engine ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 1231 of 1503

Troubleshooting

Tips and Precautions

Before Troubleshooting

Check applicable fuses in the appropriate fuse box.

Check the battery for damage, state of charge, and

clean and tight connections.

Check the alternator belt tension.

CAUTION:

Do not quick-charge a battery unless the battery

ground cable has been disconnected.

Otherwise you will damage the alternator

diodes.

Do not attempt to crank the engine with the bat-

tery ground cable loosely connected or you will

severely damage the wiring.

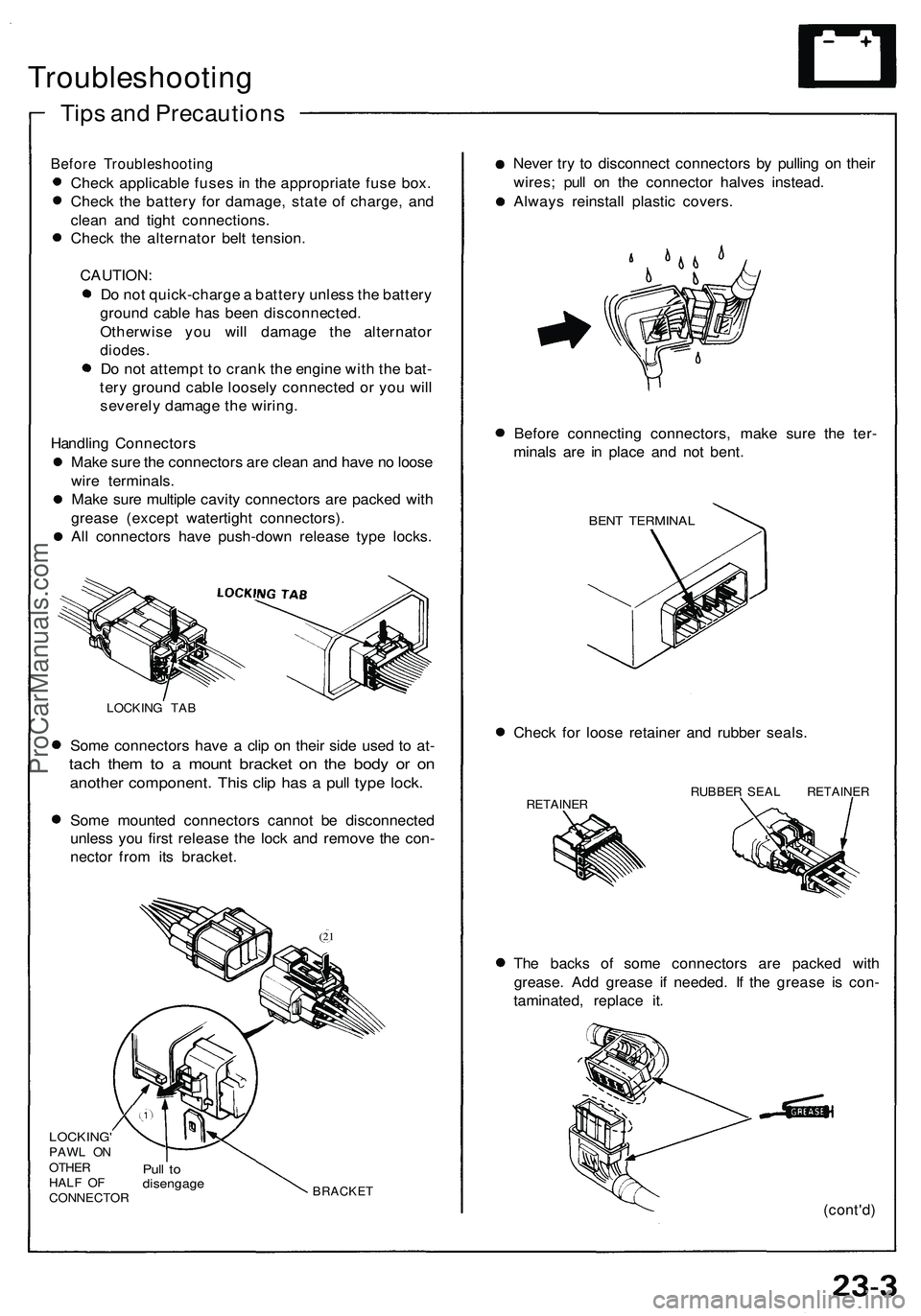

Handling Connectors

Make sure the connectors are clean and have no loose

wire terminals.

Make sure multiple cavity connectors are packed with

grease (except watertight connectors).

All connectors have push-down release type locks.

LOCKING TAB

Some connectors have a clip on their side used to at-

tach them to a mount bracket on the body or on

another component. This clip has a pull type lock.

Some mounted connectors cannot be disconnected

unless you first release the lock and remove the con-

nector from its bracket.

(21

LOCKING'

PAWL ON

OTHER

HALF OF

CONNECTOR

Pull to

disengage

BRACKET

Never try to disconnect connectors by pulling on their

wires; pull on the connector halves instead.

Always reinstall plastic covers.

Before connecting connectors, make sure the ter-

minals are in place and not bent.

BENT TERMINAL

Check for loose retainer and rubber seals.

RETAINER

RUBBER SEAL RETAINER

The backs of some connectors are packed with

grease. Add grease if needed. If the grease is con-

taminated, replace it.

(cont'd)ProCarManuals.com

Page 1239 of 1503

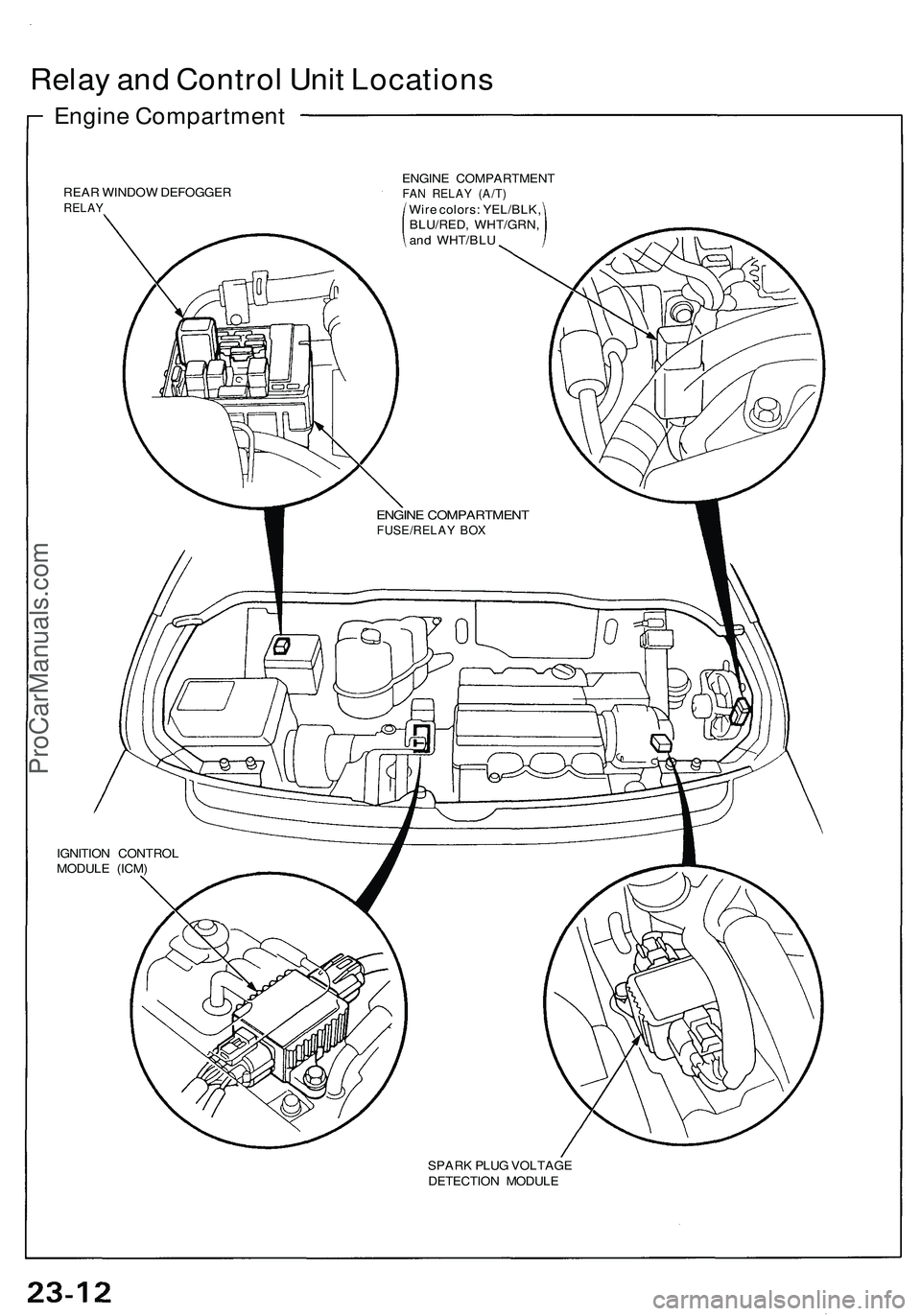

Relay an d Contro l Uni t Location s

Engine Compartmen t

REAR WINDOW DEFOGGE RRELAY

ENGIN E COMPARTMEN TFAN RELA Y (A/T )Wire colors : YEL/BLK ,

BLU/RED , WHT/GRN ,

an d WHT/BL U

ENGINE COMPARTMEN TFUSE/RELAY BO X

IGNITIO N CONTRO L

MODUL E (ICM )

SPARK PLU G VOLTAG E

DETECTIO N MODUL E

ProCarManuals.com

Page 1250 of 1503

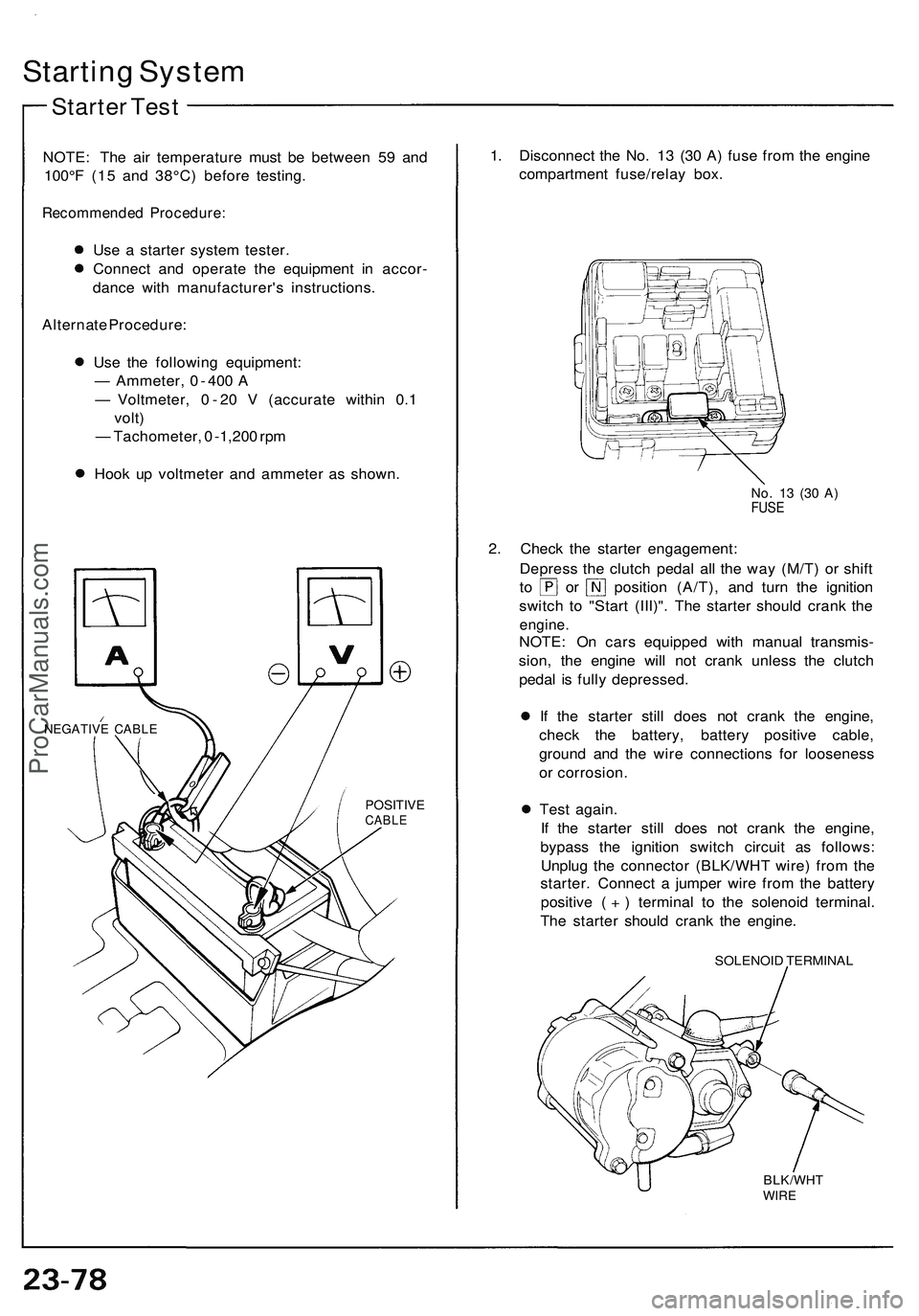

Starting Syste m

Starte r Tes t

NOTE : Th e ai r temperatur e mus t b e betwee n 5 9 an d

100° F (1 5 an d 38°C ) befor e testing .

Recommende d Procedure :

Use a starte r syste m tester .

Connec t an d operat e th e equipmen t i n accor -

danc e wit h manufacturer' s instructions .

Alternat e Procedure :

Us e th e followin g equipment :

— Ammeter , 0 - 40 0 A

— Voltmeter , 0 - 2 0 V (accurat e withi n 0. 1

volt )

— Tachometer , 0 -1,20 0 rp m

Hoo k u p voltmete r an d ammete r a s shown .

NEGATIV E CABL E

POSITIV ECABLE

1. Disconnec t th e No . 1 3 (3 0 A ) fus e fro m th e engin e

compartmen t fuse/rela y box .

No. 1 3 (3 0 A )FUS E

2. Chec k th e starte r engagement :

Depres s th e clutc h peda l al l th e wa y (M/T ) o r shif t

to o r positio n (A/T) , an d tur n th e ignitio n

switc h t o "Star t (III)" . Th e starte r shoul d cran k th e

engine .

NOTE: O n car s equippe d wit h manua l transmis -

sion , th e engin e wil l no t cran k unles s th e clutc h

peda l i s full y depressed .

I f th e starte r stil l doe s no t cran k th e engine ,

chec k th e battery , batter y positiv e cable ,

ground and th e wir e connection s fo r loosenes s

o r corrosion .

Tes t again .

If th e starte r stil l doe s no t cran k th e engine ,

bypas s th e ignitio n switc h circui t a s follows :

Unplu g th e connecto r (BLK/WH T wire ) fro m th e

starter . Connec t a jumpe r wir e fro m th e batter y

positiv e ( + ) termina l t o th e solenoi d terminal .

Th e starte r shoul d cran k th e engine .

SOLENOI D TERMINA L

BLK/WHTWIRE

ProCarManuals.com

Page 1251 of 1503

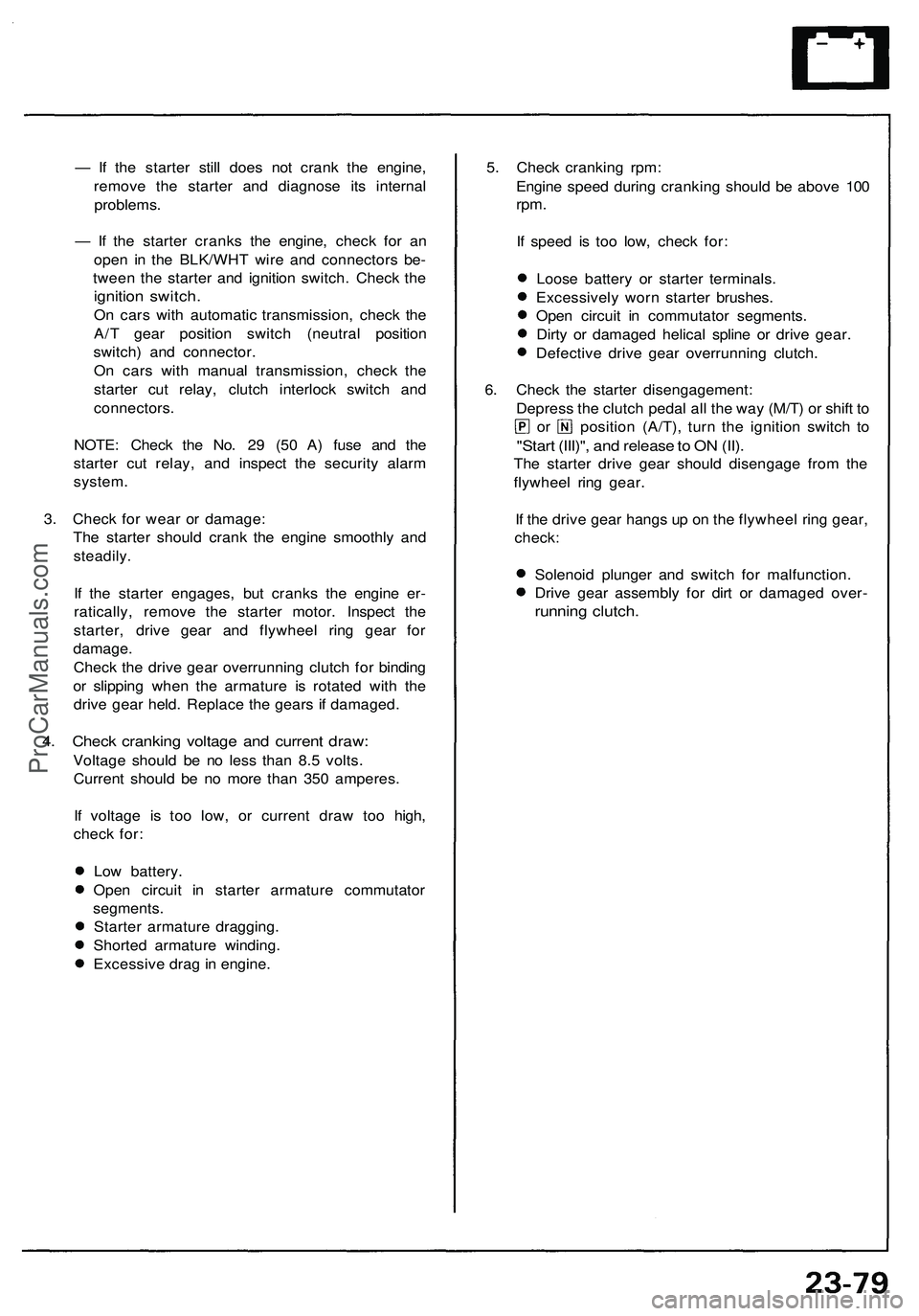

— If the starter still does not crank the engine,

remove the starter and diagnose its internal

problems.

— If the starter cranks the engine, check for an

open in the BLK/WHT wire and connectors be-

tween the starter and ignition switch. Check the

ignition switch.

On cars with automatic transmission, check the

A/T gear position switch (neutral position

switch) and connector.

On cars with manual transmission, check the

starter cut relay, clutch interlock switch and

connectors.

NOTE: Check the No. 29 (50 A) fuse and the

starter cut relay, and inspect the security alarm

system.

3. Check for wear or damage:

The starter should crank the engine smoothly and

steadily.

If the starter engages, but cranks the engine er-

ratically, remove the starter motor. Inspect the

starter, drive gear and flywheel ring gear for

damage.

Check the drive gear overrunning clutch for binding

or slipping when the armature is rotated with the

drive gear held. Replace the gears if damaged.

4. Check cranking voltage and current draw:

Voltage should be no less than 8.5 volts.

Current should be no more than 350 amperes.

If voltage is too low, or current draw too high,

check for:

Low battery.

Open circuit in starter armature commutator

segments.

Starter armature dragging.

Shorted armature winding.

Excessive drag in engine.

5. Check cranking rpm:

Engine speed during cranking should be above 100

rpm.

If speed is too low, check for:

Loose battery or starter terminals.

Excessively worn starter brushes.

Open circuit in commutator segments.

Dirty or damaged helical spline or drive gear.

Defective drive gear overrunning clutch.

6. Check the starter disengagement:

Depress the clutch pedal all the way (M/T) or shift to

or position (A/T), turn the ignition switch to

"Start (III)", and release to ON (II).

The starter drive gear should disengage from the

flywheel ring gear.

If the drive gear hangs up on the flywheel ring gear,

check:

Solenoid plunger and switch for malfunction.

Drive gear assembly for dirt or damaged over-

running clutch.ProCarManuals.com

Page 1253 of 1503

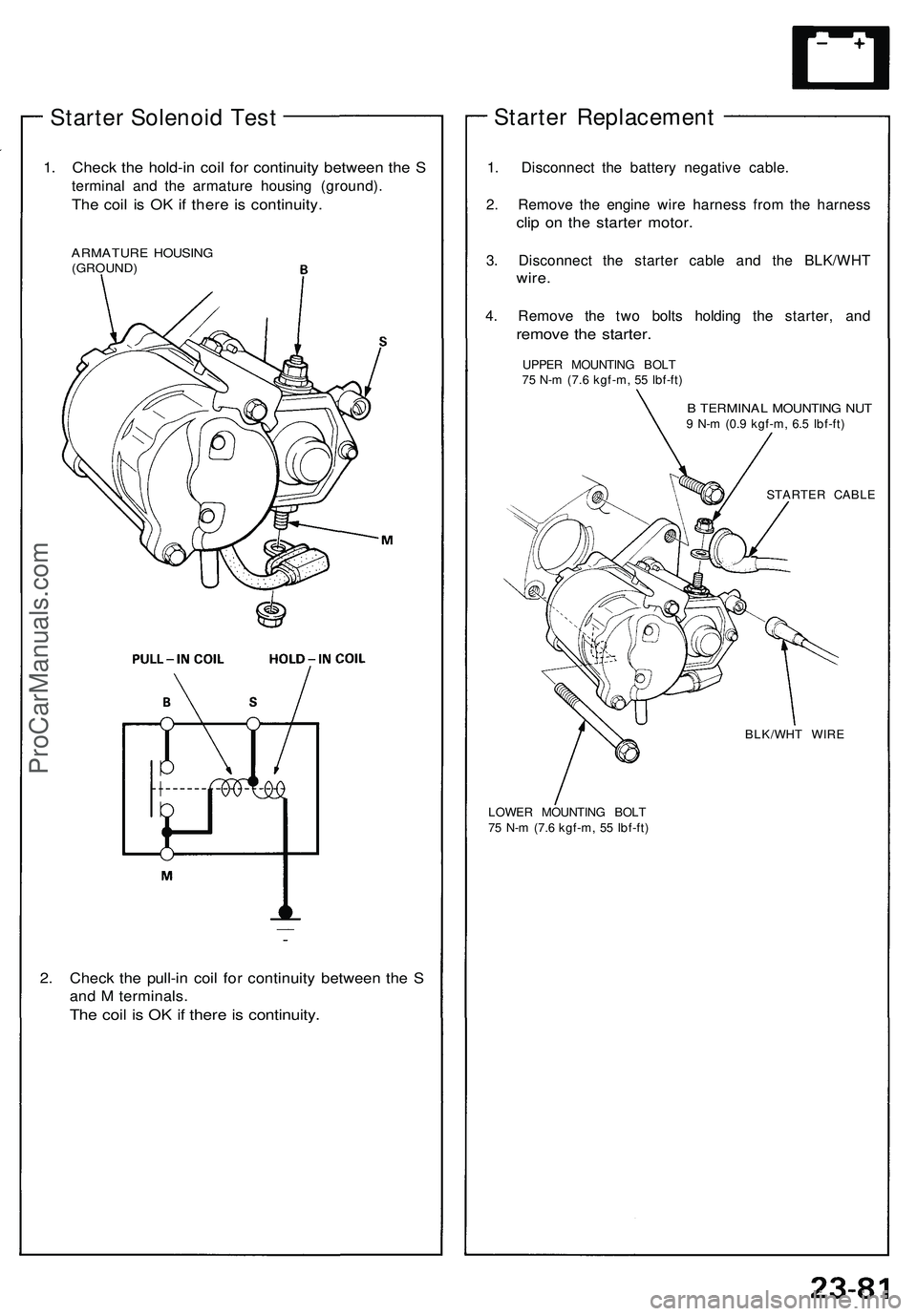

Starter Solenoid Test

1. Check the hold-in coil for continuity between the S

terminal and the armature housing (ground).

The coil is OK if there is continuity.

ARMATURE HOUSING

(GROUND)

2. Check the pull-in coil for continuity between the S

and M terminals.

The coil is OK if there is continuity.

Starter Replacement

1. Disconnect the battery negative cable.

2. Remove the engine wire harness from the harness

clip on the starter motor.

3. Disconnect the starter cable and the BLK/WHT

wire.

4. Remove the two bolts holding the starter, and

remove the starter.

UPPER MOUNTING BOLT

75 N-m (7.6 kgf-m, 55 Ibf-ft)

B TERMINAL MOUNTING NUT

9 N-m (0.9 kgf-m, 6.5 Ibf-ft)

STARTER CABLE

LOWER MOUNTING BOLT

75 N-m (7.6 kgf-m, 55 Ibf-ft)

BLK/WHT WIREProCarManuals.com

Page 1262 of 1503

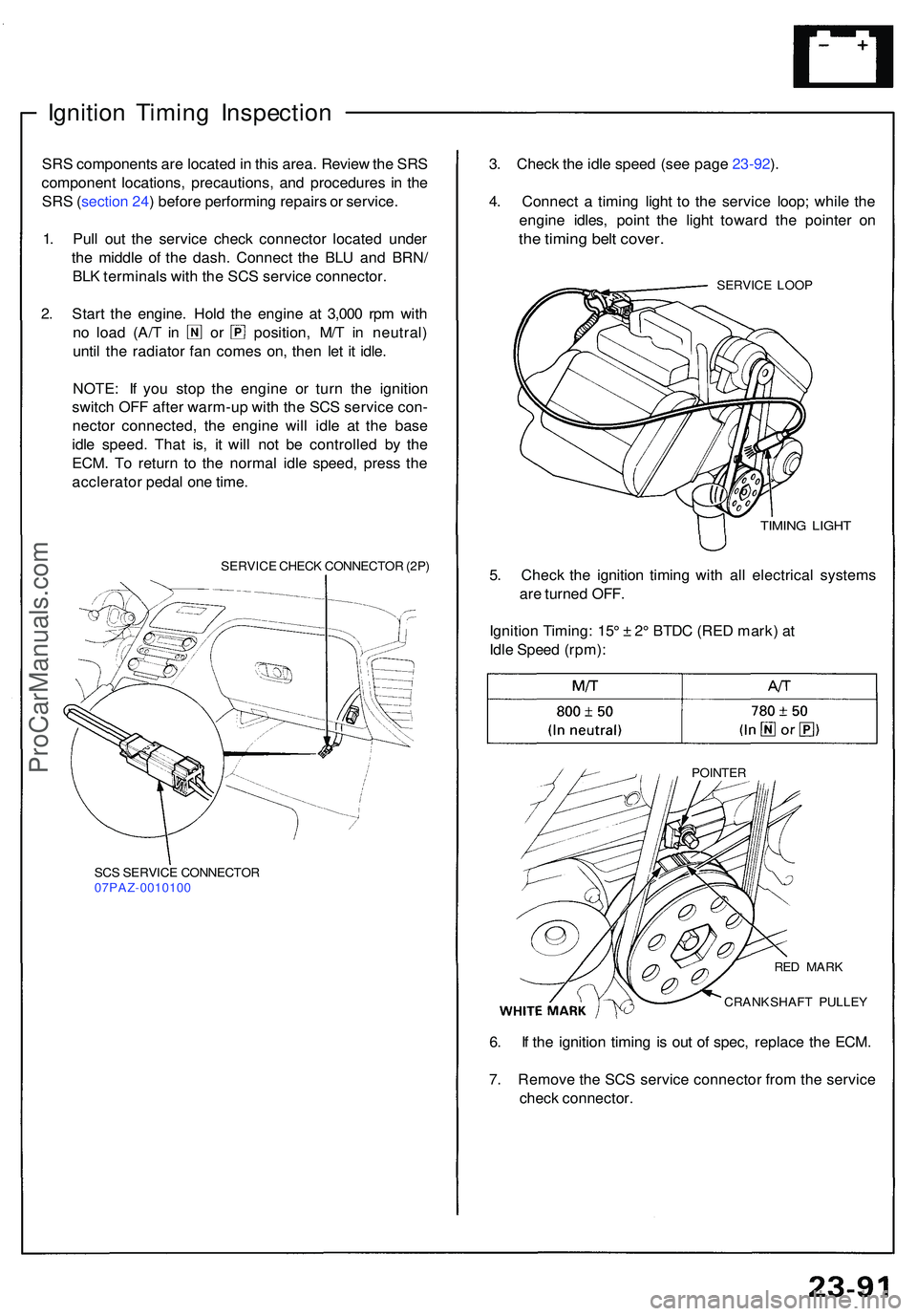

Ignition Timin g Inspectio n

SRS component s ar e locate d in thi s area . Revie w th e SR S

componen t locations , precautions , an d procedure s i n th e

SR S (sectio n 24 ) befor e performin g repair s o r service .

1 . Pul l ou t th e servic e chec k connecto r locate d unde r

th e middl e o f th e dash . Connec t th e BL U an d BRN /

BL K terminal s wit h th e SC S servic e connector .

2 . Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (A/ T i n o r position , M/ T i n neutral )

unti l th e radiato r fa n come s on , the n le t i t idle .

NOTE : I f yo u sto p th e engin e o r tur n th e ignitio n

switc h OF F afte r warm-u p wit h th e SC S servic e con -

necto r connected , th e engin e wil l idl e a t th e bas e

idl e speed . Tha t is , i t wil l no t b e controlle d b y th e

ECM . T o retur n t o th e norma l idl e speed , pres s th e

acclerato r peda l on e time .

SERVIC E CHEC K CONNECTO R (2P )

SC S SERVIC E CONNECTO R

07PAZ-001010 0

3. Chec k th e idl e spee d (se e pag e 23-92 ).

4 . Connec t a timin g ligh t t o th e servic e loop ; whil e th e

engin e idles , poin t th e ligh t towar d th e pointe r o n

the timin g bel t cover .

SERVIC E LOO P

TIMIN G LIGH T

5. Chec k th e ignitio n timin g wit h al l electrica l system s

ar e turne d OFF .

Ignitio n Timing : 15 ° ± 2° BTD C (RE D mark ) a t

Idl e Spee d (rpm) :

POINTE R

6. I f th e ignitio n timin g i s ou t o f spec , replac e th e ECM .

7 . Remov e th e SC S servic e connecto r fro m th e servic e

chec k connector .

CRANKSHAF T PULLE Y

RE

D MAR K

ProCarManuals.com

Page 1263 of 1503

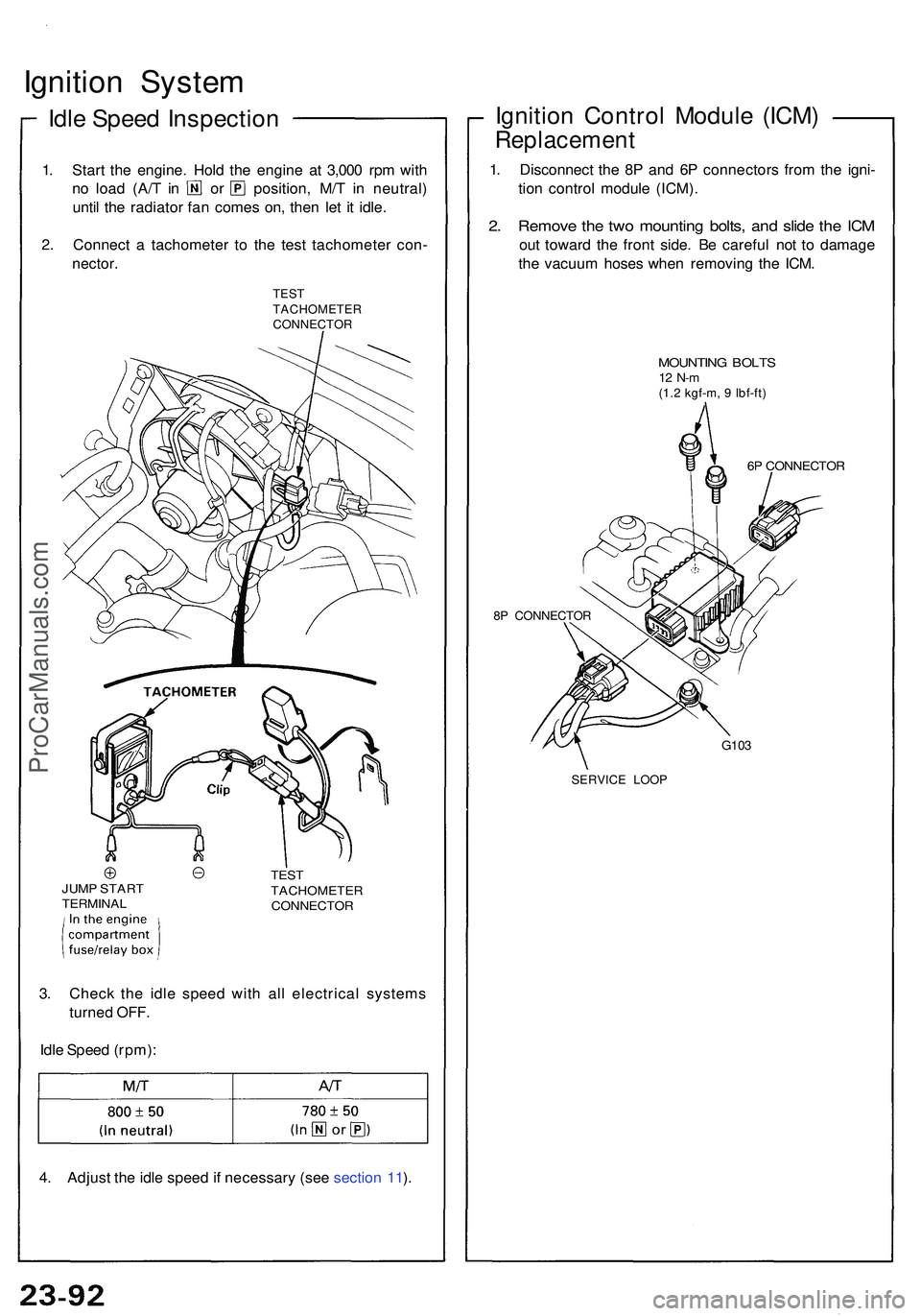

Ignition Syste m

Idle Spee d Inspectio n

1. Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (A/ T i n o r position , M/ T i n neutral )

unti l th e radiato r fa n come s on , the n le t i t idle .

2 . Connec t a tachomete r t o th e tes t tachomete r con -

nector .

TEST

TACHOMETE R

CONNECTO R

3. Chec k th e idl e spee d wit h al l electrica l system s

turne d OFF .

Idl e Spee d (rpm) :

4 . Adjus t th e idl e spee d if necessar y (se e sectio n 11 ).

Ignitio n Contro l Modul e (ICM )

Replacemen t

1. Disconnec t th e 8 P an d 6 P connector s fro m th e igni -

tio n contro l modul e (ICM) .

2. Remov e th e tw o mountin g bolts , an d slid e th e IC M

out towar d th e fron t side . B e carefu l no t t o damag e

th e vacuu m hose s whe n removin g th e ICM .

MOUNTIN G BOLT S12 N- m(1.2 kgf-m , 9 Ibf-ft )

6P CONNECTO R

8P CONNECTO R

G103

SERVIC E LOO P

JUMP STAR TTERMINA L

TESTTACHOMETE RCONNECTOR

ProCarManuals.com

Page 1265 of 1503

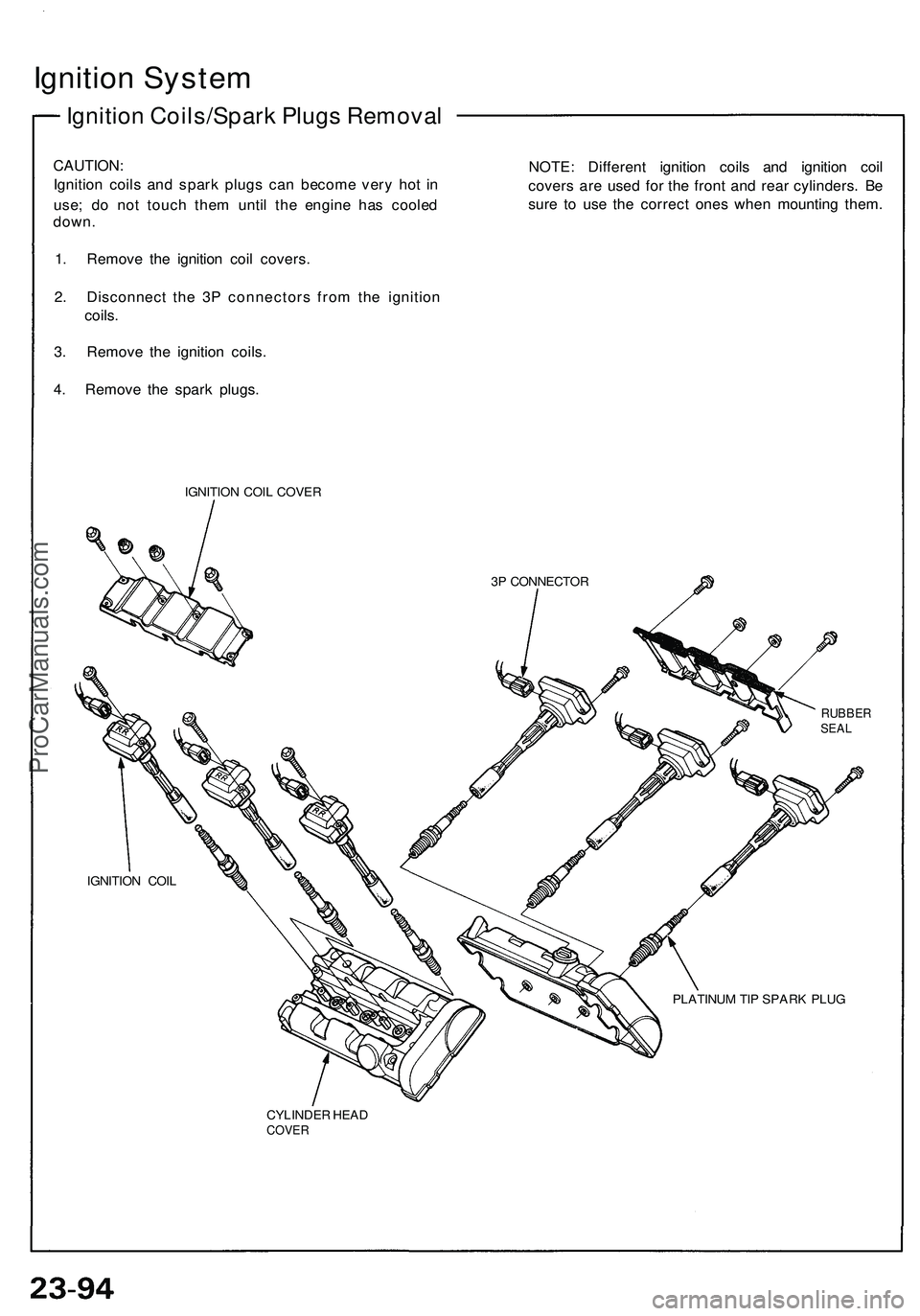

Ignition System

Ignition Coils/Spark Plugs Removal

CAUTION:

Ignition coils and spark plugs can become very hot in

use; do not touch them until the engine has cooled

down.

1. Remove the ignition coil covers.

2. Disconnect the 3P connectors from the ignition

coils.

3. Remove the ignition coils.

4. Remove the spark plugs.

NOTE: Different ignition coils and ignition coil

covers are used for the front and rear cylinders. Be

sure to use the correct ones when mounting them.

IGNITION COIL COVER

RUBBER

SEAL

PLATINUM TIP SPARK PLUG

CYLINDER HEAD

COVER

3P CONNECTOR

IGNITION COILProCarManuals.com

Page 1268 of 1503

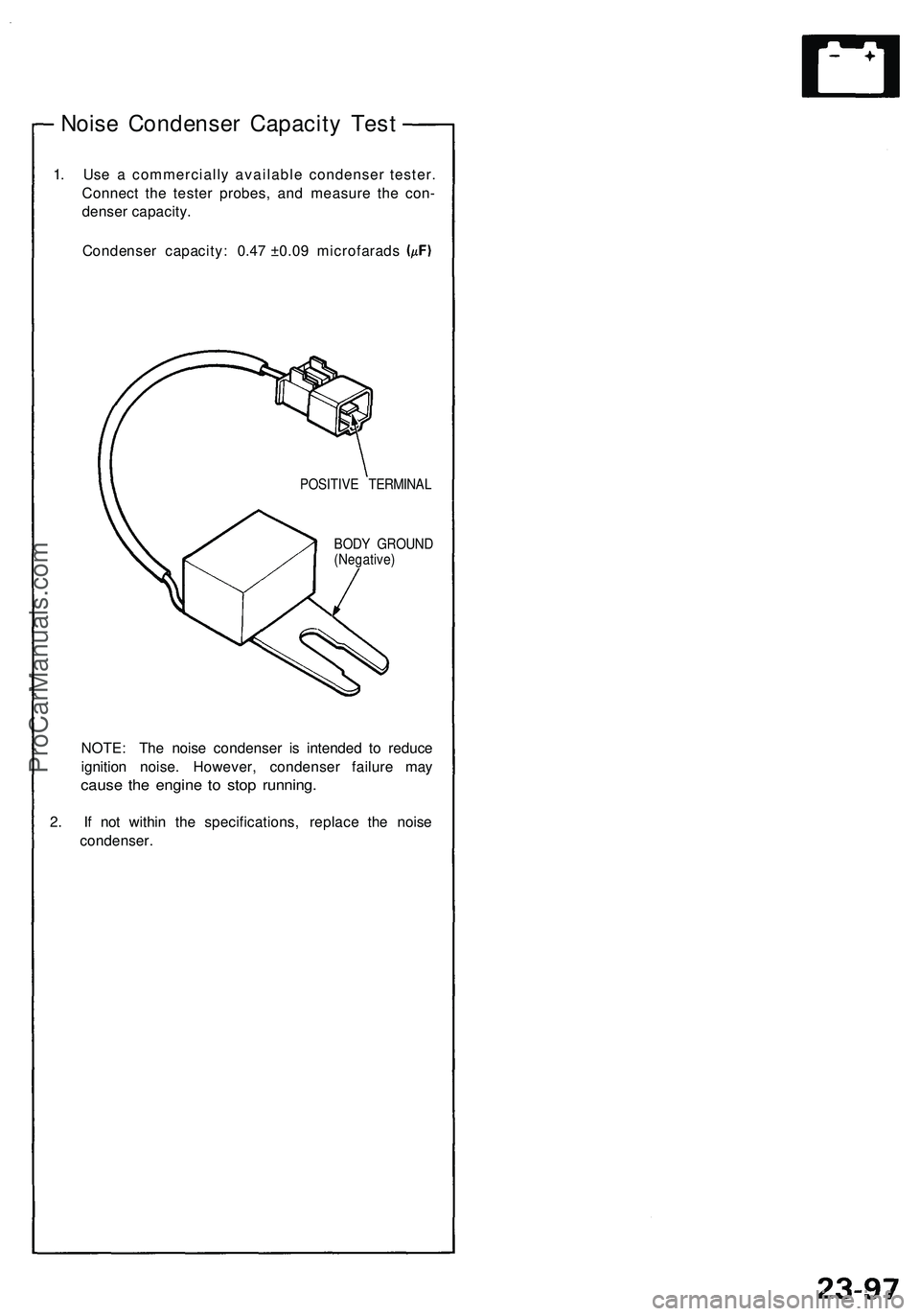

Noise Condenser Capacity Test

1. Use a commercially available condenser tester.

Connect the tester probes, and measure the con-

denser capacity.

Condenser capacity: 0.47 ±0.09 microfarads

POSITIVE TERMINAL

BODY GROUND

(Negative)

NOTE: The noise condenser is intended to reduce

ignition noise. However, condenser failure may

cause the engine to stop running.

2. If not within the specifications, replace the noise

condenser.ProCarManuals.com

Page 1270 of 1503

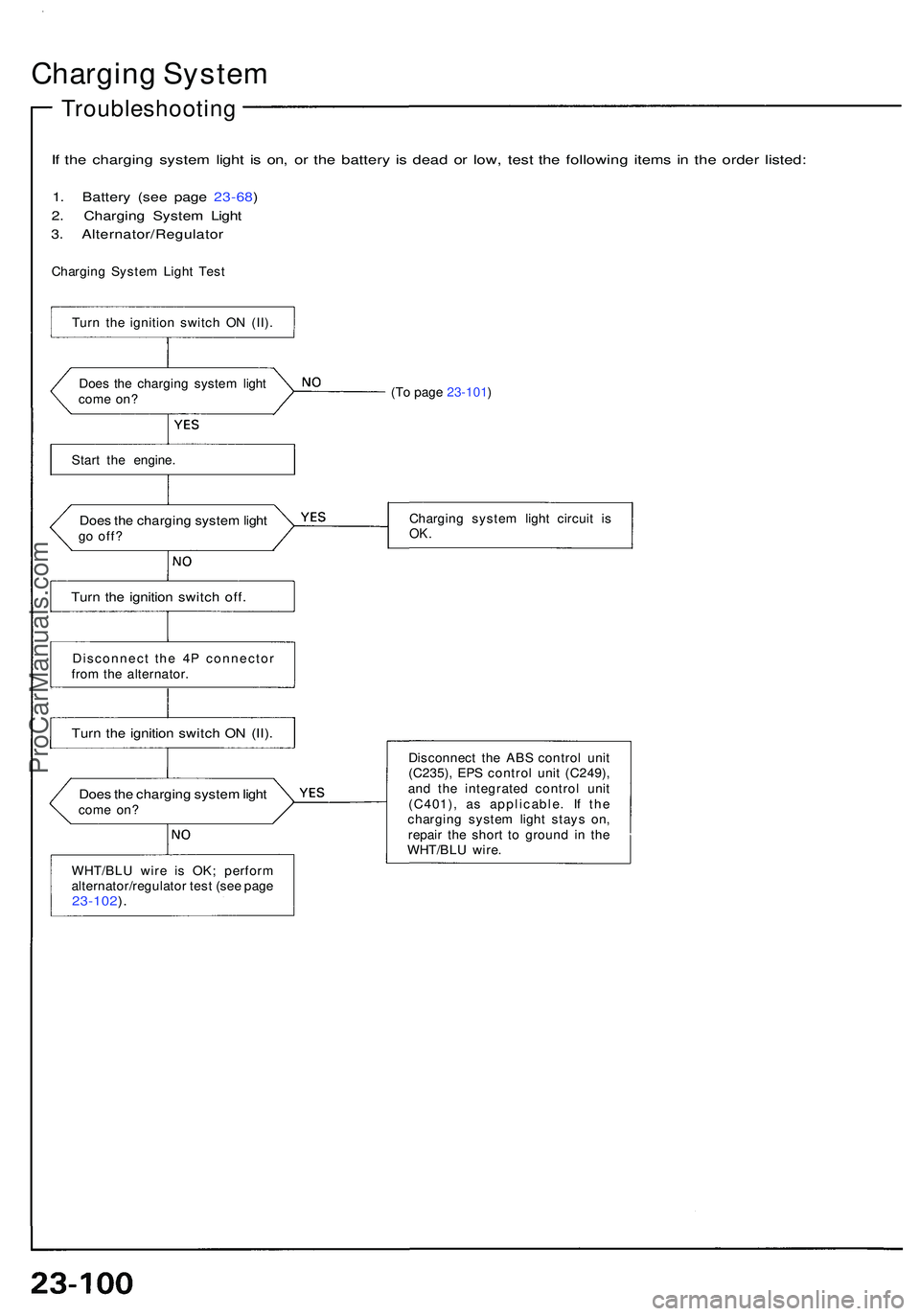

Charging Syste m

Troubleshootin g

If th e chargin g syste m ligh t i s on , o r th e batter y i s dea d o r low , tes t th e followin g item s i n th e orde r listed :

1. Batter y (se e pag e 23-68 )

2 . Chargin g Syste m Ligh t

3 . Alternator/Regulato r

Charging Syste m Ligh t Tes t

Doe s th e chargin g syste m ligh t

com e on ?

Star t th e engine .

Does th e chargin g syste m ligh tgo off ?

Turn th e ignitio n switc h off .

Disconnec t th e 4 P connecto r

fro m th e alternator .

Turn th e ignitio n switc h O N (II) .

WHT/BL U wir e i s OK ; perfor m

alternator/regulato r tes t (se e pag e

23-102 ).

(T o page 23-101 )

Chargin g syste m ligh t circui t i s

OK .

Disconnec t th e AB S contro l uni t

(C235) , EP S contro l uni t (C249) ,

an d th e integrate d contro l uni t

(C401) , a s applicable . I f th e

chargin g syste m ligh t stay s on ,

repai r th e shor t t o groun d i n th e

WHT/BL U wire .

Does th e chargin g syste m ligh tcom e on ?

Tur

n th e ignitio n switc h O N (II) .

ProCarManuals.com