YAMAHA YZF-R7 1999 Repair Manual

YZF-R7 1999

YAMAHA

YAMAHA

https://www.carmanualsonline.info/img/51/54468/w960_54468-0.png

YAMAHA YZF-R7 1999 Repair Manual

Trending: check engine, oil type, low beam, oil, lights, warning light, ABS

Page 61 of 381

2 - 23

SPEC

EB202010

CHASSIS LUBRICATION POINTS AND LUBRICANT TYPES

Lubrication point Lubricant

Steering bearings and bearing races (upper and lower)

LS

Front wheel oil seal (right and left)LS

Rear wheel oil sealLS

Rear wheel drive hub oil sealLS

Rear wheel drive hub mating surfaceLS

Rear brake pedalLS

Sidestand pivoting point and metal-to-metal moving partsLS

Throttle grip inner surfaceLS

Brake lever pivoting point and metal-to-metal moving partsLS

Clutch lever pivoting point and metal-to-metal moving partsLS

Pivot shaftM

Connecting arm bearing (left and right)M

Spacer (relay arm and connecting arm)M

Oil seal (relay arm and connecting arm)M

LUBRICATION POINTS AND LUBRICANT TYPES

Page 62 of 381

2 - 24

SPEC

OIL FLOW CHART

Pressure feed

Timing chain area camshaft

Valve lifter Check bolt

Piston

Connecting rod

Big end bearing

Nozzle

Nozzle

Back torque limiter clutch

Starter clutch Main axleMain gallery

Drive axle

Oil filter cartridge

Oil cooler

Relief valve

Oil pump

Oil strainer

Oil pan

Drain bolt Main axle gears

Drive axle gearsCrankshaft journal (#2, #4)

Crankshaft journal (#3, #5)Crankshaft journal (#1)

OIL FLOW CHART

Page 63 of 381

ELECTRICAL SPECIFICATIONSSPEC

2 - 25

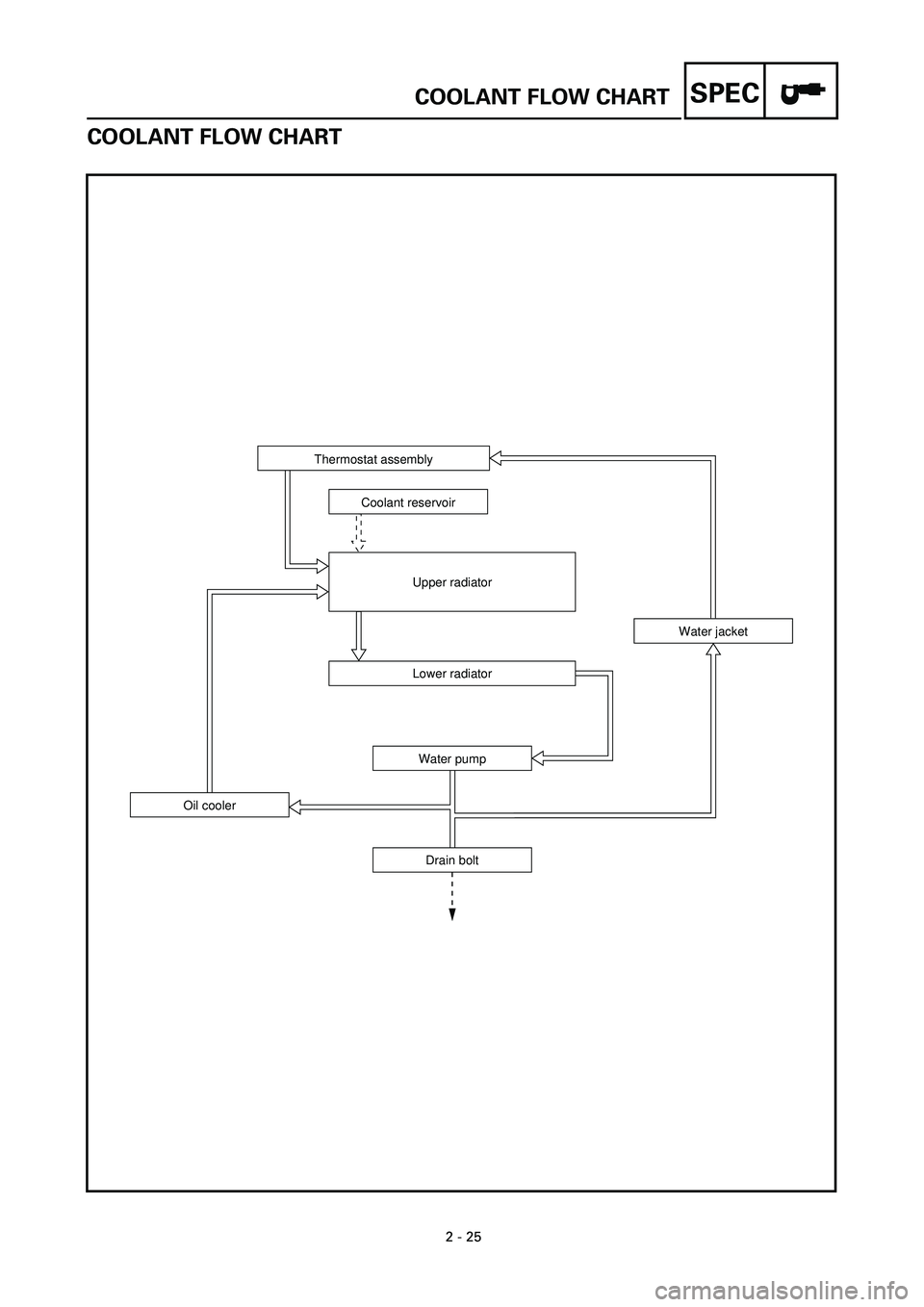

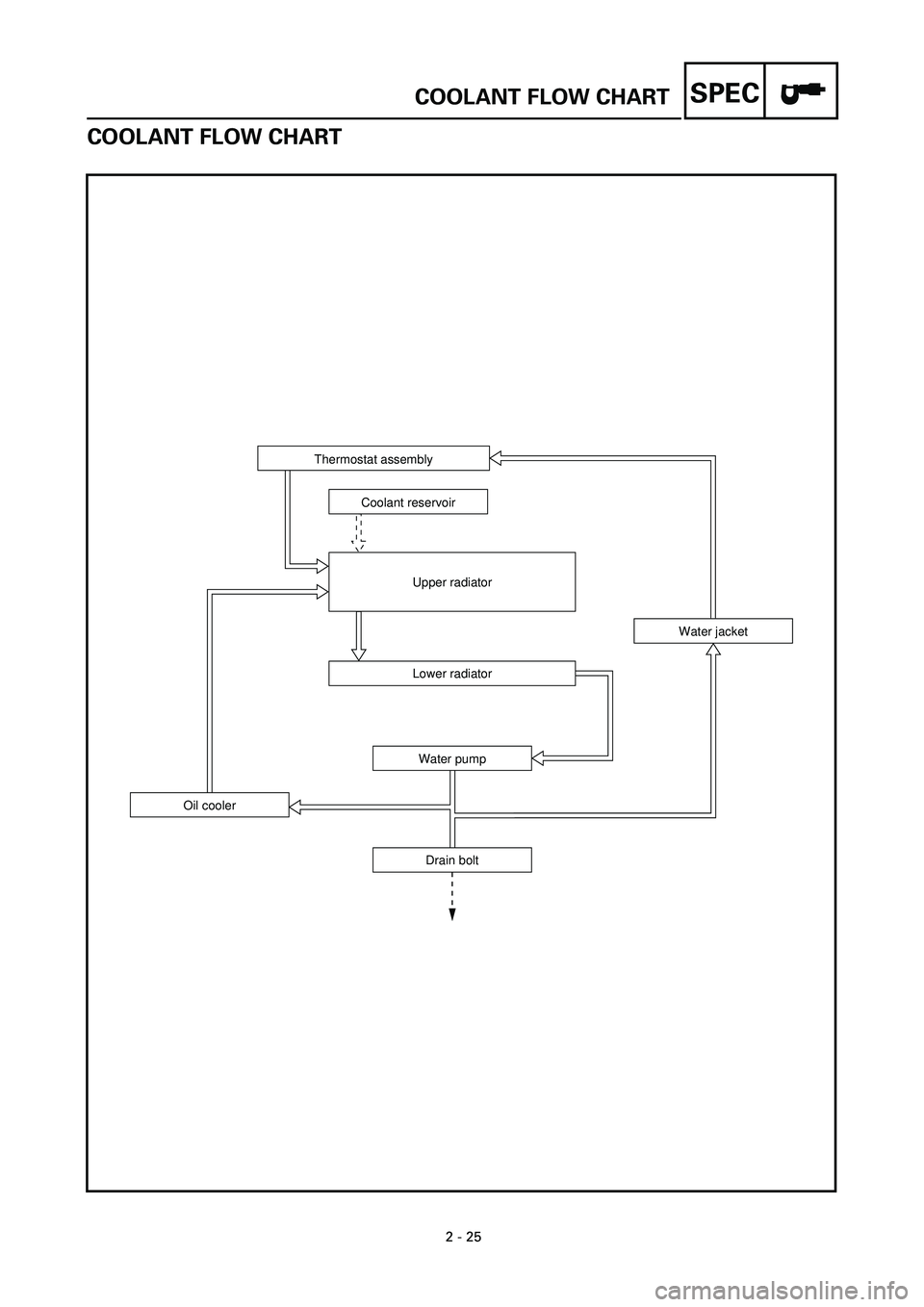

COOLANT FLOW CHART

Thermostat assembly

Coolant reservoir

Upper radiator

Lower radiator

Water pump

Drain bolt Oil coolerWater jacket

COOLANT FLOW CHART

Page 64 of 381

2 - 26

SPEC

CABLE ROUTING

1Front turn signal coupler

2Auxiliary light lead

3Headlight lead

4Throttle cable

5Left handlebar switch lead

6Clutch hose

7Front brake hose

8Right handlebar switch lead

9Main switch lead

CABLE ROUTING

Page 65 of 381

2 - 27

SPEC

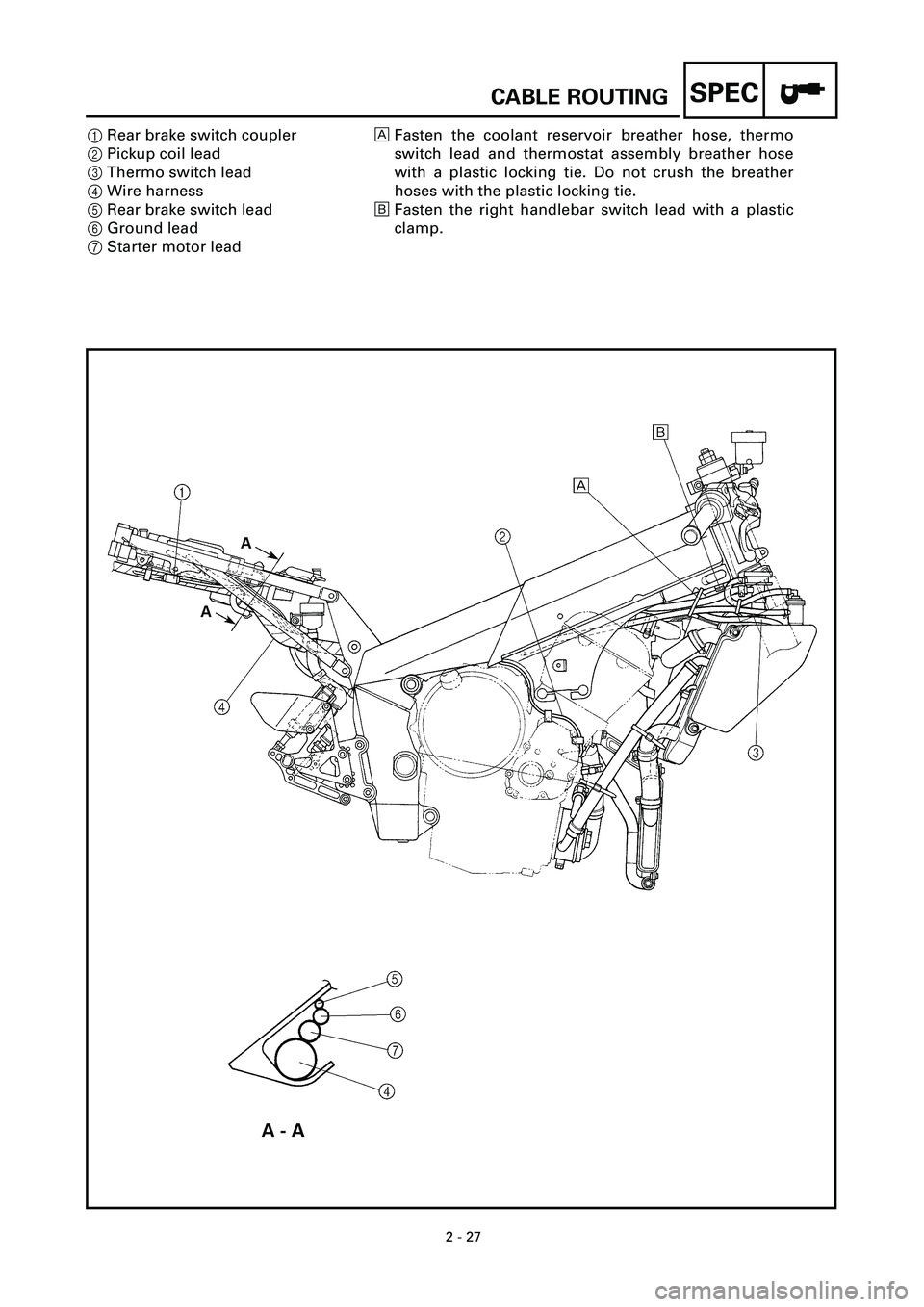

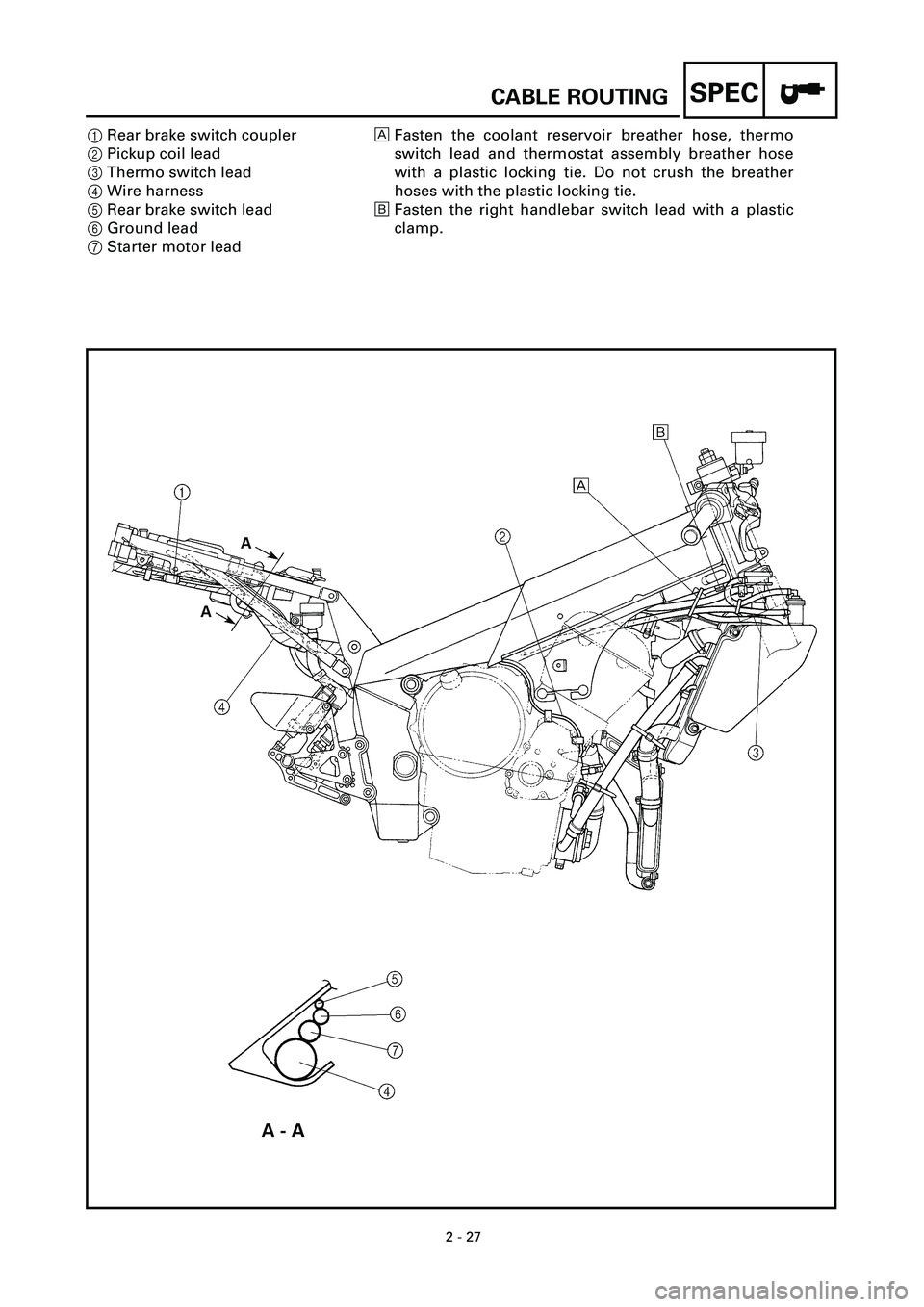

1Rear brake switch coupler

2Pickup coil lead

3Thermo switch lead

4Wire harness

5Rear brake switch lead

6Ground lead

7Starter motor leadFasten the coolant reservoir breather hose, thermo

switch lead and thermostat assembly breather hose

with a plastic locking tie. Do not crush the breather

hoses with the plastic locking tie.

õFasten the right handlebar switch lead with a plastic

clamp.

CABLE ROUTING

Page 66 of 381

2 - 28

SPEC

1Left handlebar switch lead

2Starter cable

3Main relay

4Speed sensor

5Throttle stop screw

6Sidestand switch lead

7Oil level switch lead

8Main switch lead

9Headlight and meter sub-wire har-

ness coupler0Horn lead

AHeadlight and meter sub-wire harness lead

BThrottle cable

CClutch hose

DWire harness (to headlight and meter sub-wire harness)

EWire harness

FFuel tank overflow hose

GWater pump breather hose

HCoolant reservoir breather hose

IAir filter case breather hose

CABLE ROUTING

Page 67 of 381

2 - 29

SPEC

JFuel tank breather hose

KCDI unit

LFall detection switch

MFuse box

NRelay unit

Align the portions of the main

switch lead and left handle-

bar switch lead marked with

white tape with the radiator

bracket at the frame.õFasten the starter cable and wire harness with a plastic band.

‚Fasten the oil level switch lead, speed sensor lead, sidestand

switch lead and stator coil assembly lead with a plastic band.

ëFasten the air filter breather hose, fuel tank overflow hose, clutch

hose and fuel tank breather hose with a plastic band.

ä20 mm (0.79 in)

ìRoute the sidestand switch lead behind the water pump breather

hose.

íRoute the oil level switch lead to the outside of the water pump

breather hose guide.

CABLE ROUTING

Page 68 of 381

2 - 30

SPEC

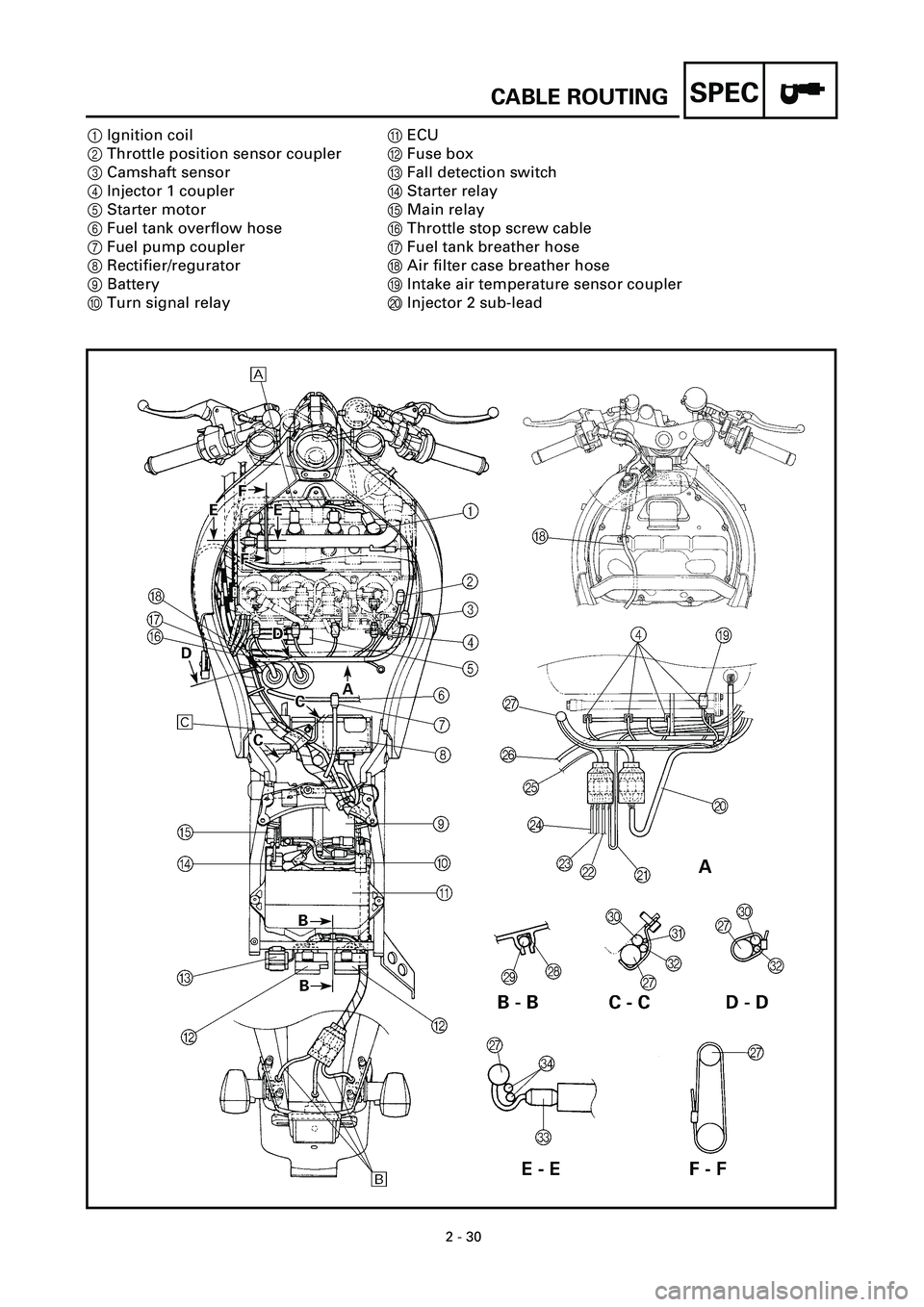

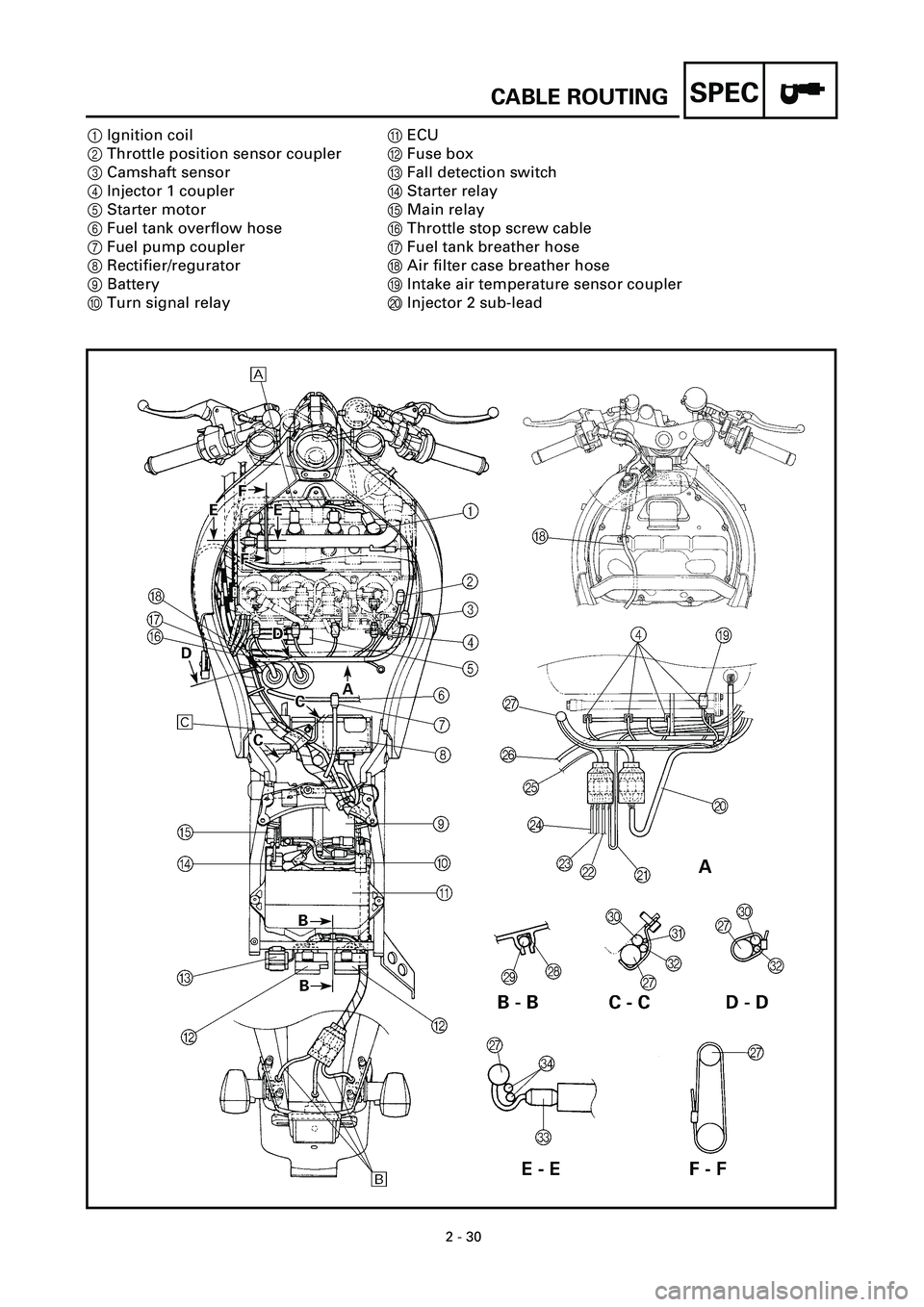

1Ignition coil

2Throttle position sensor coupler

3Camshaft sensor

4Injector 1 coupler

5Starter motor

6Fuel tank overflow hose

7Fuel pump coupler

8Rectifier/regurator

9Battery

0Turn signal relayAECU

BFuse box

CFall detection switch

DStarter relay

EMain relay

FThrottle stop screw cable

GFuel tank breather hose

HAir filter case breather hose

IIntake air temperature sensor coupler

JInjector 2 sub-lead

CABLE ROUTING

Page 69 of 381

2 - 31

SPEC

KPickup coil lead

LStator coil lead

MSpeed sensor lead

NSidestand switch lead

OOil level switch lead

PCoolant reservoir breather hose

QWire harness

RWire harness lead (to fall detection

switch coupler)

SWire harness lead (to fuse box)

TStarter motor leadUNeutral switch lead

VGround lead

WCoolant temperature sensor coupler

XThrottle cable

Route the wire harness in front of the ignition coils.

õBe sure that there is no slack in the tail/brake light lead

and rear turn signal leads below the rear fender panel.

‚Align the portions of the wire harness, ground lead and

starter motor lead marked with white tape with the lead

holder.

CABLE ROUTING

Page 70 of 381

3 - 1

CHK

ADJ

INTRODUCTION/PERIODIC MAINTENANCE AND

LUBRICATION INTERVALS

EB300000

PERIODIC CHECKS AND ADJUSTMENTS

INTRODUCTION

This chapter includes all information necessary to perform recommended checks and adjust-

ments. If followed, these preventive maintenance procedures will ensure more reliable vehi-

cle operation, a longer service life and reduce the need for costly overhaul work. This

information applies to vehicles already in service as well as to new vehicles that are being

prepared for sale. All service technicians should be familiar with this entire chapter.

PERIODIC MAINTENANCE AND LUBRICATION INTERVALS

No. ITEM CHECKS AND MAINTENANCE JOBSINITIAL

1,000 km EVERY

6,000 km or

6 months

(whichever

comes first)12,000 km or

12 months

(whichever

comes first)

1

*

Fuel line

• Check fuel hoses for cracks or damage.

• Replace if necessary.

ÖÖ

2

*

Fuel filter

• Check condition.

• Replace if necessary.

Every 50,000 km

3 Spark plugs

• Check condition.

• Clean, regap or replace if necessary.

ÖÖÖ

4

*

Valves

• Check valve clearance.

• Adjust if necessary.

Every 42,000 km or 42 months (whichever

comes first)

5 Air filter element

• Clean or replace if necessary.

ÖÖ

6 Clutch

• Check operation and fluid leakage. (See NOTE on

page 3-2.)

• Correct if necessary.

ÖÖÖ

7

*

Front brake

• Check operation, fluid level and vehicle for fluid leak-

age. (See NOTE on page 3-2.)

• Correct accordingly.

• Replace brake pads if necessary.

ÖÖÖ

8

*

Rear brake

• Check operation, fluid level and vehicle for fluid leak-

age. (See NOTE on page 3-2.)

• Correct accordingly.

• Replace brake pads if necessary.

ÖÖÖ

9

*

Wheels

• Check balance, runout and for damage.

• Rebalance or replace if necessary.

ÖÖ

10

*

Tires

• Check tread depth and for damage.

• Replace if necessary.

• Check air pressure.

• Correct if necessary.

ÖÖ

11

*

Wheel bearings

• Check bearing for looseness or damage.

• Replace if necessary.

ÖÖ

12

*

Swingarm

• Check swingarm pivoting point for play.

• Correct if necessary.

• Lubricate with lithium soap base grease every 24,000

km or 24 months (whichever comes first).

ÖÖ

13 Drive chain

• Check chain slack.

• Adjust if necessary. Make sure that the rear wheel is

properly aligned.

• Clean and lubricate.

Every 1,000 km and after washing the

motorcycle or riding in rain.

14

*

Steering bearings

• Check bearing play and steering for roughness.

• Correct accordingly.

• Lubricate with lithium soap base grease every 24,000

km or 24 months (whichever comes first).

ÖÖ

3

Trending: brake fluid, lights, oil filter, lug pattern, key battery, fuse diagram, fuses