radiator ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 72 of 1640

9. Relieve fuel pressure by loosening the service bolt

on the fuel filter about one turn (see section 11).

Do not smoke while working on the

fuel

system.

Keep open flame away from work

area. Drain fuel only into an approved container.

10. Remove the fuel feed pipe and fuel return hose.

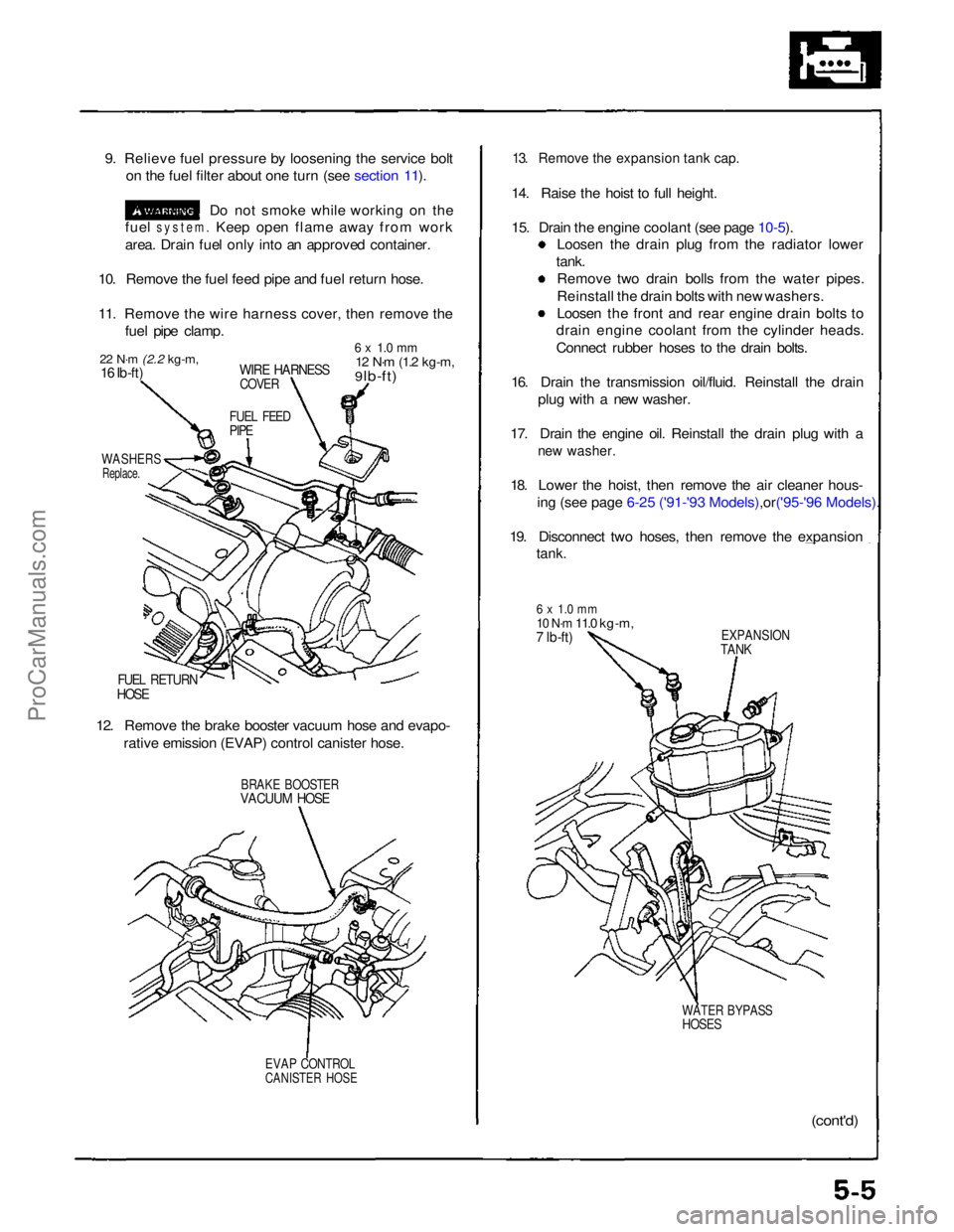

11. Remove the wire harness cover, then remove the fuel pipe clamp.

22 N·m

(2.2 kg-m,

16 Ib-ft)

WIRE HARNESS

COVER

6 x 1.0 mm

12 N·m

(1.2 kg-m,

9 lb-ft)

FUEL FEED

PIPE

WASHERS

Replace.

FUEL RETURN

HOSE

12. Remove the brake booster vacuum hose and evapo- rative emission (EVAP) control canister hose.

BRAKE BOOSTER

VACUUM HOSE

EVAP CONTROL

CANISTER HOSE

13. Remove the expansion tank cap.

14. Raise the hoist to full height.

15. Drain the engine coolant (see page

10-5).

Loosen the drain plug from the radiator lower

tank. Remove two drain bolls from the water pipes.

Reinstall the drain bolts with new washers.

Loosen the front and rear engine drain bolts to

drain engine coolant from the cylinder heads.

Connect rubber hoses to the drain bolts.

16. Drain the transmission oil/fluid. Reinstall the drain plug with a new washer.

17. Drain the engine oil. Reinstall the drain plug with a

new washer.

18. Lower the hoist, then remove the air cleaner hous-

ing (see page 6-25 ('91-'93 Mode ls),or('95-'96 Models).

19. Disconnect two hoses, then remove the expansion

tank.

6 x 1.0 mm

10 N·m

11.0 kg-m,

7 lb-ft)

EXPANSION

TANK

WATER BYPASS

HOSES

(cont'd)ProCarManuals.com

Page 73 of 1640

Engine Removal/Installation

Removal

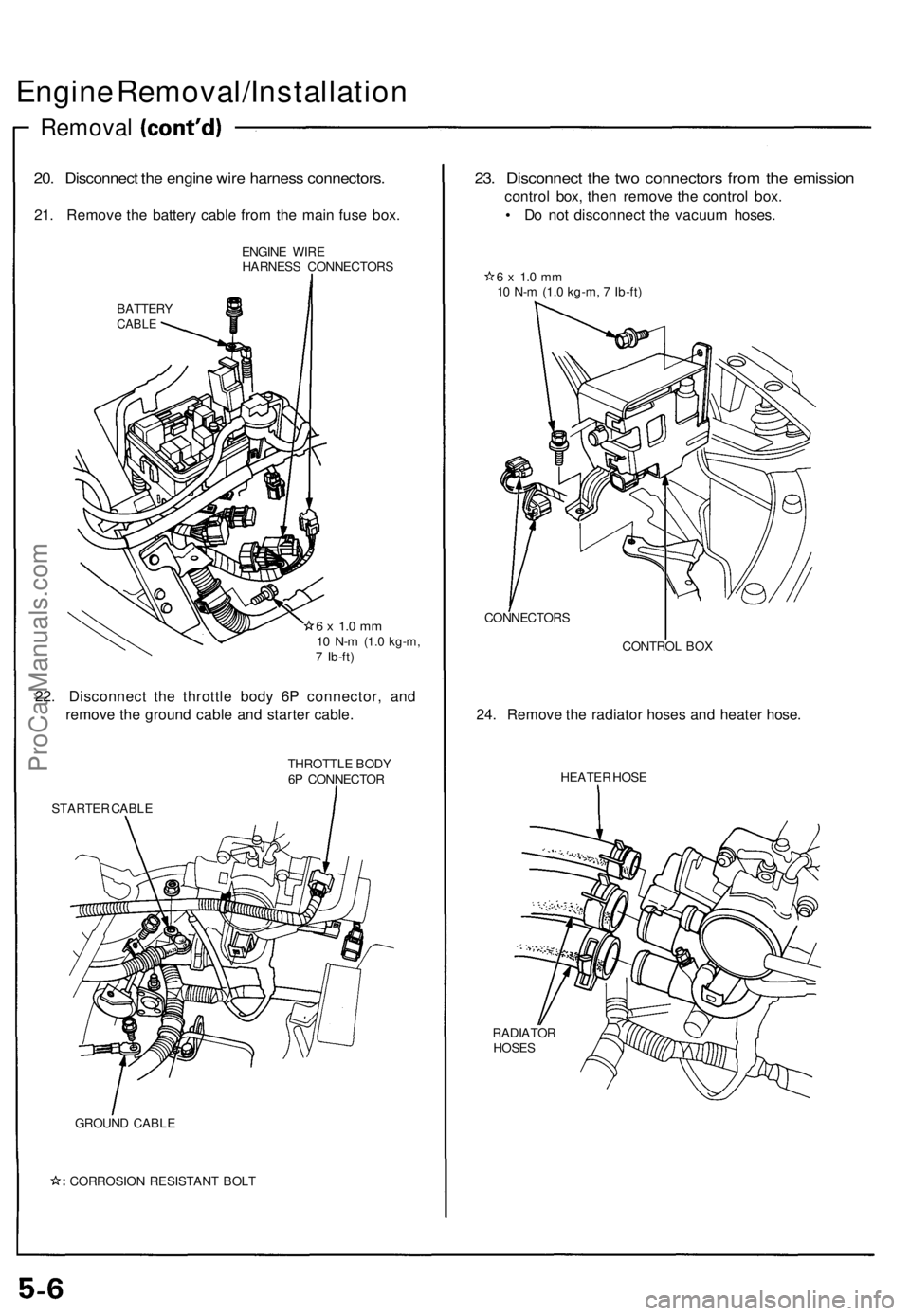

20. Disconnect the engine wire harness connectors.

21. Remove the battery cable from the main fuse box.

ENGINE WIRE

HARNESS CONNECTORS

BATTERY

CABLE

6 x 1.0 mm

10 N-m

(1.0 kg-m,

7 Ib-ft)

22. Disconnect the throttle body 6P connector, and

remove the ground cable and starter cable.

STARTER CABLE

THROTTLE BODY

6P CONNECTOR

GROUND CABLE

CORROSION RESISTANT BOLT

23. Disconnect the two connectors from the emission

control box, then remove the control box.

• Do not disconnect the vacuum hoses.

6 x 1.0 mm

10 N-m (1.0 kg-m, 7 Ib-ft)

CONNECTORS

CONTROL BOX

24. Remove the radiator hoses and heater hose.

HEATER HOSE

RADIATOR

HOSESProCarManuals.com

Page 100 of 1640

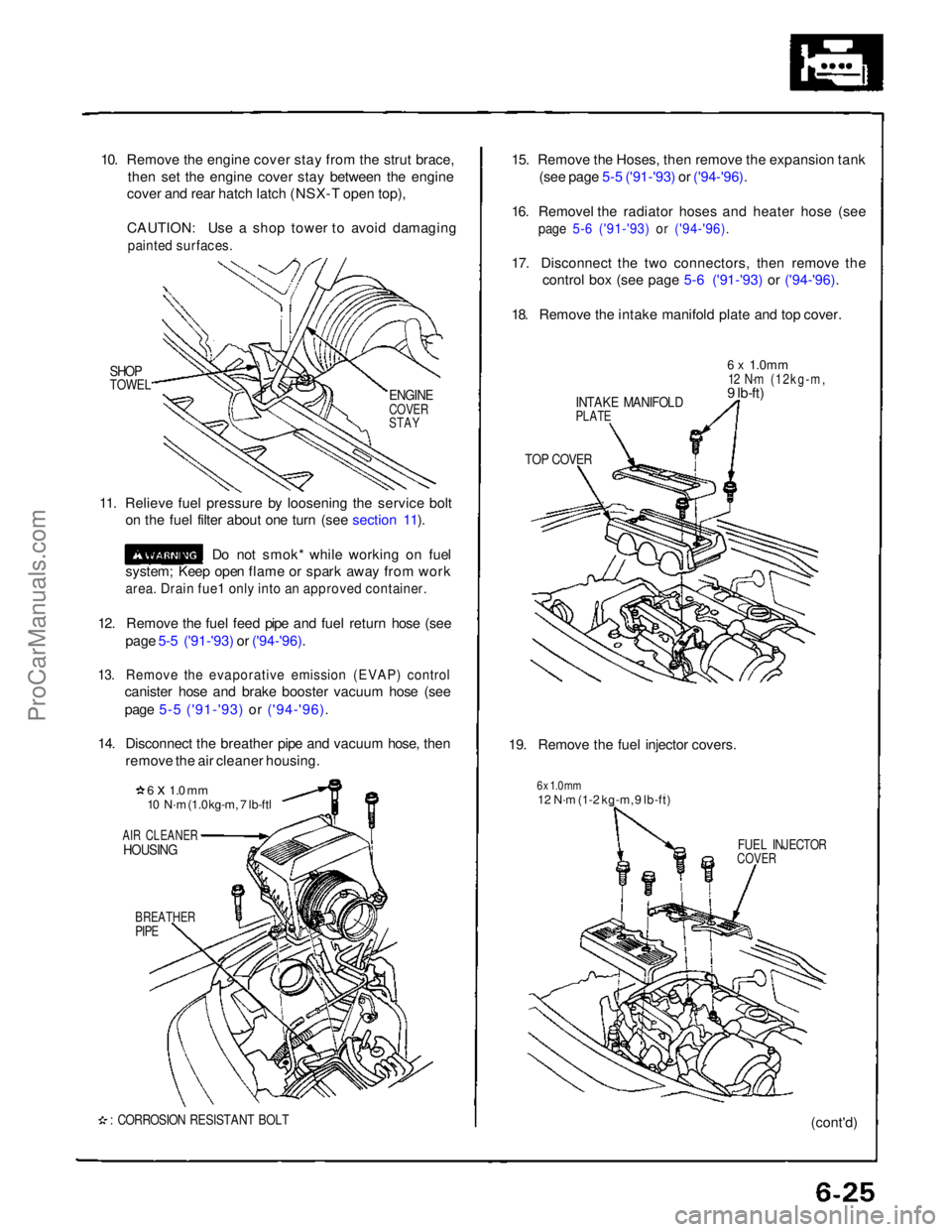

10. Remove the engine cover stay from the strut brace,

then set the engine cover stay between the engine

cover and rear hatch latch (NSX-T open top),

CAUTION: Use a shop tower to avoid damaging

painted surfaces.

SHOP

TOWEL

11. Relieve fuel pressure by loosening the service bolt on the fuel filter about one turn (see section 11).

Do not smok* while working on fuel

system; Keep open flame or spark away from work

area. Drain fue1 only into an approved container.

12. Remove the fuel feed pipe and fuel return hose (see page 5-5 ('91-'93) or ('94-'96).

13. Remove the evaporative emission (EVAP) control

canister hose and brake booster vacuum hose (see

page 5-5 ('91-'93) or ('94-'96).

14. Disconnect the breather pipe and vacuum hose, then remove the air cleaner housing.

6 x 1.0 mm

10 N·m (1.0 kg-m, 7 lb-ftl

AIR CLEANER

HOUSING

BREATHER

PIPE

: CORROSION RESISTANT BOLT

15. Remove the Hoses, then remove the expansion tank

(see page 5-5 ('91-'93) or ('94-'96).

16. Removel the radiator hoses and heater hose (see

page 5-6 ('91-'93) or ('94-'96).

17. Disconnect the two connectors, then remove the

control box (see page 5-6 ('91-'93) or ('94-'96).

18. Remove the intake manifold plate and top cover.

INTAKE MANIFOLD

PLATE

6 x

1.0mm

12 N·m (12kg-m,

9 lb-ft)

TOP COVER

19. Remove the fuel injector covers.

6 x 1.0 mm

12 N·m (1-2 kg-m, 9 lb-ft)

FUEL INJECTOR

COVER

(cont'd)

ENGINE

COVER

STAYProCarManuals.com

Page 162 of 1640

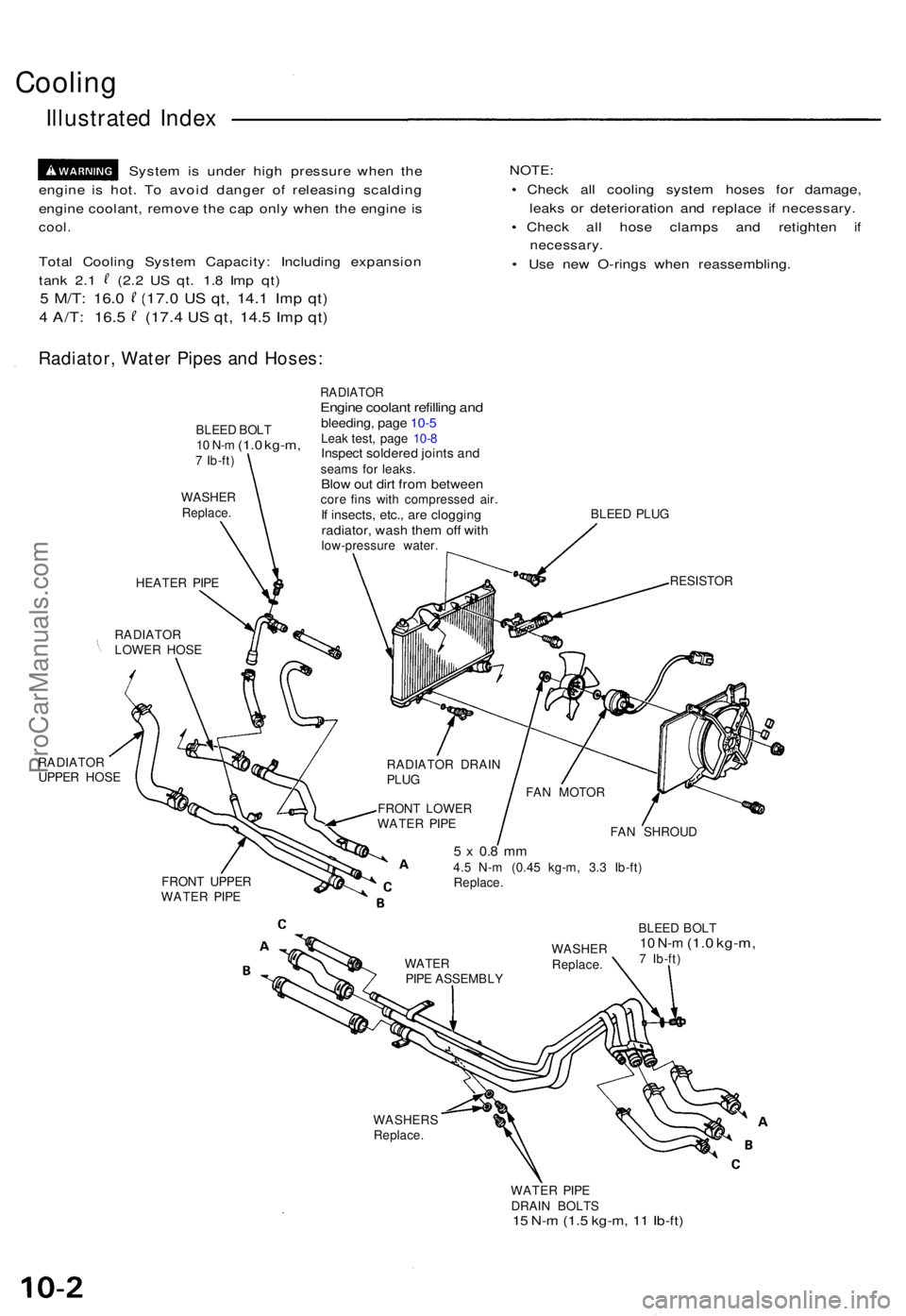

Cooling

Illustrated Index

Syste m is unde r hig h pressur e whe n th e

engin e i s hot . T o avoi d dange r o f releasin g scaldin g

engin e coolant , remov e th e ca p onl y whe n th e engin e i s

cool .

Tota l Coolin g Syste m Capacity : Includin g expansio n

tank 2. 1 (2. 2 U S qt . 1. 8 Im p qt )

5 M/T : 16. 0 (17. 0 US qt , 14. 1 Imp qt )

4 A/T : 16. 5 (17. 4 US qt , 14. 5 Imp qt )

NOTE :

• Chec k al l coolin g syste m hose s fo r damage ,

leak s o r deterioratio n an d replac e i f necessary .

• Chec k al l hos e clamp s an d retighte n i f

necessary .

• Us e ne w O-ring s whe n reassembling .

Radiator, Wate r Pipe s an d Hoses :

BLEED BOL T10 N- m (1. 0 kg-m ,7 Ib-ft )

WASHE RReplace .

HEATER PIP E

RADIATO R

LOWE R HOS E

RADIATO R

UPPE R HOS E

RADIATO REngine coolan t refillin g an dbleeding , pag e 10- 5Leak test , pag e 10- 8Inspec t soldere d joint s an dseam s fo r leaks .Blow ou t dir t fro m betwee ncore fin s wit h compresse d air .If insects , etc. , ar e cloggin gradiator, was h the m of f wit hlow-pressur e water . BLEE

D PLU G

RESISTO R

RADIATO R DRAI N

PLU G

FRON T LOWE R

WATE R PIP E

FRON T UPPE R

WATE R PIP E FA

N SHROU D

5 x 0. 8 m m4.5 N- m (0.4 5 kg-m , 3. 3 Ib-ft )

Replace .

BLEED BOL T

10 N- m (1. 0 kg-m ,7 Ib-ft )

WASHER S

Replace .

WATER PIP E

DRAI N BOLT S

15 N- m (1. 5 kg-m , 1 1 Ib-ft )

WATE RPIPE ASSEMBL YWASHE

RReplace .

FAN MOTO R

ProCarManuals.com

Page 164 of 1640

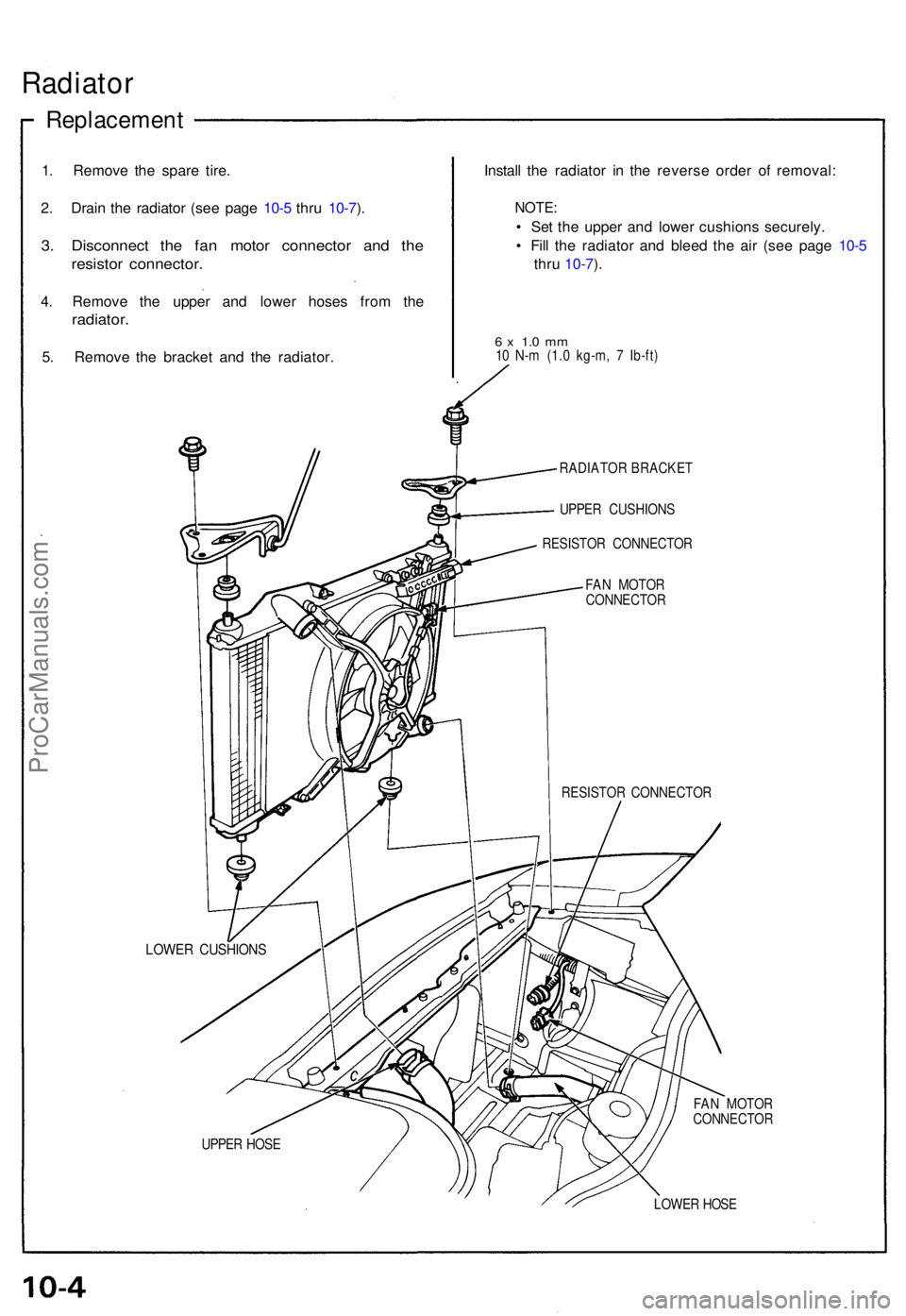

Radiator

Replacemen t

1. Remov e th e spar e tire .

2 . Drai n th e radiato r (se e pag e 10- 5 thr u 10-7 ).

3 . Disconnec t th e fa n moto r connecto r an d th e

resisto r connector .

4. Remov e th e uppe r an d lowe r hose s fro m th e

radiator .

5. Remov e th e bracke t an d th e radiator . Instal

l th e radiato r i n th e revers e orde r o f removal :

NOTE:

• Se t th e uppe r an d lowe r cushion s securely .

• Fil l th e radiato r an d blee d th e ai r (se e pag e 10- 5

thr u 10-7 ).

6 x 1. 0 m m10 N- m (1. 0 kg-m , 7 Ib-ft )

RADIATO R BRACKE T

UPPE R CUSHION S

RESISTO R CONNECTO R

FA N MOTO R

CONNECTO R

RESISTO R CONNECTO R

LOWER CUSHION S

FAN MOTO R

CONNECTO R

UPPE R HOS E

LOWER HOS E

ProCarManuals.com

Page 165 of 1640

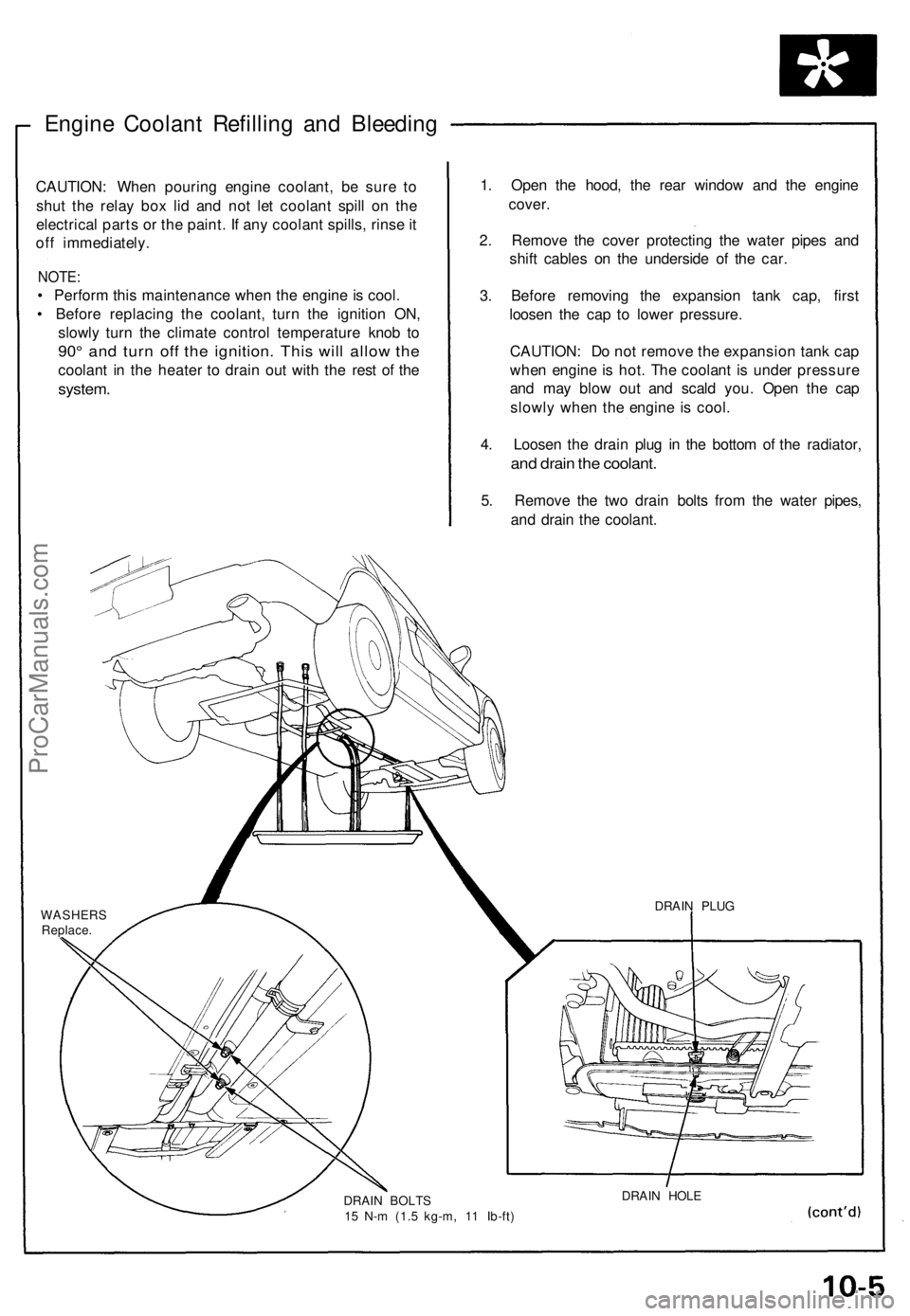

Engine Coolant Refilling and Bleeding

CAUTION: When pouring engine coolant, be sure to

shut the relay box lid and not let coolant spill on the

electrical parts or the paint. If any coolant spills, rinse it

off immediately.

NOTE:

• Perform this maintenance when the engine is cool.

• Before replacing the coolant, turn the ignition ON,

slowly turn the climate control temperature knob to

90° and turn off the ignition. This will allow the

coolant in the heater to drain out with the rest of the

system.

1. Open the hood, the rear window and the engine

cover.

2. Remove the cover protecting the water pipes and

shift cables on the underside of the car.

3. Before removing the expansion tank cap, first

loosen the cap to lower pressure.

CAUTION: Do not remove the expansion tank cap

when engine is hot. The coolant is under pressure

and may blow out and scald you. Open the cap

slowly when the engine is cool.

4. Loosen the drain plug in the bottom of the radiator,

and drain the coolant.

5. Remove the two drain bolts from the water pipes,

and drain the coolant.

WASHERS

Replace.

DRAIN BOLTS

15 N-m (1.5 kg-m, 11 Ib-ft)

DRAIN HOLE

DRAIN PLUGProCarManuals.com

Page 166 of 1640

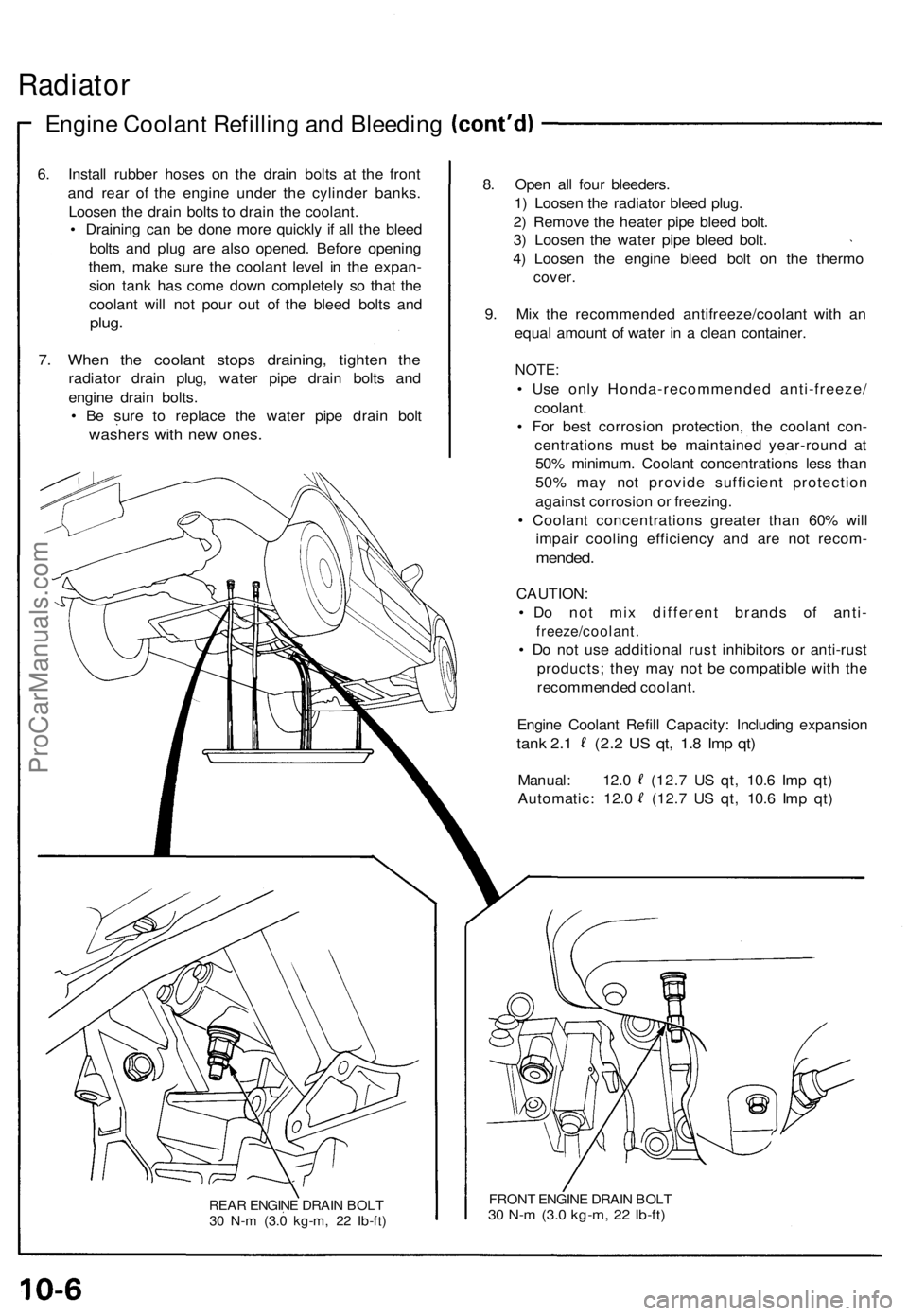

Radiator

Engine Coolan t Refillin g an d Bleedin g

6. Instal l rubbe r hose s o n th e drai n bolt s a t th e fron t

an d rea r of the engin e unde r th e cylinde r banks .

Loose n th e drai n bolt s t o drai n th e coolant .

• Drainin g ca n b e don e mor e quickl y i f al l th e blee d

bolt s an d plu g ar e als o opened . Befor e openin g

them , mak e sur e th e coolan t leve l i n th e expan -

sio n tan k ha s com e dow n completel y s o tha t th e

coolan t wil l no t pou r ou t o f th e blee d bolt s an d

plug .

7. Whe n th e coolan t stop s draining , tighte n th e

radiato r drai n plug , wate r pip e drai n bolt s an d

engin e drai n bolts .

• B e sur e t o replac e th e wate r pip e drai n bol t

washer s wit h ne w ones .

REAR ENGIN E DRAI N BOL T

3 0 N- m (3. 0 kg-m , 2 2 Ib-ft )

8. Ope n al l fou r bleeders .

1 ) Loose n th e radiato r blee d plug .

2 ) Remov e th e heate r pip e blee d bolt .

3 ) Loose n th e wate r pip e blee d bolt .

4 ) Loose n th e engin e blee d bol t o n th e therm o

cover.

9. Mi x th e recommende d antifreeze/coolan t wit h a n

equa l amoun t o f wate r i n a clea n container .

NOTE:

• Us e onl y Honda-recommende d anti-freeze /

coolant.

• Fo r bes t corrosio n protection , th e coolan t con -

centration s mus t b e maintaine d year-roun d a t

50 % minimum . Coolan t concentration s les s tha n

50 % ma y no t provid e sufficien t protectio n

agains t corrosio n o r freezing .

• Coolan t concentration s greate r tha n 60 % wil l

impai r coolin g efficienc y an d ar e no t recom -

mended.

CAUTION :

• D o no t mi x differen t brand s o f anti -

freeze/coolant .

• D o no t us e additiona l rus t inhibitor s o r anti-rus t

products ; the y ma y no t b e compatibl e wit h th e

recommende d coolant .

Engin e Coolan t Refil l Capacity : Includin g expansio n

tank 2. 1 (2. 2 U S qt , 1. 8 Im p qt )

Manual : 12. 0 (12. 7 U S qt , 10. 6 Im p qt )

Automatic : 12. 0 (12. 7 U S qt , 10. 6 Im p qt )

FRON T ENGIN E DRAI N BOL T30 N- m (3. 0 kg-m , 2 2 Ib-ft )

ProCarManuals.com

Page 438 of 1640

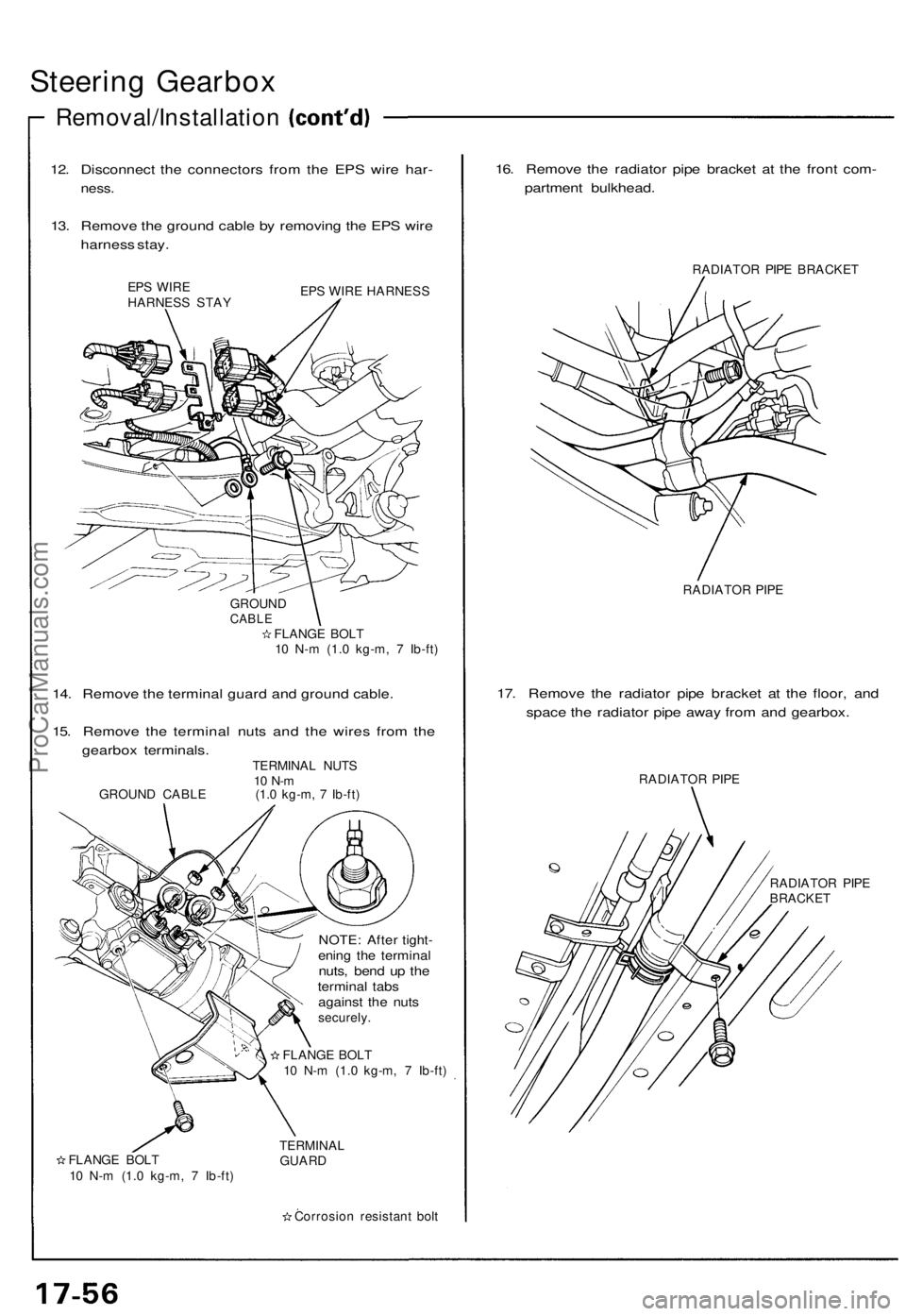

Steering Gearbo x

Removal/Installatio n

12. Disconnec t th e connector s fro m th e EP S wir e har -

ness .

13. Remov e th e groun d cabl e b y removin g th e EP S wir e

harnes s stay .

EPS WIR E

HARNES S STA Y EP

S WIR E HARNES S

GROUN D

CABLEFLANG E BOL T

1 0 N- m (1. 0 kg-m , 7 Ib-ft )

14. Remov e th e termina l guar d an d groun d cable .

15 . Remov e th e termina l nut s an d th e wire s fro m th e

gearbo x terminals .

TERMINAL NUT S10 N- mGROUN D CABL E (1.0 kg-m , 7 Ib-ft )

FLANG E BOL T

1 0 N- m (1. 0 kg-m , 7 Ib-ft )

NOTE : Afte r tight -ening th e termina lnuts, ben d u p th etermina l tab sagains t th e nut ssecurely .

FLANG E BOL T

1 0 N- m (1. 0 kg-m , 7 Ib-ft )

TERMINA L

GUAR D

Corrosio n resistan t bol t

16. Remov e th e radiato r pip e bracke t a t th e fron t com -

partmen t bulkhead .

RADIATOR PIP E BRACKE T

RADIATO R PIP E

17. Remov e th e radiato r pip e bracke t a t th e floor , an d

spac e th e radiato r pip e awa y fro m an d gearbox .

RADIATO R PIP E

RADIATO R PIP E

BRACKE T

ProCarManuals.com

Page 439 of 1640

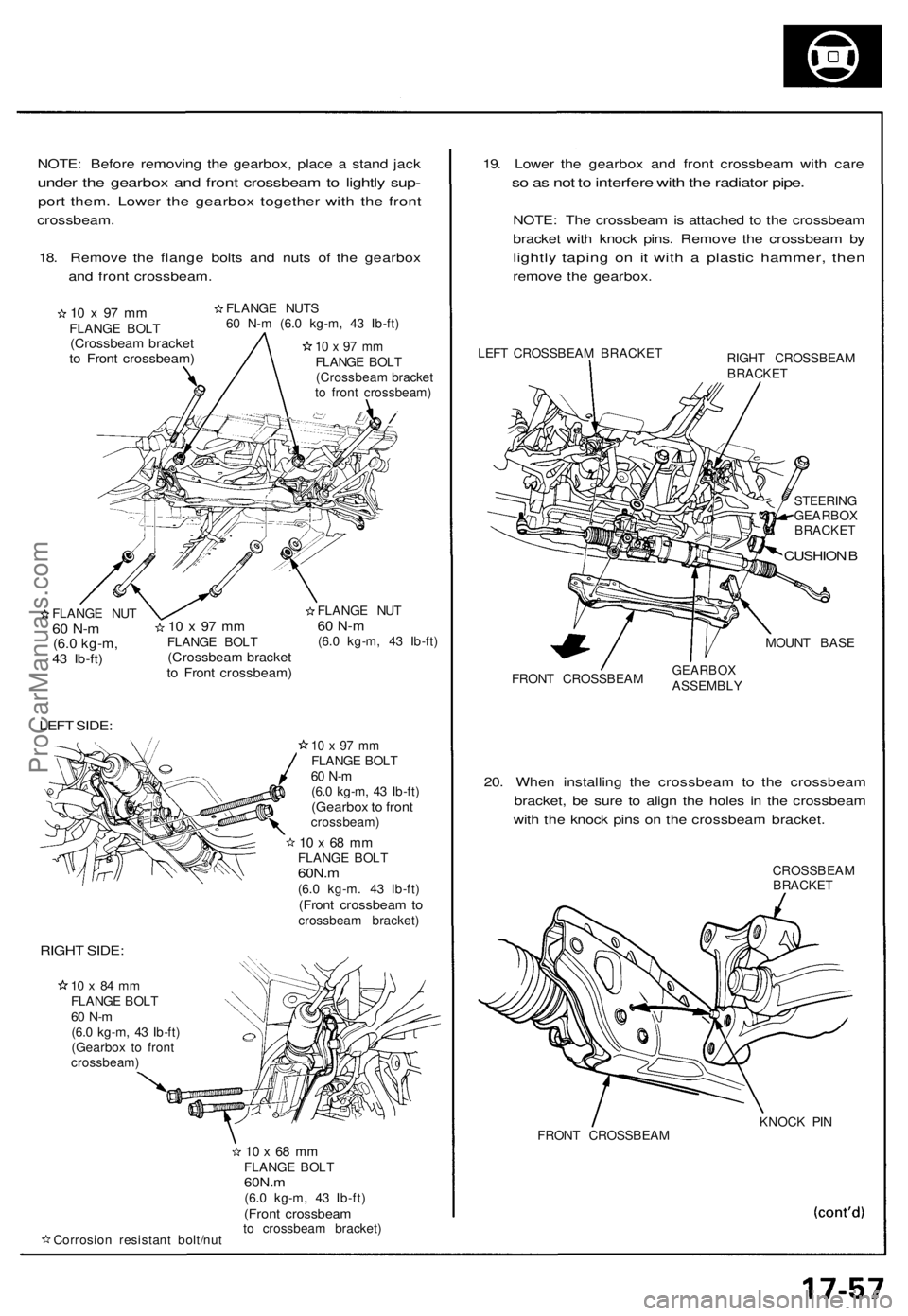

NOTE: Before removing the gearbox, place a stand jack

under the gearbox and front crossbeam to lightly sup-

port them. Lower the gearbox together with the front

crossbeam.

18. Remove the flange bolts and nuts of the gearbox

and front crossbeam.

10 x 97 mm

FLANGE BOLT

(Crossbeam bracket

to Front crossbeam)

FLANGE NUTS

60 N-m (6.0 kg-m, 43 Ib-ft)

10 x 97 mm

FLANGE BOLT

(Crossbeam bracket

to front crossbeam)

/

FLANGE NUT

60 N-m

(6.0 kg-m,

43 Ib-ft)

LEFT SIDE:

10 x 97 mm

FLANGE BOLT

(Crossbeam bracket

to Front crossbeam)

FLANGE NUT

60 N-m

(6.0 kg-m, 43 Ib-ft)

10 x 97 mm

FLANGE BOLT

60 N-m

(6.0 kg-m, 43 Ib-ft)

(Gearbox to front

crossbeam)

10 x 68 mm

FLANGE BOLT

60N.m

(6.0 kg-m. 43 Ib-ft)

(Front crossbeam to

crossbeam bracket)

RIGHT SIDE:

10 x 84 mm

FLANGE BOLT

60 N-m

(6.0 kg-m, 43 Ib-ft)

(Gearbox to front

crossbeam)

Corrosion resistant bolt/nut

10 x 68 mm

FLANGE BOLT

60N.m

(6.0 kg-m, 43 Ib-ft)

(Front crossbeam

to crossbeam bracket)

19. Lower the gearbox and front crossbeam with care

so as not to interfere with the radiator pipe.

NOTE: The crossbeam is attached to the crossbeam

bracket with knock pins. Remove the crossbeam by

lightly taping on it with a plastic hammer, then

remove the gearbox.

LEFT CROSSBEAM BRACKET

RIGHT CROSSBEAM

BRACKET

STEERING

GEARBOX

BRACKET

CUSHION B

MOUNT BASE

FRONT CROSSBEAM

GEARBOX

ASSEMBLY

20. When installing the crossbeam to the crossbeam

bracket, be sure to align the holes in the crossbeam

with the knock pins on the crossbeam bracket.

CROSSBEAM

BRACKET

FRONT CROSSBEAM

KNOCK PINProCarManuals.com

Page 683 of 1640

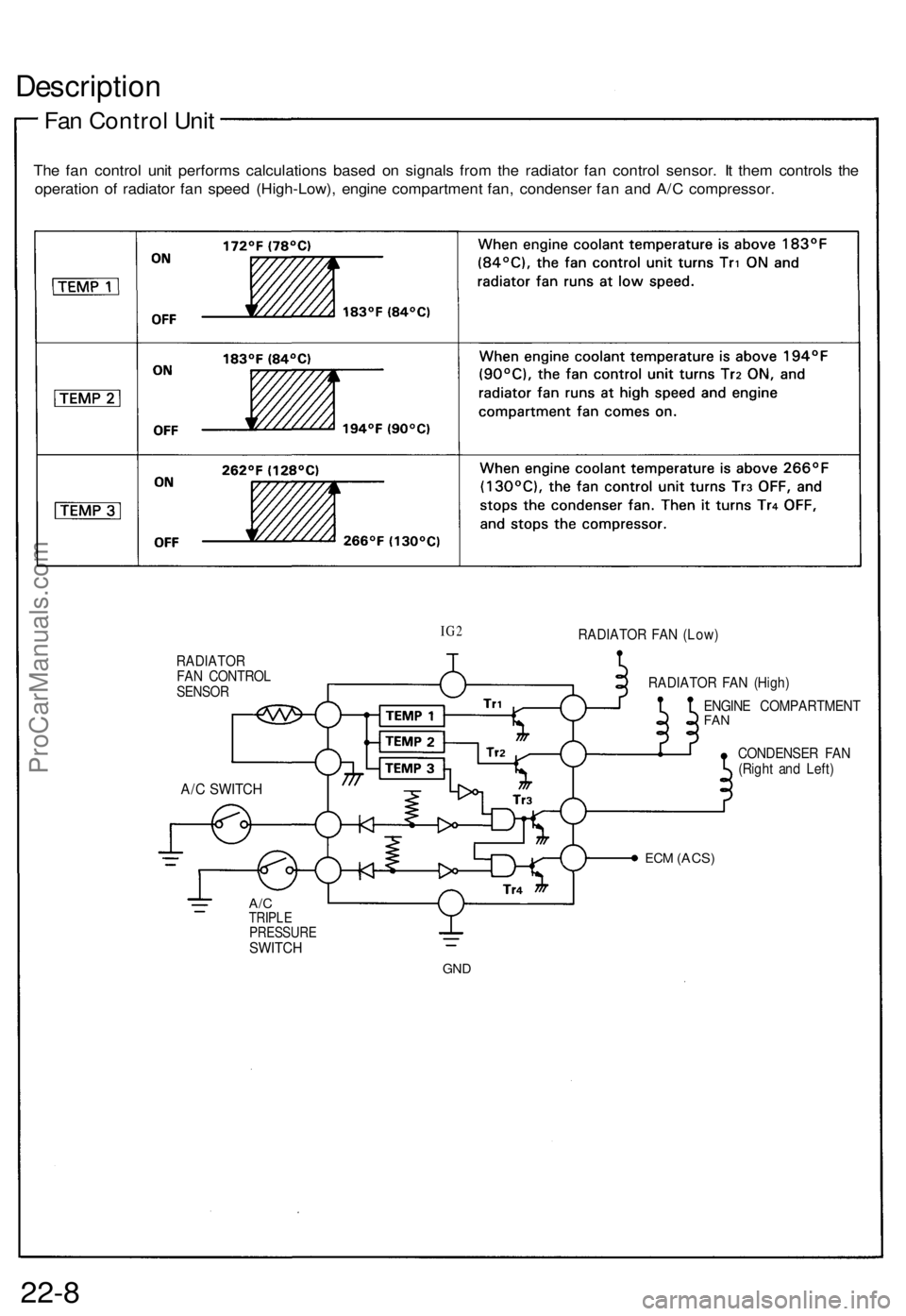

Description

Fan Control Unit

The fan control unit performs calculations based on signals from the radiator fan control sensor. It them controls the

operation of radiator fan speed (High-Low), engine compartment fan, condenser fan and A/C compressor.

IG2

RADIATOR FAN (Low)

RADIATOR

FAN CONTROL

SENSOR

RADIATOR FAN (High)

ENGINE COMPARTMENT

FAN

CONDENSER FAN

(Right and Left)

ECM

(ACS)

A/C

TRIPLE

PRESSURE

SWITCH

GND

22-8

A/C SWITCHProCarManuals.com