YAMAHA YZF-R7 1999 Owners Manual

YZF-R7 1999

YAMAHA

YAMAHA

https://www.carmanualsonline.info/img/51/54468/w960_54468-0.png

YAMAHA YZF-R7 1999 Owners Manual

Trending: compression ratio, oil level, maintenance, key, brake pads, gas type, ESP

Page 171 of 381

ENG

4 - 39

CLUTCH

EB405000

CLUTCH

Order Job/Part Q’ty Remarks

Removing the clutch coverRemove the parts in the order listed.

Bottom cowling and front cowling Refer to “COWLINGS” in chapter 3.

Engine oil Drain.

Refer to “CHANGING THE ENGINE

OIL” in chapter 3.

1 Clutch cover 1

2 Clutch cover gasket 1

3 Dowel pin 2

For installation, reverse the removal

procedure.

Page 172 of 381

ENG

4 - 40

CLUTCH

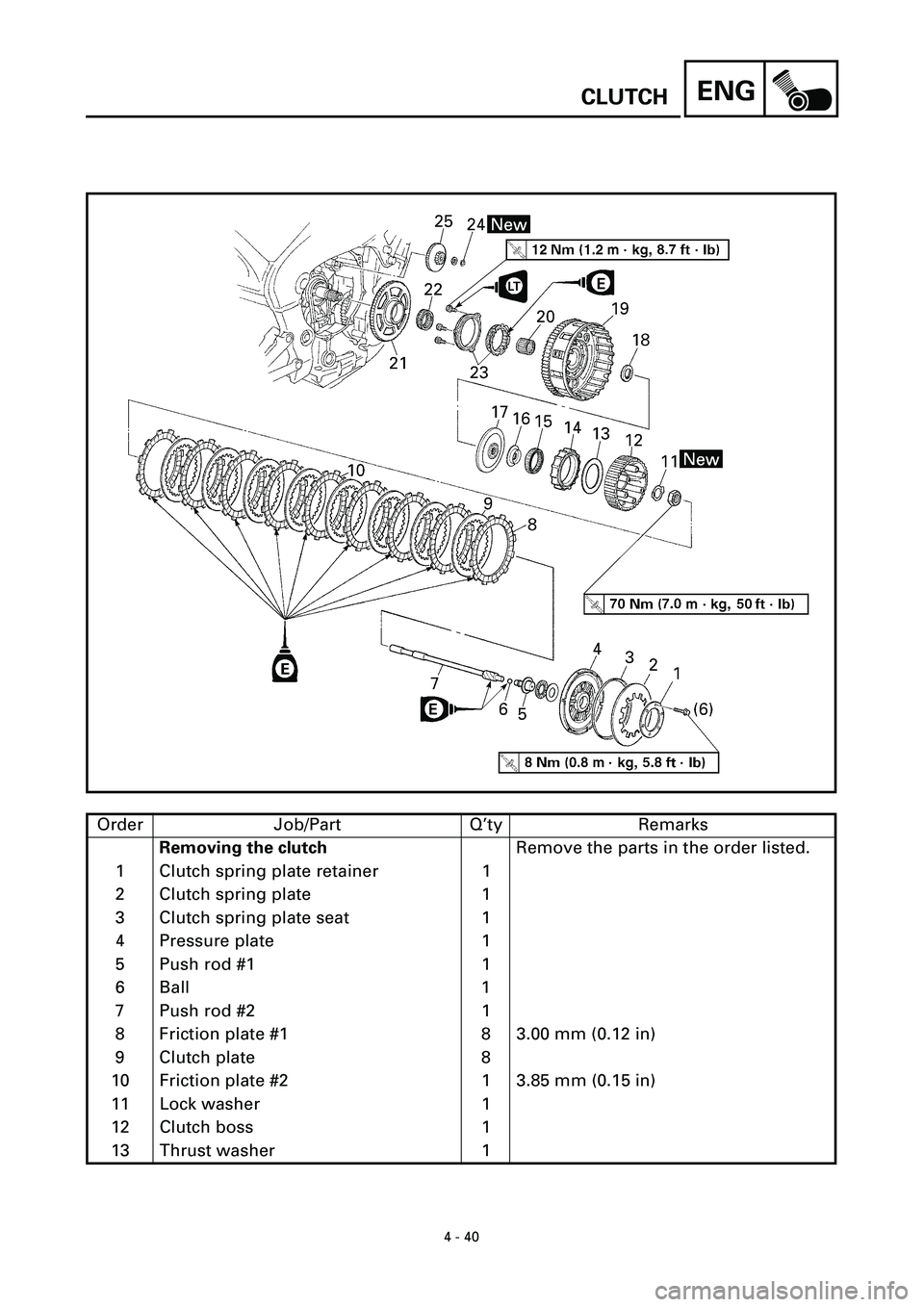

Order Job/Part Q’ty Remarks

Removing the clutchRemove the parts in the order listed.

1 Clutch spring plate retainer 1

2 Clutch spring plate 1

3 Clutch spring plate seat 1

4 Pressure plate 1

5 Push rod #1 1

6 Ball 1

7 Push rod #2 1

8 Friction plate #1 8 3.00 mm (0.12 in)

9 Clutch plate 8

10 Friction plate #2 1 3.85 mm (0.15 in)

11 Lock washer 1

12 Clutch boss 1

13 Thrust washer 1

Page 173 of 381

ENG

4 - 41

CLUTCH

Order Job/Part Q’ty Remarks

14 Back torque limiter outer boss 1

15 Back torque limiter bearing 1

16 Back torque limiter inner boss 1

17 Thrust plate 1

18 Thrust washer 1

19 Clutch housing 1

20 Bearing 1

21 Starter clutch gear 1

22 Bearing 1

23 Starter clutch assembly 1

24 Circlip 1

25 Starter clutch idle gear 1

For installation, reverse the removal

procedure.

Page 174 of 381

4 - 42

ENGCLUTCH

EB405102

REMOVING THE CLUTCH

1. Remove:

• clutch cover 1

NOTE:

Loosen each bolt 1/4 of a turn at a time,

in stages and in a crisscross pattern.

After all of the bolts are fully loosened,

remove them.

1�

1�

2. Straighten the lock washer tab.

3. Loosen:

• clutch boss nut 1

NOTE:

While holding the clutch boss 2 with

the clutch holding tool 3, loosen the

clutch boss nut.

Clutch holding tool

90890-04086

EB405400

CHECKING THE FRICTION PLATES

The following procedure applies to all of

the friction plates.

1. Check:

• friction plate

Damage/wear ® Replace the friction

plates as a set.

2. Measure:

• friction plate thickness

Out of specification ® Replace the fric-

tion plates as a set.

NOTE:

Measure the friction plate at four places.

Friction plate #1 thickness

2.9 ~ 3.1 mm

(0.114 ~ 0.122 in)

: 2.8 mm (0.110 in)

Friction plate #2 thickness

3.7 ~ 3.9 mm

(0.146 ~ 0.154 in)

: 3.6 mm (0.142 in)

Page 175 of 381

4 - 43

ENGCLUTCH

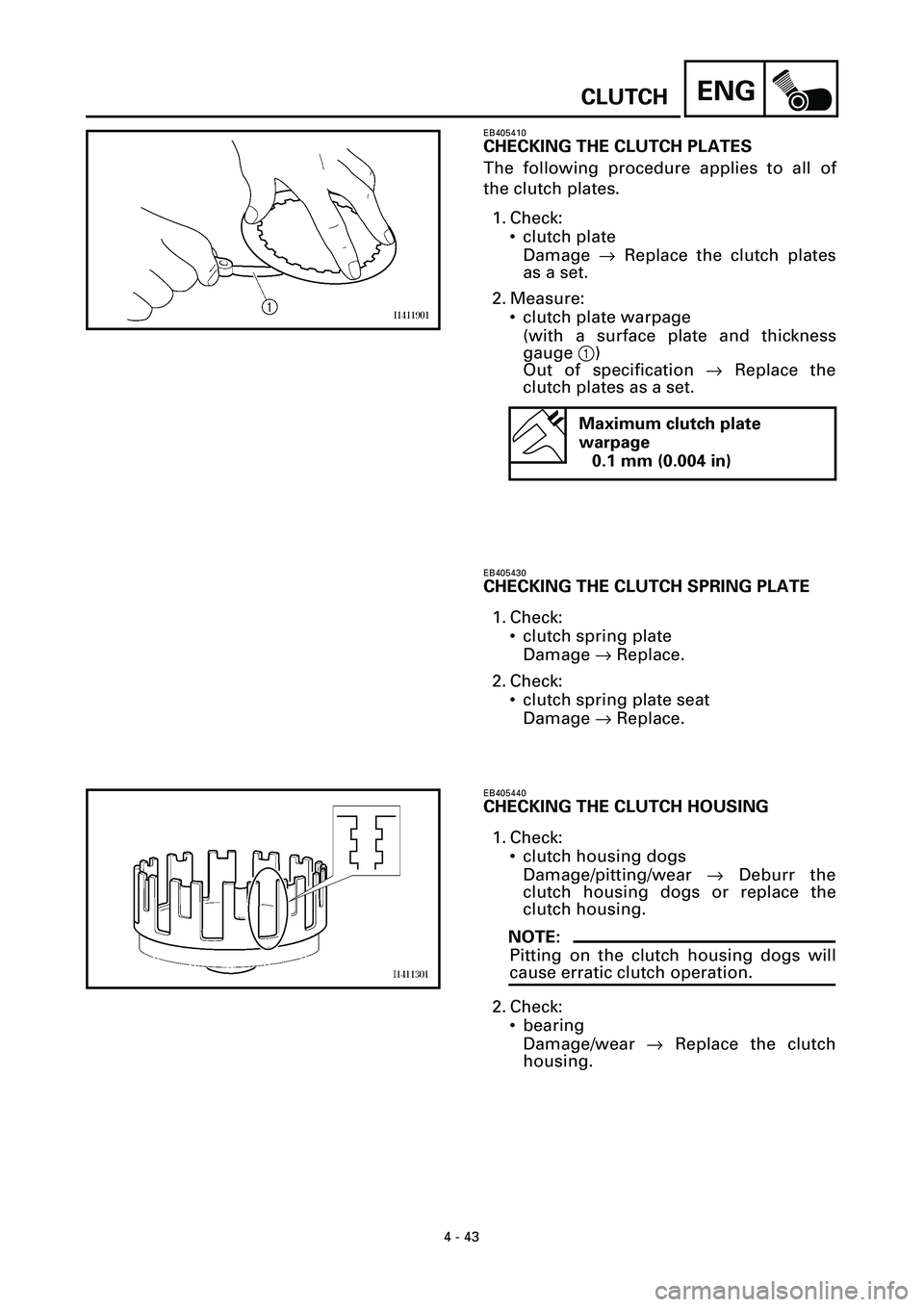

EB405410

CHECKING THE CLUTCH PLATES

The following procedure applies to all of

the clutch plates.

1. Check:

• clutch plate

Damage ® Replace the clutch plates

as a set.

2. Measure:

• clutch plate warpage

(with a surface plate and thickness

gauge 1)

Out of specification ® Replace the

clutch plates as a set.

Maximum clutch plate

warpage

0.1 mm (0.004 in)

EB405430

CHECKING THE CLUTCH SPRING PLATE

1. Check:

• clutch spring plate

Damage ® Replace.

2. Check:

• clutch spring plate seat

Damage ® Replace.

EB405440

CHECKING THE CLUTCH HOUSING

1. Check:

• clutch housing dogs

Damage/pitting/wear ® Deburr the

clutch housing dogs or replace the

clutch housing.

NOTE:

Pitting on the clutch housing dogs will

cause erratic clutch operation.

2. Check:

• bearing

Damage/wear ® Replace the clutch

housing.

Page 176 of 381

4 - 44

ENGCLUTCH

EB405450

CHECKING THE CLUTCH BOSS

1. Check:

• clutch boss splines

Damage/pitting/wear ® Replace the

clutch boss.

NOTE:

Pitting on the clutch boss splines will

cause erratic clutch operation.

EB405460

CHECKING THE PRESSURE PLATE

1. Check:

• pressure plate 1

Cracks/damage ® Replace.

• bearing 2

Damage/wear ® Replace.

CHECKING THE PUSH RODS AND BALL

1. Check:

• push rod #1 1

• push rod #2 2

• ball 3

Damage/wear ® Replace the pull rods

and ball as a set.

2. Check:

• push rod bearing 4

Damage/wear ® Replace.

CHECKING THE BACK TORQUE LIMITER

1. Check:

• back torque limiter outer boss splines

Damage/pitting/wear ® Replace the

back torque limiter outer boss.

Page 177 of 381

4 - 45

ENGCLUTCH

2. Check:

• back torque limiter clutch

t t t t t t t t t t t t t t t t t t t t t t t t t t t

a. Install the back torque limiter bearing

and back torque limiter outer boss

onto the back torque limiter inner

boss and hold the back torque limiter

inner boss.

b. When turning the back torque limiter

outer boss clockwise , the back

torque limiter inner boss and back

torque limiter outer boss should

engage, otherwise the back torque

limiter is faulty and must be replaced.

c. When turning the back torque limiter

outer boss counterclockwise õ, it

should turn freely, otherwise the back

torque limiter is faulty and must be

replaced.

s s s s s s s s s s s s s s s s s s s s s s s s s s s

CHECKING THE STARTER CLUTCH

1. Check:

• starter clutch gear

• starter clutch idle gear

Chips/pitting/roughness/wear ®

Replace the defective part(-s).

2. Check:

• starter clutch operation

t t t t t t t t t t t t t t t t t t t t t t t t t t t

a. Install the starter clutch gear 1 onto

the starter clutch2 and hold the

starter clutch.

b. When turning the starter clutch gear

clockwise , the starter clutch and

the starter clutch gear should engage,

otherwise the starter clutch is faulty

and must be replaced.

c. When turning the starter clutch gear

counterclockwise õ, it should turn

freely, otherwise the starter clutch is

faulty and must be replaced.

s s s s s s s s s s s s s s s s s s s s s s s s s s s

Page 178 of 381

4 - 46

ENGCLUTCH

EB405703

INSTALLING THE CLUTCH

1. Install:

• clutch housing

NOTE:

• Make sure that the slots a in the

clutch housing align with the tabs b

on the oil/water pump assembly drive

sprocket.

• Make sure that the primary driven gear

teeth and primary drive gear teeth

mesh correctly.

• Make sure that the starter clutch gear

teeth and starter clutch idle gear teeth

mesh correctly.

2. Install:

• back torque limiter inner boss 1

• back torque limiter bearing 2

• back torque limiter outer boss 3

ACHTUNG:CAUTION:

Be sure that the back torque limiter

bearing is installed facing in the correct

direction as shown.

3. Install:

• lock washer

• clutch boss nut 1

NOTE:

While holding the clutch boss 2 with

the clutch holding tool 3, tighten the

clutch boss nut.

Clutch holding tool

90890-04086

New

T R..70 Nm (7.0 m · kg, 50 ft · lb)

Page 179 of 381

4 - 47

ENGCLUTCH

4. Bend the lock washer tab along a flat

side of the nut.

5. Lubricate:

• friction plates

• clutch plates

(with the recommended lubricant)

Recommended lubricant

Engine oil

6. Install:

• friction plates 1 - 3.00 mm (0.12 in)

• clutch plates 2

• friction plate 3 - 3.85 mm (0.15 in)

NOTE:

First, install a friction plate and then

alternate between a clutch plate and a

friction plate.

13

2

Page 180 of 381

ENG

4 - 48

SHIFT SHAFT

EB408000

SHIFT SHAFT

Order Job/Part Q’ty Remarks

Removing the shift shaft and stop-

per leverRemove the parts in the order listed.

Drive sprocket cover Refer to “ENGINE”.

1 Shift shaft cover 1

2 Shift shaft cover gasket 1

3 Dowel pin 2

4 Shift shaft 1

5 Shift shaft spring 1

6 Spacer 1

7 Stopper lever spring 1

8 Stopper lever 1

9 Circlip 1

10 Collar 1

11 Shift shaft spring stopper 1

For installation, reverse the removal

procedure.

Trending: torque, transmission, boot, tow, steering wheel adjustment, run flat, odometer