YAMAHA YZF-R7 1999 Owner's Guide

Manufacturer: YAMAHA, Model Year: 1999, Model line: YZF-R7, Model: YAMAHA YZF-R7 1999Pages: 381, PDF Size: 18.88 MB

Page 31 of 381

1 - 19

TROUBLESHOOTING CHART

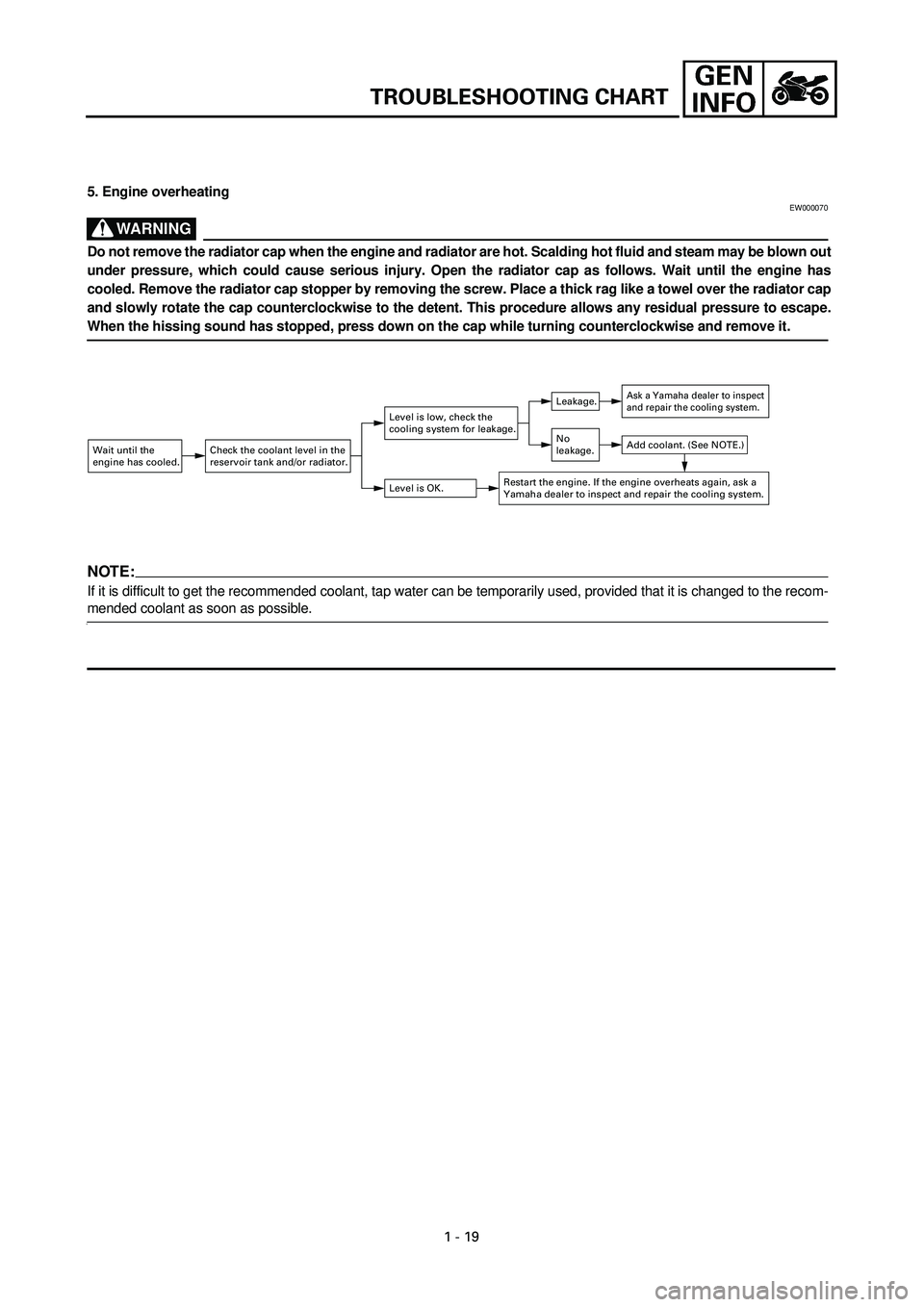

5. Engine overheatingEW000070

WARNING

Do not remove the radiator cap when the engine and radiator are hot. Scalding hot fluid and steam may be blown out

under pressure, which could cause serious injury. Open the radiator cap as follows. Wait until the engine has

cooled. Remove the radiator cap stopper by removing the screw. Place a thick rag like a towel over the radiator cap

and slowly rotate the cap counterclockwise to the detent. This procedure allows any residual pressure to escape.

When the hissing sound has stopped, press down on the cap while turning counterclockwise and remove it.

NOTE:

If it is difficult to get the recommended coolant, tap water can be temporarily used, provided that it is changed to the recom-

mended coolant as soon as possible.

Wait until the

engine has cooled.Check the coolant level in the

reservoir tank and/or radiator.

Level is OK.

Level is low, check the

cooling system for leakage.

No

leakage.

Leakage.Ask a Yamaha dealer to inspect

and repair the cooling system.

Add coolant. (See NOTE.)

Restart the engine. If the engine overheats again, ask a

Yamaha dealer to inspect and repair the cooling system.

Page 32 of 381

1 - 20

IMPORTANT INFORMATION

EB102000

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL AND

DISASSEMBLY

1. Before removal and disassembly,

remove all dirt, mud, dust, and foreign

material.

2. Use only the proper tools and cleaning

equipment.

Refer to “SPECIAL TOOLS”.

3. When disassembling, always keep

mated parts together. This includes

gears, cylinders, pistons and other parts

that have been “mated” through normal

wear. Mated parts must always be

reused or replaced as an assembly.

4. During disassembly, clean all of the

parts and place them in trays in the

order of disassembly. This will speed up

assembly and allow for the correct

installation of all parts.

5. Keep all parts away from any source of

fire.

EB102010

REPLACEMENT PARTS

Use only genuine Yamaha parts for all

replacements. Use oil and grease recom-

mended by Yamaha for all lubrication jobs.

Other brands may be similar in function

and appearance, but inferior in quality.

EB102020

GASKETS, OIL SEALS AND O-RINGS

1. When overhauling the engine, replace

all gaskets, seals, and O-rings. All gasket

surfaces, oil seal lips, and O-rings must

be cleaned.

2. During reassembly, properly oil all mat-

ing parts and bearings and lubricate the

oil seal lips with grease.

Page 33 of 381

1 - 21

IMPORTANT INFORMATION

USING A DYNAMOMETER

The YZF-R7 has a carbon muffler that may

change color when exposed to high tem-

peratures. Therefore, when using a dyna-

mometer always use a fan to cool the

muffler.

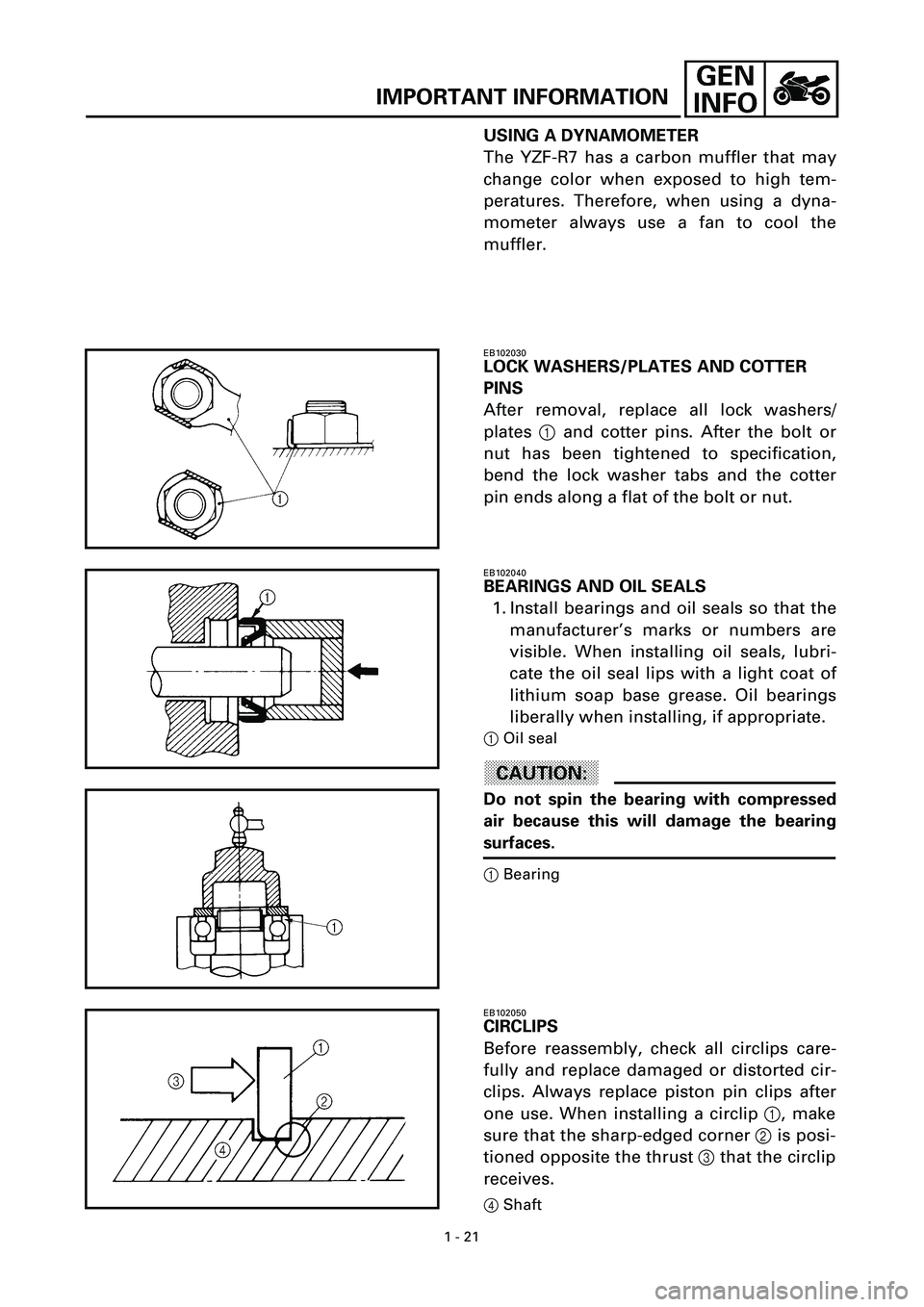

EB102030

LOCK WASHERS/PLATES AND COTTER

PINS

After removal, replace all lock washers/

plates

1

and cotter pins. After the bolt or

nut has been tightened to specification,

bend the lock washer tabs and the cotter

pin ends along a flat of the bolt or nut.

EB102040

BEARINGS AND OIL SEALS

1. Install bearings and oil seals so that the

manufacturer’s marks or numbers are

visible. When installing oil seals, lubri-

cate the oil seal lips with a light coat of

lithium soap base grease. Oil bearings

liberally when installing, if appropriate.

1

Oil seal

ACHTUNG:CAUTION:

Do not spin the bearing with compressed

air because this will damage the bearing

surfaces.

1

Bearing

EB102050

CIRCLIPS

Before reassembly, check all circlips care-

fully and replace damaged or distorted cir-

clips. Always replace piston pin clips after

one use. When installing a circlip

1

, make

sure that the sharp-edged corner

2

is posi-

tioned opposite the thrust

3

that the circlip

receives.

4

Shaft

Page 34 of 381

1 - 22

CHECKING THE CONNECTIONS

EB103000

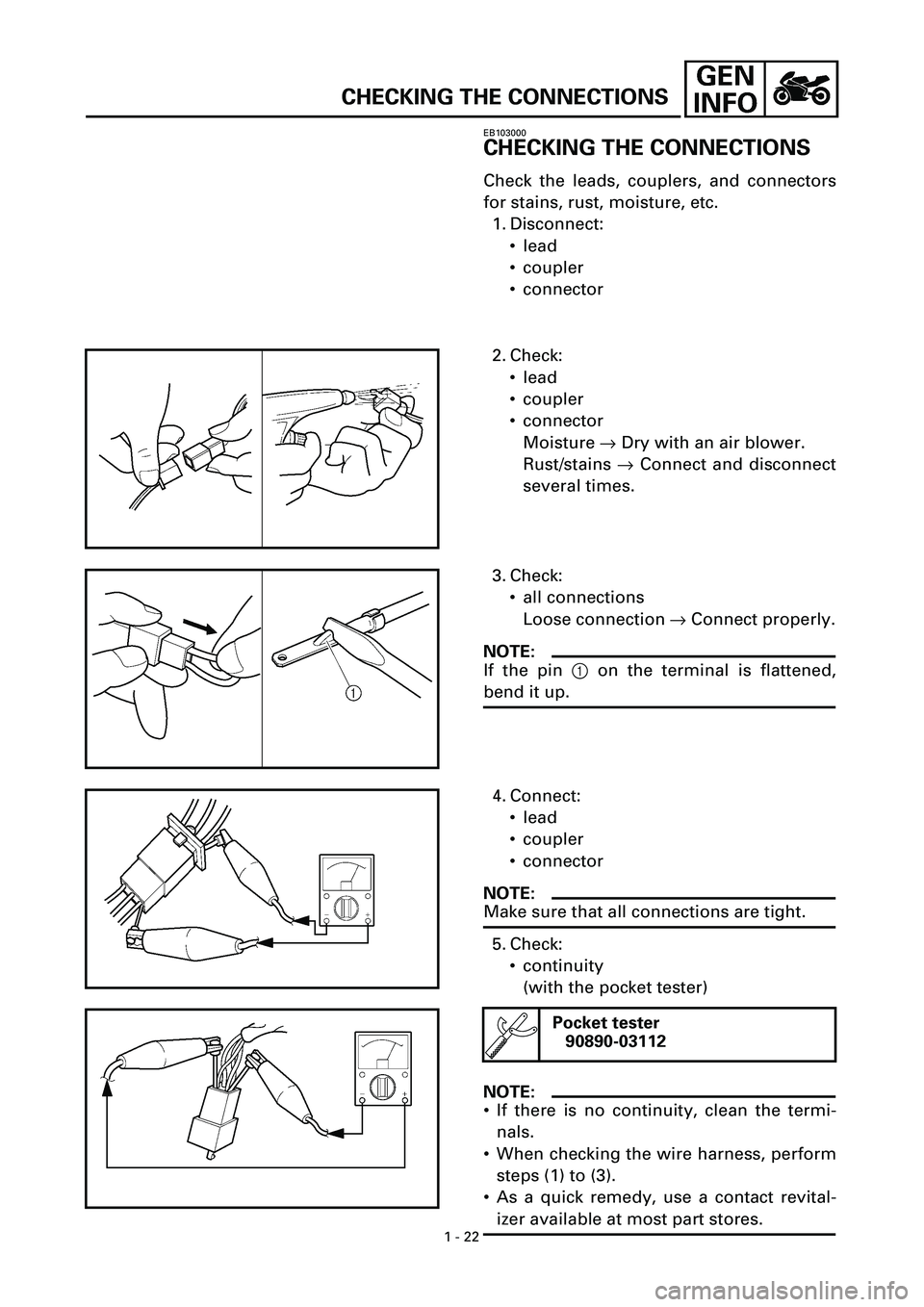

CHECKING THE CONNECTIONS

Check the leads, couplers, and connectors

for stains, rust, moisture, etc.

1. Disconnect:

• lead

• coupler

• connector

2. Check:

• lead

• coupler

• connector

Moisture

®

Dry with an air blower.

Rust/stains

®

Connect and disconnect

several times.

3. Check:

• all connections

Loose connection

®

Connect properly.

NOTE:

If the pin

1

on the terminal is flattened,

bend it up.

4. Connect:

• lead

• coupler

• connector

NOTE:

Make sure that all connections are tight.

5. Check:

• continuity

(with the pocket tester)

NOTE:

• If there is no continuity, clean the termi-

nals.

• When checking the wire harness, perform

steps (1) to (3).

• As a quick remedy, use a contact revital-

izer available at most part stores.

Pocket tester

90890-03112

Page 35 of 381

1 - 23

SPECIAL TOOLS

EB104000

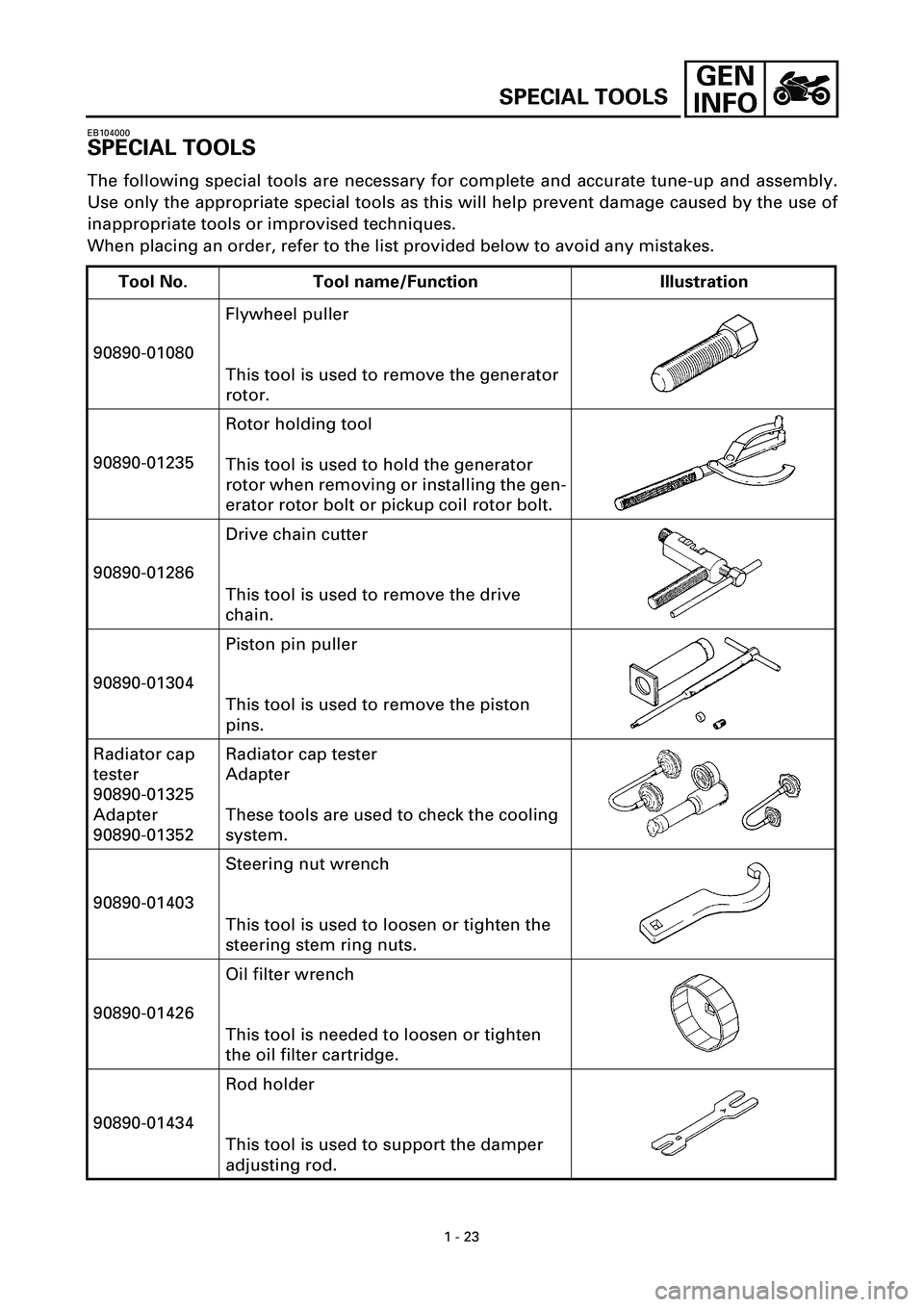

SPECIAL TOOLS

The following special tools are necessary for complete and accurate tune-up and assembly.

Use only the appropriate special tools as this will help prevent damage caused by the use of

inappropriate tools or improvised techniques.

When placing an order, refer to the list provided below to avoid any mistakes.

Tool No. Tool name/Function Illustration

90890-01080Flywheel puller

This tool is used to remove the generator

rotor.

90890-01235Rotor holding tool

This tool is used to hold the generator

rotor when removing or installing the gen-

erator rotor bolt or pickup coil rotor bolt.

90890-01286Drive chain cutter

This tool is used to remove the drive

chain.

90890-01304Piston pin puller

This tool is used to remove the piston

pins.

Radiator cap

tester

90890-01325

Adapter

90890-01352Radiator cap tester

Adapter

These tools are used to check the cooling

system.

90890-01403Steering nut wrench

This tool is used to loosen or tighten the

steering stem ring nuts.

90890-01426Oil filter wrench

This tool is needed to loosen or tighten

the oil filter cartridge.

90890-01434Rod holder

This tool is used to support the damper

adjusting rod.

Page 36 of 381

1 - 24

SPECIAL TOOLS

Rod puller

90890-01437

Rod puller

attachment

90890-01436Rod puller

Rod puller attachment

These tools are used to pull up the front

fork damper rod.

90890-01441Fork spring compressor

This tool is used to disassemble or assem-

ble the front fork legs.

90890-01442Fork seal driver

This tool is used to install the front fork’s

oil seal and dust seal.

90890-01471Pivot shaft wrench

This tool is used to remove or install the

engine mounting spacer bolts.

90890-01472Front fork cap bolt wrench

This tool is used to remove or install the

front fork cap bolt.

90890-01473Damper rod holder

This tool is used to hold the damper rod

assembly when loosening or tightening

the damper rod assembly bolt.

90890-03008Micrometer (50 ~ 75 mm)

This tool is used to measure the piston

skirt diameter.

90890-03017Cylinder bore gauge (50 ~ 100 mm)

This tool is used to measure the cylinder

bore.

Vacuum gauge

90890-03094

Vacuum gauge

attachment

90890-03060Vacuum gauge

Vacuum gauge attachment

This gauge is used to synchronize the

throttle bodies.

Tool No. Tool name/Function Illustration

Page 37 of 381

1 - 25

SPECIAL TOOLS

Compression

gauge

90890-03081

Adapter

90890-04136Compression gauge

Adapter

These tools are used to measure engine

compression.

90890-03112Pocket tester

This tool is used to check the electrical

system.

Pressure

gauge

90890-03153

Adapter

90890-03151Pressure gauge

Adapter

These tools are used to measure the fuel

pressure.

90890-03149Test coupler adapter

This tool is used to check the electrical

control system.

90890-03171Co, diagnosis switch box

This tool is used to check the electrical

control system.

Valve spring com-

pressor

90890-04019

Attachment

90890-04108

90890-04114

Valve spring compressor

Attachment

These tools are used to remove or install

the valve assemblies.

Middle driven shaft

bearing driver

90890-04058

Mechanical seal

installer

90890-04078

Middle driven shaft bearing driver

Mechanical seal installer

These tools are used to install the water

pump seal.

90890-04086Clutch holding tool

This tool is used to hold the clutch boss

when removing or installing the clutch

boss nut.

90890-04111Valve guide remover

This tool is used to remove or install the

valve guides.

Tool No. Tool name/Function Illustration

MODEUP

YES/ON

DOWN

NO/OFF

Page 38 of 381

1 - 26

SPECIAL TOOLS

90890-04112Valve guide installer

This tool is used to install the valve

guides.

90890-04113Valve guide reamer

This tool is used to rebore the new valve

guides.

90890-06754Ignition checker

This tool is used to check the ignition sys-

tem components.

90890-06756Mity vac

This tool is used to measure the vacuum

pressure.

90890-06760Engine tachometer

This tool is used to check engine speed.

90890-85505Yamaha bond No. 1215

This bond is used to seal two mating sur-

faces (e.g., crankcase mating surfaces).

Tool No. Tool name/Function Illustration

Page 39 of 381

GENERAL SPECIFICATIONS

SPEC

2 - 1

SPECIFICATIONS

GENERAL SPECIFICATIONS

Item Standard Limit

Dimensions

Overall length 2,060 mm (81.1 in) ----

Overall width 720 mm (28.3 in) ----

Overall height 1,125 mm (44.3 in) ----

Seat height 840 mm (33.1 in) ----

Wheelbase 1,400 mm (55.1 in) ----

Minimum ground clearance 120 mm (4.72 in) ----

Minimum turning radius 3,800 mm (150 in) ----

Weight

Wet (with oil and a full fuel tank) 207 kg (456 lb) ----

Dry (without oil and fuel) 176 kg (388 lb) ----

Maximum load (total of rider and

accessories) 317 kg (699 lb) ----

2

Page 40 of 381

ENGINE SPECIFICATIONS

SPEC

2 - 2

ENGINE SPECIFICATIONS

Item Standard Limit

Engine

Engine type Liquid-cooled, 4-stroke, DOHC ----

Displacement 749 cm

3

----

Cylinder arrangement Forward-inclined parallel 4-cylinder ----

Bore

´

stroke 72

´

46 mm (2.83

´

1.81 in) ----

Compression ratio 11.4:1 ----

Engine idling speed 1,000 ~ 1,200 r/min ----

Vacuum pressure at engine idling

speed15.8 ~ 18.4 kPa

(120 ~ 140 mm Hg, 4.72 ~ 5.51 in Hg)----

Standard compression pressure

(at sea level) 157 kPa

(1.57 kgf/cm

2

, 22.3 psi) at 500 r/min----

Fuel

Recommended fuel Premium unleaded gasoline ----

Fuel tank capacity

Total (including reserve) 23 L (20.2 Imp qt, 24.3 US qt) ----

Reserve only 4.8 L (4.22 Imp qt, 5.07 US qt) ----

Engine oil

Lubrication system Wet sump ----

Recommended oil

Yamalube 4 (20W40) or SAE 20W40 type

SE motor oil (40˚F/5˚C or above)

(Non-Friction modified)

Yamalube 4 (10W40) or SAE 10W40 type

SE motor oil (60˚F/15˚C or below)

(Non-Friction modified)----

Quantity

Total amount 3.6 L (3.2 Imp qt, 3.8 US qt) ----

Without oil filter cartridge

replacement2.6 L (2.3 Imp qt, 2.7 US qt) ----

With oil filter cartridge replace-

ment2.8 L (2.5 Imp qt, 3.0 US qt) ----

Oil pressure (hot) 40 kPa (0.4 kgf/cm

2

, 5.69 psi) at

1,100 r/min ----

Relief valve opening pressure 480 ~ 560 kPa

(4.8 ~ 5.6 kgf/cm

2

, 68.3 ~ 79.7 psi)----

2