check engine ACURA INTEGRA 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1998, Model line: INTEGRA, Model: ACURA INTEGRA 1998Pages: 1680, PDF Size: 53.14 MB

Page 662 of 1680

I

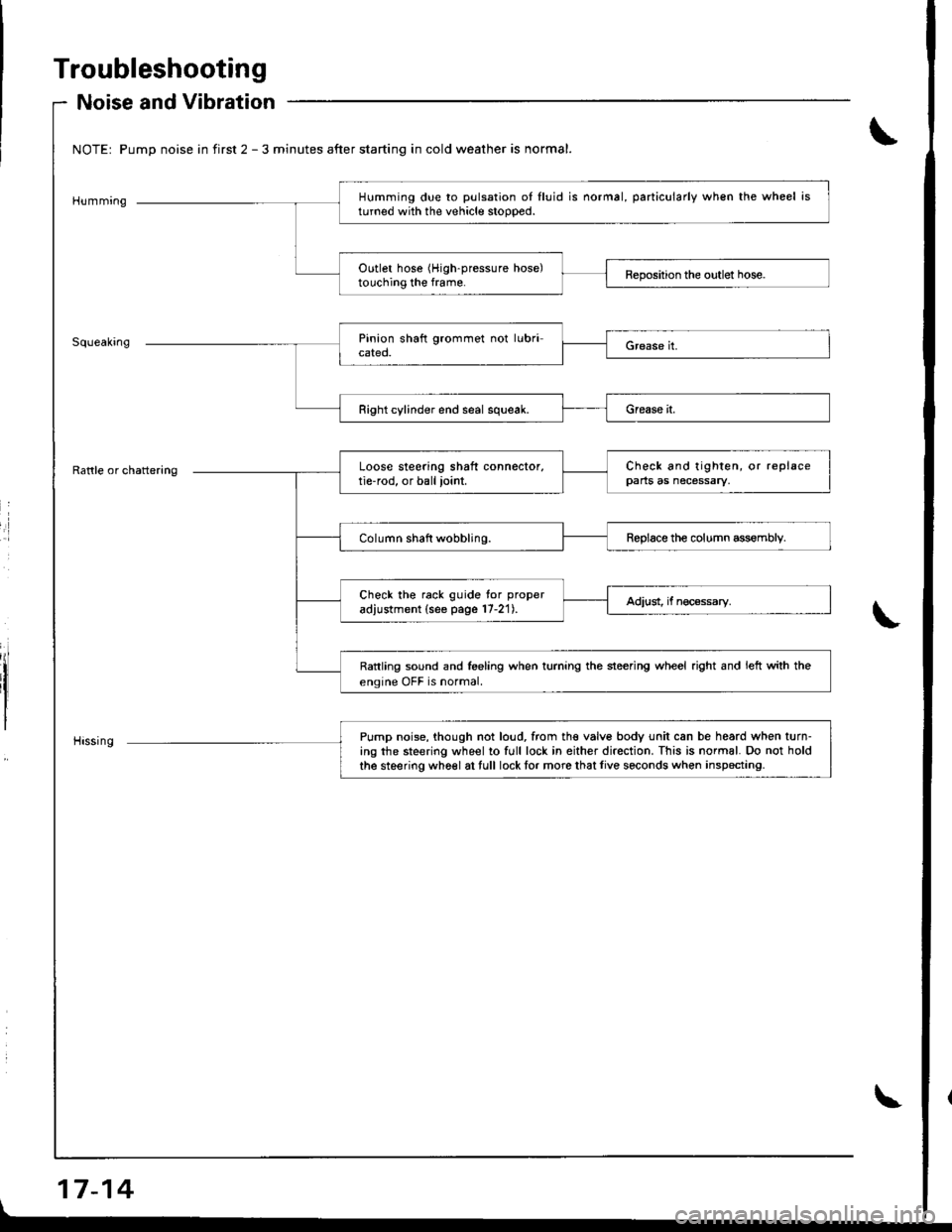

Troubleshooting

17-14

Noise and Vibration

NOTEr Pump noise in first 2 - 3 minutes after starting in cold weather is normal.

Humming

Rattle or chattering

Humming due to pulsation oI lluid is normal, particularly when the wheel isturned with the vehicle stoooed.

Outlet hose (High-pressure hose)touching the frame.

Right cylinder end seal squeak.

Pump noise, though not loud, from tho valv6 body unit can be heard when turn-ing the steering wheel to full lock in either direction. This is normal. Do not hold

the steering wh6el at tull lock tor more that live seconds wh€n inspecting.

Loose steering shaft connector,tie-rod, or ball ioint.

Check and tighten, or replacepans as necessary,

Column shaft wobbling.Reolace the column assemblv.

Check ihe rack guide tor proper

adjustment (see page 17-21).Adiust, if nec€ssary.

Rattling sound and feeling when turning the steering wheel right and left with the

engine OFF is normal.

Page 666 of 1680

Inspection and Adjustment

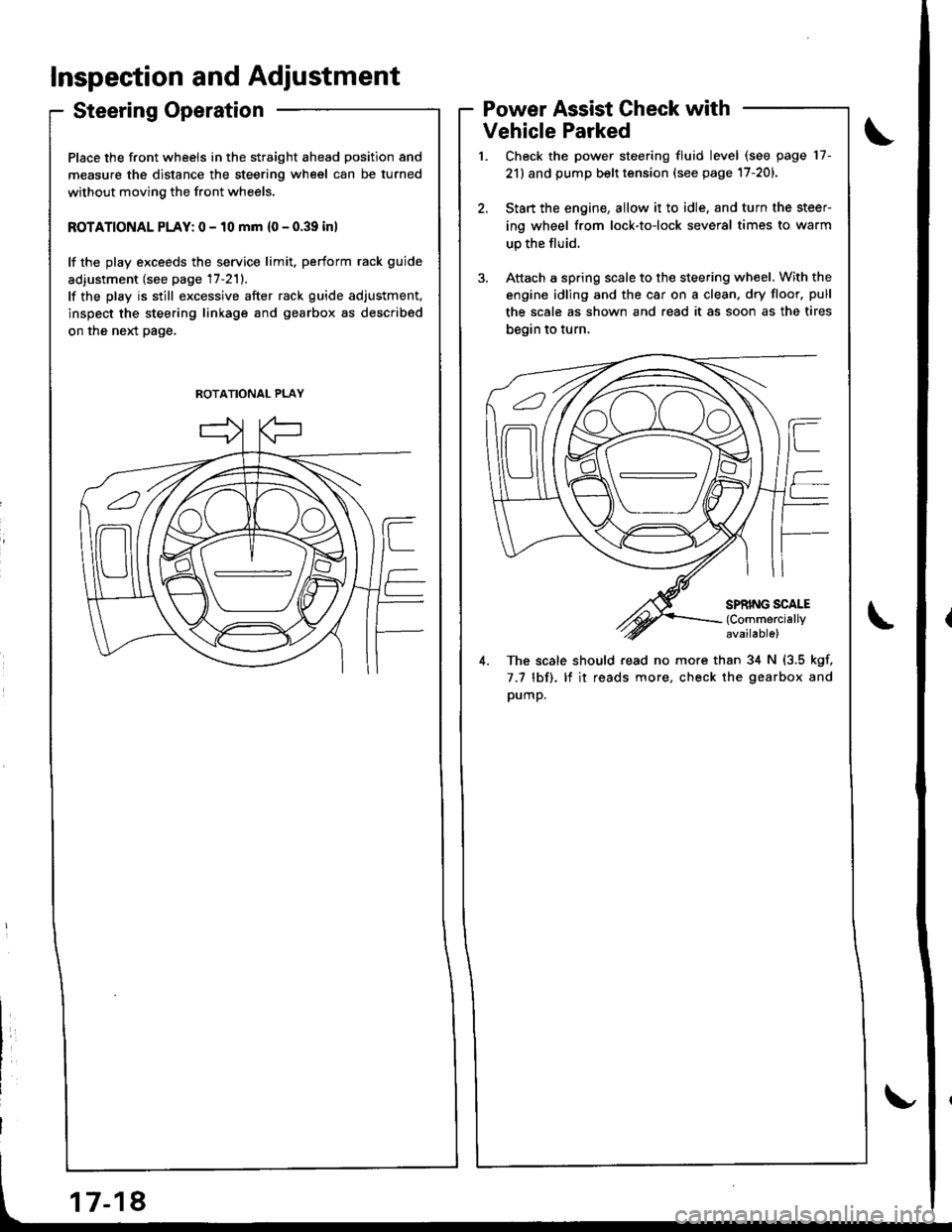

Steering Operation

Place the front wheels in the straight ahead position and

measure the distance the steering wheel can be turned

without moving the front wheels.

ROTATIONAL PLAY: 0 - 10 mm {0 - 0.39 inl

lf the play exceeds the service limit. perform rack guide

adiustment (see page 17-211.

lf the play is still excessive after rack guide adjustment.

inspect the steering linkage and gearbox as described

on the neld page.

Power Assist Check with

Vehicle Parked

Check the power steering fluid level (see page 17-

21) and pump belt tension (see page 17-201.

Start the engine, allow it to idle. and turn the steer

ing wheel from lock-to-lock several times to warm

up the fluid.

Attach a spring scale to the steering wheel. With the

engine idling and the car on a clean. dry floor. pull

the scale as shown and read it as soon as the tires

begin to turn,

4. The scale should read no more than 34 N (3.5 kgf,

7.7 lbf). lf it reads more, check the gearbox and

pump.

ROTATIONAL PLAY

Page 668 of 1680

Inspection and Adjustment

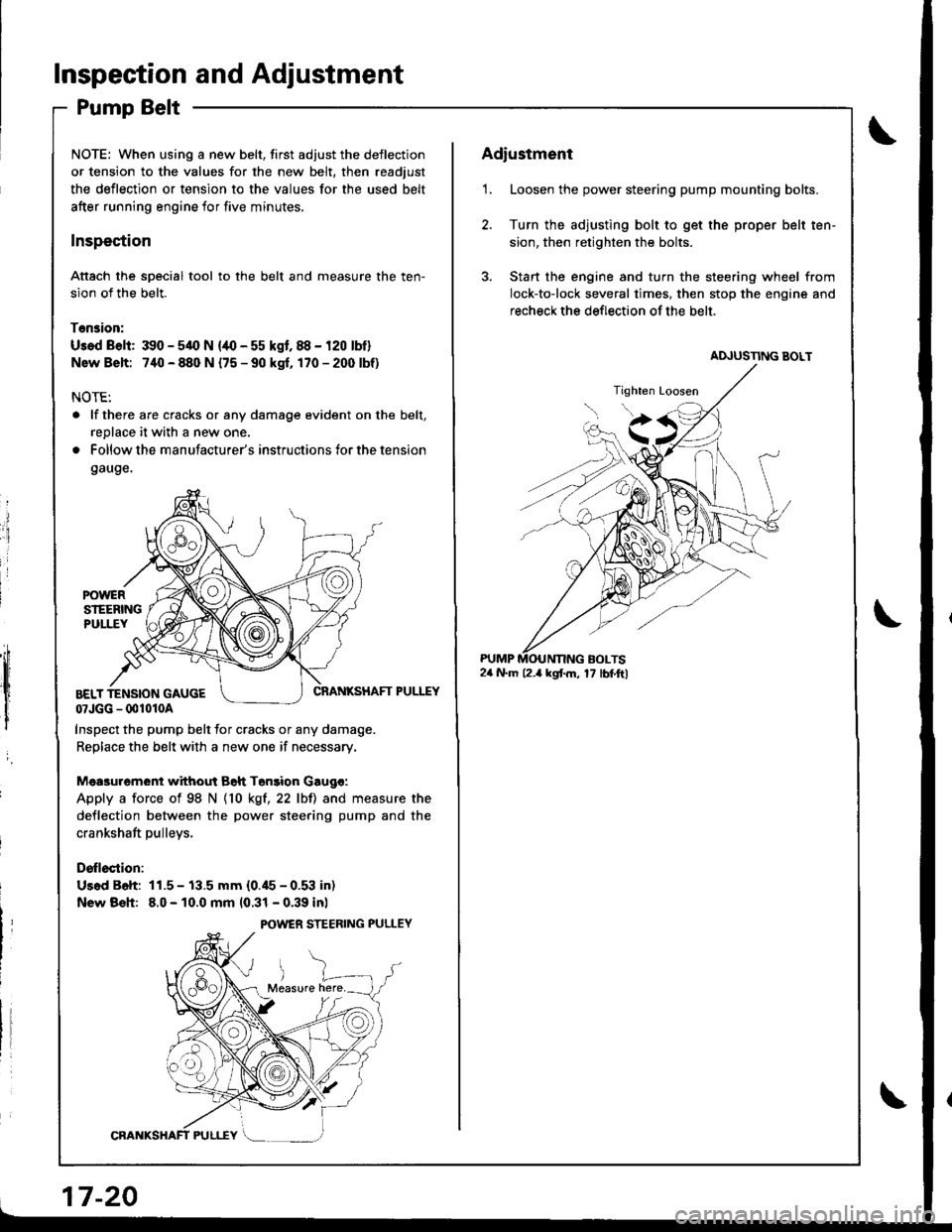

Pump Belt

NOTE: When using a new belt, first adjust the deflection

or tension to the values for the new belt, then readjust

the deflection or tension to the values for the used belt

after running engine for five minutes,

Inspection

Attach the soecial tool to the belt and measure the ten-

sion of the belt.

Tension:

Usad Belt: 390 - 54O N {/10 - 55 kgf. 88 - 120 lbf}

Nsw Belt: 740 - 880 N {75 - 90 kgf. 170-2(X)lbf)

NOTE:

. lf there are cracks or any damage evident on the belt,

replace it with a new one.

. Follow the manufacturer's instructions for the tension

gauge.

ii

:i

i

I

,;h

,lt l

I

i

CRANKSHAFT PULEYBELT TENSION GAUGE07JGG - 001010A

Inspect the pump belt for cracks or any damage.

Replace the belt with a new one if necessary.

Mea3urement without Bah Tonsion Gaugo:

Apply a force of 98 N {10 kgt,22 lbll and measure the

deflection between the power steering pump and the

crankshaft pulleys,

Drllection:

Us.d B6h: 11.5 - 13.5 mm (0.45 - 0.53 in)

New Bsh: 8.0 - 10.0 mm 10.31 - 0.39 inl

POWER STEERING PULLEY

17-20

Adiustment

1. Loosen the power steering pump mounting bolts.

2. Turn the adjusting bolt to get the proper belt ten-

sion, then retighten the bolts.

3. Stan the engine and turn the steering wheel from

lock-to-lock several times. then stop the engine and

recheck the deflection of the belt.

24 N.m l2.a kgf.m, 17 lbf.ftl

Page 669 of 1680

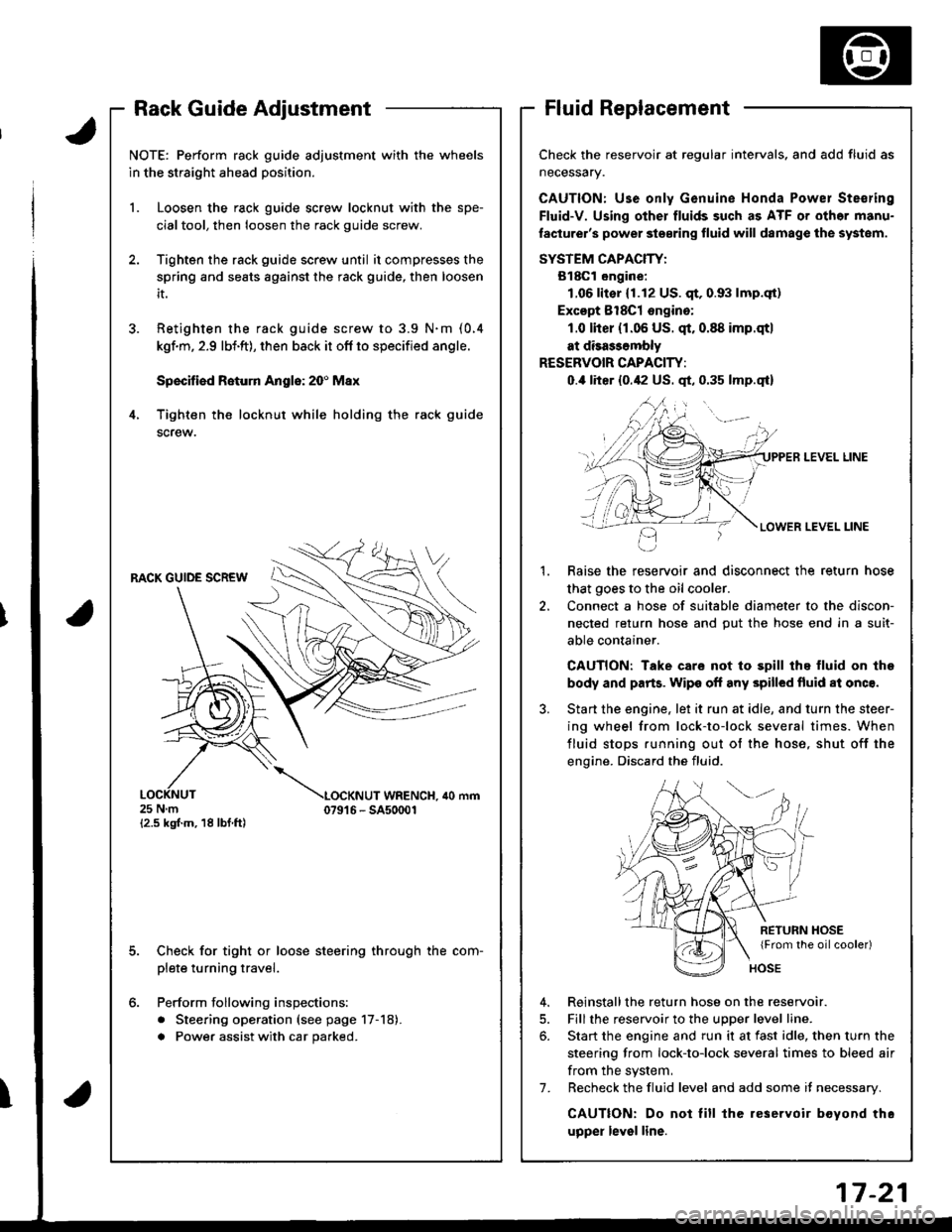

Rack Guide AdjustmentFluid Replacement

Check the reservoir at regular intervals, and add fluid as

neceSsary.

CAUTION: Use only Genuine Honda Powel Ste€ring

Fluid-V. Using other fluids such as ATF or othor manu-

laclurer's power ste€ring fluid will damag€ the systom.

SYSTEM CAPACIW:

B18Gl ongine:

1.06lit€r (1.12 US. qt,0.93 lmp.qt)

Excopt 8l8Cl ongino:

1.0 lher (r.06 US. qt.0.88 imp.qtl

at disa$ombly

RESERVOIR CAPACITY:

0.,0 liter {0.42 US. qt, 0.35 lmp.qt}

LEVEL LINE

LEVEL LINE

Raise the reservoir and disconnect the return hose

that goes to the oil cooler.

Connect a hose of suitable diameter to the discon-

nected return hose and put the hose end in a suit-

able container.

CAUTION: Take care not to spill thq fluid on lhe

body and parts. Wipe off any spilled fluid al onc€.

Start the engine. let it run at idle, and turn the steer-

ing wheel from lock-to-lock several times. When

fluid stops running out of the hose, shut off the

engine. Discard the fluid.

2.

RETURN HOSE{From the oilcooler)

4. Reinstallthe return hose on the reservoir.

5. Fill the reservoir to the uDDer level line.

6. Start the engine and run it at fast idle, then turn the

steering from lock-to-lock several times to bleed air

from the system,

7. Recheck the fluid level and add some it necessary.

CAUTION: Do not lill the reservoir boyond thc

upper level line.

J.

4.

NOTE: Perform rack guide adjustment with the wheels

in the straight ahead position.

1. Loosen the rack guide screw locknut with the spe-

cialtool, then loosen the rack guide screw.

Tighten the rack guide screw until it compresses the

spring and seats against the rack guide, then loosen

it.

Retighten ihe rack guide screw to 3.9 N.m (0.4

kgf.m, 2.9 lbi.ft), then back it ofl to specified angle.

Speciliad Roturn Anglo: 20' Max

Tighten th€ locknut while holding the rack guide

screw.

RACK GUIDE SCREW

25Nm{2.5 kgf.m, 18 lbf ft)

LOCKNUT WRENCH. ilo mm079't 6 - SA50001

E

6.

Check for tight or loose steering through the com-

plete turning travel.

Perform following inspections:

. Steering operation (see page 17-18).

a Power assist with car parked.

I

Page 670 of 1680

Inspection and Adjustment

Pump Pressure Check

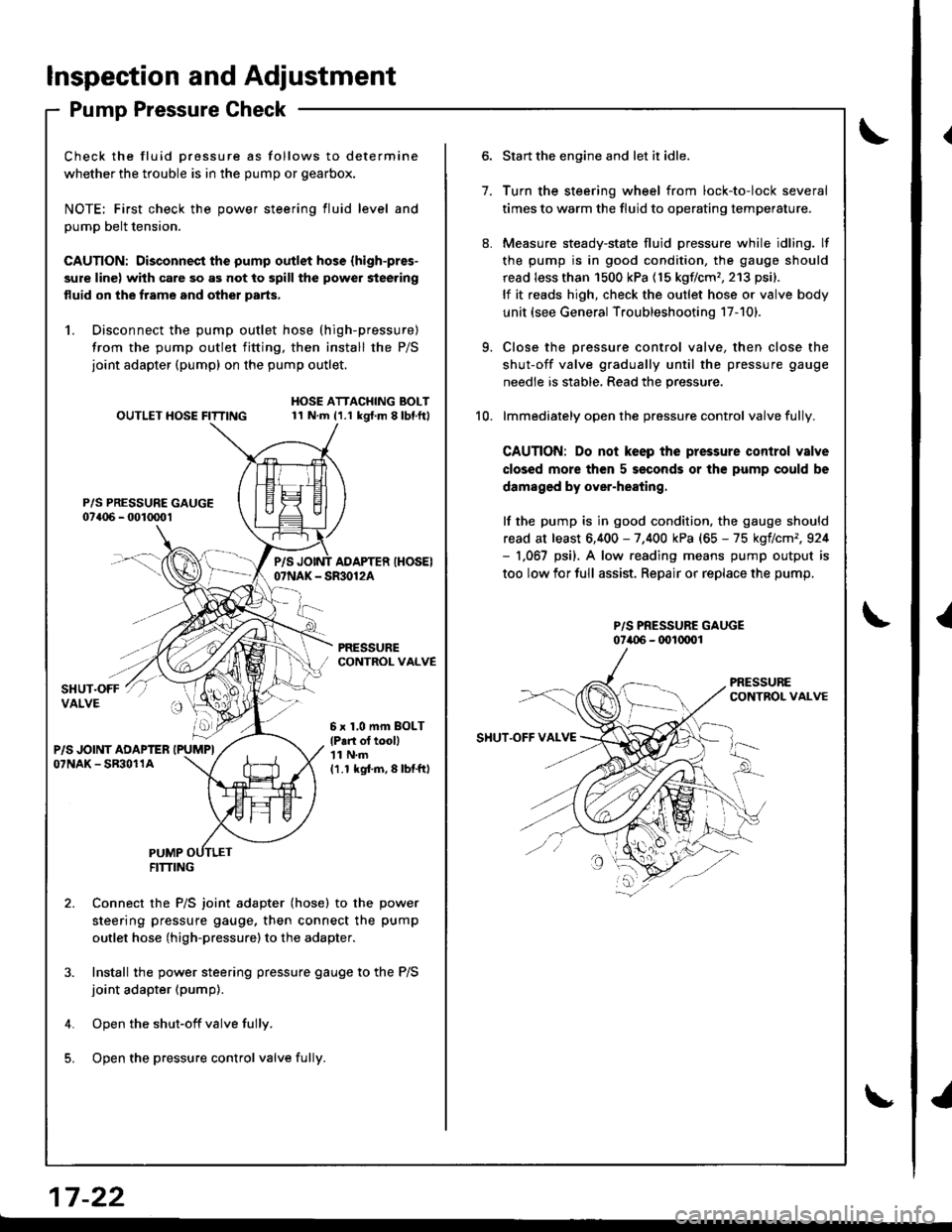

Check the fluid Dressure as follows to determine

whether the trouble is in the pump or gearbox.

NOTE; First check the power steering fluid level and

pump belt tension.

CAUTION: Disconnect the pump outlet hose (high-pres-

sure line) with care so as not to spill the power steering

fluid on the frame and other parts,

1. Disconnect the pump outlet hose (high-pressure)

from the pump outlet fitting, then install the P/S

joint adapter (pump) on the pump outlet.

P/S PRESSURE GAUGE07a06 - 001mo1

OUTLET HOSE FITTINGHOSE ATTACHING BOLT11 N.m (1.1 kgt.m 8lbl.ft)

PRESSURECONTROL VALVE

P/SAOAPTER IHOSEI07NAK - SR30124

6 x 1,0 mm BOLT

lP.n ol tooll'| 1 N.m

11.1 kgi.m,8lbtftl

PUMPFITTING

Connect the P/S joint adapter (hose) to the power

steering pressure gauge, then connect the pump

outlet hose (high-pressure)to the adapter.

Install the power steering pressure gauge to the P/S

joint adapter (pump).

Open the shut-off valve fully.

Open the pressure control valve fulli.

1.

Start the engine and let it idle.

Turn the steering wheel from lock-to-lock several

times to warm the fluid to operating temperature.

Measure steady-state fluid pressure while idling. lf

the pump is in good condition, the gauge should

read less than 1500 kPa (15 kgflcm'�,213 psi).

lf it reads high, check the outlet hose or valve body

unit (see General Troubleshooting 17-101.

Close the pressure control valve, then close the

shut-off valve gradually until the pressure gauge

needle is stable, Read the pressure.

lmmediately open the pressure control valve fully.

CAUTION: Do not keep the pressure control valve

closed more then 5 seconds or the pump could be

damaged by over-heating.

lf the pump is in good condition, the gauge should

read at least 6,400 - 7,400 kPa (65 - 75 kgflcm',924- 1,067 psi). A low.eading means pump output is

too low for full assist. Repair or replace the pump.

P/S PRESSURE GAUGE07i.{)6 - (x)l(xrol

9.

10.

SHUT.OFF VAI.VE

17 -22

{

I

Page 671 of 1680

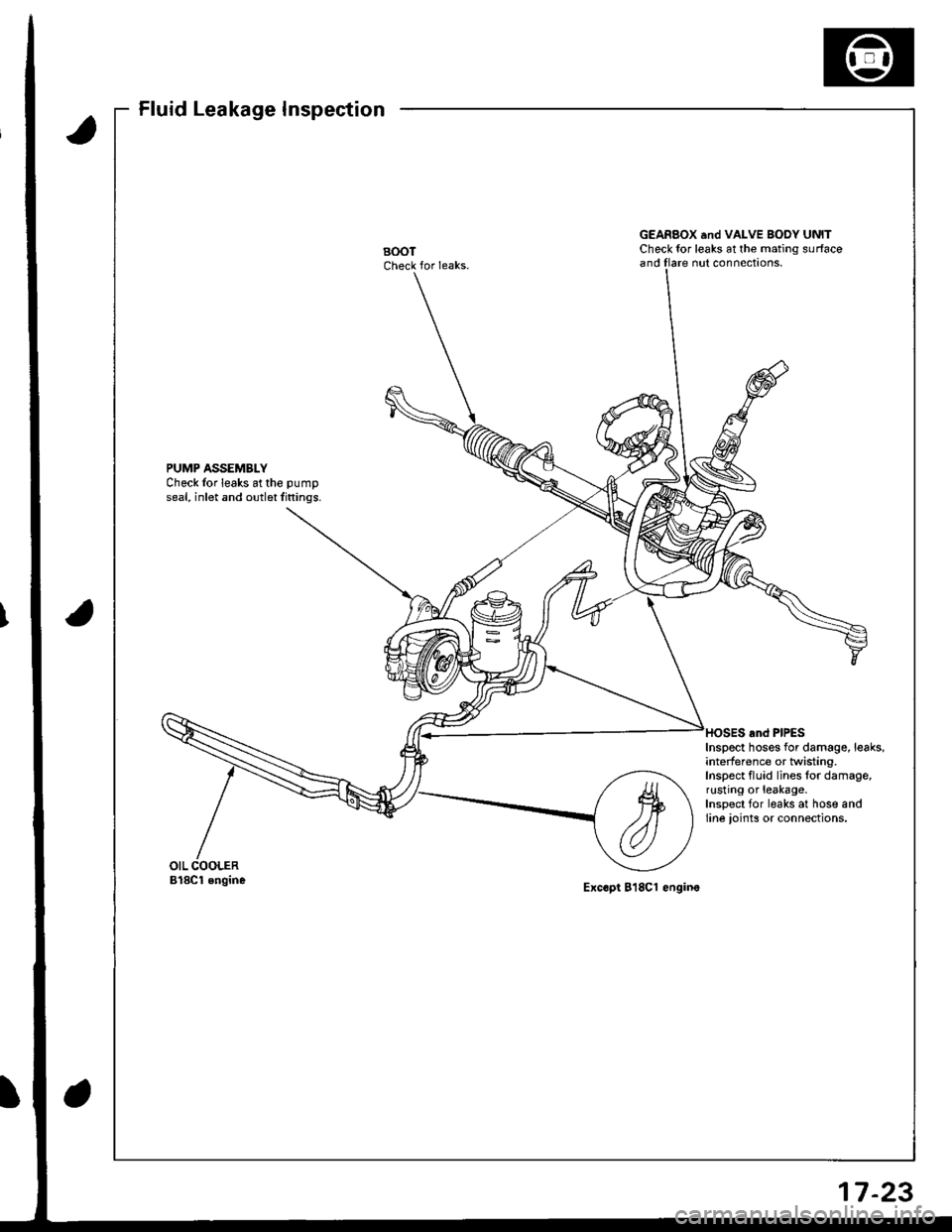

Fluid Leakage Inspection

BOOTCheck for Ieaks.

GEARBOX and VALVE BOoY UNITCheck tor leaks at the mating surfaceand Ilare nut connections,

PUMP ASSEMBLYCheck Ior leaks at the pumD

seal, inlet and outlet fittings.

Inspect hoses for damage, leaks,interfe re n ce or twisting,Inspect fluid lines for damage,rusting or leakage.Inspect for leaks at hose andline ioints or connections.

Bl8Cl engineExc.pl 818Cl engine

17-23

Page 756 of 1680

a

BrakePedal

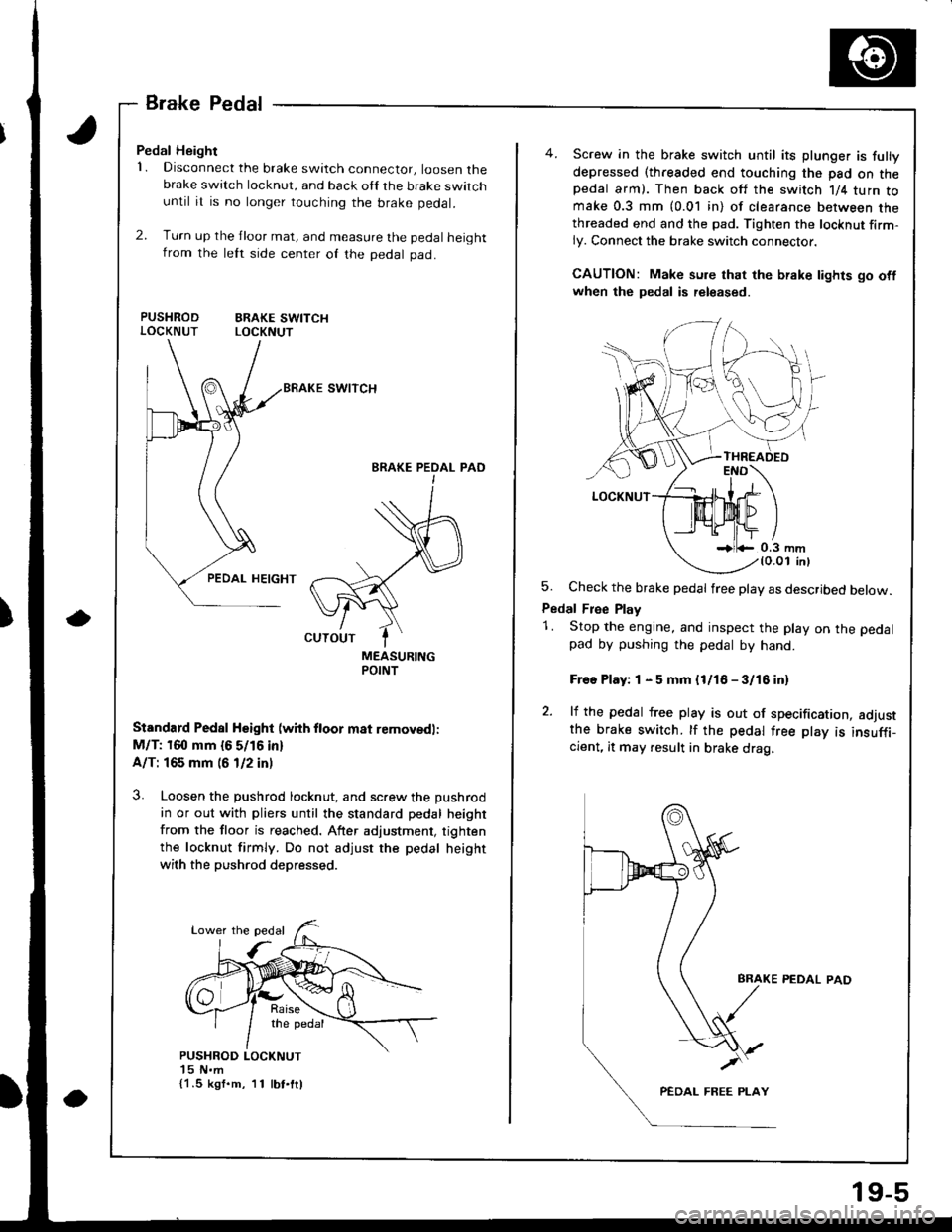

Pedal Height

1. Disconnect the brake switch connector, loosen thebrake switch locknut, and back oll the brake switchuntil it is no longer touching the brake pedal.

2. Turn up the jloor mat, and measure the pedal heightfrom the lett srde center of the pedal pad.

PUSHROD ERAKE SWITCHLOCKNUT LOCKNUT

swtTcH

BRAKE PEOAL PAOI

MEASURINGPOINT

Standard Pedal Hsight (wiih ftoor m8t removedl:

M/T: 160 mm {6 5/16 in}

A/T: 165 mm (6 1/2 in)

3. Loosen the pushrod locknut, and screw the pushrod

in or out with pliers until the standard pedal height

from the floor is reached. After adjustment, tighten

the locknut firmly. Do not adjust the pedal height

with the pushrod depressed.

{1.5 kgf.m, 11 lbt.ftl

19-5

Screw in the brake switch until its plunger is fully

depressed (threaded end touching the pad on thepedal arm). Then back off the switch 1/4 turn tomake 0.3 mm (0.01 in) of clearance between thethreaded end and the pad. Tighten the locknut firm-ly. Connect the brake switch connector.

CAUTION: Make sure that the brake lights go oflwhen the pedal is released.

5. Check the brake pedal free play as described below.

Pedal Free Play

1. Stop the engine, and inspect the play on the pedal

pad by pushing the pedal by hand.

Free Play: 1 - 5 mm {l/16 - 3/16 in)

2. lf the pedal free play is out of specification, adjustthe brake switch. tf the pedal free play is insuffi_cient, it may result in brake drag.

PEDAL PAD

Page 757 of 1680

Inspection and Adiustment

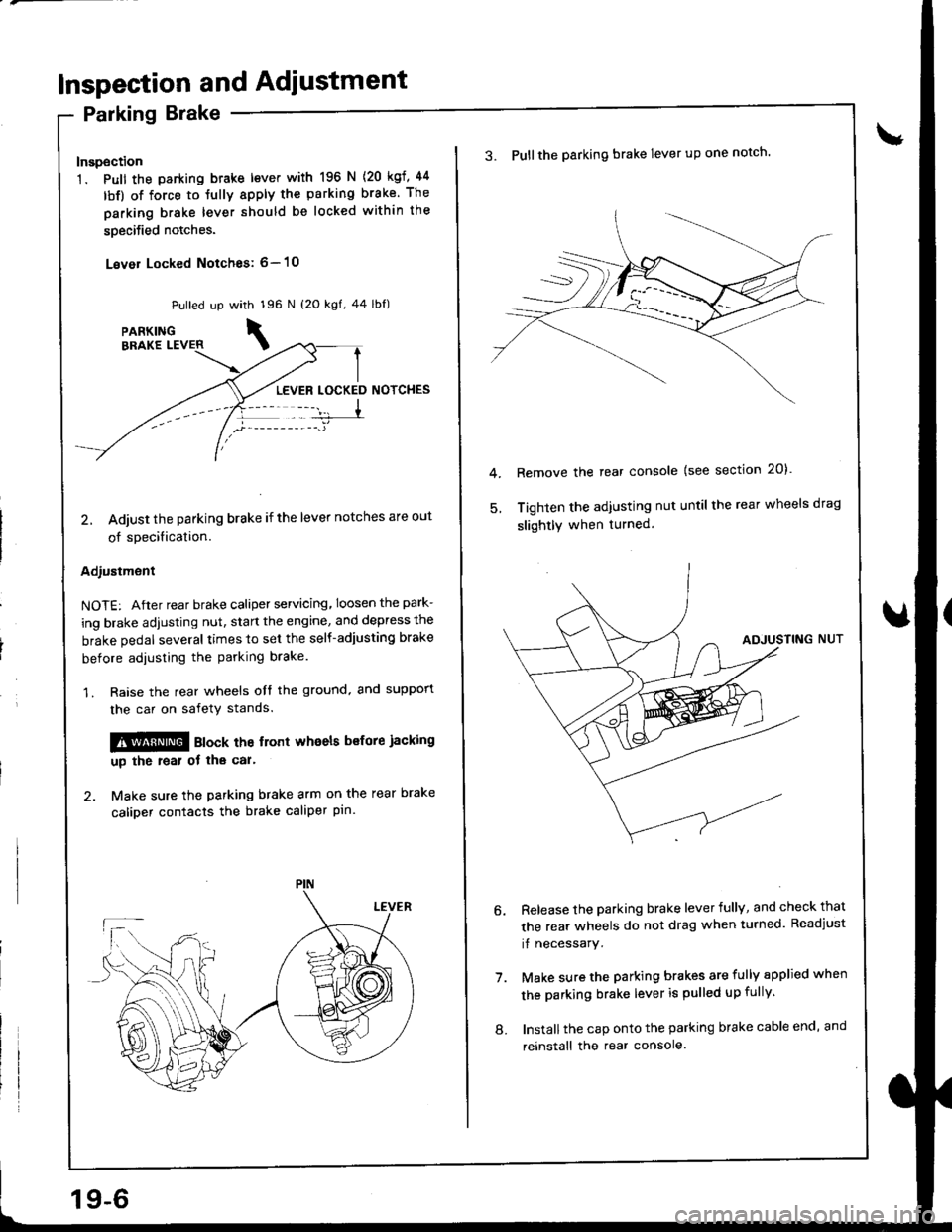

Parking Brake

Inspection

1. Pull the parking btake lever with 196 N

lbf) of force to Jully apply the parking

parking brake lever should be locked

soecified notches.

Lever Locked Notches: 6- l0

{20 kgf, 44

brake. The

within the

Pulled up with 196 N {2O kgf, 44 lbf)

LEVER LOCKED NOTCHES

2, Adjust the parking brake if the lever notches are out

of specification.

Adjustment

NOTE: After rear brake caliper servicing.loosen the park-

ing brake adjusting nut, start the engine, and depress the

brake pedal several times to set the self-adjusting brake

before adiusting the parking brake

1. Raise the rear wheels oIt the ground. and suppon

the car on safety stands.

!!@ ato"t the trort whoels bsfore jacking

up the roal ot tha car'

2. Make sure the parking brake arm on the rear brake

caliDer contacts the brake caliper pin.

19-6

8.

3. Pullthe parking brake lever up one notch'

Remove the rear console {see section 20)'

Tighten the adjusting nut until the rear wheels drag

slightly when turned.

7.

Release the parking brake lever fully, and check that

the rear wheels do not drag when turned. Readjust

if necessary.

Make sure the parking brakes are fully spplied when

the parking brake lever is pulled up fully.

Install the cap onto the parking brake cable end, and

reinstall the rear console.

Page 765 of 1680

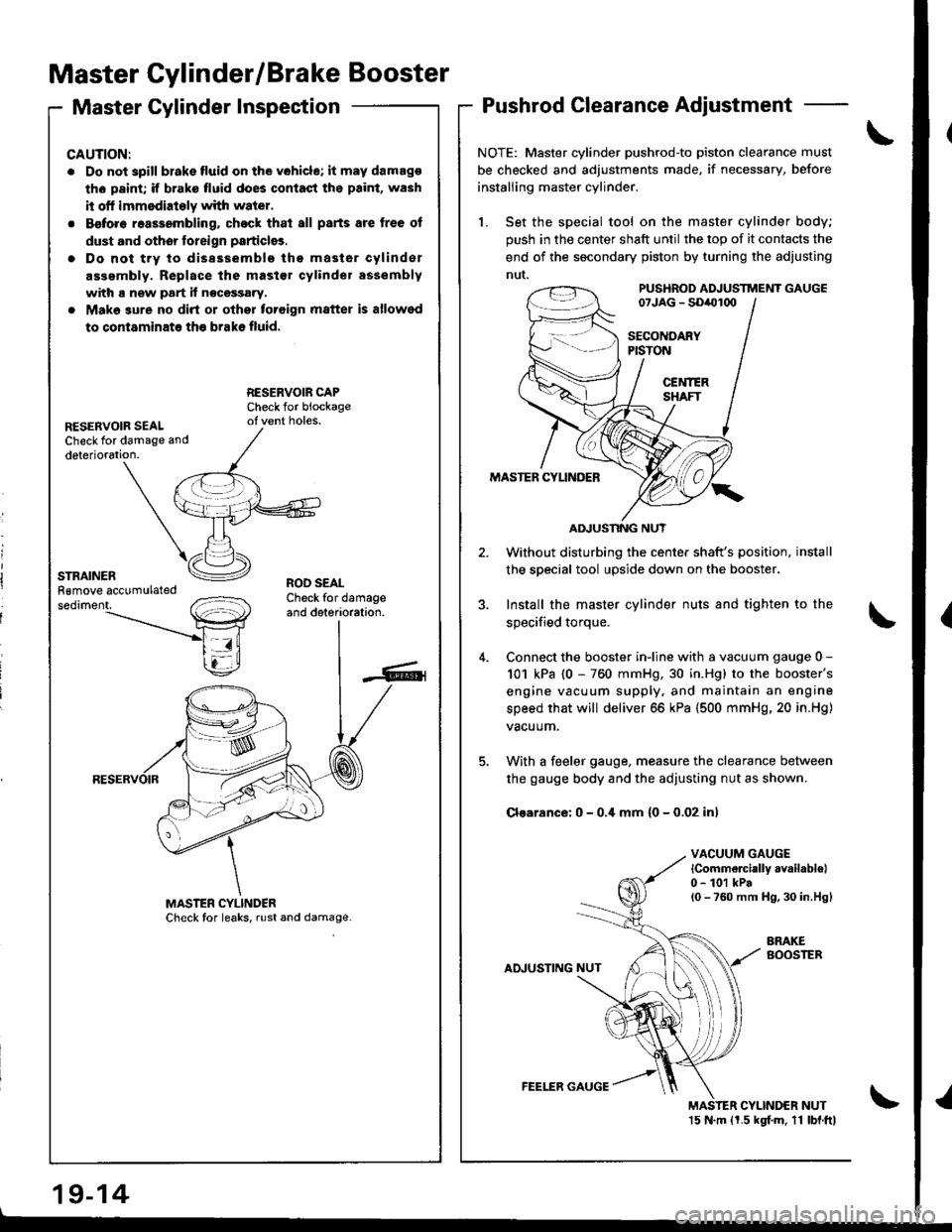

Master Cylinder/Brake Booster

Master Cylinder InspectionPushrod Clearance Adjustment

NOTE: Master cylinder pushrod'to piston clearance must

be checked and adjustments made, if necessary, before

installing master cylinder.

1. Set the special tool on the master cylinder body;

push in the center shaft until the top of it contacts the

end of the socondary piston by turning the adjusting

nut.PUS'IROD ADJUSTTTiENT GAUGE07JAG - SDiOl(xl

SECOITDARYPISTON

CEl{IERSHAFT

MASTER CYLINDER

Without disturbing the center shaft's position,

the soecial tool upside down on the booster.

3. Install the master cylinder nuts and tighten to the

sDecified toroue.

4. Connect the booster inline with a vacuum gauge 0 -

101 kPa {0 - 760 mmHg, 30 in.Hg) to the booster's

engine vacuum supply, and maintain an engine

speed that will deliver 66 kPa (500 mmHg, 20 in.Hg)

vacuum.

5. With a feeler gauge, measure the clearance between

the gauge body and the adjusting nut as shown.

Clsarance: 0 - 0,i[ mm (0 - 0.02 inl

VACUUM GAUGElCommelcially availabl€|0 - 101 kPal0 - 760 mm H9,30 in.Hgl

AINUSTING NUT

BRAKEBOOSTEB

MAS'ER CYLINDER NUT15 N.m ll.5 kgf.m. 11 lbl.ftl

CAUTION:

. Do not spill blake fluid on the vohicle; it may damago

th6 paint; if brake fluid does contast ths paint, wash

it off immsdiately with water.

. Before reassembling. chock that all parts are tree of

dust and othor toreign particlgs,

. Do not trv to dissssemblo the master cylinder

assembly. Replace the mast€r cylinder assembly

with s new part if nocossary.

. Make sure no dirt or othor toroign matter is allowed

to contaminate th€ brako fluid.

RESERVOIR SEALCheck for damage and

deterioration.

ROD SEALCheck for damageand deterioration.

AIIUSNNG NUT

19-14

FEELER GAUGE

Page 766 of 1680

1.

8.

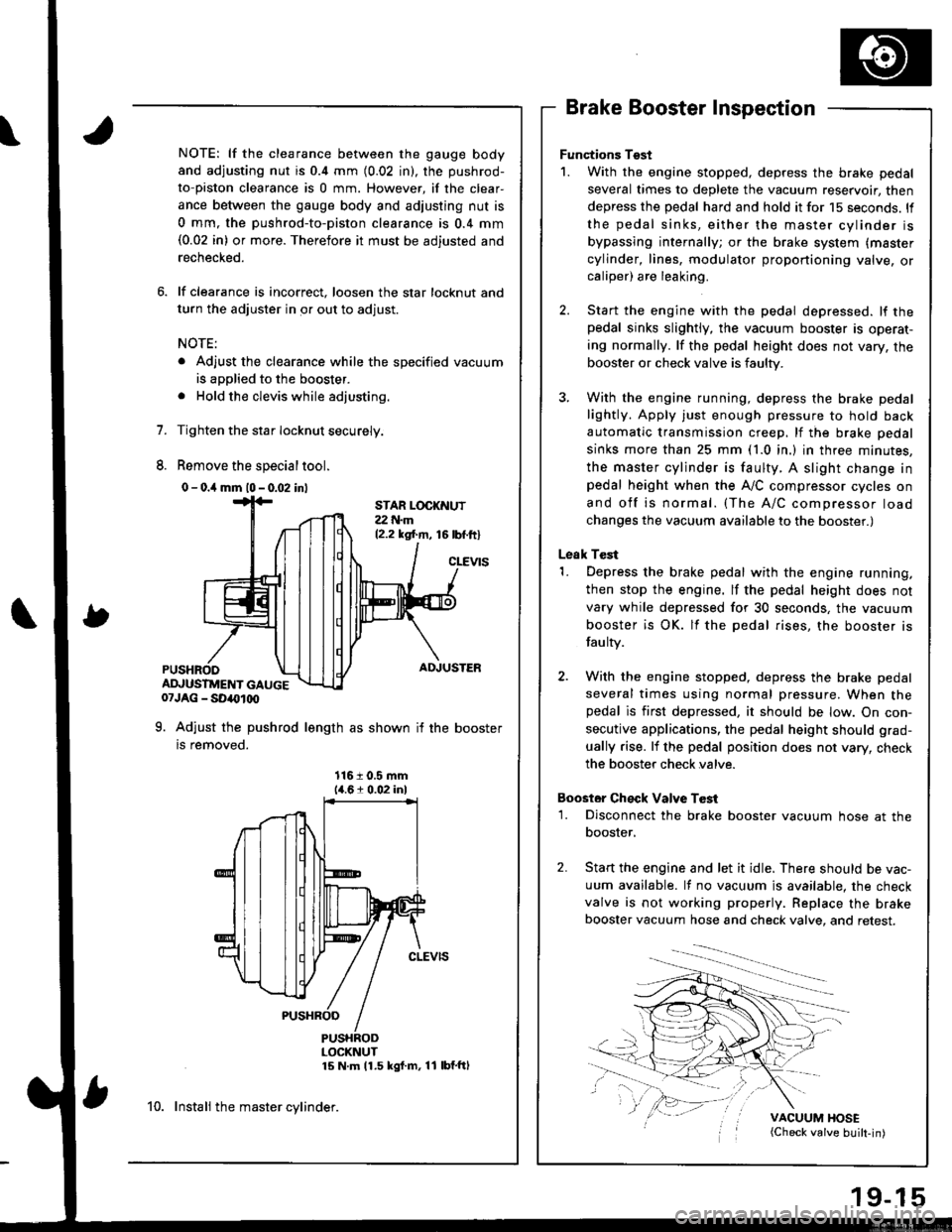

NOTE: lf the clearance between the gauge body

and adjusting nut is 0.4 mm (0.02 in), the pushrod-

to-piston clearance is 0 mm. However, if the clear-

ance between the gauge body and adjusting nut is

0 mm, the pushrod-to-piston clearance is 0.4 mm(0.02 in) or more. Therefore it must be adjusted and

rechecked.

lf clearance is incorrect, loosen the star locknut and

turn the adjuster in or out to adjust.

NOTE:

. Adjust the clearance while the specified vacuum

is applied to the booster.

. Hold the clevis while adjusting.

Tighten the star Iocknut securely.

Remove the special tool.

0 - o.il mm l0 - 0.02 inl

Brake Booster Inspection

Functions Tgst

1. With the engine stopped, depress the brake pedal

several times to deplete the vacuum reservoir, then

depress the pedal hard and hold it for 15 seconds. ll

the pedal sinks, either the master cylinder is

bypassing internally; or the brake system (master

cylinder, lines, modulator proportioning valve, orcaliper) are leaking.

Start the engine with the pedal depressed. lf thepedal sinks slightly, the vacuum booster is operat-

ing normally. lf the pedal height does not vary, the

booster or check valve is faulty.

With the engine running, depress the brake pedal

lightly. Apply just enough pressure to hold back

automatic transmission creep, lf the brake pedal

sinks more than 25 mm (1.0 in.) in three minutes,

the master cylinder is faulty. A slight change inpedal height when the A,,/C compressor cycles on

and off is normal. (The A/C compressor load

changes the vacuum available to the booster.)

Leak Test

1. Depress the brake pedal with the engine running,

then stop the engine. lf the pedal height does not

vary while depressed for 30 seconds, the vacuum

booster is OK. lf the pedal rises, the booster is

fau lty.

2. With the engine stopped, depress the brake pedal

several times using normal pressure. When thepedal is first depressed, it should be low. On con-

secutive applications, the pedal height should grad-

ually rise. lf the pedal position does not vary, check

the booster check valve.

Boostor Ch€ck Valve T6st

1. Disconnect the brake booster vacuum hose at the

booster,

Start the engine and let it idle. There should be vac-

uum available. It no vacuum is available. the check

valve is not working properly. Replace the brake

booster vacuum hose and check valve, and retest.

VACUUM HOSE(Check valve built-in)

STAR LOCKNUT22 t{.m12.2 ksl.m, 16lbf.ftl

cLEVtS

ADJUSTER

ADJUSTMENT GAUGE07JAG - SD40t00

9. Adjust the pushrod length as shown if the booster

is removed.

1161 0.5 mm14.61 0.02 inl

PUSHRODLOCKNUT15 N m 11.5 kgf m, 11 lbf'ftl

10. Instali the master cylinder.