engine ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 1056 of 1503

Steering angl e senso r syste m chec k

1 . Star t th e engine .

2 . Pus h th e TC S switc h thre e time s withi n thre e seconds .

NOTE : Alway s maintai n th e sam e numbe r o f rota -

tions .

3 . Tur n th e steerin g whee l slowl y fro m lef t t o righ t mor e

tha n 1. 5 turns .

NOTE :

• Star t checkin g afte r th e steerin g whee l move s a t

leas t 1. 5 turn s fro m righ t t o left .

• Tur n th e steerin g whee l slowly , n o faste r tha n

on e tur n in fou r seconds .

4 . Pus h th e TC S switc h twic e withi n thre e seconds .

NOTE : Alway s maintai n th e sam e numbe r o f rota -

tions .

5 . Retur n th e steerin g whee l t o th e lef t sid e slowly , an d

chec k th e numbe r o f time s th e TC S indicato r ligh t

flashe s afte r th e whee l ha s move d approximatel y

on e turn .

NOTE :

• Star t th e chec k fro m th e beginnin g whe n th e steer -

in g whee l move s a t leas t on e tur n fro m lef t t o

right .

• Tur n th e steerin g whee l slowly , n o faste r tha n on e

tur n in fou r seconds .

Standar d numbe r o f time s th e TC S indicato r ligh t

flashes :

Manual Transmission : 5 time s

Automati c Transmission : 2 time s

6 . I f ther e is a n abnormality , chec k th e troubleshootin g

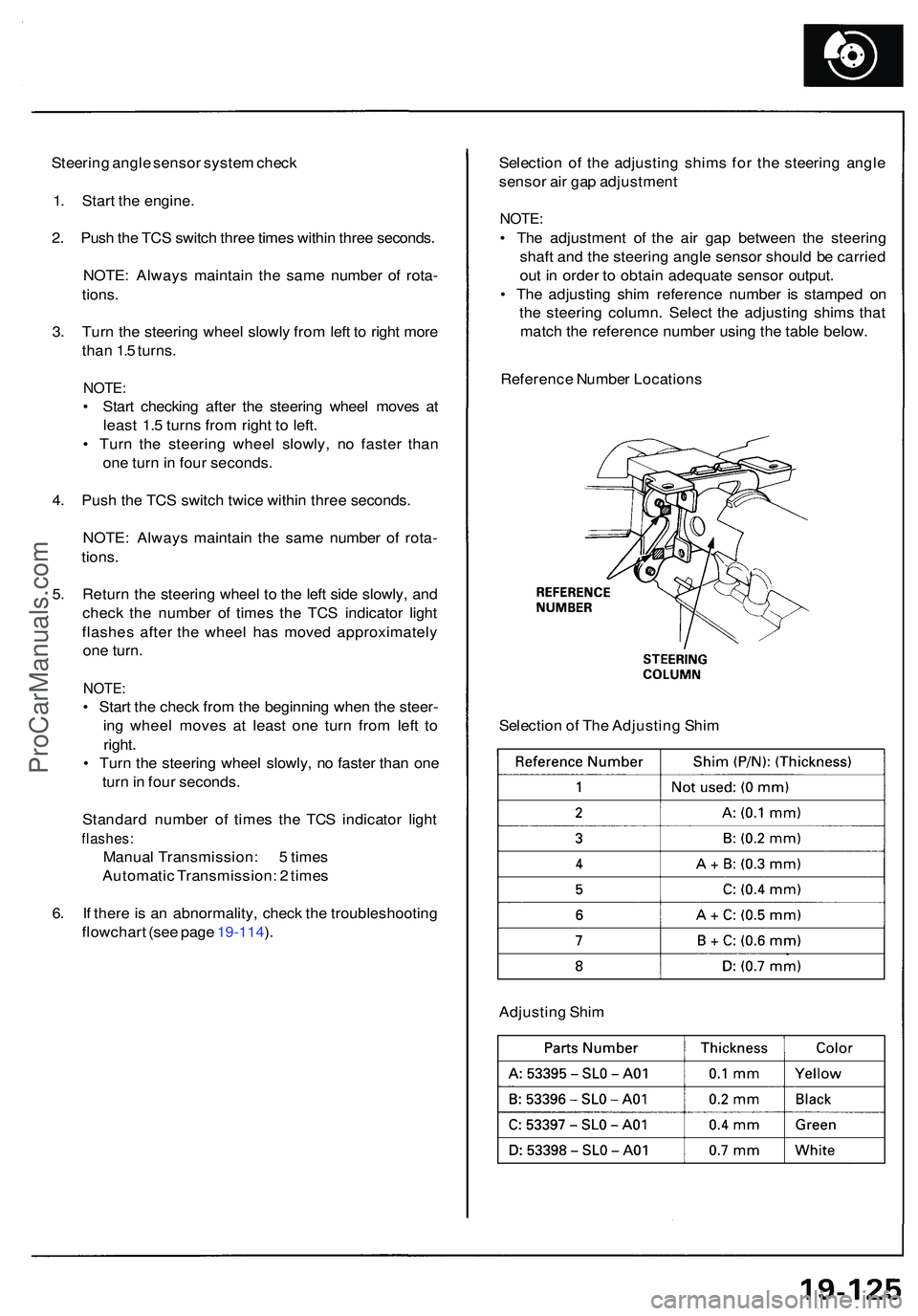

flowchar t (se e pag e 19-114 ). Selectio

n o f th e adjustin g shim s fo r th e steerin g angl e

senso r ai r ga p adjustmen t

NOTE:

• Th e adjustmen t o f th e ai r ga p betwee n th e steerin g

shaf t an d th e steerin g angl e senso r shoul d b e carrie d

ou t i n orde r t o obtai n adequat e senso r output .

• Th e adjustin g shi m referenc e numbe r i s stampe d o n

th e steerin g column . Selec t th e adjustin g shim s tha t

matc h th e referenc e numbe r usin g th e tabl e below .

Referenc e Numbe r Location s

Selectio n o f Th e Adjustin g Shi m

Adjustin g Shi m

ProCarManuals.com

Page 1121 of 1503

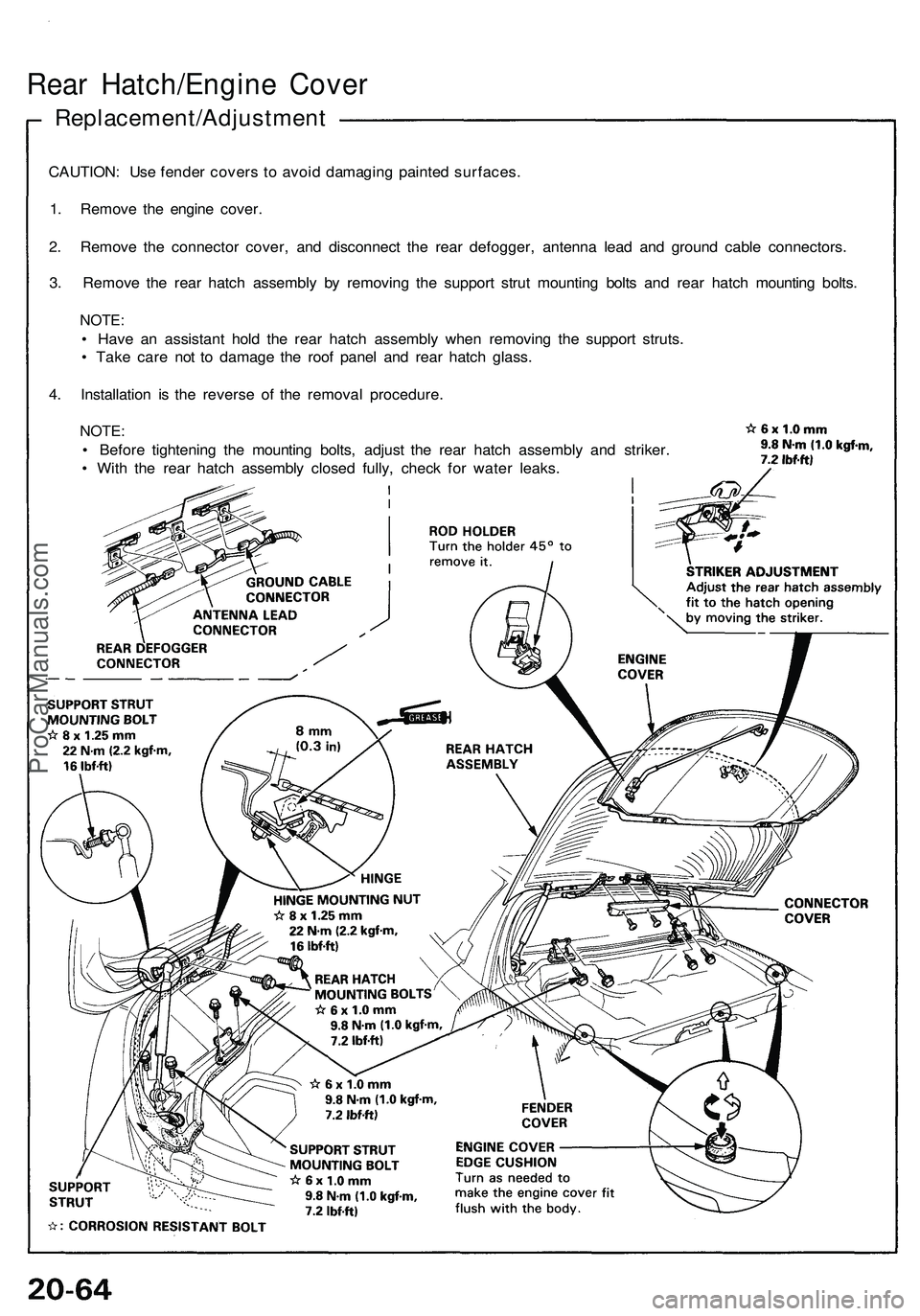

Rear Hatch/Engine Cover

Replacement/Adjustment

CAUTION: Use fender covers to avoid damaging painted surfaces.

1. Remove the engine cover.

2. Remove the connector cover, and disconnect the rear defogger, antenna lead and ground cable connectors.

3. Remove the rear hatch assembly by removing the support strut mounting bolts and rear hatch mounting bolts.

NOTE:

• Have an assistant hold the rear hatch assembly when removing the support struts.

• Take care not to damage the roof panel and rear hatch glass.

4. Installation is the reverse of the removal procedure.

NOTE:

• Before tightening the mounting bolts, adjust the rear hatch assembly and striker.

• With the rear hatch assembly closed fully, check for water leaks.ProCarManuals.com

Page 1174 of 1503

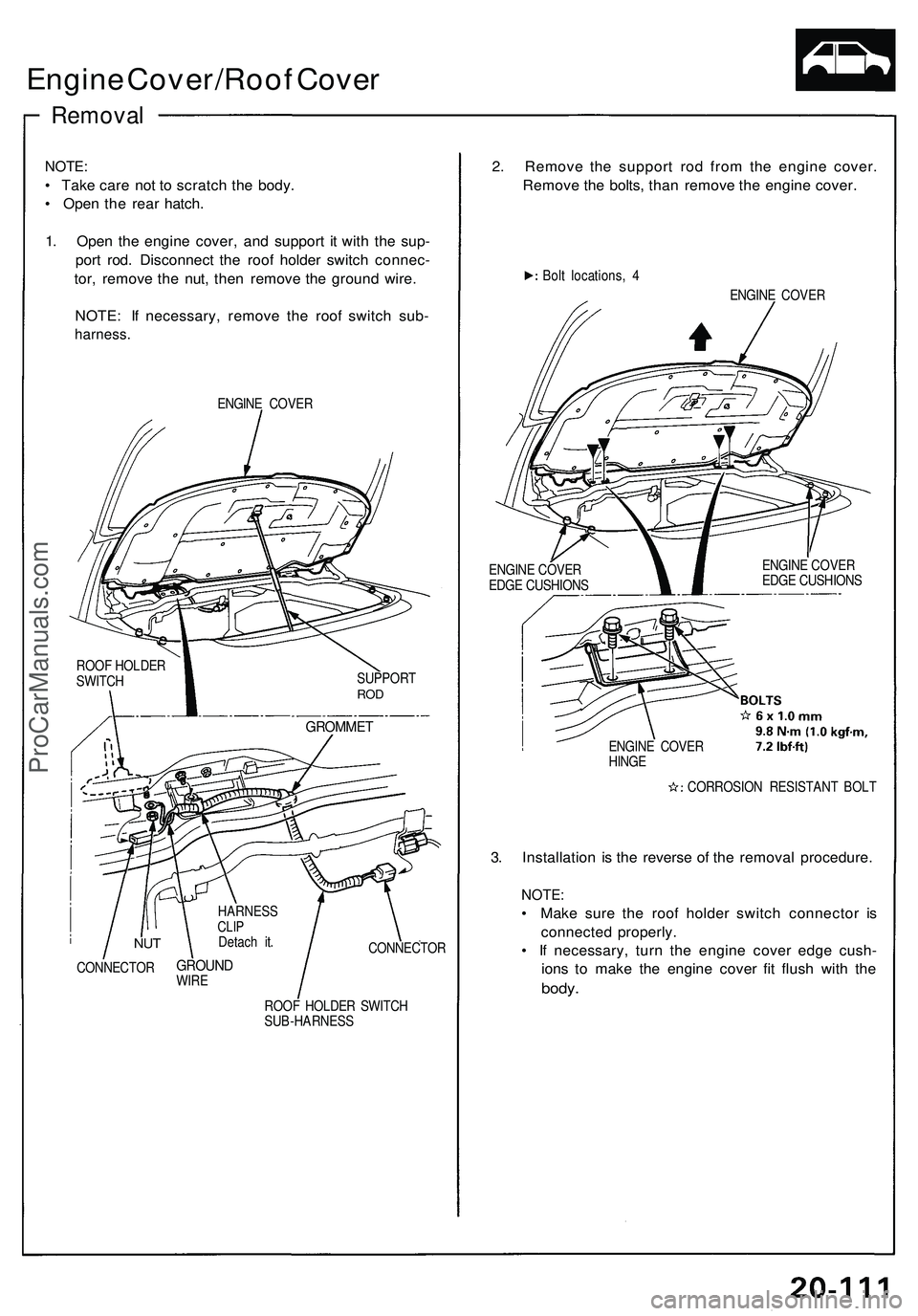

Engine Cover/Roo f Cove r

Remova l

NOTE:

• Tak e car e no t t o scratc h th e body .

• Ope n th e rea r hatch .

1 . Ope n th e engin e cover , an d suppor t i t wit h th e sup -

por t rod . Disconnec t th e roo f holde r switc h connec -

tor , remov e th e nut , the n remov e th e groun d wire .

NOTE : I f necessary , remov e th e roo f switc h sub -

harness .

ENGINE COVE R

NUT

CONNECTO R CONNECTO

RGROUNDWIRE

ROOF HOLDE R SWITC H

SUB-HARNES S

2. Remov e th e suppor t ro d fro m th e engin e cover .

Remov e th e bolts , tha n remov e th e engin e cover .

Bolt locations , 4

ENGINE COVE R

ENGIN E COVE R

HING E

CORROSIO N RESISTAN T BOL T

3. Installatio n i s th e revers e o f th e remova l procedure .

NOTE:

• Mak e sur e th e roo f holde r switc h connecto r i s

connecte d properly .

• I f necessary , tur n th e engin e cove r edg e cush -

ion s t o mak e th e engin e cove r fi t flus h wit h th e

body .

ROO F HOLDE R

SWITC H

SUPPOR

T

ROD

GROMME T

HARNESSCLIPDetac h it . ENGIN

E COVE R

EDG E CUSHION S

ENGIN

E COVE R

EDG E CUSHION S

ProCarManuals.com

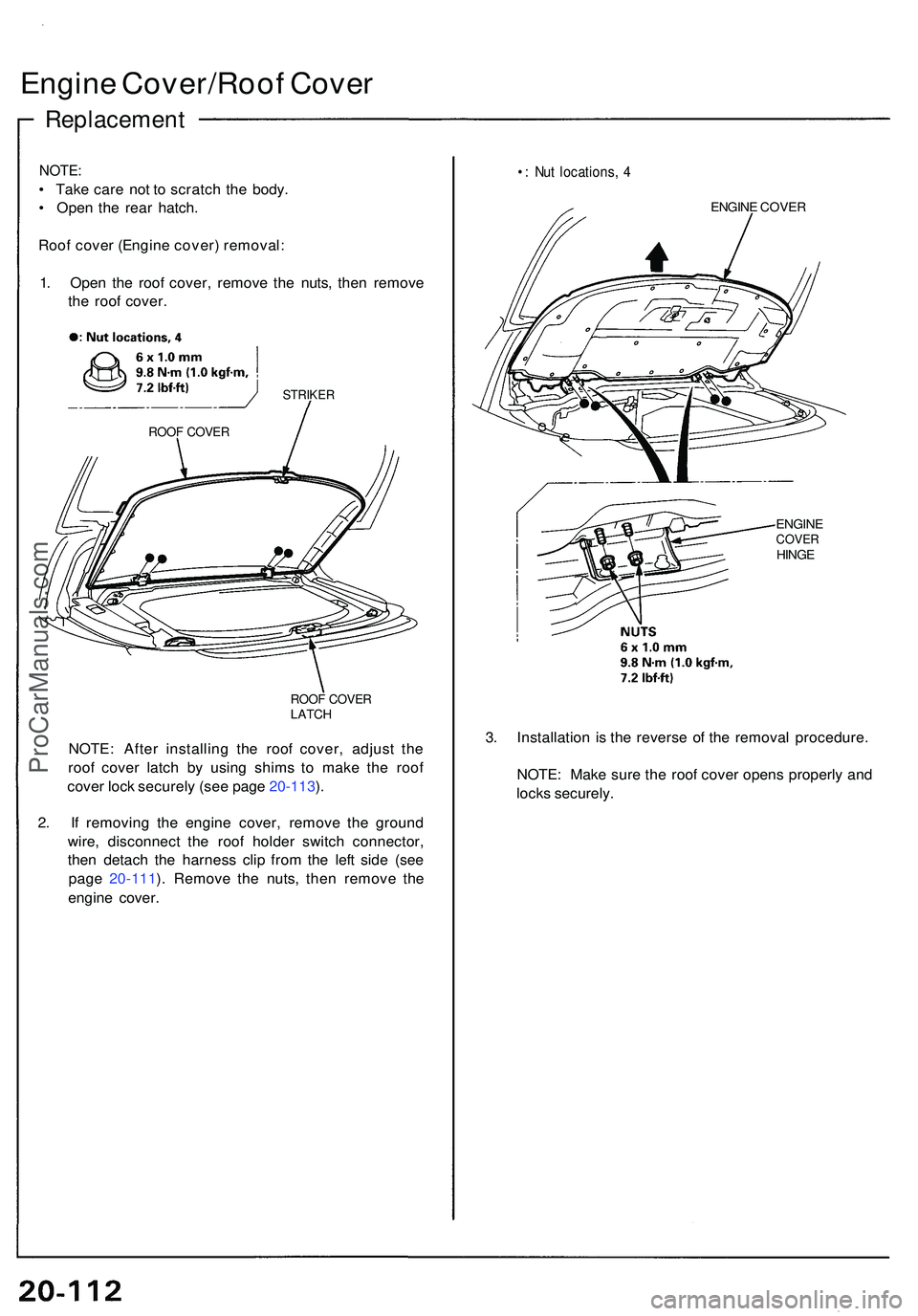

Page 1175 of 1503

Engine Cover/Roo f Cove r

Replacemen t

ROOF COVE RLATCH

NOTE : Afte r installin g th e roo f cover , adjus t th e

roo f cove r latc h b y usin g shim s t o mak e th e roo f

cove r loc k securel y (se e pag e 20-113 ).

2 . I f removin g th e engin e cover , remov e th e groun d

wire , disconnec t th e roo f holde r switc h connector ,

the n detac h th e harnes s cli p fro m th e lef t sid e (se e

pag e 20-111 ). Remov e th e nuts , the n remov e th e

engine cover.

• : Nu t locations , 4

ENGIN E COVE R

ENGIN E

COVERHINGE

3. Installatio n i s th e revers e o f th e remova l procedure .

NOTE : Mak e sur e th e roo f cove r open s properl y an d

lock s securely .

NOTE:

• Tak e car e no t t o scratc h th e body .

• Ope n th e rea r hatch .

Roo f cove r (Engin e cover ) removal :

1 . Ope n th e roo f cover , remov e th e nuts , the n remov e

th e roo f cover .

ROOF COVE R

STRIKE R

ProCarManuals.com

Page 1176 of 1503

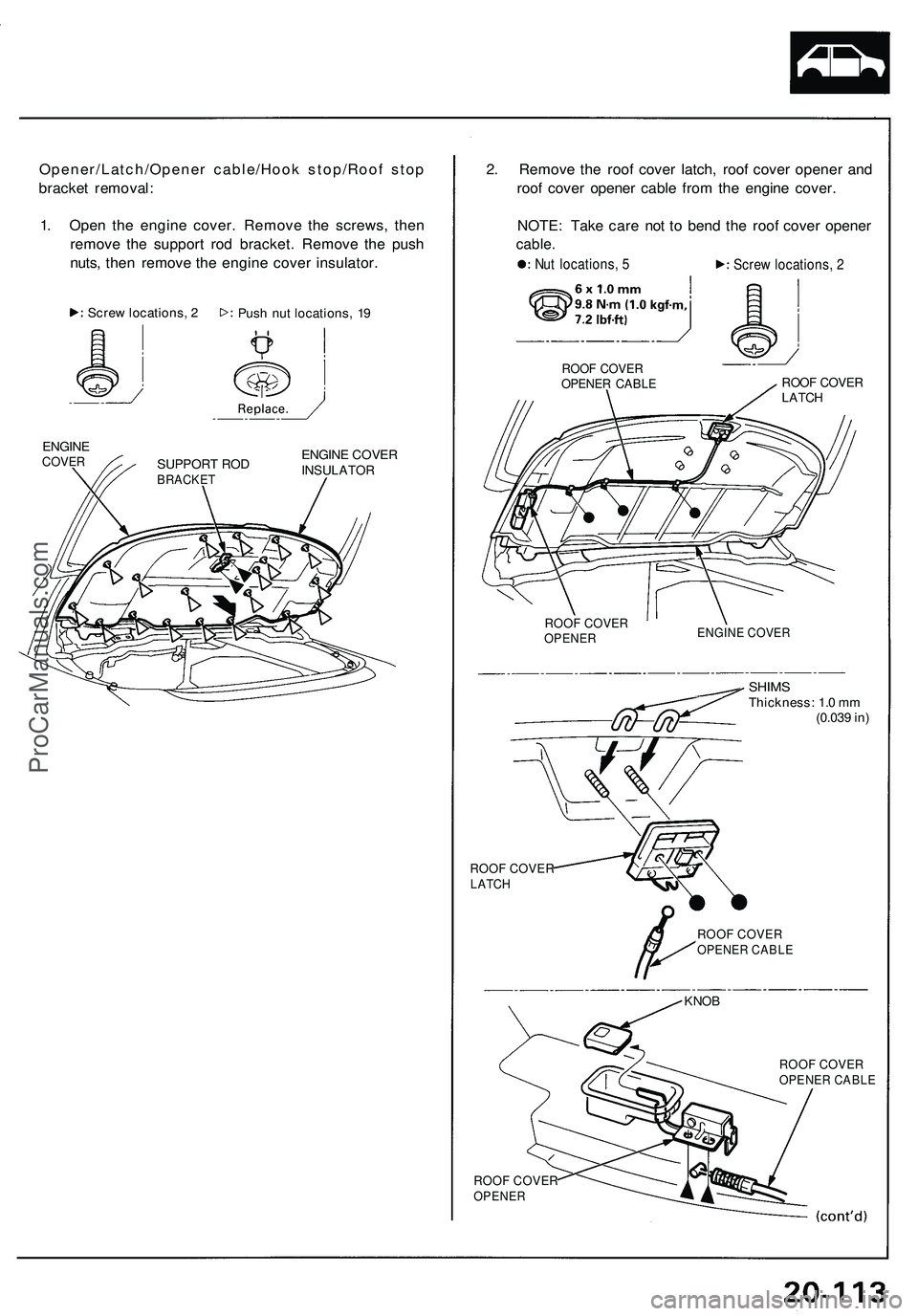

Opener/Latch/Opener cable/Hoo k stop/Roo f sto p

bracke t removal :

1 . Ope n th e engin e cover . Remov e th e screws , the n

remov e th e suppor t ro d bracket . Remov e th e pus h

nuts , the n remov e th e engin e cove r insulator .

ENGINECOVERSUPPOR T RO DBRACKE T

ENGINE COVE RINSULATO R

2. Remov e th e roo f cove r latch , roo f cove r opene r an d

roo f cove r opene r cabl e fro m th e engin e cover .

NOTE : Tak e car e no t t o ben d th e roo f cove r opene r

cable.

Nut locations , 5Scre w locations , 2

ROO F COVE ROPENE R ENGINE COVE R

SHIMSThickness : 1. 0 m m

(0.03 9 in )

ROO F COVE RLATCH

ROOF COVE ROPENE R CABL E

ROOF COVE ROPENE R

PROOF COVE ROPENE R CABL E

KNOB

ROO F COVE RLATCH

ROOF COVE ROPENE R CABL E

Screw locations , 2

Push nu t locations , 1 9

ProCarManuals.com

Page 1177 of 1503

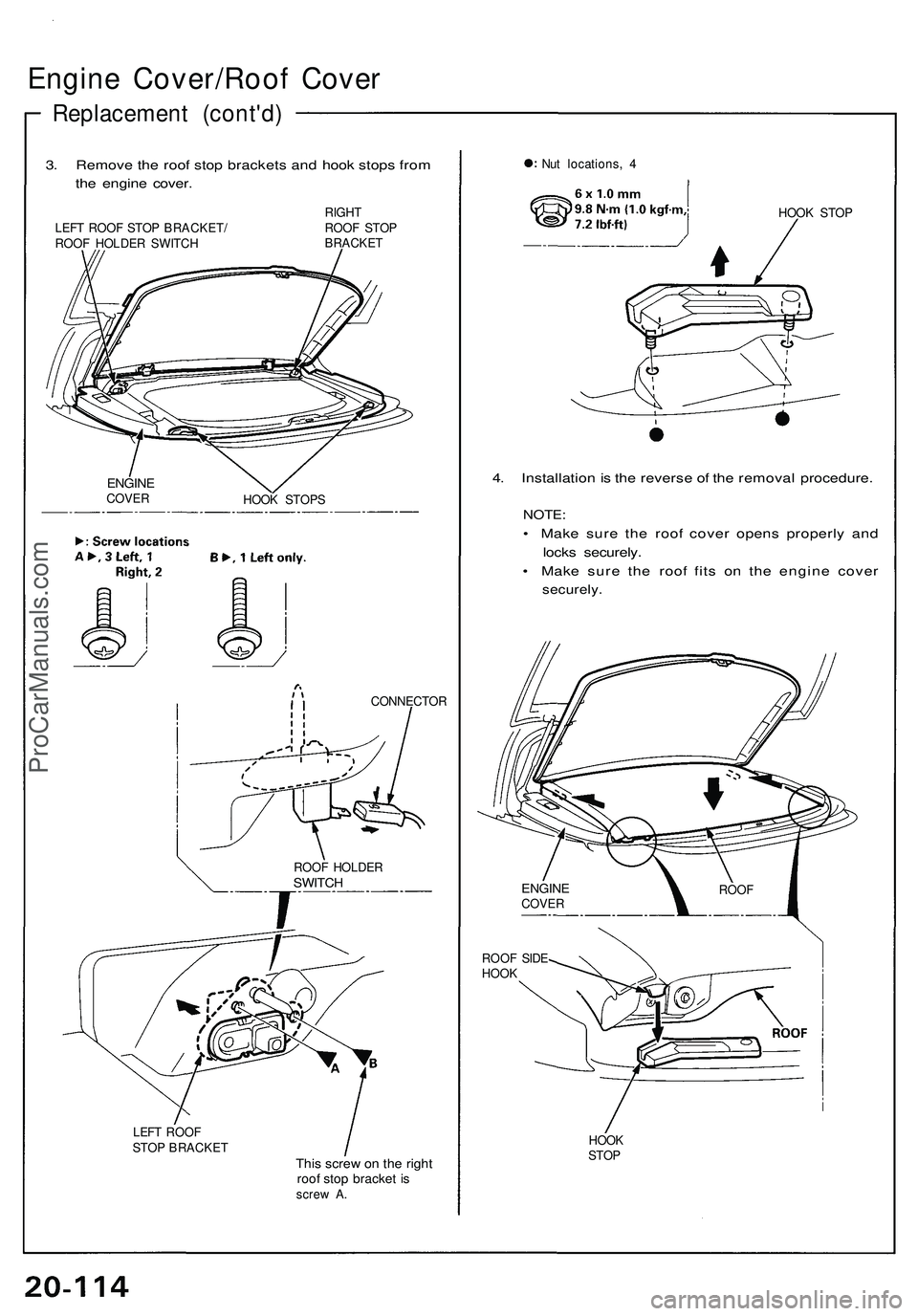

Engine Cover/Roo f Cove r

Replacemen t (cont'd )

3. Remov e th e roo f sto p bracket s an d hoo k stop s fro m

th e engin e cover .

LEFT ROO F STO P BRACKET /

ROO F HOLDE R SWITC H RIGH

T

ROO F STO PBRACKE T

ENGINECOVER

HOOK STOP S

CONNECTO R

LEF T ROO F

STO P BRACKE T

This scre w o n th e righ troof sto p bracke t i sscre w A . Nu

t locations , 4

HOOK STO P

4. Installatio n is th e revers e o f th e remova l procedure .

NOTE:

• Mak e sur e th e roo f cove r open s properl y an d

lock s securely .

• Mak e sur e th e roo f fit s o n th e engin e cove r

securely .

HOOK

STO P

ROO

F HOLDE R

SWITCH

ROOF SID E

HOO K

ENGIN ECOVER ROO

F

ProCarManuals.com

Page 1184 of 1503

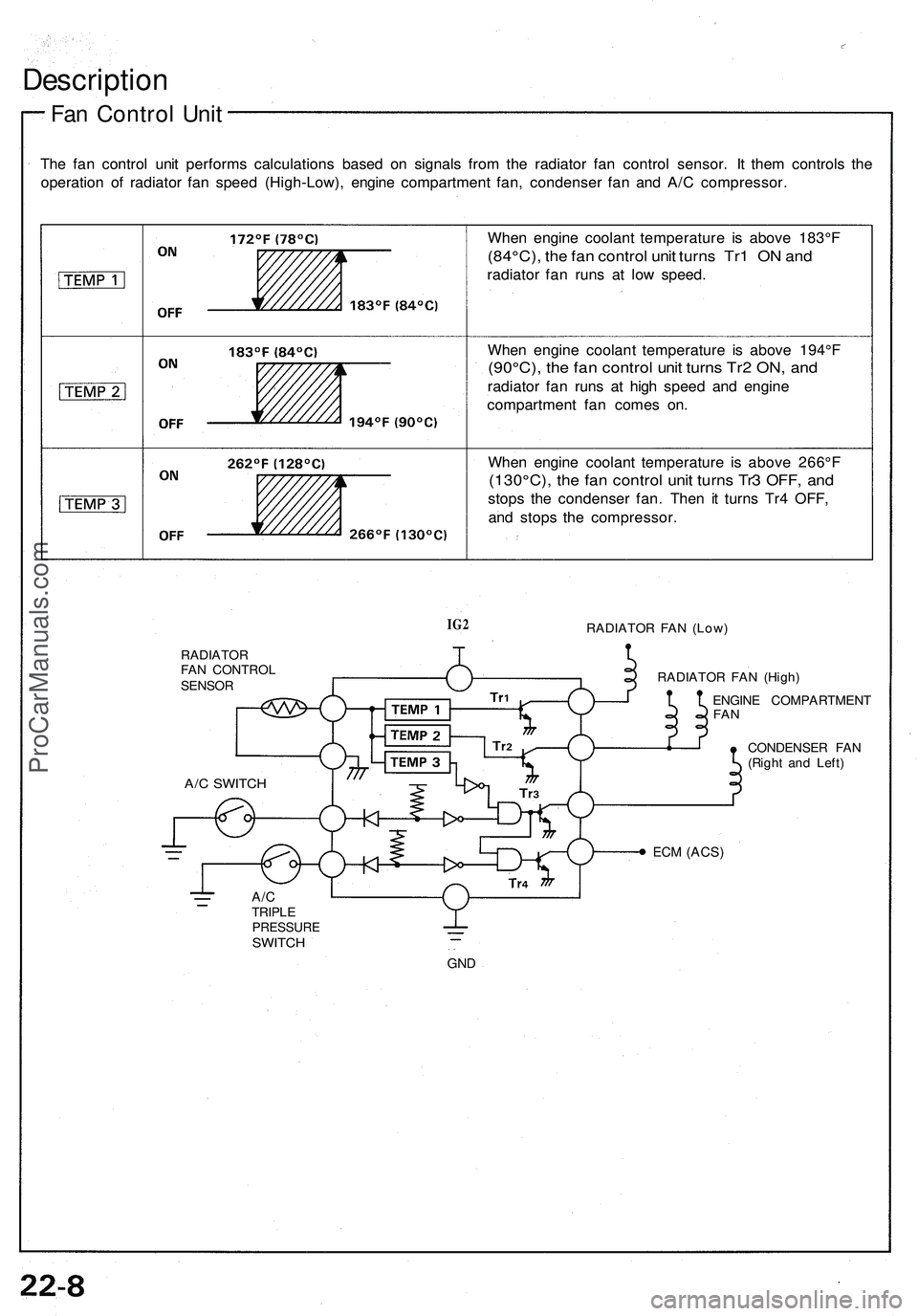

Description

Fan Control Unit

The fan control unit performs calculations based on signals from the radiator fan control sensor. It them controls the

operation of radiator fan speed (High-Low), engine compartment fan, condenser fan and A/C compressor.

When engine coolant temperature is above 183°F

(84°C), the fan control unit turns Tr1 ON and

radiator fan runs at low speed.

When engine coolant temperature is above 194°F

(90°C), the fan control unit turns Tr2 ON, and

radiator fan runs at high speed and engine

compartment fan comes on.

When engine coolant temperature is above 266°F

(130°C), the fan control unit turns Tr3 OFF, and

stops the condenser fan. Then it turns Tr4 OFF,

and stops the compressor.

IG2

RADIATOR FAN (Low)

RADIATOR

FAN CONTROL

SENSOR

RADIATOR FAN (High)

ENGINE COMPARTMENT

FAN

CONDENSER FAN

(Right and Left)

ECM

(ACS)

A/C

TRIPLE

PRESSURE

SWITCH

GND

A/C SWITCHProCarManuals.com

Page 1187 of 1503

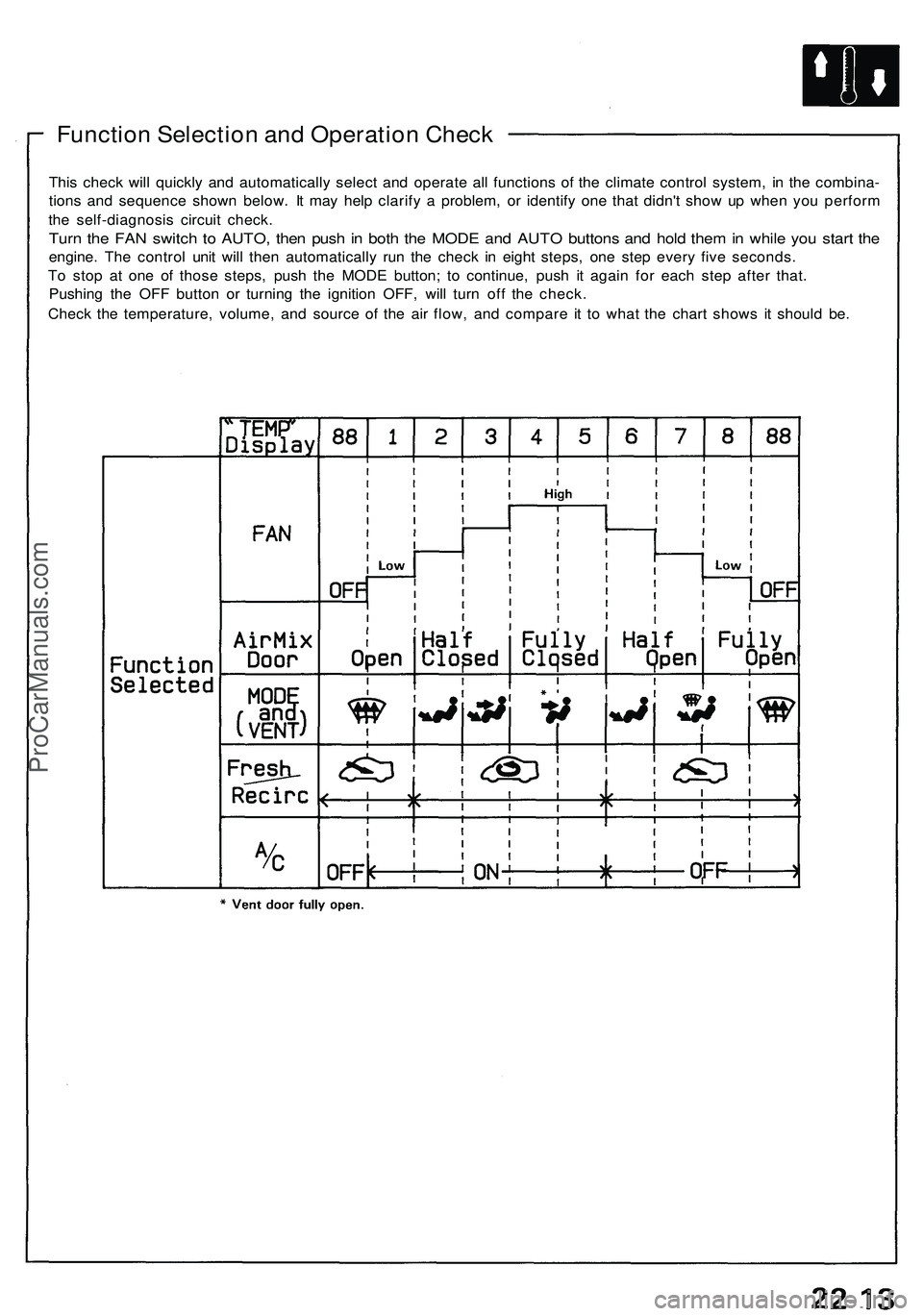

Function Selection and Operation Check

This check will quickly and automatically select and operate all functions of the climate control system, in the combina-

tions and sequence shown below. It may help clarify a problem, or identify one that didn't show up when you perform

the self-diagnosis circuit check.

Turn the FAN switch to AUTO, then push in both the MODE and AUTO buttons and hold them in while you start the

engine. The control unit will then automatically run the check in eight steps, one step every five seconds.

To stop at one of those steps, push the MODE button; to continue, push it again for each step after that.

Pushing the OFF button or turning the ignition OFF, will turn off the check.

Check the temperature, volume, and source of the air flow, and compare it to what the chart shows it should be.ProCarManuals.com

Page 1207 of 1503

A/C System Service

Performance Test

The performance test will help determine if the air con-

ditioning system is operating within specifications.

Only use service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioning system.

CAUTION: Exposure to air conditioner refrigerant

and lubricant vapor or mist can irritate eyes, nose

and throat. Avoid breathing the air conditioner

refrigerant and lubricant vapor or mist.

If accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioning sys-

tem should not be pressure tested or leak tested with

compressed air.

Some mixtures of air and R-134a have

been shown to be combustible at elevated pressures

and can result in fire or explosion causing injury or

property damage. Never use compressed air to pres-

sure test R-134a service equipment or vehicle air

conditioning systems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

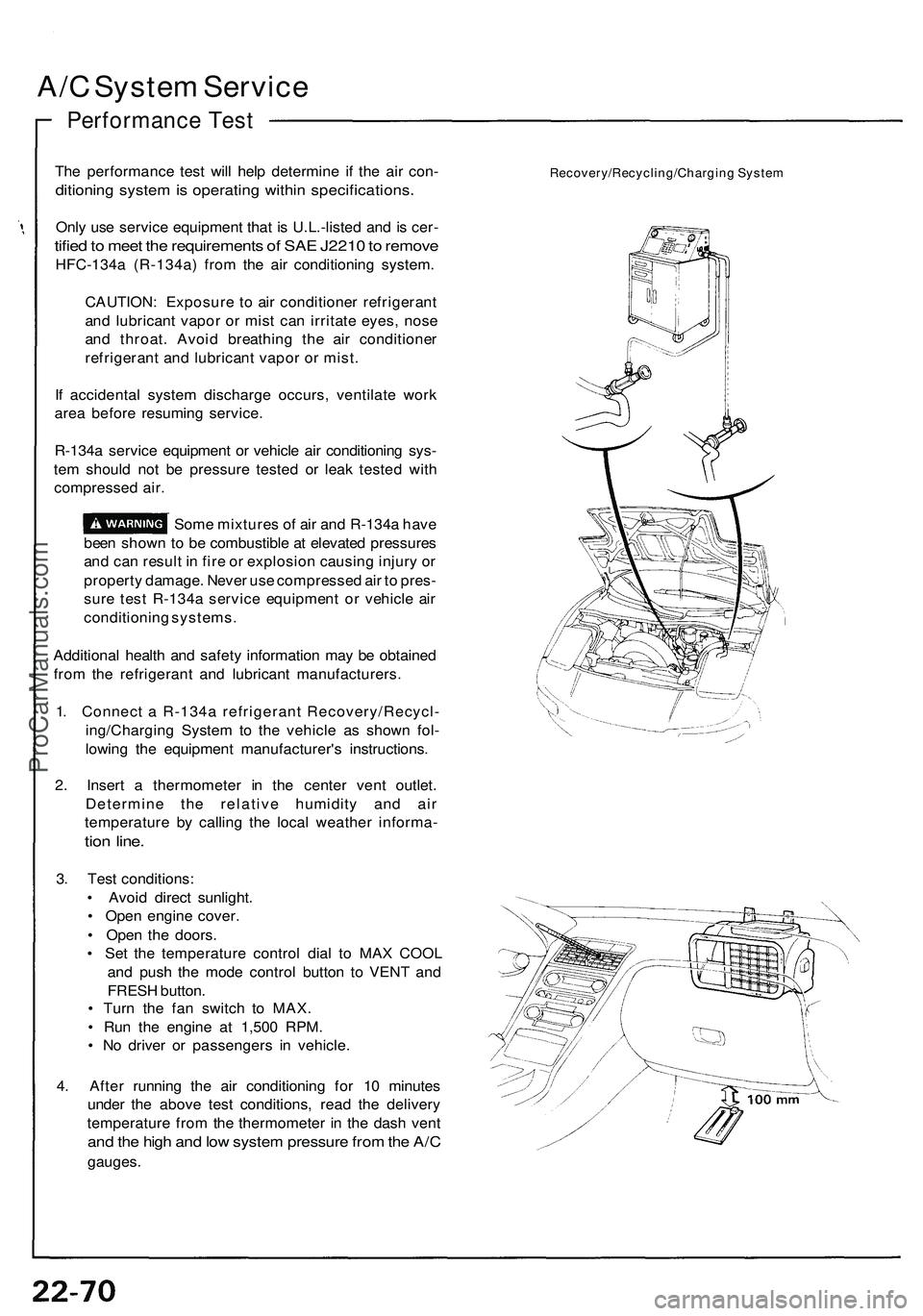

1. Connect a R-134a refrigerant Recovery/Recycl-

ing/Charging System to the vehicle as shown fol-

lowing the equipment manufacturer's instructions.

2. Insert a thermometer in the center vent outlet.

Determine the relative humidity and air

temperature by calling the local weather informa-

tion line.

3. Test conditions:

• Avoid direct sunlight.

• Open engine cover.

• Open the doors.

• Set the temperature control dial to MAX COOL

and push the mode control button to VENT and

FRESH button.

• Turn the fan switch to MAX.

• Run the engine at 1,500 RPM.

• No driver or passengers in vehicle.

4. After running the air conditioning for 10 minutes

under the above test conditions, read the delivery

temperature from the thermometer in the dash vent

and the high and low system pressure from the A/C

gauges.

Recovery/Recycling/Charging SystemProCarManuals.com

Page 1212 of 1503

11. Disconnec t th e connector s fro m al l th e contro l

motors an d sensor s attache d t o th e heater -

evaporato r unit .

1 2 . Remov e th e tw o mountin g bolt s an d tw o nuts , the n

remov e th e heater-evaporato r uni t throug h th e

passenge r door .

CORROSIO N RESISTAN TBOLTHEATER-EVAPORATO R UNIT

NUT S29 N- m (3. 0 kgf-m ,

2 2 Ibf-ft )

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

13. Instal l th e heater-evaporato r uni t i n th e revers e

orde r of removal , and :

• I f you'r e installin g a ne w evaporator , ad d

refrigeran t oi l (ND-OI L 8 ) se e pag e 22-69 ).

• Replac e O-ring s wit h ne w one s a t eac h fitting ,

and appl y refrigeran t oi l t o them .

NOTE : B e sur e t o us e th e righ t O-ring s fo r

R-134 a t o avoi d leakage .

14. Fil l th e radiato r an d reservoi r tan k wit h th e prope r

engine coolan t mixture . Blee d th e ai r fro m th e cool -

in g syste m (se e sectio n 10 ).

CAUTION : Follo w th e sequenc e describe d in th e ai r

blee d procedure . I f you don't , yo u ma y leav e ai r i n

th e syste m whic h coul d damag e th e engine .

15. I f necessary , adjus t th e heate r valv e cable :

• Se t th e ai r mi x contro l moto r a t COO L positio n

(se e pag e 22-57 ).

• Connec t th e en d o f th e heate r valv e cabl e t o th e

heate r valv e arm .

• Gentl y slid e th e cabl e oute r housin g bac k fro m

the en d enoug h to tak e u p an y slac k in th e cable ,

but no t enoug h t o mak e th e othe r en d mov e th e

ar m o n th e ai r mi x contro l motor . The n sna p th e

clam p dow n ove r th e cabl e housing .

CLAMP

HEATE R VALV EARM

HEATE R VALV ECABLE

16. Tur n th e blowe r on , an d mak e sur e tha t ther e is n o

air leakage .

1 7 . Charg e th e syste m (se e pag e 22-91 ), an d tes t per -

formanc e (se e pag e 22-70 ).

SR S UNI T

ProCarManuals.com