ECU ACURA NSX 1997 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 523 of 1503

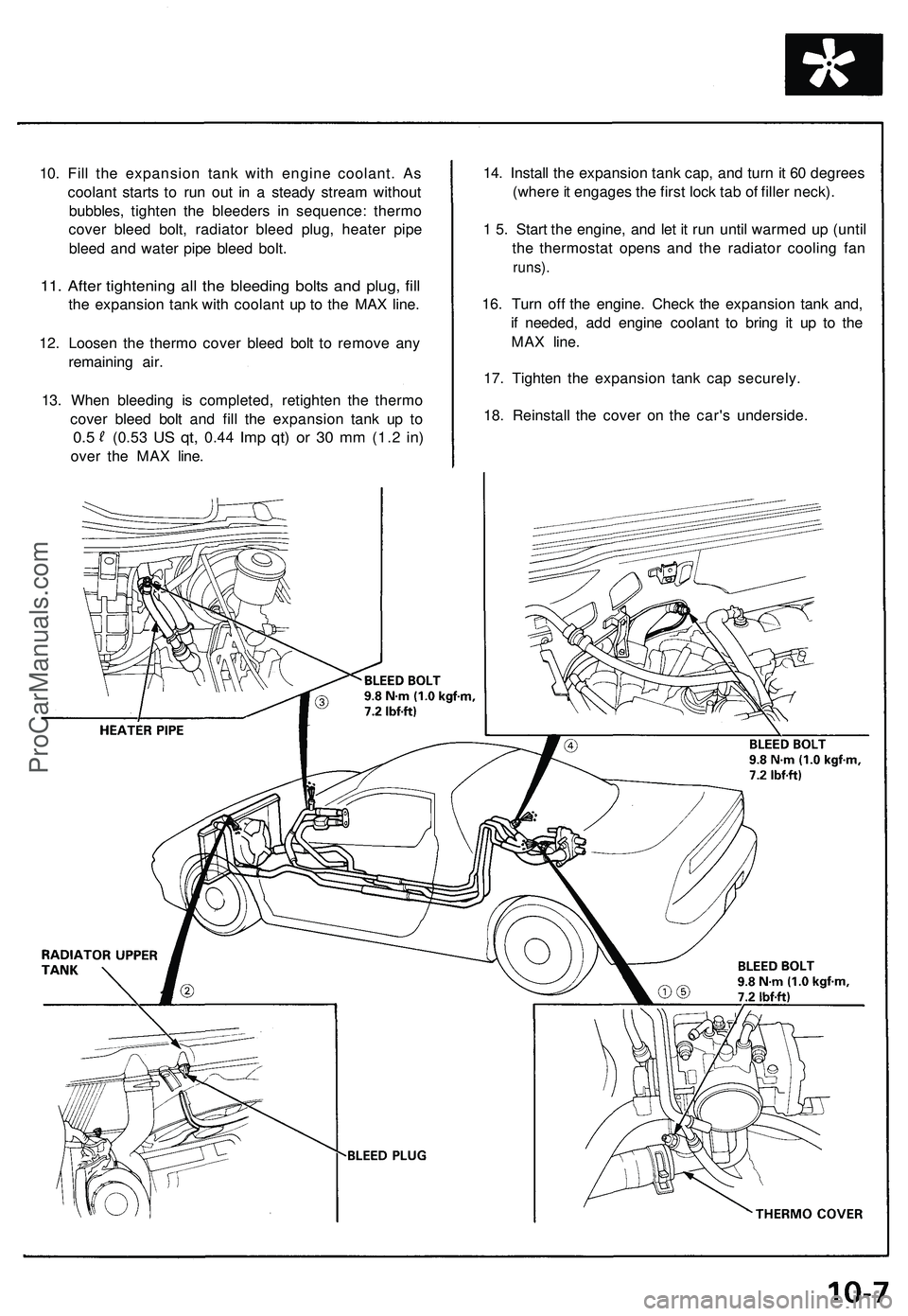

10. Fill the expansion tank with engine coolant. As

coolant starts to run out in a steady stream without

bubbles, tighten the bleeders in sequence: thermo

cover bleed bolt, radiator bleed plug, heater pipe

bleed and water pipe bleed bolt.

11. After tightening all the bleeding bolts and plug, fill

the expansion tank with coolant up to the MAX line.

12. Loosen the thermo cover bleed bolt to remove any

remaining air.

13. When bleeding is completed, retighten the thermo

cover bleed bolt and fill the expansion tank up to

0.5

(0.53

US qt,

0.44

Imp qt) or 30 mm

(1.2

in)

over the MAX line.

14. Install the expansion tank cap, and turn it 60 degrees

(where it engages the first lock tab of filler neck).

1 5. Start the engine, and let it run until warmed up (until

the thermostat opens and the radiator cooling fan

runs).

16. Turn off the engine. Check the expansion tank and,

if needed, add engine coolant to bring it up to the

MAX line.

17. Tighten the expansion tank cap securely.

18. Reinstall the cover on the car's underside.ProCarManuals.com

Page 586 of 1503

PGM-FI System

System Description (cont'd)

3. Fuel Cut-off Control

During deceleration with the throttle valve closed, current to the fuel injectors is cut off to improve fuel economy at

speeds over 1,500 rpm.

Fuel cut-off action also takes place when engine speed exceeds 8,300 rpm, regardless of the position of the throttle

valve, to protect the engine from over-revving.

4. A/C Compressor Clutch Relay

When the ECM receives a demand for cooling from the air conditioning system, it delays the compressor from being

energized, and enriches the mixture to assure smooth translation to the A/C mode.

5. Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant temperature is below 153°F (67°C), the ECM controls the EVAP purge control solenoid valve

which cuts vacuum to the EVAP purge control canister diaphragm.

6. Intake Air Bypass (IAB) Control Solenoid Valve

When the engine speed is below 4,800 rpm, the IAB control solenoid valve is activated by a signal from the ECM. Intake

air then flows through the smaller chamber, and high torque is delivered. To increase air flow at engine speeds higher

than 4,800 rpm, the solenoid valve is deactivated by the ECM, and the intake air flows through the larger chamber.

7. Exhaust Gas Recirculation (EGR) Control Solenoid Valve

When the EGR is required for control of oxides of nitrogen (NOx) emissions, the ECM supplies ground to the EGR

control solenoid valve which supplies regulated vacuum to the EGR valve.

ECM Fail-safe/Back-up Functions

1. Fail-Safe Function

When an abnormality occurs in a signal from a sensor, the ECM ignores that signal and assumes a pre-programmed

valve for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the ECM itself, the fuel injectors are controlled by a back-up circuit independent of the

system in order to permit minimal driving.

3. Self-diagnosis Function [Malfunction Indicator Lamp (MIL)]

When an abnormality occurs in a signal from a sensor, the ECM lights the MIL and stores the diagnostic trouble code

in erasable memory. When the ignition is initially turned on, the ECM supplies ground for the MIL for two seconds to

check the MIL bulb condition.

4. Two Trip Detection Method

To prevent false indications, the Two Trip Detection Method is used for the H02S, fuel metering-related, idle control

system, ECT sensor, EGR system self-diagnostic functions and EVAP control system. When an abnormality occurs,

the ECM stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and ON (II)

again, the ECM informs the driver by lighting the MIL.

However, to ease troubleshooting, this function is cancelled when you short the service check connector. The MIL will

then blink immediately when an abnormality occurs.

5. Two (or three) Driving Cycle Detection Method

A "Driving Cycle" consists of starting the engine, beginning closed loop operation, and stopping the engine. If misfir-

ing that increases emissions or EVAP control system malfunction is detected during two consecutive driving cycles,

or TWC deterioration is detected during three consecutive driving cycles, the ECM turns the MIL on.

However,

to

ease

troubleshooting,

this

function

is

cancelled when

you

short

the

service check connector.

The MIL

will

then blink immediately when an abnormality occurs.ProCarManuals.com

Page 690 of 1503

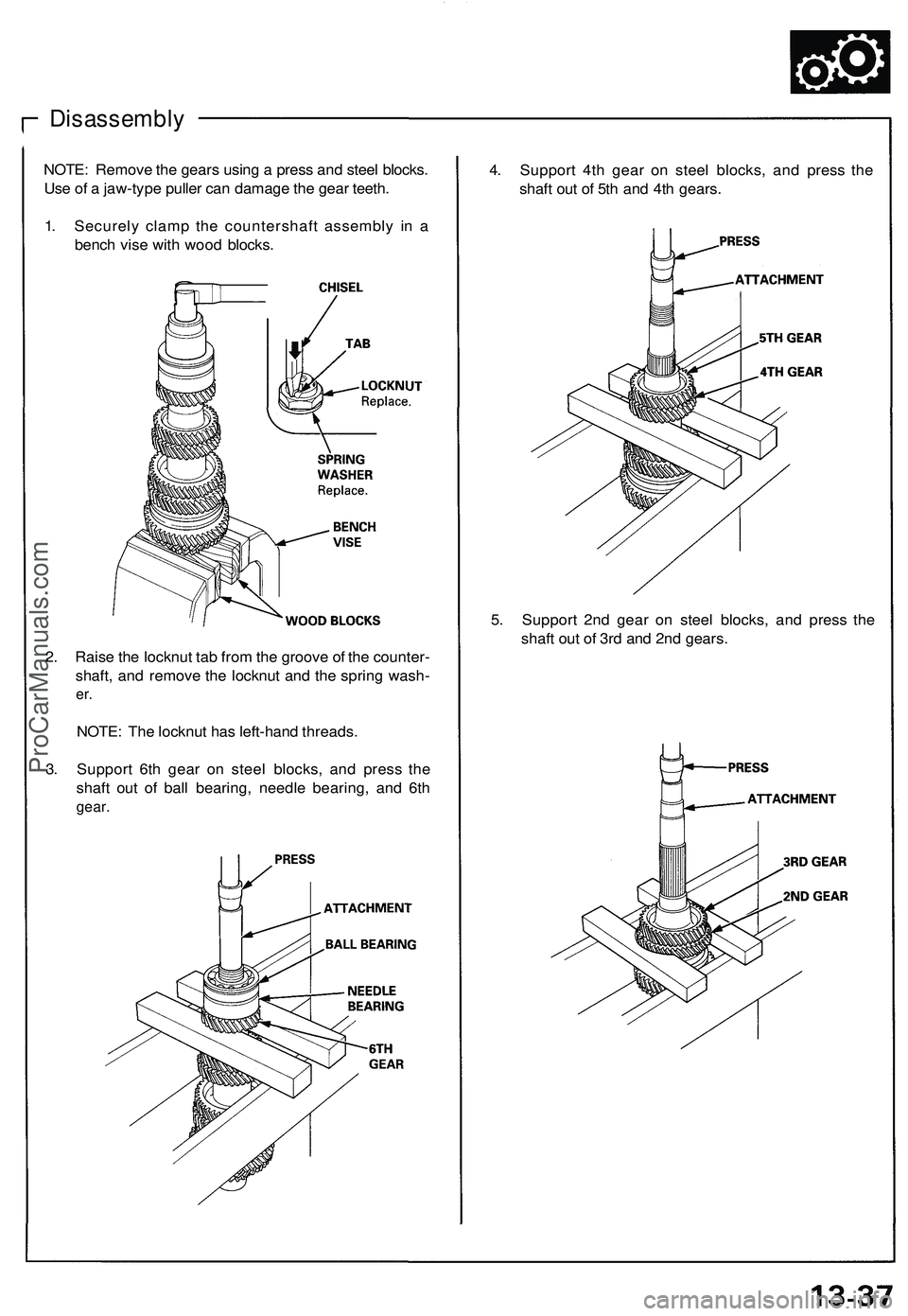

Disassembly

NOTE: Remove the gears using a press and steel blocks.

Use of a jaw-type puller can damage the gear teeth.

1. Securely clamp the countershaft assembly in a

bench vise with wood blocks.

4. Support 4th gear on steel blocks, and press the

shaft out of 5th and 4th gears.

5. Support 2nd gear on steel blocks, and press the

shaft out of 3rd and 2nd gears.

2. Raise the locknut tab from the groove of the counter-

shaft, and remove the locknut and the spring wash-

er.

NOTE: The locknut has left-hand threads.

3. Support 6th gear on steel blocks, and press the

shaft out of ball bearing, needle bearing, and 6th

gear.ProCarManuals.com

Page 693 of 1503

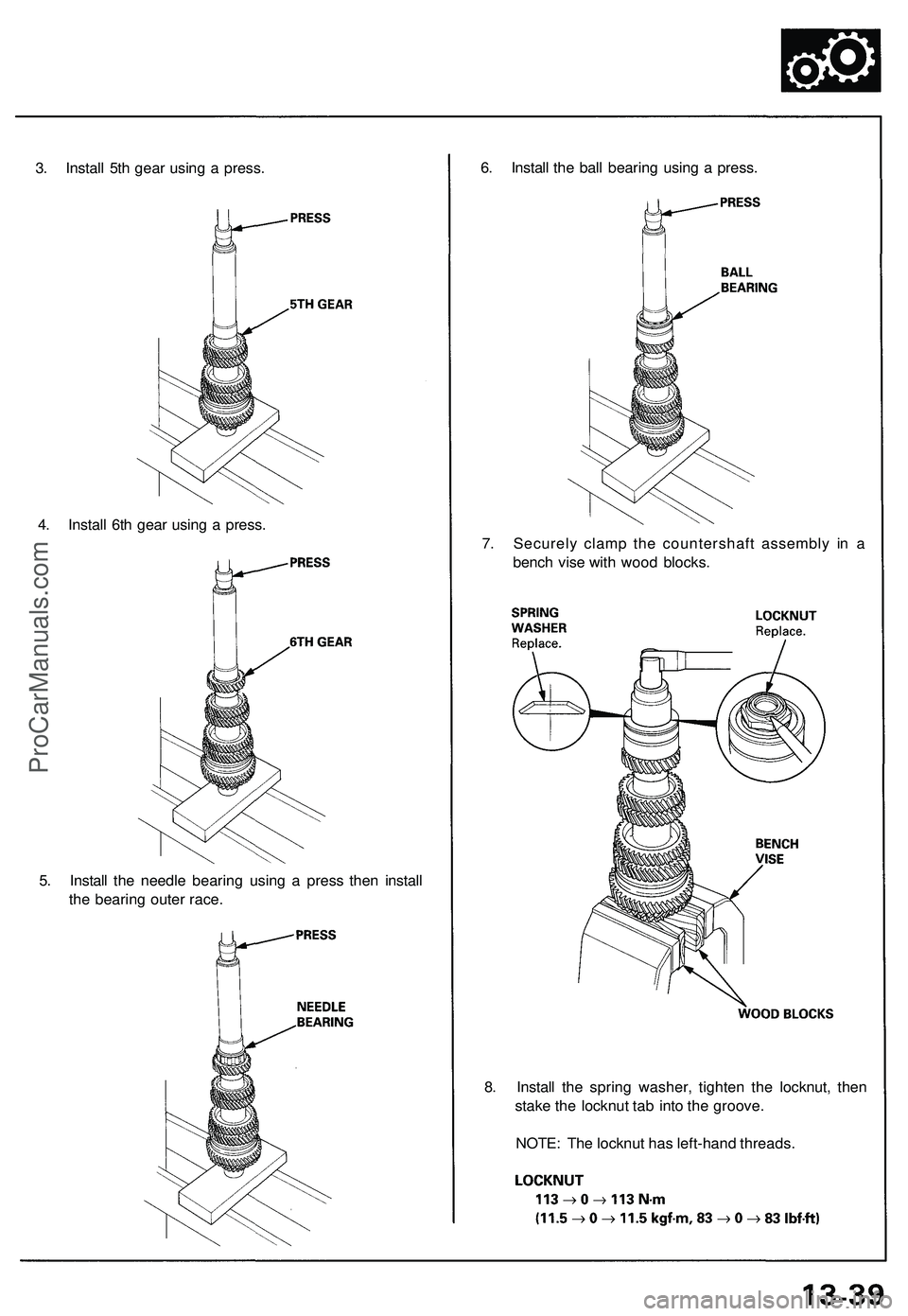

5. Install the needle bearing using a press then install

the bearing outer race.

8. Install the spring washer, tighten the locknut, then

stake the locknut tab into the groove.

NOTE: The locknut has left-hand threads.

6. Install the ball bearing using a press.

7. Securely clamp the countershaft assembly in a

bench vise with wood blocks.

3. Install 5th gear using a press.

4. Install 6th gear using a press.ProCarManuals.com

Page 705 of 1503

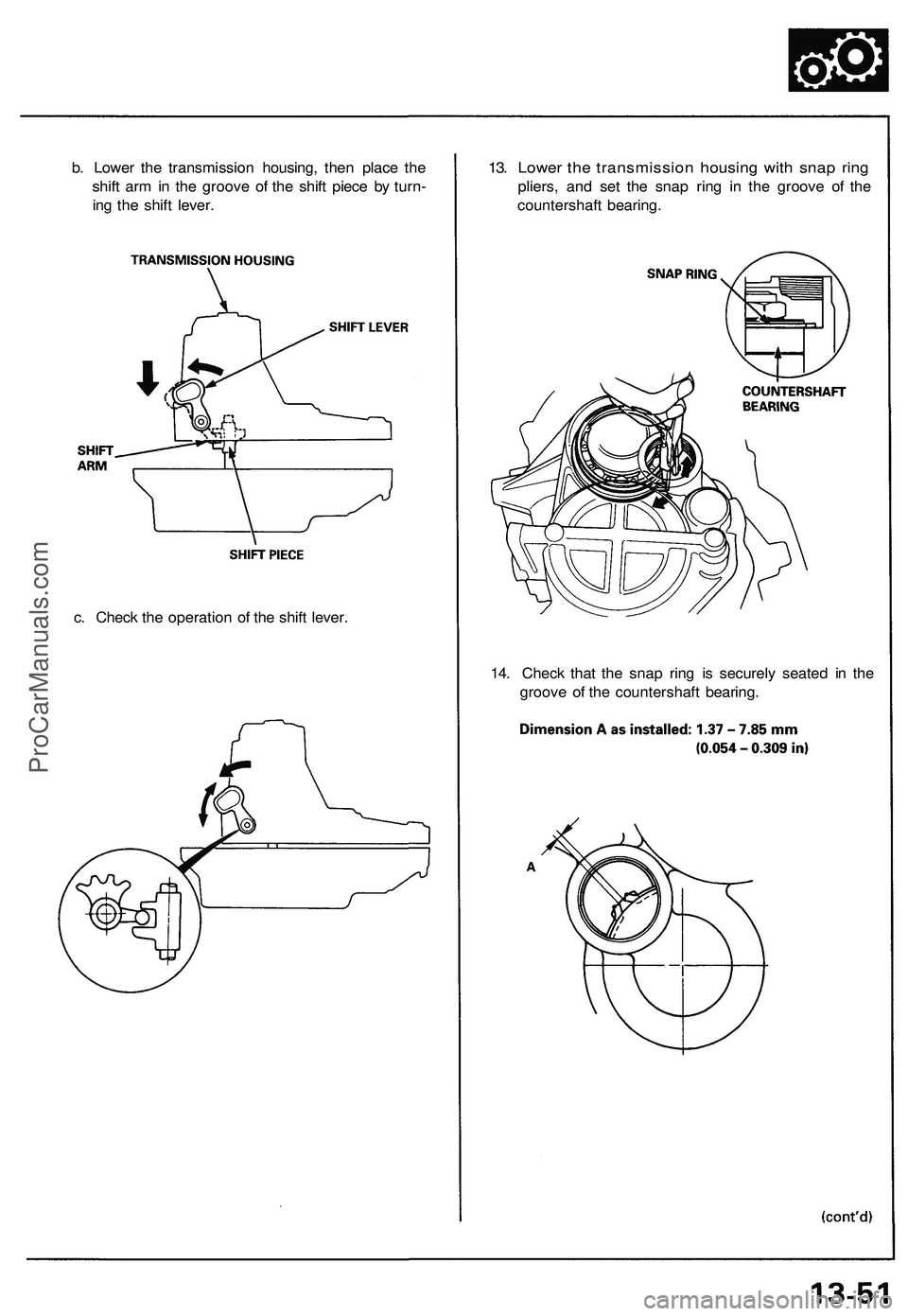

13. Lower the transmission housing with snap ring

pliers, and set the snap ring in the groove of the

countershaft bearing.

b. Lower the transmission housing, then place the

shift arm in the groove of the shift piece by turn-

ing the shift lever.

c. Check the operation of the shift lever.

14. Check that the snap ring is securely seated in the

groove of the countershaft bearing.ProCarManuals.com

Page 774 of 1503

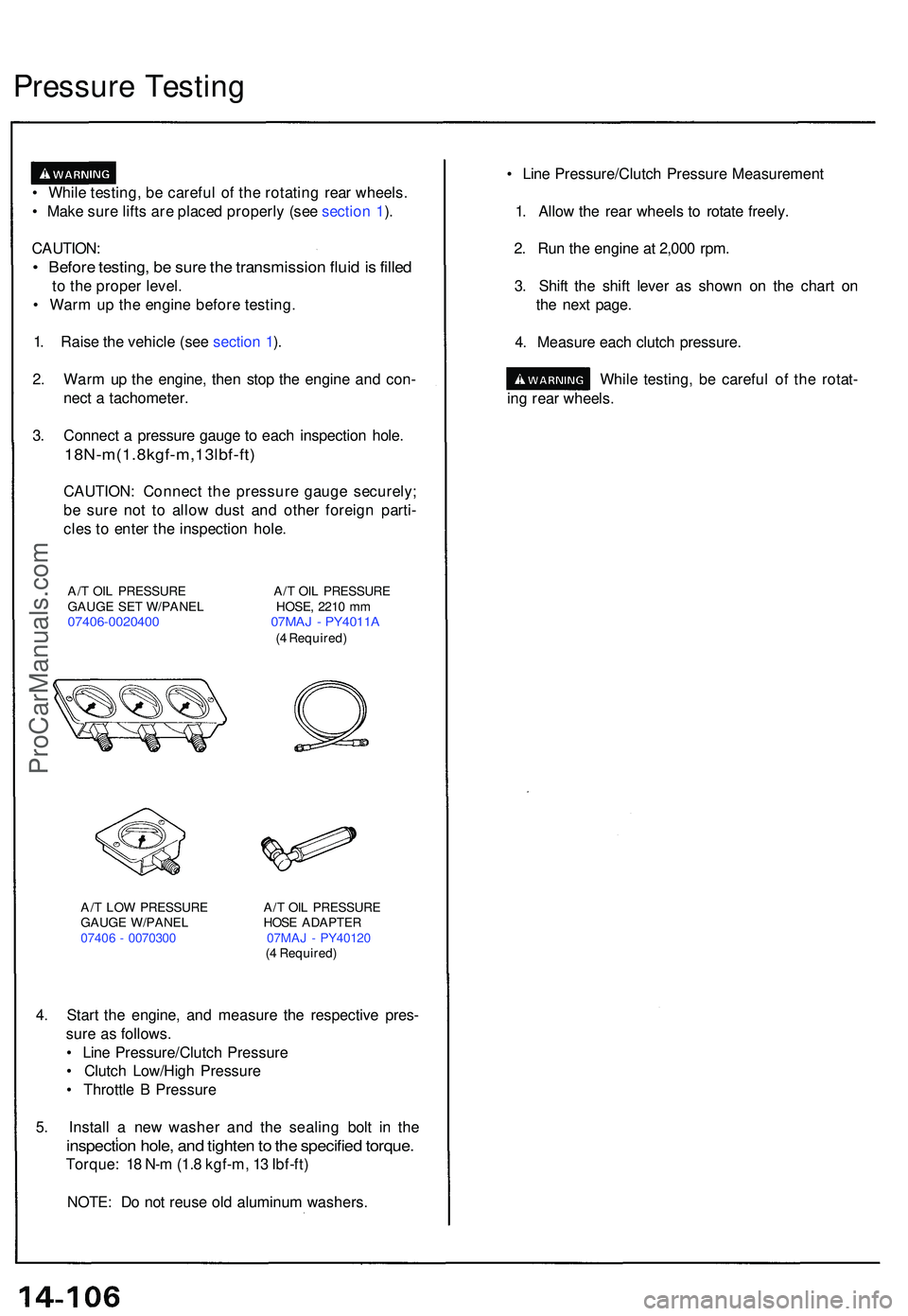

• Whil e testing , b e carefu l o f th e rotatin g rea r wheels .

• Mak e sur e lift s ar e place d properl y (se e sectio n 1 ).

CAUTION :

• Befor e testing , b e sur e th e transmissio n flui d is fille d

to th e prope r level .

• War m u p th e engin e befor e testing .

1 . Rais e th e vehicl e (se e sectio n 1 ).

2 . War m u p th e engine , the n sto p th e engin e an d con -

nec t a tachometer .

3 . Connec t a pressur e gaug e t o eac h inspectio n hole .

18N-m(1.8kgf-m,13lbf-ft )

CAUTION: Connec t th e pressur e gaug e securely ;

b e sur e no t t o allo w dus t an d othe r foreig n parti -

cle s t o ente r th e inspectio n hole .

A/T OI L PRESSUR E A/ T OI L PRESSUR E

GAUG E SE T W/PANE L HOSE , 221 0 m m

07406-002040 0 07MA J - PY4011 A(4 Required )

A/ T LO W PRESSUR E A/ T OI L PRESSUR E

GAUG E W/PANE L HOS E ADAPTE R

0740 6 - 007030 0 07MA J - PY4012 0

( 4 Required )

4. Star t th e engine , an d measur e th e respectiv e pres -

sur e a s follows .

• Lin e Pressure/Clutc h Pressur e

• Clutc h Low/Hig h Pressur e

• Throttl e B Pressur e

5 . Instal l a ne w washe r an d th e sealin g bol t i n th e

inspectio n hole , an d tighte n to th e specifie d torque .

Torque : 1 8 N- m (1. 8 kgf-m , 1 3 Ibf-ft )

NOTE : D o no t reus e ol d aluminu m washers . •

Lin e Pressure/Clutc h Pressur e Measuremen t

1 . Allo w th e rea r wheel s t o rotat e freely .

2 . Ru n th e engin e a t 2,00 0 rpm .

3 . Shif t th e shif t leve r a s show n o n th e char t o n

th e nex t page .

4 . Measur e eac h clutc h pressure .

While testing , b e carefu l o f th e rotat -

in g rea r wheels .

Pressur e Testin g

ProCarManuals.com

Page 819 of 1503

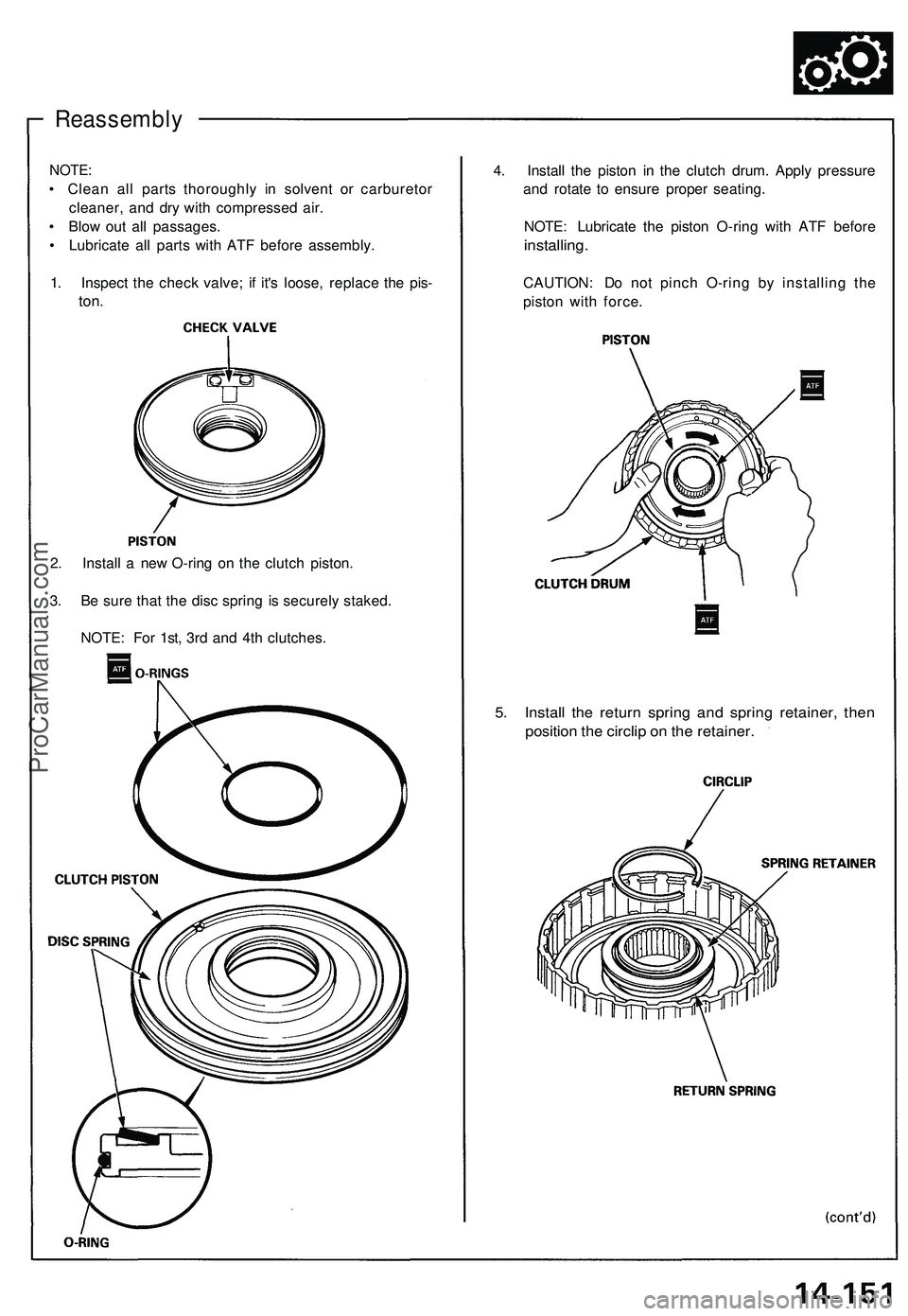

Reassembly

NOTE:

• Clean all parts thoroughly in solvent or carburetor

cleaner, and dry with compressed air.

• Blow out all passages.

• Lubricate all parts with ATF before assembly.

1. Inspect the check valve; if it's loose, replace the pis-

ton.

4. Install the piston in the clutch drum. Apply pressure

and rotate to ensure proper seating.

NOTE: Lubricate the piston O-ring with ATF before

installing.

CAUTION: Do not pinch O-ring by installing the

piston with force.

2. Install a new O-ring on the clutch piston.

3. Be sure that the disc spring is securely staked.

NOTE: For 1st, 3rd and 4th clutches.

5. Install the return spring and spring retainer, then

position the circlip on the retainer.ProCarManuals.com

Page 876 of 1503

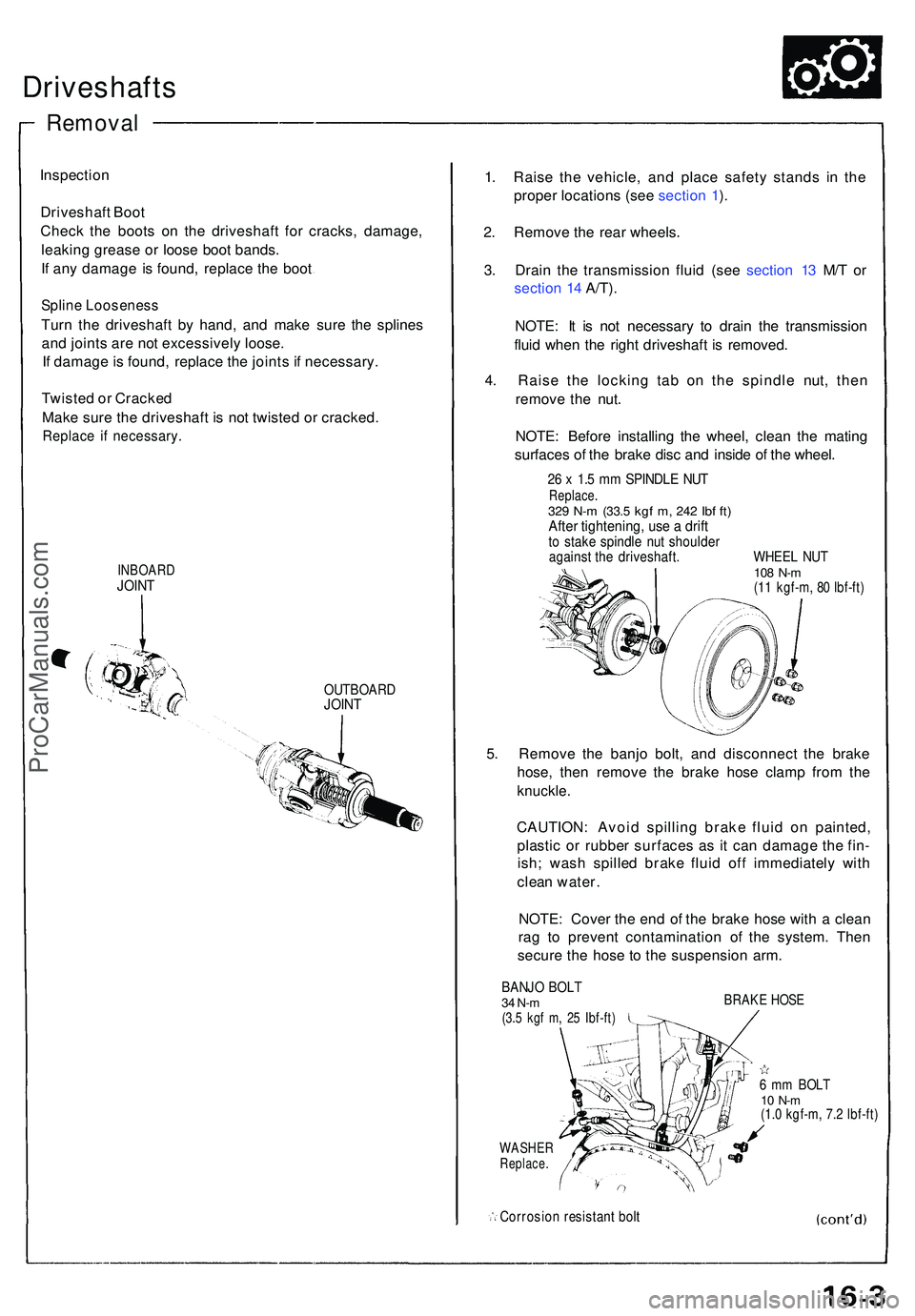

Driveshafts

Inspection

Driveshaf t Boo t

Chec k th e boot s o n th e driveshaf t fo r cracks , damage ,

leakin g greas e o r loos e boo t bands .

I f an y damag e i s found , replac e th e boo t

Splin e Loosenes s

Turn th e driveshaf t b y hand , an d mak e sur e th e spline s

an d joint s ar e no t excessivel y loose .

I f damag e is found , replac e th e joint s i f necessary .

Twiste d o r Cracked

Mak e sur e th e driveshaf t i s not twiste d o r cracked .

Replace i f necessary .

INBOARDJOINT

OUTBOAR DJOINT

1. Rais e th e vehicle , an d plac e safet y stand s i n th e

prope r location s (se e sectio n 1 ).

2 . Remov e th e rea r wheels .

3 . Drai n th e transmissio n flui d (se e sectio n 1 3 M/ T o r

sectio n 1 4 A/T) .

NOTE : I t i s no t necessar y t o drai n th e transmissio n

flui d whe n th e righ t driveshaf t i s removed .

4 . Rais e th e lockin g ta b o n th e spindl e nut , the n

remov e th e nut .

NOTE : Befor e installin g th e wheel , clea n th e matin g

surface s o f th e brak e dis c an d insid e o f th e wheel .

26 x 1. 5 m m SPINDL E NU TReplace .329 N- m (33. 5 kgf m , 24 2 Ib f ft )Afte r tightening , us e a drif tto stak e spindl e nu t shoulde ragainst th e driveshaft . WHEE L NU T108 N- m(11 kgf-m , 8 0 Ibf-ft )

5. Remov e th e banj o bolt , an d disconnec t th e brak e

hose , the n remov e th e brak e hos e clam p fro m th e

knuckle .

CAUTION : Avoi d spillin g brak e flui d o n painted ,

plasti c o r rubbe r surface s a s i t ca n damag e th e fin -

ish ; was h spille d brak e flui d of f immediatel y wit h

clea n water .

NOTE : Cove r th e en d o f th e brak e hos e wit h a clea n

ra g t o preven t contaminatio n o f th e system . The n

secur e th e hos e t o th e suspensio n arm .

BANJ O BOL T34 N-m(3.5 kg f m , 2 5 Ibf-ft )

WASHE RReplace .

Corrosio n resistan t bol t

BRAK E HOS E

6 m m BOL T10 N- m(1.0 kgf-m , 7. 2 Ibf-ft )

Remova l

ProCarManuals.com

Page 877 of 1503

Driveshafts

Removal

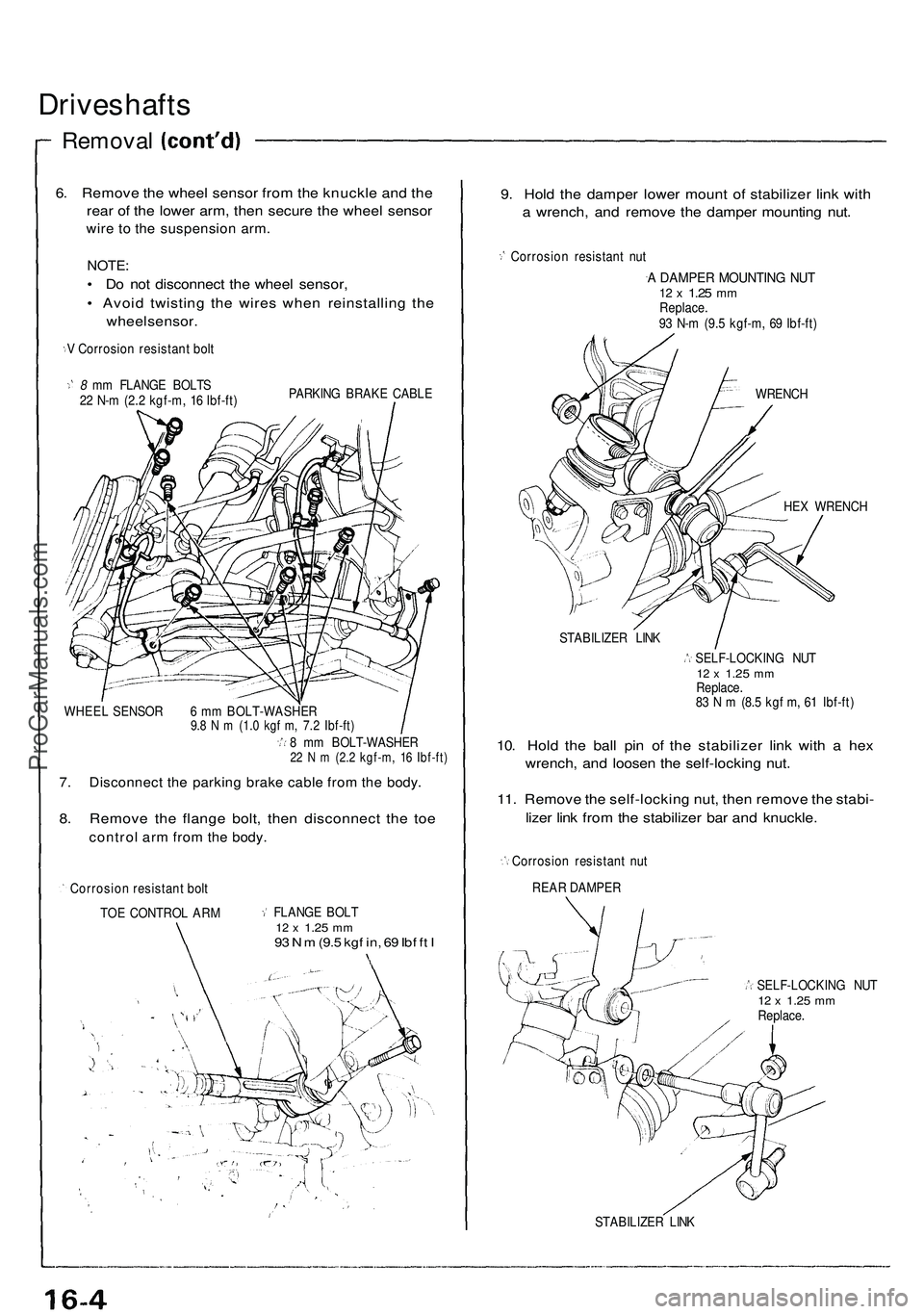

6. Remove the wheel sensor from the knuckle and the

rear of the lower arm, then secure the wheel sensor

wire to the suspension arm.

NOTE:

• Do not disconnect the wheel sensor,

• Avoid twisting the wires when reinstalling the

wheel sensor.

V Corrosion resistant bolt

8 mm FLANGE BOLTS

22 N-m (2.2 kgf-m, 16 Ibf-ft)

PARKING BRAKE CABLE

WHEEL SENSOR 6 mm BOLT-WASHER

9.8 N m (1.0 kgf m, 7.2 Ibf-ft)

8 mm BOLT-WASHER

22 N m (2.2 kgf-m, 16 Ibf-ft)

7. Disconnect the parking brake cable from the body.

8. Remove the flange bolt, then disconnect the toe

control arm from the body.

Corrosion resistant bolt

TOE CONTROL ARM

FLANGE BOLT

12 x

1.25

mm

93 N m

(9.5

kgf in, 69 Ibf ft I

9. Hold the damper lower mount of stabilizer link with

a wrench, and remove the damper mounting nut.

Corrosion resistant nut

A DAMPER MOUNTING NUT

12 x

1.25

mm

Replace.

93 N-m (9.5 kgf-m, 69 Ibf-ft)

WRENCH

HEX WRENCH

STABILIZER LINK

SELF-LOCKING NUT

12 x

1.25

mm

Replace.

83 N m (8.5 kgf m, 61 Ibf-ft)

10. Hold the ball pin of the stabilizer link with a hex

wrench, and loosen the self-locking nut.

11. Remove the self-locking nut, then remove the stabi-

lizer link from the stabilizer bar and knuckle.

Corrosion resistant nut

REAR DAMPER

SELF-LOCKING NUT

12 x

1.25

mm

Replace.

STABILIZER LINKProCarManuals.com

Page 893 of 1503

System Description

Steering Column

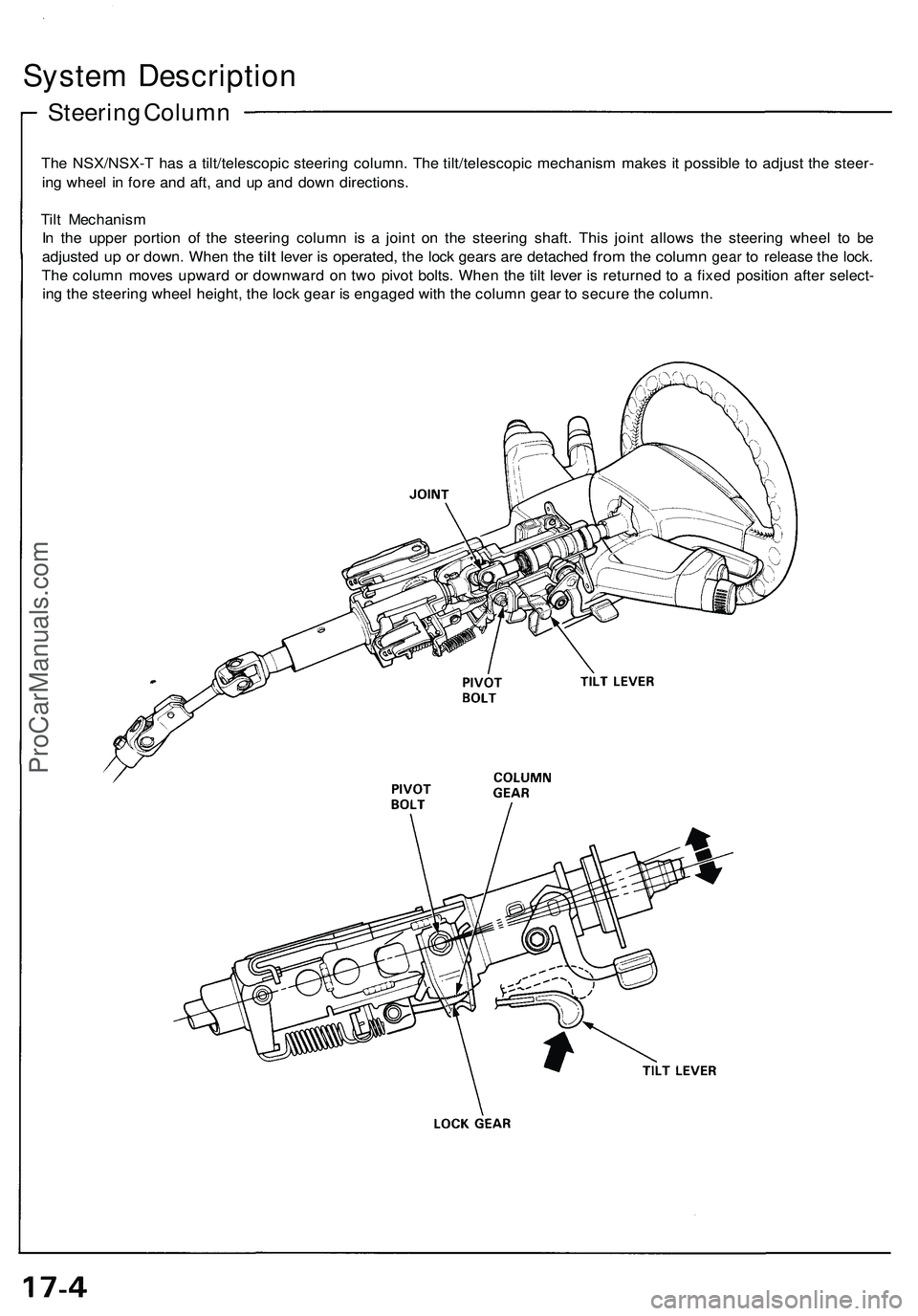

The NSX/NSX-T has a tilt/telescopic steering column. The tilt/telescopic mechanism makes it possible to adjust the steer-

ing wheel in fore and aft, and up and down directions.

Tilt Mechanism

In the upper portion of the steering column is a joint on the steering shaft. This joint allows the steering wheel to be

adjusted

up or

down. When

the

tilt

lever

is

operated,

the

lock gears

are

detached

from

the

column

gear

to

release

the

lock.

The column moves upward or downward on two pivot bolts. When the tilt lever is returned to a fixed position after select-

ing the steering wheel height, the lock gear is engaged with the column gear to secure the column.ProCarManuals.com