YAMAHA YZF-R125 2017 Service Manual

Manufacturer: YAMAHA, Model Year: 2017, Model line: YZF-R125, Model: YAMAHA YZF-R125 2017Pages: 96, PDF Size: 6.43 MB

Page 41 of 96

Operation and important riding points

5-4

5

EAU16811

Tips for reducing fuel con-

sumption

Fuel consumption depends largely on

your riding style. Consider the follow-

ing tips to reduce fuel consumption:

Shift up swiftly, and avoid high en-

gine speeds during acceleration.

Do not rev the engine while shift-

ing down, and avoid high engine

speeds with no load on the en-

gine.

Turn the engine off instead of let-

ting it idle for an extended length

of time (e.g., in traffic jams, at traf-

fic lights or at railroad crossings).

EAU16831

Engine break-in

There is never a more important period

in the life of your engine than the period

between 0 and 1000 km (600 mi). For

this reason, you should read the fol-

lowing material carefully.

Since the engine is brand new, do not

put an excessive load on it for the first

1000 km (600 mi). The various parts in

the engine wear and polish themselves

to the correct operating clearances.

During this period, prolonged full-throt-

tle operation or any condition that

might result in engine overheating

must be avoided.

EAU16983

0–500 km (0–300 mi)

Avoid prolonged operation above 6000

r/min.

After every hour of operation, stop the

engine, and then let it cool for five to

ten minutes.

Vary the engine speed from time to

time. Do not operate the engine at one

set throttle position.

500–1000 km (300–600 mi)

Avoid prolonged operation above 8000

r/min.

Rev the engine freely through the

gears, but do not use full throttle at any

time. NOTICE: After 1000 km (600 mi)

of operation, the engine oil must be

changed, the oil filter cartridge or el-

ement replaced, and the oil strainer

cleaned.

[ECA10322]

UBR6E0E0.book Page 4 Wednesday, August 17, 2016 1:26 PM

Page 42 of 96

Operation and important riding points

5-5

51000 km (600 mi) and beyond

The vehicle can now be operated nor-

mally.

NOTICE

ECA10311

Keep the engine speed out of

the tachometer red zone.

If any engine trouble should oc-

cur during the engine break-in

period, immediately have a

Yamaha dealer check the vehi-

cle.

EAU17214

Parking

When parking, stop the engine, and

then remove the key from the main

switch.

WARNING

EWA10312

Since the engine and exhaust

system can become very hot,

park in a place where pedestri-

ans or children are not likely to

touch them and be burned.

Do not park on a slope or on soft

ground, otherwise the vehicle

may overturn, increasing the

risk of a fuel leak and fire.

Do not park near grass or other

flammable materials which

might catch fire.

UBR6E0E0.book Page 5 Wednesday, August 17, 2016 1:26 PM

Page 43 of 96

Periodic maintenance and adjustment

6-1

6

EAU17246

Periodic inspection, adjustment, and

lubrication will keep your vehicle in the

safest and most efficient condition

possible. Safety is an obligation of the

vehicle owner/operator. The most im-

portant points of vehicle inspection,

adjustment, and lubrication are ex-

plained on the following pages.

The intervals given in the periodic

maintenance charts should be simply

considered as a general guide under

normal riding conditions. However, de-

pending on the weather, terrain, geo-

graphical location, and individual use,

the maintenance intervals may need to

be shortened.

WARNING

EWA10322

Failure to properly maintain the vehi-

cle or performing maintenance ac-

tivities incorrectly may increase

your risk of injury or death during

service or while using the vehicle. If

you are not familiar with vehicle ser-

vice, have a Yamaha dealer perform

service.

WARNING

EWA15123

Turn off the engine when performing

maintenance unless otherwise

specified.

A running engine has moving

parts that can catch on body

parts or clothing and electrical

parts that can cause shocks or

fires.

Running the engine while ser-

vicing can lead to eye injury,

burns, fire, or carbon monoxide

poisoning – possibly leading todeath. See page 1-3 for more in-

formation about carbon monox-

ide.

WARNING

EWA15461

Brake discs, calipers, drums, and

linings can become very hot during

use. To avoid possible burns, let

brake components cool before

touching them.

UBR6E0E0.book Page 1 Wednesday, August 17, 2016 1:26 PM

Page 44 of 96

Periodic maintenance and adjustment

6-2

6

EAU17303

Emission controls not only function to

ensure cleaner air, but are also vital to

proper engine operation and maximum

performance. In the following periodic

maintenance charts, the services relat-

ed to emissions control are grouped

separately. These services require

specialized data, knowledge, and

equipment. Maintenance, replace-

ment, or repair of the emission control

devices and systems may be per-

formed by any repair establishment or

individual that is certified (if applicable).

Yamaha dealers are trained and

equipped to perform these particular

services.

EAU17362

Owner’s tool kit

The owner’s tool kit is located under

the rider seat. (See page 3-19.)

The service information included in this

manual and the tools provided in the

owner’s tool kit are intended to assist

you in the performance of preventive

maintenance and minor repairs. How-

ever, additional tools such as a torque

wrench may be necessary to perform

certain maintenance work correctly.

TIP

If you do not have the tools or experi-

ence required for a particular job, have

a Yamaha dealer perform it for you.

1.

ZAUM1454

UBR6E0E0.book Page 2 Wednesday, August 17, 2016 1:26 PM

Page 45 of 96

Periodic maintenance and adjustment

6-3

6

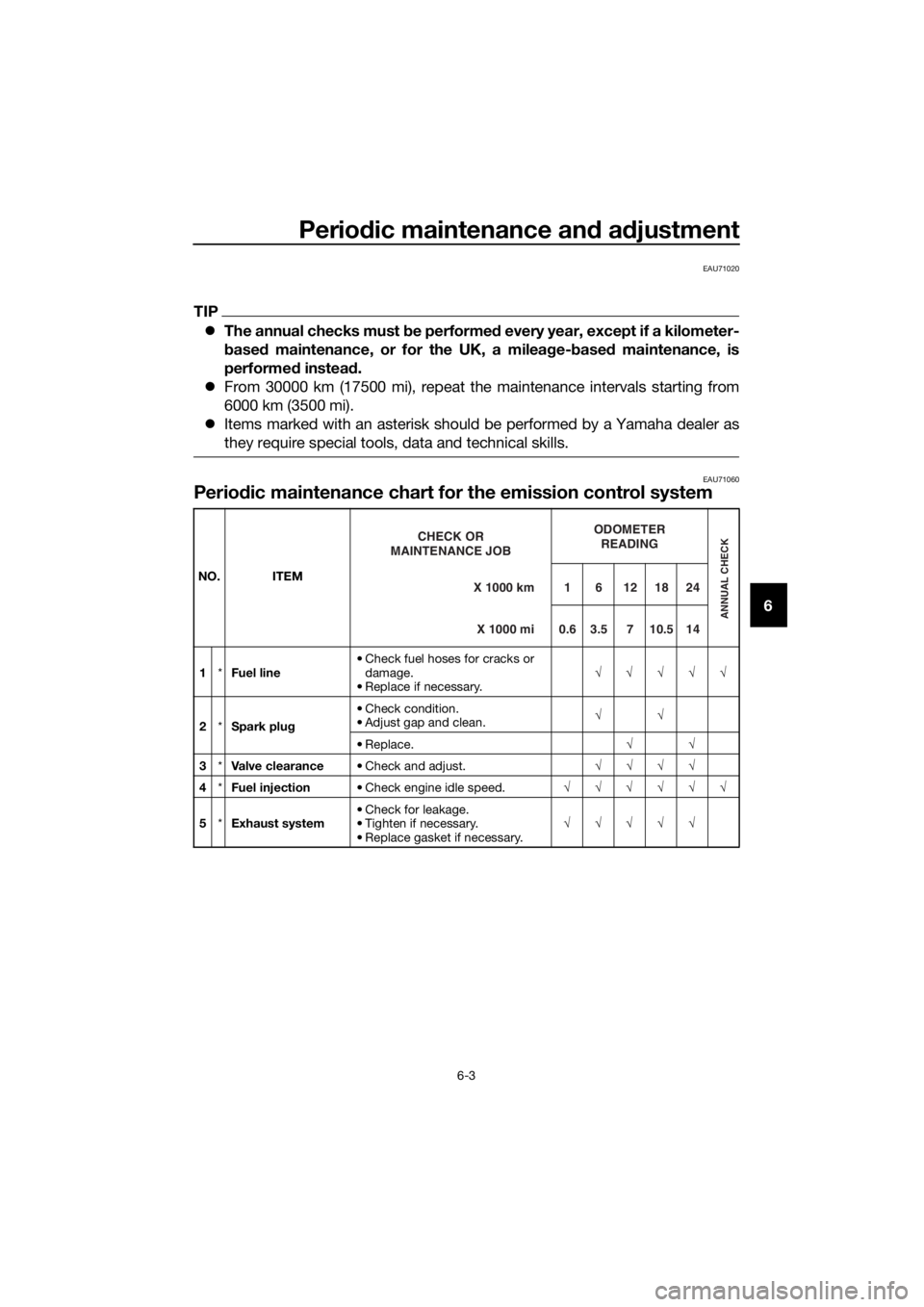

EAU71020

TIP

The annual checks must be performed every year, except if a kilometer-

based maintenance, or for the UK, a mileage-based maintenance, is

performed instead.

From 30000 km (17500 mi), repeat the maintenance intervals starting from

6000 km (3500 mi).

Items marked with an asterisk should be performed by a Yamaha dealer as

they require special tools, data and technical skills.

EAU71060

Periodic maintenance chart for the emission control system

NO. ITEM

1*Fuel line• Check fuel hoses for cracks or

damage.

• Replace if necessary.√√√√√

2*Spark plug• Check condition.

• Adjust gap and clean.√√

• Replace.√√

3*Valve clearance• Check and adjust.√√√√

4*Fuel injection• Check engine idle speed.√√√√√√

5*Exhaust system• Check for leakage.

• Tighten if necessary.

• Replace gasket if necessary.√√√√√X 1000 km CHECK OR

MAINTENANCE JOB

X 1000 mi

ODOMETER

READING

ANNUAL CHECK

16121824

0.63.5710.514

UBR6E0E0.book Page 3 Wednesday, August 17, 2016 1:26 PM

Page 46 of 96

Periodic maintenance and adjustment

6-4

6

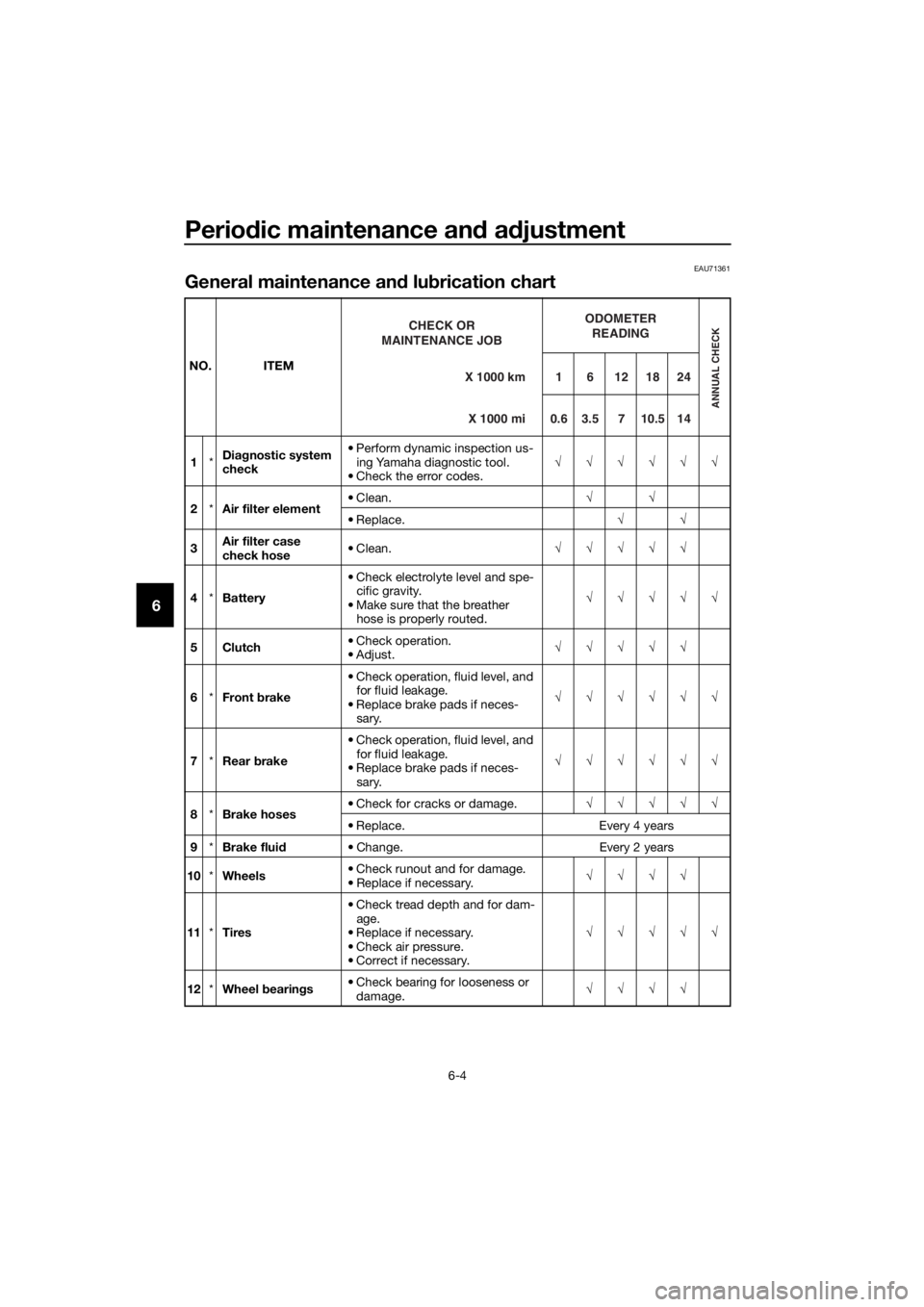

EAU71361

General maintenance and lubrication chart

NO. ITEM

1*Diagnostic system

check• Perform dynamic inspection us-

ing Yamaha diagnostic tool.

• Check the error codes.√√√√√√

2*Air filter element• Clean.√√

• Replace.√√

3Air filter case

check hose• Clean.√√√√√

4*Battery• Check electrolyte level and spe-

cific gravity.

• Make sure that the breather

hose is properly routed.√√√√√

5Clutch• Check operation.

•Adjust.√√√√√

6*Front brake• Check operation, fluid level, and

for fluid leakage.

• Replace brake pads if neces-

sary.√√√√√√

7*Rear brake• Check operation, fluid level, and

for fluid leakage.

• Replace brake pads if neces-

sary.√√√√√√

8*Brake hoses• Check for cracks or damage.√√√√√

• Replace. Every 4 years

9*Brake fluid• Change. Every 2 years

10*Wheels• Check runout and for damage.

• Replace if necessary.√√√√

11*Tires• Check tread depth and for dam-

age.

• Replace if necessary.

• Check air pressure.

• Correct if necessary.√√√√√

12*Wheel bearings• Check bearing for looseness or

damage.√√√√X 1000 km CHECK OR

MAINTENANCE JOB

X 1000 miODOMETER

READINGANNUAL CHECK

1 6 12 18 24

0.6 3.5 7 10.5 14

UBR6E0E0.book Page 4 Wednesday, August 17, 2016 1:26 PM

Page 47 of 96

Periodic maintenance and adjustment

6-5

6

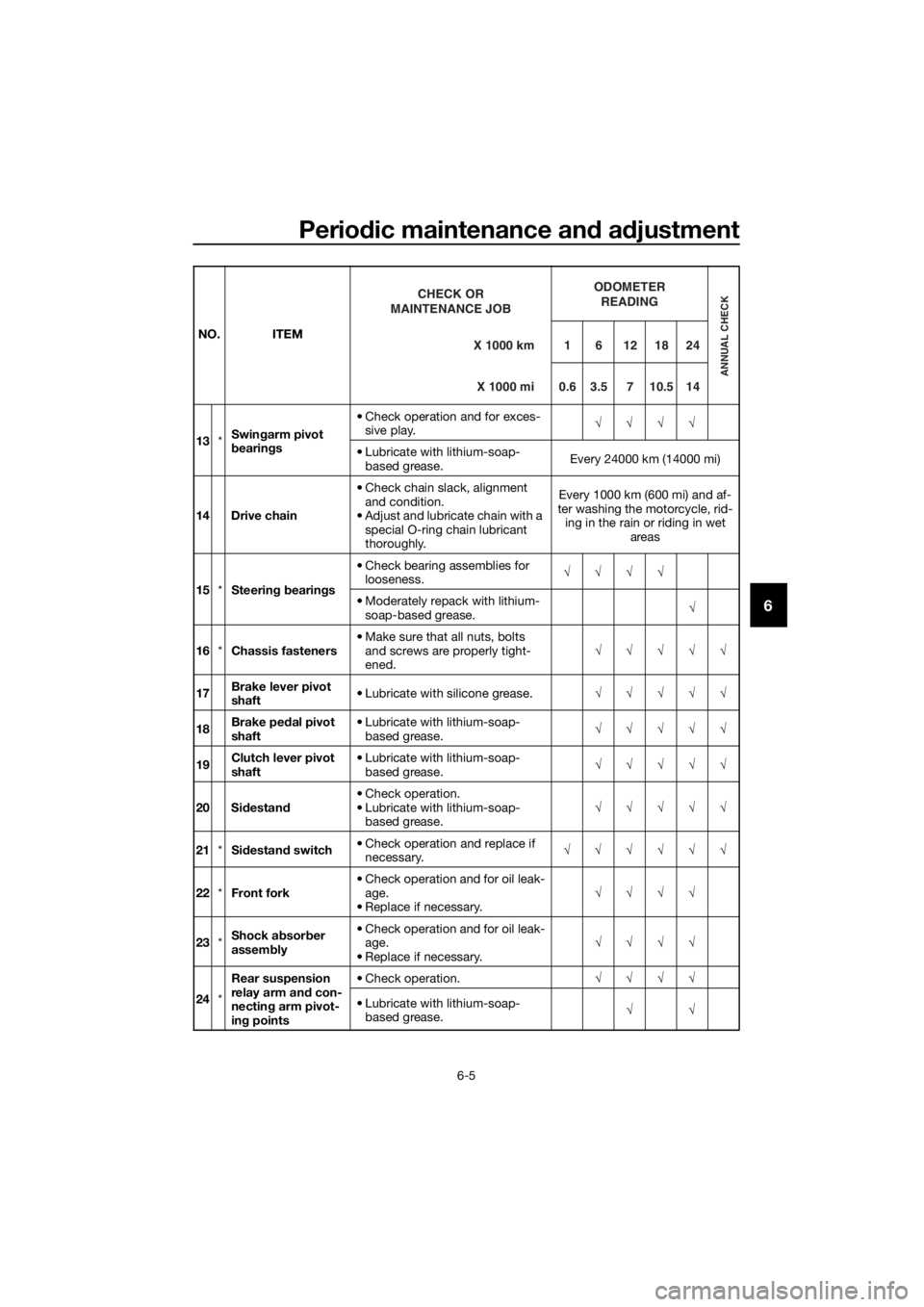

13*Swingarm pivot

bearings• Check operation and for exces-

sive play.√√√√

• Lubricate with lithium-soap-

based grease.Every 24000 km (14000 mi)

14 Drive chain• Check chain slack, alignment

and condition.

• Adjust and lubricate chain with a

special O-ring chain lubricant

thoroughly.Every 1000 km (600 mi) and af-

ter washing the motorcycle, rid-

ing in the rain or riding in wet

areas

15*Steering bearings• Check bearing assemblies for

looseness.√√√√

• Moderately repack with lithium-

soap-based grease.√

16*Chassis fasteners• Make sure that all nuts, bolts

and screws are properly tight-

ened.√√√√√

17Brake lever pivot

shaft• Lubricate with silicone grease.√√√√√

18Brake pedal pivot

shaft• Lubricate with lithium-soap-

based grease.√√√√√

19Clutch lever pivot

shaft• Lubricate with lithium-soap-

based grease.√√√√√

20 Sidestand• Check operation.

• Lubricate with lithium-soap-

based grease.√√√√√

21*Sidestand switch• Check operation and replace if

necessary.√√√√√√

22*Front fork• Check operation and for oil leak-

age.

• Replace if necessary.√√√√

23*Shock absorber

assembly• Check operation and for oil leak-

age.

• Replace if necessary.√√√√

24*Rear suspension

relay arm and con-

necting arm pivot-

ing points• Check operation.√√√√

• Lubricate with lithium-soap-

based grease.√√ NO. ITEM

X 1000 km CHECK OR

MAINTENANCE JOB

X 1000 mi

ODOMETER

READING

ANNUAL CHECK

16121824

0.63.5710.514

UBR6E0E0.book Page 5 Wednesday, August 17, 2016 1:26 PM

Page 48 of 96

Periodic maintenance and adjustment

6-6

6

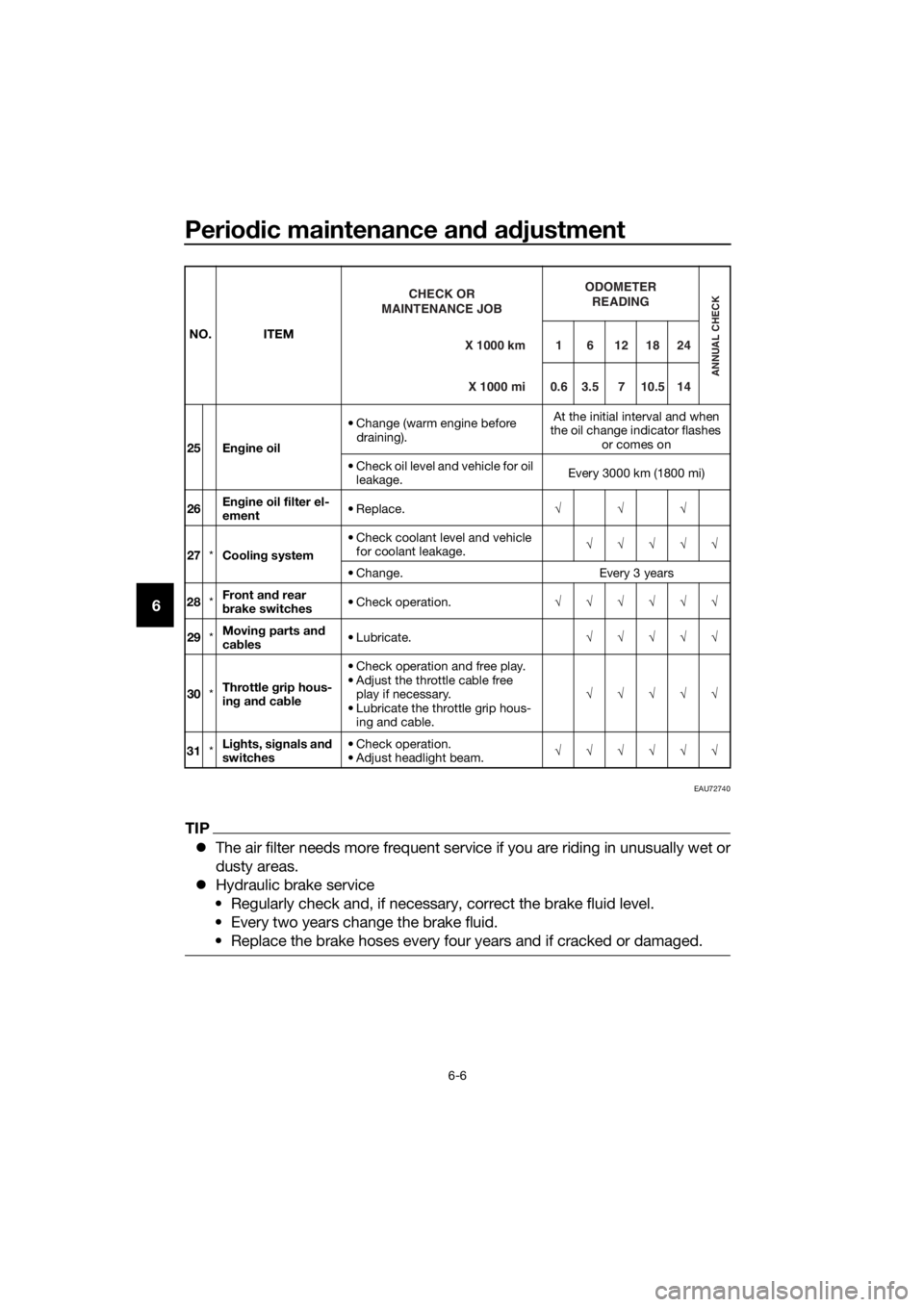

EAU72740

TIP

The air filter needs more frequent service if you are riding in unusually wet or

dusty areas.

Hydraulic brake service

• Regularly check and, if necessary, correct the brake fluid level.

• Every two years change the brake fluid.

• Replace the brake hoses every four years and if cracked or damaged.

25 Engine oil• Change (warm engine before

draining).At the initial interval and when

the oil change indicator flashes

or comes on

• Check oil level and vehicle for oil

leakage.Every 3000 km (1800 mi)

26Engine oil filter el-

ement• Replace.√√√

27*Cooling system• Check coolant level and vehicle

for coolant leakage.√√√√√

• Change. Every 3 years

28*Front and rear

brake switches• Check operation.√√√√√√

29*Moving parts and

cables• Lubricate.√√√√√

30*Throttle grip hous-

ing and cable• Check operation and free play.

• Adjust the throttle cable free

play if necessary.

• Lubricate the throttle grip hous-

ing and cable.√√√√√

31*Lights, signals and

switches• Check operation.

• Adjust headlight beam.√√√√√√ NO. ITEM

X 1000 km CHECK OR

MAINTENANCE JOB

X 1000 miODOMETER

READING

ANNUAL CHECK

16121824

0.6 3.5 7 10.5 14

UBR6E0E0.book Page 6 Wednesday, August 17, 2016 1:26 PM

Page 49 of 96

Periodic maintenance and adjustment

6-7

6

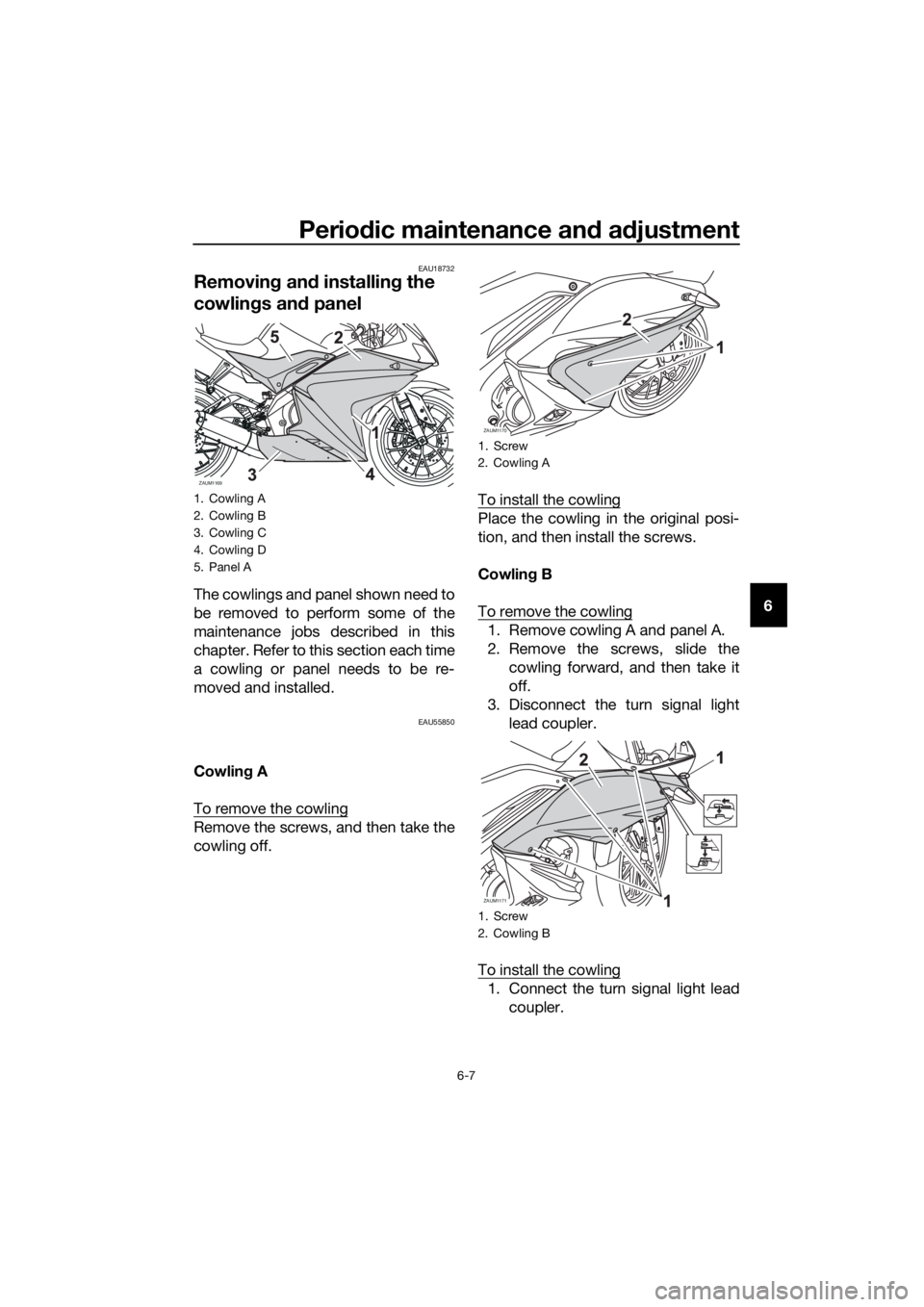

EAU18732

Removing and installing the

cowlings and panel

The cowlings and panel shown need to

be removed to perform some of the

maintenance jobs described in this

chapter. Refer to this section each time

a cowling or panel needs to be re-

moved and installed.

EAU55850

Cowling A

To remove the cowling

Remove the screws, and then take the

cowling off.To install the cowling

Place the cowling in the original posi-

tion, and then install the screws.

Cowling B

To remove the cowling

1. Remove cowling A and panel A.

2. Remove the screws, slide the

cowling forward, and then take it

off.

3. Disconnect the turn signal light

lead coupler.

To install the cowling

1. Connect the turn signal light lead

coupler.

1. Cowling A

2. Cowling B

3. Cowling C

4. Cowling D

5. Panel A

ZAUM1169

1. Screw

2. Cowling A

1. Screw

2. Cowling B

ZAUM1170

ZAUM1171

UBR6E0E0.book Page 7 Wednesday, August 17, 2016 1:26 PM

Page 50 of 96

Periodic maintenance and adjustment

6-8

62. Fit the projection on the cowling

into the slot, and then slide the

cowling backward.

3. Install the screws.

4. Install cowling A and panel A.

Cowling C

To remove the cowling

Remove the screws, and then pull the

cowling off as shown.

To install the cowling

Place the cowling in the original posi-

tion, and then install the screws.

Cowling D

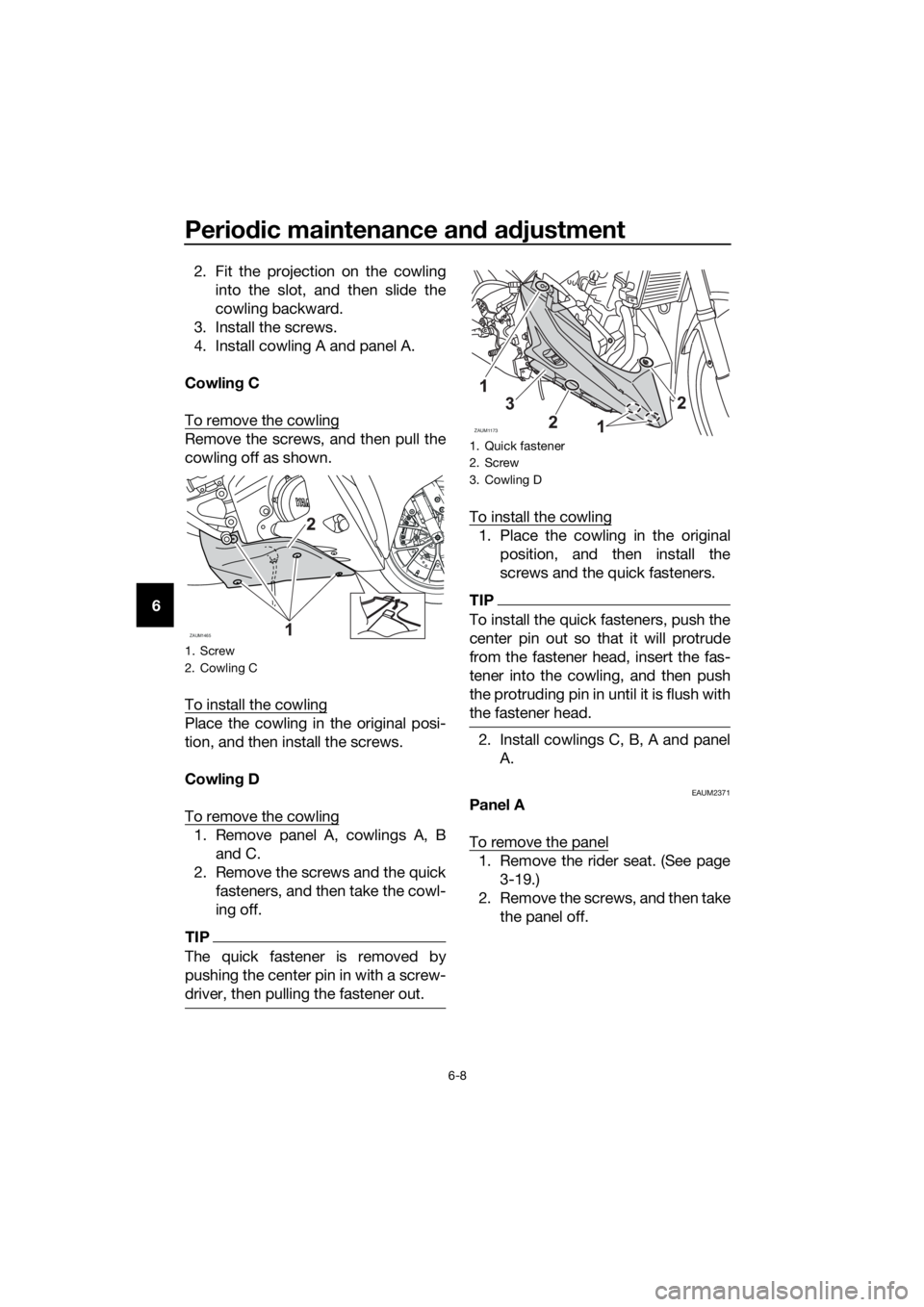

To remove the cowling

1. Remove panel A, cowlings A, B

and C.

2. Remove the screws and the quick

fasteners, and then take the cowl-

ing off.

TIP

The quick fastener is removed by

pushing the center pin in with a screw-

driver, then pulling the fastener out.

To install the cowling

1. Place the cowling in the original

position, and then install the

screws and the quick fasteners.

TIP

To install the quick fasteners, push the

center pin out so that it will protrude

from the fastener head, insert the fas-

tener into the cowling, and then push

the protruding pin in until it is flush with

the fastener head.

2. Install cowlings C, B, A and panel

A.

EAUM2371Panel A

To remove the panel

1. Remove the rider seat. (See page

3-19.)

2. Remove the screws, and then take

the panel off.

1. Screw

2. Cowling C

ZAUM1465

1. Quick fastener

2. Screw

3. Cowling D

ZAUM1173

UBR6E0E0.book Page 8 Wednesday, August 17, 2016 1:26 PM