reset ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 121 of 1640

Cylinder Head s

Installatio n

Rear:

8 x 1.2 5 mm22 N- m (2. 2 kg-m ,16 Ib-ft ) REA

R PRIMAR Y

HO2S45 N- m (4. 5 kg-m ,33 Ib-ft )

B e carefu l no t t o damage .

GASKE T

Replace .

REA R EXHAUS T

MANIFOLD

EXHAUSTMANIFOL DCOVER

SELF-LOCKIN G NU T8 x 1.2 5 mm34 N- m (3. 4 kg-m ,25 Ib-ft )Replace .

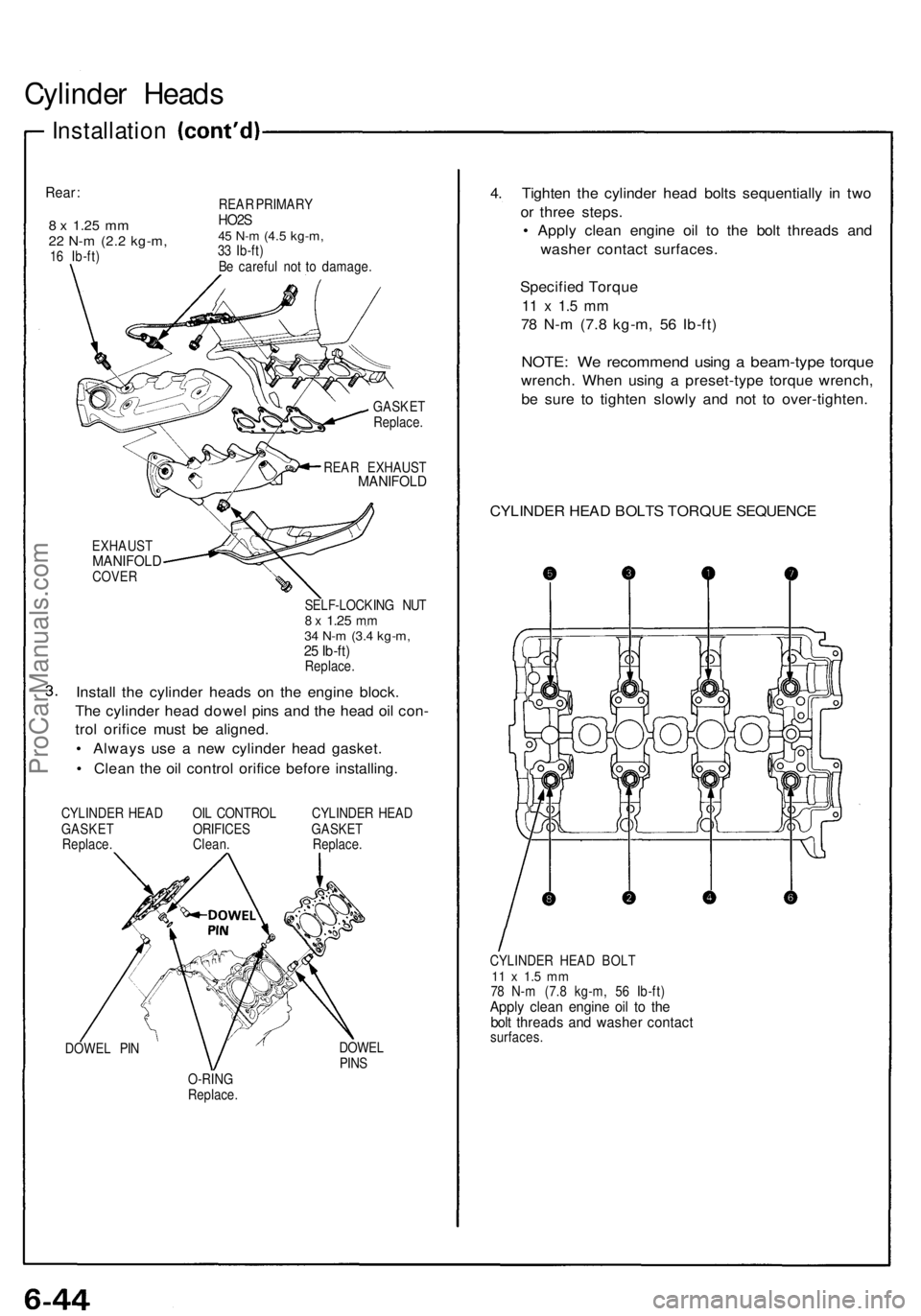

Install th e cylinde r head s o n th e engin e block .

Th e cylinde r hea d dowe l pin s an d th e hea d oi l con -

tro l orific e mus t b e aligned .

• Alway s us e a ne w cylinde r hea d gasket .

• Clea n th e oi l contro l orific e befor e installing .

CYLINDE R HEA D OI L CONTRO L CYLINDE R HEA D

GASKE T ORIFICE S GASKE T

Replace . Clean . Replace .

DOWE L PI N DOWE

L

PIN S

O-RIN G

Replace .

4. Tighte n th e cylinde r hea d bolt s sequentiall y i n tw o

o r thre e steps .

• Appl y clea n engin e oi l t o th e bol t thread s an d

washe r contac t surfaces .

Specifie d Torqu e

11 x 1. 5 m m

78 N- m (7. 8 kg-m , 5 6 Ib-ft )

NOTE : W e recommen d usin g a beam-typ e torqu e

wrench . Whe n usin g a preset-typ e torqu e wrench ,

b e sur e t o tighte n slowl y an d no t t o over-tighten .

CYLINDE R HEA D BOLT S TORQU E SEQUENC E

CYLINDER HEA D BOL T11 x 1. 5 m m78 N- m (7. 8 kg-m , 5 6 Ib-ft )Apply clea n engin e oi l t o th ebolt thread s an d washe r contac tsurfaces .

ProCarManuals.com

Page 208 of 1640

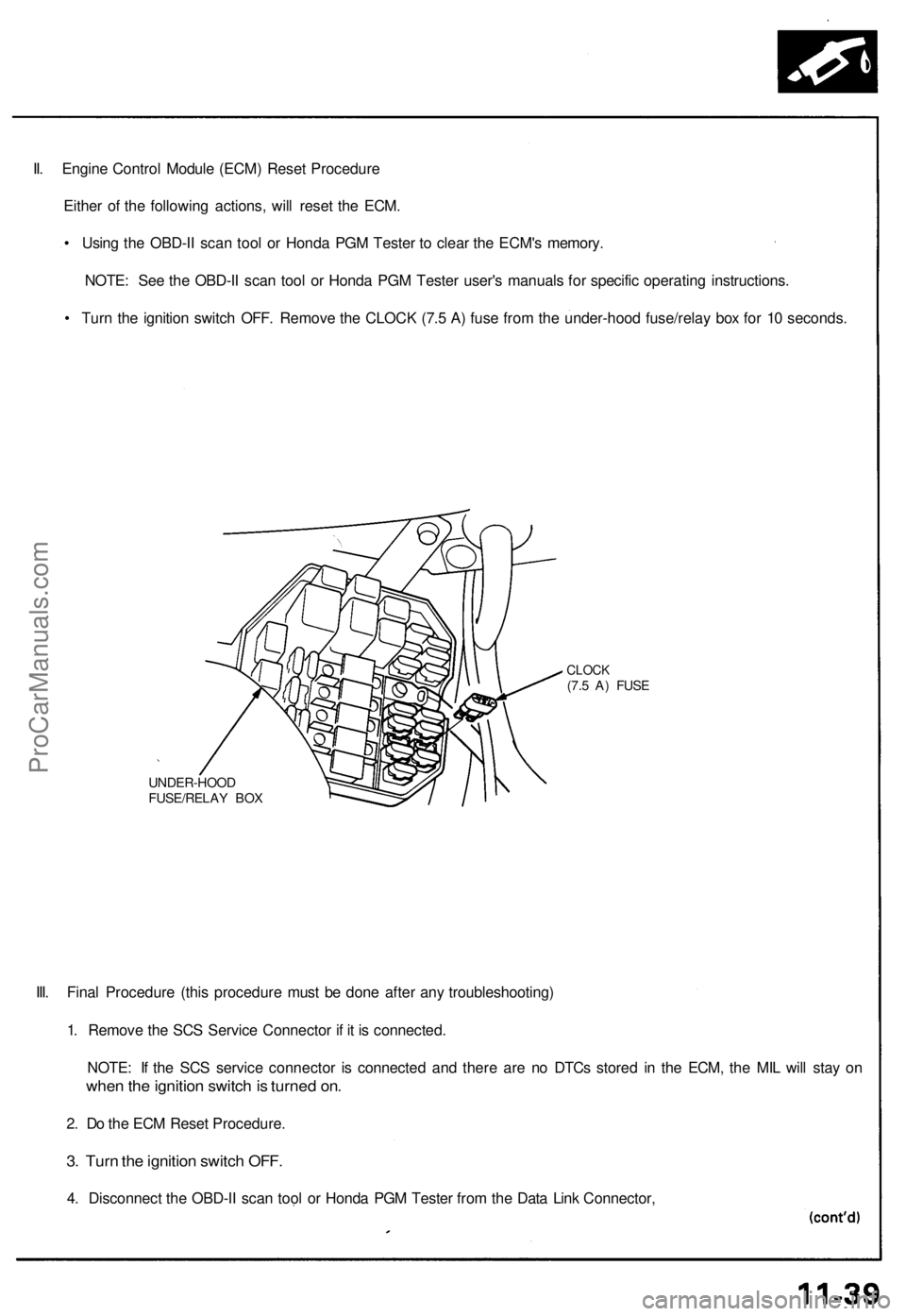

II. Engine Control Module (ECM) Reset Procedure

Either of the following actions, will reset the ECM.

• Using the OBD-II scan tool or Honda PGM Tester to clear the ECM's memory.

NOTE: See the OBD-II scan tool or Honda PGM Tester user's manuals for specific operating instructions.

• Turn the ignition switch OFF. Remove the CLOCK (7.5 A) fuse from the under-hood fuse/relay box for 10 seconds.

UNDER-HOOD

FUSE/RELAY BOX

CLOCK

(7.5 A) FUSE

III. Final Procedure (this procedure must be done after any troubleshooting)

1. Remove the SCS Service Connector if it is connected.

NOTE: If the SCS service connector is connected and there are no DTCs stored in the ECM, the MIL will stay on

when the ignition switch is turned on.

2. Do the ECM Reset Procedure.

3. Turn the ignition switch OFF.

4. Disconnect the OBD-II scan tool or Honda PGM Tester from the Data Link Connector,ProCarManuals.com

Page 358 of 1640

Preset Torqu e

Inspectio n

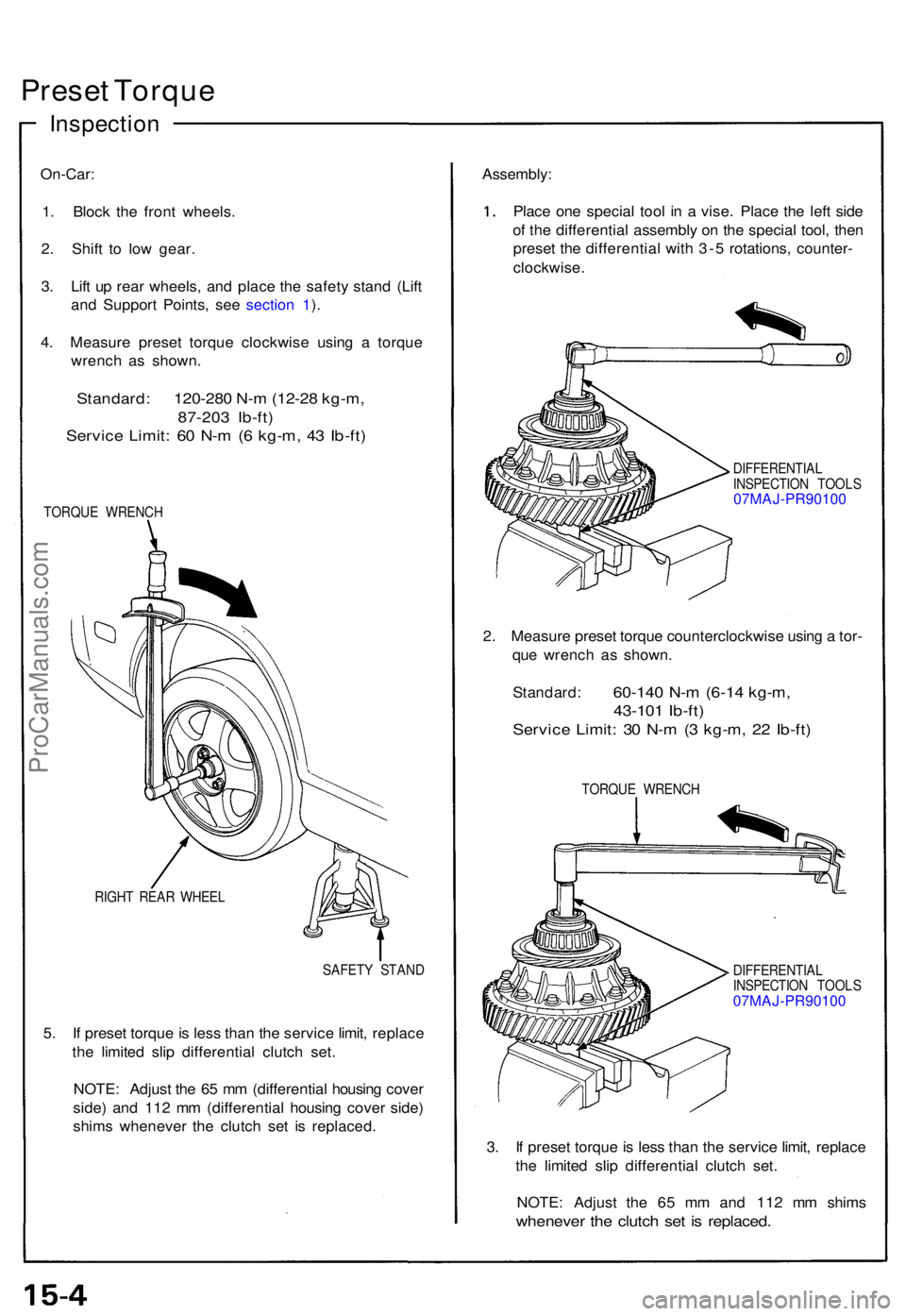

On-Car:

1 . Bloc k th e fron t wheels .

2 . Shif t t o low gear .

3 . Lif t u p rea r wheels , an d plac e th e safet y stan d (Lif t

an d Suppor t Points , se e sectio n 1 ).

4 . Measur e prese t torqu e clockwis e usin g a torqu e

wrenc h a s shown .

Standard: 120-280 N-m (12-28 kg-m,

87-20 3 Ib-ft )

Servic e Limit : 6 0 N- m (6 kg-m , 4 3 Ib-ft )

TORQU E WRENC H

RIGH T REA R WHEE L

SAFETY STAN D

5. I f prese t torqu e is les s tha n th e servic e limit , replac e

th e limite d sli p differentia l clutc h set .

NOTE : Adjus t th e 6 5 m m (differentia l housin g cove r

side ) an d 11 2 m m (differentia l housin g cove r side )

shim s wheneve r th e clutc h se t i s replaced . Assembly

:

Plac e on e specia l too l i n a vise . Plac e th e lef t sid e

o f th e differentia l assembl y o n th e specia l tool , the n

prese t th e differentia l wit h 3- 5 rotations , counter -

clockwise .

DIFFERENTIA L

INSPECTIO N TOOL S

07MAJ-PR90100

2. Measur e prese t torqu e counterclockwis e usin g a tor -

qu e wrenc h a s shown.

Standard :

60-140 N- m (6-1 4 kg-m ,

43-10 1 Ib-ft )

Servic e Limit : 3 0 N- m (3 kg-m , 2 2 Ib-ft )

TORQU E WRENC H

DIFFERENTIA L

INSPECTIO N TOOL S

07MAJ-PR90100

3 . I f prese t torqu e is les s tha n th e servic e limit , replac e

th e limite d sli p differentia l clutc h set .

NOTE : Adjus t th e 6 5 m m an d 11 2 m m shim s

wheneve r th e clutc h se t i s replaced .

ProCarManuals.com

Page 367 of 1640

I

Oil Seal

Removal

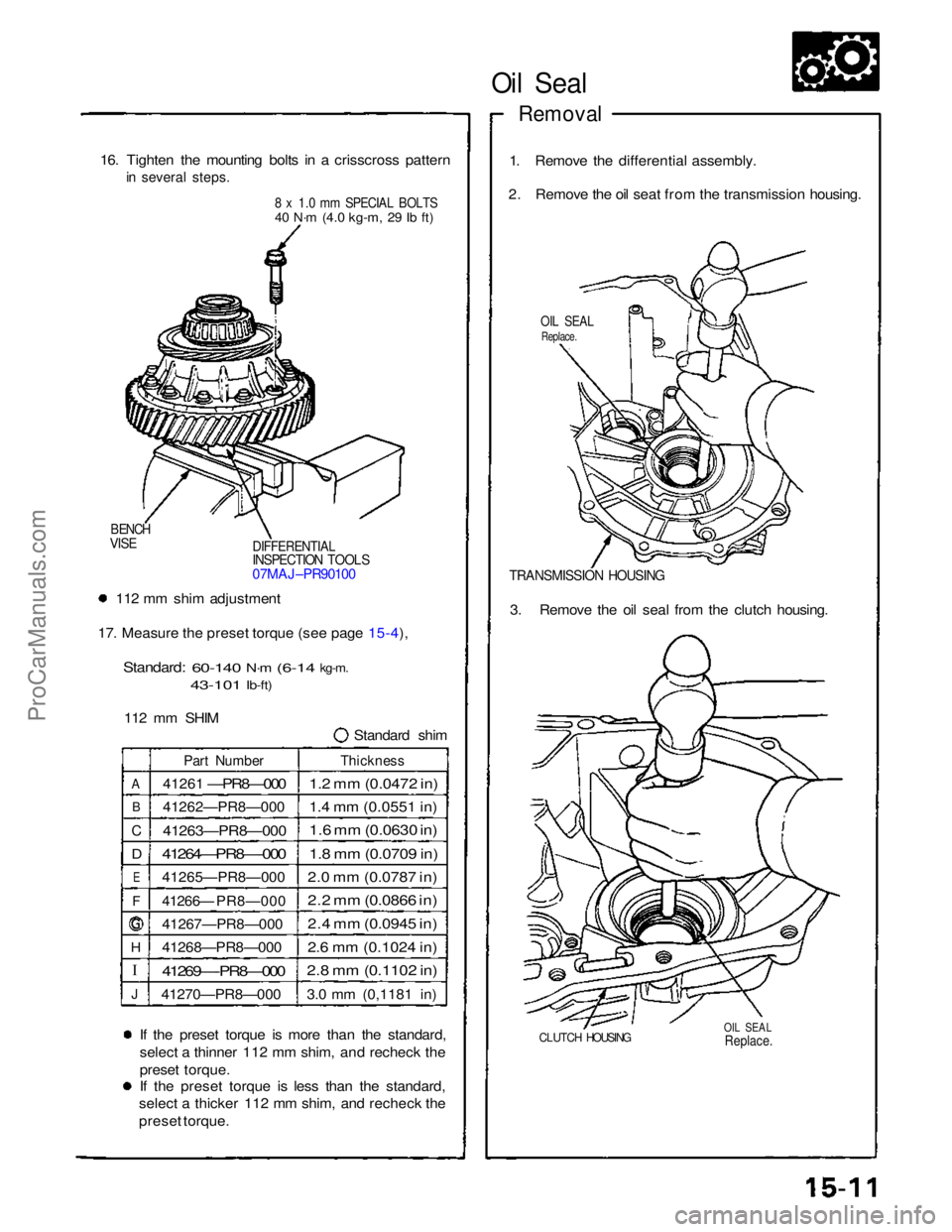

16. Tighten the mounting bolts in a crisscross pattern

in several steps.

8 x 1.0 mm SPECIAL BOLTS

40 N·m

(4.0 kg-m,

29 Ib ft)

1. Remove the differential assembly.

2. Remove the oil seat from the transmission housing.

OIL SEAL

Replace.

DIFFERENTIAL

INSPECTION TOOLS

07MAJ–PR90100

BENCH

VISE

TRANSMISSION HOUSING

112 mm shim adjustment

17. Measure the preset torque (see page 15-4),

Standard:

60-140

N·m

(6-14

kg-m.

43-101

Ib-ft)

112 mm SHIM Standard shim3. Remove the oil seal from the clutch housing.

A

B

C

D

E

F

H

J

Part Number

41261

—PR8—000

41262—PR8—000

41263—PR8—000

41264—PR8—-000

41265—PR8—000

41266— PR8—000

41267—PR8—000

41268—PR8—000

41269—-PR8—000

41270—PR8—000

Thickness

1.2 mm (0.0472 in)

1.4 mm (0.0551 in)

1.6 mm (0.0630 in)

1.8 mm (0.0709 in)

2.0 mm (0.0787 in)

2.2 mm (0.0866 in)

2.4 mm (0.0945 in)

2.6 mm (0.1024 in)

2.8 mm (0.1102 in)

3.0 mm (0,1181 in)

If the preset torque is more than the standard,

select a thinner 112 mm shim, and recheck the

preset torque.

If the preset torque is less than the standard,

select a thicker 112 mm shim, and recheck the

preset torque.

CLUTCH HOUSING

OIL SEAL

Replace.

ProCarManuals.com

Page 373 of 1640

Preset Torque

Inspection

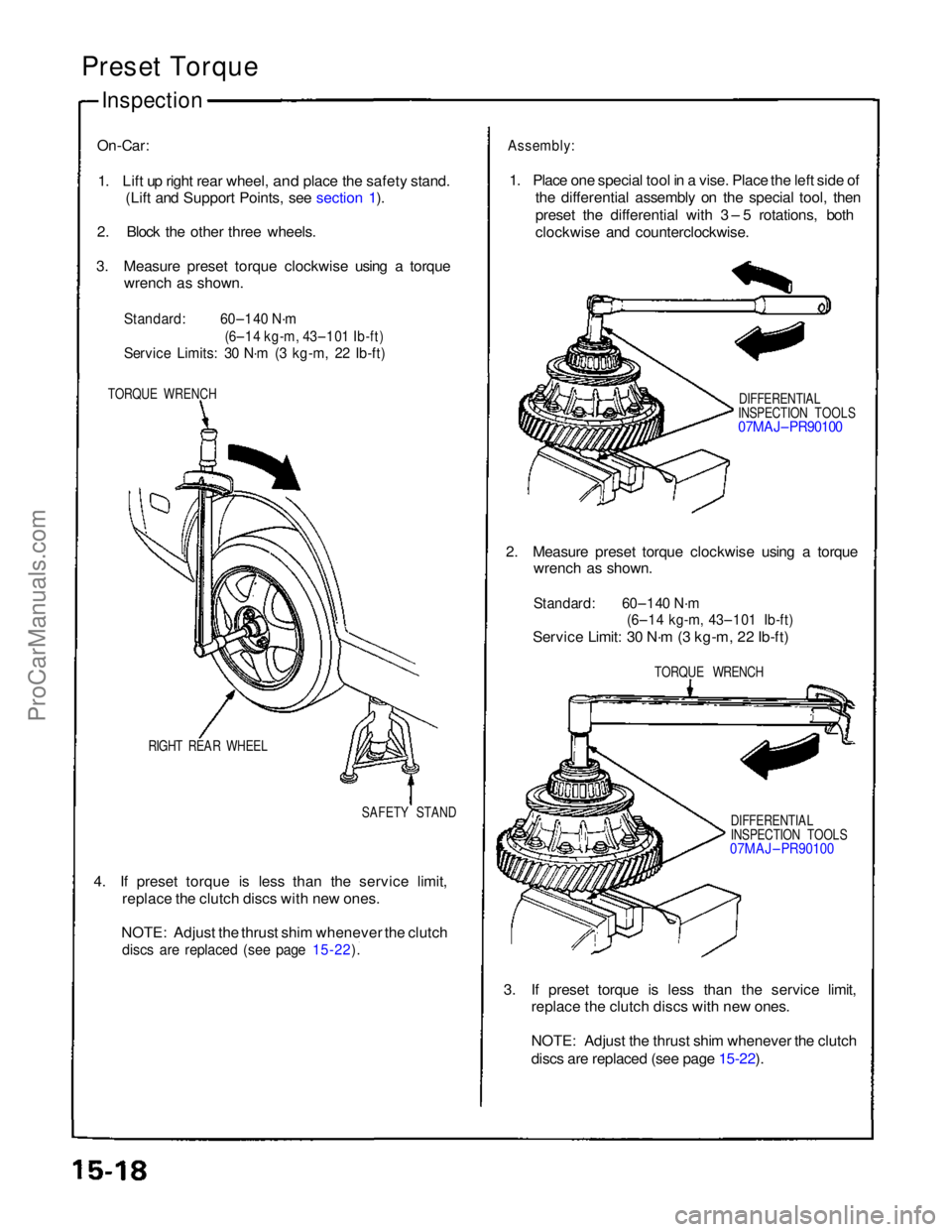

On-Car:

1. Lift up right rear wheel,

and place the safety stand.

(Lift and Support Points, see section 1).

2. Block the other three wheels.

3. Measure preset torque clockwise using a torque wrench as shown.

Standard:

60–140 N·m

(6–14 kg-m, 43–101 Ib-ft)

Service Limits: 30 N·m (3 kg-m, 22 Ib-ft)

TORQUE WRENCH

RIGHT REAR WHEEL SAFETY STAND

4. If preset torque is less than the service limit, replace the clutch discs with new ones.

NOTE: Adjust the thrust shim whenever the clutch

discs are replaced (see page 15-22).

Assembly:

1. Place one special tool in a vise. Place the left side of the differential assembly on the special tool, then

preset the differential with 3 – 5 rotations, both

clockwise and counterclockwise.

DIFFERENTIAL

INSPECTION TOOLS

07MAJ– PR90100

2. Measure preset torque clockwise using a torque wrench as shown.

Standard: 60–140 N·m

(6–14 kg-m, 43–101 Ib-ft)

Service Limit: 30 N·m (3 kg-m, 22 Ib-ft)

TORQUE WRENCH

DIFFERENTIAL

INSPECTION TOOLS

07MAJ – PR90100

3. If preset torque is less than the service limit, replace the clutch discs with new ones.

NOTE: Adjust the thrust shim whenever the clutch

discs are replaced (see page 15-22).

ProCarManuals.com

Page 377 of 1640

\

I

Clutch Disc, Clutch Plate

Replacement

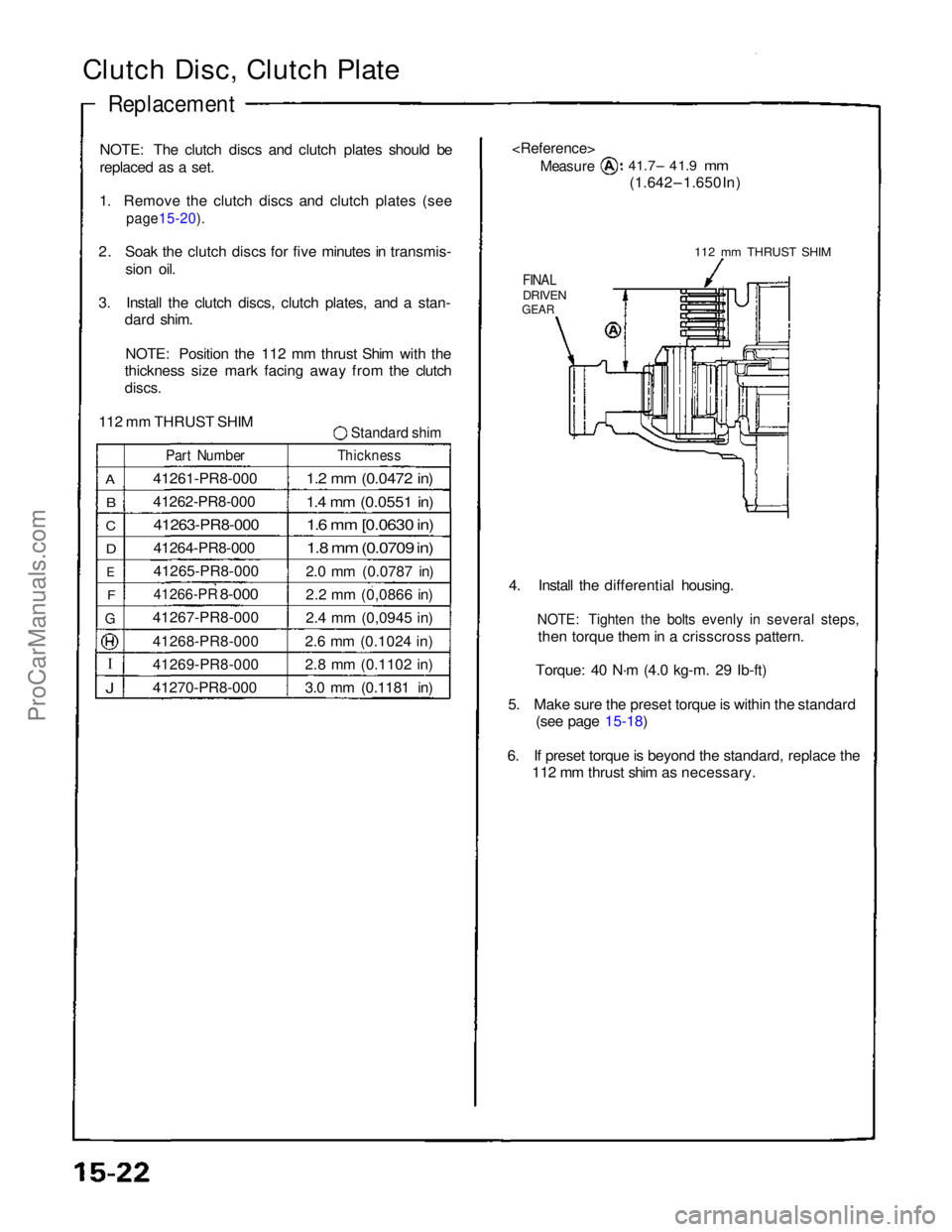

NOTE: The clutch discs and clutch plates should be

replaced as a set.

1. Remove the clutch discs and clutch plates (see

page15-20).

2. Soak the clutch discs for five minutes in transmis-

sion oil.

3. Install the clutch discs, clutch plates, and a stan- dard shim.

NOTE: Position the 112 mm thrust Shim with the

thickness size mark facing away from the clutch

discs.

112 mm THRUST SHIM

Standard shim

A

B

C

D

E

F

G

J

Part Number

41261-PR8-000

41262-PR8-000

41263-PR8-000

41264-PR8-000

41265-PR8-000

41266-PR

8-000

41267-PR8-000

41268-PR8-000

41269-PR8-000

41270-PR8-000

Thickness

1.2 mm (0.0472 in)

1.4 mm (0.0551 in)

1.6 mm [0.0630 in)

1.8 mm (0.0709 in)

2.0 mm (0.0787 in)

2.2 mm (0,0866 in)

2.4 mm (0,0945 in)

2.6 mm (0.1024 in)

2.8 mm (0.1102 in)

3.0 mm (0.1181 in)

Measure

41.7– 41.9

mm

(1.642 – 1.650 In)

112 mm THRUST SHIM

FINAL

DRIVEN

GEAR

4. Install the differential housing.

NOTE: Tighten the bolts evenly in several steps,

then torque them in a crisscross pattern.

Torque: 40 N·m (4.0 kg-m. 29 Ib-ft)

5. Make sure the preset torque is within the standard (see page 15-18)

6. If preset torque is beyond the standard, replace the 112 mm thrust shim as necessary.ProCarManuals.com

Page 420 of 1640

Troubleshooting Precautions

EPS Indicator Light

Under normal conditions, the EPS indicator light in the gauge assembly comes on when the ignition switch is turned to

the ON (II) position, then goes off after the engine is started. This indicates that the bulb and its circuits are operating cor-

rectly. If there is any trouble in the system, the EPS indicator light turns on during driving, and the power steering assist is

turned off. When the EPS indicator light comes on, the control unit memorizes the DTC. In this case, the control unit does

not activate the EPS system after the engine starts again but it keeps the EPS indicator light on.

Diagnostic Trouble Code (DTC)

• The lowest DTC is indicated first.

• The DTCs continue blinking until the ignition switch is turned off.

• The DTCs are erased from the control unit when the EPS control unit VBU power supply or connector is disconnected.

• The EPS system can be reset and the control unit's memory can be erased by disconnecting the CLOCK (7.5 A) fuse for

more than ten seconds.

Self-diagnosis:

The CPU (central processing unit) controls the following when it detects a problem during self-diagnosis:

1. Turns the EPS indicator light ON to alert the driver.

2. Power assist stops, and normal manual steering operation resumes (except DTC 21 and DTC 33).

3. The EPS control unit memorizes the diagnostic trouble code (DTC).

4. After the DTC is stored in the control unit, the CPU stops self-diagnosis.

Troubleshooting:

• Before starting the troubleshooting, clear the DTC by disconnecting the CLOCK (7.5 A) fuse for ten seconds or more,

and test-drive the car. Check that the symptom of the trouble appears again, and then troubleshoot. If the problem is an

intermittent problem, the system does not become active after the engine starts even though the problem is solved.

• When both EPS indicator light and A/T "D" indicator light come on, perform the A/T troubleshooting first.

• When the customer's reported problem cannot be verified in the car, ask the customer about the conditions when the

EPS indicator light came ON, then test-drive the car under those conditions, if possible. If the EPS indicator light does

not come ON during the test, check for loose connections or poor contacts at the connectors by wiggling the harness,

etc.

• The connector terminal numbers are viewed from the wire side for the female terminals and from the terminal side for

the male terminals.

• After the repair, test-drive the car and check that the EPS indicator light does not come ON again during the test. (Refer

to the Symptom-to-System Chart for diagnostic period.)ProCarManuals.com

Page 553 of 1640

Troubleshooting

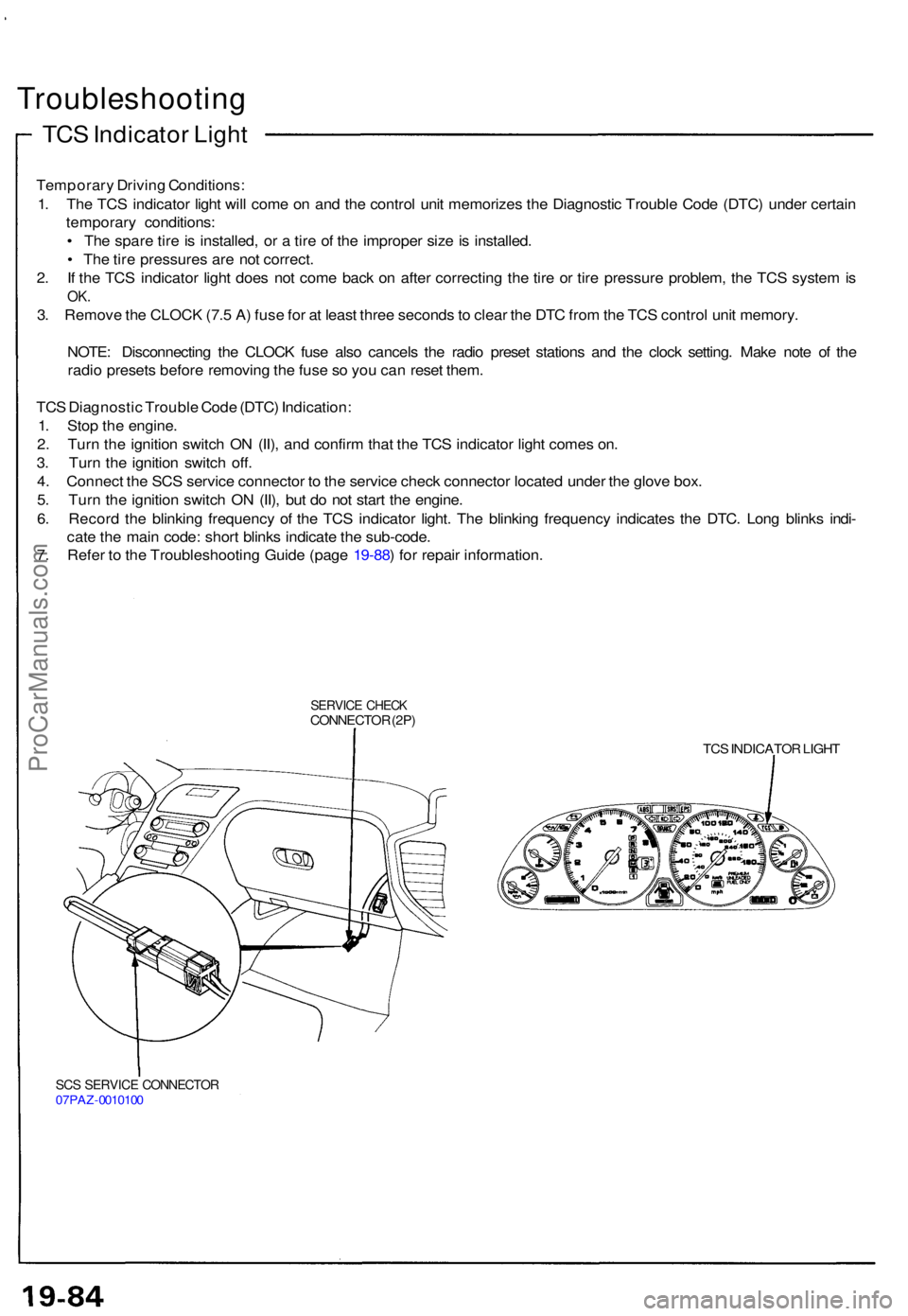

TCS Indicato r Ligh t

Temporar y Drivin g Conditions :

1 . Th e TC S indicato r ligh t wil l com e o n an d th e contro l uni t memorize s th e Diagnosti c Troubl e Cod e (DTC ) unde r certai n

temporar y conditions :

• Th e spar e tir e is installed , o r a tir e o f th e imprope r siz e is installed .

• Th e tir e pressure s ar e no t correct .

2 . I f th e TC S indicato r ligh t doe s no t com e bac k o n afte r correctin g th e tir e o r tir e pressur e problem , th e TC S syste m is

OK .

3. Remov e th e CLOC K (7. 5 A ) fus e fo r a t leas t thre e second s to clea r th e DT C fro m th e TC S contro l uni t memory .

NOTE : Disconnectin g th e CLOC K fus e als o cancel s th e radi o prese t station s an d th e cloc k setting . Mak e not e o f th e

radi o preset s befor e removin g th e fus e s o yo u ca n rese t them .

TC S Diagnosti c Troubl e Cod e (DTC ) Indication :

1 . Sto p th e engine .

2 . Tur n th e ignitio n switc h O N (II) , an d confir m tha t th e TC S indicato r ligh t come s on .

3 . Tur n th e ignitio n switc h off .

4 . Connec t th e SC S servic e connecto r t o th e servic e chec k connecto r locate d unde r th e glov e box .

5 . Tur n th e ignitio n switc h O N (II) , bu t d o no t star t th e engine .

6 . Recor d th e blinkin g frequenc y o f th e TC S indicato r light . Th e blinkin g frequenc y indicate s th e DTC . Lon g blink s indi -

cat e th e mai n code : shor t blink s indicat e th e sub-code .

7 . Refe r t o th e Troubleshootin g Guid e (pag e 19-88 ) fo r repai r information .

SERVICE CHEC KCONNECTO R (2P )

TCS INDICATO R LIGH T

SCS SERVIC E CONNECTO R07PAZ-001010 0

ProCarManuals.com

Page 790 of 1640

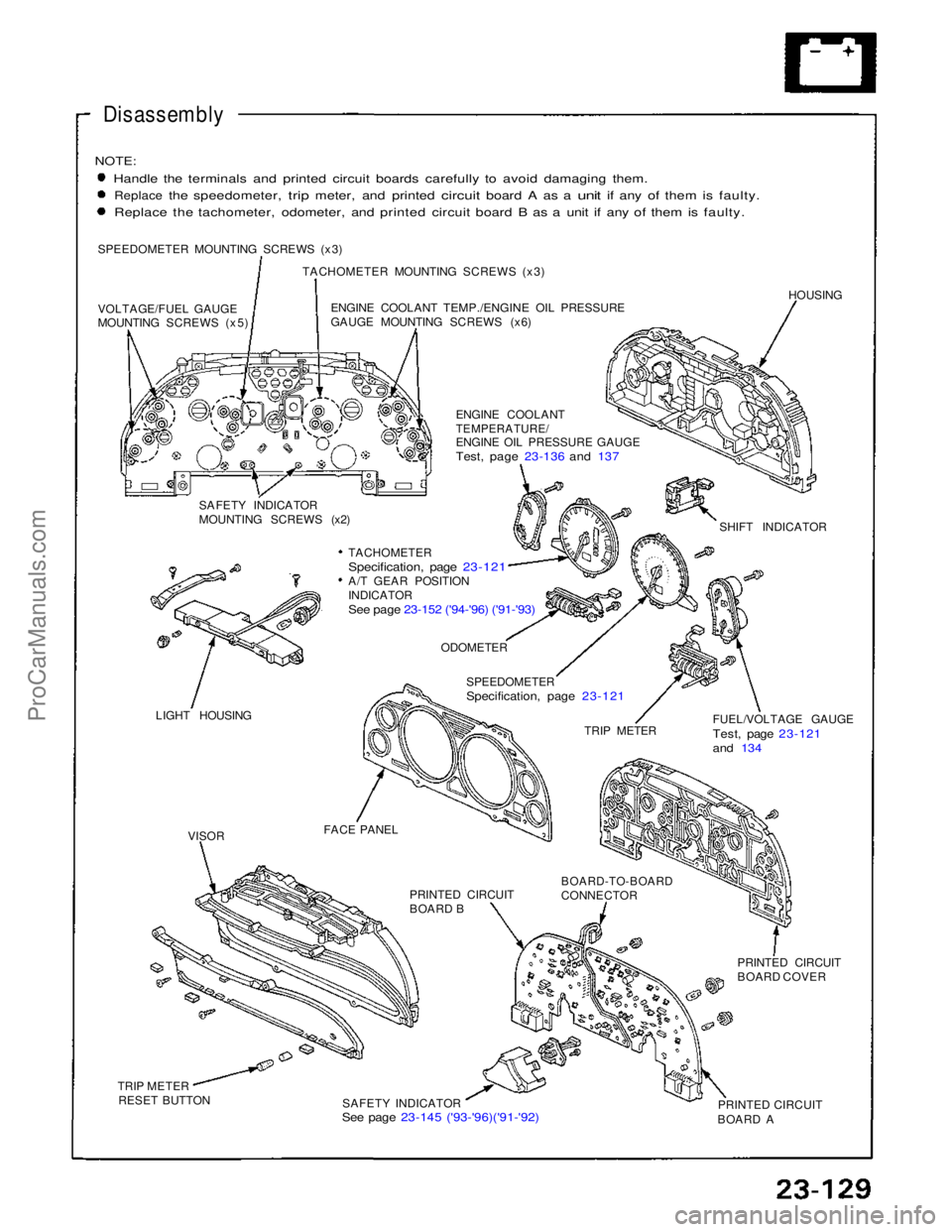

Disassembly

NOTE:

Handle the terminals and printed circuit boards carefully to avoid damaging them.

Replace

the

speedometer,

trip

meter,

and

printed

circuit

board

A as a

unit

if any of

them

is

faulty. Replace the tachometer, odometer, and printed circuit board B as a unit if any of them is faulty.

SPEEDOMETER MOUNTING SCREWS (x3) TACHOMETER MOUNTING SCREWS (x3)

VOLTAGE/FUEL GAUGE

MOUNTING SCREWS (x5) ENGINE COOLANT TEMP./ENGINE OIL PRESSURE

GAUGE MOUNTING SCREWS (x6)

HOUSING

ENGINE COOLANT

TEMPERATURE/

ENGINE OIL PRESSURE GAUGE

Test, page 23-136 and 137

SAFETY INDICATOR

MOUNTING SCREWS (x2) SHIFT INDICATOR

TACHOMETER

Specification, page 23-121

A/T GEAR POSITION

INDICATOR

See page 23-152 ('94-'96) ('91-'93)

LIGHT HOUSING

ODOMETER

SPEEDOMETER

Specification, page 23-121

TRIP METER FUEL/VOLTAGE GAUGE

Test, page 23-121

and 134

FACE PANEL PRINTED CIRCUIT

BOARD B

BOARD-TO-BOARD

CONNECTOR

PRINTED CIRCUIT

BOARD COVER

PRINTED CIRCUIT

BOARD A

SAFETY INDICATOR

See page 23-145 ('93-'96)('91-'92)

TRIP METER

RESET BUTTON

VISORProCarManuals.com

Page 1036 of 1640

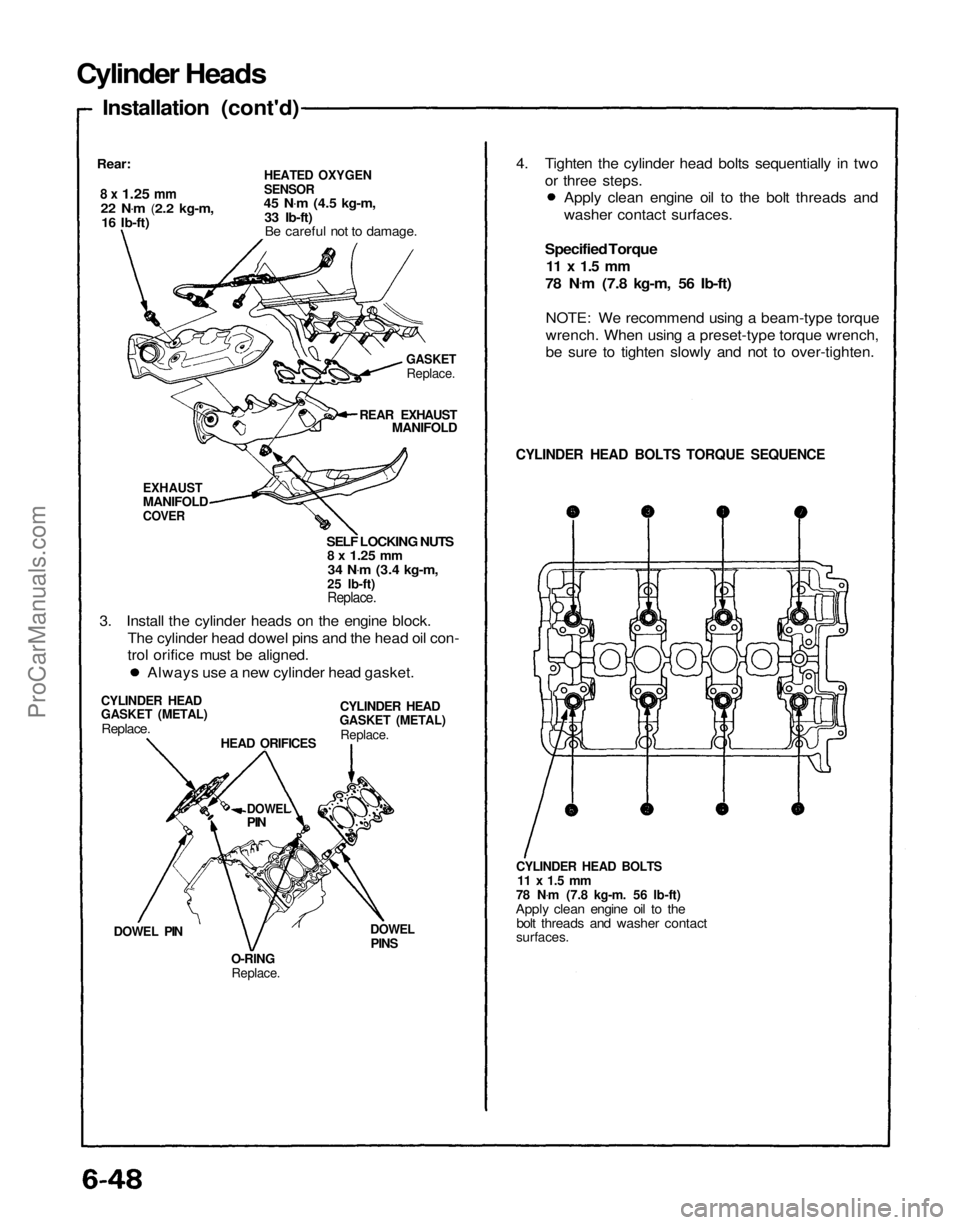

Cylinder Heads

Installation (cont'd)

Rear:

8 x

1.25

mm

22 N .

m

(2.2 kg-m,

16 Ib-ft)

HEATED OXYGEN

SENSOR

45 N .

m

(4.5 kg-m,

33 Ib-ft) Be careful not to damage.

GASKET

Replace.

REAR EXHAUST

MANIFOLD

EXHAUST

MANIFOLD

COVER

SELF LOCKING NUTS

8 x

1.25

mm

34 N .

m

(3.4 kg-m,

25 Ib-ft)

Replace.

3. Install the cylinder heads on the engine block. The cylinder head dowel pins and the head oil con-

trol orifice must be aligned.

CYLINDER HEAD

GASKET (METAL)

Replace.

CYLINDER HEAD

GASKET (METAL)

Replace.

HEAD ORIFICES

DOWEL

PIN

DOWEL PIN

O-RING

Replace.

DOWEL

PINS

CYLINDER HEAD BOLTS

11 x 1.5 mm

78 N .

m (7.8 kg-m. 56 Ib-ft)

Apply clean engine oil to the bolt threads and washer contact

surfaces.

CYLINDER HEAD BOLTS TORQUE SEQUENCE

Specified Torque

11 x 1.5 mm

78 N .

m (7.8 kg-m, 56 Ib-ft)

NOTE: We recommend using a beam-type torque

wrench. When using a preset-type torque wrench,

be sure to tighten slowly and not to over-tighten.

Always use a new cylinder head gasket. Apply clean engine oil to the bolt threads and

washer contact surfaces.

4. Tighten the cylinder head bolts sequentially in two

or three steps.ProCarManuals.com