ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1151 of 1640

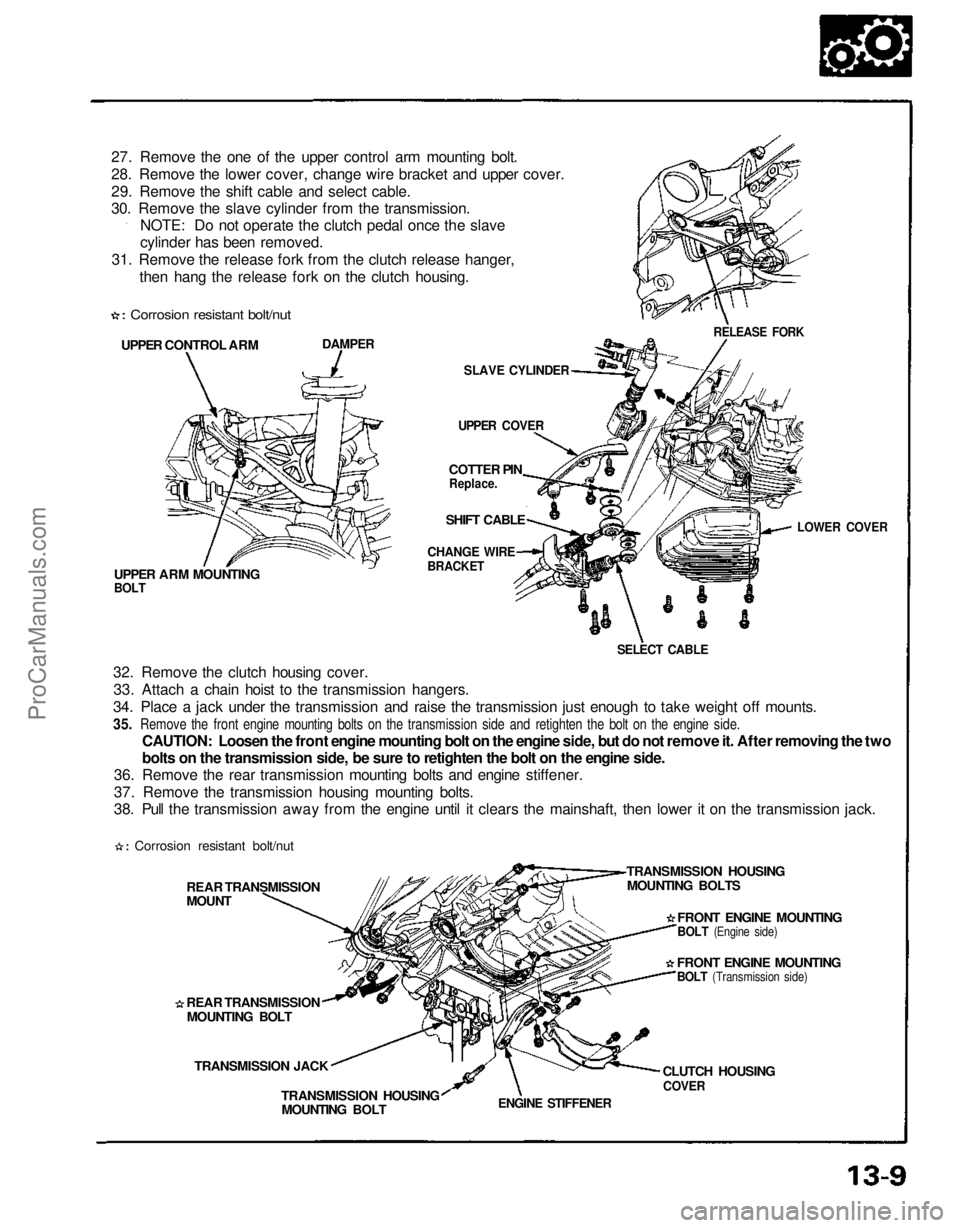

27. Remove the one of the upper control arm mounting bolt.

28. Remove the lower cover, change wire bracket and upper cover.

29. Remove the shift cable and select cable.

30. Remove the slave cylinder from the transmission.

NOTE: Do not operate the clutch pedal once the slave

cylinder has been removed.

31. Remove the release fork from the clutch release hanger, then hang the release fork on the clutch housing.

UPPER CONTROL ARM

DAMPER

SLAVE CYLINDER

UPPER COVER

UPPER ARM MOUNTING

BOLT

32. Remove the clutch housing cover. 33. Attach a chain hoist to the transmission hangers.

34. Place a jack under the transmission and raise the transmission just enough to take weight off mounts.

35. Remove the front engine mounting bolts on the transmission side and retighten the bolt on the engine side.

CAUTION: Loosen the front engine mounting bolt on the engine side, but do not remove it. After removing the two

bolts on the transmission side, be sure to retighten the bolt on the engine side.

36. Remove the rear transmission mounting bolts and engine stiffener.

37. Remove the transmission housing mounting bolts.

38. Pull the transmission away from the engine until it clears the mainshaft, then lower it on the transmission jack.

REAR TRANSMISSION

MOUNT

REAR TRANSMISSIONMOUNTING BOLT

TRANSMISSION JACK TRANSMISSION HOUSINGMOUNTING BOLT

ENGINE STIFFENER

CLUTCH HOUSING

COVER

TRANSMISSION HOUSING

MOUNTING BOLTS

FRONT ENGINE MOUNTING

BOLT

(Engine side)

FRONT ENGINE MOUNTING

BOLT

(Transmission side)

RELEASE FORK

COTTER PIN

Replace.

SHIFT CABLE

CHANGE WIRE

BRACKET

SELECT CABLE

LOWER COVER

Corrosion resistant bolt/nut

Corrosion resistant bolt/nutProCarManuals.com

Page 1152 of 1640

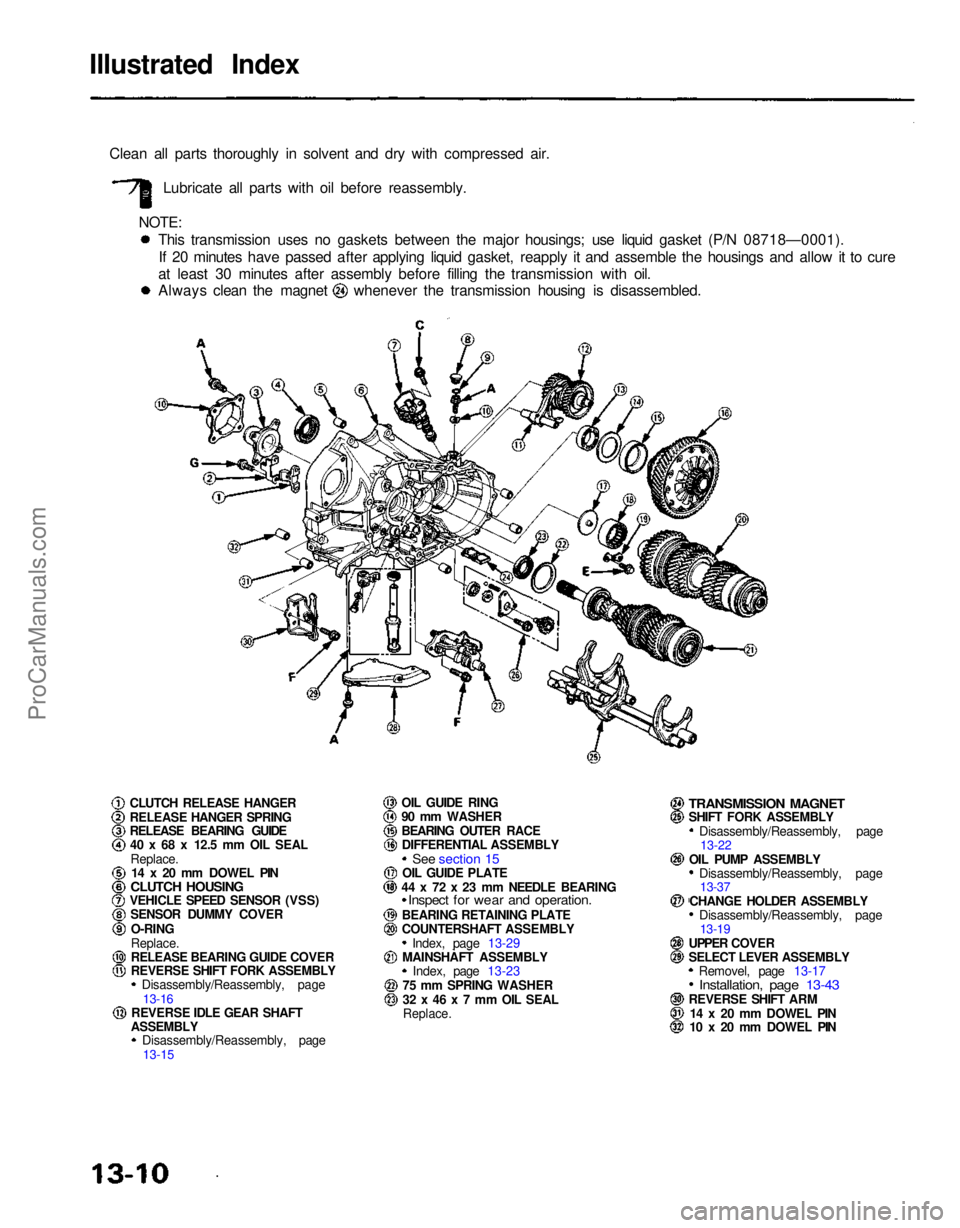

Illustrated Index

Clean all parts thoroughly in solvent and dry with compressed air. Lubricate all parts with oil before reassembly.

NOTE: This transmission uses no gaskets between the major housings; use liquid gasket (P/N 08718—0001).If 20 minutes have passed after applying liquid gasket, reapply it and assemble the housings and allow it to cure

at least 30 minutes after assembly before filling the transmission with oil. Always clean the magnet whenever the transmission housing is disassembled.

Disassembly/Reassembly, page13-22

Disassembly/Reassembly, page 13-37

Disassembly/Reassembly, page 13-19

Removel, page 13-17

Installation, page 13-43

REVERSE SHIFT ARM 14 x 20 mm DOWEL PIN

10 x 20 mm DOWEL PIN

CLUTCH RELEASE HANGER

RELEASE HANGER SPRING

RELEASE BEARING GUIDE

40 x 68 x 12.5 mm OIL SEAL

Replace. 14 x 20 mm DOWEL PIN

CLUTCH HOUSING

VEHICLE SPEED SENSOR (VSS)

SENSOR DUMMY COVER

O-RING

Replace.

RELEASE BEARING GUIDE COVER

REVERSE SHIFT FORK ASSEMBLY Disassembly/Reassembly, page

13-16

REVERSE IDLE GEAR SHAFT

ASSEMBLY Disassembly/Reassembly, page

13-15 OIL GUIDE RING

90 mm WASHER

BEARING OUTER RACE

DIFFERENTIAL ASSEMBLY

See section 15

OIL GUIDE PLATE

44 x 72 x 23 mm NEEDLE BEARING

Inspect for wear and operation.

BEARING RETAINING PLATE

COUNTERSHAFT ASSEMBLY Index, page 13-29

MAINSHAFT ASSEMBLY Index, page 13-23

75 mm SPRING WASHER

32 x 46 x 7 mm OIL SEAL

Replace.

TRANSMISSION MAGNET

SHIFT FORK ASSEMBLY

OIL PUMP ASSEMBLYCHANGE HOLDER ASSEMBLY

UPPER COVER

SELECT LEVER ASSEMBLYProCarManuals.com

Page 1153 of 1640

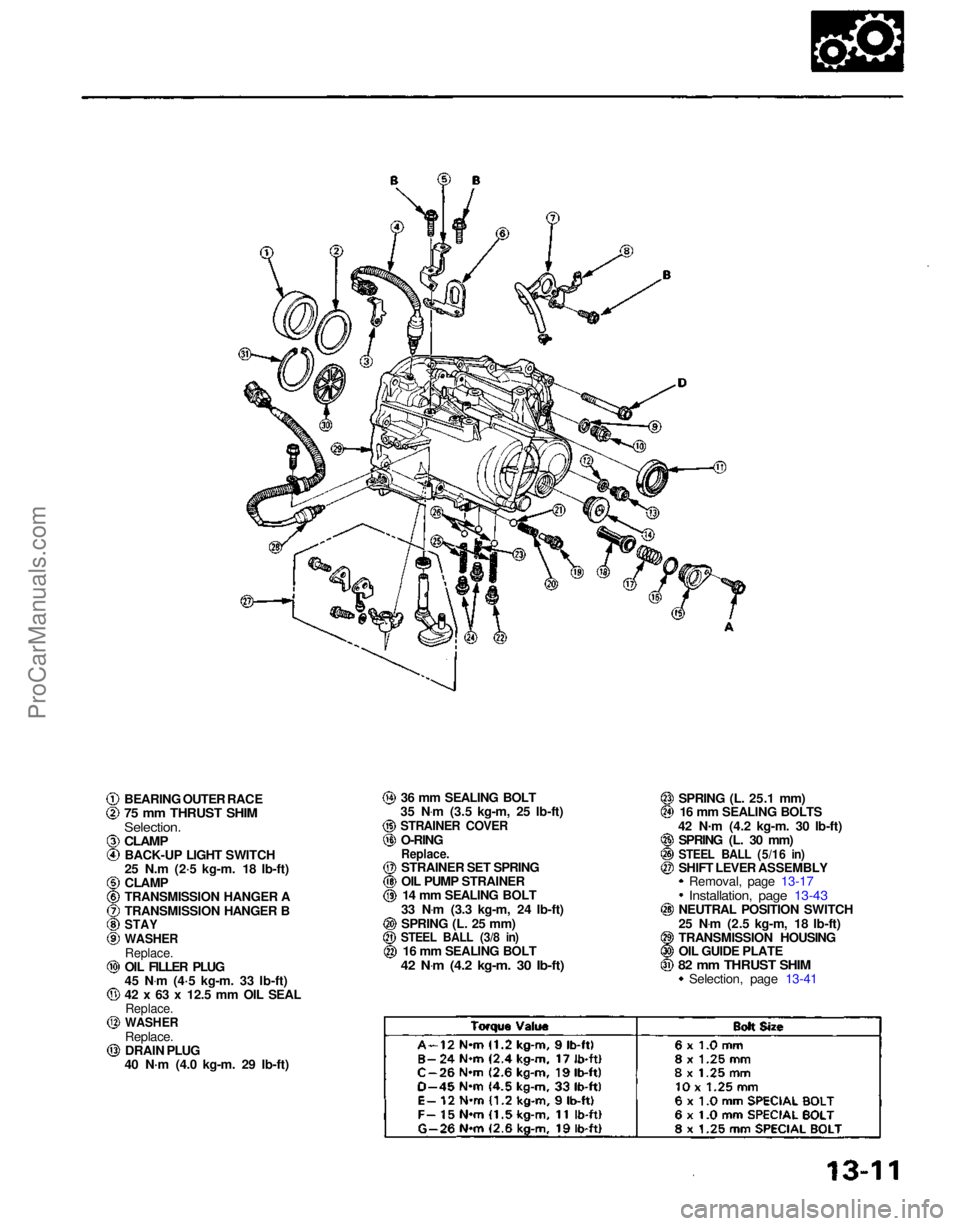

BEARING OUTER RACE

75 mm THRUST SHIM

Selection.

CLAMP

BACK-UP LIGHT SWITCH

25 N.m (2·5 kg-m. 18 Ib-ft)

CLAMP

TRANSMISSION HANGER A

TRANSMISSION HANGER B

STAY

WASHER

Replace.

OIL FILLER PLUG

45 N .

m (4·5 kg-m. 33 Ib-ft)

42 x 63 x 12.5 mm OIL SEAL

Replace.

WASHER

Replace.

DRAIN PLUG

40 N·m (4.0 kg-m. 29 Ib-ft) 36 mm SEALING BOLT

35 N .

m (3.5 kg-m, 25 Ib-ft)

STRAINER COVER

O-RING

Replace.

STRAINER SET SPRING

OIL PUMP STRAINER 14 mm SEALING BOLT

33 N .

m (3.3 kg-m, 24 Ib-ft)

SPRING (L. 25 mm)

STEEL BALL (3/8 in)

16 mm SEALING BOLT

42 N .

m (4.2 kg-m. 30 Ib-ft)

SPRING (L. 25.1 mm)

16 mm SEALING BOLTS

42 N .

m (4.2 kg-m. 30 Ib-ft)

SPRING (L. 30 mm)

STEEL BALL (5/16 in)

SHIFT LEVER ASSEMBLY Removal, page 13-17

Installation, page 13-43

NEUTRAL POSITION SWITCH

25 N .

m (2.5 kg-m, 18 Ib-ft)

TRANSMISSION HOUSING

OIL GUIDE PLATE

82 mm THRUST SHIM

Selection, page 13-41ProCarManuals.com

Page 1154 of 1640

SEALING

BOLT

STEEL

BALLS (5/16 in)

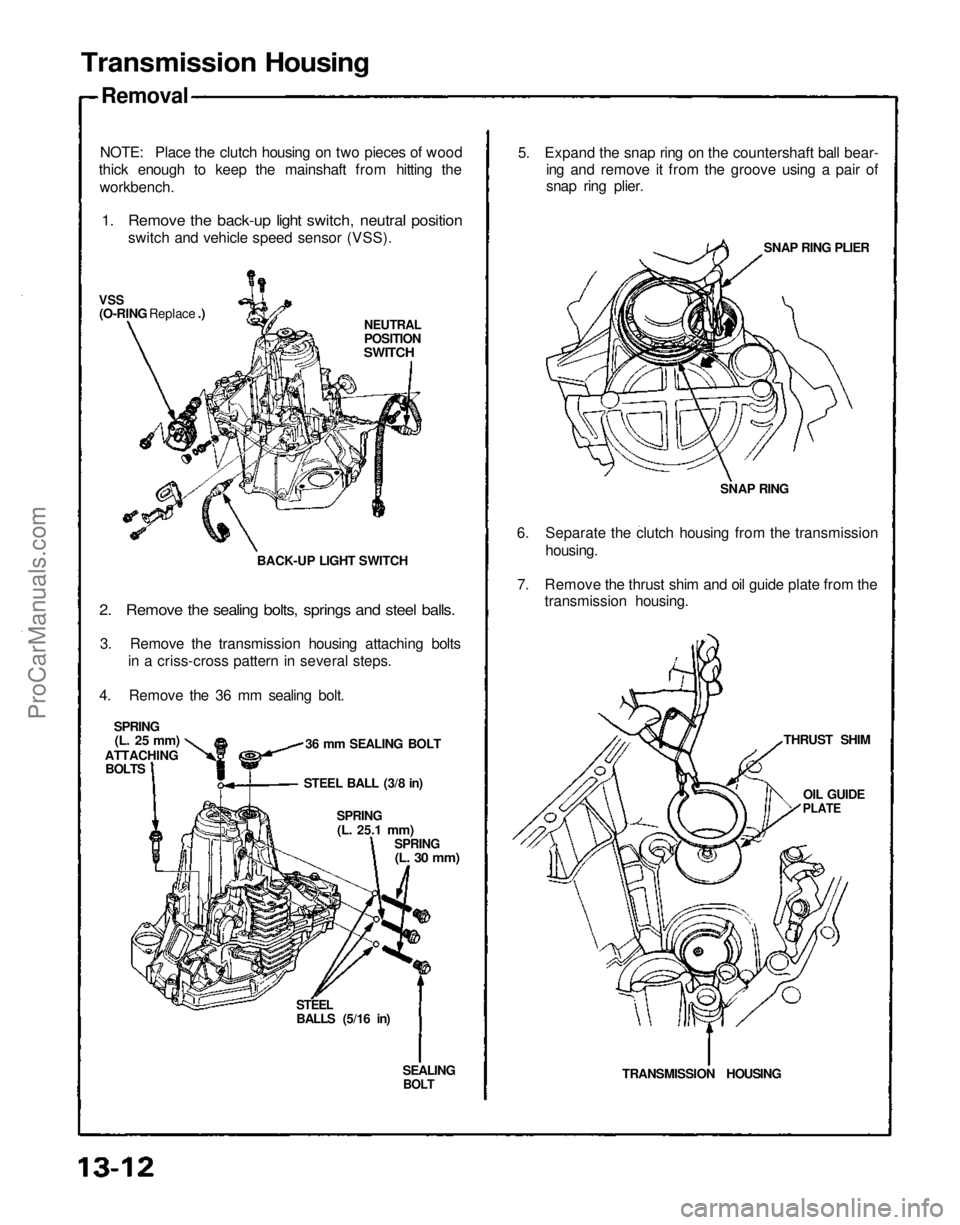

Transmission Housing

Removal

NOTE: Place the clutch housing on two pieces of wood

thick enough to keep the mainshaft from hitting the

workbench.

1. Remove the back-up light switch, neutral position

switch and vehicle speed sensor (VSS).

NEUTRAL

POSITION

SWITCH

VSS

(O-RING Replace .)

BACK-UP LIGHT SWITCH36 mm SEALING BOLT

SPRING

(L. 25 mm)

ATTACHING BOLTS

2. Remove the sealing bolts, springs and steel balls.

3. Remove the transmission housing attaching bolts in a criss-cross pattern in several steps.

4. Remove the 36 mm sealing bolt.

STEEL BALL (3/8 in)

SPRING

(L.

25.1

mm)

SPRING

(L. 30 mm)

TRANSMISSION HOUSINGTHRUST SHIM

OIL GUIDE

PLATE

6. Separate the clutch housing from the transmission

housing. SNAP RINGSNAP RING PLIER

5. Expand the snap ring on the countershaft ball bear-

ing and remove it from the groove using a pair of

snap ring plier.

7. Remove the thrust shim and oil guide plate from the transmission housing.ProCarManuals.com

Page 1155 of 1640

Transmission

Reassembly

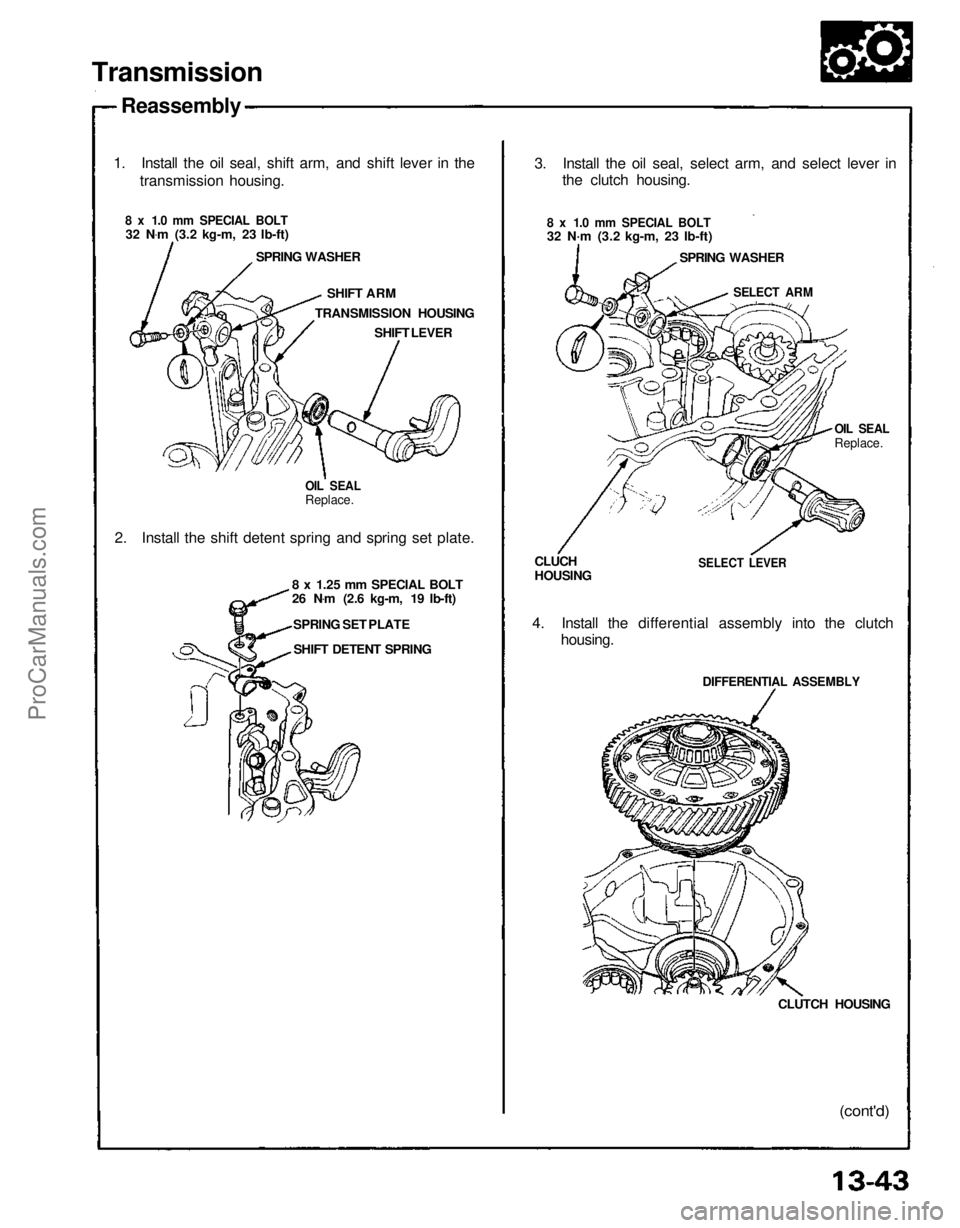

1. Install the oil seal, shift arm, and shift lever in the transmission housing.

8 x 1.0 mm SPECIAL BOLT

32 N .

m (3.2 kg-m, 23 Ib-ft)

SPRING WASHER

SHIFT ARM

TRANSMISSION HOUSING SHIFT LEVER

OIL SEAL

Replace.

2. Install the shift detent spring and spring set plate.

8 x 1.25 mm SPECIAL BOLT

26 N.

m (2.6 kg-m, 19 Ib-ft)

SPRING SET PLATE SHIFT DETENT SPRING 3. Install the oil seal, select arm, and select lever in

the clutch housing.

8 x 1.0 mm SPECIAL BOLT

32 N·m (3.2 kg-m, 23 Ib-ft) SPRING WASHER

SELECT ARM

OIL SEAL

Replace.

SELECT LEVER

CLUCH

HOUSING

4. Install the differential assembly into the clutch housing.

DIFFERENTIAL ASSEMBLY

CLUTCH HOUSING

(cont'd)ProCarManuals.com

Page 1156 of 1640

Transmission

Reassembly (cont'd)

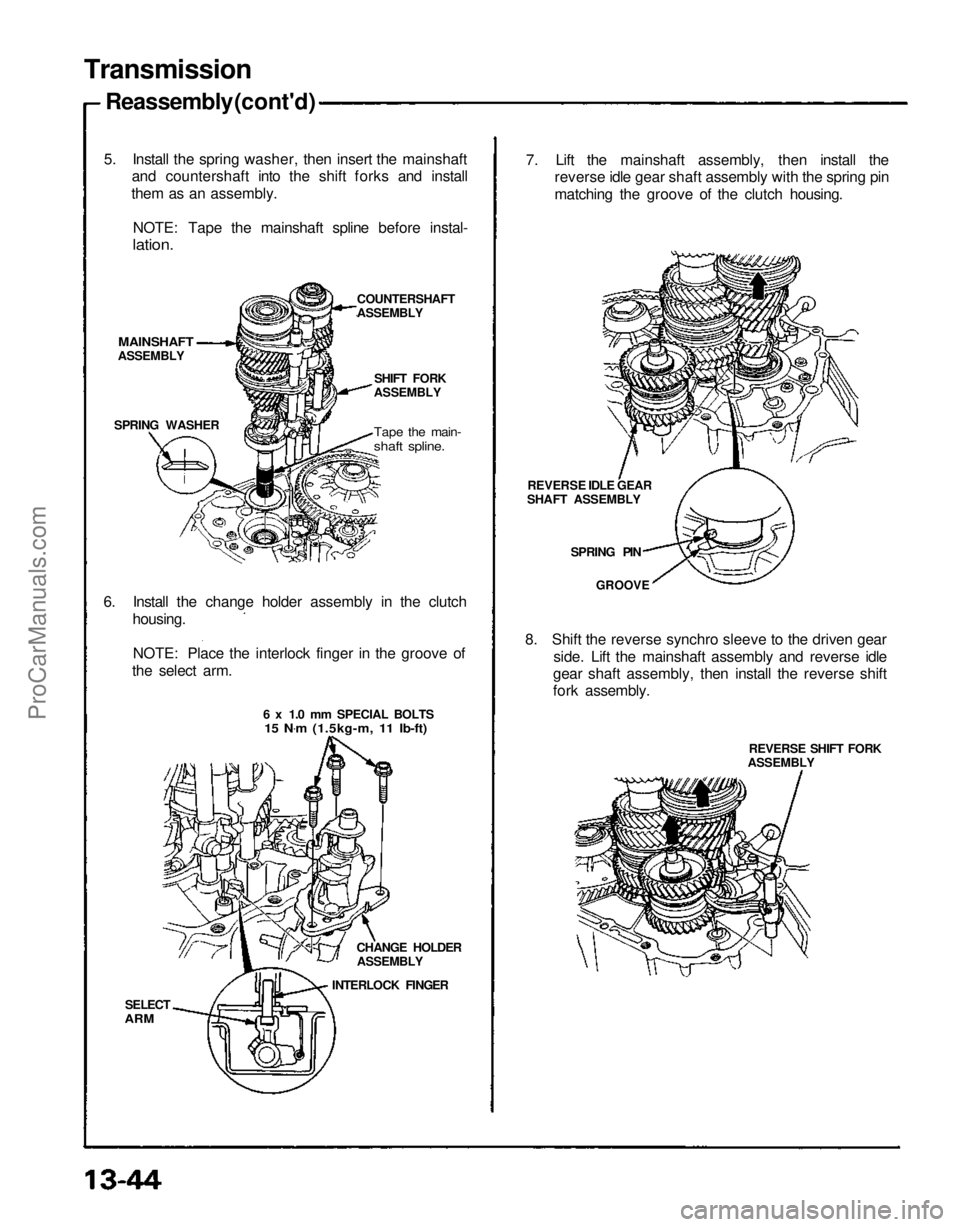

5. Install the spring washer, then insert the mainshaft and countershaft into the shift forks and install

them as an assembly.

NOTE: Tape the mainshaft spline before instal-

lation.

COUNTERSHAFT

ASSEMBLY

SPRING WASHER

6. Install the change holder assembly in the clutch housing.

NOTE: Place the interlock finger in the groove of

the select arm.

SELECT

ARM

CHANGE HOLDER

ASSEMBLY

INTERLOCK FINGER 8. Shift the reverse synchro sleeve to the driven gear

side. Lift the mainshaft assembly and reverse idle

gear shaft assembly, then install the reverse shift

fork assembly.

REVERSE SHIFT FORK

ASSEMBLY

7. Lift the mainshaft assembly, then install the

reverse idle gear shaft assembly with the spring pin

matching the groove of the clutch housing.

REVERSE IDLE GEAR

SHAFT ASSEMBLY

SPRING PIN

GROOVE

MAINSHAFT

ASSEMBLY

6 x 1.0 mm SPECIAL BOLTS

15 N .

m (1.5kg-m, 11 Ib-ft)

SHIFT FORK

ASSEMBLY

Tape the main-

shaft spline.ProCarManuals.com

Page 1157 of 1640

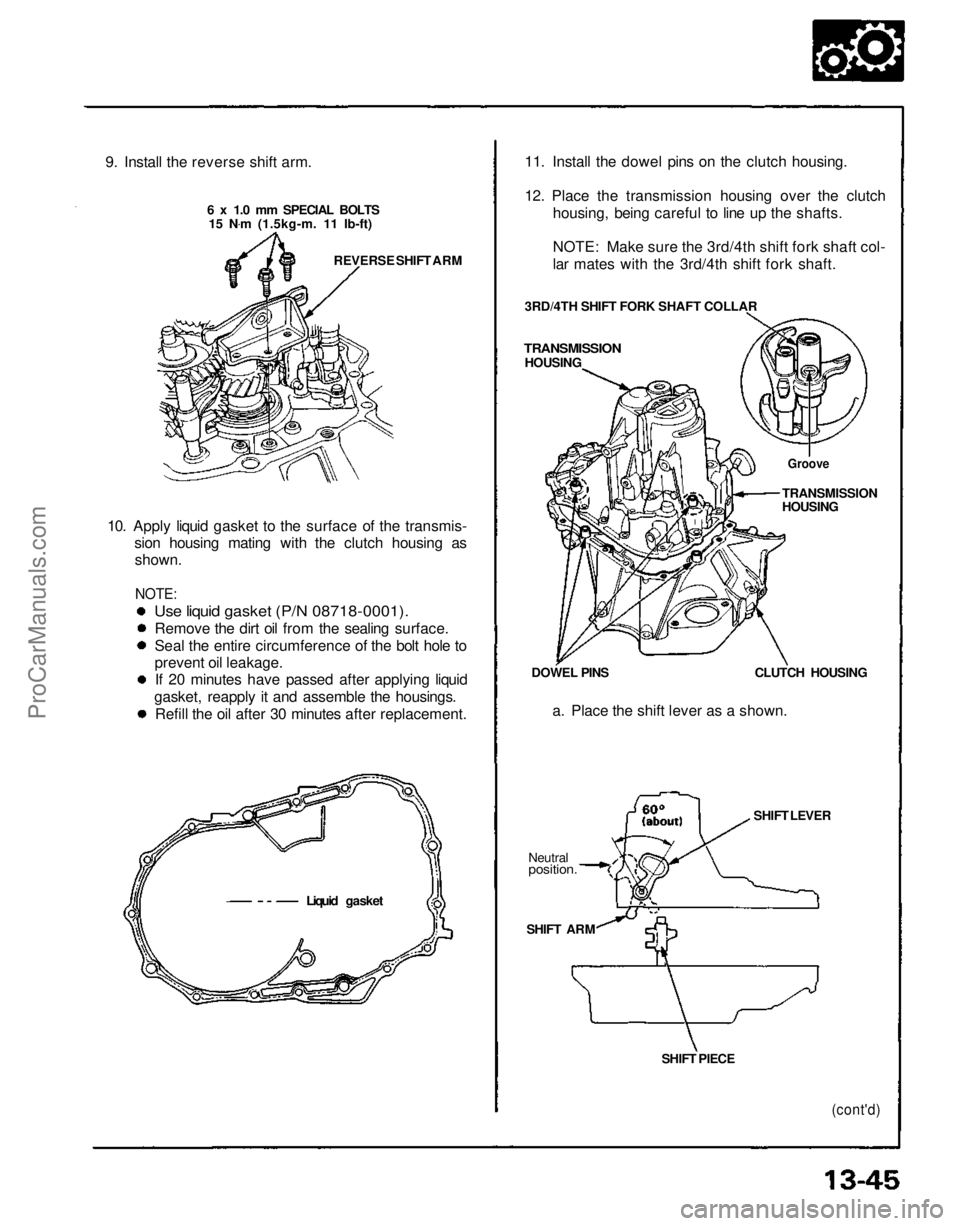

9. Install the reverse shift arm.

6 x 1.0 mm SPECIAL BOLTS15 N .

m (1.5kg-m. 11 Ib-ft)

REVERSE SHIFT ARM

10. Apply liquid gasket to the surface of the transmis- sion housing mating with the clutch housing asshown.

NOTE:

Use liquid gasket (P/N 08718-0001).

Remove the dirt oil from the sealing surface.

Seal the entire circumference of the bolt hole to

prevent oil leakage.If 20 minutes have passed after applying liquid

gasket, reapply it and assemble the housings. Refill the oil after 30 minutes after replacement.

Liquid gasket SHIFT PIECE

SHIFT ARM

Neutral

position.

SHIFT LEVERCLUTCH HOUSING

a. Place the shift lever as a shown.

DOWEL PINS

TRANSMISSION

HOUSING 3RD/4TH SHIFT FORK SHAFT COLLAR 11. Install the dowel pins on the clutch housing.

12. Place the transmission housing over the clutch

housing, being careful to line up the shafts.

NOTE: Make sure the 3rd/4th shift fork shaft col-

lar mates with the 3rd/4th shift fork shaft.

Groove

TRANSMISSION

HOUSING

(cont'd)ProCarManuals.com

Page 1158 of 1640

Transmission

Reassembly (cont'd)

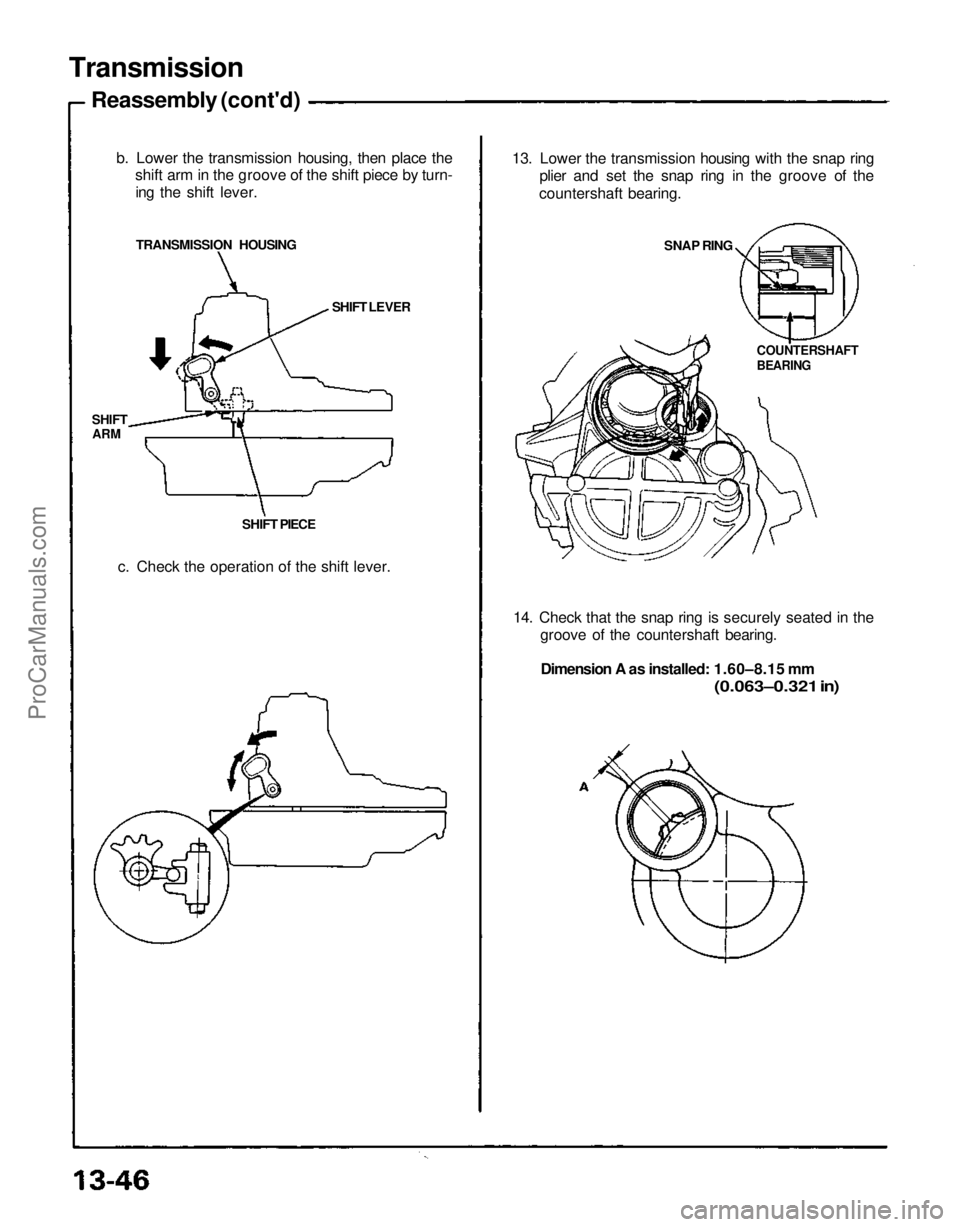

b. Lower the transmission housing, then place theshift arm in the groove of the shift piece by turn-

ing the shift lever.

TRANSMISSION HOUSING

SHIFT

ARM

SHIFT PIECESHIFT LEVER

c. Check the operation of the shift lever. 13. Lower the transmission housing with the snap ring

plier and set the snap ring in the groove of the

countershaft bearing.

SNAP RING

COUNTERSHAFT

BEARING

14. Check that the snap ring is securely seated in the groove of the countershaft bearing.

Dimension A as installed: 1.60–8.15 mm

(0.063–0.321 in)ProCarManuals.com

Page 1159 of 1640

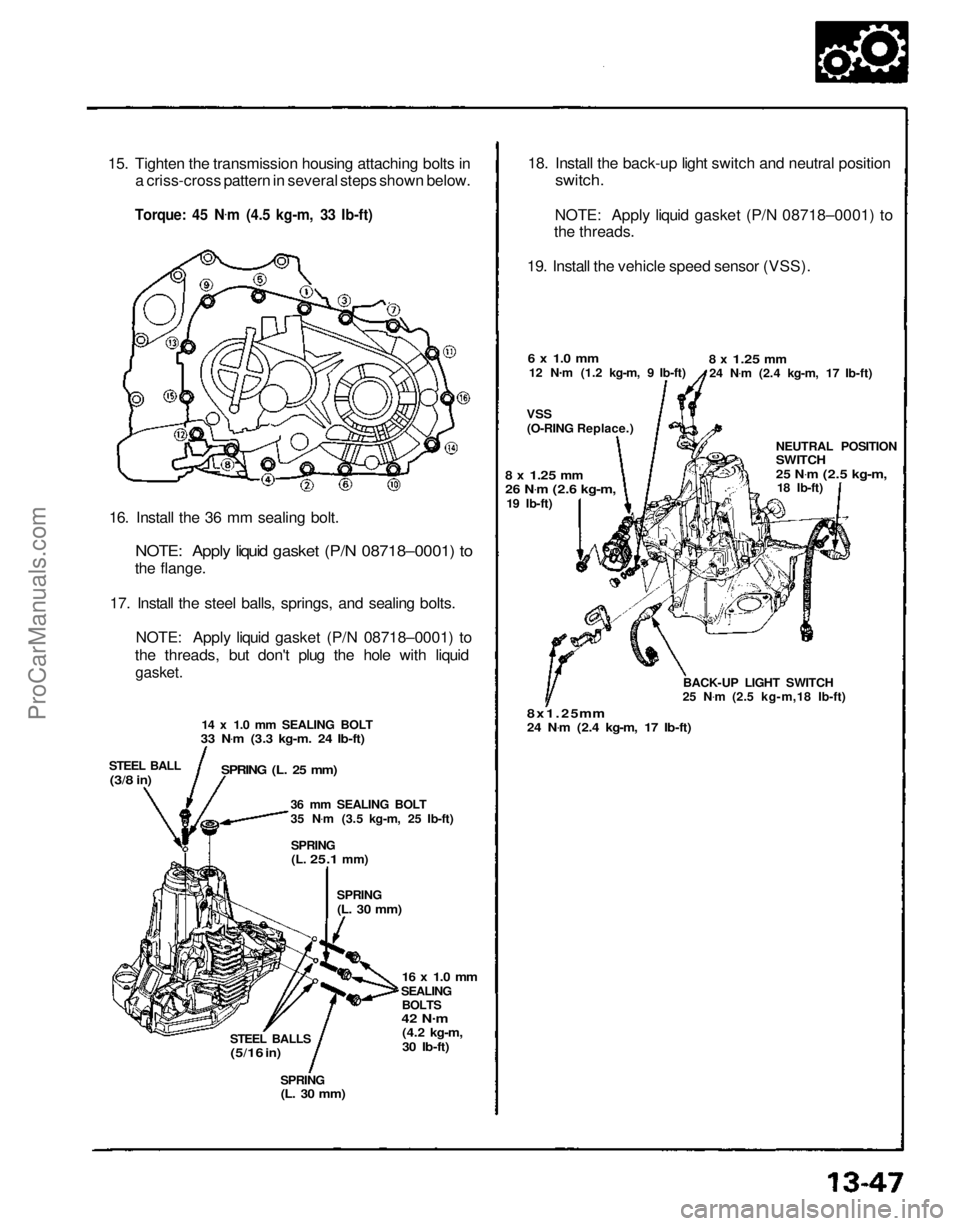

15. Tighten the transmission housing attaching bolts in

a criss-cross pattern in several steps shown below.

Torque: 45 N .

m (4.5 kg-m, 33 Ib-ft)

16. Install the 36 mm sealing bolt.

NOTE: Apply liquid gasket (P/N 08718–0001) to

the flange.

17. Install the steel balls, springs, and sealing bolts. NOTE: Apply liquid gasket (P/N 08718–0001) to

the threads, but don't plug the hole with liquid

gasket.

14 x 1.0 mm SEALING BOLT

33 N .

m (3.3 kg-m. 24 Ib-ft)

STEEL BALL

(3/8

in)

SPRING (L. 25 mm)

36 mm SEALING BOLT

35 N.

m (3.5 kg-m, 25 Ib-ft)

SPRING

(L.

25.1

mm)

SPRING

(L. 30 mm)

16 x 1.0 mm

SEALING BOLTS

42 N .

m

(4.2 kg-m,

30 Ib-ft)

STEEL BALLS

(5/16

in)

SPRING

(L. 30 mm)

18. Install the back-up light switch and neutral position

switch.

NOTE: Apply liquid gasket (P/N 08718–0001) to

the threads.

19. Install the vehicle speed sensor (VSS).

6 x 1.0 mm

12 N .

m (1.2 kg-m, 9 Ib-ft)

VSS

(O-RING Replace.)

8 x

1.25

mm

24 N .

m (2.4 kg-m, 17 Ib-ft)

NEUTRAL POSITION

SWITCH

25 N.

m

(2.5 kg-m,

18 Ib-ft)

BACK-UP LIGHT SWITCH

25 N .

m (2.5 kg-m,18 Ib-ft)

8x1.25 mm

24 N .

m (2.4 kg-m, 17 Ib-ft)

8 x

1.25

mm

26 N

.

m

(2.6 kg-m,

19 Ib-ft)ProCarManuals.com

Page 1160 of 1640

Transmission Assembly

Installation

NOTE:

Check that the two dowel pins are installed in the clutch housing.

Use

only Super High Temp

Urea

Grease

(P/N

08798-9002).

1. Place the transmission on the transmission jack, and raise it to the engine level.

2. Set the release fork to the clutch housing.

3. Install the two transmission housing mounting bolts and engine stiffener.

4. Install the three rear transmission mounting bolts.

5. Loosen the front engine mounting bolt, then install the two front engine

mounting bolts to the transmission side.

6. Remove the transmission jack.

7. Install the clutch housing cover.

Corrosion resistant bolt/nut

DOWEL PINS

(P/N

08798-9002)

REAR TRANSMISSION

MOUNTING BOLTS

12 x

1.25

mm

105 N .

m

(10.5 kg-m, 76 Ib-ft)

(P/lN 08798-9002)

TRANSMISSION HOUSING

MOUNTING BOLTS

12 x

1.25

mm

65 N .

m (6.5 kg-m, 47 Ib-ft)

FRONT ENGINE

MOUNTING BOLT

10 x

1.25

mm

60 N .

m (6.5 kg-m, 43 Ib-ft)

8 x

1.25

mm

22 N .

m (2.2 kg-m, 16 Ib-ft)

6 x 1.0 mm

12 N .

m

(1.2

kg-m,

9 Ib-ft)

CLUTCH HOUSING

COVER

10 x

1.25

mm

45 N.m (4.5 kg-m, 33 Ib-ft)

TRANSMISSION HOUSING MOUNTING BOLT

12 x

1.25

mm

65 N .

m (6.5 kg-m, 47 Ib-ft)

TRANSMISSION

JACK

8. Install the release fork in the release hanger, then install the slave cylinder.

9. Connect the shift cable and select cable. CAUTION: Take care not to bend the cables.

10. Install the upper cover, change wire bracket and lower cover.

11. Install the upper control arm mounting bolt.

Corrosion resistant bolt/nut

8 x

1.25

mm

22 N .

m

(2.2

kg-m,

16 Ib-ft)

UPPER COVER

COTTER PIN Replace.

6 x 1.0 mm

12 N .

m

(1.2

kg-m,

9 Ib-ft)

CHANGE

WIRE

BRACKET

8 x

1.25

mm

26 N .

m (2.6 kg-m, 19 Ib-ft)

6 x 1.0 mm

12 N .

m (1.2 kg-m, 9 Ib-ft) LOWER

COVER

UPPER CONTROL ARM MOUNTING BOLT

10 x

1.25

mm

60 N .

m (6.0 kg-m. 43 Ib-ft)

(Silicone Grease)

SLAVE CYLINDERProCarManuals.com