ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1161 of 1640

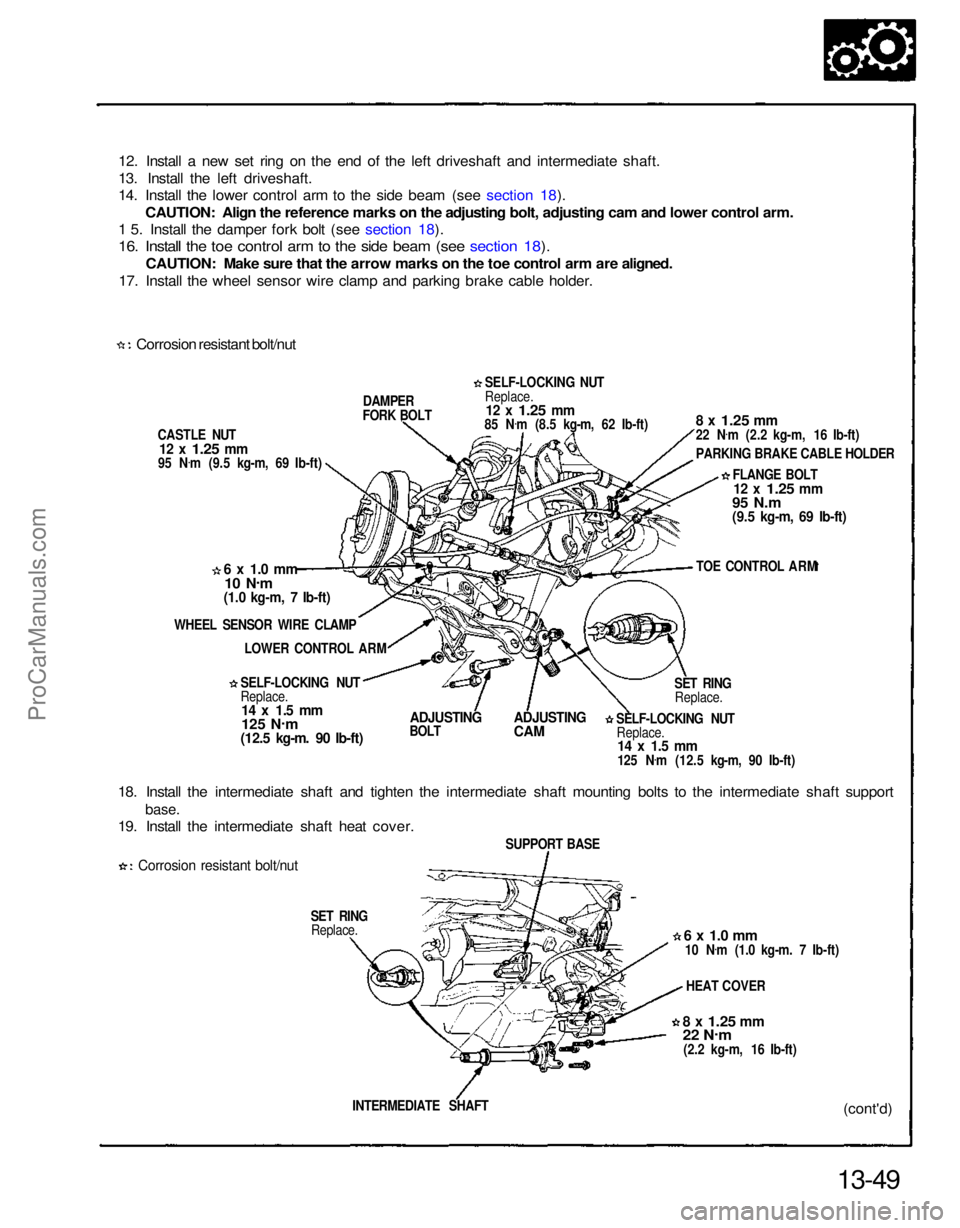

12. Install a new set ring on the end of the left driveshaft and intermediate shaft.

13. Install the left driveshaft.

14. Install the lower control arm to the side beam (see section 18).

CAUTION: Align the reference marks on the adjusting bolt, adjusting cam and lower control arm.

1 5. Install the damper fork bolt (see section 18).

16. Install the toe control arm to the side beam (see section 18).

CAUTION: Make sure that the arrow marks on the toe control arm are aligned.

17. Install the wheel sensor wire clamp and parking brake cable holder.

Corrosion resistant bolt/nut

CASTLE NUT

12 x

1.25

mm

95 N .

m (9.5 kg-m, 69 Ib-ft) DAMPER

FORK BOLT

6 x 1.0 mm

10 N .

m

(1.0 kg-m, 7 Ib-ft)

WHEEL SENSOR WIRE CLAMP LOWER CONTROL ARM

SELF-LOCKING NUT

Replace.

14 x 1.5 mm

125 N .

m

(12.5 kg-m. 90 Ib-ft)

ADJUSTING

BOLT

ADJUSTING

CAM

18. Install the intermediate shaft and tighten the intermediate shaft mounting bolts to the intermediate shaft support

base.

19. Install the intermediate shaft heat cover.

Corrosion resistant bolt/nut

SET RINGReplace.

13-49(cont'd)

INTERMEDIATE SHAFT

8 x

1.25

mm

22 N

.

m

(2.2 kg-m, 16 Ib-ft) HEAT COVER

6 x 1.0 mm

10 N .

m (1.0 kg-m. 7 Ib-ft)

SUPPORT BASE SELF-LOCKING NUT

Replace.

14 x 1.5 mm

125 N .

m (12.5 kg-m, 90 Ib-ft) SET RING

Replace. TOE CONTROL ARM

FLANGE BOLT

12 x

1.25

mm

95 N.m

(9.5 kg-m, 69 Ib-ft)

8 x

1.25

mm

22 N

.

m (2.2 kg-m, 16 Ib-ft)

PARKING BRAKE CABLE HOLDER

SELF-LOCKING NUT

Replace.

12 x

1.25

mm

85 N .

m (8.5 kg-m, 62 Ib-ft)ProCarManuals.com

Page 1162 of 1640

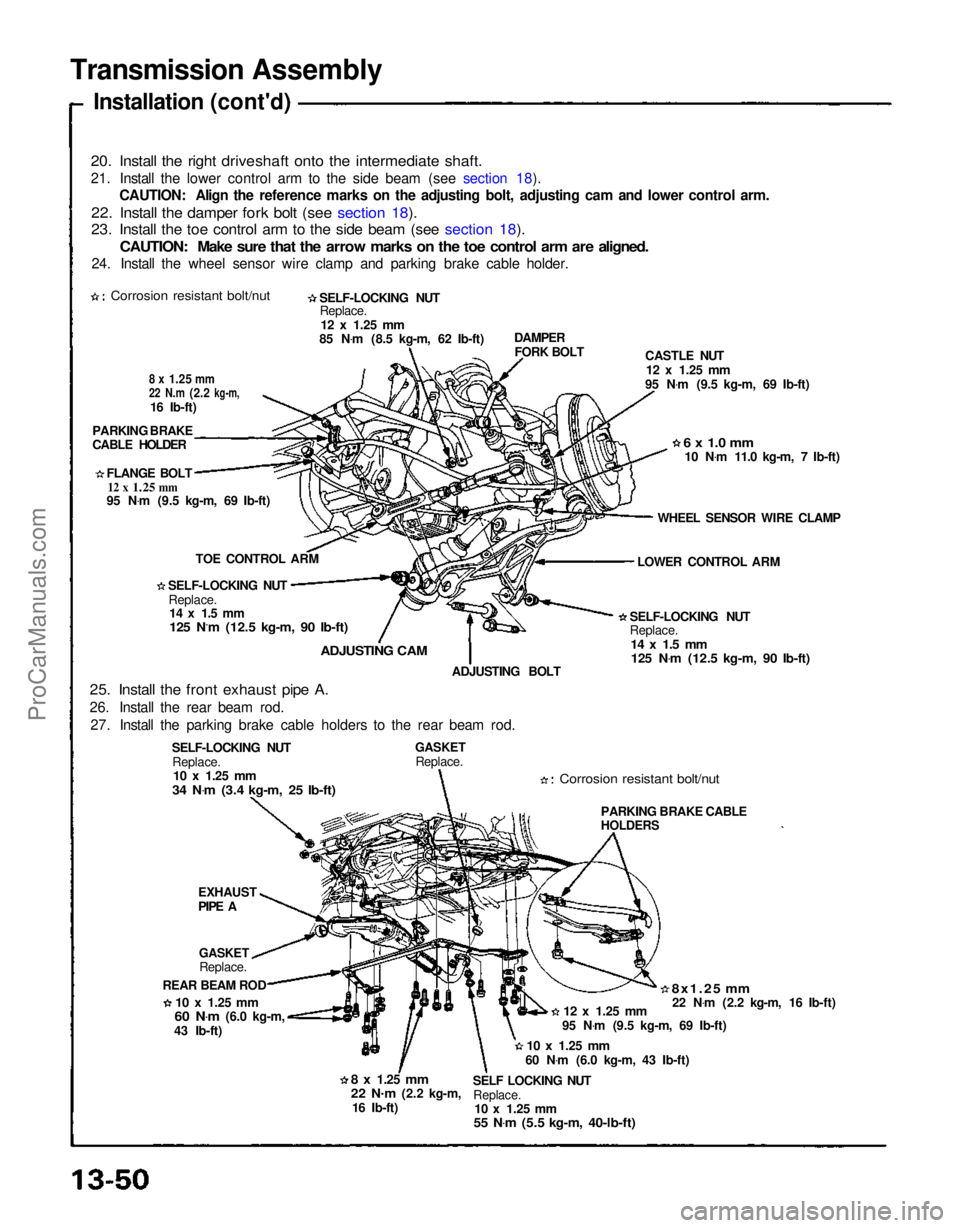

Transmission Assembly

Installation (cont'd)

20. Install the right driveshaft onto the intermediate shaft.

21. Install the lower control arm to the side beam (see section 18). CAUTION: Align the reference marks on the adjusting bolt, adjusting cam and lower control arm.

22. Install the damper fork bolt (see section 18).

23. Install the toe control arm to the side beam (see section 18).

CAUTION: Make sure that the arrow marks on the toe control arm are aligned.

24. Install the wheel sensor wire clamp and parking brake cable holder.

Corrosion resistant bolt/nut

SELF-LOCKING NUT

Replace.

12 x

1.25

mm

85 N .

m (8.5 kg-m, 62 Ib-ft)

8 x

1.25

mm

22 N.m

(2.2

kg-m,

16 Ib-ft)

PARKING BRAKE

CABLE HOLDER

FLANGE BOLT

12 x

1.25

mm

95 N .

m (9.5 kg-m, 69 Ib-ft)

TOE CONTROL ARM

SELF-LOCKING NUT Replace.

14 x 1.5 mm

125 N.m (12.5 kg-m, 90 Ib-ft)

ADJUSTING CAM

25. Install the front exhaust pipe A.

26. Install the rear beam rod. 27. Install the parking brake cable holders to the rear beam rod. ADJUSTING BOLT

SELF-LOCKING NUT Replace.

10 x

1.25

mm

34 N .

m (3.4 kg-m, 25 Ib-ft)

GASKET

Replace.

Corrosion resistant bolt/nut

SELF-LOCKING NUT

Replace.

14 x 1.5 mm

125 N .

m (12.5 kg-m, 90 Ib-ft)

LOWER CONTROL ARM

WHEEL SENSOR WIRE CLAMP

6 x 1.0 mm

10 N .

m 11.0 kg-m, 7 Ib-ft)

CASTLE NUT

12 x

1.25

mm

95 N .

m (9.5 kg-m, 69 Ib-ft)

DAMPER

FORK BOLT

EXHAUST

PIPE A

GASKET

Replace.

REAR BEAM ROD

10 x

1.25

mm

60 N .

m

(6.0 kg-m,

43 Ib-ft)

8 x

1.25

mm

22 N.

m

(2.2 kg-m,

16 Ib-ft) SELF LOCKING NUT

Replace.

10 x

1.25

mm

55 N .

m (5.5 kg-m, 40-lb-ft)

10 x

1.25

mm

60 N .

m (6.0 kg-m, 43 Ib-ft) 95 N

.

m (9.5 kg-m, 69 Ib-ft)

12 x

1.25

mm

8x1.25 mm

22 N .

m (2.2 kg-m, 16 Ib-ft)

PARKING BRAKE CABLE

HOLDERSProCarManuals.com

Page 1163 of 1640

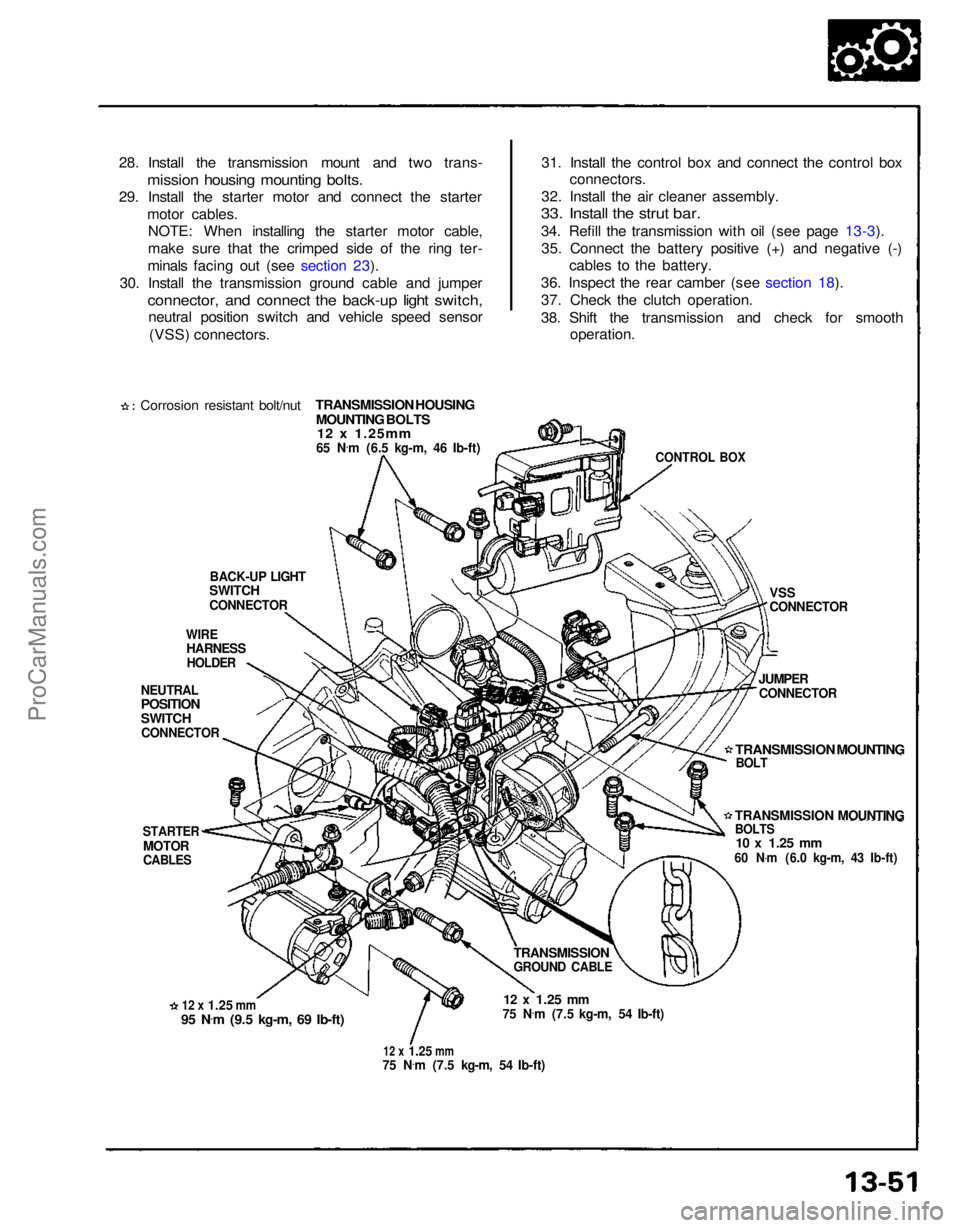

28. Install the transmission mount and two trans-

mission housing mounting bolts.

29. Install the starter motor and connect the starter

motor cables.NOTE: When installing the starter motor cable,

make sure that the crimped side of the ring ter-

minals facing out (see section 23).

30. Install the transmission ground cable and jumper

connector, and connect the back-up light switch,

neutral position switch and vehicle speed sensor

(VSS) connectors.

Corrosion resistant bolt/nut

TRANSMISSION HOUSING

MOUNTING BOLTS12 x 1.25mm

65 N

.

m (6.5 kg-m, 46 Ib-ft)

BACK-UP LIGHT

SWITCH

CONNECTOR

WIRE

HARNESS

HOLDER

NEUTRAL

POSITION

SWITCH

CONNECTOR

STARTER

MOTOR

CABLES

12 x

1.25

mm

95 N

.

m (9.5 kg-m, 69 Ib-ft)

12 x

1.25

mm

75 N

.

m (7.5 kg-m, 54 Ib-ft)

12 x

1.25

mm

75 N .

m (7.5 kg-m, 54 Ib-ft)

TRANSMISSION

GROUND CABLE

TRANSMISSION MOUNTING

BOLTS

10 x

1.25

mm

60 N .

m (6.0 kg-m, 43 Ib-ft)

JUMPER

CONNECTOR

VSS

CONNECTOR

CONTROL BOX

31. Install the control box and connect the control box

connectors.

32. Install the air cleaner assembly.

33. Install the strut bar.

34. Refill the transmission with oil (see page 13-3).

35. Connect the battery positive (+) and negative (-) cables to the battery.

36. Inspect the rear camber (see section 18).

37. Check the clutch operation.

38. Shift the transmission and check for smooth operation.

TRANSMISSION MOUNTING

BOLTProCarManuals.com

Page 1164 of 1640

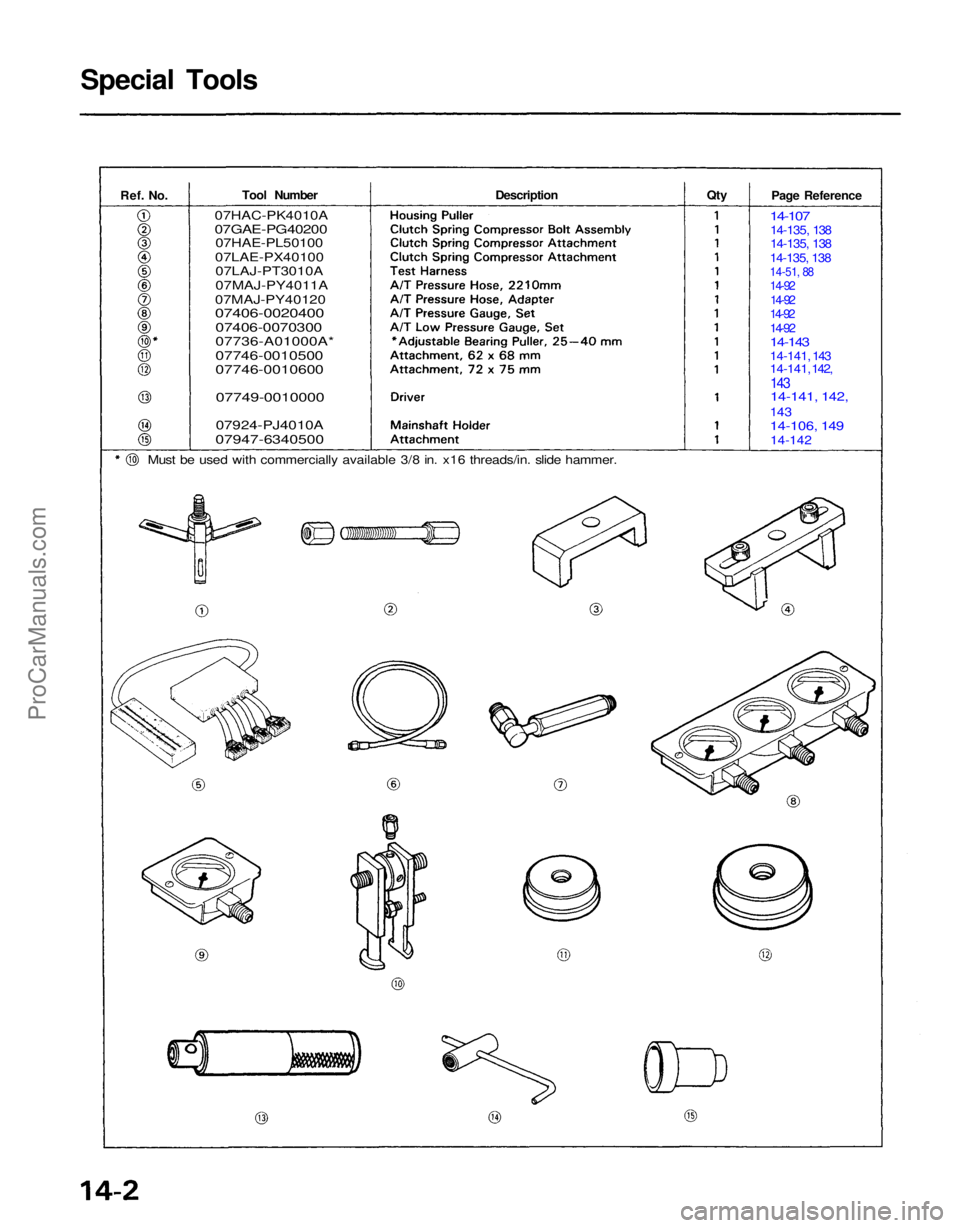

Ref.

No.

Tool Number

Description

Must be used with commercially available 3/8 in. x16 threads/in. slide hammer.

Special Tools

Page Reference

14-107

14-135, 138

14-135, 138

14-135, 138

14-51, 88

14-92

14-92

14-92

14-92

14-143

14-141, 143

14-141, 142,

143

14-141, 142,

143

14-106, 149

14-142

07HAC-PK4010A

07GAE-PG40200

07HAE-PL50100

07LAE-PX40100 07LAJ-PT3010A

07MAJ-PY4011A

07MAJ-PY40120

07406-0020400

07406-0070300

07736-A01000A*

07746-0010500

07746-0010600

07749-0010000

07924-PJ4010A

07947-6340500

QtyProCarManuals.com

Page 1165 of 1640

Description

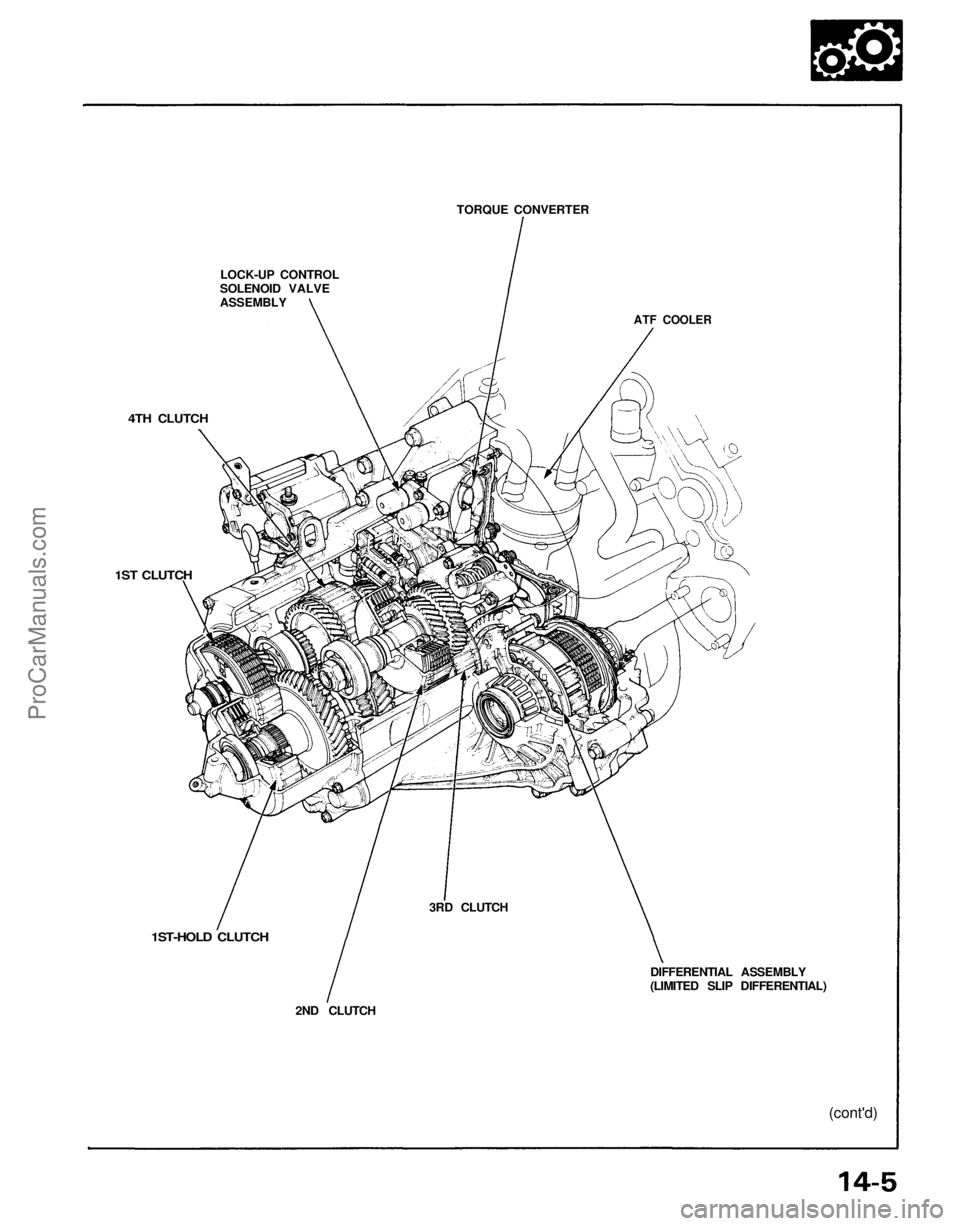

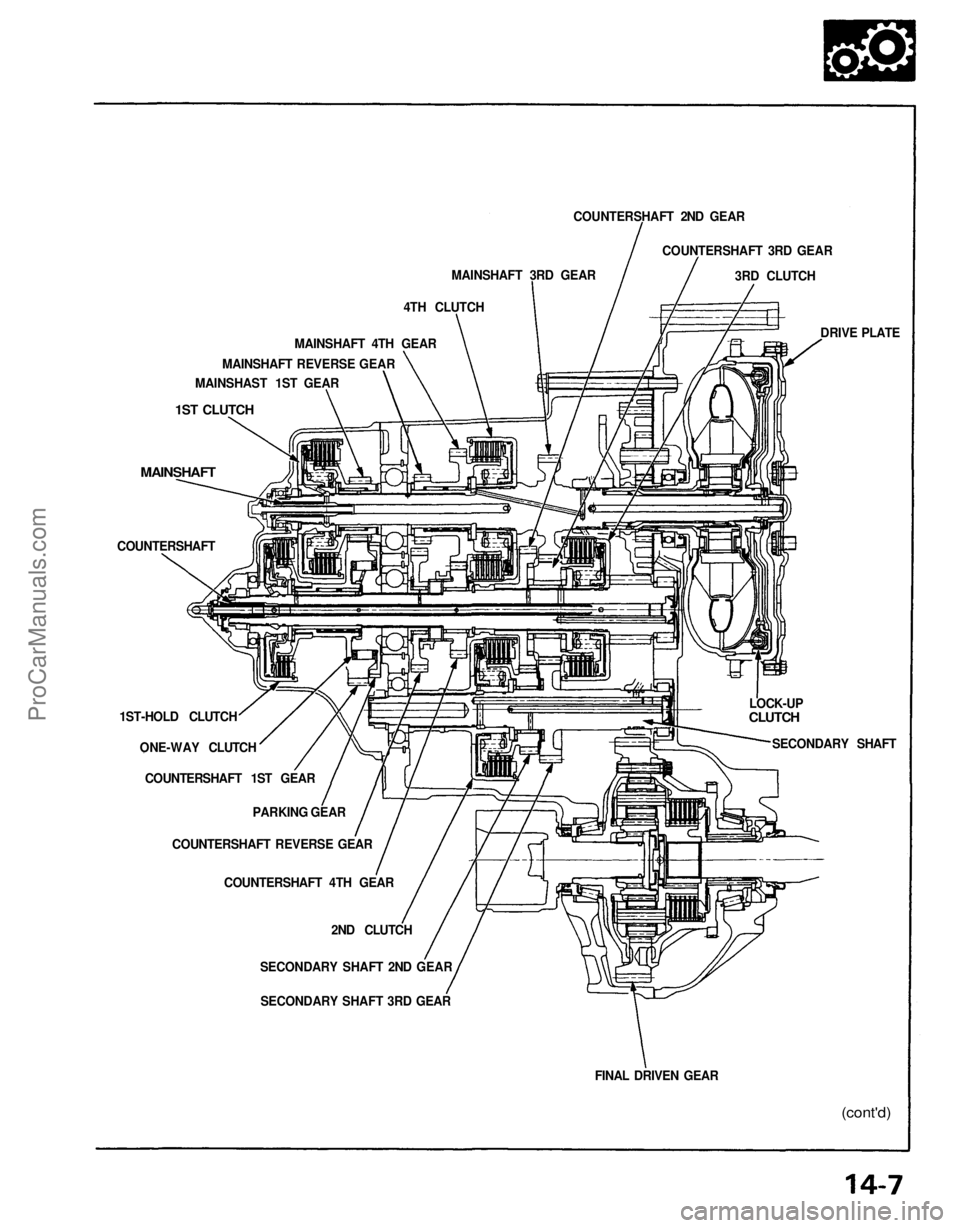

The automatic transmission is a combination of a 3-element torque converter and a triple-shaft electronically controlled

automatic transmission which provides 4 speeds forward and 1 in reverse. The entire unit is positioned in line with the

engine.

TORQUE CONVERTER, GEARS AND CLUTCHES

The torque converter consists of a pump, turbine and stator, assembled in a single unit.

They are connected to the engine crankshaft so they turn together as a unit as the engine turns.

Around the outside of the torque converter is a ring gear which meshes with the starter pinion when the engine is being

started. The entire torque converter assembly serves as a flywheel while transmitting power to the transmission mainshaft.

The transmission has three parallel shafts, the mainshaft, the countershaft, and the secondary shaft. The mainshaft is

in line with the engine crankshaft.

The mainshaft includes the clutches for 1st, and 4th, and gears for 3rd, 4th, Reverse and 1st (3rd gear is integral with

the mainshaft, while reverse gear is integral with 4th gear).

The countershaft includes the clutches for 1st-Hold and 3rd, and gears for 2nd, 3rd, 4th, Reverse and 1st.

The secondary shaft includes the 2nd clutch and gears for 2nd and 3rd.

The 4th and reverse gears can be locked to the countershaft at its center, providing 4th gear or Reverse, depending on

which way the selector is moved.

The gears on the mainshaft and secondary shaft are in constant mesh with those on the countershaft.

When certain combinations of gears in the transmission are engaged by clutches, power is transmitted from the main-

shaft to the countershaft to provide , , , and

ELECTRONIC CONTROL

The electronic control system consists of the Transmission Control Module (TCM), sensors, a linear solenoid and 4

solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located on the insulator center bulkhead, behind the driver's seat.

HYDRAULIC CONTROL

The valve bodies include the main valve body, secondary valve body, servo body, regulator valve body, throttle valve

body, lock-up valve body and the 2nd accumulator body.

They are bolted to the torque converter housing as an assembly.

The main valve body contains the manual valve, 1-2 shift valve, 2-3 shift valve, 3-4 shift valve, relief valve, one-way

relief valve and oil pump gears.

The secondary valve body contains the 3-2 kick-down valve, CPC (clutch pressure control) valve, 2nd orifice control

valve, 3rd orifice control valve, modulator valve, 4th exhaust valve, servo control valve, 2nd exhaust valve and 4-3 kick-

down valve.

The servo body contains the accumulator pistons and servo valve. The throttle valve body includes the throttle valve B

which is bolted onto the servo body.

The regulator valve body contains the pressure regulator valve, lock-up control valve and cooler relief valve. Fluid from

the regulator passes through the manual valve to the various control valves.

The lock-up valve body contains the lock-up timing B valve and lock-up shift valve. The 2nd accumulator body contains

the accumulator pistons and limited slip differential (LSD) relief valve.

The torque converter check valve is located in the torque converter housing, under the main valve body.

The 1st, 1st-hold, 3rd and 4th clutches receive oil from their respective feed pipes.

SHIFT CONTROL MECHANISM

Input from various sensors located throughout the car determines which shift control solenoid valve the TCM will ac-

tivate. Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This

pressurizes a line to one of the clutches, engaging that clutch and its corresponding gear.

LOCK-UP MECHANISM

In position and position in 2nd, 3rd and 4th, pressurized fluid is drained from the back of the torque converter

through an oil passage, causing the lock-up piston to be held, against the torque converter cover. As this takes place, the

mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the TCM optimizes the

timing of the lock-up mechaism.

The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B.

When lock-up control solenoid valves A and B activate, modulator pressure changes. The lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)ProCarManuals.com

Page 1166 of 1640

REVERSE,

Description

(cont'd)

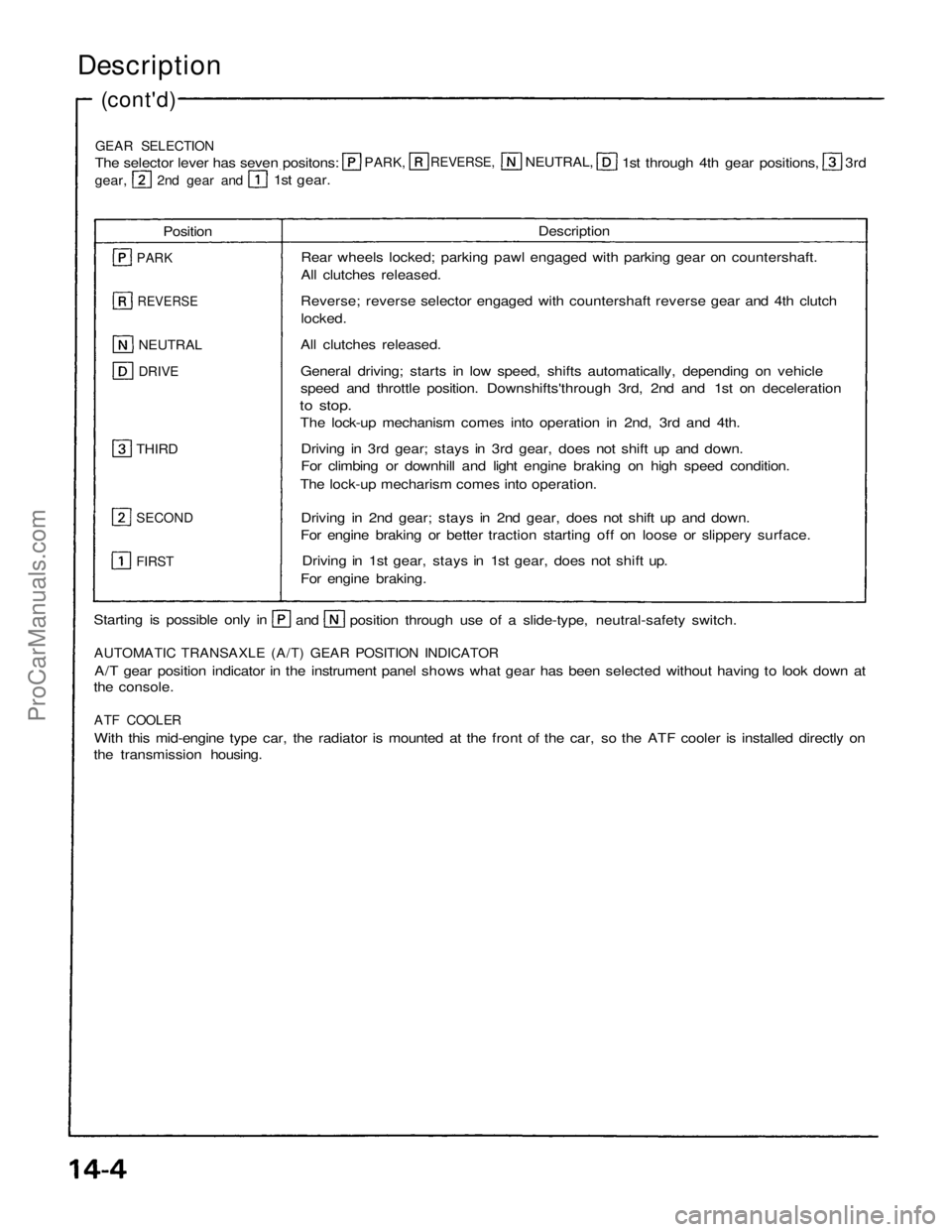

AUTOMATIC TRANSAXLE (A/T) GEAR POSITION INDICATOR

A/T gear position indicator in the instrument panel shows what gear has been selected without having to look down at

the console.

ATF COOLER

With this mid-engine type car, the radiator is mounted at the front of the car, so the ATF cooler is installed directly on

the transmission housing. Position

Description

PARK

REVERSE

NEUTRAL

DRIVE

THIRD

SECOND

FIRST

Rear wheels locked; parking pawl engaged with parking gear on countershaft.

All clutches released.

Reverse; reverse selector engaged with countershaft reverse gear and 4th clutch locked.

All clutches released.

General driving; starts in low speed, shifts automatically, depending on vehicle

speed and throttle position. Downshifts'through 3rd, 2nd and 1st on deceleration

to stop.

The lock-up mechanism comes into operation in 2nd, 3rd and 4th.

Driving in 3rd gear; stays in 3rd gear, does not shift up and down.

For climbing or downhill and light engine braking on high speed condition.

The lock-up mecharism comes into operation.

Driving in 2nd gear; stays in 2nd gear, does not shift up and down.

For engine braking or better traction starting off on loose or slippery surface.

Driving in 1st gear, stays in 1st gear, does not shift up.

For engine braking.

GEAR SELECTION

The selector lever has seven positons:

PARK,

NEUTRAL,

1st through 4th gear positions,

3rd

gear,

2nd gear and

1st gear.

Starting is possible only in

and

position through use of a slide-type, neutral-safety switch.

ProCarManuals.com

Page 1167 of 1640

LOCK-UP CONTROL

SOLENOID VALVE

ASSEMBLY

TORQUE CONVERTER

ATF COOLER

4TH CLUTCH

1ST CLUTCH

1ST-HOLD CLUTCH

2ND CLUTCH

3RD CLUTCH

DIFFERENTIAL ASSEMBLY

(LIMITED SLIP DIFFERENTIAL)

(cont'd)ProCarManuals.com

Page 1168 of 1640

Description

Clutches

The four speed automatic transmission uses hydraulically actuated clutches to engage or disengage the transmission

gears. When clutch pressure is introduced into the clutch drum, the clutch piston is applied. This presses the friction

discs and steel plates together, locking them so they don't slip. Power is then transmitted through the engaged clutch

pack to its hub-mounted gear.

Likewise, when clutch pressure is bled from the clutch pack, the piston releases the friction discs and steel plates, and

they are free to slide past each other while disengaged. This allows the gear to spin independently of its shaft, transmitting

no power.

1st Clutch

The 1st clutch engages/disengages 1st gear, and is located at the end of the mainshaft, just behind the left side cover.

The 1 st clutch is supplied clutch pressure by its oil feed pipe within the mainshaft.

1st-hold Clutch

The 1 st-hold clutch engages/disengages 1 st-hold or position, and is located at the end of the countershaft, just

behind the left side cover. The 1 st-hold clutch is supplied clutch pressure by its oil feed pipe within the countershaft.

2nd Clutch

The 2nd clutch engages/disengages 2nd gear, and is located on the secondary shaft. The 2nd clutch is supplied clutch

pressure through the secondary shaft by a circuit connected to the 2nd accumulator body.

3rd Clutch

The 3rd clutch engages/disengages 3rd gear, and is located at the end of the countershaft, opposite the left side cover.

The 3rd clutch is supplied clutch pressure by its oil feed pipe within the countershaft.

4th Clutch

The 4th clutch engages/disengages 4th gear, as well as reverse gear, and is located at the center of the mainshaft. The

4th clutch is supplied clutch pressure by its oil feed pipe within the mainshaft.

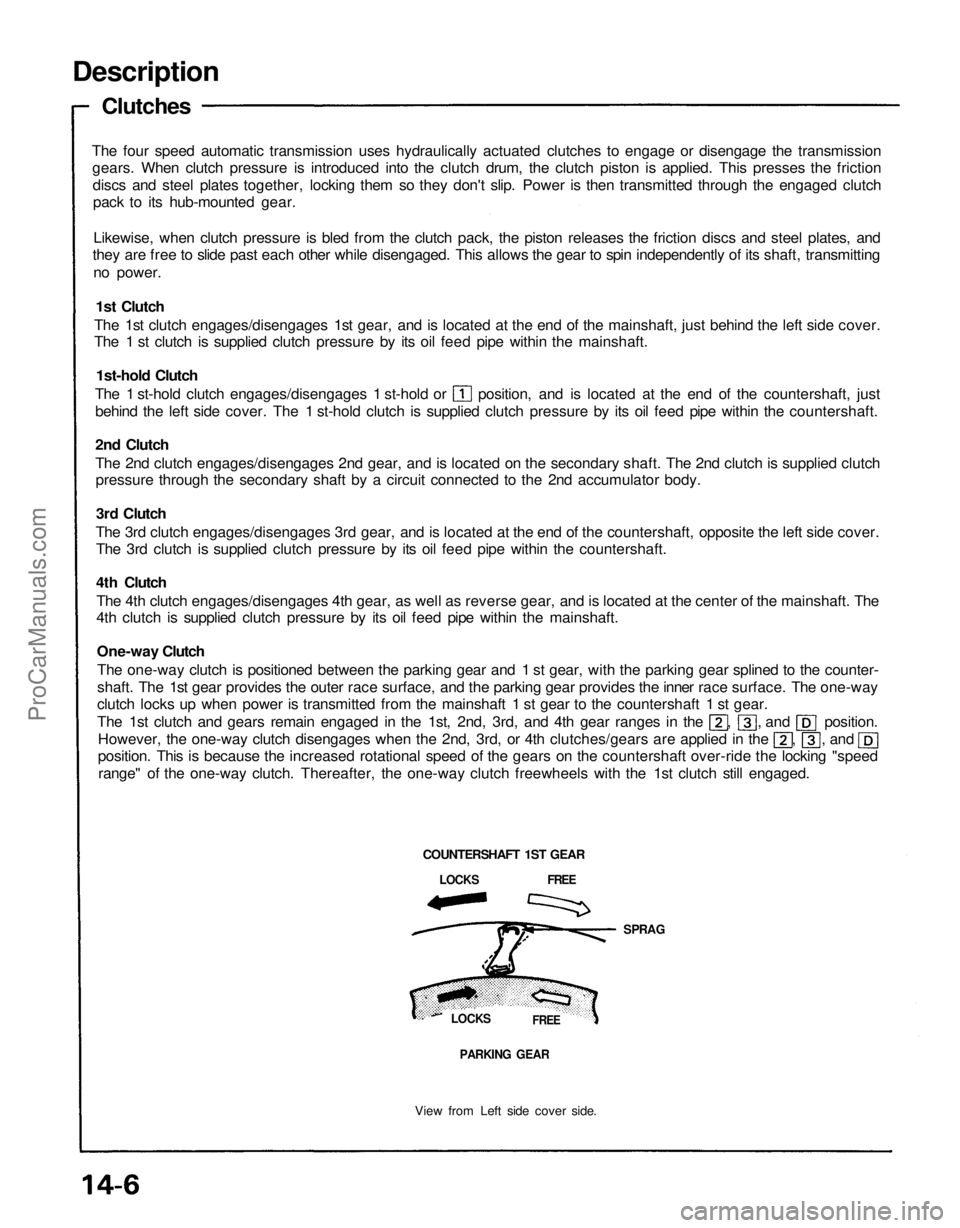

One-way Clutch

The one-way clutch is positioned between the parking gear and 1 st gear, with the parking gear splined to the counter-

shaft. The 1st gear provides the outer race surface, and the parking gear provides the inner race surface. The one-way

clutch locks up when power is transmitted from the mainshaft 1 st gear to the countershaft 1 st gear.

The 1st clutch and gears remain engaged in the 1st, 2nd, 3rd, and 4th gear ranges in the , , and position.

However, the one-way clutch disengages when the 2nd, 3rd, or 4th clutches/gears are applied in the , , and

position. This is because the increased rotational speed of the gears on the countershaft over-ride the locking "speed

range" of the one-way clutch. Thereafter, the one-way clutch freewheels with the 1st clutch still engaged.

COUNTERSHAFT 1ST GEAR

LOCKS FREE

SPRAG

LOCKS

FREE

PARKING GEAR

View from Left side cover side.ProCarManuals.com

Page 1169 of 1640

COUNTERSHAFT 2ND GEAR

COUNTERSHAFT 3RD GEAR

3RD CLUTCH

DRIVE PLATE

LOCK-UP

CLUTCH

SECONDARY SHAFT

(cont'd)

FINAL DRIVEN GEAR

SECONDARY SHAFT 2ND GEAR

SECONDARY SHAFT 3RD GEAR

2ND CLUTCH

COUNTERSHAFT 4TH GEAR

COUNTERSHAFT REVERSE GEAR

PARKING GEAR

COUNTERSHAFT 1ST GEAR

ONE-WAY CLUTCH

1ST-HOLD CLUTCH

COUNTERSHAFT

MAINSHAFT

1ST CLUTCH

MAINSHAST 1ST GEAR

MAINSHAFT REVERSE GEAR

MAINSHAFT 4TH GEAR

4TH CLUTCH

MAINSHAFT 3RD GEARProCarManuals.com

Page 1170 of 1640

Description

Clutches (cont'd)

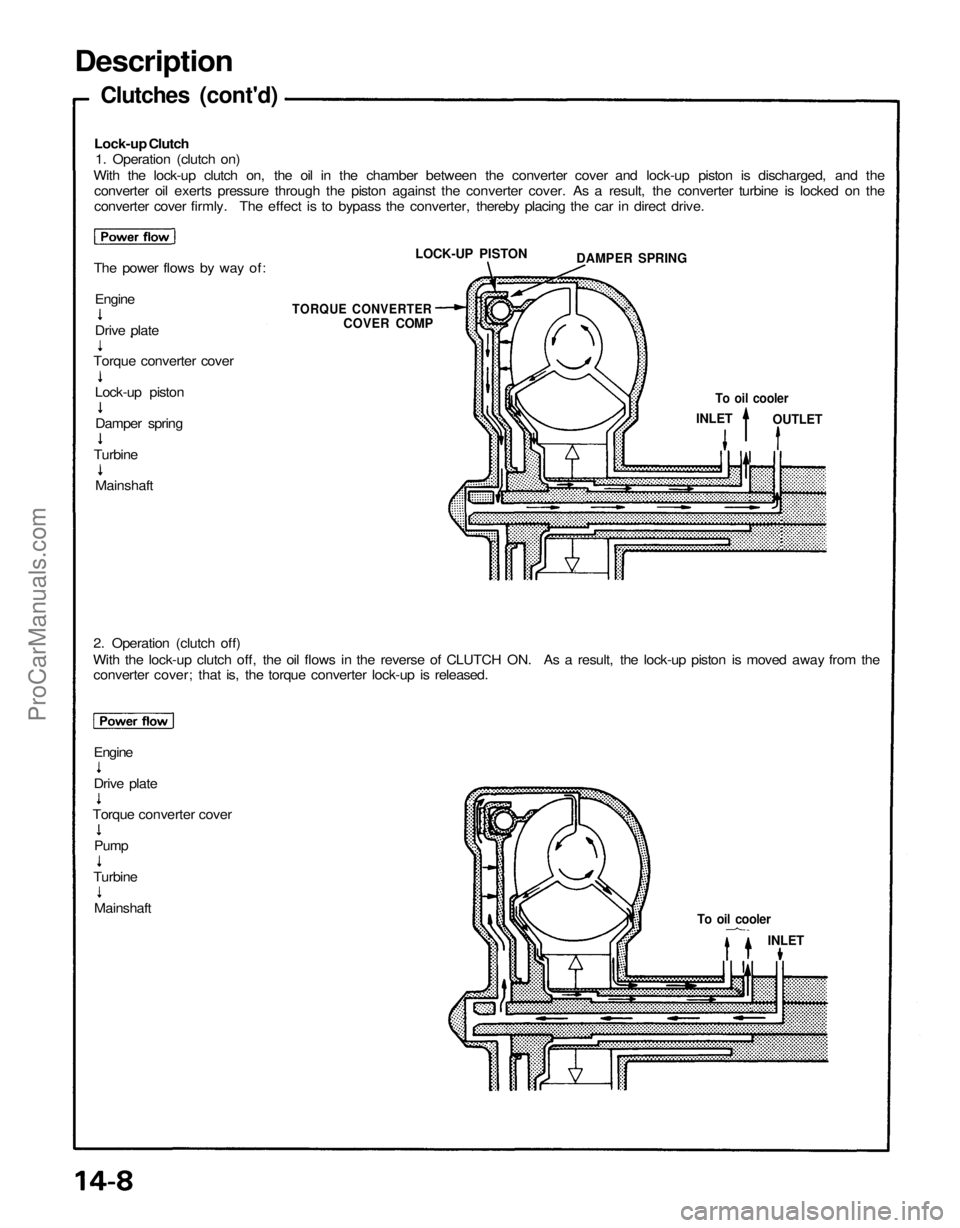

Lock-up Clutch

1. Operation (clutch on)

With the lock-up clutch on, the oil in the chamber between the converter cover and lock-up piston is discharged, and the

converter oil exerts pressure through the piston against the converter cover. As a result, the converter turbine is locked on the

converter cover firmly. The effect is to bypass the converter, thereby placing the car in direct drive.

The power flows by way of:

2. Operation (clutch off)

With the lock-up clutch off, the oil flows in the reverse of CLUTCH ON. As a result, the lock-up piston is moved away from the

converter cover; that is, the torque converter lock-up is released.

Engine

To oil cooler

INLET

To oil cooler

INLET

OUTLET

TORQUE CONVERTER

COVER COMP

LOCK-UP PISTON

DAMPER SPRING

Engine

Drive plate

Torque converter cover

Lock-up piston

Damper spring

Turbine

Mainshaft

Drive plate

Torque converter cover

Pump

Turbine

MainshaftProCarManuals.com