ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1121 of 1640

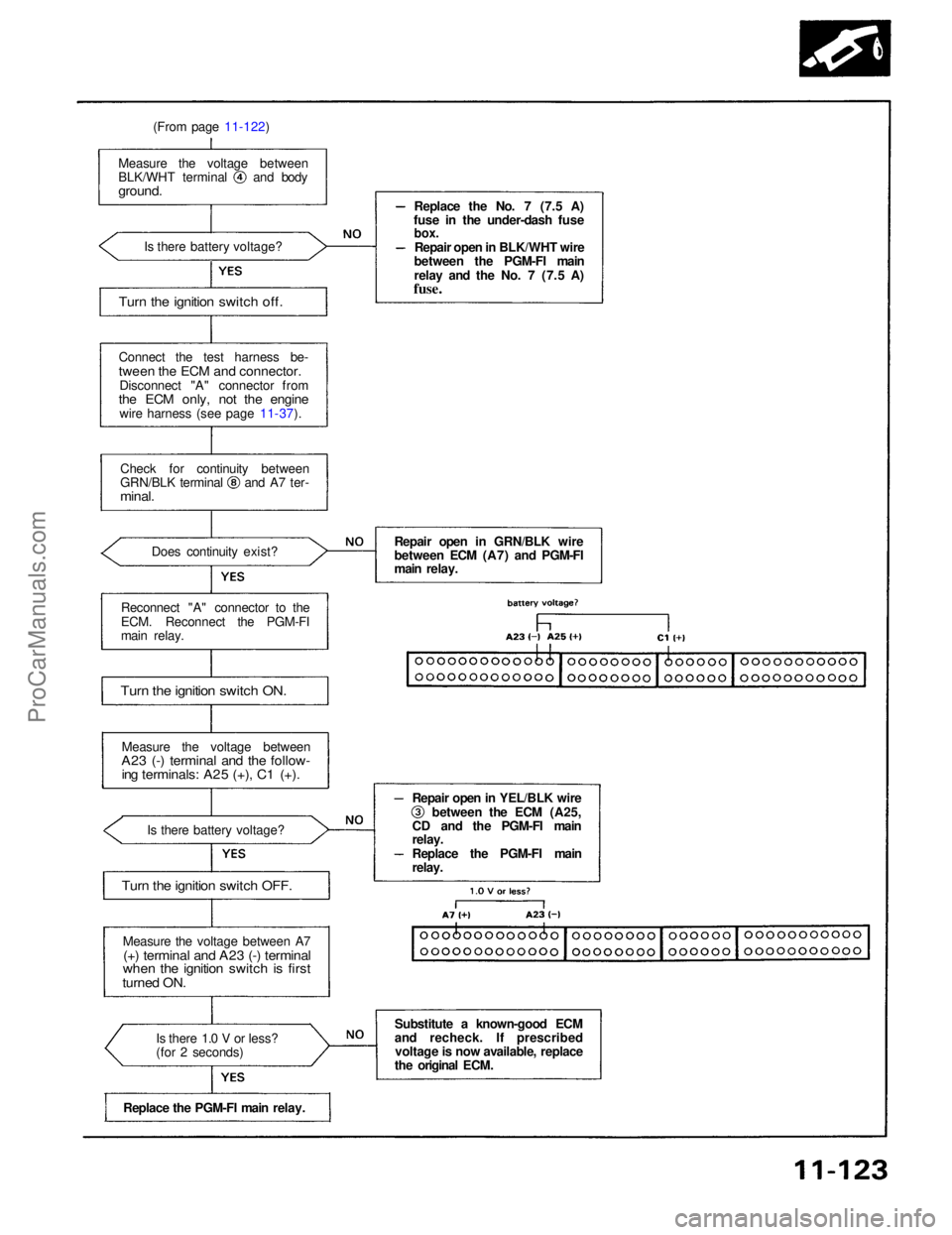

(From page 11-122)

Connect the test harness be-

tween the ECM and connector.

Disconnect "A" connector from

the ECM only, not the engine

wire harness (see page 11-37).

Measure the voltage between BLK/WHT terminal and body

ground.

Is there battery voltage?

Check for continuity between GRN/BLK terminal and A7 ter-

minal.

Does continuity exist?

Reconnect "A" connector to the

ECM. Reconnect the PGM-FI

main relay.

Turn the ignition switch ON.

Measure the voltage between

A23 (-) terminal and the follow-

ing terminals: A25 (+), C1 (+).

Is there battery voltage?

Turn the ignition switch OFF.

Measure the voltage between A7

(+) terminal and A23 (-) terminal

when the ignition switch is first

turned ON.

Is there 1.0 V or less?

(for 2 seconds)

Replace the PGM-FI main relay. Replace the No. 7 (7.5 A)

fuse in the under-dash fuse

box.

Repair open in BLK/WHT wire

between the PGM-FI main

relay and the No. 7 (7.5 A)

fuse.

Repair open in GRN/BLK wire

between ECM (A7) and PGM-FI

main relay. Repair open in YEL/BLK wire between the ECM (A25,

CD and the PGM-FI main

relay.

Replace the PGM-FI main

relay.

Substitute a known-good ECM

and recheck. If prescribed voltage is now available, replace

the original ECM.

Turn the ignition switch off.ProCarManuals.com

Page 1122 of 1640

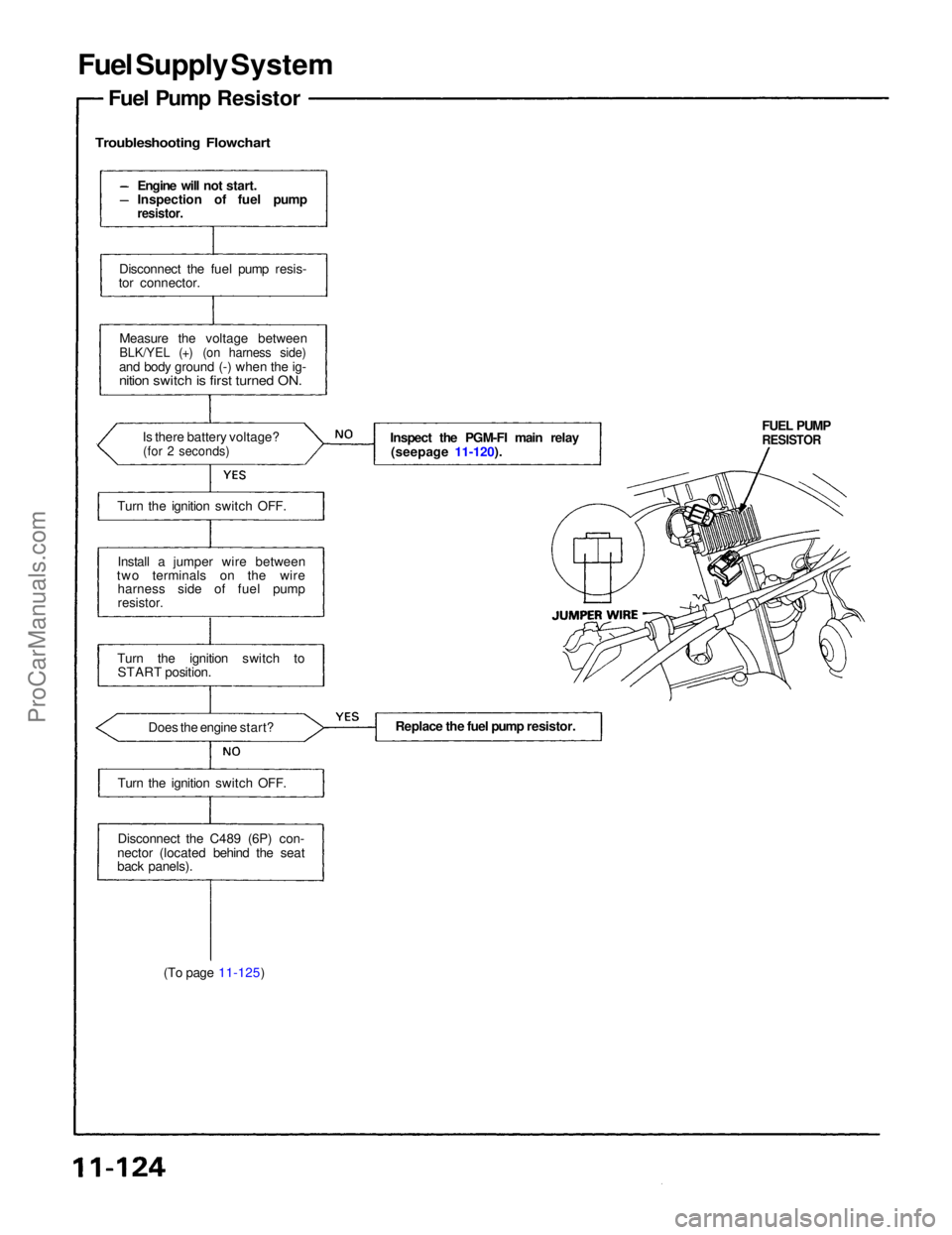

Fuel Supply System

Fuel Pump Resistor

Troubleshooting Flowchart

(To page 11-125) FUEL PUMP

RESISTOR

Inspect the PGM-FI main relay

(seepage 11-120).

Engine will not start.

Inspection of fuel pump

resistor.

Disconnect the fuel pump resis-

tor connector.

Measure the voltage between

BLK/YEL (+) (on harness side)

and body ground (-) when the ig-

nition switch is first turned ON.

Is there battery voltage?

(for 2 seconds)

Turn the ignition switch OFF.

Install a jumper wire between

two terminals on the wire harness side of fuel pump

resistor.

Turn the ignition switch to START position.

Does the engine start?

Turn the ignition switch OFF.

Disconnect the C489 (6P) con-

nector (located behind the seat

back panels). Replace the fuel pump resistor.ProCarManuals.com

Page 1123 of 1640

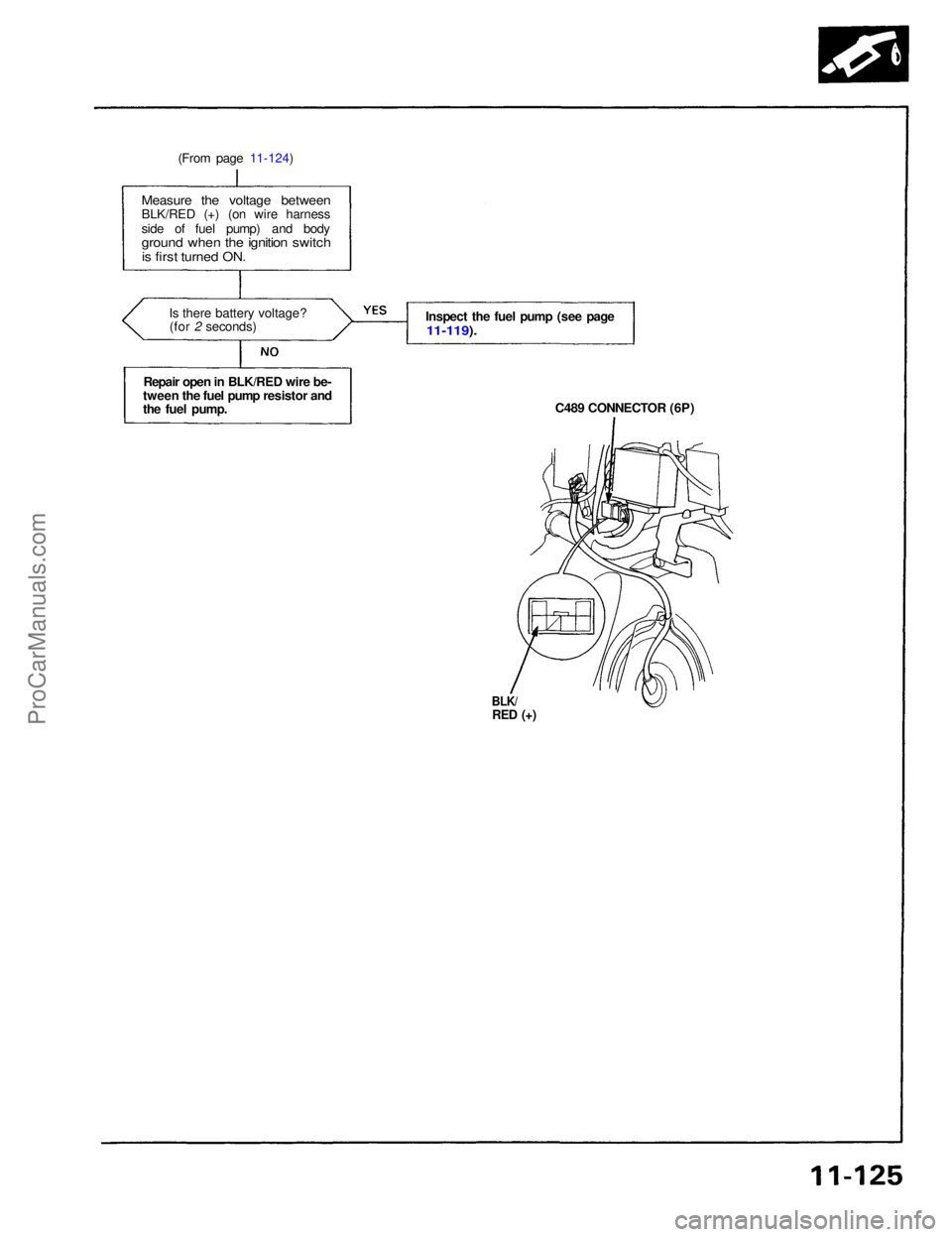

(From page 11-124)

C489 CONNECTOR (6P)

Inspect the fuel pump (see page

11-119).

BLK/

RED (+)

Measure the voltage between

BLK/RED (+) (on wire harness

side of fuel pump) and body

ground when the ignition switch

is first turned ON.

Is there battery voltage?(for 2 seconds)

Repair open in BLK/RED wire be-

tween the fuel pump resistor and

the fuel pump.ProCarManuals.com

Page 1124 of 1640

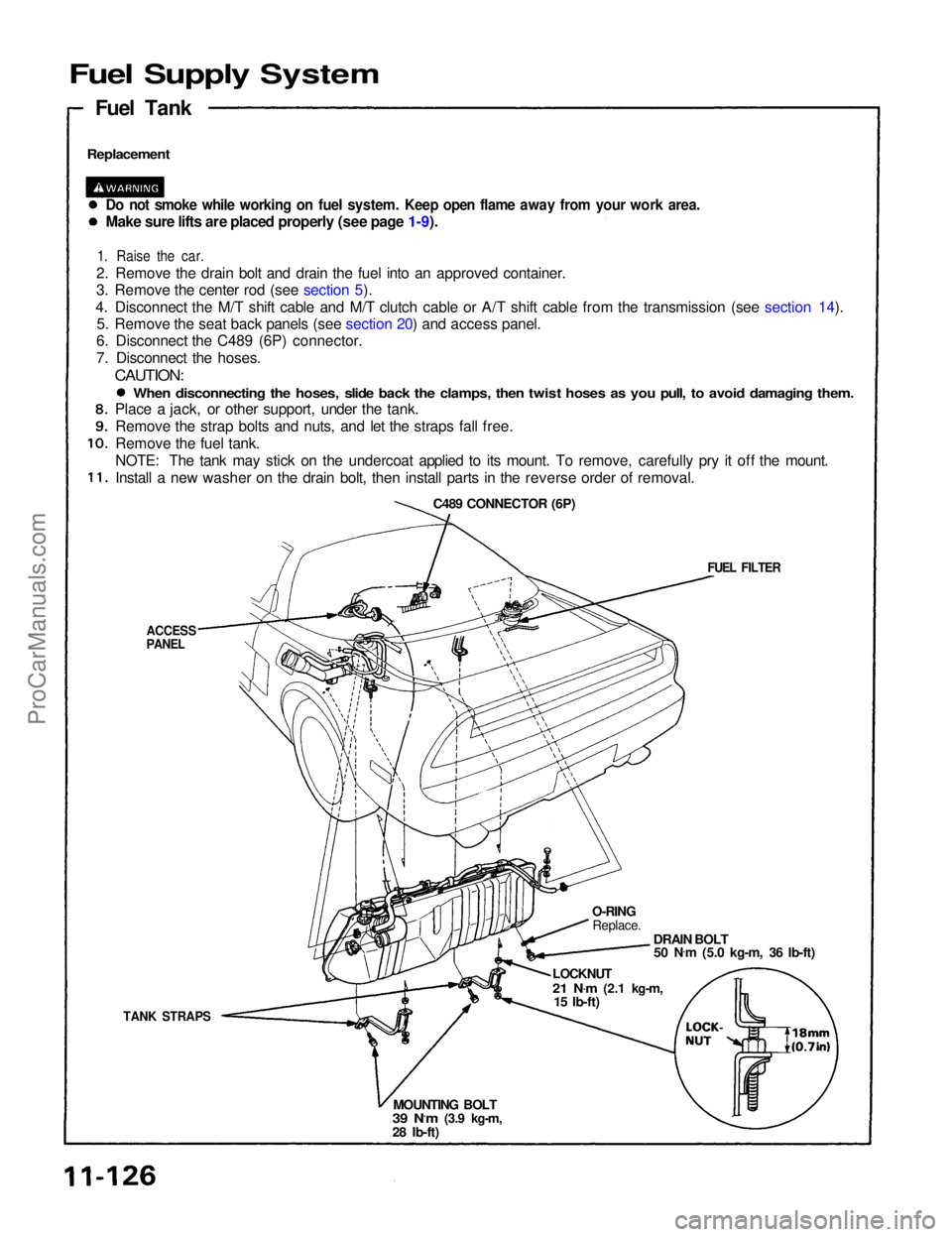

Fuel Supply System

Replacement

Fuel Tank

Do not smoke while working on fuel system. Keep open flame away from your work area.

Make sure lifts are placed properly (see page 1-9).

1. Raise the car.

2. Remove the drain bolt and drain the fuel into an approved container.

3. Remove the center rod (see section 5).

4. Disconnect the M/T shift cable and M/T clutch cable or A/T shift cable from the transmission (see section 14). 5. Remove the seat back panels (see section 20) and access panel.

6. Disconnect the C489 (6P) connector.

7. Disconnect the hoses.

CAUTION:

TANK STRAPS

O-RING

Replace.

DRAIN BOLT50 N .

m (5.0 kg-m, 36 Ib-ft)

LOCKNUT

21 N .

m

(2.1 kg-m,

15 Ib-ft)

MOUNTING BOLT

39 N.m

(3.9 kg-m,

28 Ib-ft)

FUEL FILTER

C489 CONNECTOR (6P)

ACCESS

PANEL

When disconnecting the hoses, slide back the clamps, then twist hoses as you pull, to avoid damaging them.

Place a jack, or other support, under the tank.

Remove the strap bolts and nuts, and let the straps fall free.

Remove the fuel tank.

NOTE: The tank may stick on the undercoat applied to its mount. To remove, carefully pry it off the mount.

Install a new washer on the drain bolt, then install parts in the reverse order of removal.ProCarManuals.com

Page 1125 of 1640

Intake Air System

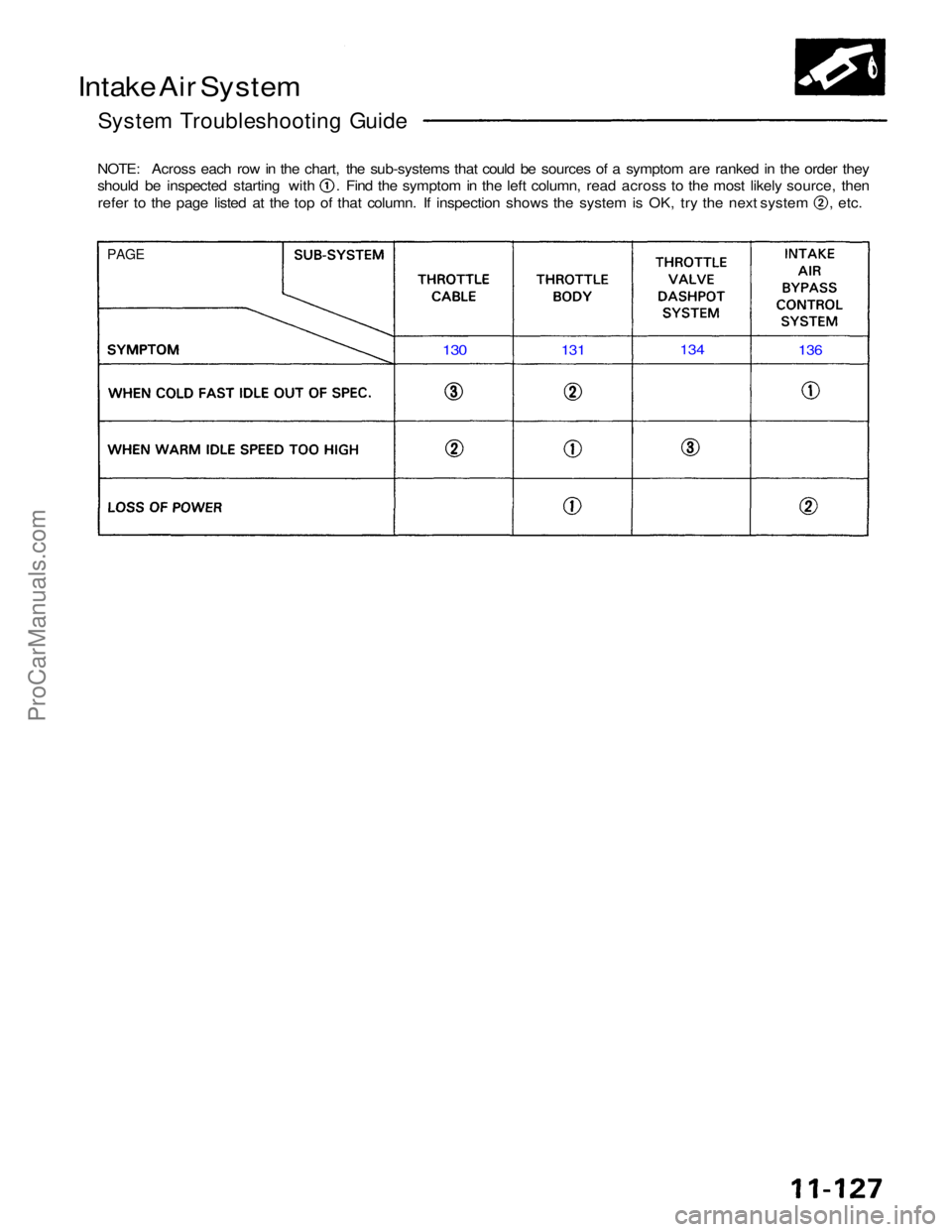

System Troubleshooting Guide

NOTE: Across each row in the chart, the sub-systems that could be sources of a symptom are ranked in the order they should be inspected starting with . Find the symptom in the left column, read across to the most likely source, then

refer to the page listed at the top of that column. If inspection shows the system is OK, try the next system , etc.

PAGE

130

131

134

136ProCarManuals.com

Page 1126 of 1640

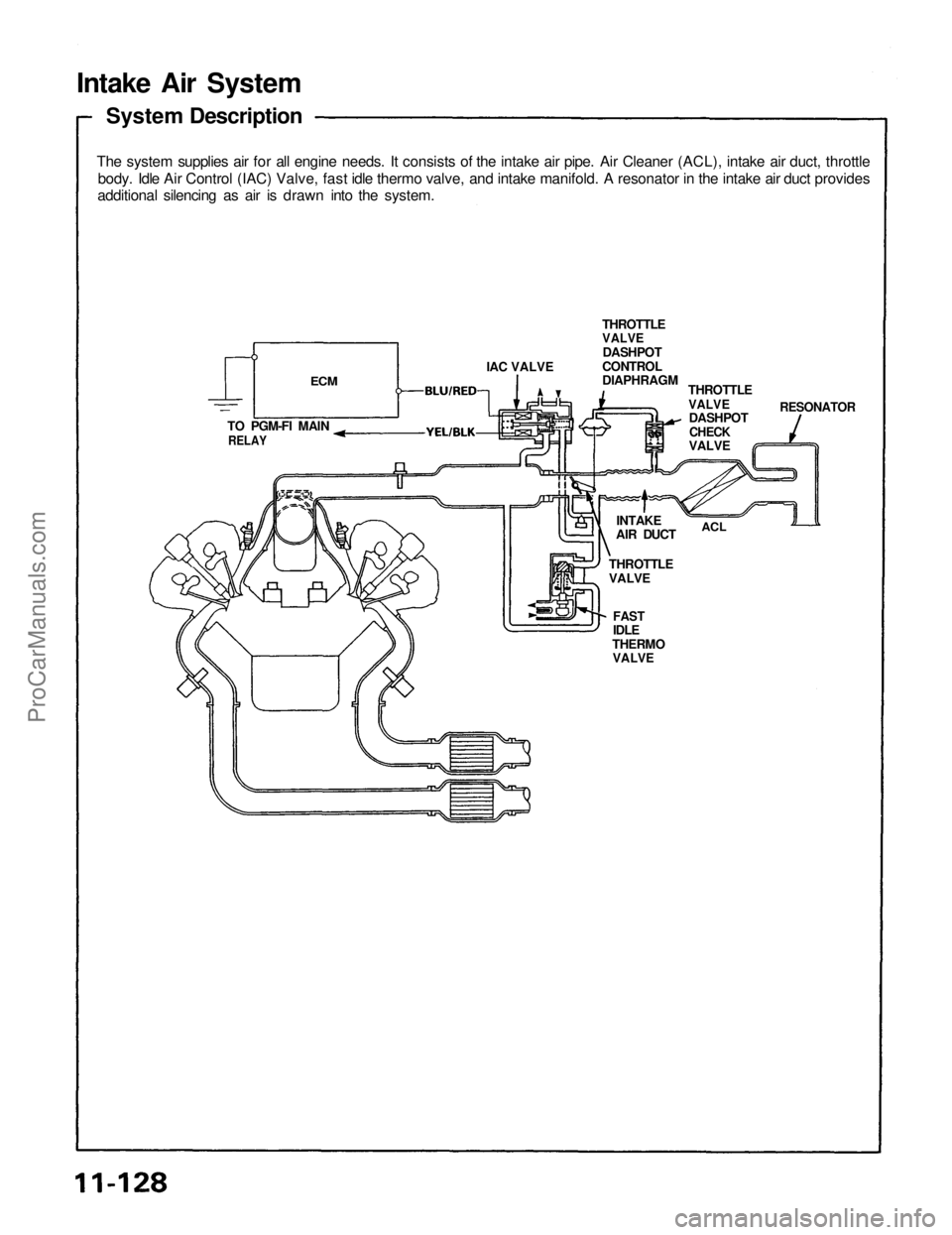

Intake Air System

System Description

The system supplies air for all engine needs. It consists of the intake air pipe. Air Cleaner (ACL), intake air duct, throttle

body. Idle Air Control (IAC) Valve, fast idle thermo valve, and intake manifold. A resonator in the intake air duct provides

additional silencing as air is drawn into the system.

FAST

IDLE

THERMO

VALVE

ECM

IAC VALVE

TO PGM-FI MAIN

RELAY

THROTTLE

VALVE

INTAKE

AIR DUCT

ACL

THROTTLE

VALVE

DASHPOT

CONTROL

DIAPHRAGM

THROTTLE

VALVE

RESONATOR

DASHPOT

CHECK

VALVEProCarManuals.com

Page 1127 of 1640

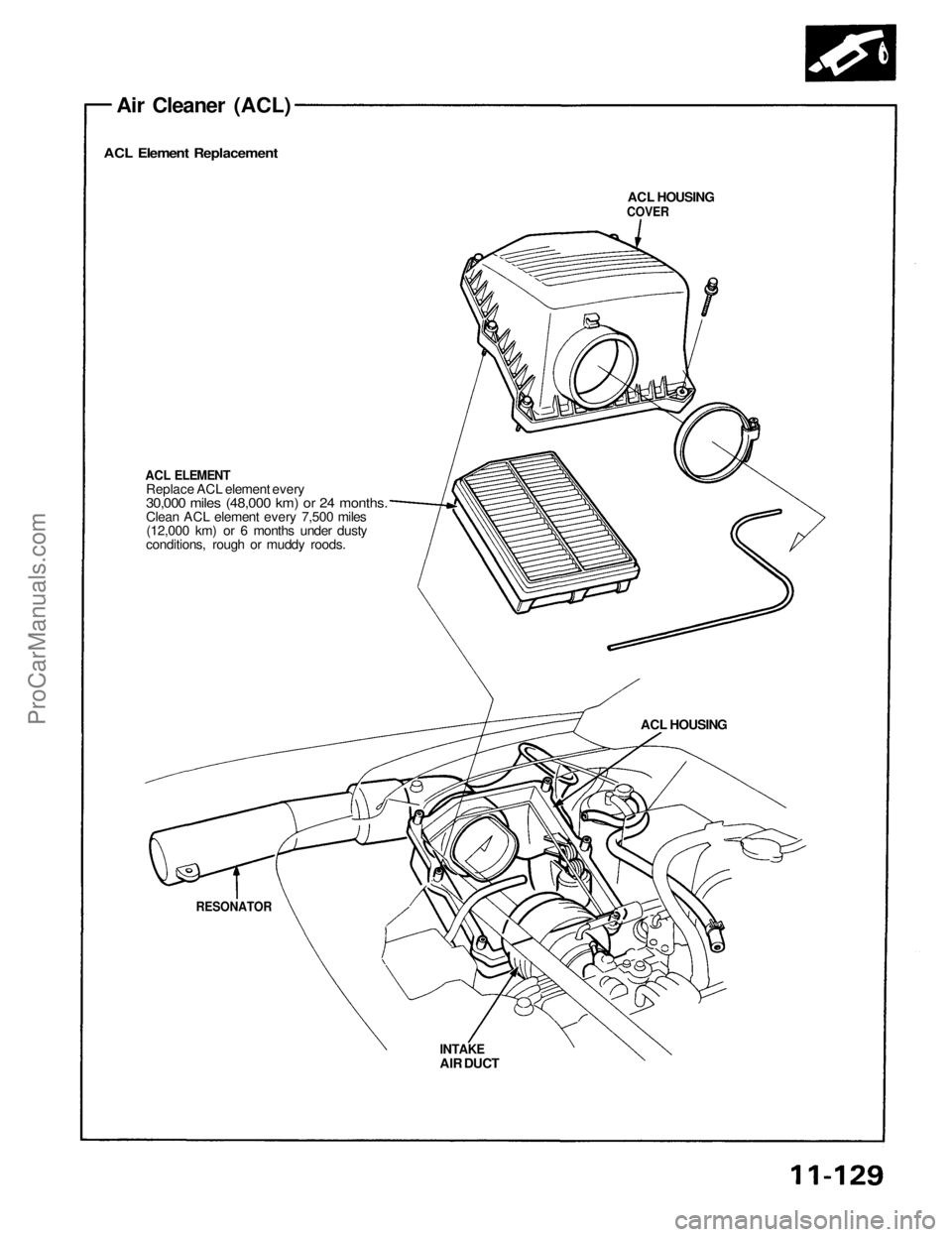

Air Cleaner (ACL)

ACL Element Replacement

ACL HOUSING

COVER

ACL ELEMENT

Replace ACL element every

30,000 miles (48,000 km) or 24 months.

Clean ACL element every 7,500 miles

(12,000 km) or 6 months under dusty

conditions, rough or muddy roods.

INTAKE

AIR DUCT

RESONATOR

ACL HOUSINGProCarManuals.com

Page 1128 of 1640

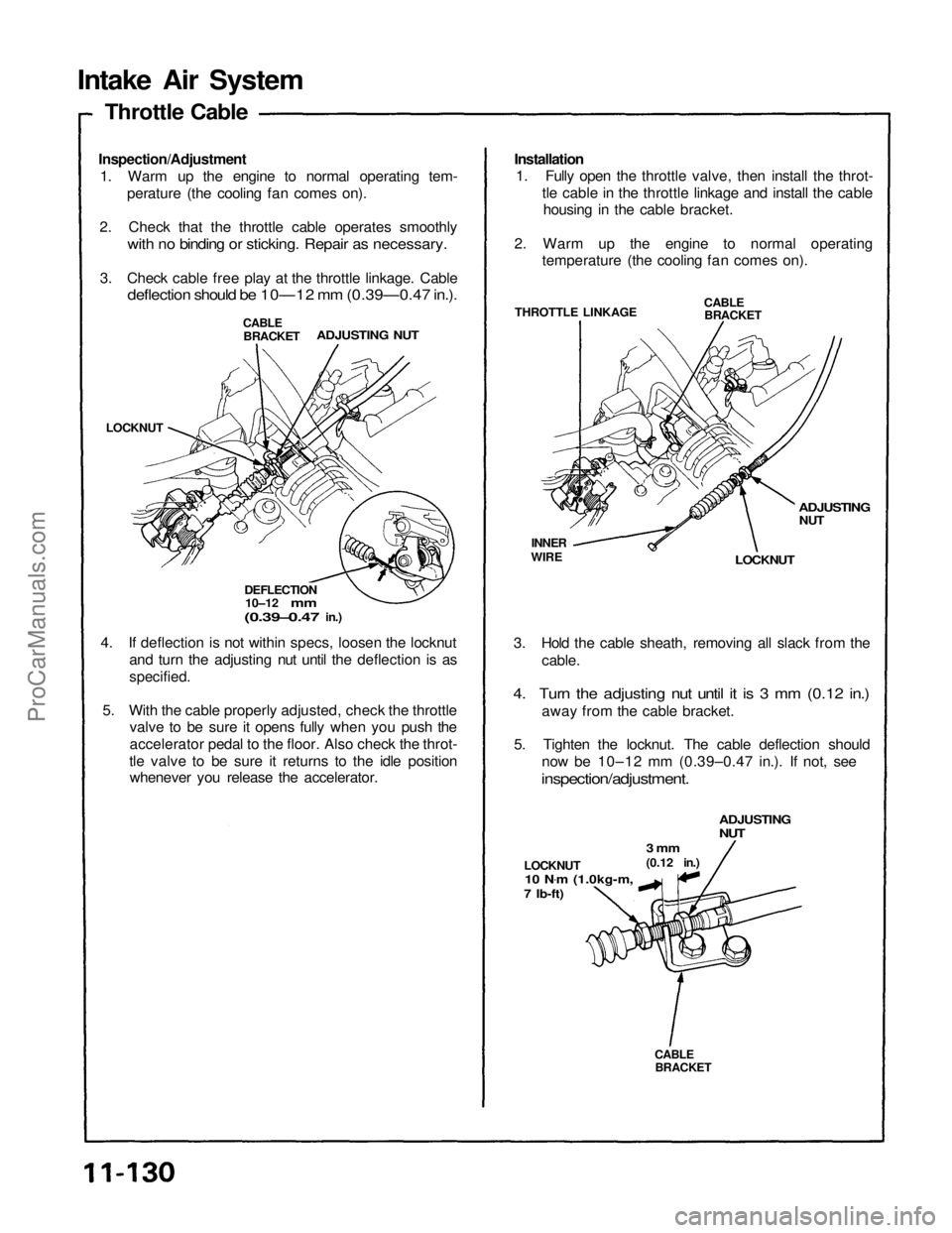

Intake Air System

Inspection/Adjustment

1. Warm up the engine to normal operating tem- perature (the cooling fan comes on).

2. Check that the throttle cable operates smoothly

with no binding or sticking. Repair as necessary.

3. Check cable free play at the throttle linkage. Cable

deflection should be 10—12 mm (0.39—0.47 in.).

Installation

1. Fully open the throttle valve, then install the throt-

tle cable in the throttle linkage and install the cablehousing in the cable bracket.

2. Warm up the engine to normal operating temperature (the cooling fan comes on).

4. If deflection is not within specs, loosen the locknut and turn the adjusting nut until the deflection is as

specified.

5. With the cable properly adjusted, check the throttle valve to be sure it opens fully when you push the

accelerator pedal to the floor. Also check the throt-

tle valve to be sure it returns to the idle position whenever you release the accelerator. 3. Hold the cable sheath, removing all slack from the

cable.

4. Turn the adjusting nut until it is 3 mm (0.12 in.)

away from the cable bracket.

5. Tighten the locknut. The cable deflection should now be 10–12 mm (0.39–0.47 in.). If not, see

inspection/adjustment.

CABLE

BRACKET

LOCKNUT

10 N .

m (1.0kg-m,

7 Ib-ft)

3 mm

(0.12 in.)

ADJUSTING

NUT

DEFLECTION

10–12

mm

(0.39–0.47

in.)

ADJUSTING NUT

CABLE

BRACKET

LOCKNUT

INNER

WIRE

THROTTLE LINKAGE

LOCKNUT

ADJUSTING

NUT

CABLE

BRACKET

Throttle CableProCarManuals.com

Page 1129 of 1640

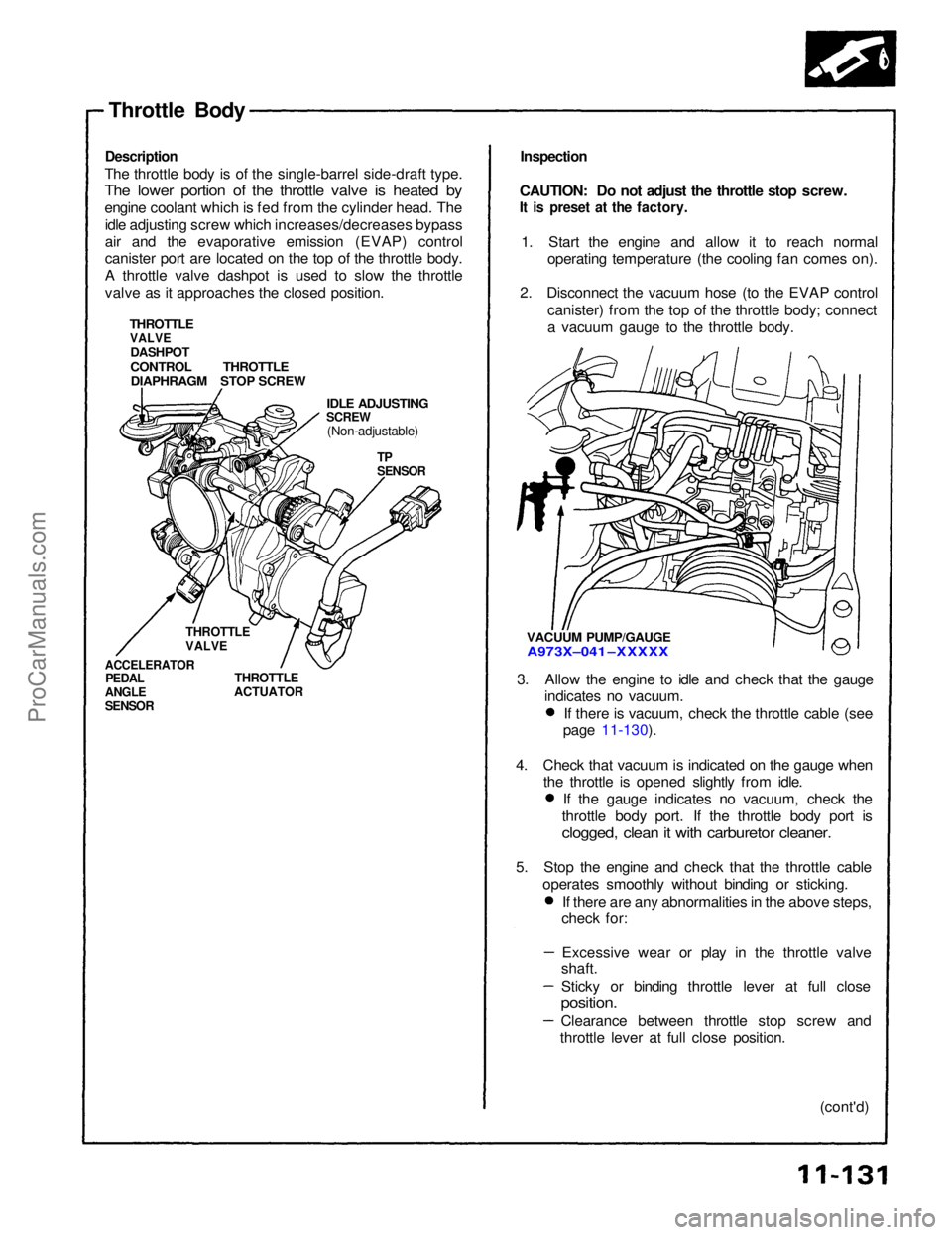

Throttle Bod y

Descriptio n

The throttl e bod y i s o f th e single-barre l side-draf t type .

The lowe r portio n o f th e throttl e valv e i s heate d b y

engin e coolan t whic h is fe d fro m th e cylinde r head . Th e

idl e adjustin g scre w whic h increases/decrease s bypas s

ai r an d th e evaporativ e emissio n (EVAP ) contro l

caniste r por t ar e locate d o n th e to p o f th e throttl e body .

A throttl e valv e dashpo t i s use d t o slo w th e throttl e

valv e a s i t approache s th e close d position .

THROTTL EVALVEDASHPO TCONTRO L THROTTL E

DIAPHRAG M STO P SCRE W

Inspectio n

CAUTION : D o no t adjus t th e throttl e sto p screw .

It i s prese t a t th e factory .

1. Star t th e engin e an d allo w i t t o reac h norma l

operatin g temperatur e (th e coolin g fa n come s on) .

2 . Disconnec t th e vacuu m hos e (t o th e EVA P contro l

canister ) fro m th e to p o f th e throttl e body ; connec t

a vacuu m gaug e t o th e throttl e body .

3 . Allo w th e engin e t o idl e an d chec k tha t th e gaug e

indicate s n o vacuum .

IDLE ADJUSTIN GSCREW(Non-adjustable )

TPSENSO R

THROTTL EACTUATO R

THROTTLEVALVE

ACCELERATO RPEDALANGL ESENSO R

VACUU M PUMP/GAUG EA973X–041 –XXXX X

If ther e is vacuum , chec k th e throttl e cabl e (se e

pag e 11-130 ).

4 . Chec k tha t vacuu m is indicate d o n th e gaug e whe n

th e throttl e i s opene d slightl y fro m idle .

I f th e gaug e indicate s n o vacuum , chec k th e

throttl e bod y port . I f th e throttl e bod y por t i s

clogged , clea n it wit h carbureto r cleaner .

5. Sto p th e engin e an d chec k tha t th e throttl e cabl e

operate s smoothl y withou t bindin g o r sticking .

I f ther e ar e an y abnormalitie s in th e abov e steps ,

chec k for :

Excessiv e wea r o r pla y i n th e throttl e valv e

shaft .

Stick y o r bindin g throttl e leve r a t ful l clos e

position .

Clearanc e betwee n throttl e sto p scre w an d

throttl e leve r a t ful l clos e position .

(cont'd )

ProCarManuals.com

Page 1130 of 1640

Intake Air System

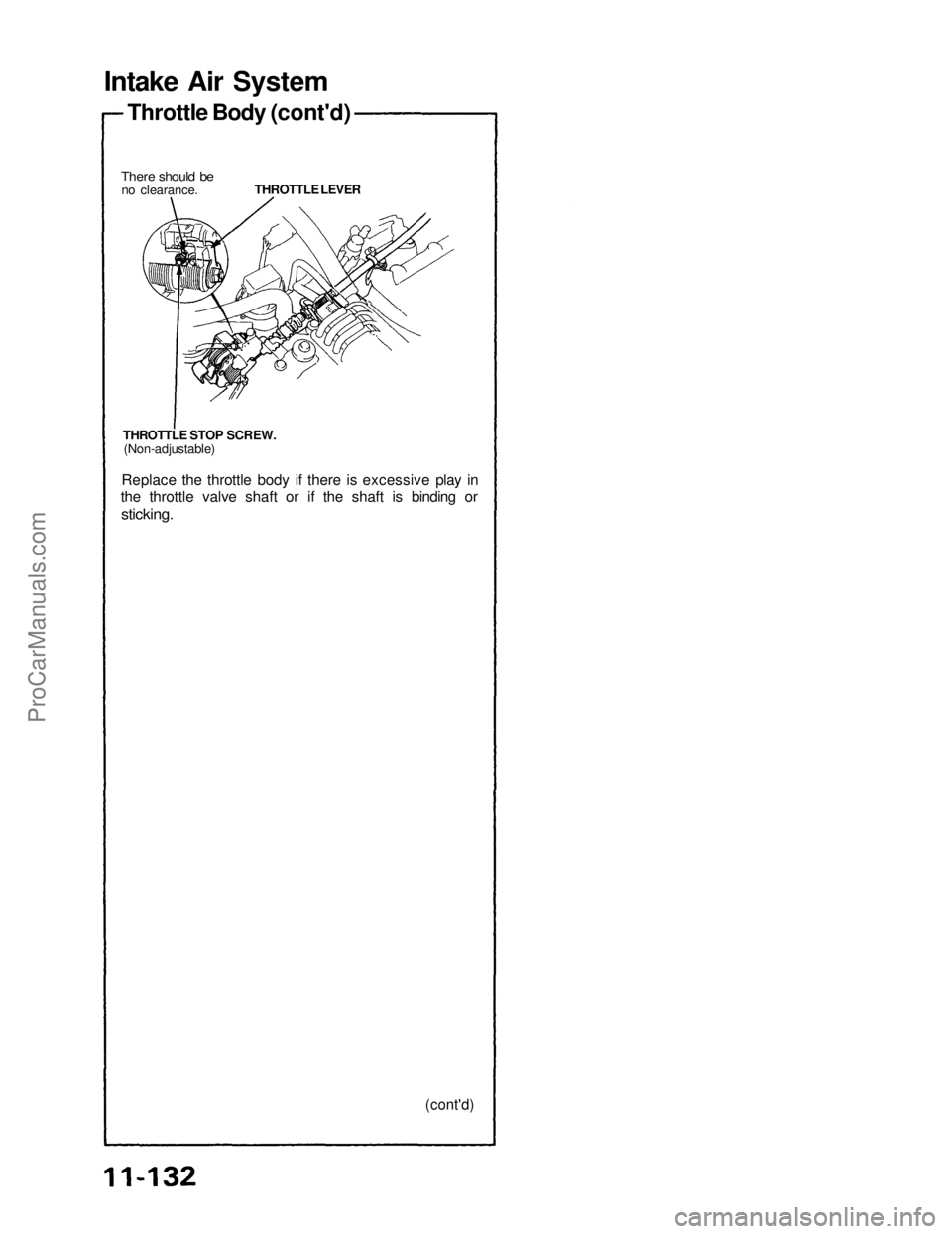

There should be

no clearance.

Throttle Body (cont'd)

THROTTLE LEVER

THROTTLE STOP SCREW.

(Non-adjustable)

Replace the throttle body if there is excessive play in

the throttle valve shaft or if the shaft is binding or

sticking.

(cont'd)ProCarManuals.com