YAMAHA YZF-R7 1999 Owners Manual

YZF-R7 1999

YAMAHA

YAMAHA

https://www.carmanualsonline.info/img/51/54468/w960_54468-0.png

YAMAHA YZF-R7 1999 Owners Manual

Trending: rear view mirror, fuel pump, spark plugs replace, bolt pattern, air suspension, tow, engine oil capacity

Page 181 of 381

4 - 49

ENGSHIFT SHAFT

EB408401

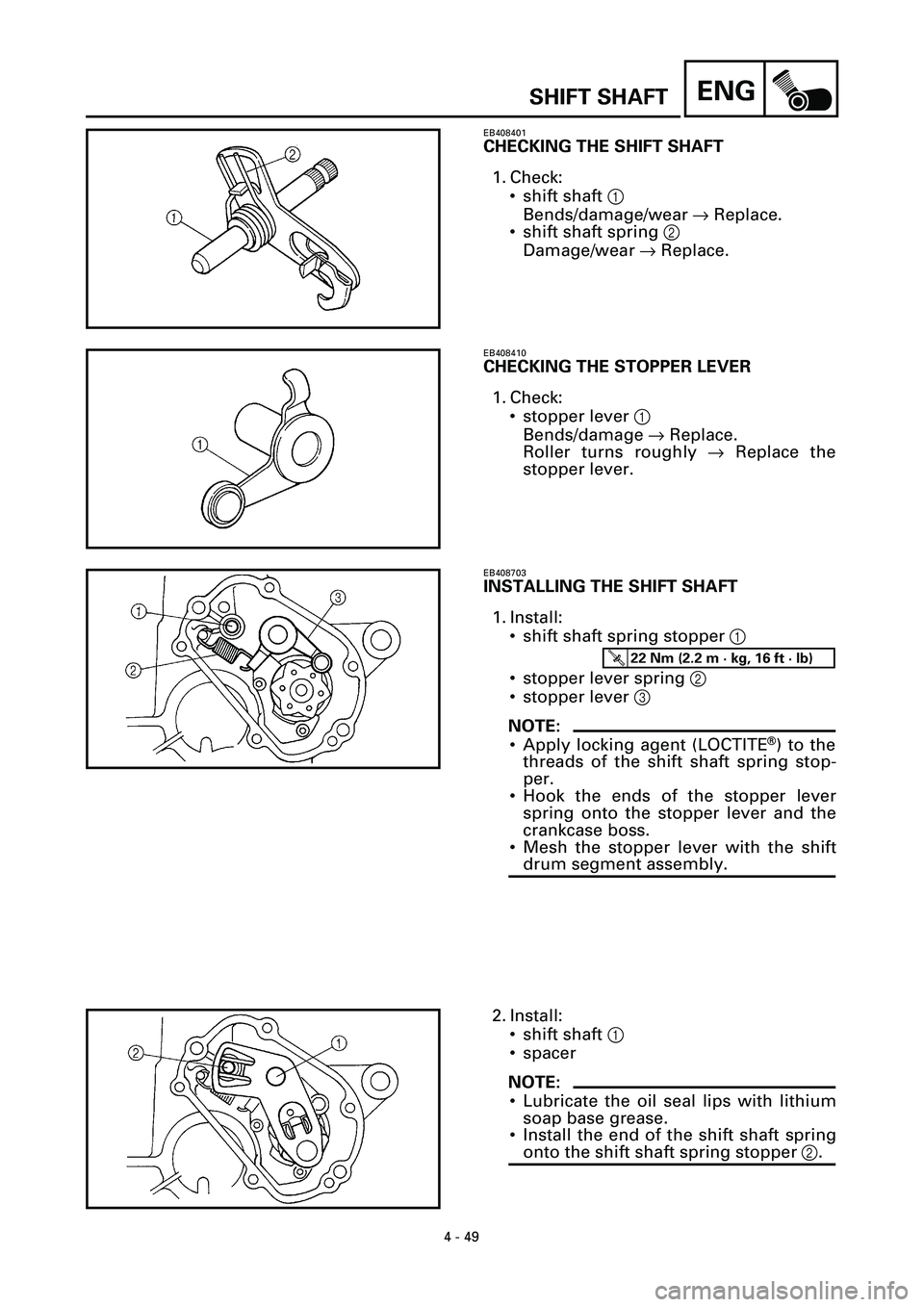

CHECKING THE SHIFT SHAFT

1. Check:

• shift shaft 1

Bends/damage/wear ® Replace.

• shift shaft spring 2

Damage/wear ® Replace.

EB408410

CHECKING THE STOPPER LEVER

1. Check:

• stopper lever 1

Bends/damage ® Replace.

Roller turns roughly ® Replace the

stopper lever.

EB408703

INSTALLING THE SHIFT SHAFT

1. Install:

• shift shaft spring stopper 1

• stopper lever spring 2

• stopper lever 3

NOTE:

• Apply locking agent (LOCTITE®) to the

threads of the shift shaft spring stop-

per.

• Hook the ends of the stopper lever

spring onto the stopper lever and the

crankcase boss.

• Mesh the stopper lever with the shift

drum segment assembly.

T R..22 Nm (2.2 m · kg, 16 ft · lb)

2. Install:

• shift shaft 1

• spacer

NOTE:

• Lubricate the oil seal lips with lithium

soap base grease.

• Install the end of the shift shaft spring

onto the shift shaft spring stopper 2.

Page 182 of 381

ENG

4 - 50

OIL PAN AND OIL PUMP

EB411000

OIL PAN AND OIL PUMP

Order Job/Part Q’ty Remarks

Removing the oil pan and oil pumpRemove the parts in the order listed.

Engine oil Drain.

Refer to “CHANGING THE ENGINE

OIL” in chapter 3.

Coolant Drain.

Refer to “CHANGING THE COOLANT”

in chapter 3.

Radiator assembly and water pump

outlet pipeRefer to “RADIATOR AND THERMO-

STAT” and “OIL COOLER” in chapter 5.

Exhaust pipe assembly Refer to “ENGINE”.

1 Oil level switch connector 1 Disconnect.

2 Oil level switch 1

3 Oil level switch lead holder 1

4 Oil pan 1

5 Oil pan gasket 1

6 Dowel pin 2

Page 183 of 381

ENG

4 - 51

OIL PAN AND OIL PUMP

EB411001

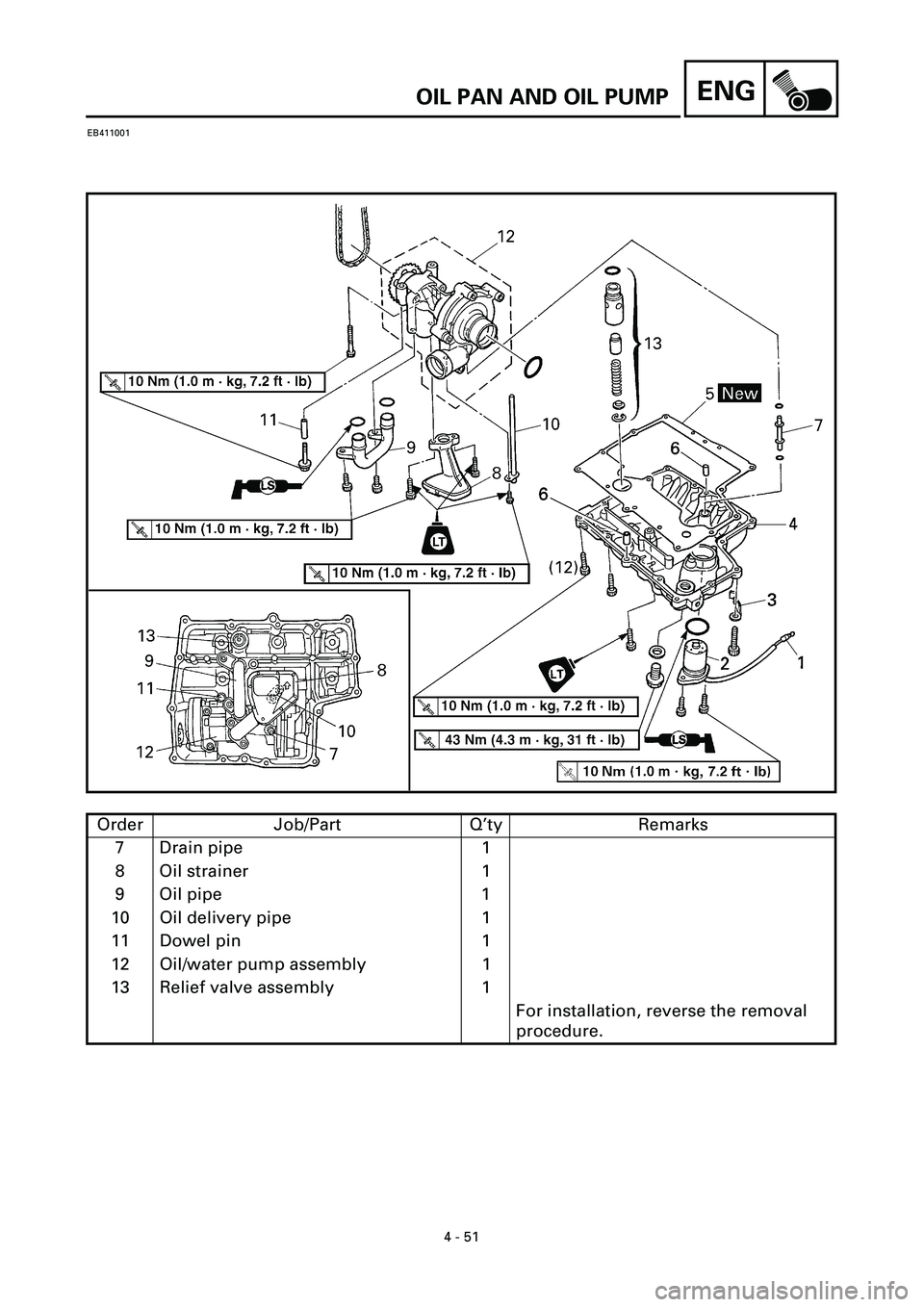

Order Job/Part Q’ty Remarks

7 Drain pipe 1

8 Oil strainer 1

9 Oil pipe 1

10 Oil delivery pipe 1

11 Dowel pin 1

12 Oil/water pump assembly 1

13 Relief valve assembly 1

For installation, reverse the removal

procedure.

Page 184 of 381

ENG

4 - 52

OIL PAN AND OIL PUMP

EB411003

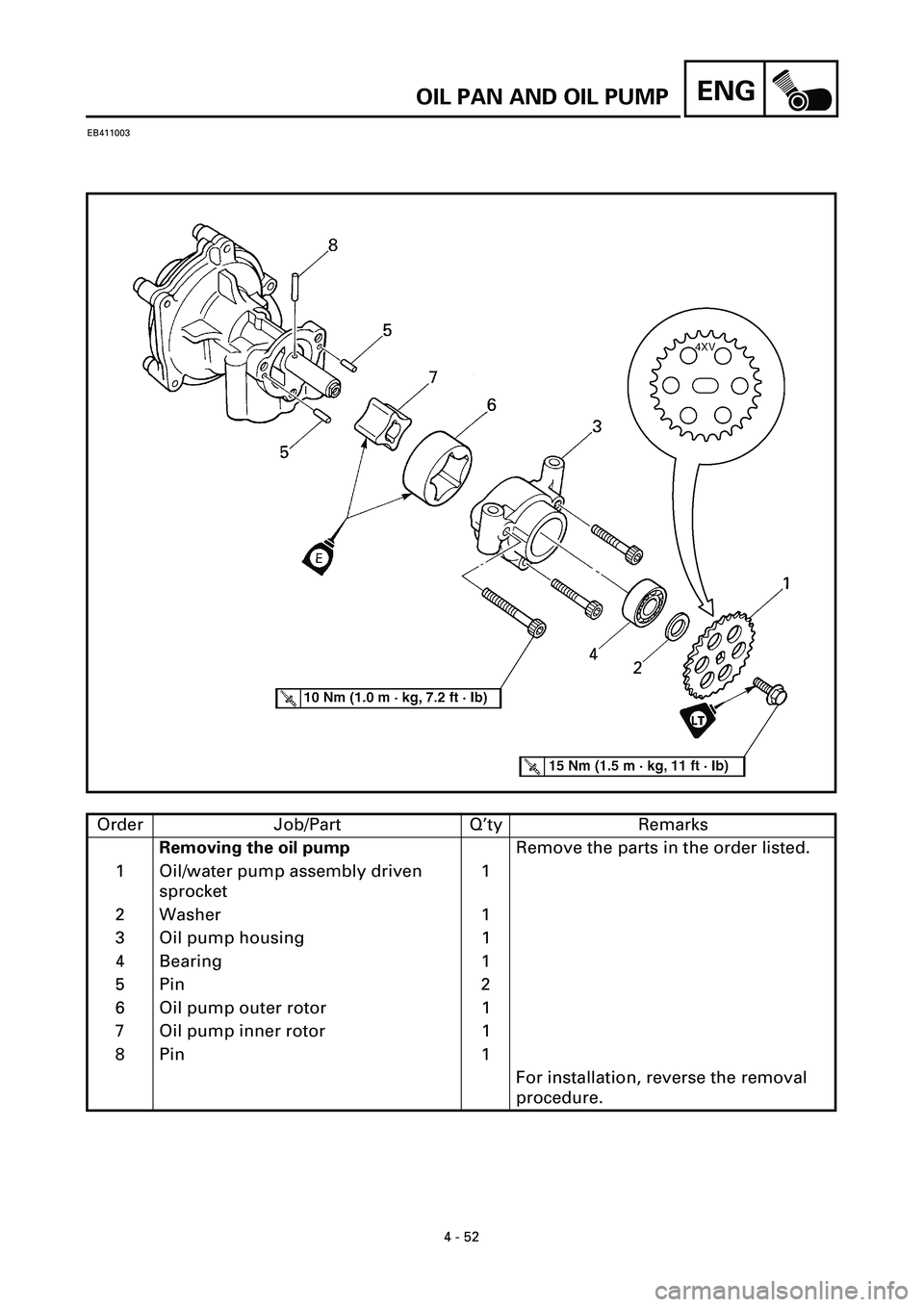

Order Job/Part Q’ty Remarks

Removing the oil pumpRemove the parts in the order listed.

1 Oil/water pump assembly driven

sprocket1

2 Washer 1

3 Oil pump housing 1

4 Bearing 1

5 Pin 2

6 Oil pump outer rotor 1

7 Oil pump inner rotor 1

8 Pin 1

For installation, reverse the removal

procedure.

Page 185 of 381

4 - 53

ENGOIL PAN AND OIL PUMP

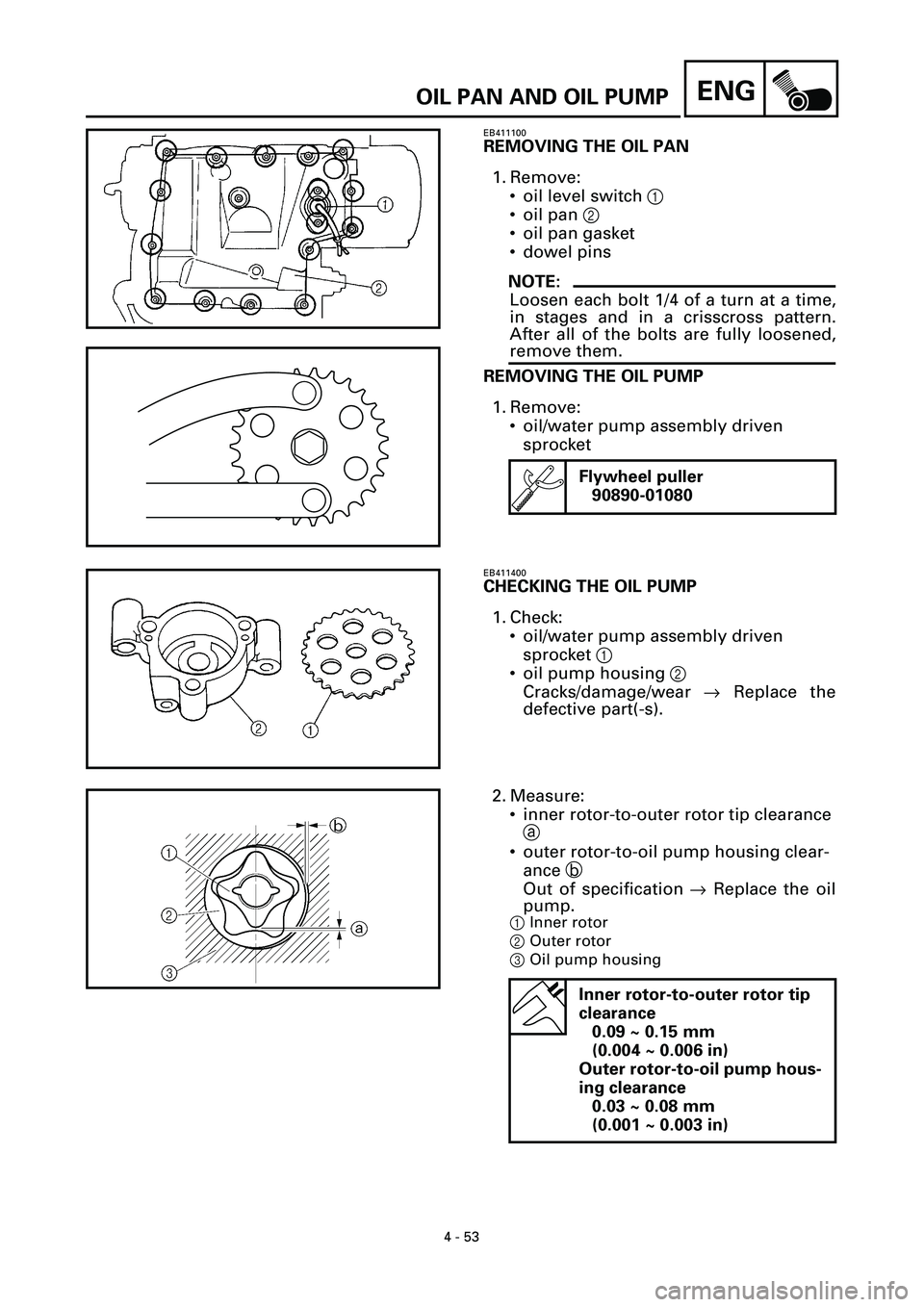

EB411100

REMOVING THE OIL PAN

1. Remove:

• oil level switch 1

• oil pan 2

• oil pan gasket

• dowel pins

NOTE:

Loosen each bolt 1/4 of a turn at a time,

in stages and in a crisscross pattern.

After all of the bolts are fully loosened,

remove them.

REMOVING THE OIL PUMP

1. Remove:

• oil/water pump assembly driven

sprocket

Flywheel puller

90890-01080

EB411400

CHECKING THE OIL PUMP

1. Check:

• oil/water pump assembly driven

sprocket 1

• oil pump housing 2

Cracks/damage/wear ® Replace the

defective part(-s).

2. Measure:

• inner rotor-to-outer rotor tip clearance

a

• outer rotor-to-oil pump housing clear-

ance b

Out of specification ® Replace the oil

pump.

1 Inner rotor

2 Outer rotor

3 Oil pump housing

Inner rotor-to-outer rotor tip

clearance

0.09 ~ 0.15 mm

(0.004 ~ 0.006 in)

Outer rotor-to-oil pump hous-

ing clearance

0.03 ~ 0.08 mm

(0.001 ~ 0.003 in)

Page 186 of 381

4 - 54

ENGOIL PAN AND OIL PUMP

3. Check:

• oil pump operation

Unsmooth ® Repair or replace the

defective part(-s).

Refer to “WATER PUMP” in chapter 5.

EB411410

CHECKING THE RELIEF VALVE

1. Check:

• relief valve body 1

• relief valve 2

• spring 3

• O-ring 4

Damage/wear ® Replace the defective

part(-s).

EB411421

CHECKING THE OIL DELIVERY PIPE AND

OIL PIPE

1. Check:

• oil delivery pipe 1

• oil pipe 2

Damage ® Replace.

Obstruction ® Wash and blow out

with compressed air.

EB411430

CHECKING THE OIL STRAINER

1. Check:

• oil strainer 1

Damage ® Replace.

Contaminants ® Clean with engine oil.

EB411701

ASSEMBLING THE OIL PUMP

1. Lubricate:

• inner rotor

• outer rotor

• impeller shaft

(with the recommended lubricant)

Recommended lubricant

Engine oil

Page 187 of 381

4 - 55

ENGOIL PAN AND OIL PUMP

2. Check:

• oil pump operation

Refer to “CHECKING THE OIL PUMP”.

EB411710

INSTALLING THE OIL PUMP

1. Install:

• oil pump 1

NOTE:

Install the oil/water pump assembly

drive chain onto the oil/water pump

assembly driven sprocket.

T R..12 Nm (1.2 m · kg, 8.7 ft · lb)

EB411720

INSTALLING THE OIL STRAINER

1. Install:

• oil strainer 1

NOTE:

The arrow a on the oil strainer housing

must point towards the front of the

engine.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

EB411730

INSTALLING THE OIL PAN

1. Install:

• dowel pins

• oil pan gasket

• oil pan 1

• oil level switch 2

• engine oil drain bolt 3

WARNINGWARNING

Always use new copper washers.

NOTE:

• Tighten the oil pan bolts in stages and

in a crisscross pattern.

• Lubricate the oil level switch O-ring

with lithium soap base grease.

New

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

T R..43 Nm (4.3 m · kg, 31 ft · lb)

Page 188 of 381

ENG

4 - 56

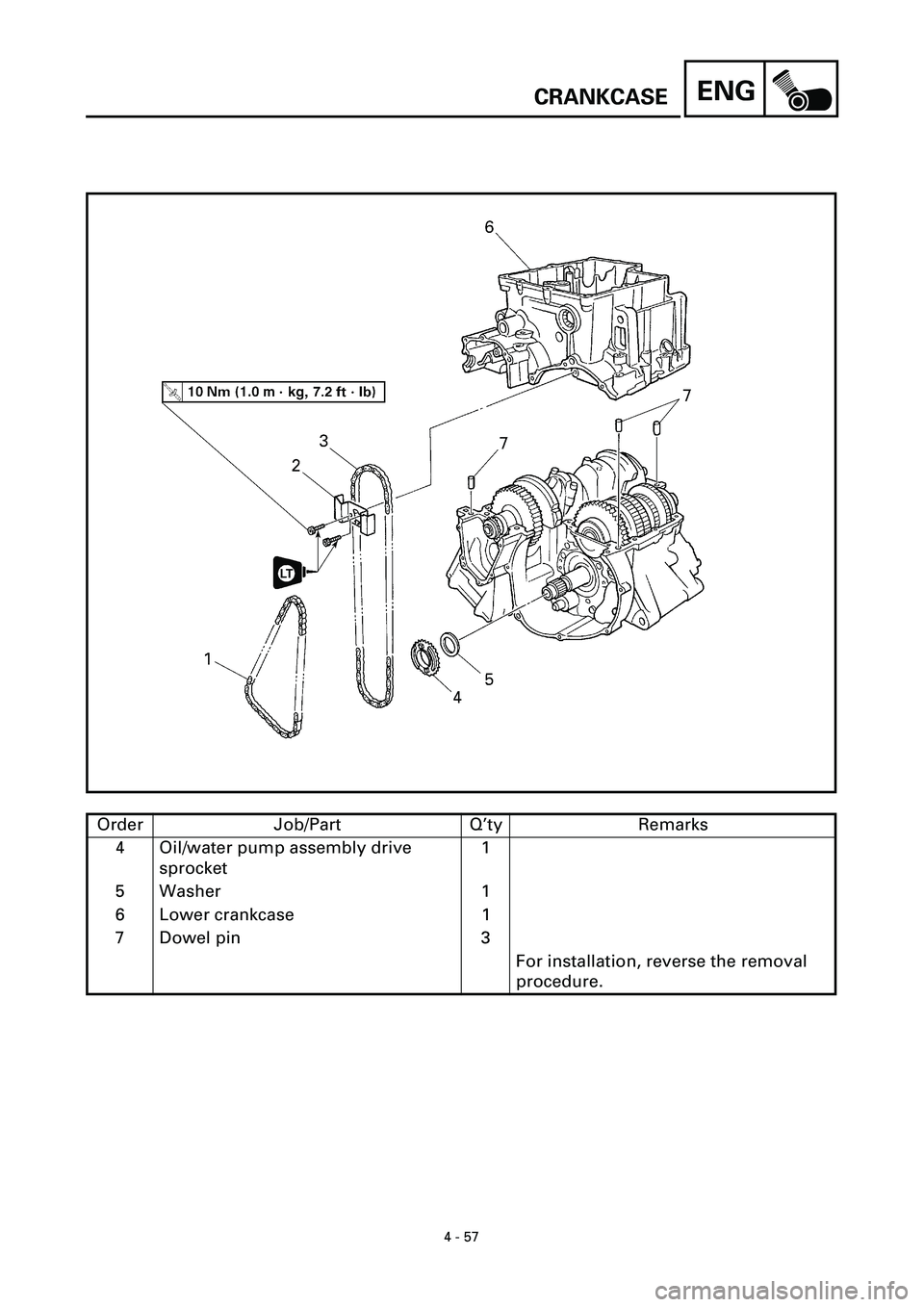

CRANKCASE

CRANKCASE

Order Job/Part Q’ty Remarks

Separating the crankcaseRemove the parts in the order listed.

Engine Refer to “ENGINE”.

Cylinder head Refer to “CYLINDER HEAD”.

Pickup coil and pickup coil rotor Refer to “PICKUP COIL”.

Stator coil assembly Refer to “GENERATOR”.

Clutch housing and starter clutch

idle gearRefer to “CLUTCH”.

Oil/water pump assembly Refer to “OIL PAN AND OIL PUMP”.

1 Timing chain 1

2 Oil/water pump assembly drive

chain guide1

3 Oil/water pump assembly drive

chain1

Page 189 of 381

ENG

4 - 57

CRANKCASE

Order Job/Part Q’ty Remarks

4 Oil/water pump assembly drive

sprocket1

5 Washer 1

6 Lower crankcase 1

7 Dowel pin 3

For installation, reverse the removal

procedure.

Page 190 of 381

ENG

4 - 58

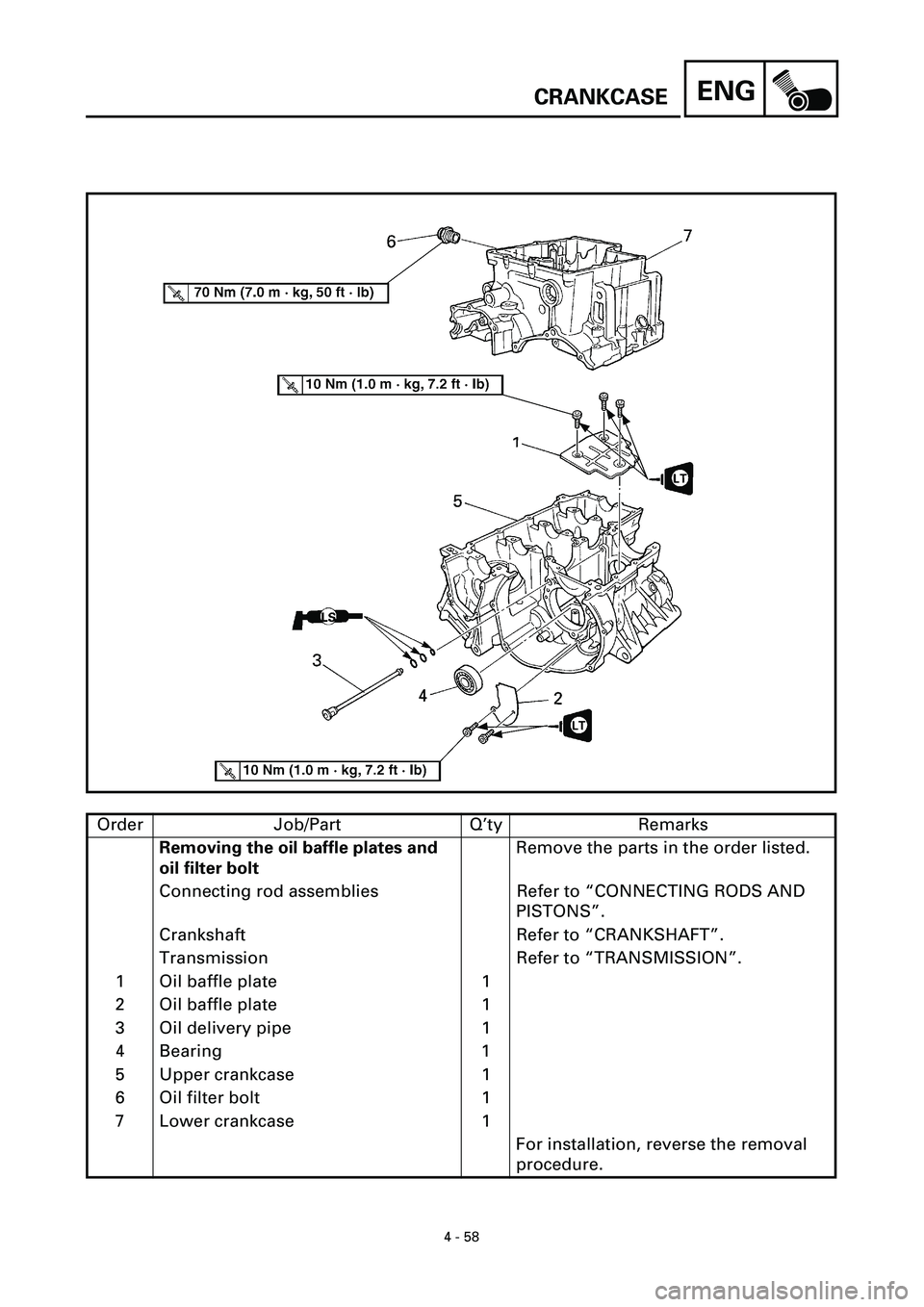

CRANKCASE

Order Job/Part Q’ty Remarks

Removing the oil baffle plates and

oil filter boltRemove the parts in the order listed.

Connecting rod assemblies Refer to “CONNECTING RODS AND

PISTONS”.

Crankshaft Refer to “CRANKSHAFT”.

Transmission Refer to “TRANSMISSION”.

1 Oil baffle plate 1

2 Oil baffle plate 1

3 Oil delivery pipe 1

4 Bearing 1

5 Upper crankcase 1

6 Oil filter bolt 1

7 Lower crankcase 1

For installation, reverse the removal

procedure.

Trending: steering, air suspension, tire type, light, oil type, drain bolt, rear view mirror