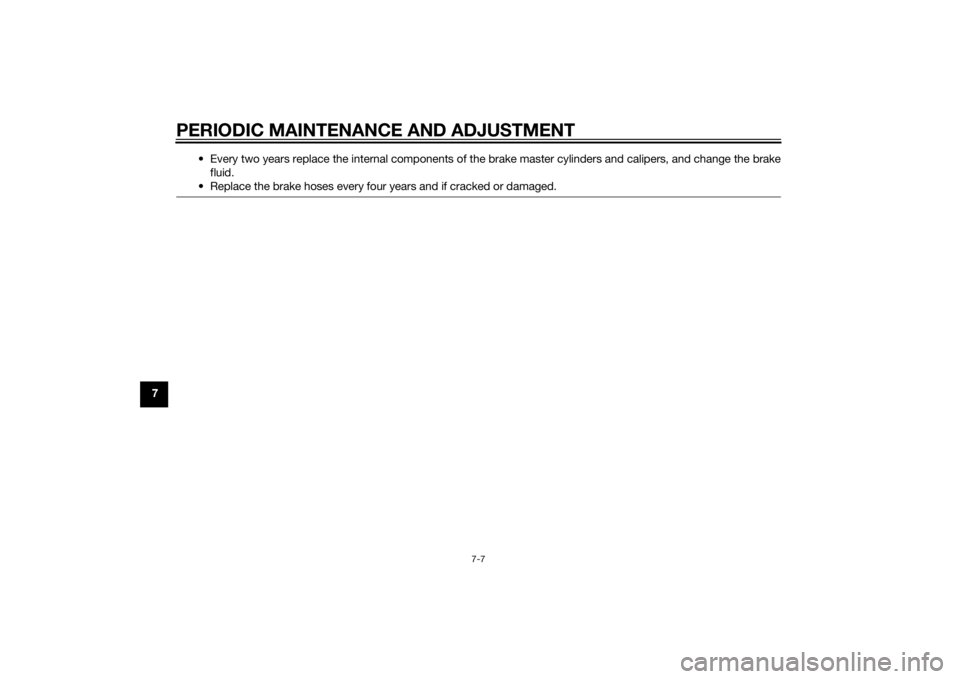

Checking the spark plugThe spark plug is an important engine

component, which is easy to check.

Since heat and deposits will cause any

spark plug to slowly erode, the spark

plug should be removed and checked

in accordance with the periodic main-

tenance and lubrication chart. In addi-

tion, the condition of the spark plug

can reveal the condition of the engine.

To remove the spark plu g

1. Remove the spark plug cap.

2. Remove the spark plug as shown, with a spark plug wrench available

at a Yamaha dealer. To check the spark plu

g

1. Check that the porcelain insulator around the center electrode of the

spark plug is a medium-to-light

tan (the ideal color when the vehi-

cle is ridden normally).

TIPIf the spark plug shows a distinctly dif-

ferent color, the engine could be oper-

ating improperly. Do not attempt to

diagnose such problems yourself. In-

stead, have a Yamaha dealer check

the vehicle.

2. Check the spark plug for electrodeerosion and excessive carbon or

other deposits, and replace it if

necessary.

3. Measure the spark plug gap with a wire thickness gauge and, if nec-

essary, adjust the gap to specifi-

cation.

1. Spark plug cap

1. Spark plug wrench

Specified spark plu g:

NGK/BR10EG

1. Spark plug gap

Spark plu g g ap:

0.5ŌĆō0.6 mm (0.020ŌĆō0.024 in)

U1SN82E0.book Page 8 Friday, June 7, 2013 3:51 PM

Page 54 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-9

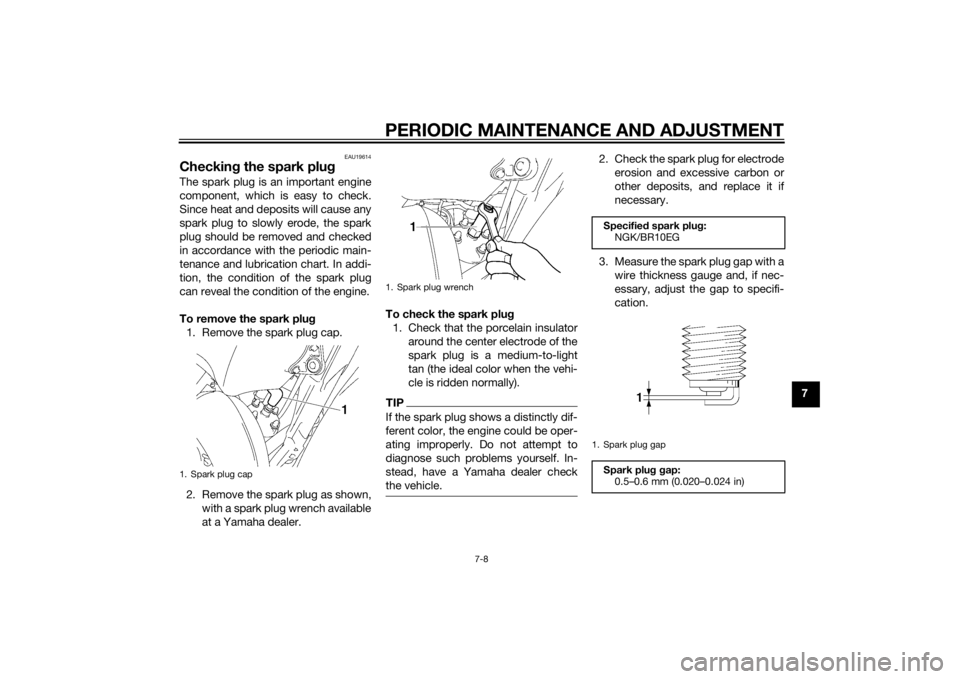

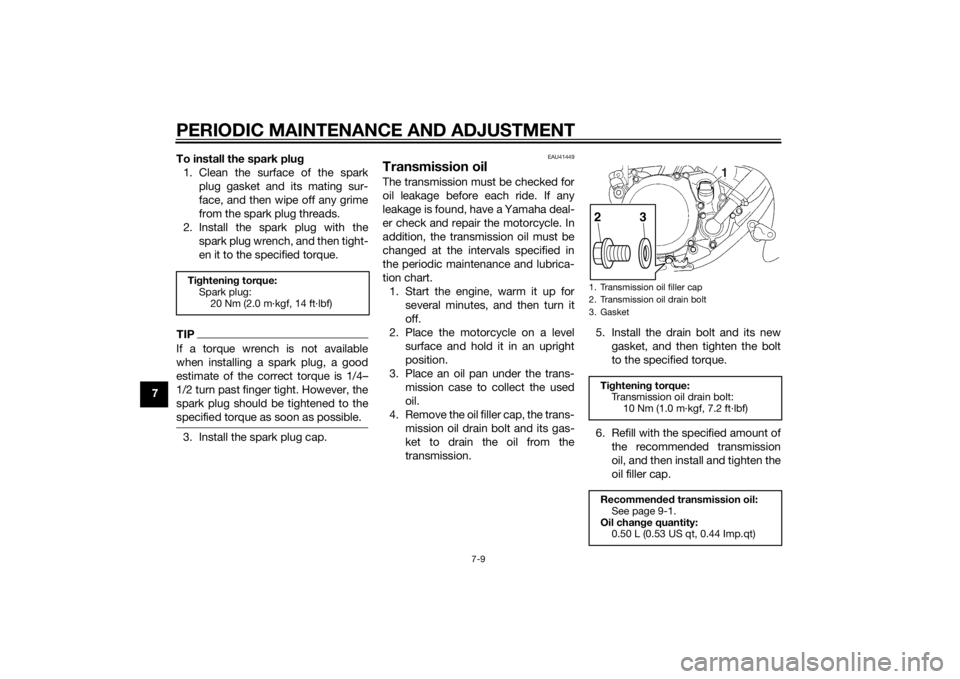

7To install the spark plu

g

1. Clean the surface of the spark plug gasket and its mating sur-

face, and then wipe off any grime

from the spark plug threads.

2. Install the spark plug with the spark plug wrench, and then tight-

en it to the specified torque.

TIPIf a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4ŌĆō

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.3. Install the spark plug cap.

EAU41449

Transmission oilThe transmission must be checked for

oil leakage before each ride. If any

leakage is found, have a Yamaha deal-

er check and repair the motorcycle. In

addition, the transmission oil must be

changed at the intervals specified in

the periodic maintenance and lubrica-

tion chart.1. Start the engine, warm it up for several minutes, and then turn it

off.

2. Place the motorcycle on a level surface and hold it in an upright

position.

3. Place an oil pan under the trans- mission case to collect the used

oil.

4. Remove the oil filler cap, the trans- mission oil drain bolt and its gas-

ket to drain the oil from the

transmission. 5. Install the drain bolt and its new

gasket, and then tighten the bolt

to the specified torque.

6. Refill with the specified amount of the recommended transmission

oil, and then install and tighten the

oil filler cap.

Tightenin g torque:

Spark plug: 20 Nm (2.0 m┬Ękgf, 14 ft┬Ęlbf)

1. Transmission oil filler cap

2. Transmission oil drain bolt

3. GasketTightenin g torque:

Transmission oil drain bolt:

10 Nm (1.0 m┬Ękgf, 7.2 ft┬Ęlbf)

Recommen ded transmission oil:

See page 9-1.

Oil chan ge quantity:

0.50 L (0.53 US qt, 0.44 Imp.qt)

1

2

3

U1SN82E0.book Page 9 Friday, June 7, 2013 3:51 PM

Page 55 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-10

7

NOTICE

ECA10453

’ü¼In or der to prevent clutch slip-

pa ge (since the transmission oil

also lu bricates the clutch), do

not mix any chemical additives.

Do not use oils with a d iesel

specification of ŌĆ£CDŌĆØ or oils of a

hi gher quality than specifie d. In

a ddition, do not use oils lab eled

ŌĆ£ENERGY CONSERVING IIŌĆØ or

hi gher.

’ü¼ Make sure that no forei gn mate-

rial enters the transmission.7. Start the engine, and then let it idle for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

EAU20071

CoolantThe coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

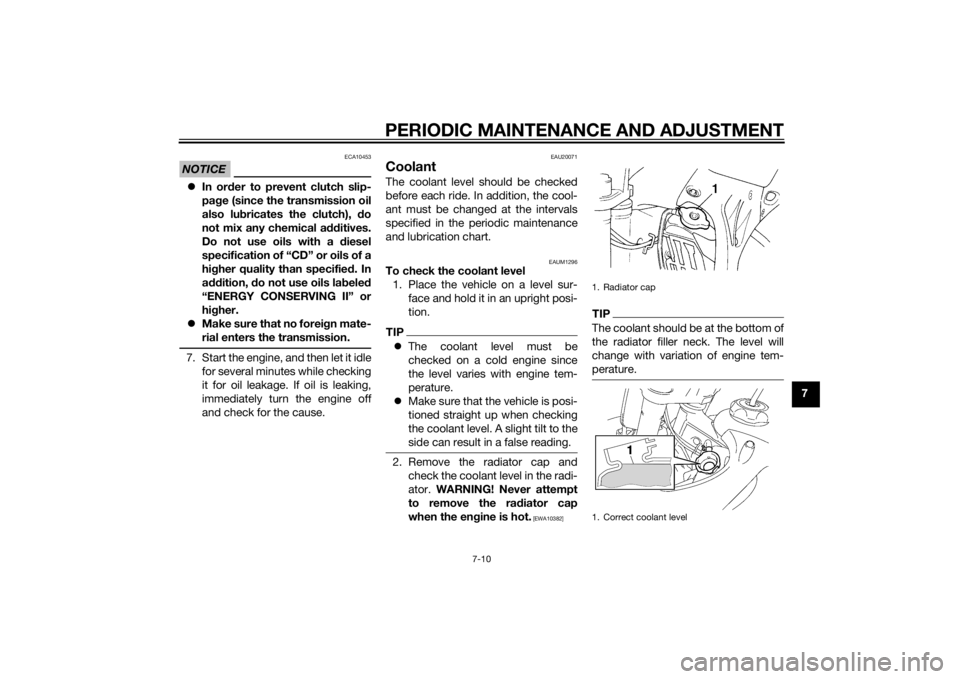

EAUM1296

To check the coolant level1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion.TIP’ü¼The coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

’ü¼ Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.2. Remove the radiator cap and

check the coolant level in the radi-

ator. WARNING! Never attempt

to remove the ra diator cap

when the en gine is hot.

[EWA10382]

TIPThe coolant should be at the bottom of

the radiator filler neck. The level will

change with variation of engine tem-

perature.1. Radiator cap

1. Correct coolant level

U1SN82E0.book Page 10 Friday, June 7, 2013 3:51 PM

Page 56 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-11

73. If the coolant is below the correct

coolant level, add coolant, and

then install the radiator cap.

NOTICE: If coolant is not avail-

a b le, use distille d water or soft

tap water instea d. Do not use

har d water or salt water since it

is harmful to the en gine. If water

has been used instead of cool-

ant, replace it with coolant as

soon as possi ble, otherwise the

coolin g system will not be pro-

tected against frost an d corro-

sion. If water has been adde d to

the coolant, have a Yamaha

d ealer check the antifreeze con-

tent of the coolant as soon as

possi ble, otherwise the effec-

tiveness of the coolant will be

re duce d.

[ECA10473]

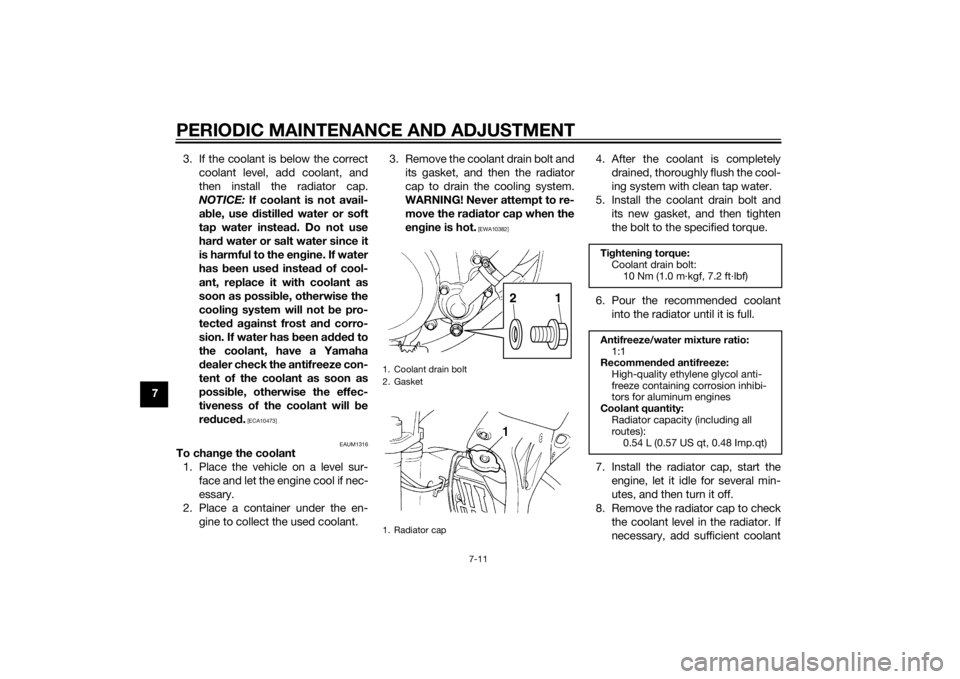

EAUM1316

To change the coolant

1. Place the vehicle on a level sur- face and let the engine cool if nec-

essary.

2. Place a container under the en- gine to collect the used coolant. 3. Remove the coolant drain bolt and

its gasket, and then the radiator

cap to drain the cooling system.

WARNING! Never attempt to re-

move the ra diator cap when the

en gine is hot.

[EWA10382]

4. After the coolant is completely

drained, thoroughly flush the cool-

ing system with clean tap water.

5. Install the coolant drain bolt and its new gasket, and then tighten

the bolt to the specified torque.

6. Pour the recommended coolant into the radiator until it is full.

7. Install the radiator cap, start the engine, let it idle for several min-

utes, and then turn it off.

8. Remove the radiator cap to check the coolant level in the radiator. If

necessary, add sufficient coolant

1. Coolant drain bolt

2. Gasket

1. Radiator cap

1

2

Tightenin g torque:

Coolant drain bolt: 10 Nm (1.0 m┬Ękgf, 7.2 ft┬Ęlbf)

Antifreeze/water mixture ratio: 1:1

Recommen ded antifreeze:

High-quality ethylene glycol anti-

freeze containing corrosion inhibi-

tors for aluminum engines

Coolant quantity: Radiator capacity (including all

routes):

0.54 L (0.57 US qt, 0.48 Imp.qt)

U1SN82E0.book Page 11 Friday, June 7, 2013 3:51 PM

Page 57 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-12

7

until it reaches the bottom of the

radiator filler neck, and then install

the radiator cap.

9. Start the engine, and then check the vehicle for coolant leakage. If

coolant is leaking, have a Yamaha

dealer check the cooling system.

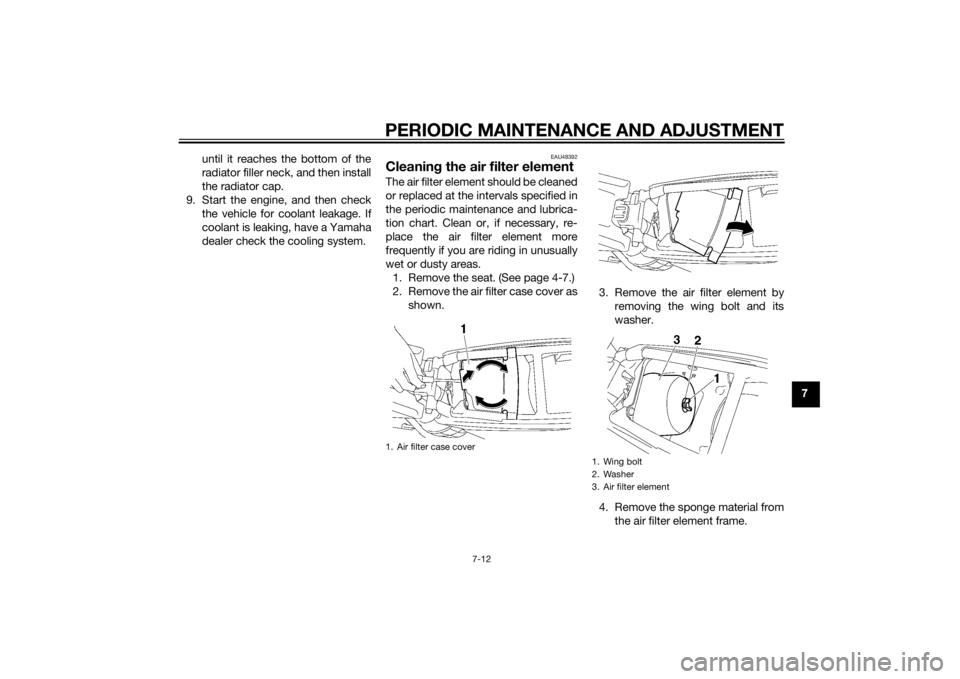

EAU48392

Cleanin g the air filter elementThe air filter element should be cleaned

or replaced at the intervals specified in

the periodic maintenance and lubrica-

tion chart. Clean or, if necessary, re-

place the air filter element more

frequently if you are riding in unusually

wet or dusty areas.

1. Remove the seat. (See page 4-7.)

2. Remove the air filter case cover as shown. 3. Remove the air filter element by

removing the wing bolt and its

washer.

4. Remove the sponge material from the air filter element frame.1. Air filter case cover

1. Wing bolt

2. Washer

3. Air filter element

U1SN82E0.book Page 12 Friday, June 7, 2013 3:51 PM

Page 58 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-13

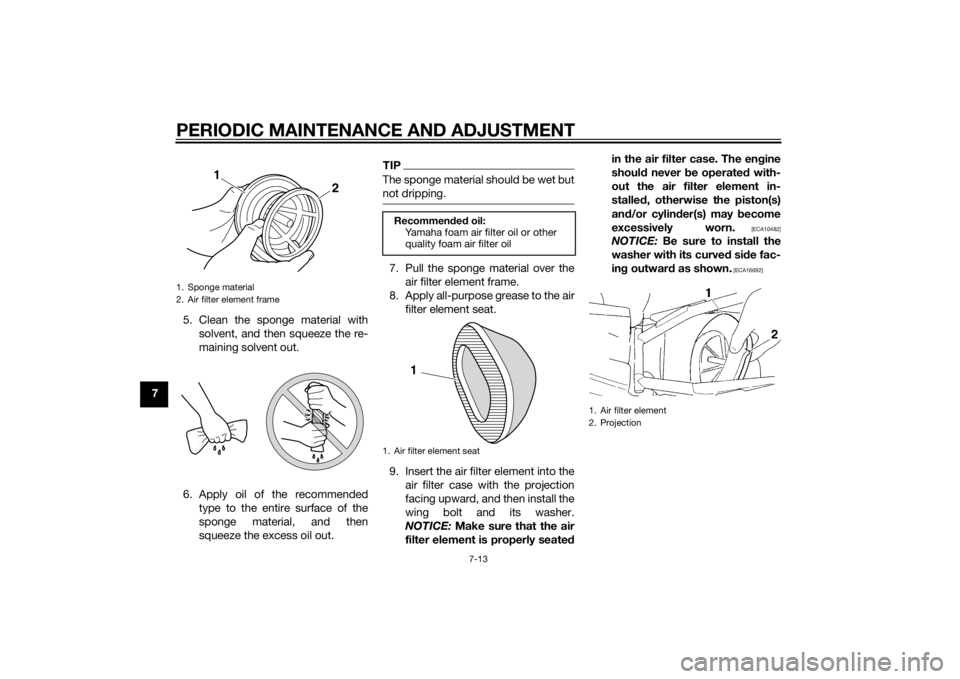

75. Clean the sponge material with

solvent, and then squeeze the re-

maining solvent out.

6. Apply oil of the recommended type to the entire surface of the

sponge material, and then

squeeze the excess oil out.

TIPThe sponge material should be wet but

not dripping.7. Pull the sponge material over theair filter element frame.

8. Apply all-purpose grease to the air filter element seat.

9. Insert the air filter element into the air filter case with the projection

facing upward, and then install the

wing bolt and its washer.

NOTICE: Make sure that the air

filter element is properly seate din the air filter case. The en

gine

shoul d never b e operated with-

out the air filter element in-

stalle d, otherwise the piston(s)

an d/or cylin der(s) may become

excessively worn.

[ECA10482]

NOTICE: Be sure to install the

washer with its curve d si de fac-

in g outwar d as shown.

[ECA16692]

1. Sponge material

2. Air filter element frame

1

2

Recommended oil:

Yamaha foam air filter oil or other

quality foam air filter oil1. Air filter element seat

1

1. Air filter element

2. Projection

U1SN82E0.book Page 13 Friday, June 7, 2013 3:51 PM

Page 59 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-14

7

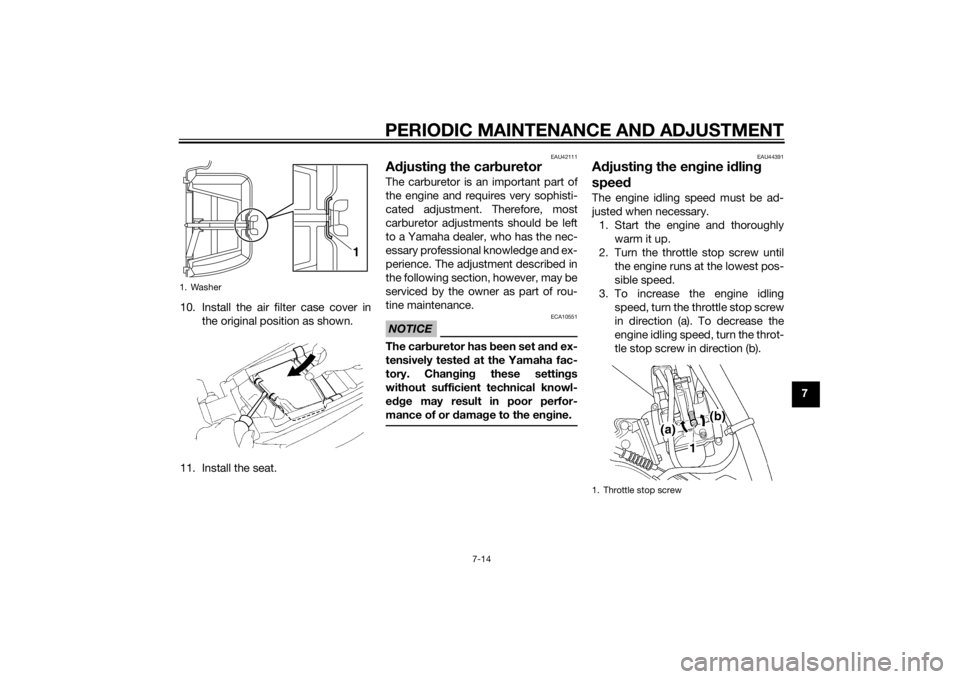

10. Install the air filter case cover in

the original position as shown.

11. Install the seat.

EAU42111

A djustin g the car buretorThe carburetor is an important part of

the engine and requires very sophisti-

cated adjustment. Therefore, most

carburetor adjustments should be left

to a Yamaha dealer, who has the nec-

essary professional knowledge and ex-

perience. The adjustment described in

the following section, however, may be

serviced by the owner as part of rou-

tine maintenance.NOTICE

ECA10551

The car buretor has b een set and ex-

tensively teste d at the Yamaha fac-

tory. Chan gin g these settin gs

without sufficient technical knowl-

e dge may result in poor perfor-

mance of or damag e to the en gine.

EAU44391

A djustin g the en gine i dlin g

spee dThe engine idling speed must be ad-

justed when necessary.

1. Start the engine and thoroughly warm it up.

2. Turn the throttle stop screw until the engine runs at the lowest pos-

sible speed.

3. To increase the engine idling speed, turn the throttle stop screw

in direction (a). To decrease the

engine idling speed, turn the throt-

tle stop screw in direction (b).

1. Washer

1

1. Throttle stop screw

U1SN82E0.book Page 14 Friday, June 7, 2013 3:51 PM

Page 60 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

7-15

7

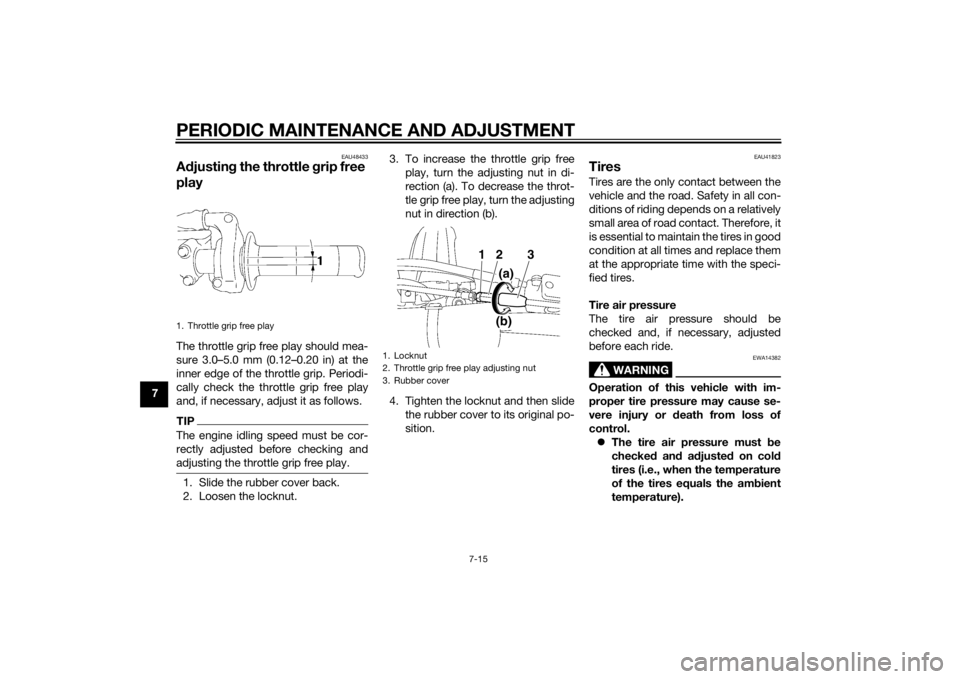

EAU48433

Adjustin g the throttle grip free

playThe throttle grip free play should mea-

sure 3.0ŌĆō5.0 mm (0.12ŌĆō0.20 in) at the

inner edge of the throttle grip. Periodi-

cally check the throttle grip free play

and, if necessary, adjust it as follows.TIPThe engine idling speed must be cor-

rectly adjusted before checking and

adjusting the throttle grip free play.1. Slide the rubber cover back.

2. Loosen the locknut. 3. To increase the throttle grip free

play, turn the adjusting nut in di-

rection (a). To decrease the throt-

tle grip free play, turn the adjusting

nut in direction (b).

4. Tighten the locknut and then slide the rubber cover to its original po-

sition.

EAU41823

TiresTires are the only contact between the

vehicle and the road. Safety in all con-

ditions of riding depends on a relatively

small area of road contact. Therefore, it

is essential to maintain the tires in good

condition at all times and replace them

at the appropriate time with the speci-

fied tires.

Tire air pressure

The tire air pressure should be

checked and, if necessary, adjusted

before each ride.

WARNING

EWA14382

Operation of this vehicle with im-

proper tire pressure may cause se-

vere injury or death from loss of

control. ’ü¼ The tire air pressure must be

checked and a djuste d on col d

tires (i.e., when the temperature

of the tires equals the am bient

temperature).

1. Throttle grip free play

1. Locknut

2. Throttle grip free play adjusting nut

3. Rubber cover

2

3

(a)

(b)

1

U1SN82E0.book Page 15 Friday, June 7, 2013 3:51 PM