engine ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1335 of 1640

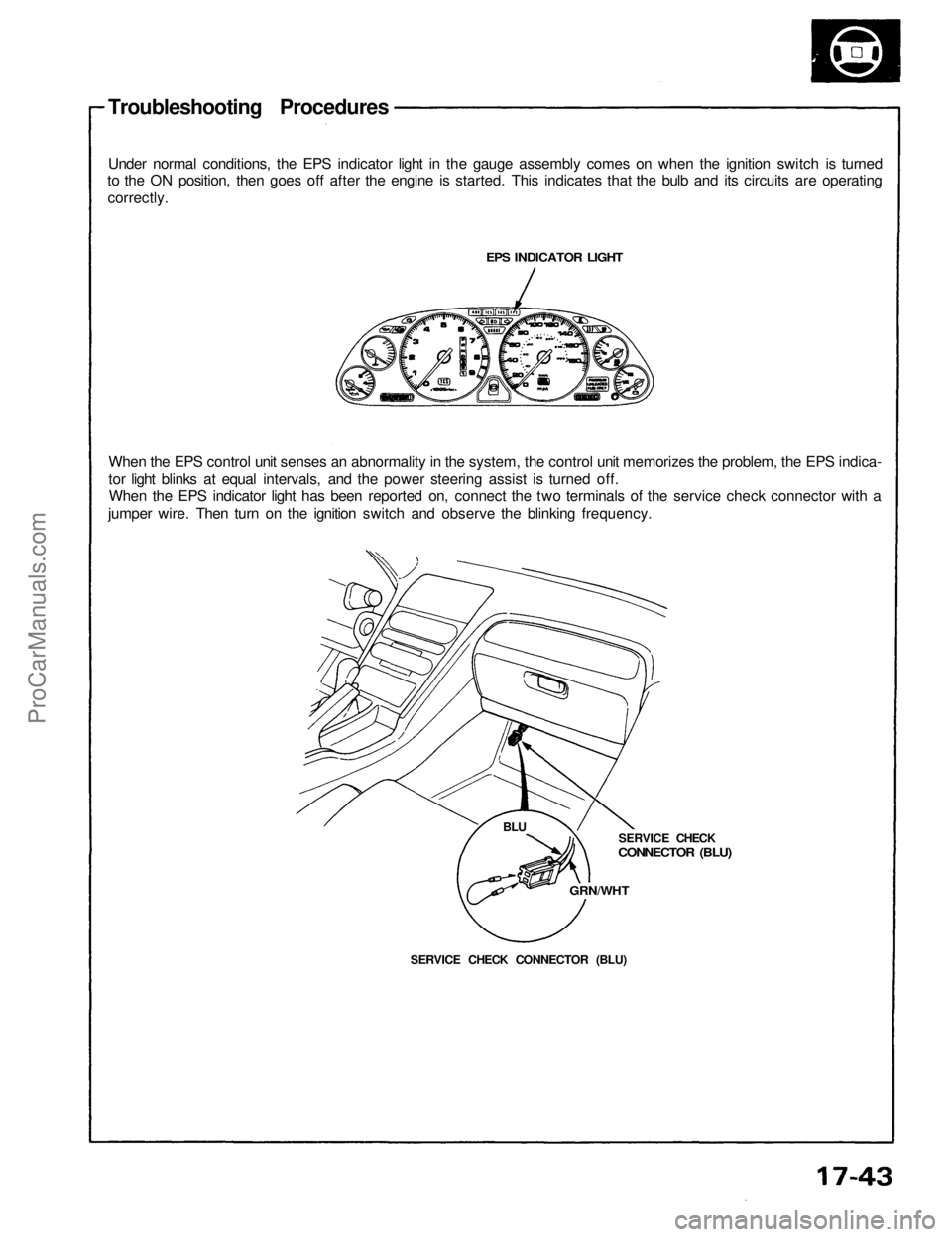

Troubleshooting Procedures

Under normal conditions, the EPS indicator light in the gauge assembly comes on when the ignition switch is turned

to the ON position, then goes off after the engine is started. This indicates that the bulb and its circuits are operating

correctly.

EPS INDICATOR LIGHT

When the EPS control unit senses an abnormality in the system, the control unit memorizes the problem, the EPS indica-

tor light blinks at equal intervals, and the power steering assist is turned off.

When the EPS indicator light has been reported on, connect the two terminals of the service check connector with a

jumper wire. Then turn on the ignition switch and observe the blinking frequency.

SERVICE CHECK

CONNECTOR (BLU)

GRN/WHT

SERVICE CHECK CONNECTOR (BLU)

BLUProCarManuals.com

Page 1361 of 1640

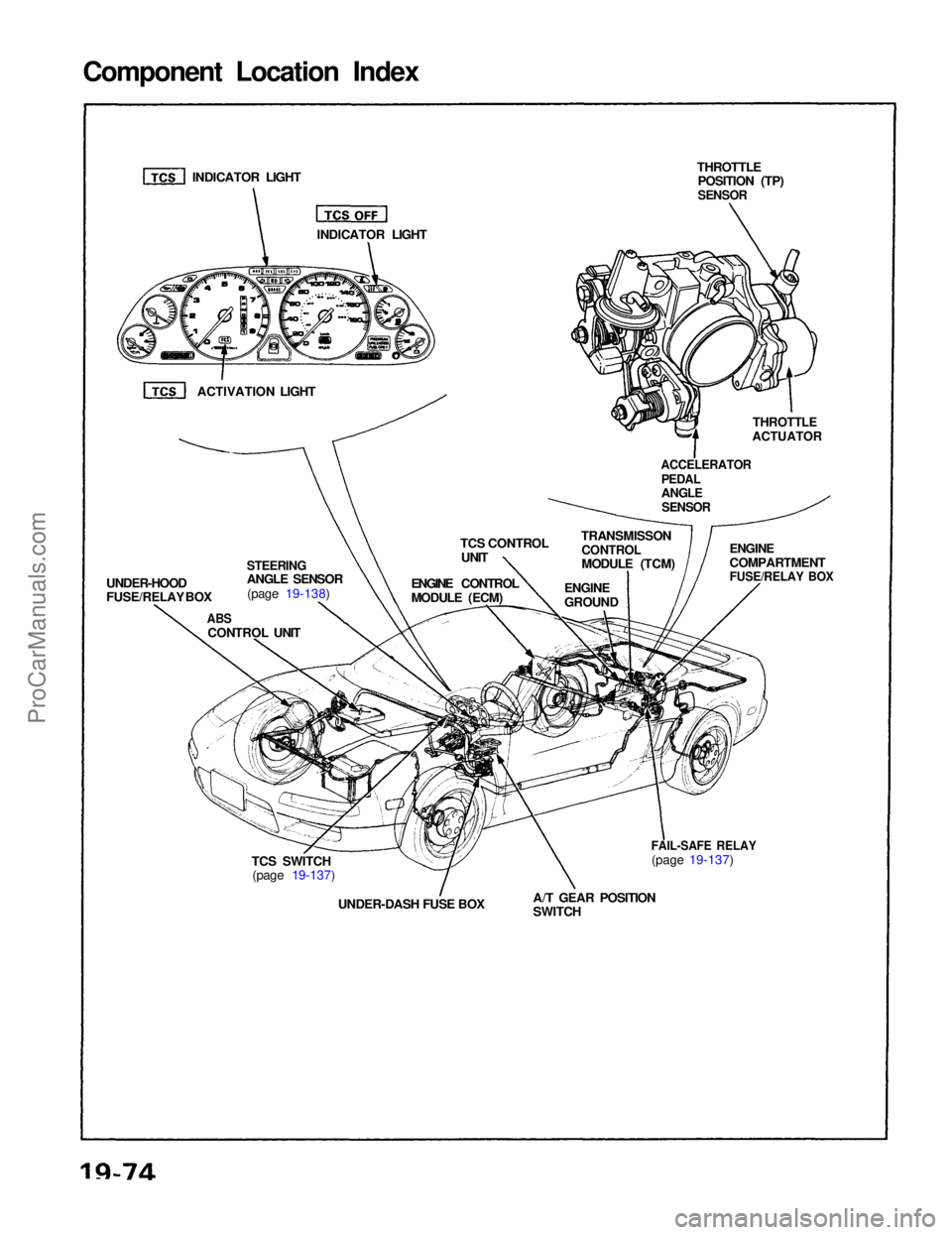

Component Location Index

INDICATOR LIGHT

ACTIVATION LIGHT INDICATOR LIGHT

UNDER-HOOD

FUSE/RELAY BOX

ABS

CONTROL UNIT

STEERING

ANGLE SENSOR

(page 19-138)

TCS SWITCH(page 19-137)

UNDER-DASH FUSE BOX

A/T GEAR POSITION

SWITCH

FAIL-SAFE RELAY

(page 19-137)

ENGINE

COMPARTMENT

FUSE/RELAY BOX

TRANSMISSON

CONTROL

MODULE (TCM)

ENGINE

GROUND

TCS CONTROL

UNIT

ENGINE CONTROL

MODULE (ECM)

ACCELERATOR

PEDAL

ANGLE

SENSOR

THROTTLE

ACTUATOR

THROTTLE

POSITION (TP)

SENSORProCarManuals.com

Page 1362 of 1640

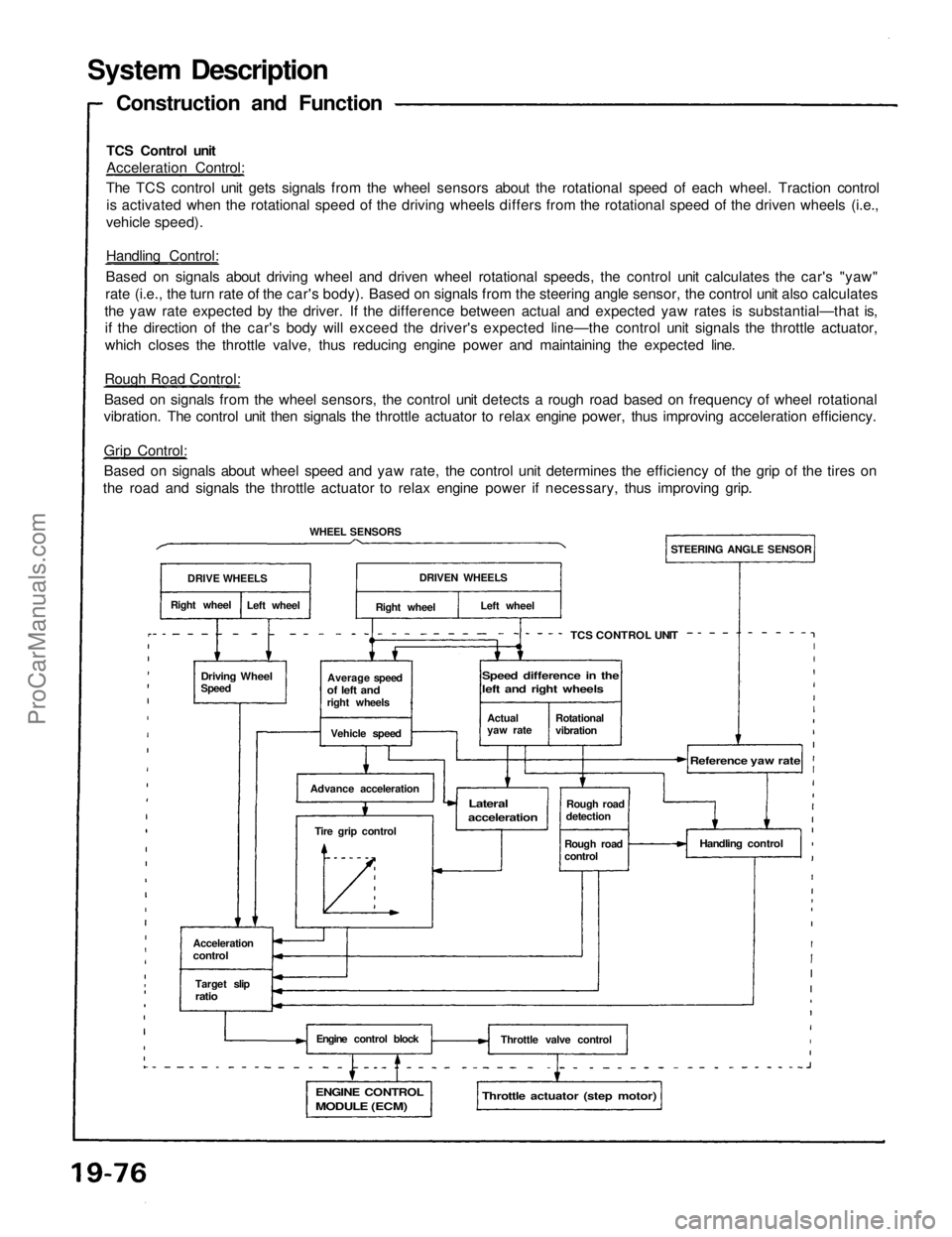

System Description

TCS Control unit

Acceleration Control:

The TCS control unit gets signals from the wheel sensors about the rotational speed of each wheel. Traction control

is activated when the rotational speed of the driving wheels differs from the rotational speed of the driven wheels (i.e.,

vehicle speed).

Handling Control:

Based on signals about driving wheel and driven wheel rotational speeds, the control unit calculates the car's "yaw"

rate (i.e., the turn rate of the car's body). Based on signals from the steering angle sensor, the control unit also calculates

the yaw rate expected by the driver. If the difference between actual and expected yaw rates is substantial—that is,

if the direction of the car's body will exceed the driver's expected line—the control unit signals the throttle actuator,

which closes the throttle valve, thus reducing engine power and maintaining the expected line.

Rough Road Control:

Based on signals from the wheel sensors, the control unit detects a rough road based on frequency of wheel rotational

vibration. The control unit then signals the throttle actuator to relax engine power, thus improving acceleration efficiency.

Grip Control:

Based on signals about wheel speed and yaw rate, the control unit determines the efficiency of the grip of the tires on

the road and signals the throttle actuator to relax engine power if necessary, thus improving grip.

Construction and Function

DRIVE WHEELS

Right wheel

Left wheel

WHEEL SENSORS

Driving Wheel

Speed

Average speed

of left and

right wheels

Vehicle speed

Advance acceleration

Tire grip control

Acceleration

control

Target slip

ratio

Engine control block

ENGINE CONTROL

MODULE (ECM)

Throttle actuator (step motor)

Throttle valve control

Handling control

Rough road

detection

Rough road

control

Reference yaw rate

Lateral

acceleration

TCS CONTROL UNIT

STEERING ANGLE SENSOR

DRIVEN WHEELS

Right wheel

Left wheel

Actual

yaw rate

Rotational

vibration

Speed difference in the

left and right wheelsProCarManuals.com

Page 1364 of 1640

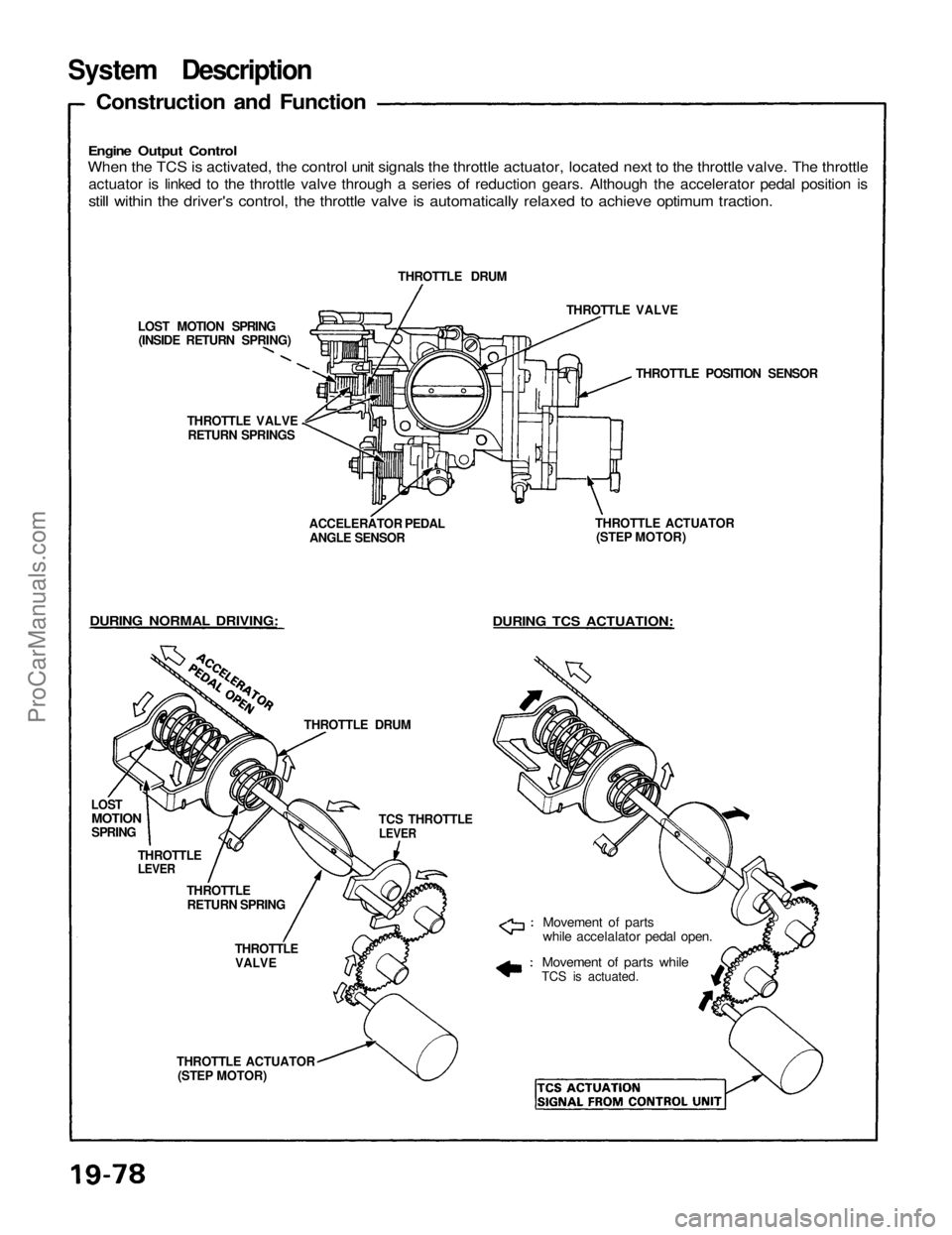

System Description

Engine Output Control

When the TCS is activated, the control unit signals the throttle actuator, located next to the throttle valve. The throttle

actuator is linked to the throttle valve through a series of reduction gears. Although the accelerator pedal position is

still within the driver's control, the throttle valve is automatically relaxed to achieve optimum traction.

Construction and Function

LOST MOTION SPRING

(INSIDE RETURN SPRING)

THROTTLE VALVE

RETURN SPRINGS

DURING NORMAL DRIVING:

LOST

MOTION

SPRING

THROTTLE

LEVER

THROTTLE

RETURN SPRING

THROTTLE DRUM

THROTTLE

VALVE

THROTTLE ACTUATOR

(STEP MOTOR)

Movement of parts

while accelalator pedal open.

Movement of parts while

TCS is actuated.

DURING TCS ACTUATION:

THROTTLE ACTUATOR

(STEP MOTOR)

THROTTLE POSITION SENSOR

THROTTLE VALVE

THROTTLE DRUM

ACCELERATOR PEDAL

ANGLE SENSOR

TCS THROTTLE

LEVERProCarManuals.com

Page 1365 of 1640

Troubleshooting

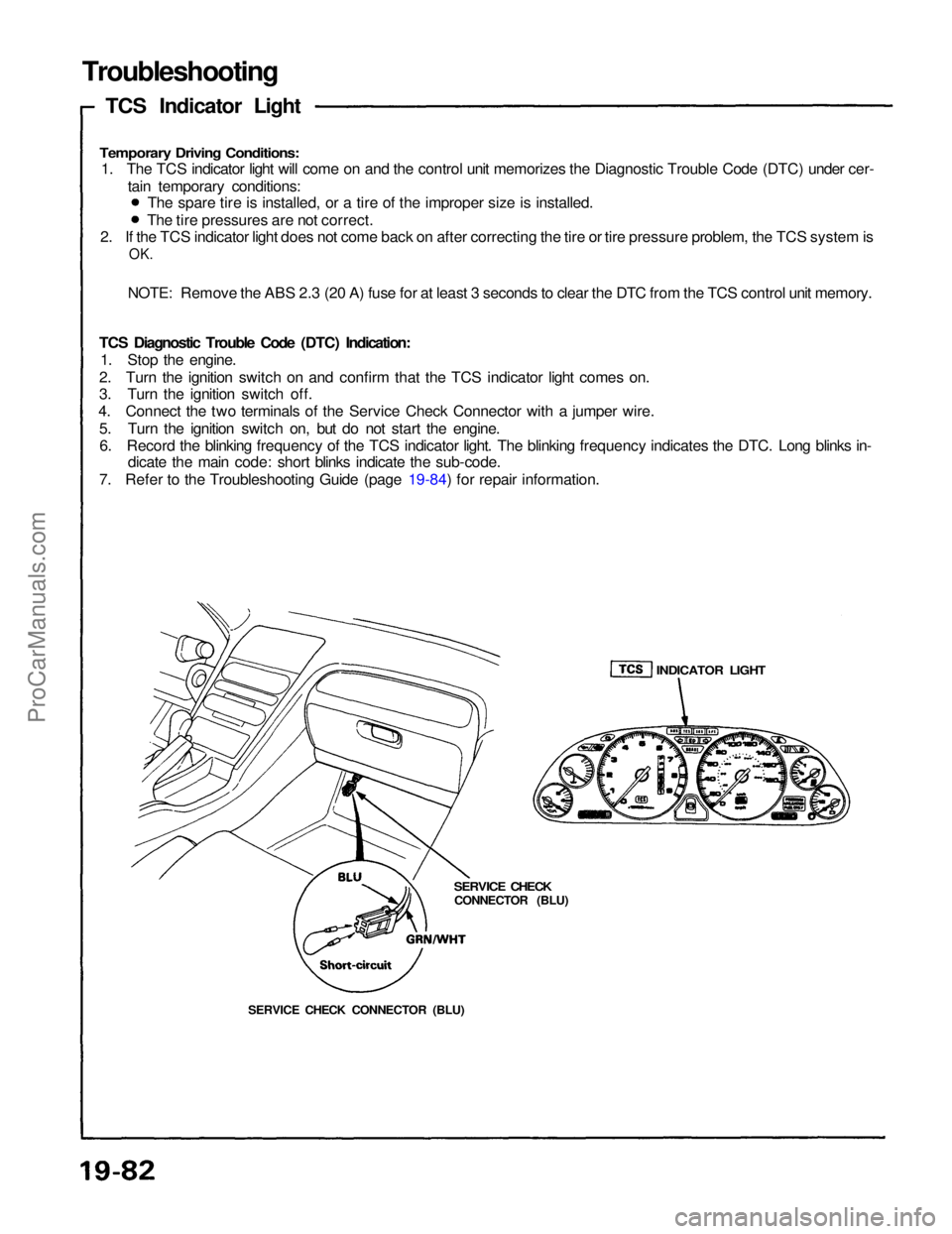

TCS Indicator Light

Temporary Driving Conditions:

1. The TCS indicator light will come on and the control unit memorizes the Diagnostic Trouble Code (DTC) under cer-

tain temporary conditions:

2. If the TCS indicator light does not come back on after correcting the tire or tire pressure problem, the TCS system is

OK.

NOTE: Remove the ABS 2.3 (20 A) fuse for at least 3 seconds to clear the DTC from the TCS control unit memory.

TCS Diagnostic Trouble Code (DTC) Indication: 1. Stop the engine.

2. Turn the ignition switch on and confirm that the TCS indicator light comes on.

3. Turn the ignition switch off.

4. Connect the two terminals of the Service Check Connector with a jumper wire.

5. Turn the ignition switch on, but do not start the engine.6. Record the blinking frequency of the TCS indicator light. The blinking frequency indicates the DTC. Long blinks in- dicate the main code: short blinks indicate the sub-code.

7. Refer to the Troubleshooting Guide (page 19-84) for repair information. The spare tire is installed, or a tire of the improper size is installed.

The tire pressures are not correct.

SERVICE CHECK CONNECTOR (BLU)

SERVICE CHECK

CONNECTOR (BLU)

INDICATOR LIGHTProCarManuals.com

Page 1366 of 1640

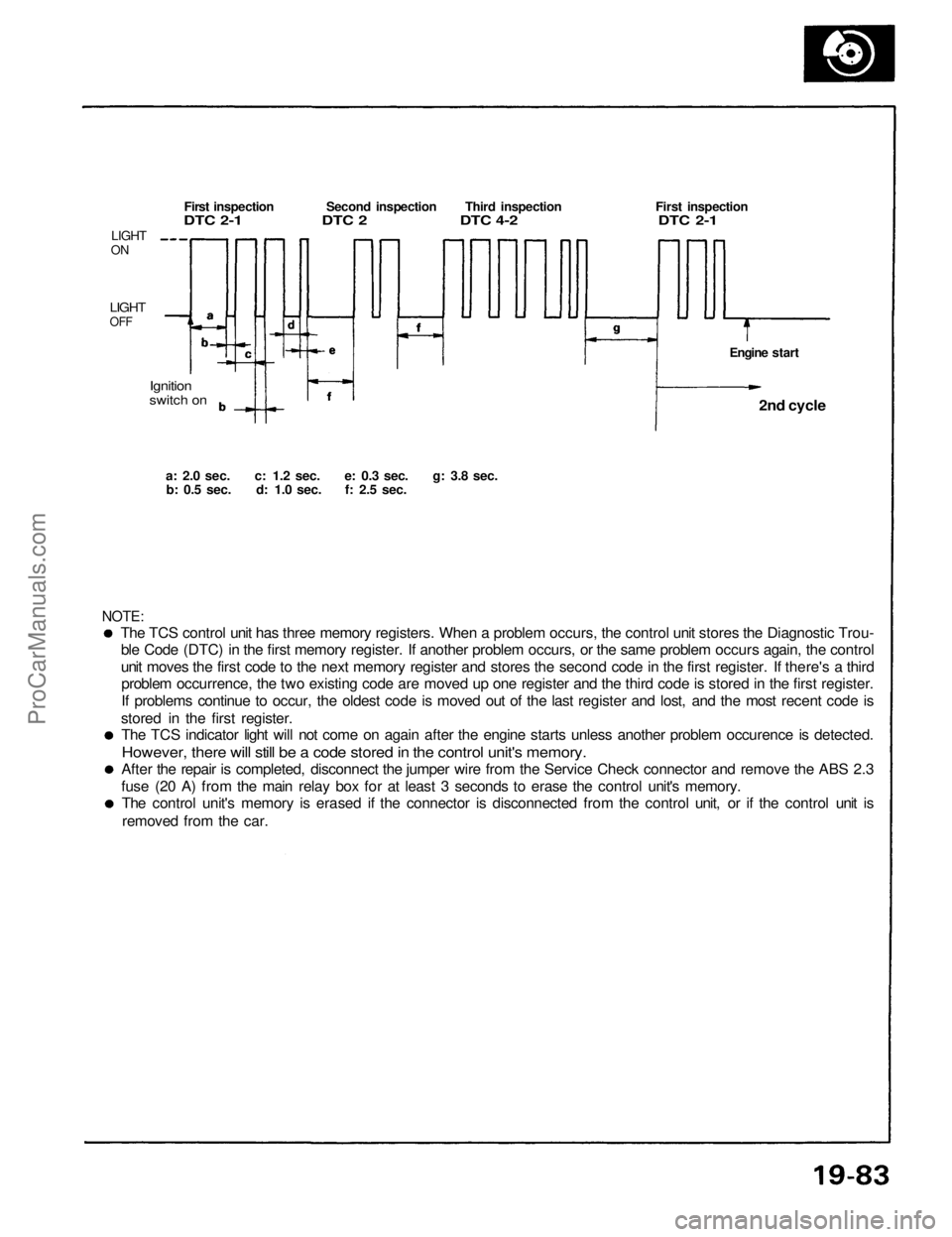

The TCS control unit has three memory registers. When a problem occurs, the control unit stores the Diagnostic Trou-

ble Code (DTC) in the first memory register. If another problem occurs, or the same problem occurs again, the control

unit moves the first code to the next memory register and stores the second code in the first register. If there's a thirdproblem occurrence, the two existing code are moved up one register and the third code is stored in the first register.

If problems continue to occur, the oldest code is moved out of the last register and lost, and the most recent code is

stored in the first register. The TCS indicator light will not come on again after the engine starts unless another problem occurence is detected.

However, there will still be a code stored in the control unit's memory.

After the repair is completed, disconnect the jumper wire from the Service Check connector and remove the ABS 2.3

fuse (20 A) from the main relay box for at least 3 seconds to erase the control unit's memory. The control unit's memory is erased if the connector is disconnected from the control unit, or if the control unit is

removed from the car.

NOTE:

a: 2.0

sec.

c: 1.2

sec.

e: 0.3

sec.

g: 3.8

sec.

b: 0.5

sec.

d: 1.0

sec.

f: 2.5

sec.

Ignition

switch on

LIGHT

ON

LIGHT

OFF

First inspection Second inspection Third inspection First inspection

DTC 2-1 DTC 2 DTC 4-2 DTC 2-1

Engine start2nd cycle

ProCarManuals.com

Page 1388 of 1640

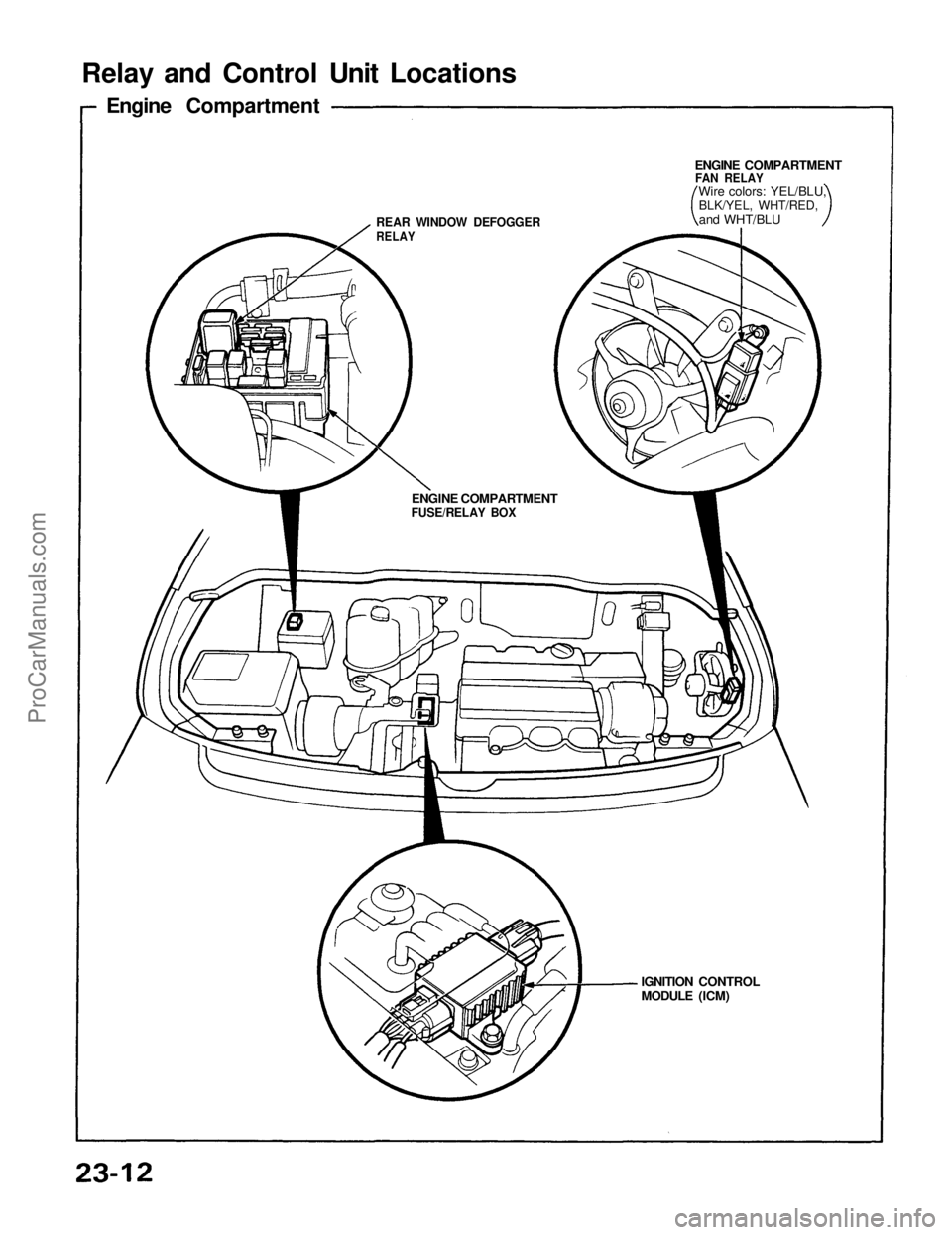

Relay and Control Unit Locations

Engine Compartment

REAR WINDOW DEFOGGER

RELAY

ENGINE COMPARTMENT

FUSE/RELAY BOX

ENGINE COMPARTMENT

FAN RELAY

Wire colors: YEL/BLU,

BLK/YEL, WHT/RED,

and WHT/BLU

IGNITION CONTROL

MODULE (ICM)ProCarManuals.com

Page 1393 of 1640

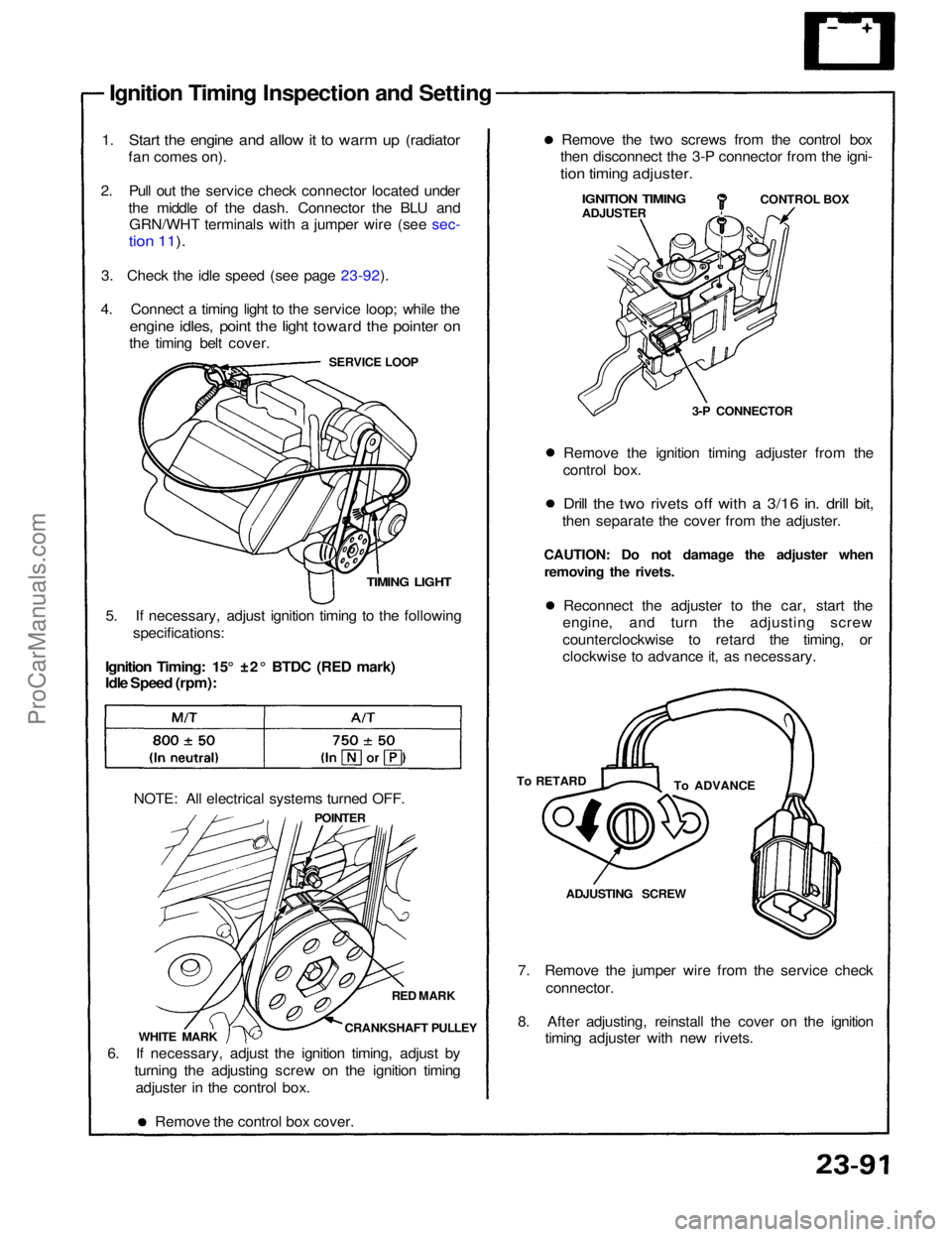

Ignition Timing Inspection and Setting

1. Start the engine and allow it to warm up (radiator

fan comes on).

2. Pull out the service check connector located under the middle of the dash. Connector the BLU andGRN/WHT terminals with a jumper wire (see sec-

tion 11).

3. Check the idle speed (see page 23-92).

4. Connect a timing light to the service loop; while the

engine idles, point the light toward the pointer on

the timing belt cover.

SERVICE LOOP

TIMING LIGHT

5. If necessary, adjust ignition timing to the following specifications:

Ignition Timing: 15° ±2° BTDC (RED mark)

Idle Speed (rpm):

NOTE: All electrical systems turned OFF. POINTER

RED MARK

CRANKSHAFT PULLEY

WHITE MARK

6. If necessary, adjust the ignition timing, adjust by turning the adjusting screw on the ignition timingadjuster in the control box.

Remove the control box cover. 7. Remove the jumper wire from the service check

connector.

8. After adjusting, reinstall the cover on the ignition timing adjuster with new rivets.ADJUSTING SCREW

To ADVANCE

To RETARD Reconnect the adjuster to the car, start the

engine, and turn the adjusting screw

counterclockwise to retard the timing, or

clockwise to advance it, as necessary.

CAUTION: Do not damage the adjuster when

removing the rivets. Remove the ignition timing adjuster from the

control box.

Drill the two rivets off with a 3/16 in. drill bit,

then separate the cover from the adjuster. 3-P CONNECTORCONTROL BOX

IGNITION TIMING

ADJUSTER

Remove the two screws from the control box

then disconnect the 3-P connector from the igni-

tion timing adjuster.ProCarManuals.com

Page 1394 of 1640

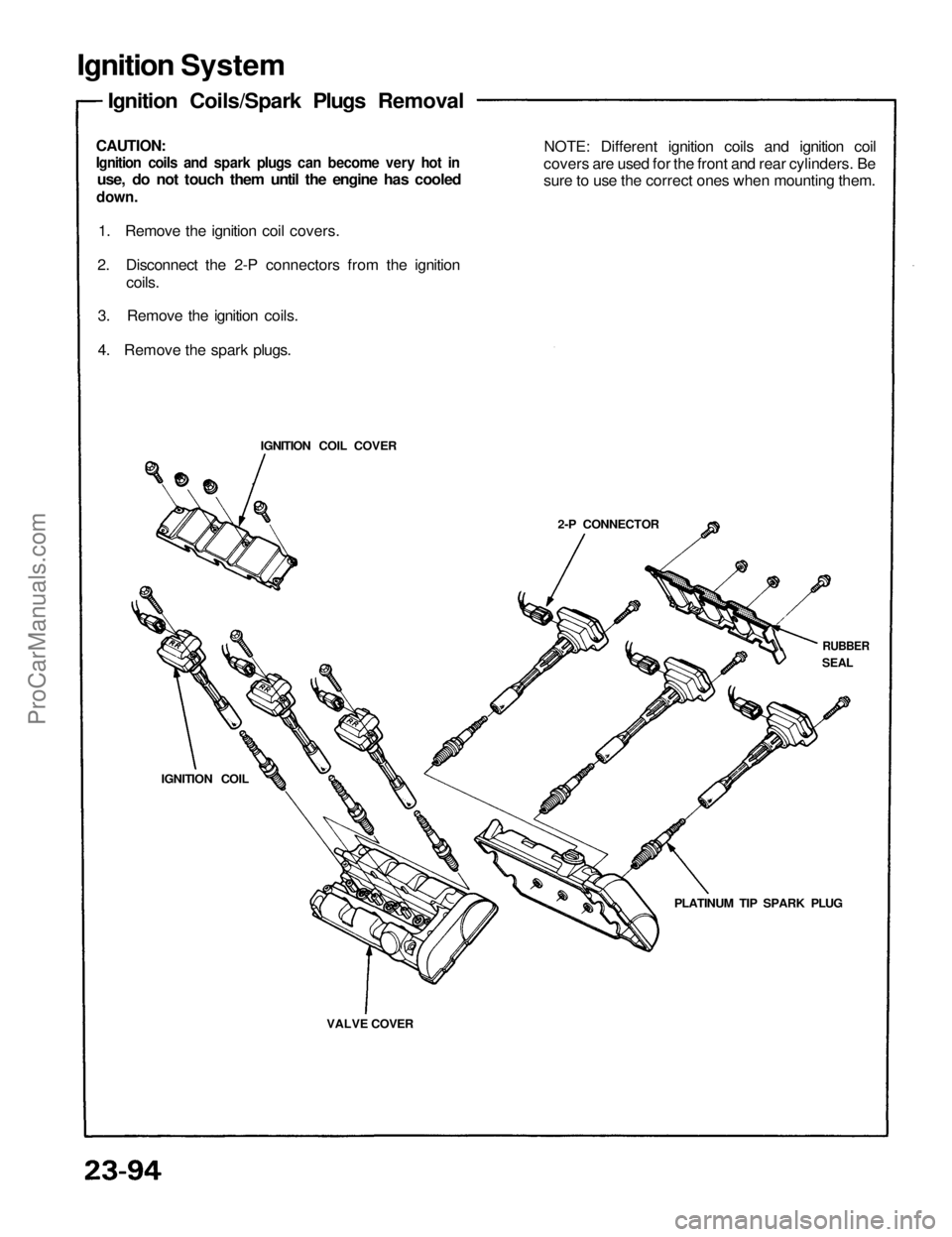

Ignition System

Ignition Coils/Spark Plugs Removal

CAUTION:

Ignition coils and spark plugs can become very hot in

use, do not touch them until the engine has cooled

down.

1. Remove the ignition coil covers.

2. Disconnect the 2-P connectors from the ignition

coils.

3. Remove the ignition coils.

4. Remove the spark plugs.

IGNITION COIL COVER

IGNITION COIL

VALVE COVER

PLATINUM TIP SPARK PLUG

RUBBER

SEAL

2-P CONNECTOR

NOTE: Different ignition coils and ignition coil

covers are used for the front and rear cylinders. Be

sure to use the correct ones when mounting them.ProCarManuals.com

Page 1398 of 1640

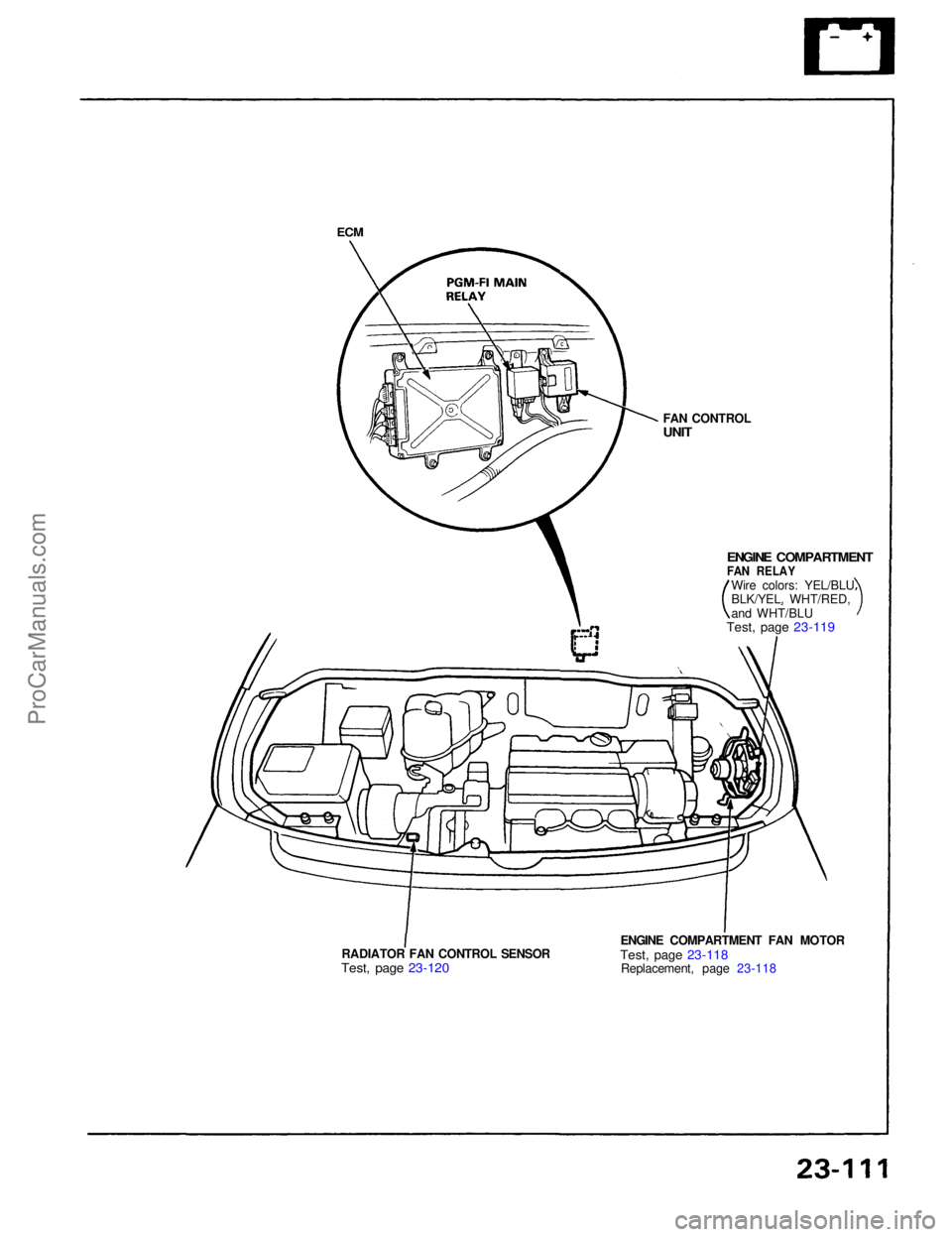

ECM

RADIATOR FAN CONTROL SENSOR

Test, page 23-120

ENGINE COMPARTMENT FAN MOTOR

Test, page 23-118

Replacement, page 23-118

ENGINE COMPARTMENT

FAN RELAY

Wire colors: YEL/BLU

BLK/YEL, WHT/RED,

and WHT/BLU

Test, page 23-119

FAN CONTROL

UNITProCarManuals.com