engine ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 994 of 1503

Tests

Brake Booster

Functional Test

1. With the engine stopped, depress the brake pedal

several times to deplete the vacuum reservoir, then

depress the pedal hard and hold it for 15 seconds. If

the pedal sinks, either the master cylinder is

bypassing internally, or the brake system (master

cylinder, lines, modulator, proportioning valve, or

calipers) is leaking.

2. Start the engine with the pedal depressed. If the

pedal sinks slightly, the vacuum booster is operat-

ing normally, if the pedal height does not vary, the

booster or check valve is faulty.

3. With the engine running, depress the brake pedal

lightly. Apply just enough pressure to hold back

automatic transmission creep. If the brake pedal

sinks more than 10 mm (3/8 in.) in three minutes,

the master cylinder is faulty. A slight change in

pedal height when the A/C compressor cycles on

and off if normal. (The A/C compressor load

changes the vacuum available to the booster.)

Leak Test

1. Depress the brake pedal with the engine running,

then stop the engine. If the pedal height does not

vary while depressed for 30 seconds, the vacuum

booster is OK. If the pedal rises, the booster is

faulty.

2. With the engine stopped, depress the brake pedal

several times using normal pressure. When the

pedal is first depressed, it should be low. On con-

secutive applications, the pedal height should grad-

ually rise. If the pedal position does not vary, check

the booster check valve.

Booster Check Valve Test

1. Disconnect the brake booster vacuum hose at the

booster or at the booster side of the valve.

2. Start the engine and let it idle. There should be vac-

uum. If no vacuum is available, the check valve is

not working properly. Replace the check valve and

retest.ProCarManuals.com

Page 1014 of 1503

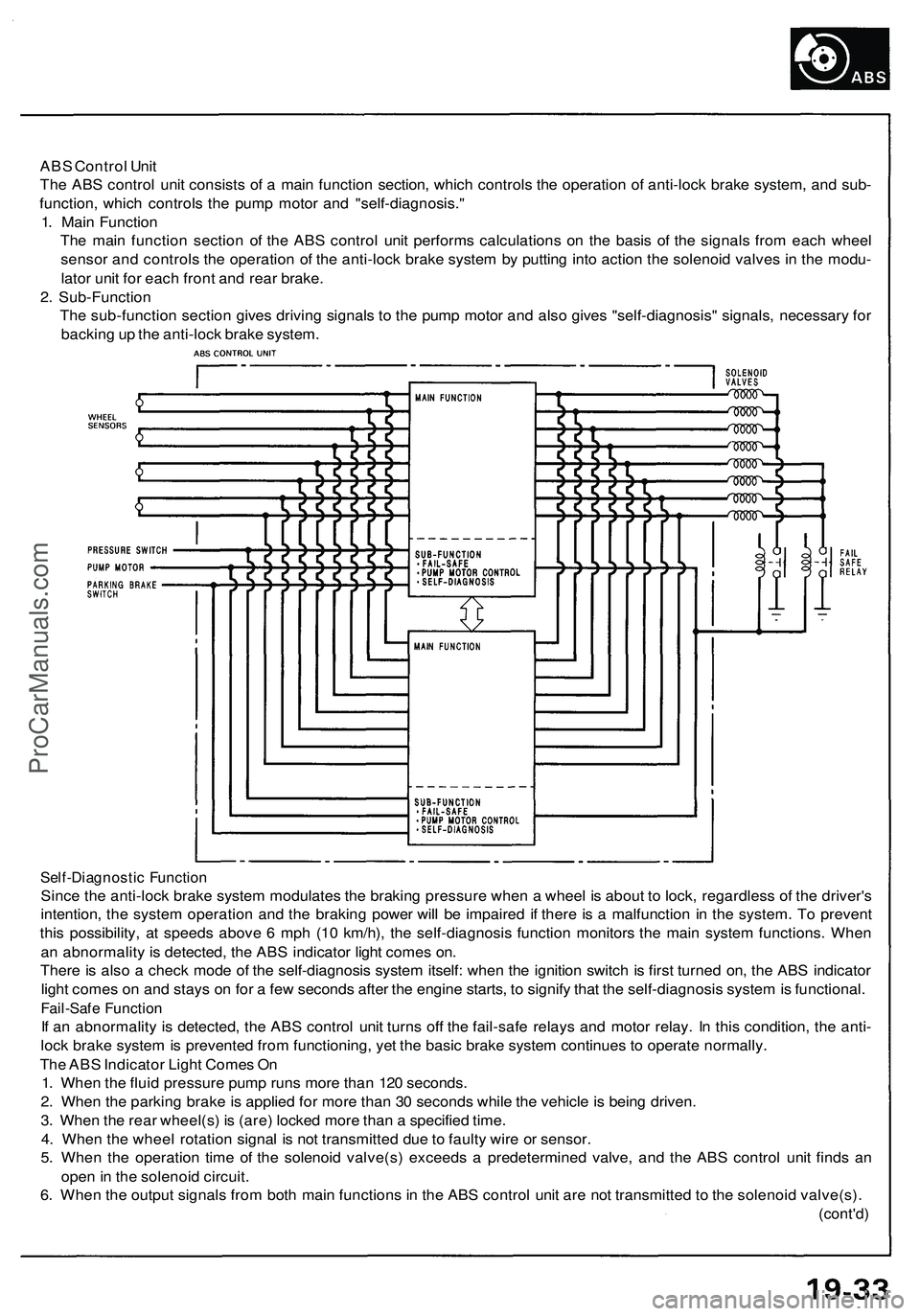

ABS Control Unit

The ABS control unit consists of a main function section, which controls the operation of anti-lock brake system, and sub-

function, which controls the pump motor and "self-diagnosis."

1. Main Function

The main function section of the ABS control unit performs calculations on the basis of the signals from each wheel

sensor and controls the operation of the anti-lock brake system by putting into action the solenoid valves in the modu-

lator unit for each front and rear brake.

2. Sub-Function

The sub-function section gives driving signals to the pump motor and also gives "self-diagnosis" signals, necessary for

backing up the anti-lock brake system.

Self-Diagnostic Function

Since the anti-lock brake system modulates the braking pressure when a wheel is about to lock, regardless of the driver's

intention, the system operation and the braking power will be impaired if there is a malfunction in the system. To prevent

this possibility, at speeds above 6 mph (10 km/h), the self-diagnosis function monitors the main system functions. When

an abnormality is detected, the ABS indicator light comes on.

There is also a check mode of the self-diagnosis system itself: when the ignition switch is first turned on, the ABS indicator

light comes on and stays on for a few seconds after the engine starts, to signify that the self-diagnosis system is functional.

Fail-Safe Function

If an abnormality is detected, the ABS control unit turns off the fail-safe relays and motor relay. In this condition, the anti-

lock brake system is prevented from functioning, yet the basic brake system continues to operate normally.

The ABS Indicator Light Comes On

1. When the fluid pressure pump runs more than 120 seconds.

2. When the parking brake is applied for more than 30 seconds while the vehicle is being driven.

3. When the rear wheel(s) is (are) locked more than a specified time.

4. When the wheel rotation signal is not transmitted due to faulty wire or sensor.

5. When the operation time of the solenoid valve(s) exceeds a predetermined valve, and the ABS control unit finds an

open in the solenoid circuit.

6. When the output signals from both main functions in the ABS control unit are not transmitted to the solenoid valve(s).

(cont'd)ProCarManuals.com

Page 1025 of 1503

Troubleshooting Precautions

ABS Indicator Light:

The ABS indicator light comes on for three seconds and then goes off when the control unit detects no problem during the

initial diagnosis right after the engine starts. The ABS indicator light comes on, and the ABS control unit memorizes the

diagnostic trouble code (DTC) under certain conditions.

• The parking brake is applied for more than 30 seconds while the vehicle is being driven. (DTC 2-1)

• The vehicle loses traction when starting from a stuck condition on a muddy, snowy, or sandy road. (DTC 4-1, 4-2, 4-4, 4-8)

• The vehicle loses traction, and the front wheels spin for more than one minute when starting from a stuck condition on

a muddy, snowy, or sandy road. (DTC 4-8)

• Tire adhesion is lost due to excessive cornering speed. (DTC 5, 5-4, 5-8)

• The vehicle is interfered by strong radio waves (noise), for example, illegal radio, etc. (DTC 8-2)

NOTE: If there is any trouble in the system, the ABS indicator light comes on during driving.

Diagnostic Trouble Code (DTC):

• When the control unit detects a problem and the ABS indicator light comes on, the control unit memorizes the DTC.

• The control unit has three memory registers. When a problem occurs, the control unit stores the DTC in the first memory

register.

• The most recent DTC is indicated first, and the oldest DTC is indicated last.

• The DTCs are erased from the control unit when the ABS control unit +B2 power supply or connector is disconnected.

• The control unit's memory can be erased by disconnecting the ABS 2, 3 fuse for more than three seconds.

Self-diagnosis:

• There are two self-diagnoses described below.

Initial diagnosis: Performed right after the engine starts until the ABS indicator light goes off.

Regular diagnosis: Continuously performed (under some conditions) after the ABS indicator light goes off until the

engine stops.

• The CPU (central processing unit) controls the following when it detects a problem during self-diagnosis:

Turns the ABS indicator light ON.

Turns the front and rear fail-safe relays off.

Stops the ABS control.

Stops the ABS pump.

After the DTC is stored in the control unit, the CPU stops self-diagnosis.ProCarManuals.com

Page 1027 of 1503

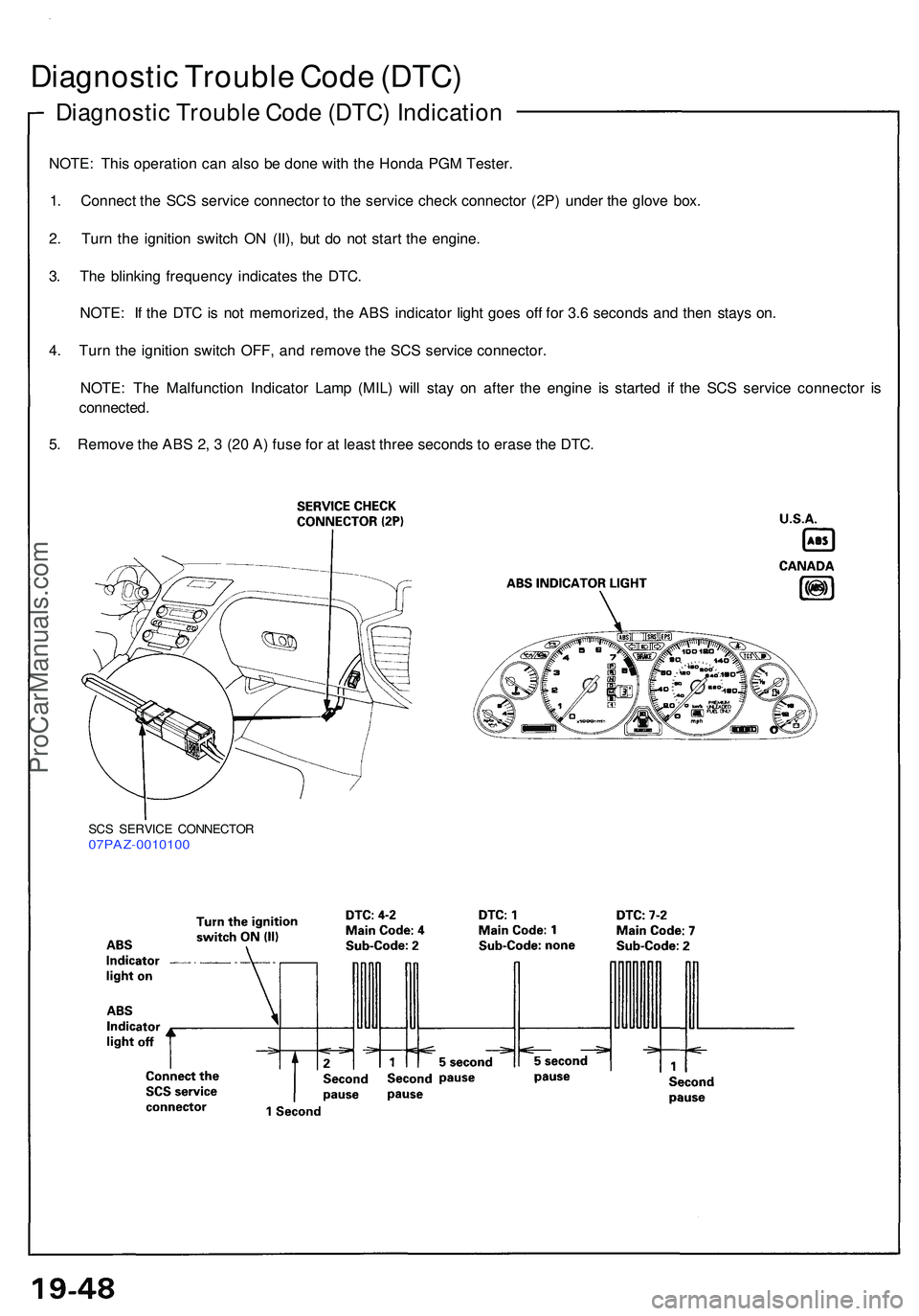

Diagnostic Troubl e Cod e (DTC ) Indicatio n

Diagnosti c Troubl e Cod e (DTC )

NOTE : Thi s operatio n ca n als o b e don e wit h th e Hond a PG M Tester .

1 . Connec t th e SC S servic e connecto r t o th e servic e chec k connecto r (2P ) unde r th e glov e box .

2 . Tur n th e ignitio n switc h O N (II) , bu t d o no t star t th e engine .

3 . Th e blinkin g frequenc y indicate s th e DTC .

NOTE : I f th e DT C is no t memorized , th e AB S indicato r ligh t goe s of f fo r 3. 6 second s an d the n stay s on .

4 . Tur n th e ignitio n switc h OFF , an d remov e th e SC S servic e connector .

NOTE : Th e Malfunctio n Indicato r Lam p (MIL ) wil l sta y o n afte r th e engin e i s starte d i f th e SC S servic e connecto r i s

connected .

5 . Remov e th e AB S 2 , 3 (2 0 A ) fus e fo r a t leas t thre e second s t o eras e th e DTC .

SCS SERVIC E CONNECTO R07PAZ-001010 0

ProCarManuals.com

Page 1034 of 1503

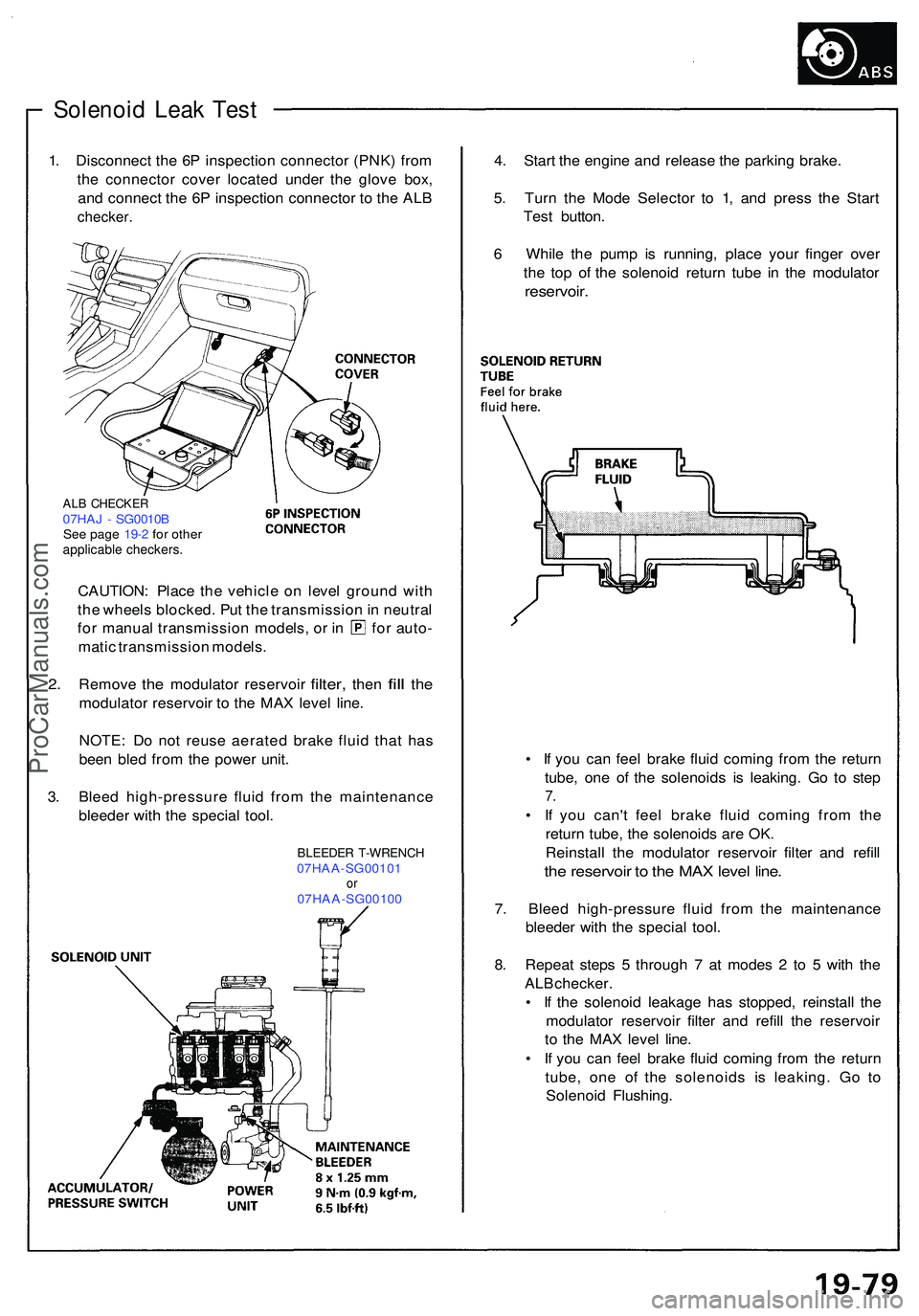

Solenoid Lea k Tes t

1. Disconnec t th e 6 P inspectio n connecto r (PNK ) fro m

th e connecto r cove r locate d unde r th e glov e box ,

an d connec t th e 6 P inspectio n connecto r t o th e AL B

checker .

ALB CHECKE R07HAJ - SG0010 B

Se e pag e 19- 2 fo r othe r

applicabl e checkers .

CAUTION : Plac e th e vehicl e o n leve l groun d wit h

th e wheel s blocked . Pu t th e transmissio n in neutra l

for manua l transmissio n models , o r i n fo r auto -

mati c transmissio n models .

2. Remov e the modulato r reservoi r filter, then fill th e

modulato r reservoi r t o th e MA X leve l line .

NOTE : D o no t reus e aerate d brak e flui d tha t ha s

bee n ble d fro m th e powe r unit .

3 . Blee d high-pressur e flui d fro m th e maintenanc e

bleede r wit h th e specia l tool .

BLEEDE R T-WRENC H07HAA-SG0010 1or07HAA-SG0010 0

• I f yo u ca n fee l brak e flui d comin g fro m th e retur n

tube , on e o f th e solenoid s i s leaking . G o t o ste p

7.

• I f yo u can' t fee l brak e flui d comin g fro m th e

retur n tube , th e solenoid s ar e OK .

Reinstal l th e modulato r reservoi r filte r an d refil l

the reservoi r t o th e MA X leve l line .

7. Blee d high-pressur e flui d fro m th e maintenanc e

bleede r wit h th e specia l tool .

8 . Repea t step s 5 throug h 7 at mode s 2 to 5 wit h th e

AL B checker .

• I f th e solenoi d leakag e ha s stopped , reinstal l th e

modulato r reservoi r filte r an d refil l th e reservoi r

t o th e MA X leve l line .

• I f yo u ca n fee l brak e flui d comin g fro m th e retur n

tube , on e o f th e solenoid s i s leaking . G o t o

Solenoi d Flushing .

4

. Star t th e engine and releas e th e parkin g brake .

5 . Tur n th e Mod e Selecto r t o 1 , an d pres s th e Star t

Tes t button .

6 Whil e th e pum p i s running , plac e you r finge r ove r

th e to p o f th e solenoi d retur n tub e i n th e modulato r

reservoir.

ProCarManuals.com

Page 1039 of 1503

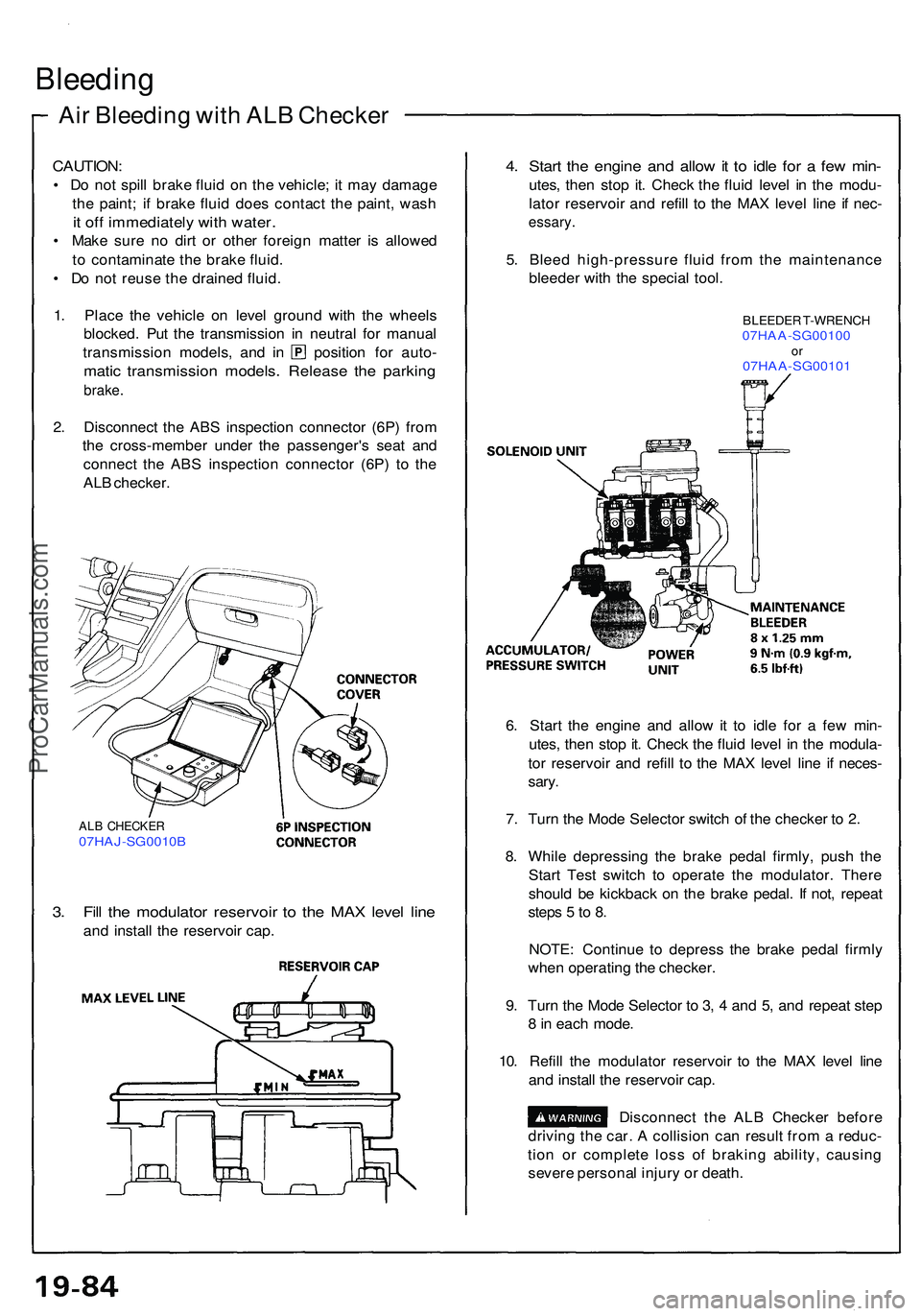

Air Bleedin g wit h AL B Checke r

Bleeding

CAUTION :

• D o no t spil l brak e flui d o n th e vehicle ; i t ma y damag e

th e paint ; i f brak e flui d doe s contac t th e paint , was h

it of f immediatel y wit h water .

• Mak e sur e n o dir t o r othe r foreig n matte r i s allowe d

t o contaminat e th e brak e fluid .

• D o no t reus e th e draine d fluid .

1 . Plac e th e vehicl e o n leve l groun d wit h th e wheel s

blocked . Pu t th e transmissio n i n neutra l fo r manua l

transmissio n models , an d i n positio n fo r auto -

matic transmissio n models . Releas e th e parkin g

brake.

2. Disconnec t th e AB S inspectio n connecto r (6P ) fro m

th e cross-membe r unde r th e passenger' s sea t an d

connec t th e AB S inspectio n connecto r (6P ) t o th e

AL B checker .

4. Star t th e engin e an d allo w it t o idl e fo r a fe w min -

utes, the n sto p it . Chec k th e flui d leve l i n th e modu -

lato r reservoi r an d refil l t o th e MA X leve l lin e i f nec -

essary .

5. Blee d high-pressur e flui d fro m th e maintenanc e

bleede r wit h th e specia l tool .

BLEEDE R T-WRENC H07HAA-SG0010 0or07HAA-SG0010 1

6. Star t th e engine and allo w it t o idl e fo r a fe w min -

utes , the n sto p it . Chec k th e flui d leve l i n th e modula -

to r reservoi r an d refil l t o th e MA X leve l lin e i f neces -

sary .

7 . Tur n th e Mod e Selecto r switc h o f th e checke r t o 2 .

8 . Whil e depressin g th e brak e peda l firmly , pus h th e

Star t Tes t switc h t o operat e th e modulator . Ther e

shoul d b e kickbac k o n th e brak e pedal . I f not , repea t

step s 5 to 8 .

NOTE : Continu e t o depres s th e brak e peda l firml y

whe n operatin g th e checker .

9 . Tur n th e Mod e Selecto r t o 3 , 4 an d 5 , an d repea t ste p

8 in eac h mode .

10 . Refil l th e modulato r reservoi r t o th e MA X leve l lin e

an d instal l th e reservoi r cap .

Disconnec t th e AL B Checke r befor e

drivin g th e car . A collisio n ca n resul t fro m a reduc -

tio n o r complete loss o f brakin g ability , causin g

sever e persona l injur y o r death .

ALB CHECKE R07HAJ-SG0010 B

3. Fil l th e modulato r reservoi r t o th e MA X leve l lin e

and instal l th e reservoi r cap .

ProCarManuals.com

Page 1045 of 1503

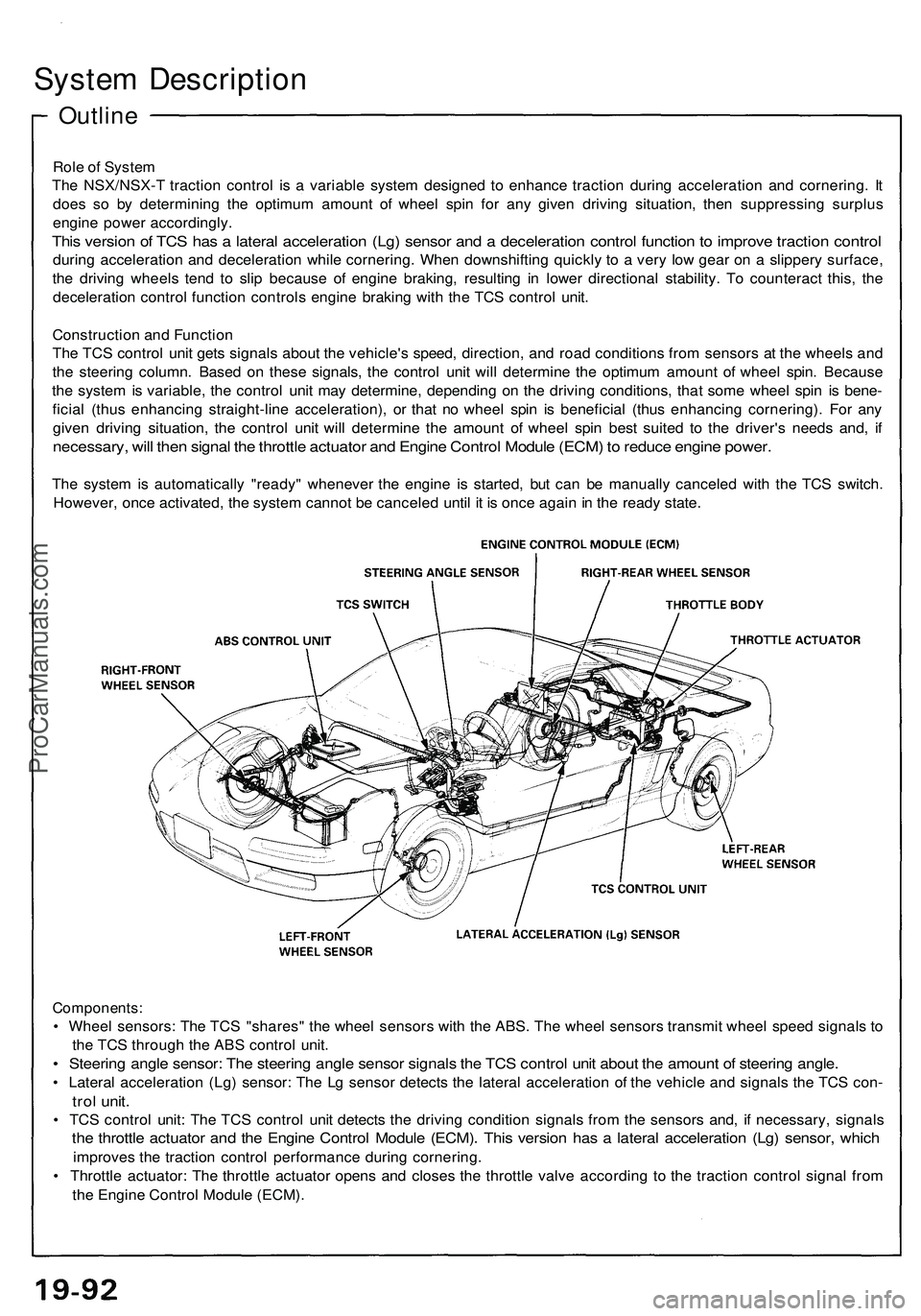

Outline

System Description

Role of System

The NSX/NSX-T traction control is a variable system designed to enhance traction during acceleration and cornering. It

does so by determining the optimum amount of wheel spin for any given driving situation, then suppressing surplus

engine power accordingly.

This version of TCS has a lateral acceleration (Lg) sensor and a deceleration control function to improve traction control

during acceleration and deceleration while cornering. When downshifting quickly to a very low gear on a slippery surface,

the driving wheels tend to slip because of engine braking, resulting in lower directional stability. To counteract this, the

deceleration control function controls engine braking with the TCS control unit.

Construction and Function

The TCS control unit gets signals about the vehicle's speed, direction, and road conditions from sensors at the wheels and

the steering column. Based on these signals, the control unit will determine the optimum amount of wheel spin. Because

the system is variable, the control unit may determine, depending on the driving conditions, that some wheel spin is bene-

ficial (thus enhancing straight-line acceleration), or that no wheel spin is beneficial (thus enhancing cornering). For any

given driving situation, the control unit will determine the amount of wheel spin best suited to the driver's needs and, if

necessary, will then signal the throttle actuator and Engine Control Module (ECM) to reduce engine power.

The system is automatically "ready" whenever the engine is started, but can be manually canceled with the TCS switch.

However, once activated, the system cannot be canceled until it is once again in the ready state.

Components:

• Wheel sensors: The TCS "shares" the wheel sensors with the ABS. The wheel sensors transmit wheel speed signals to

the TCS through the ABS control unit.

• Steering angle sensor: The steering angle sensor signals the TCS control unit about the amount of steering angle.

• Lateral acceleration (Lg) sensor: The Lg sensor detects the lateral acceleration of the vehicle and signals the TCS con-

trol unit.

• TCS control unit: The TCS control unit detects the driving condition signals from the sensors and, if necessary, signals

the throttle actuator and the Engine Control Module (ECM). This version has a lateral acceleration (Lg) sensor, which

improves the traction control performance during cornering.

• Throttle actuator: The throttle actuator opens and closes the throttle valve according to the traction control signal from

the Engine Control Module (ECM).ProCarManuals.com

Page 1046 of 1503

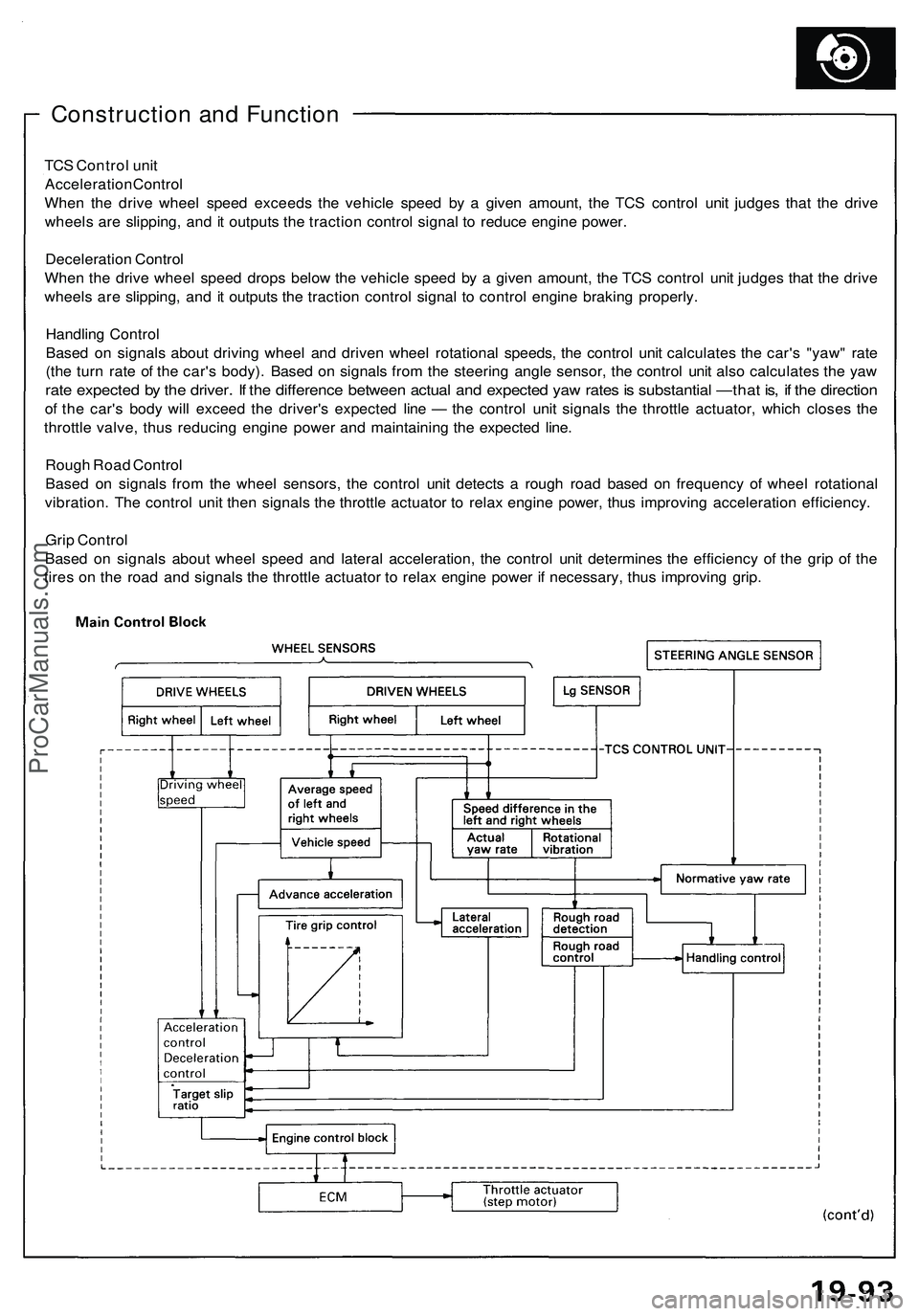

Construction and Function

TCS Control unit

Acceleration Control

When the drive wheel speed exceeds the vehicle speed by a given amount, the TCS control unit judges that the drive

wheels are slipping, and it outputs the traction control signal to reduce engine power.

Deceleration Control

When the drive wheel speed drops below the vehicle speed by a given amount, the TCS control unit judges that the drive

wheels are slipping, and it outputs the traction control signal to control engine braking properly.

Handling Control

Based on signals about driving wheel and driven wheel rotational speeds, the control unit calculates the car's "yaw" rate

(the turn rate of the car's body). Based on signals from the steering angle sensor, the control unit also calculates the yaw

rate expected by the driver. If the difference between actual and expected yaw rates is substantial —that is, if the direction

of the car's body will exceed the driver's expected line — the control unit signals the throttle actuator, which closes the

throttle valve, thus reducing engine power and maintaining the expected line.

Rough Road Control

Based on signals from the wheel sensors, the control unit detects a rough road based on frequency of wheel rotational

vibration. The control unit then signals the throttle actuator to relax engine power, thus improving acceleration efficiency.

Grip Control

Based on signals about wheel speed and lateral acceleration, the control unit determines the efficiency of the grip of the

tires on the road and signals the throttle actuator to relax engine power if necessary, thus improving grip.ProCarManuals.com

Page 1051 of 1503

TCS Indicato r Ligh t

Troubleshootin g

Temporary Drivin g Conditions :

1 . Th e TC S indicato r ligh t wil l com e o n an d th e contro l uni t memorize s th e Diagnosti c Troubl e Cod e (DTC ) unde r certai n

temporar y conditions :

• Th e spar e tir e is installed , o r a tir e o f th e imprope r siz e is installed .

• Th e tir e pressure s ar e no t correct .

2 . I f th e TC S indicato r ligh t doe s no t com e bac k o n afte r correctin g th e tir e o r tir e pressur e problem , th e TC S syste m is

OK .

3. Remov e th e CLOC K (7. 5 A ) fus e fo r a t leas t thre e second s t o clea r th e DT C fro m th e TC S contro l uni t memory .

NOTE : Disconnectin g th e CLOC K fus e als o cancel s th e radi o prese t station s an d th e cloc k setting . Mak e not e o f th e

radi o preset s befor e removin g th e fus e s o yo u ca n rese t them .

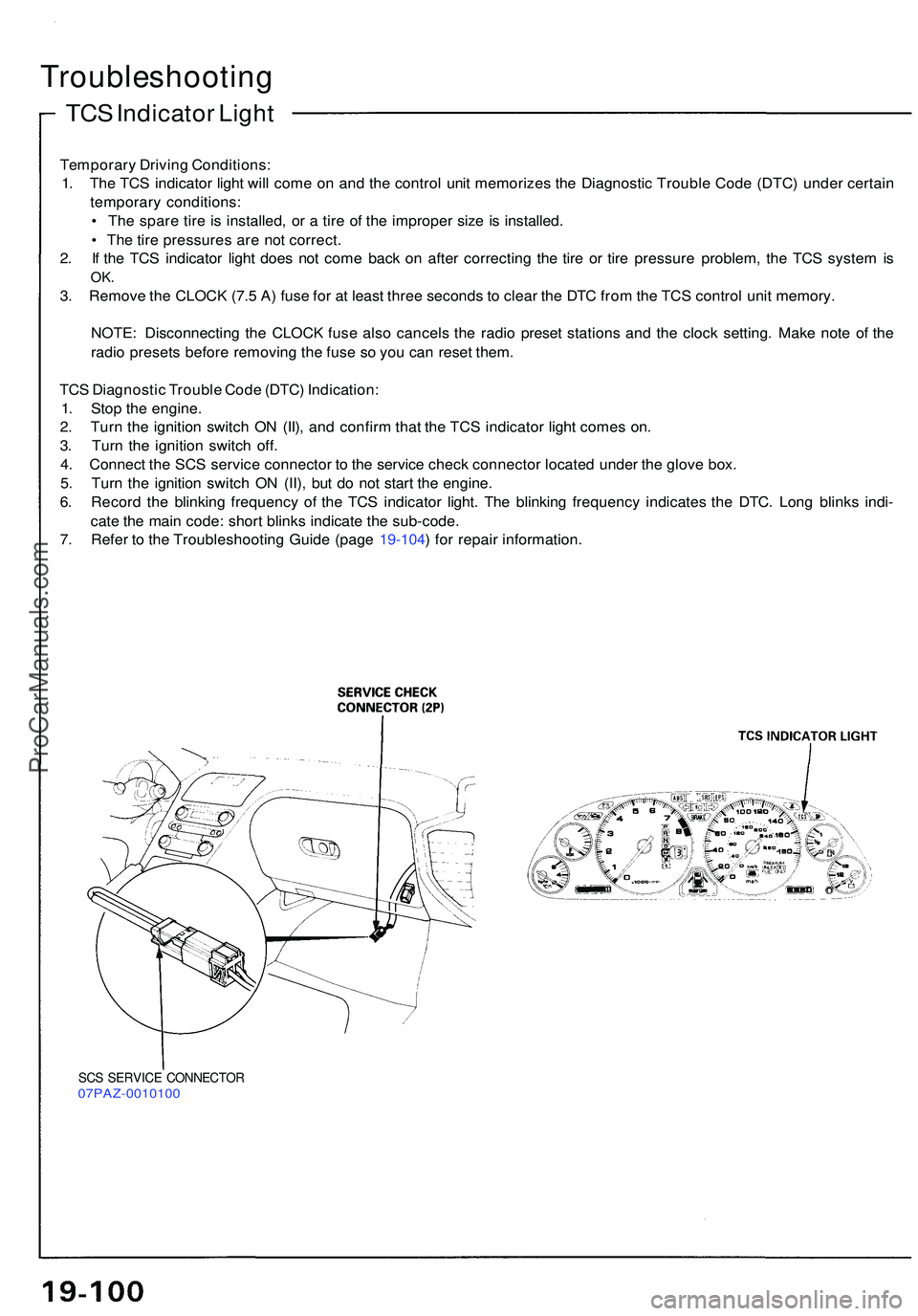

TC S Diagnosti c Troubl e Cod e (DTC ) Indication :

1 . Sto p th e engine .

2 . Tur n th e ignitio n switc h O N (II) , an d confir m tha t th e TC S indicato r ligh t come s on .

3 . Tur n th e ignitio n switc h off .

4 . Connec t th e SC S servic e connecto r t o th e servic e chec k connecto r locate d unde r th e glov e box .

5 . Tur n th e ignitio n switc h O N (II) , bu t d o no t star t th e engine .

6 . Recor d th e blinkin g frequenc y o f th e TC S indicato r light . Th e blinkin g frequenc y indicate s th e DTC . Lon g blink s indi -

cat e th e mai n code : shor t blink s indicat e th e sub-code .

7 . Refe r t o th e Troubleshootin g Guid e (pag e 19-104 ) fo r repai r information .

SCS SERVIC E CONNECTO R07PAZ-001010 0

ProCarManuals.com

Page 1052 of 1503

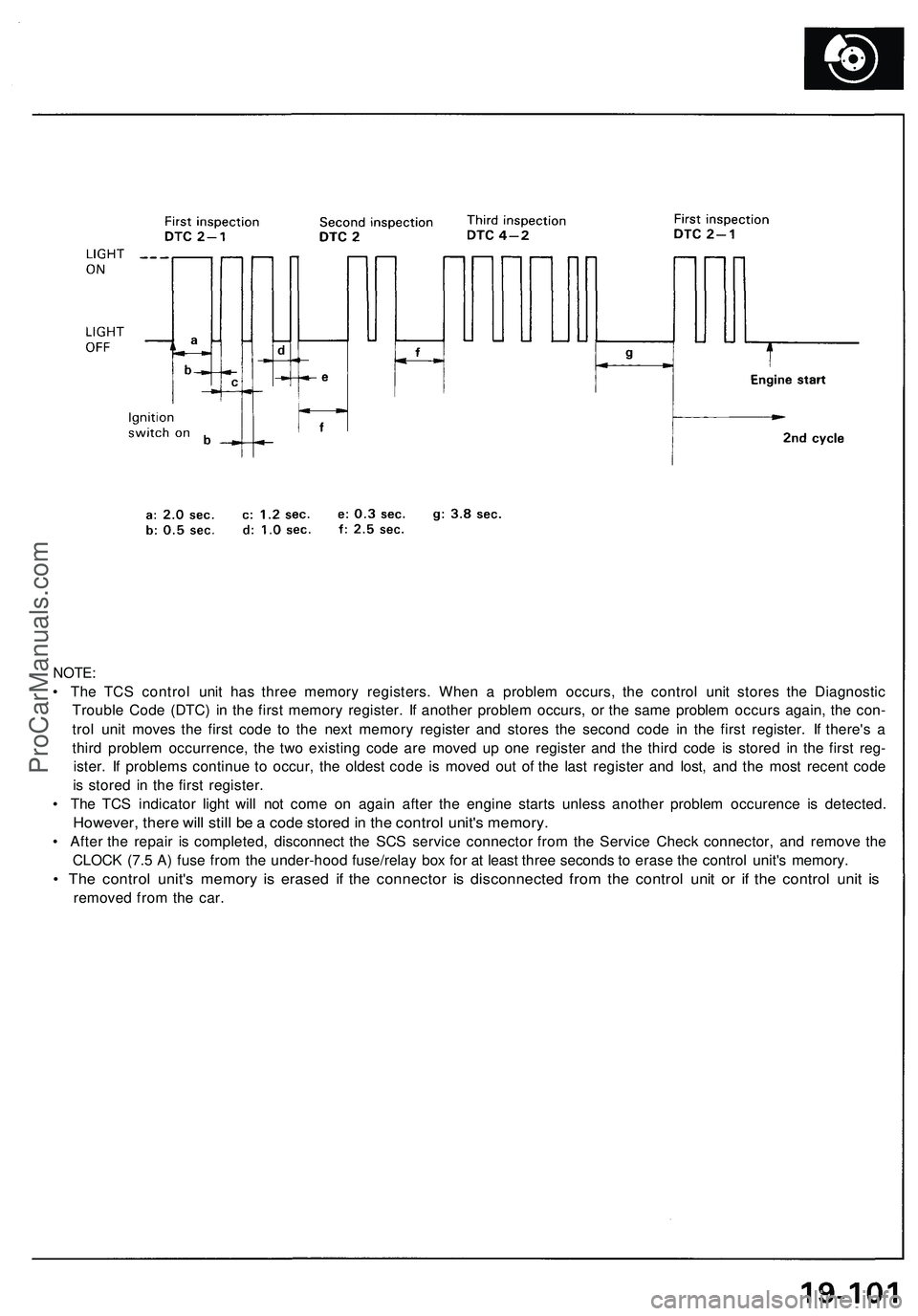

NOTE:

• The TCS control unit has three memory registers. When a problem occurs, the control unit stores the Diagnostic

Trouble Code (DTC) in the first memory register. If another problem occurs, or the same problem occurs again, the con-

trol unit moves the first code to the next memory register and stores the second code in the first register. If there's a

third problem occurrence, the two existing code are moved up one register and the third code is stored in the first reg-

ister. If problems continue to occur, the oldest code is moved out of the last register and lost, and the most recent code

is stored in the first register.

• The TCS indicator light will not come on again after the engine starts unless another problem occurence is detected.

However, there will still be a code stored in the control unit's memory.

• After the repair is completed, disconnect the SCS service connector from the Service Check connector, and remove the

CLOCK (7.5 A) fuse from the under-hood fuse/relay box for at least three seconds to erase the control unit's memory.

• The control unit's memory is erased if the connector is disconnected from the control unit or if the control unit is

removed from the car.ProCarManuals.com