ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1141 of 1640

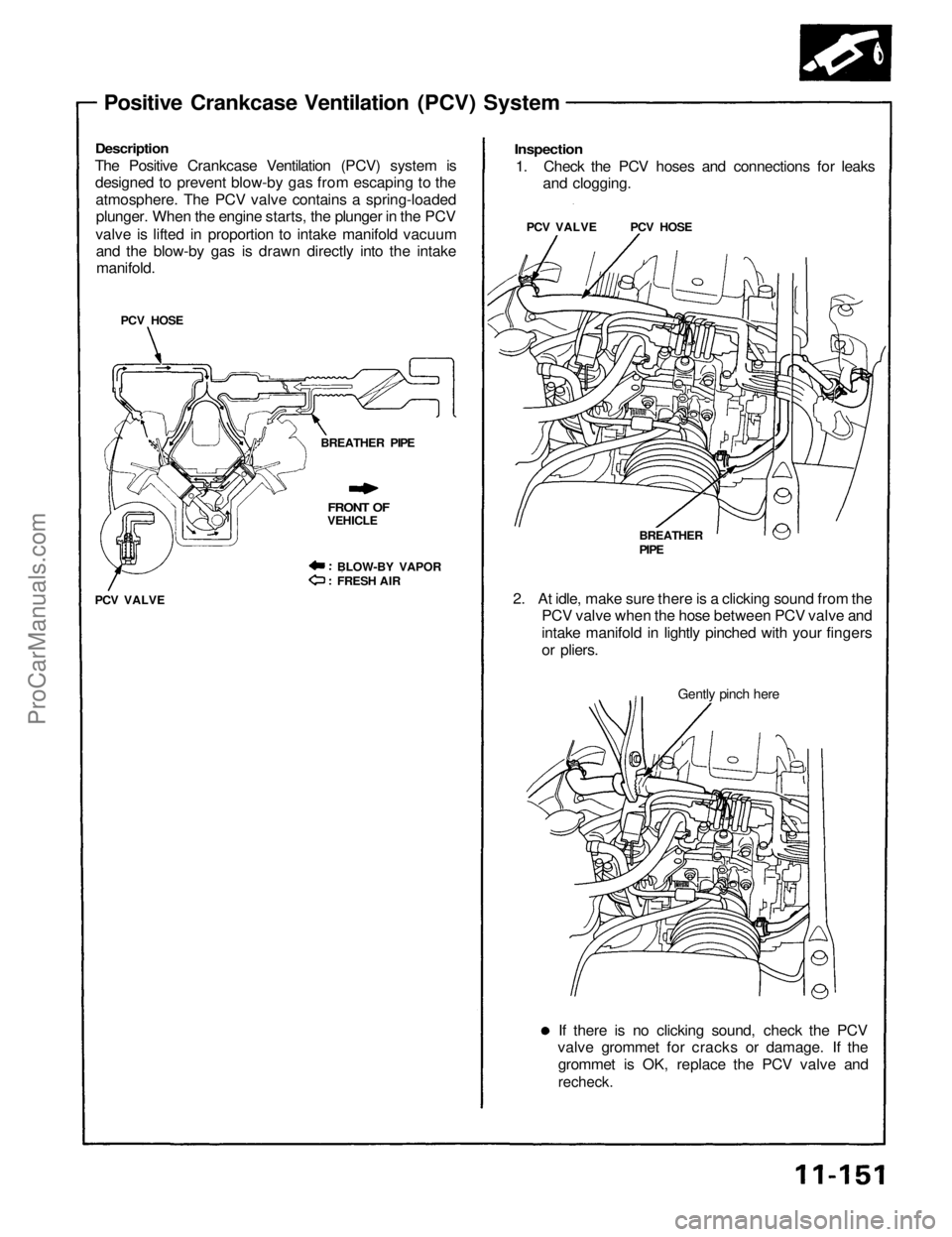

Positive Crankcase Ventilation (PCV) System

Description

The Positive Crankcase Ventilation (PCV) system is

designed to prevent blow-by gas from escaping to the

atmosphere. The PCV valve contains a spring-loaded

plunger. When the engine starts, the plunger in the PCV

valve is lifted in proportion to intake manifold vacuum

and the blow-by gas is drawn directly into the intake

manifold.

PCV HOSE

BREATHER PIPE

FRONT OF

VEHICLE

BLOW-BY VAPOR

FRESH AIR

PCV VALVE

If there is no clicking sound, check the PCV

valve grommet for cracks or damage. If the

grommet is OK, replace the PCV valve and

recheck.

Gently pinch here

2. At idle, make sure there is a clicking sound from the

PCV valve when the hose between PCV valve and

intake manifold in lightly pinched with your fingers

or pliers.

BREATHER

PIPE

PCV VALVE PCV HOSE

Inspection

1. Check the PCV hoses and connections for leaks

and clogging.ProCarManuals.com

Page 1142 of 1640

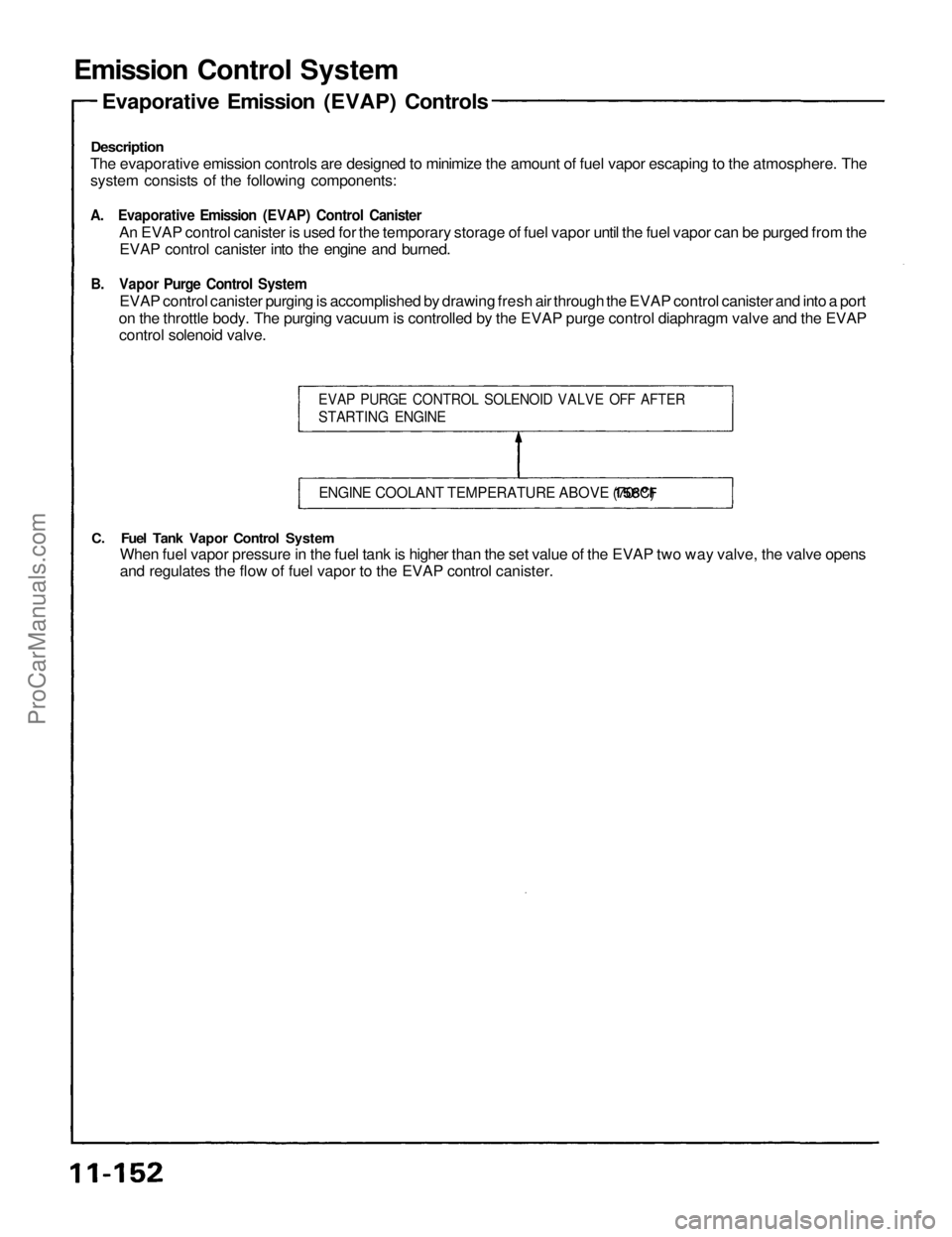

Emission Control System

Description

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the following components:

A. Evaporative Emission (EVAP) Control Canister

An EVAP control canister is used for the temporary storage of fuel vapor until the fuel vapor can be purged from the

EVAP control canister into the engine and burned.

B. Vapor Purge Control System

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a port

on the throttle body. The purging vacuum is controlled by the EVAP purge control diaphragm valve and the EVAP

control solenoid valve.

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens

and regulates the flow of fuel vapor to the EVAP control canister.

EVAP PURGE CONTROL SOLENOID VALVE OFF AFTER

STARTING ENGINE

ENGINE COOLANT TEMPERATURE ABOVE

158°F

(70°C)

Evaporative Emission (EVAP) ControlsProCarManuals.com

Page 1143 of 1640

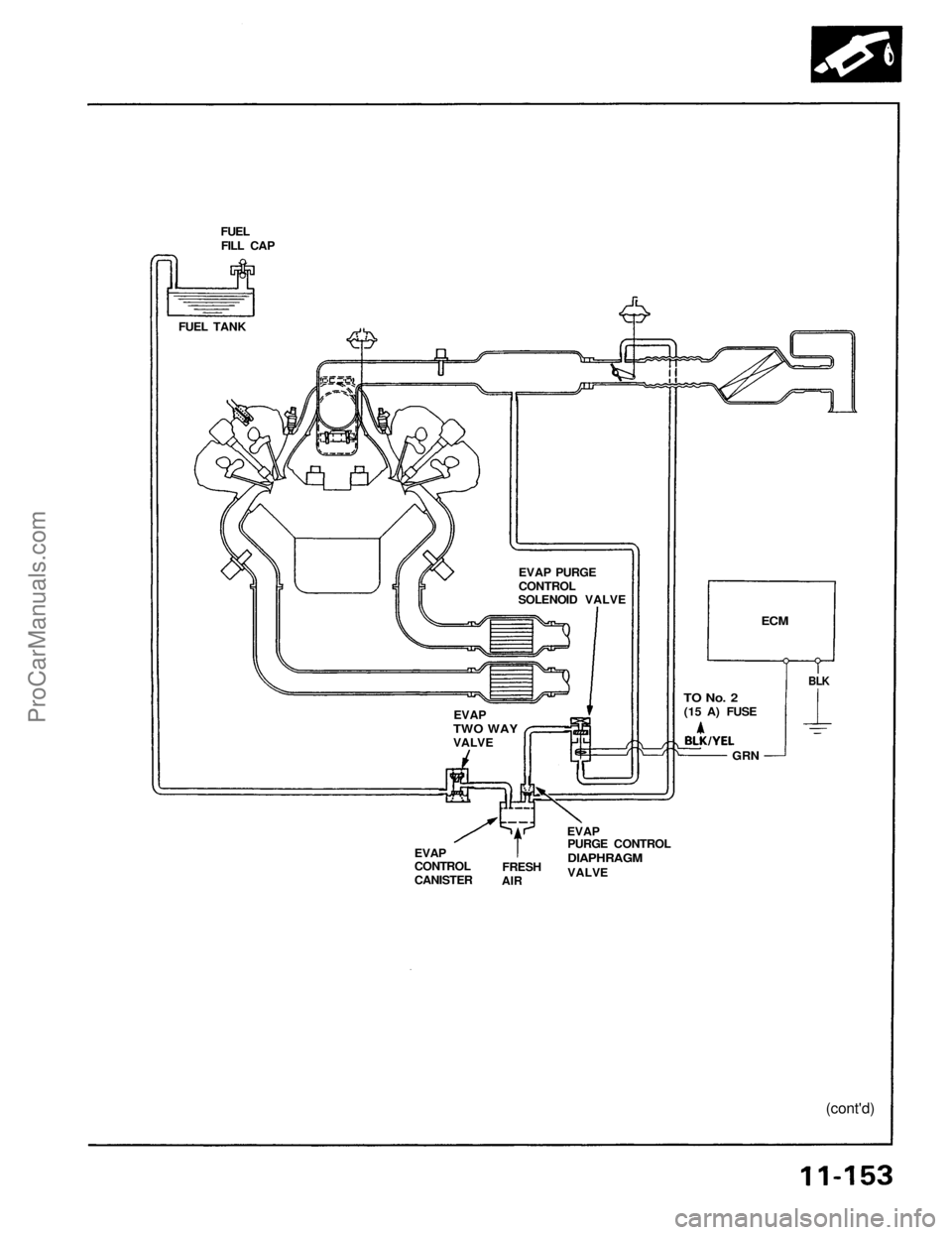

FUEL

FILL CAP

FUEL TANK

EVAP

CONTROL

CANISTER

FRESH

AIR

EVAP

PURGE CONTROL

DIAPHRAGM

VALVE

(cont'd)

BLK

ECM

TO No. 2

(15 A) FUSE

GRN

EVAP PURGE

CONTROL

SOLENOID VALVE

EVAP

TWO WAY

VALVEProCarManuals.com

Page 1144 of 1640

Emission Contro l Syste m

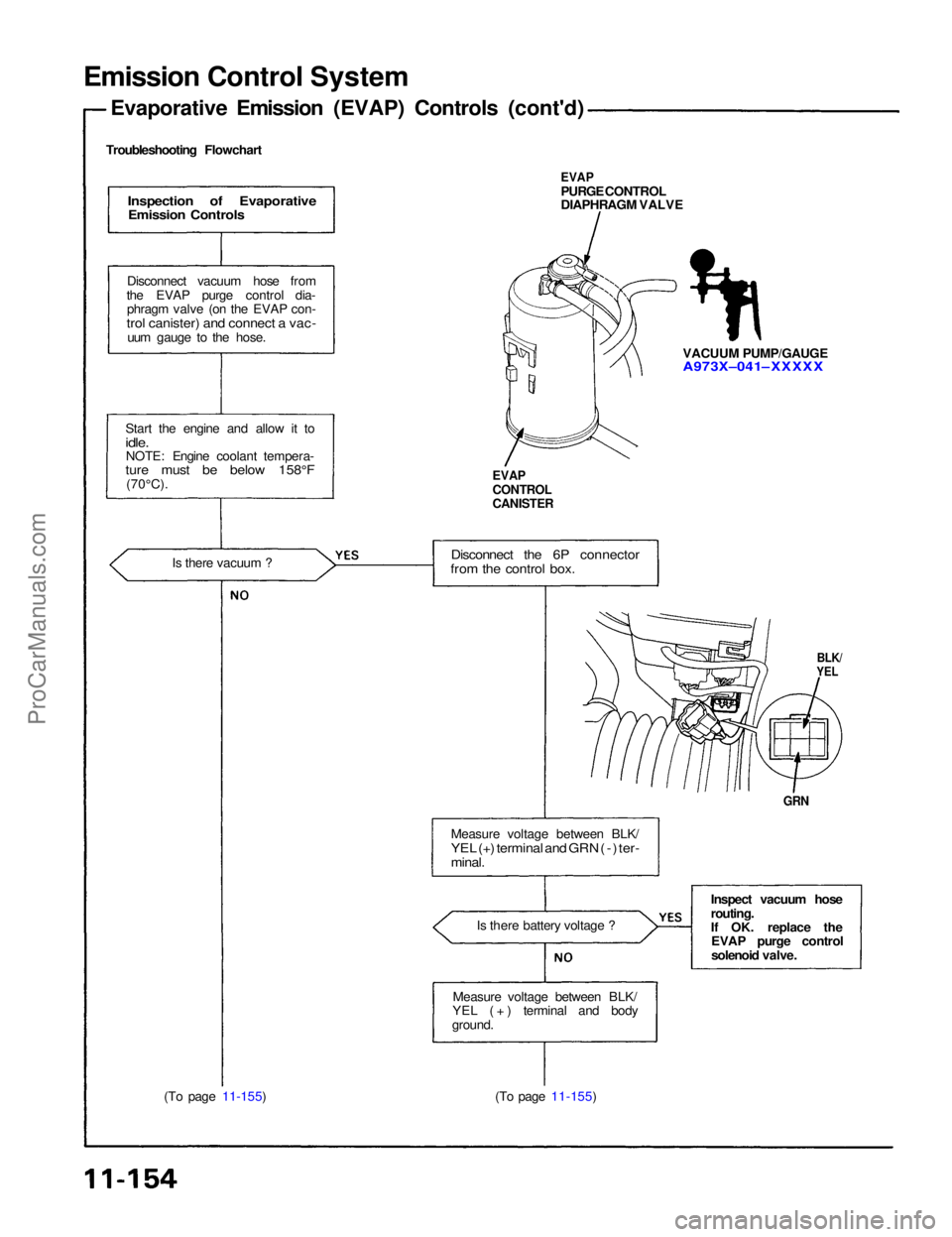

Troubleshootin g Flowchar t

Evaporativ e Emissio n (EVAP ) Control s (cont'd )

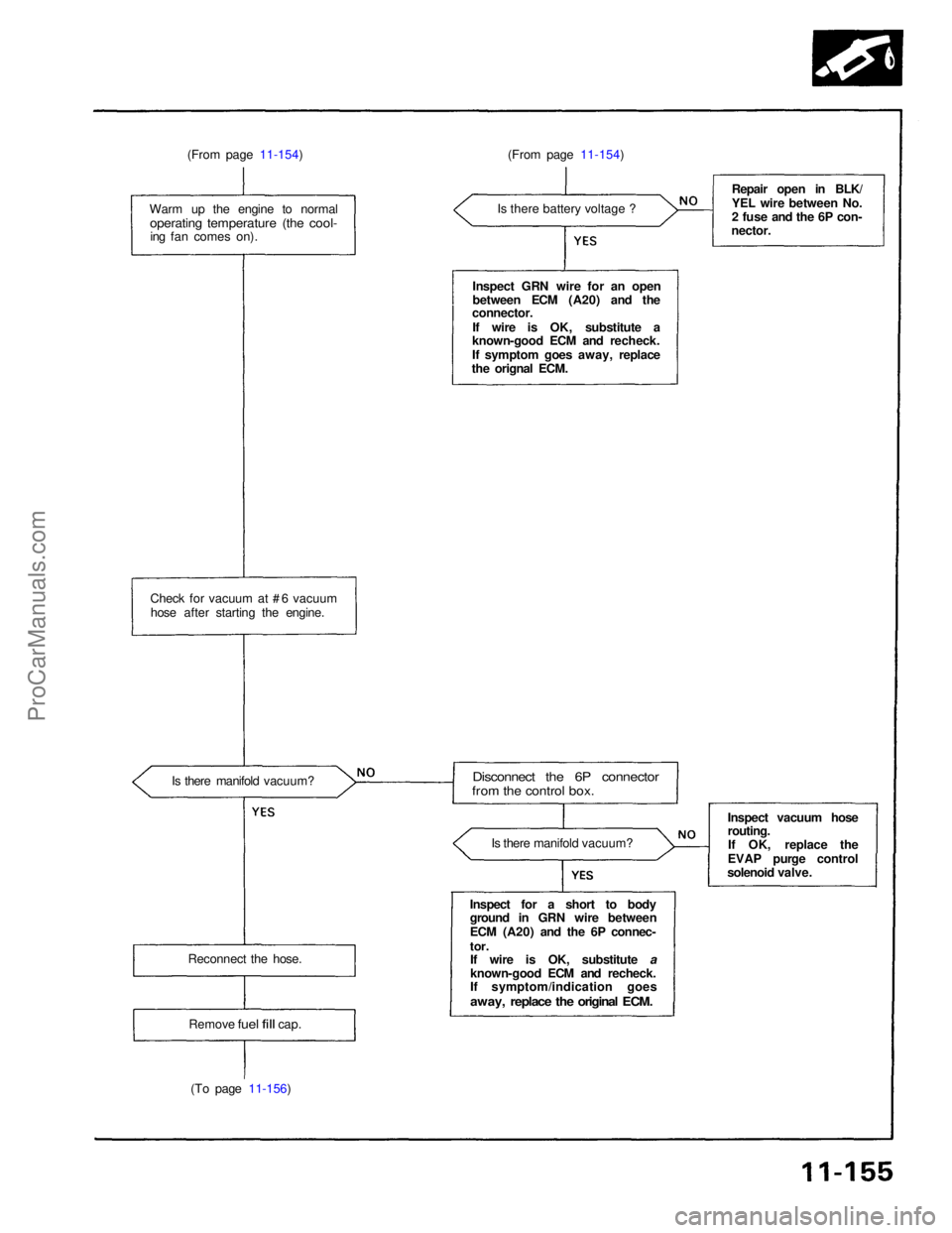

(To pag e 11-155 ) (To pag e 11-155 )

GRN

BLK /YEL

VACUU M PUMP/GAUG EA973X–041–XXXXX

EVAPCONTRO LCANISTE R

EVAPPURG E CONTRO L

DIAPHRAG M VALV EInspectio n o f Evaporativ eEmission Control s

Disconnec t vacuu m hos e fro m

th e EVA P purg e contro l dia -

phrag m valv e (o n th e EVA P con -

trol canister ) an d connec t a vac -uum gaug e t o th e hose .

Star t th e engin e an d allo w i t t o

idle .NOTE : Engin e coolan t tempera -ture mus t b e belo w 158° F(70°C).

Is ther e vacuu m ?

Disconnec t th e 6 P connecto rfrom th e contro l box .

Measur e voltag e betwee n BLK /YEL (+ ) termina l an d GR N ( - ) ter-minal .

Is ther e batter y voltag e ?

Measur e voltag e betwee n BLK /

YE L ( + ) termina l an d bod y

ground . Inspec

t vacuu m hos e

routing .

I f OK . replac e th e

EVA P purg e contro l

solenoi d valve .

ProCarManuals.com

Page 1145 of 1640

Page 1146 of 1640

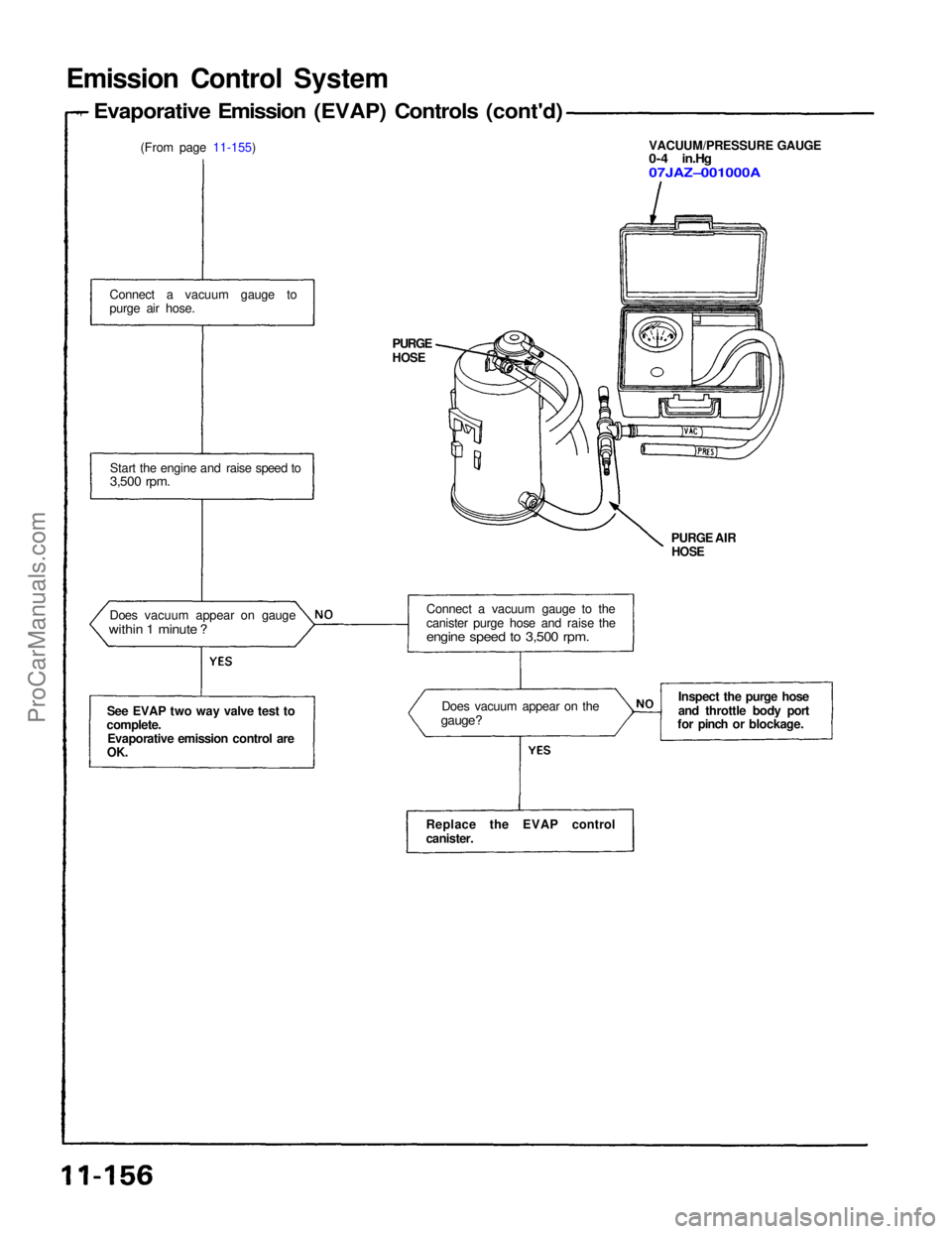

Emission Contro l Syste m

Evaporativ e Emissio n (EVAP ) Control s (cont'd )

(From pag e 11-155 ) VACUUM/PRESSUR

E GAUG E0-4 in.H g07JAZ–001000A

PURG E AI RHOS E

PURG EHOSE

Connec t a vacuu m gaug e t o

purg e ai r hose .

Star t th e engin e an d rais e spee d to

3,50 0 rpm .

Does vacuu m appea r o n gaug ewithin 1 minut e ?

Se e EVA P tw o wa y valv e tes t t o

complete .

Evaporativ e emissio n contro l ar e

OK .

Connec t a vacuu m gaug e t o th e

caniste r purg e hos e an d rais e th e

engin e spee d to 3,50 0 rpm .

Does vacuu m appea r o n th egauge ?

Replac e th e EVA P contro l

canister . Inspec

t th e purg e hos e

an d throttl e bod y por t

fo r pinc h o r blockage .

ProCarManuals.com

Page 1147 of 1640

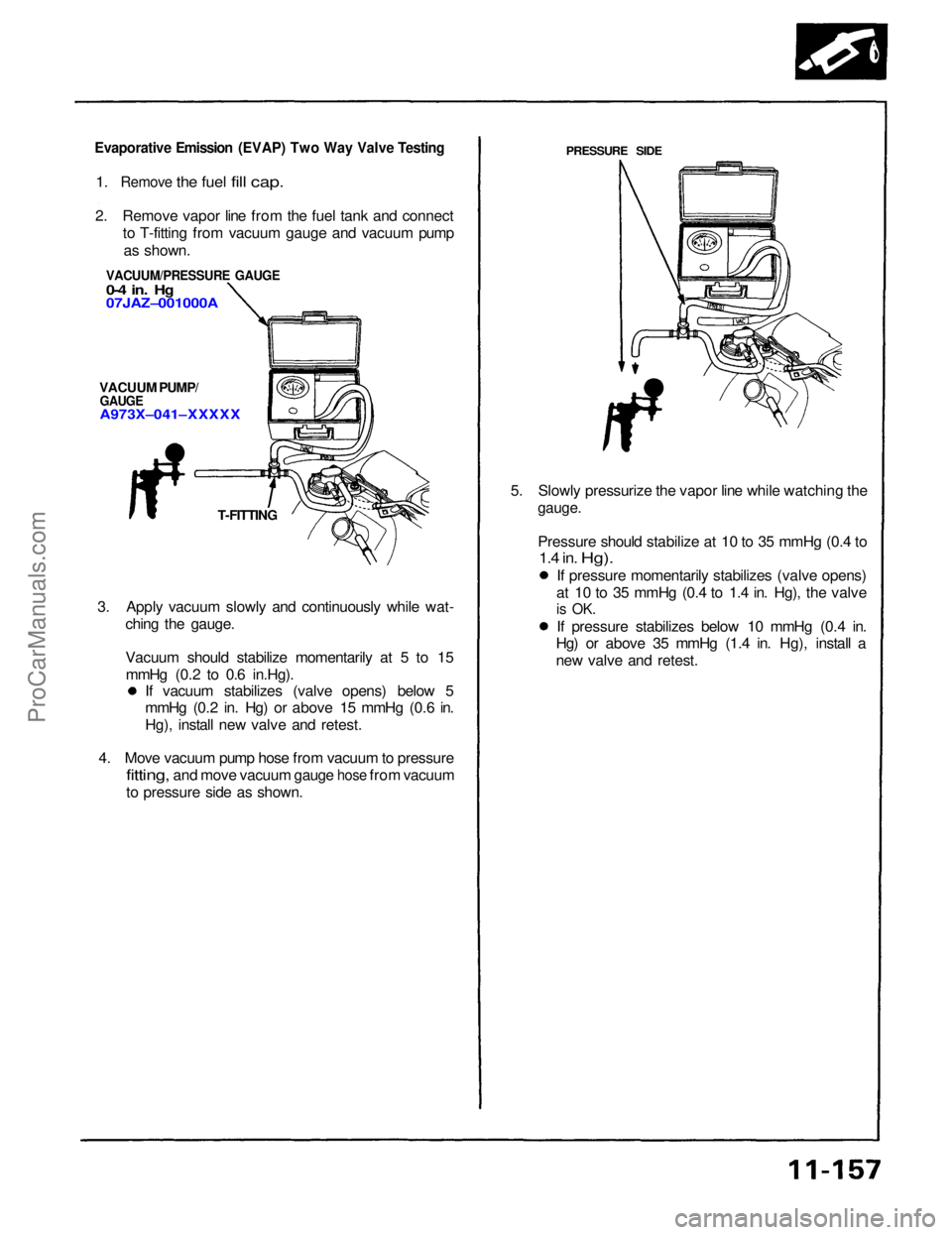

Evaporative Emissio n (EVAP ) Tw o Wa y Valv e Testin g

1. Remov e the fue l fill cap .

2. Remov e vapo r lin e fro m th e fue l tan k an d connec t

t o T-fittin g fro m vacuu m gaug e an d vacuu m pum p

a s shown .

PRESSUR E SID E

3. Appl y vacuu m slowl y an d continuousl y whil e wat -

chin g th e gauge .

Vacuu m shoul d stabiliz e momentaril y a t 5 to 1 5

mmH g (0. 2 t o 0. 6 in.Hg) . 5

. Slowl y pressuriz e th e vapo r lin e whil e watchin g th e

gauge .

Pressur e shoul d stabiliz e a t 1 0 to 3 5 mmH g (0. 4 to

1. 4 in . Hg) .

VACUUM/PRESSUR E GAUG E0-4 in . Hg07JAZ–001000A

VACUU M PUMP /GAUG EA973X–041–XXXXX

T-FITTIN G

If vacuu m stabilize s (valv e opens ) belo w 5

mmH g (0. 2 in . Hg ) o r abov e 1 5 mmH g (0. 6 in .

Hg) , instal l ne w valv e an d retest .

4 . Mov e vacuu m pum p hos e fro m vacuu m to pressur e

fitting, and mov e vacuu m gaug e hose from vacuu m

t o pressur e sid e a s shown . I

f pressur e momentaril y stabilize s (valv e opens )

a t 1 0 to 3 5 mmH g (0. 4 to 1. 4 in . Hg) , th e valv e

is OK .

If pressur e stabilize s belo w 1 0 mmH g (0. 4 in .

Hg ) o r abov e 3 5 mmH g (1. 4 in . Hg) , instal l a

ne w valv e an d retest .

ProCarManuals.com

Page 1148 of 1640

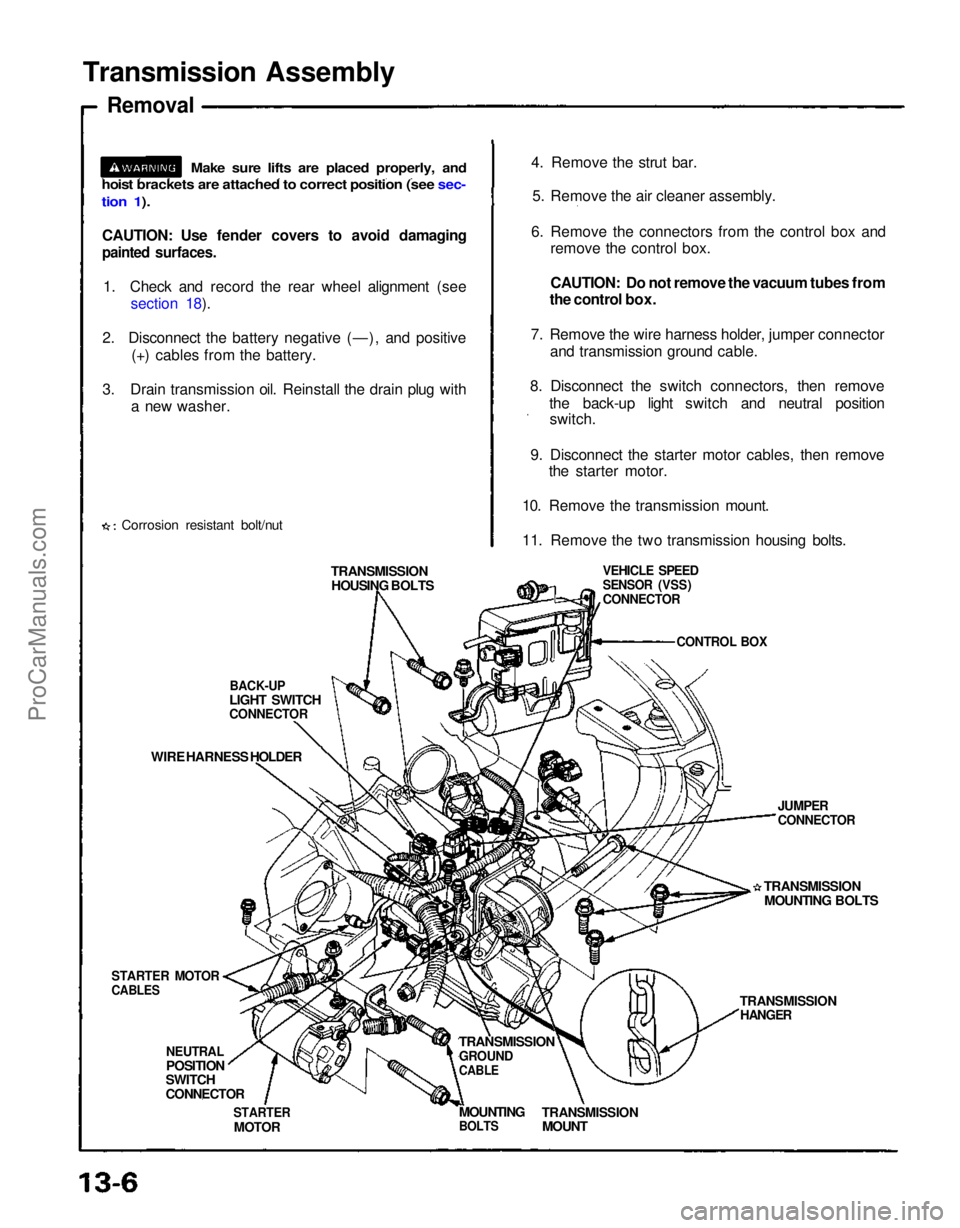

Transmission Assembly

Removal

CAUTION: Use fender covers to avoid damaging

painted surfaces.

1. Check and record the rear wheel alignment (see section 18).

2. Disconnect the battery negative (—), and positive (+) cables from the battery.

3. Drain transmission oil. Reinstall the drain plug with a new washer.

Corrosion resistant bolt/nut 4. Remove the strut bar.

5. Remove the air cleaner assembly.

6. Remove the connectors from the control box and remove the control box.

CAUTION: Do not remove the vacuum tubes from

the control box.

7. Remove the wire harness holder, jumper connector and transmission ground cable.

8. Disconnect the switch connectors, then remove the back-up light switch and neutral positionswitch.

9. Disconnect the starter motor cables, then remove the starter motor.

10. Remove the transmission mount.

11. Remove the two transmission housing bolts.

TRANSMISSION HOUSING BOLTS

BACK-UP

LIGHT SWITCH

CONNECTOR

WIRE HARNESS HOLDER

STARTER MOTOR

CABLES

NEUTRAL

POSITION

SWITCH

CONNECTOR

STARTER

MOTOR

TRANSMISSION

GROUND

CABLE

TRANSMISSION

MOUNT

MOUNTING

BOLTS

TRANSMISSION

HANGER

TRANSMISSION

MOUNTING BOLTS

JUMPER

CONNECTOR

VEHICLE SPEED

SENSOR (VSS)

CONNECTOR

CONTROL BOX

Make sure lifts are placed properly, and

hoist brackets are attached to correct position (see sec-

tion 1).ProCarManuals.com

Page 1149 of 1640

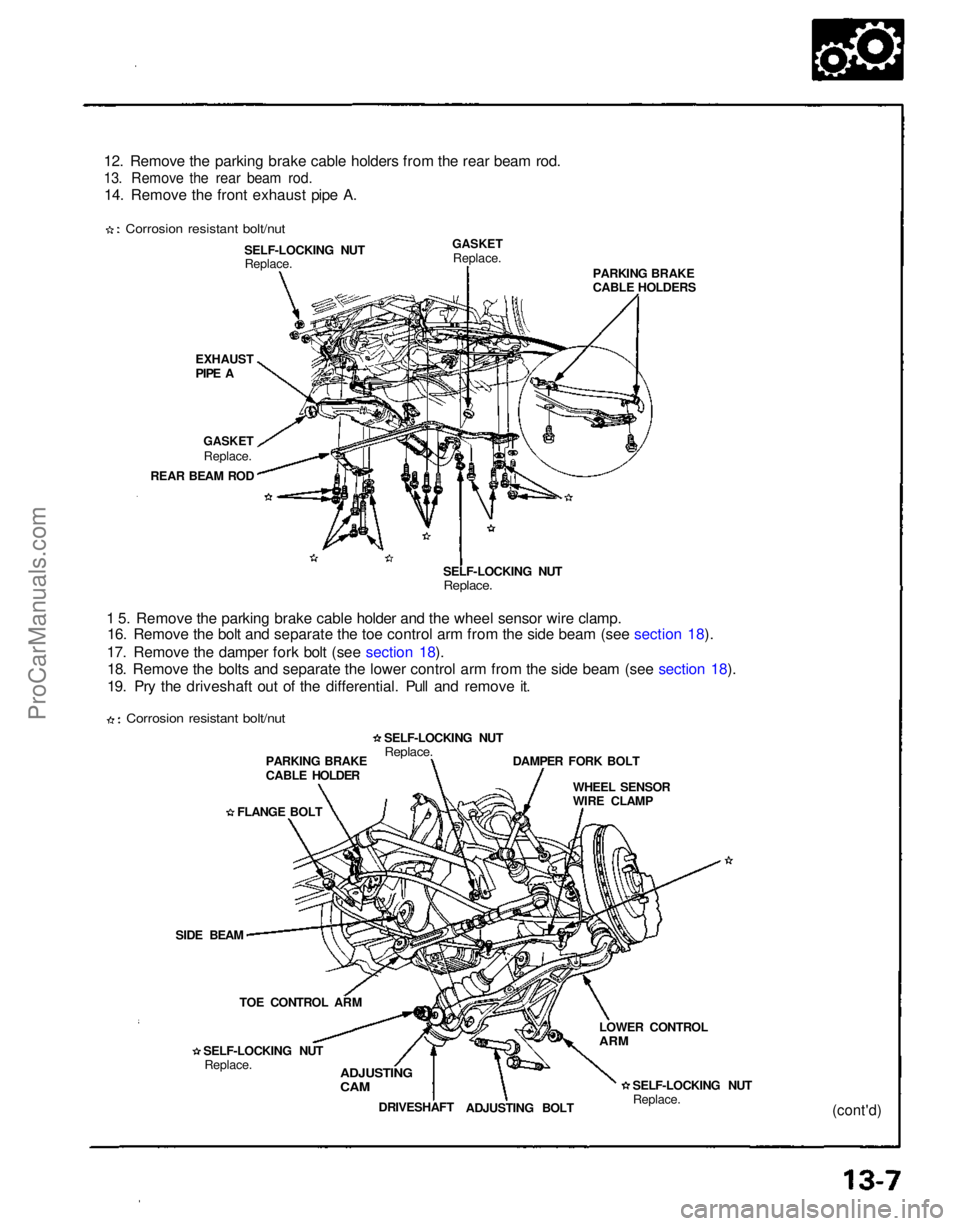

12. Remove the parking brake cable holders from the rear beam rod.

13. Remove the rear beam rod.

14. Remove the front exhaust pipe A.

Corrosion resistant bolt/nut

EXHAUST

PIPE ASELF-LOCKING NUT

Replace.

GASKET

Replace.

GASKET

Replace.

REAR BEAM ROD

1 5. Remove the parking brake cable holder and the wheel sensor wire clamp. 16. Remove the bolt and separate the toe control arm from the side beam (see section 18).

17. Remove the damper fork bolt (see section 18). 18. Remove the bolts and separate the lower control arm from the side beam (see section 18).

19. Pry the driveshaft out of the differential. Pull and remove it. SELF-LOCKING NUT

Replace.

PARKING BRAKE

CABLE HOLDERS

PARKING BRAKE

CABLE HOLDER

FLANGE BOLT

SIDE BEAM TOE CONTROL ARM

SELF-LOCKING NUT Replace. SELF-LOCKING NUT

Replace.

WHEEL SENSOR

WIRE CLAMP

DAMPER FORK BOLT

ADJUSTING

CAM

DRIVESHAFT

ADJUSTING BOLT SELF-LOCKING NUT

Replace.

LOWER CONTROL

ARM

(cont'd)

Corrosion resistant bolt/nutProCarManuals.com

Page 1150 of 1640

Transmission Assembly

Removal (cont'd)

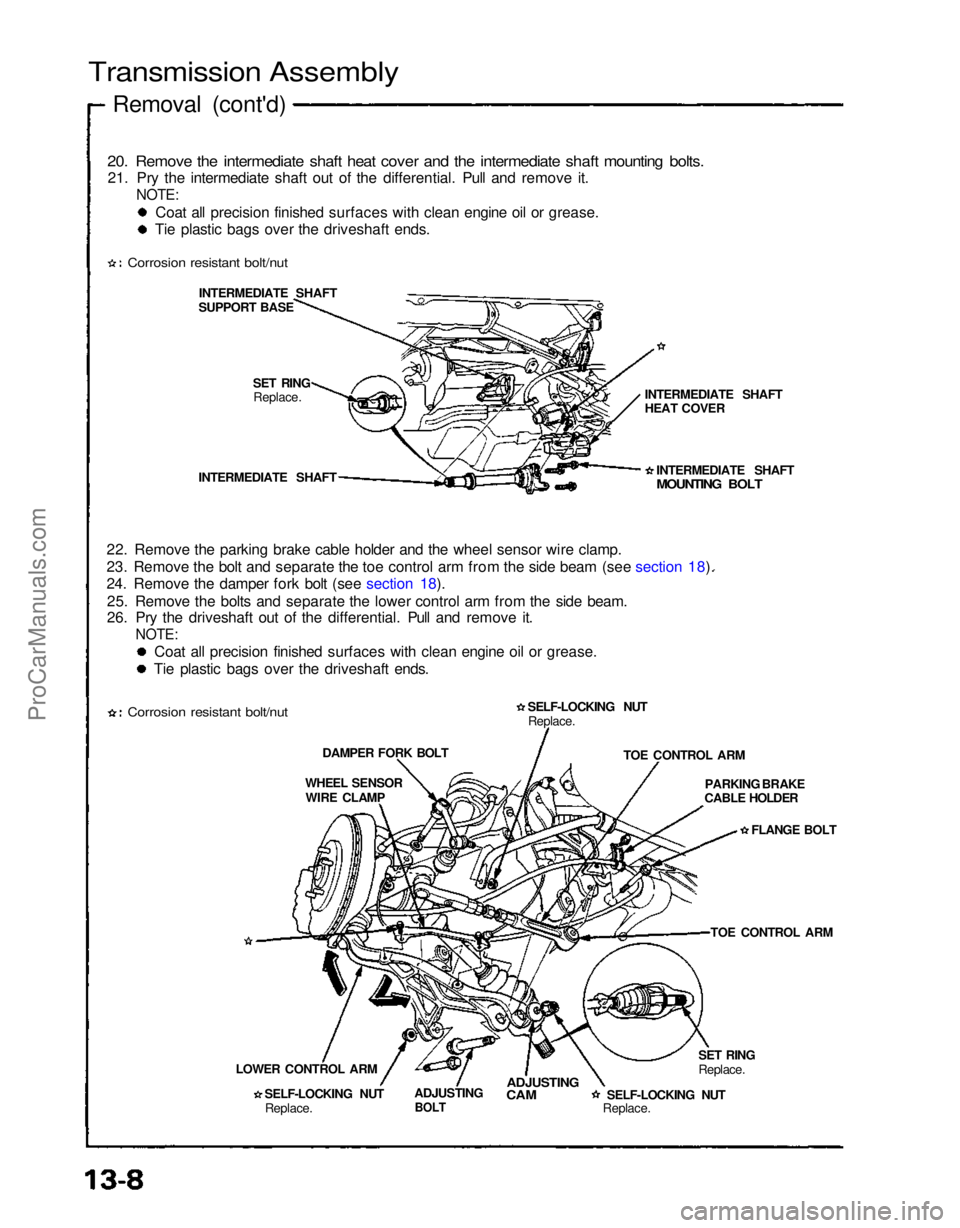

20. Remove the intermediate shaft heat cover and the intermediate shaft mounting bolts.

21. Pry the intermediate shaft out of the differential. Pull and remove it.

NOTE:

Coat all precision finished surfaces with clean engine oil or grease.

Tie plastic bags over the driveshaft ends.

Corrosion resistant bolt/nut

INTERMEDIATE SHAFT

SUPPORT BASE

SET RINGReplace.

INTERMEDIATE SHAFT

22. Remove the parking brake cable holder and the wheel sensor wire clamp.

23. Remove the bolt and separate the toe control arm from the side beam (see section 18).

24. Remove the damper fork bolt (see section 18). 25. Remove the bolts and separate the lower control arm from the side beam.

26. Pry the driveshaft out of the differential. Pull and remove it.

NOTE:

Coat all precision finished surfaces with clean engine oil or grease.

Tie plastic bags over the driveshaft ends.

Corrosion resistant bolt/nut

DAMPER FORK BOLT

WHEEL SENSOR WIRE CLAMP

LOWER CONTROL ARM SELF-LOCKING NUTReplace. ADJUSTING

BOLT

ADJUSTING

CAM

SELF-LOCKING NUT

Replace.SET RING

Replace.TOE CONTROL ARM

PARKING BRAKE

CABLE HOLDER

FLANGE BOLT

TOE CONTROL ARM

SELF-LOCKING NUT

Replace. INTERMEDIATE SHAFT

MOUNTING BOLT

INTERMEDIATE SHAFT

HEAT COVERProCarManuals.com