ECU ACURA NSX 1997 Service Manual PDF

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 1171 of 1503

Seals/Retainers Alignmen t

Adjustmen t (cont'd )

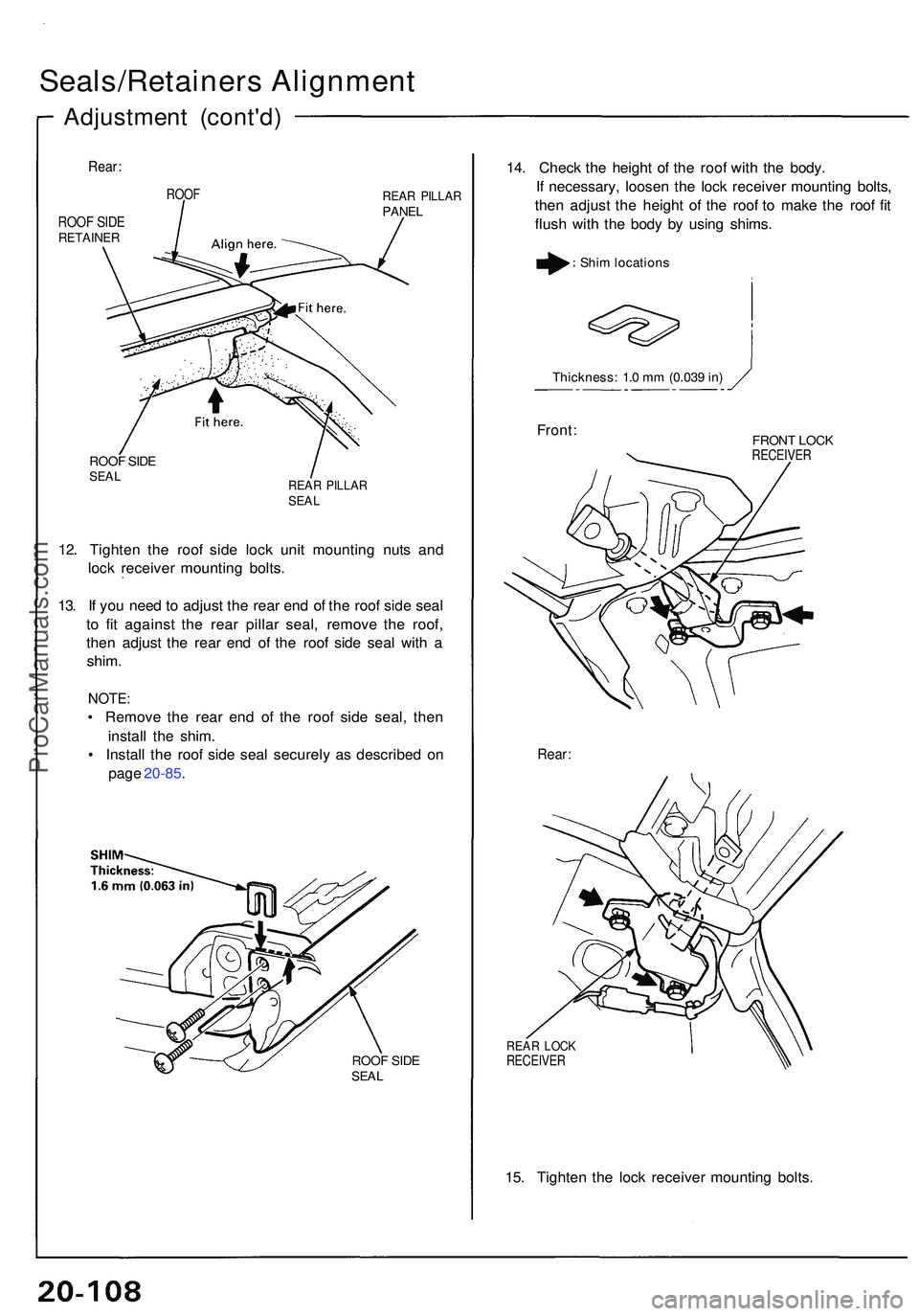

Rear:

ROO F SID ERETAINE R

ROOFREAR PILLA RPANEL

ROOF SID ESEA LREA R PILLA RSEAL

12. Tighte n th e roo f sid e loc k uni t mountin g nut s an d

loc k receive r mountin g bolts .

13 . I f yo u nee d t o adjus t th e rea r en d o f th e roo f sid e sea l

t o fi t agains t th e rea r pilla r seal , remov e th e roof ,

the n adjus t th e rea r en d o f th e roo f sid e sea l wit h a

shim .

NOTE :

• Remov e th e rea r en d o f th e roo f sid e seal , the n

instal l th e shim .

• Instal l th e roo f sid e sea l securel y a s describe d o n

pag e 20-85 .

ROOF SID ESEA L

14. Chec k th e heigh t o f th e roo f wit h th e body .

I f necessary , loose n th e loc k receive r mountin g bolts ,

the n adjus t th e heigh t o f th e roo f t o mak e th e roo f fi t

flus h wit h th e bod y b y usin g shims .

Thickness : 1. 0 m m (0.03 9 in )

Front :FRON T LOC KRECEIVE R

Rear:

REAR LOC KRECEIVE R

15. Tighte n th e loc k receive r mountin g bolts .

Shim location s

ProCarManuals.com

Page 1172 of 1503

16. Chec k tha t eac h roo f sid e loc k handl e work s

smoothly .

17 . Remov e th e roof .

18 . I f th e roo f sid e retaine r ha s no t bee n replaced , an d

o r th e EP T seale r o n th e roo f sid e retaine r ha s no t

bee n replaced , d o th e followin g (se e pag e 20-84 ):

a . Remov e th e roo f sid e sea l an d roo f sid e retaine r

fro m th e roof ,

b . Replac e th e EP T seale r o n th e roo f sid e retaine r

an d roof .

c . Replac e th e buty l tape s o n th e roo f sid e seal ,

d . Reinstal l th e roo f sid e retainer , the n appl y ne w

sealant ,

e. Reinstal l th e roo f sid e seal .

19 . Chec k th e lip s o f th e roo f sid e seal , an d glu e th e

peele d li p securel y wit h sealant , the n wip e th e

exces s sealan t of f wit h a sof t sho p towe l dampene d

wit h alcohol .

20 . Afte r applyin g th e sealant , le t th e roo f stan d fo r a t

leas t thre e hours .

21 . Instal l th e roo f o n th e body , the n mak e sur e th e

seal s fi t flush .

NOTE : Mak e sur e bot h roo f sid e loc k handle s ar e

locke d securely .

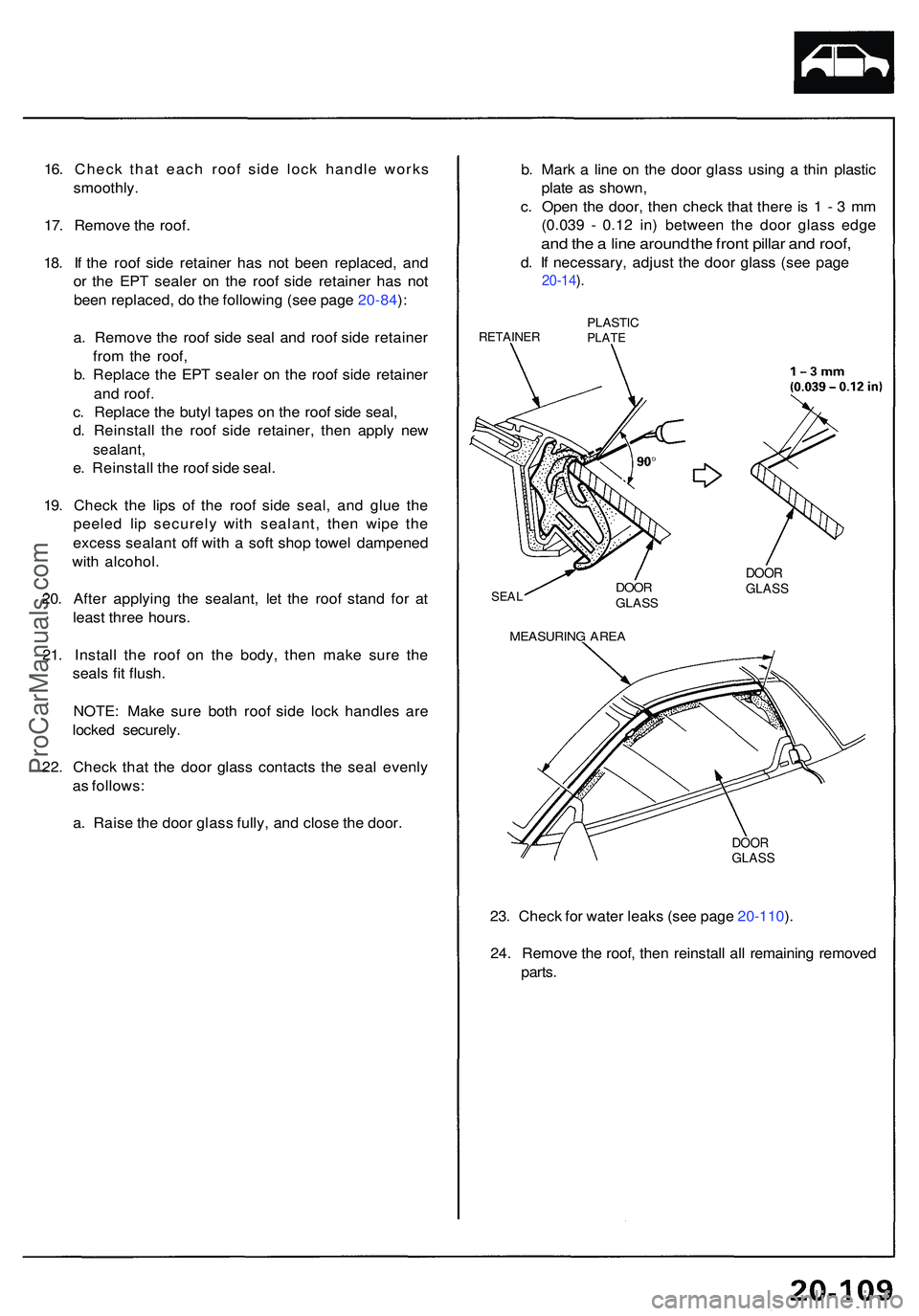

22 . Chec k tha t th e doo r glas s contact s th e sea l evenl y

a s follows :

a . Rais e th e doo r glas s fully , an d clos e th e door . b

. Mar k a lin e o n th e doo r glas s usin g a thi n plasti c

plat e a s shown ,

c . Ope n th e door , the n chec k tha t ther e is 1 - 3 m m

(0.03 9 - 0.1 2 in ) betwee n th e doo r glas s edg e

and th e a lin e aroun d th e fron t pilla r an d roof ,

d. I f necessary , adjus t th e doo r glas s (se e pag e

20-14 ).

RETAINE RPLASTICPLATE

SEAL

MEASURIN G ARE A

DOORGLAS S

DOORGLAS S

DOORGLAS S

23. Chec k fo r wate r leak s (se e pag e 20-110 ).

24 . Remov e th e roof , the n reinstal l al l remainin g remove d

parts .

ProCarManuals.com

Page 1173 of 1503

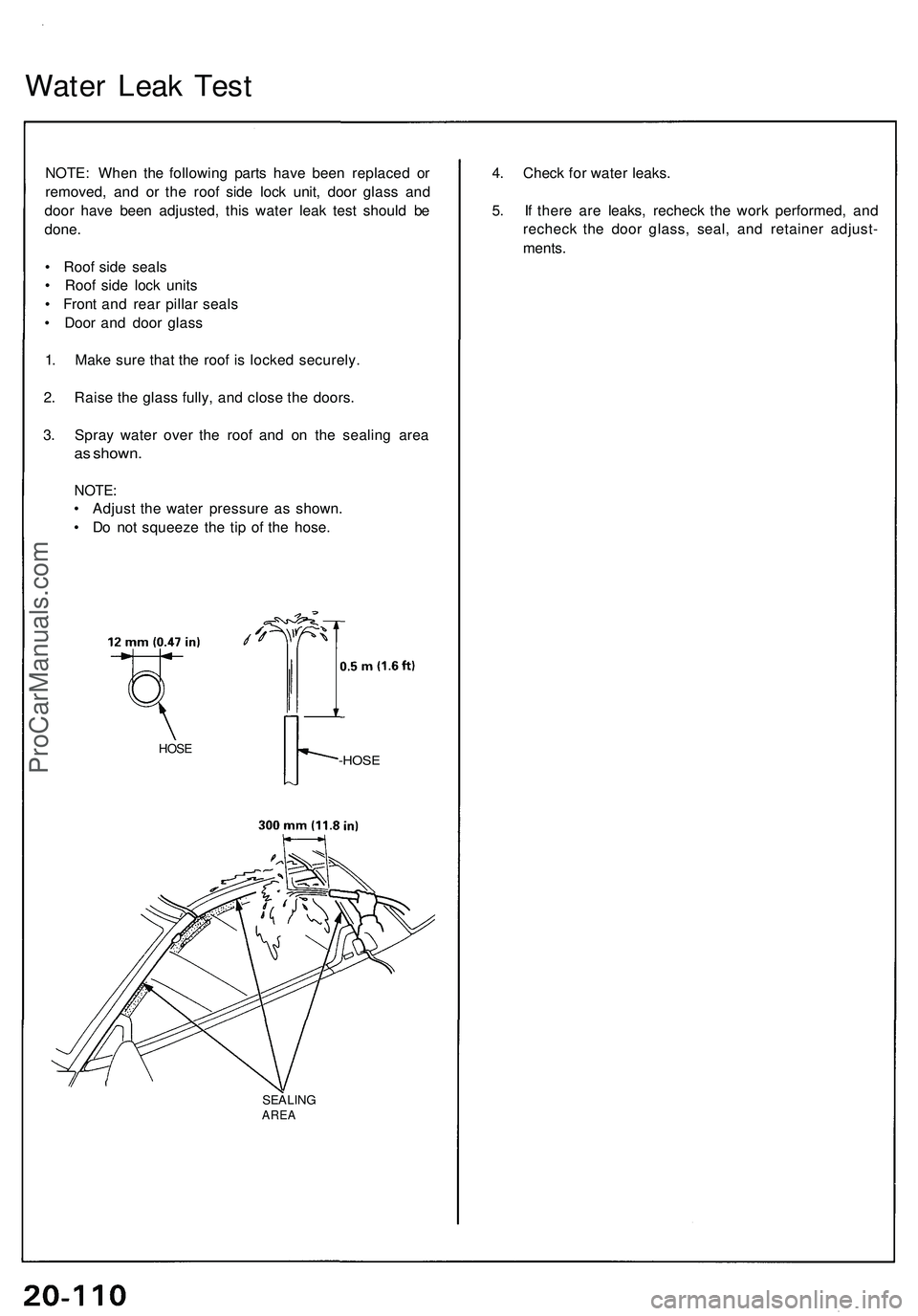

Water Leak Test

NOTE: When the following parts have been replaced or

removed, and or the roof side lock unit, door glass and

door have been adjusted, this water leak test should be

done.

• Roof side seals

• Roof side lock units

• Front and rear pillar seals

• Door and door glass

1. Make sure that the roof is locked securely.

2. Raise the glass fully, and close the doors.

3. Spray water over the roof and on the sealing area

as shown.

NOTE:

• Adjust the water pressure as shown.

• Do not squeeze the tip of the hose.

HOSE

-HOSE

SEALING

AREA

4. Check for water leaks.

5. If there are leaks, recheck the work performed, and

recheck the door glass, seal, and retainer adjust-

ments.ProCarManuals.com

Page 1175 of 1503

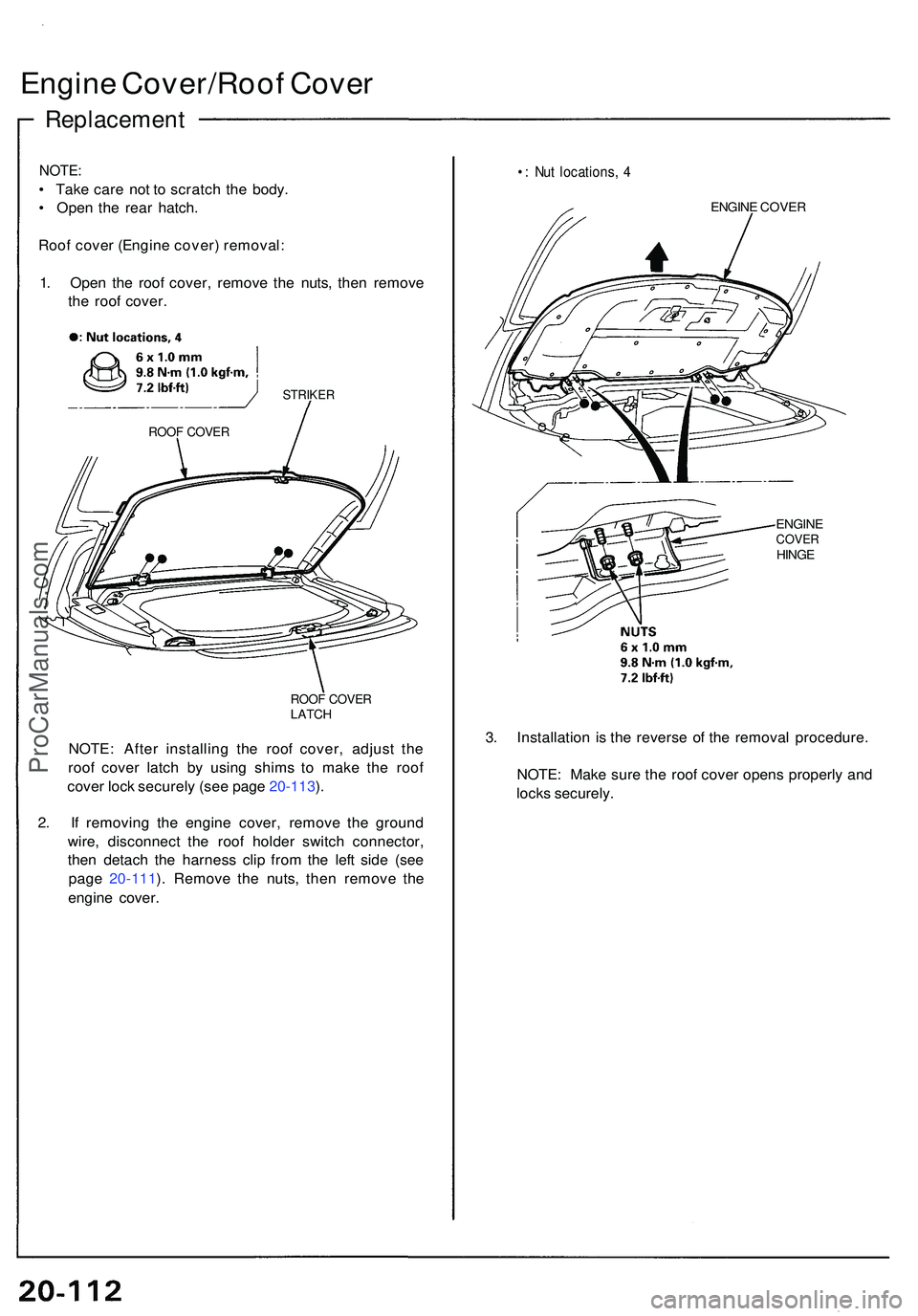

Engine Cover/Roo f Cove r

Replacemen t

ROOF COVE RLATCH

NOTE : Afte r installin g th e roo f cover , adjus t th e

roo f cove r latc h b y usin g shim s t o mak e th e roo f

cove r loc k securel y (se e pag e 20-113 ).

2 . I f removin g th e engin e cover , remov e th e groun d

wire , disconnec t th e roo f holde r switc h connector ,

the n detac h th e harnes s cli p fro m th e lef t sid e (se e

pag e 20-111 ). Remov e th e nuts , the n remov e th e

engine cover.

• : Nu t locations , 4

ENGIN E COVE R

ENGIN E

COVERHINGE

3. Installatio n i s th e revers e o f th e remova l procedure .

NOTE : Mak e sur e th e roo f cove r open s properl y an d

lock s securely .

NOTE:

• Tak e car e no t t o scratc h th e body .

• Ope n th e rea r hatch .

Roo f cove r (Engin e cover ) removal :

1 . Ope n th e roo f cover , remov e th e nuts , the n remov e

th e roo f cover .

ROOF COVE R

STRIKE R

ProCarManuals.com

Page 1177 of 1503

Engine Cover/Roo f Cove r

Replacemen t (cont'd )

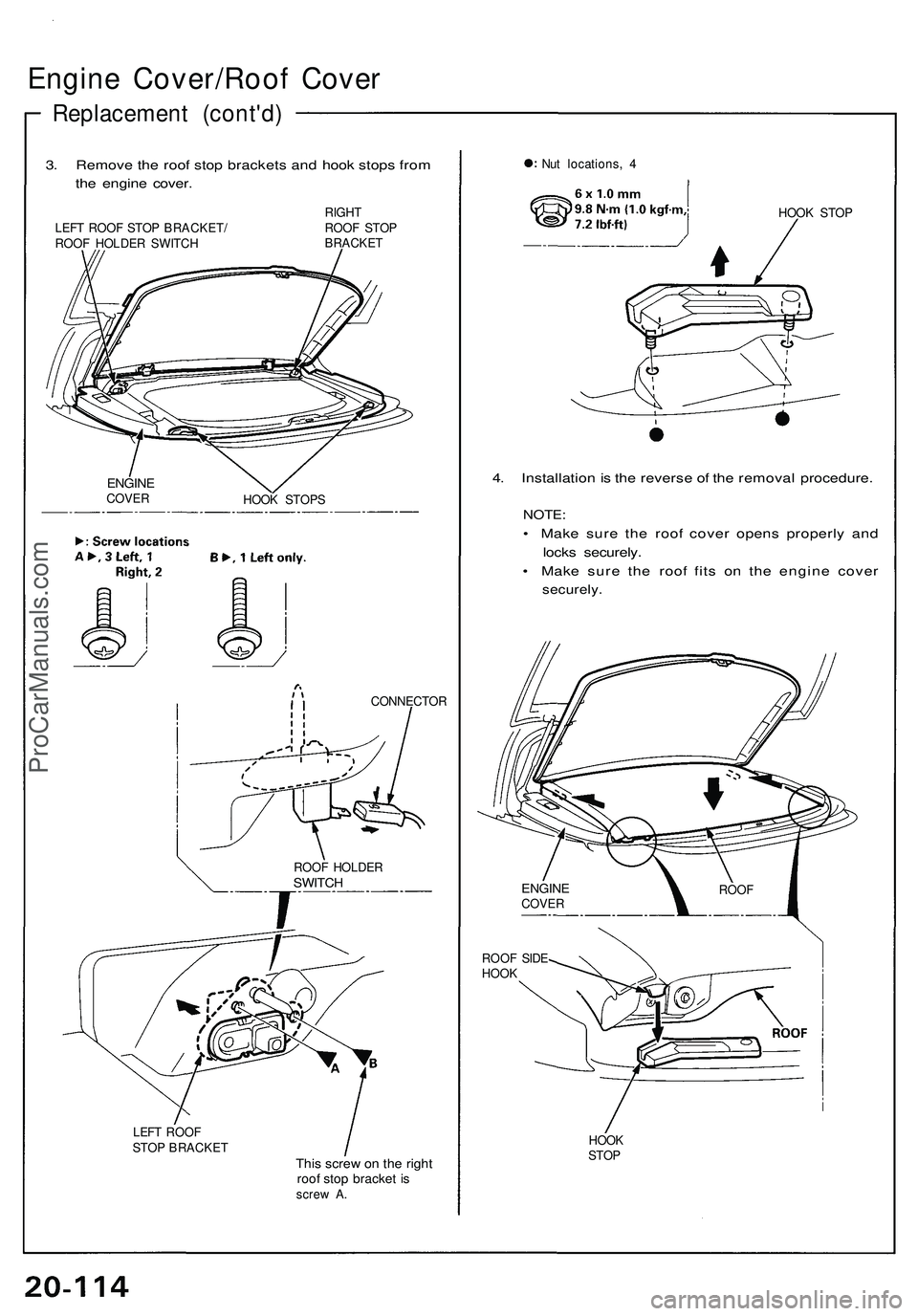

3. Remov e th e roo f sto p bracket s an d hoo k stop s fro m

th e engin e cover .

LEFT ROO F STO P BRACKET /

ROO F HOLDE R SWITC H RIGH

T

ROO F STO PBRACKE T

ENGINECOVER

HOOK STOP S

CONNECTO R

LEF T ROO F

STO P BRACKE T

This scre w o n th e righ troof sto p bracke t i sscre w A . Nu

t locations , 4

HOOK STO P

4. Installatio n is th e revers e o f th e remova l procedure .

NOTE:

• Mak e sur e th e roo f cove r open s properl y an d

lock s securely .

• Mak e sur e th e roo f fit s o n th e engin e cove r

securely .

HOOK

STO P

ROO

F HOLDE R

SWITCH

ROOF SID E

HOO K

ENGIN ECOVER ROO

F

ProCarManuals.com

Page 1221 of 1503

Compressor

Replacemen t

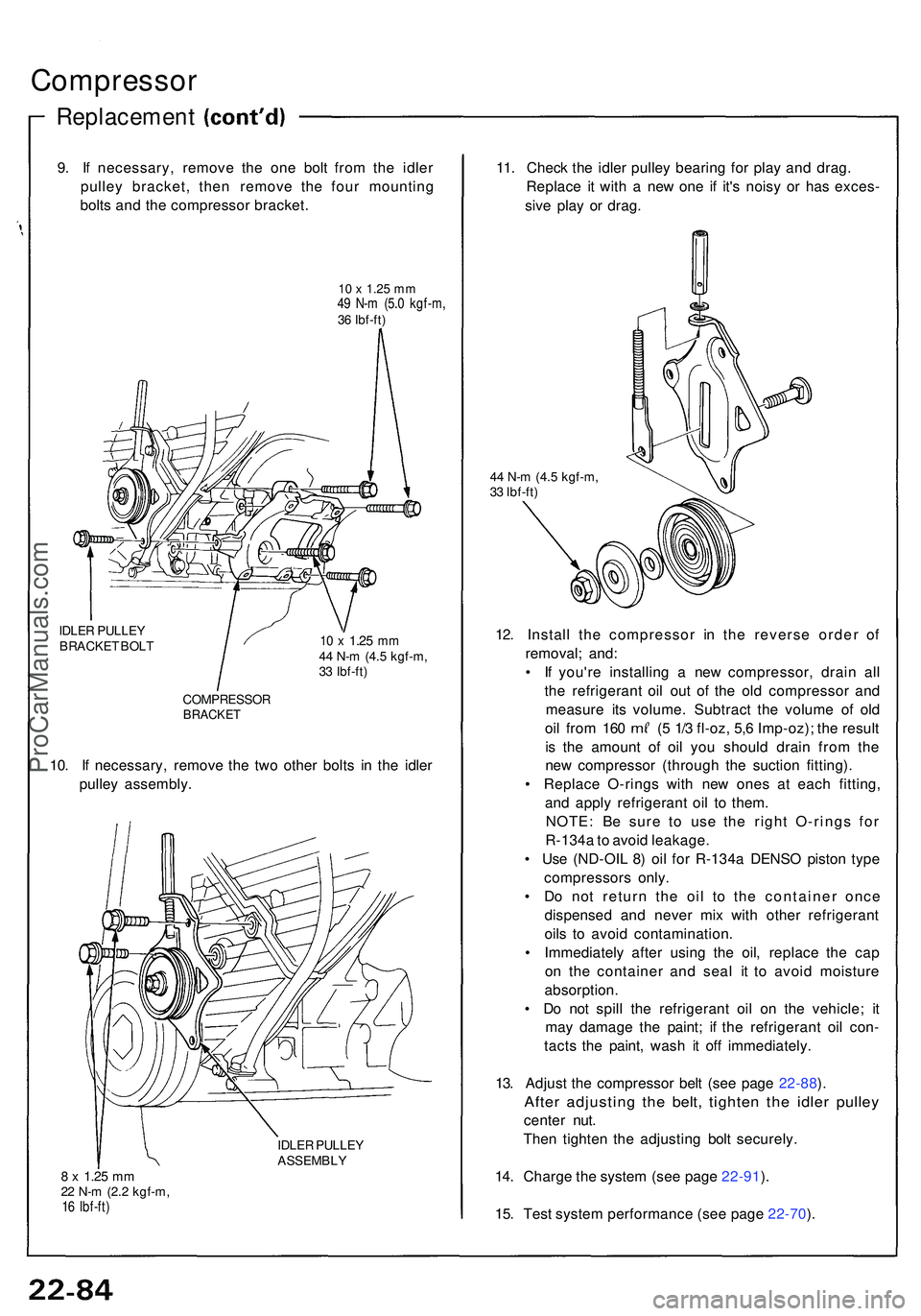

9. I f necessary , remov e th e on e bol t fro m th e idle r

pulle y bracket , the n remov e th e fou r mountin g

bolt s an d th e compresso r bracket .

10 x 1.25 mm49 N- m (5. 0 kgf-m ,36 Ibf-ft )

IDLE R PULLE Y

BRACKE T BOL T

10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

COMPRESSO R

BRACKET

10. I f necessary , remov e th e tw o othe r bolt s i n th e idle r

pulle y assembly .

IDLER PULLE Y

ASSEMBL Y

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,16 Ibf-ft )

11. Chec k th e idle r pulle y bearin g fo r pla y an d drag .

Replac e i t wit h a ne w on e i f it' s nois y o r ha s exces -

siv e pla y o r drag .

44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

12. Instal l th e compresso r i n th e revers e orde r o f

removal ; and :

• I f you'r e installin g a ne w compressor , drai n al l

th e refrigeran t oi l ou t o f th e ol d compresso r an d

measur e it s volume . Subtrac t th e volum e o f ol d

oil fro m 16 0 ( 5 1/ 3 fl-oz , 5, 6 Imp-oz) ; th e resul t

i s th e amoun t o f oi l yo u shoul d drai n fro m th e

ne w compresso r (throug h th e suctio n fitting) .

• Replac e O-ring s wit h ne w one s a t eac h fitting ,

an d appl y refrigeran t oi l t o them .

NOTE : B e sur e t o us e th e righ t O-ring s fo r

R-134 a to avoi d leakage .

• Us e (ND-OI L 8 ) oi l fo r R-134 a DENS O pisto n typ e

compressor s only .

• D o no t retur n th e oi l t o th e containe r onc e

dispense d an d neve r mi x wit h othe r refrigeran t

oil s t o avoi d contamination .

• Immediatel y afte r usin g th e oil, replac e th e ca p

o n th e containe r an d sea l i t t o avoi d moistur e

absorption .

• D o no t spil l th e refrigeran t oi l o n th e vehicle ; i t

ma y damag e th e paint ; i f th e refrigeran t oi l con -

tact s th e paint , was h i t of f immediately .

13 . Adjus t th e compresso r bel t (se e pag e 22-88 ).

Afte r adjustin g th e belt , tighte n th e idle r pulle y

center nut .

The n tighte n th e adjustin g bol t securely .

14 . Charg e th e syste m (se e pag e 22-91 ).

15 . Tes t syste m performanc e (se e pag e 22-70 ).

ProCarManuals.com

Page 1232 of 1503

Troubleshooting

Tips and Precautions (cont'd)

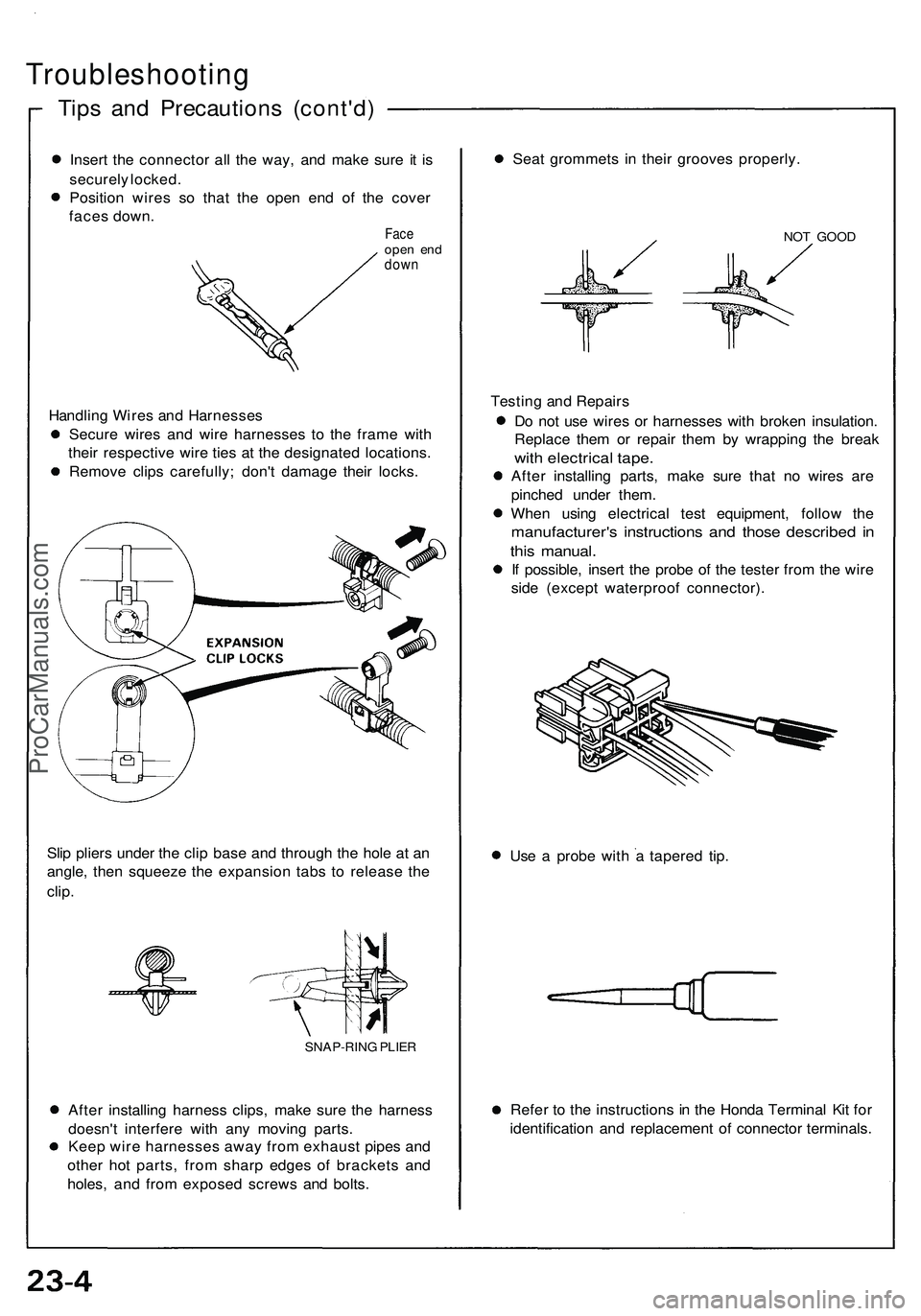

Insert the connector all the way, and make sure it is

securely locked.

Position wires so that the open end of the cover

faces down.

Face

open end

down

Handling Wires and Harnesses

Secure wires and wire harnesses to the frame with

their respective wire ties at the designated locations.

Remove clips carefully; don't damage their locks.

Slip pliers under the clip base and through the hole at an

angle, then squeeze the expansion tabs to release the

clip.

After installing harness clips, make sure the harness

doesn't interfere with any moving parts.

Keep wire harnesses away from exhaust pipes and

other hot parts, from sharp edges of brackets and

holes, and from exposed screws and bolts.

Seat grommets in their grooves properly.

NOT GOOD

Testing and Repairs

Do not use wires or harnesses with broken insulation.

Replace them or repair them by wrapping the break

with electrical tape.

After installing parts, make sure that no wires are

pinched under them.

When using electrical test equipment, follow the

manufacturer's instructions and those described in

this manual.

If possible, insert the probe of the tester from the wire

side (except waterproof connector).

Use a probe with a tapered tip.

Refer to the instructions in the Honda Terminal Kit for

identification and replacement of connector terminals.

SNAP-RING PLIERProCarManuals.com

Page 1233 of 1503

Five-step Troubleshootin g —————

1. Verif y Th e Complain t

Tur n o n al l th e component s i n th e proble m circui t t o

verif y th e custome r complaint . Not e th e symp -

toms . D o no t begi n disassembl y o r testin g unti l yo u

hav e narrowe d dow n th e proble m area .

2 . Analyz e Th e Schemati c

Loo k u p th e schemati c fo r th e proble m circuit .

Determin e ho w th e circui t i s suppose d t o wor k b y

tracin g th e curren t path s fro m th e powe r fee d

throug h th e circui t component s t o ground . I f

severa l circuit s fai l a t th e sam e time , th e fus e o r

groun d i s a likel y cause .

Base d o n th e symptom s an d you r understandin g o f

th e circui t operation , identif y on e o r mor e possibl e

cause s o f th e problem .

3 . Isolat e Th e Proble m B y Testin g Th e Circui t

Mak e circui t test s t o chec k th e diagnosi s yo u mad e

i n ste p 2 . Kee p i n min d tha t a logical , simpl e pro -

cedur e i s th e ke y t o efficien t troubleshooting . Tes t

fo r th e mos t likel y caus e o f failur e first . Tr y t o mak e

test s a t point s tha t ar e easil y accessible . 4

. Fi x Th e Proble m

Onc e th e specifi c proble m is identified , mak e th e

repair . B e sur e t o us e prope r tool s an d saf e

procedures .

5. Mak e Sur e Th e Circui t Work s

Tur n o n al l component s i n th e repaire d circui t i n al l

mode s t o mak e sur e you'v e fixe d th e entir e pro -

blem . I f th e proble m wa s a blow n fuse , b e sur e t o

tes t al l o f th e circuit s o n tha t fuse . Mak e sur e n o

ne w problem s tur n u p an d th e origina l proble m

doe s no t recur .

ProCarManuals.com

Page 1236 of 1503

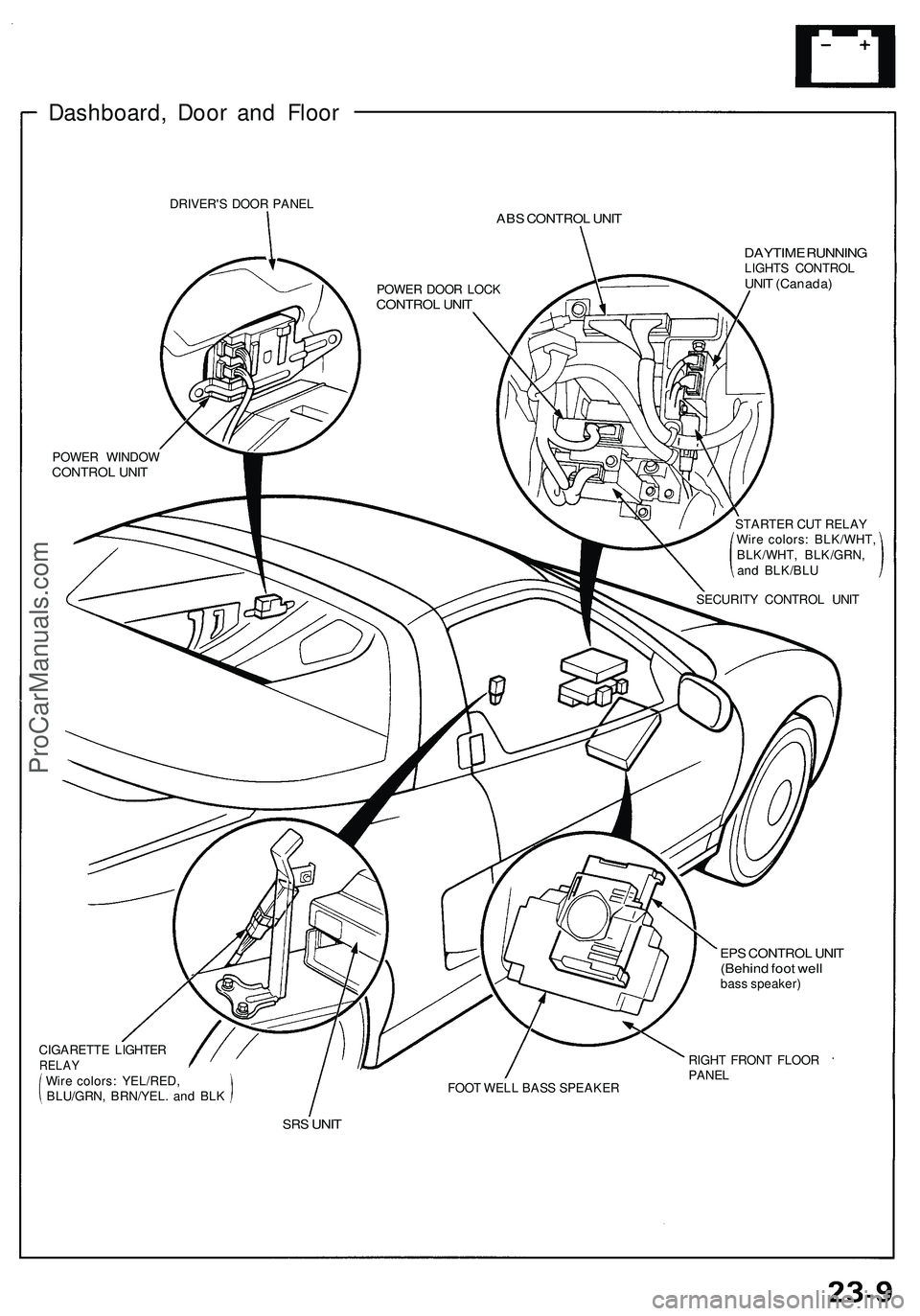

Dashboard, Doo r an d Floo r

DRIVER' S DOO R PANE LABS CONTRO L UNI T

DAYTIM E RUNNIN GLIGHTS CONTRO LUNIT (Canada )

POWER WINDO WCONTRO L UNI T

SECURIT Y CONTRO L UNI T

POWE

R DOO R LOC K

CONTRO L UNI T

CIGARETT E LIGHTE RRELAYWire colors : YEL/RED ,

BLU/GRN , BRN/YEL . an d BL K FOO

T WEL L BAS S SPEAKE R

EPS CONTRO L UNI T(Behin d foo t wel lbass speaker )

RIGH T FRON T FLOO R

PANEL

SRS UNI T

STARTE R CU T RELA Y

Wir e colors : BLK/WHT ,

BLK/WHT , BLK/GRN ,

an d BLK/BL U

ProCarManuals.com

Page 1251 of 1503

— If the starter still does not crank the engine,

remove the starter and diagnose its internal

problems.

— If the starter cranks the engine, check for an

open in the BLK/WHT wire and connectors be-

tween the starter and ignition switch. Check the

ignition switch.

On cars with automatic transmission, check the

A/T gear position switch (neutral position

switch) and connector.

On cars with manual transmission, check the

starter cut relay, clutch interlock switch and

connectors.

NOTE: Check the No. 29 (50 A) fuse and the

starter cut relay, and inspect the security alarm

system.

3. Check for wear or damage:

The starter should crank the engine smoothly and

steadily.

If the starter engages, but cranks the engine er-

ratically, remove the starter motor. Inspect the

starter, drive gear and flywheel ring gear for

damage.

Check the drive gear overrunning clutch for binding

or slipping when the armature is rotated with the

drive gear held. Replace the gears if damaged.

4. Check cranking voltage and current draw:

Voltage should be no less than 8.5 volts.

Current should be no more than 350 amperes.

If voltage is too low, or current draw too high,

check for:

Low battery.

Open circuit in starter armature commutator

segments.

Starter armature dragging.

Shorted armature winding.

Excessive drag in engine.

5. Check cranking rpm:

Engine speed during cranking should be above 100

rpm.

If speed is too low, check for:

Loose battery or starter terminals.

Excessively worn starter brushes.

Open circuit in commutator segments.

Dirty or damaged helical spline or drive gear.

Defective drive gear overrunning clutch.

6. Check the starter disengagement:

Depress the clutch pedal all the way (M/T) or shift to

or position (A/T), turn the ignition switch to

"Start (III)", and release to ON (II).

The starter drive gear should disengage from the

flywheel ring gear.

If the drive gear hangs up on the flywheel ring gear,

check:

Solenoid plunger and switch for malfunction.

Drive gear assembly for dirt or damaged over-

running clutch.ProCarManuals.com