engine ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 1272 of 1503

Charging System

Troubleshooting (cont'd)

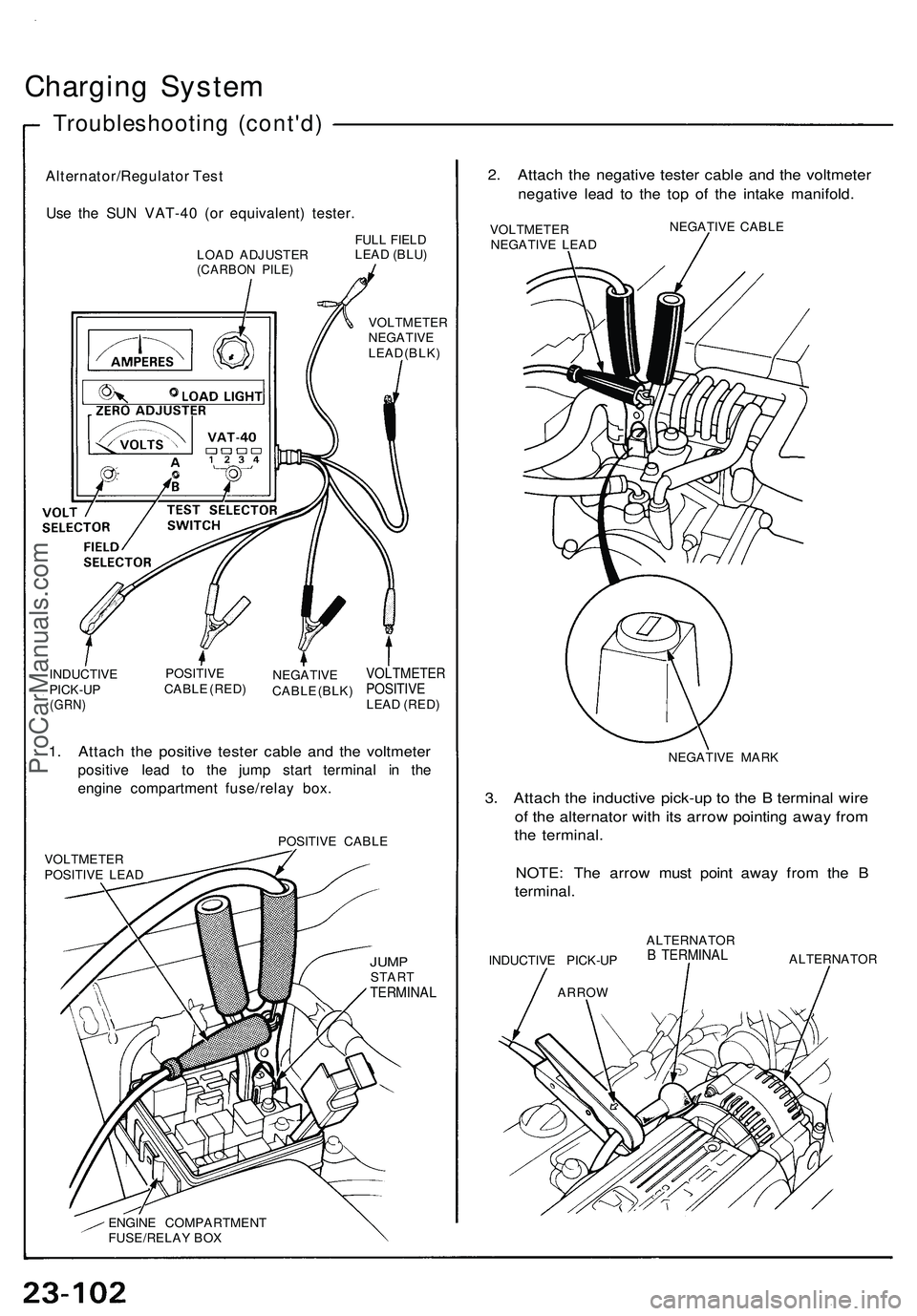

Alternator/Regulator Test

Use the SUN VAT-40 (or equivalent) tester.

LOAD ADJUSTER

(CARBON PILE)

FULL FIELD

LEAD (BLU)

VOLTMETER

NEGATIVE

LEAD (BLK)

INDUCTIVE

PICK-UP

(GRN)

POSITIVE

CABLE (RED)

NEGATIVE

CABLE (BLK)

VOLTMETER

POSITIVE

LEAD (RED)

1. Attach the positive tester cable and the voltmeter

positive lead to the jump start terminal in the

engine compartment fuse/relay box.

POSITIVE CABLE

VOLTMETER

POSITIVE LEAD

JUMP

START

TERMINAL

ENGINE COMPARTMENT

FUSE/RELAY BOX

2. Attach the negative tester cable and the voltmeter

negative lead to the top of the intake manifold.

VOLTMETER

NEGATIVE LEAD

NEGATIVE CABLE

NEGATIVE MARK

3. Attach the inductive pick-up to the B terminal wire

of the alternator with its arrow pointing away from

the terminal.

NOTE: The arrow must point away from the B

terminal.

INDUCTIVE PICK-UP

ARROW

ALTERNATOR

B TERMINAL

ALTERNATORProCarManuals.com

Page 1273 of 1503

NOTE: B e sur e th e batter y i s sufficientl y charge d (se e

page 23-68 ).

Connec t th e Su n VAT-4 0 (se e

pag e 23-102 ) an d tur n th e selec -

to r switc h to positio n 1 (starting) .

Star t th e engine , an d le t i t idl e

unti l i t reache s norma l operatin g

temperature .

Rais e th e engin e spee d t o 2,00 0

rpm , an d hol d i t there .

I s th e voltag e ove r 15. 1 V ?

Replace th e voltag e regulator .

Releas e th e accelerato r pedal ,

an d le t th e engin e idle .

Mak e sur e al l accessorie s ar e

turne d off . Tur n th e selecto r

switch to positio n 2 (charging) .

Remove th e inductiv e pick-up ,

an d zer o th e ammeter .

Attac h th e inductiv e pick-u p t o

th e B termina l wir e o f th e alterna -tor wit h it s arro w pointin g awa y

fro m th e terminal .

Rais e th e engin e spee d t o 2,00 0

rpm , an d hol d it there .

I s th e voltag e les s tha n 13. 9 V ?

Test th e batter y (se e pag e 23-68 ).

(T o page 23-104 )

(cont'd)

ProCarManuals.com

Page 1279 of 1503

Alternator Bel t Adjustmen t

Deflection Method :

1 . Appl y a forc e o f 9 8 N (1 0 kgf , 2 2 Ibf ) betwee n th e

alternato r an d crankshaf t pulley , an d measur e it s

deflection .

Deflection : 11-13. 5 m m (0.43-0.5 3 in )

NOTE : O n a brand-ne w belt , th e deflectio n shoul d

be 6- 8 m m (0.24-0.3 1 in ) befor e th e bel t ha s

had an y runnin g tim e o n th e engine .

ADJUSTIN G BOL T8 N- m (0. 8 kgf-m , 5. 8 Ibf-ft )

MOUNTIN G BOL T45 N- m (4. 6 kgf-m , 3 3 Ibf-ft )

ADJUSTMENT-LOC KNUT45 N- m (4. 6 kgf-m , 3 3 Ibf-ft )CRANKSHAF T PULLE Y

2. I f bel t deflectio n i s incorrect , loose n th e

adjustment-loc k nu t an d th e mountin g bolt .

3 . Tur n th e adjustin g bol t unti l bel t deflectio n i s cor -

rect , the n retighte n th e nu t an d bolt .

4 . Rechec k th e bel t tension . Tensio

n Gaug e Method :

1 . Attac h th e bel t tensio n gaug e t o th e belt , an d mea -

sur e bel t tension .

Tension : 45 0 - 65 0 N (4 5 - 6 5 kgf , 99-14 3 Ibf )

NOTE : O n a brand-ne w belt , th e tensio n shoul d b e

90 0 - 110 0 N (9 0 - 11 0 kgf , 19 8 - 24 3 Ibf ) befor e th e

bel t ha s ha d an y runnin g tim e o n th e engine .

MOUNTIN G BOL T45 N- m (4. 6 kgf-m , 3 3 Ibf-ft )

ADJUSTIN G BOL T8 N- m (0. 8 kgf-m , 5. 8 Ibf-ft )BELT TENSIO N GAUG E07JGG-001010 A

ADJUSTMENT-LOC KNUT45 N- m (4. 6 kgf-m ,33 Ibf-ft )CRANKSHAF T PULLE Y

2. I f bel t tensio n i s incorrect , loose n th e adjustment -

loc k nu t an d th e mountin g bolt .

3 . Tur n th e adjustin g bol t unti l bel t tensio n i s correct ,

the n retighte n th e nu t an d bolt .

4 . Rechec k th e bel t tension .

ProCarManuals.com

Page 1282 of 1503

Radiator and Condenser Fan Controls

Description

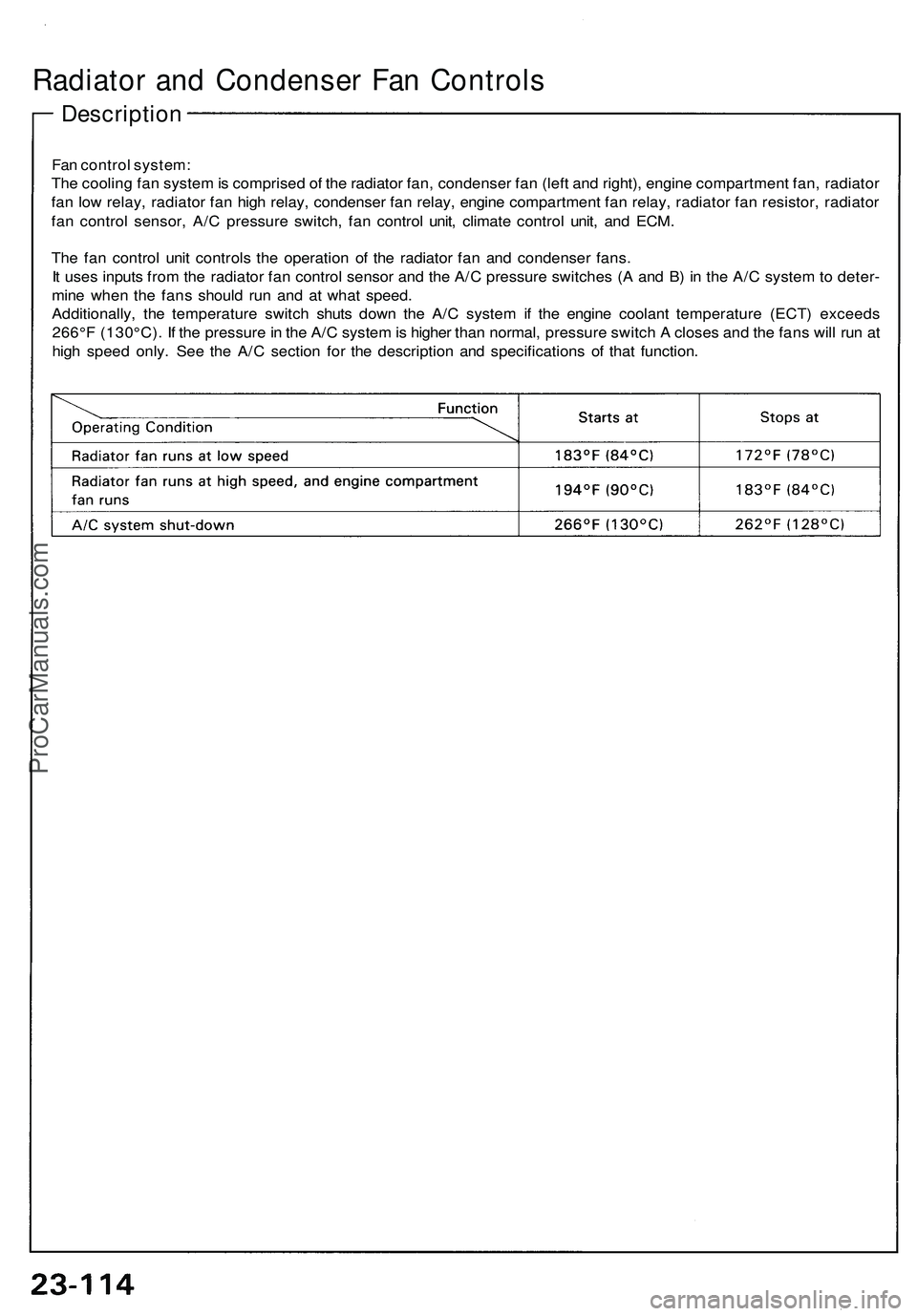

Fan control system:

The cooling fan system is comprised of the radiator fan, condenser fan (left and right), engine compartment fan, radiator

fan low relay, radiator fan high relay, condenser fan relay, engine compartment fan relay, radiator fan resistor, radiator

fan control sensor, A/C pressure switch, fan control unit, climate control unit, and ECM.

The fan control unit controls the operation of the radiator fan and condenser fans.

It uses inputs from the radiator fan control sensor and the A/C pressure switches (A and B) in the A/C system to deter-

mine when the fans should run and at what speed.

Additionally, the temperature switch shuts down the A/C system if the engine coolant temperature (ECT) exceeds

266°F (130°C). If the pressure in the A/C system is higher than normal, pressure switch A closes and the fans will run at

high speed only. See the A/C section for the description and specifications of that function.ProCarManuals.com

Page 1284 of 1503

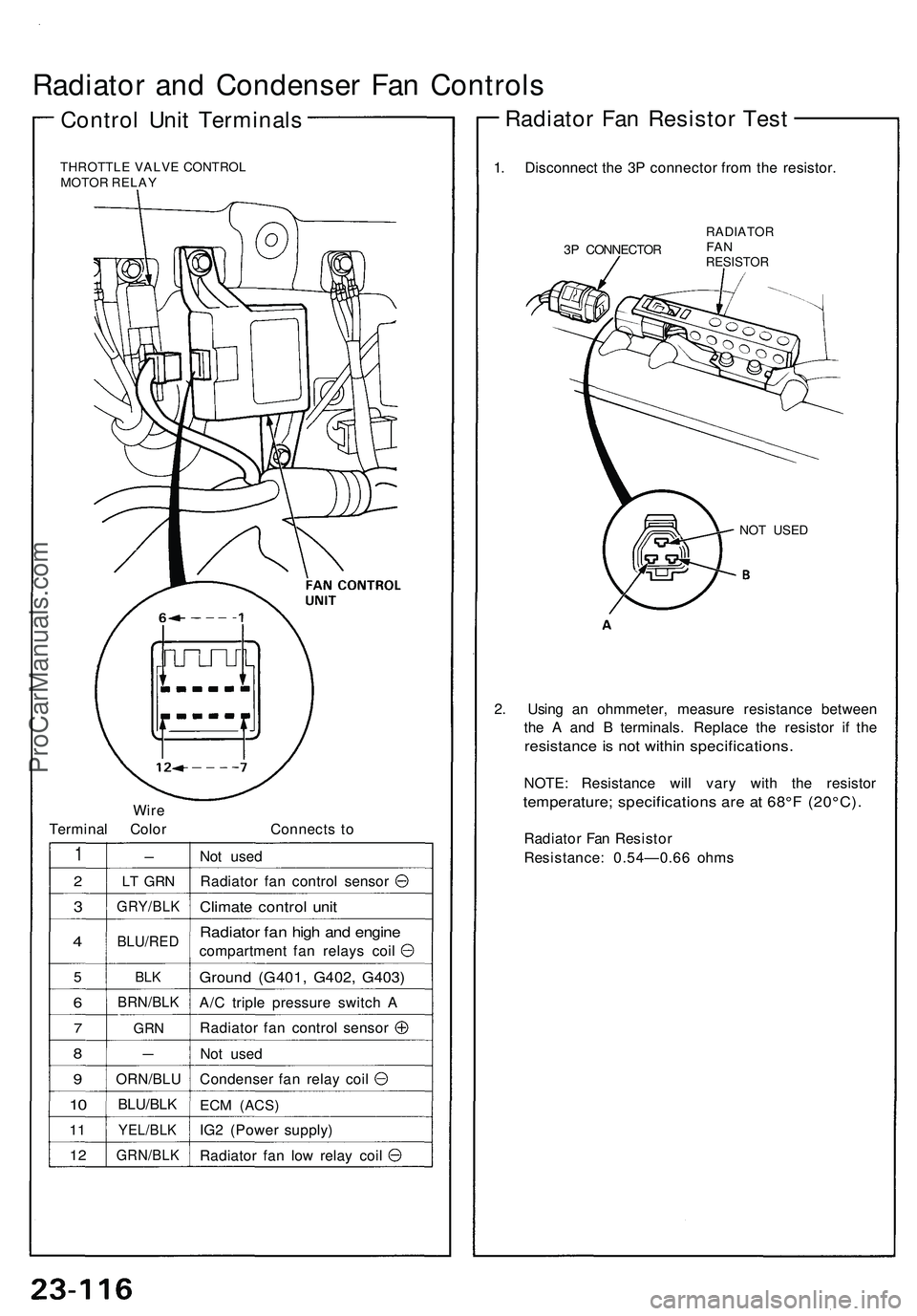

Radiator and Condenser Fan Controls

Control Unit Terminals

THROTTLE VALVE CONTROL

MOTOR RELAY

Wire

Terminal Color

Connects to

1

2

3

4

5

6

7

8

9

10

11

12

-

LT GRN

GRY/BLK

BLU/RED

BLK

BRN/BLK

GRN

—

ORN/BLU

BLU/BLK

YEL/BLK

GRN/BLK

Not used

Radiator fan control sensor

Climate control unit

Radiator fan high and engine

compartment fan relays coil

Ground (G401, G402, G403)

A/C triple pressure switch A

Radiator fan control sensor

Not used

Condenser fan relay coil

ECM

(ACS)

IG2 (Power supply)

Radiator fan low relay coil

1. Disconnect the 3P connector from the resistor.

3P CONNECTOR

RADIATOR

FAN

RESISTOR

NOT USED

2. Using an ohmmeter, measure resistance between

the A and B terminals. Replace the resistor if the

resistance is not within specifications.

NOTE: Resistance will vary with the resistor

temperature; specifications are at 68°F (20°C).

Radiator Fan Resistor

Resistance: 0.54—0.66 ohms

Radiator Fan Resistor TestProCarManuals.com

Page 1286 of 1503

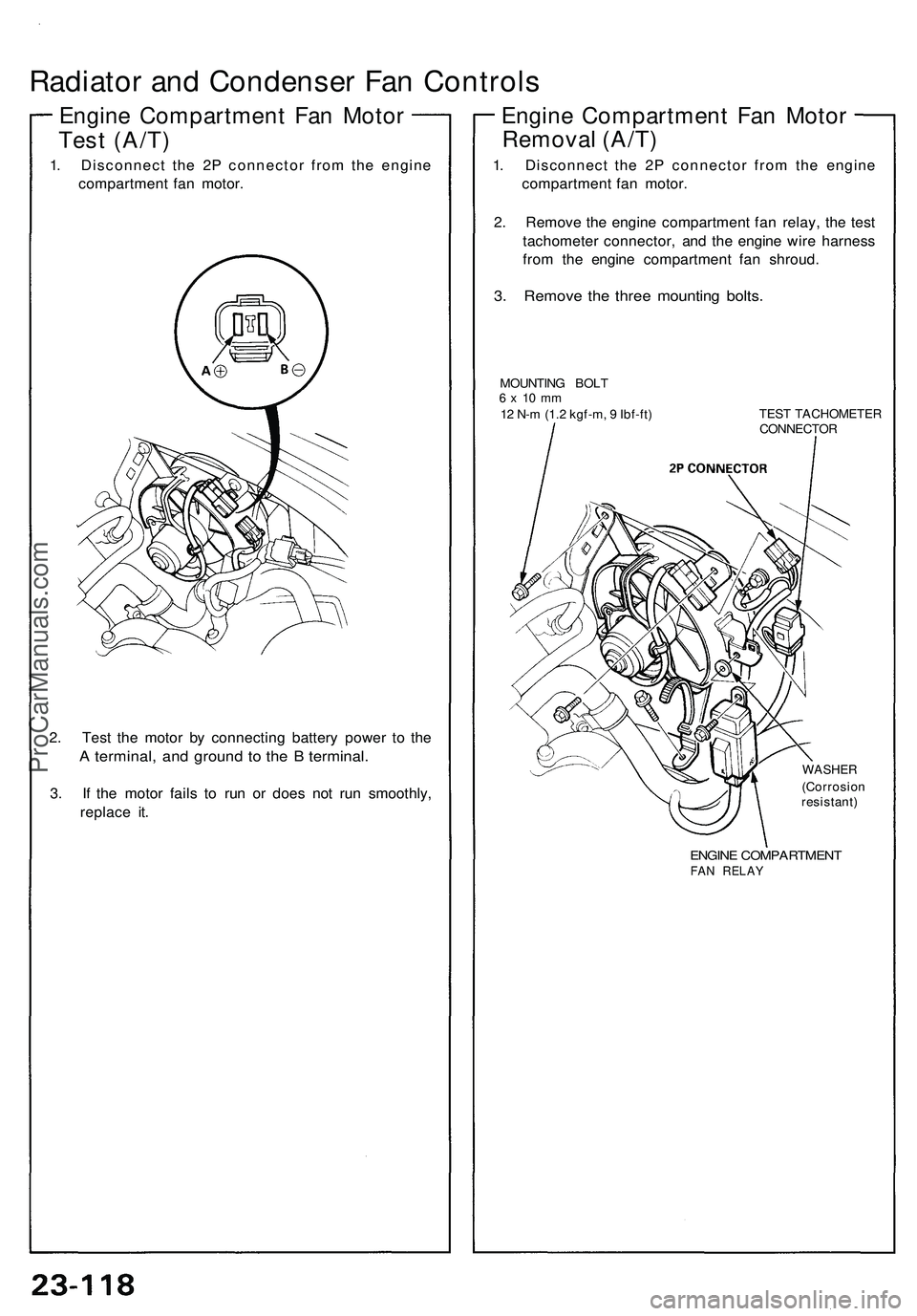

Radiator and Condenser Fan Controls

Engine Compartment Fan Motor

Test (A/T)

1. Disconnect the 2P connector from the engine

compartment fan motor.

2. Test the motor by connecting battery power to the

A terminal, and ground to the B terminal.

3. If the motor fails to run or does not run smoothly,

replace it.

Engine Compartment Fan Motor

Removal (A/T)

1. Disconnect the 2P connector from the engine

compartment fan motor.

2. Remove the engine compartment fan relay, the test

tachometer connector, and the engine wire harness

from the engine compartment fan shroud.

3. Remove the three mounting bolts.

MOUNTING BOLT

6 x 10 mm

12 N-m (1.2 kgf-m, 9 Ibf-ft)

TEST TACHOMETER

CONNECTOR

WASHER

(Corrosion

resistant)

ENGINE COMPARTMENT

FAN RELAYProCarManuals.com

Page 1287 of 1503

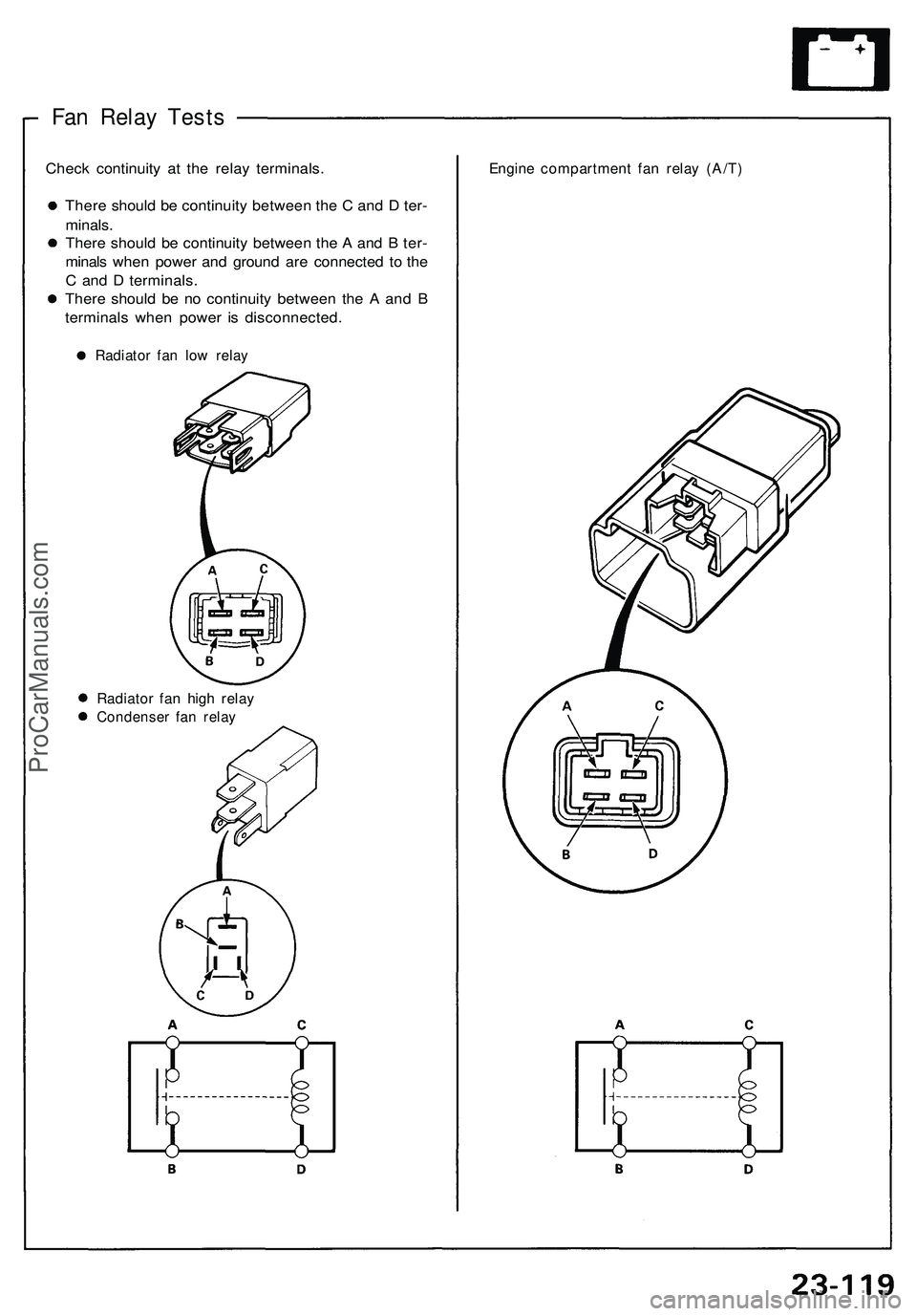

Fan Relay Tests

Check continuity at the relay terminals.

There should be continuity between the C and D ter-

minals.

There should be continuity between the A and B ter-

minals when power and ground are connected to the

C and D terminals.

There should be no continuity between the A and B

terminals when power is disconnected.

Radiator fan low relay

Engine compartment fan relay (A/T)

Radiator fan high relay

Condenser fan relayProCarManuals.com

Page 1298 of 1503

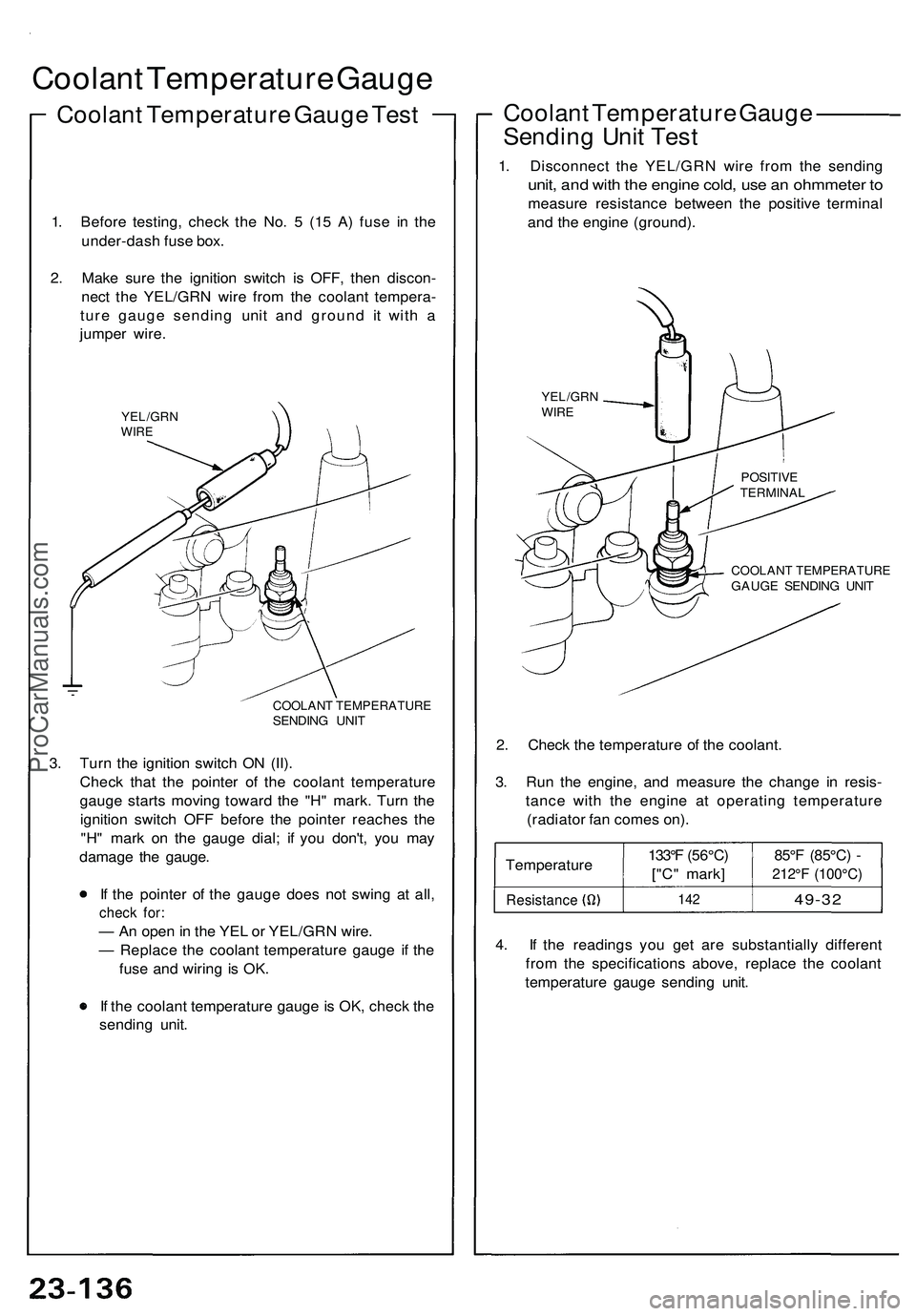

Coolant Temperatur e Gaug e

Coolan t Temperatur e Gaug e Tes t

1. Befor e testing , chec k th e No . 5 (1 5 A ) fus e i n th e

under-das h fus e box .

2 . Mak e sur e th e ignitio n switc h i s OFF , the n discon -

nec t th e YEL/GR N wir e fro m th e coolan t tempera -

tur e gaug e sendin g uni t an d groun d i t wit h a

jumpe r wire .

YEL/GR NWIRE

COOLAN T TEMPERATUR ESENDING UNI T

3. Tur n th e ignitio n switc h O N (II) .

Chec k tha t th e pointe r o f th e coolan t temperatur e

gaug e start s movin g towar d th e "H " mark . Tur n th e

ignitio n switc h OF F befor e th e pointe r reache s th e

"H " mar k o n th e gaug e dial ; i f yo u don't , yo u ma y

damag e th e gauge .

I f th e pointe r o f th e gaug e doe s no t swin g a t all ,

chec k for :

— An ope n in th e YE L o r YEL/GR N wire .

— Replac e th e coolan t temperatur e gaug e i f th e

fus e an d wirin g i s OK .

I f th e coolan t temperatur e gaug e is OK , chec k th e

sendin g unit .

Coolan t Temperatur e Gaug e ———

Sendin g Uni t Tes t

1. Disconnec t th e YEL/GR N wir e fro m th e sendin g

unit, an d wit h th e engin e cold , us e a n ohmmete r t o

measur e resistanc e betwee n th e positiv e termina l

an d th e engin e (ground) .

COOLAN T TEMPERATUR EGAUGE SENDIN G UNI T

2. Chec k th e temperatur e o f th e coolant .

3 . Ru n th e engine , an d measur e th e chang e i n resis -

tanc e wit h th e engin e a t operatin g temperatur e

(radiato r fa n come s on) .

Temperatur e

Resistance

133°F (56°C )

["C " mark ]

142

85° F (85°C ) -

212° F (100°C )

49-32

4. I f th e reading s yo u ge t ar e substantiall y differen t

fro m th e specification s above , replac e th e coolan t

temperatur e gaug e sendin g unit .

YEL/GR NWIRE

POSITIV ETERMINA L

ProCarManuals.com

Page 1299 of 1503

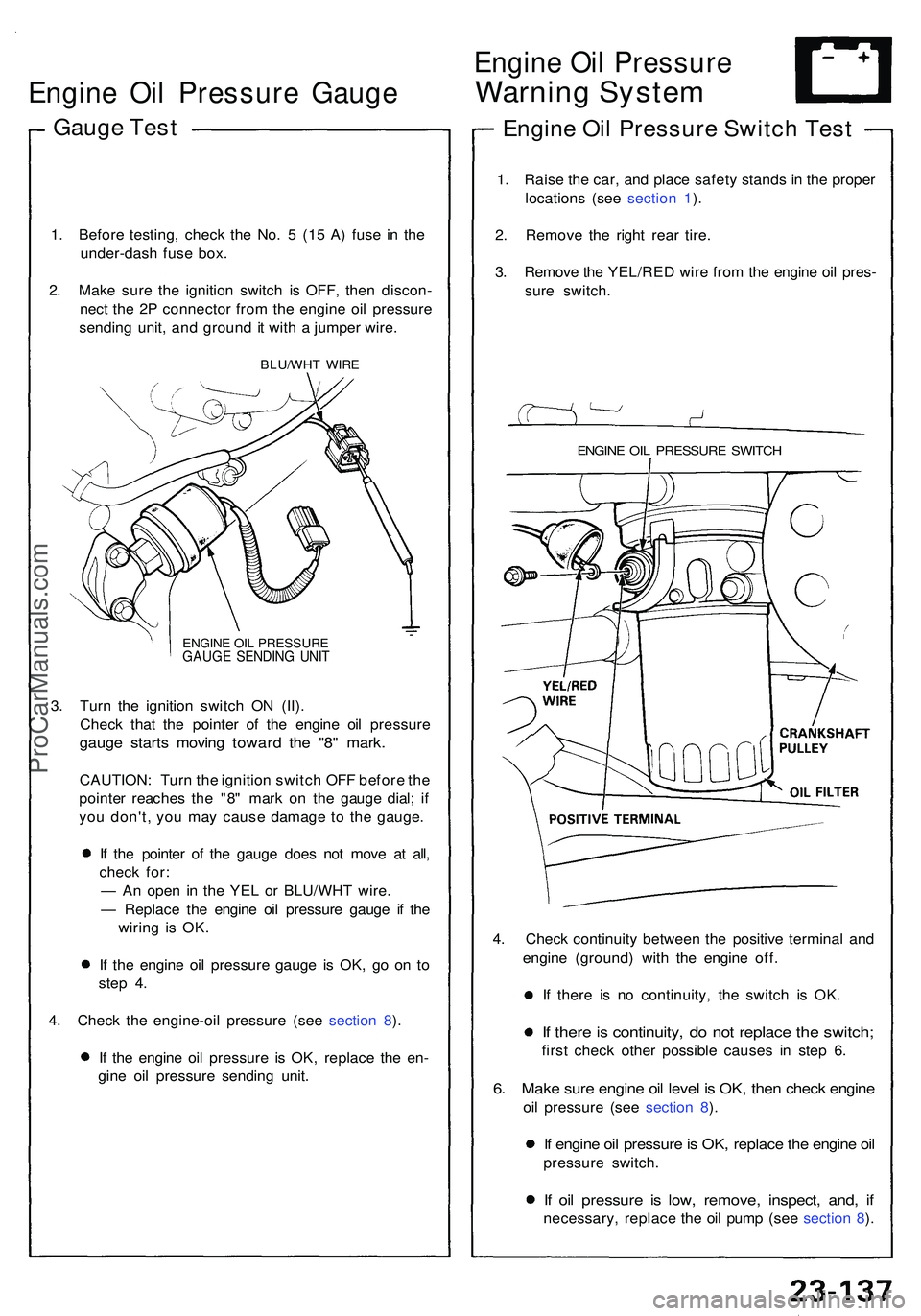

Engine Oi l Pressur e Gaug e

Gauge Tes t

1. Befor e testing , chec k th e No . 5 (15 A ) fus e i n th e

under-das h fus e box .

2 . Mak e sur e th e ignitio n switc h i s OFF , the n discon -

nec t th e 2 P connecto r fro m th e engin e oi l pressur e

sendin g unit , an d groun d i t wit h a jumpe r wire .

BLU/WH T WIR E

ENGIN E OI L PRESSUR E

GAUGE SENDIN G UNI T

3. Tur n th e ignitio n switc h O N (II) .

Chec k tha t th e pointe r o f th e engin e oi l pressur e

gauge start s movin g towar d th e "8 " mark .

CAUTION : Tur n th e ignitio n switc h OF F befor e th e

pointe r reache s th e "8 " mar k o n th e gaug e dial ; i f

yo u don't , yo u ma y cause damag e t o th e gauge .

I f th e pointe r o f th e gaug e doe s no t mov e a t all ,

chec k for :

— A n ope n i n th e YE L o r BLU/WH T wire .

— Replac e th e engin e oi l pressur e gaug e i f th e

wirin g i s OK .

I f th e engin e oi l pressur e gaug e i s OK , g o o n t o

ste p 4 .

4 . Chec k th e engine-oi l pressur e (se e sectio n 8 ).

I f th e engin e oi l pressur e i s OK , replac e th e en -

gin e oi l pressur e sendin g unit .

Engin e Oi l Pressur e

Warning Syste m

Engine Oi l Pressur e Switc h Tes t

1. Rais e th e car , an d plac e safet y stand s i n th e prope r

location s (se e sectio n 1 ).

2 . Remov e th e righ t rea r tire .

3 . Remov e th e YEL/RE D wir e fro m th e engin e oi l pres -

sur e switch .

ENGINE OI L PRESSUR E SWITC H

4. Chec k continuit y betwee n th e positiv e termina l an d

engin e (ground ) wit h th e engin e off .

I f ther e i s n o continuity , th e switc h i s OK .

If ther e is continuity , d o no t replac e th e switch ;

first chec k othe r possible causes i n ste p 6 .

6. Mak e sur e engin e oi l leve l i s OK , the n chec k engin e

oil pressur e (se e sectio n 8 ).

If engin e oi l pressur e is OK , replac e th e engin e oi l

pressur e switch .

If oi l pressur e i s low , remove , inspect , and , i f

necessary , replac e th e oi l pum p (se e sectio n 8 ).

ProCarManuals.com

Page 1314 of 1503

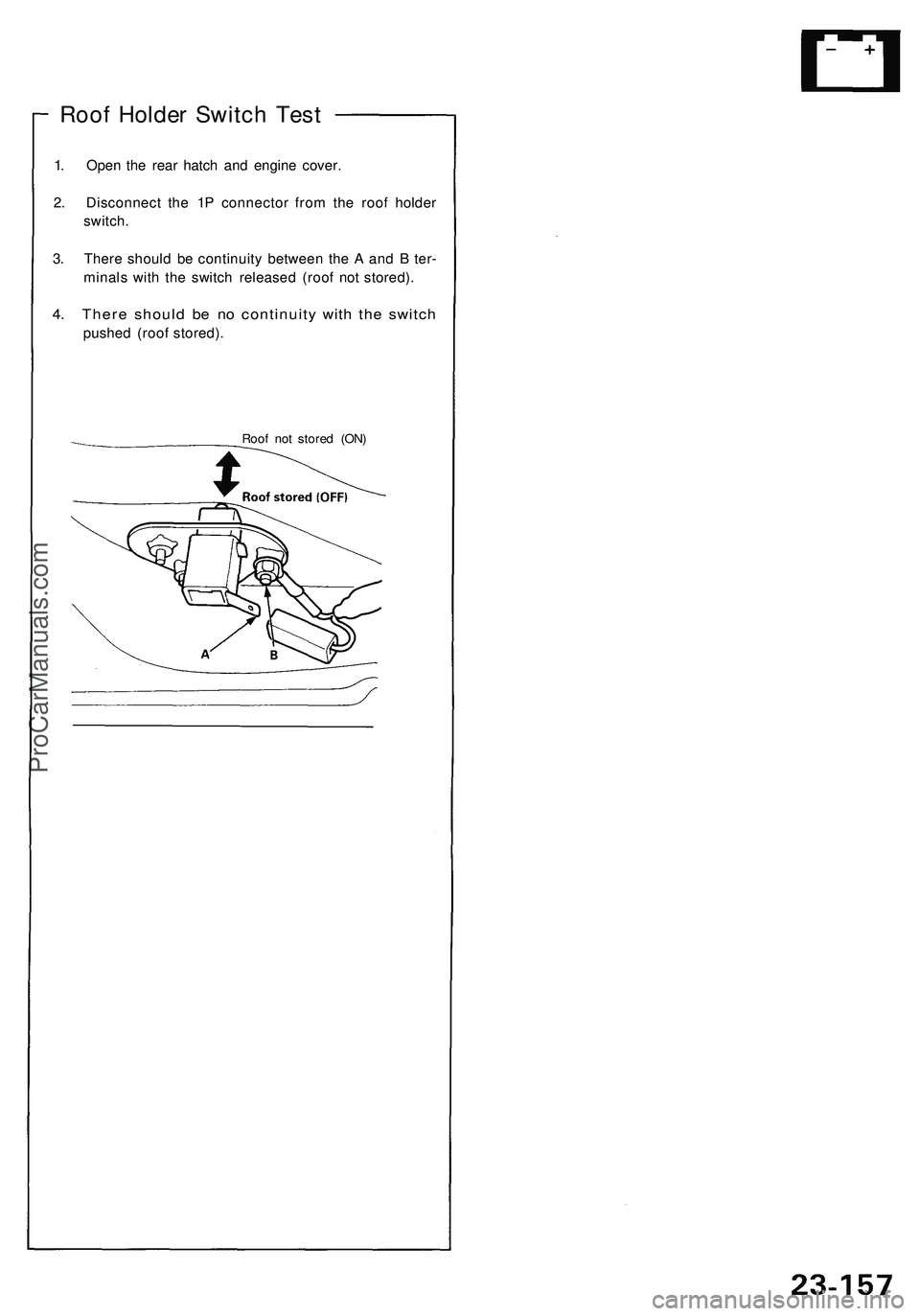

Roof Holder Switch Test

1. Open the rear hatch and engine cover.

2. Disconnect the 1P connector from the roof holder

switch.

3. There should be continuity between the A and B ter-

minals with the switch released (roof not stored).

4. There should be no continuity with the switch

pushed (roof stored).

Roof not stored (ON)ProCarManuals.com